Page 1

AN3255

Application note

Building an RFID short-range reader

using the STM8S-DISCOVERY

Application overview

High frequency 13,56 MHz RFID solutions offer ideal close-proximity identification for

product authentication, parcel tracking, document management, library and ticketing

applications.

This application note describes how to build an RFID (radio frequency identification) shortrange reader using STMicroelectronics STM8S-DISCOVERY and ISO14443 type-B CR14

contactless coupler. The STM8S-DISCOVERY and the CR14 communicate through an I

bus.

The resulting RFID reader can exchange data with ISO 14443-2 type-B proximity PICCs

(proximity integrated coupling cards) also called tags. Communications are possible only

when the tags are present in the electromagnetic field generated by the reader built-in

antenna.

Once the STM8S-DISCOVERY is powered up through a USB cable connected to the host

PC, an electromagnetic field is generated by the RFID reader. A beep is emitted and the

LED LD1 briefly lights up when an ISO 14443-2 type-B proximity tag is detected by the

reader and its unique identifier (UID) successfully read.

2

C

The STM8S-DISCOVERY can be used to evaluate the main features of all STM8S MCUs,

even if it is built on an STM8S105C6T6.

Reference documents

■ STM8S-DISCOVERY evaluation board user manual (UM0817).

■ Developing and debugging your STM8S-DISCOVERY application code (UM0834).

■ User manual “CR14 and CRX14 reference design PCB Gerber files” (UM0672) and RFID

Gerber files.

■ CR14 datasheet: “Low cost ISO14443 type-B contactless coupler chip with anti-collision

and CRC management”

■ SRI2K datasheet: “13,56 MHz short-range contactless memory chip with 2048 bit

EEPROM and anti-collision functions”

■ Application note “Antenna (and associated components) matching-circuit calculation of

the CRX14 coupler” (AN1806)

■ Application note “How to design a 13.56 MHz customized antenna” (AN2866)

These documents can be downloaded from http://www.st.com.

October 2010 Doc ID 17784 Rev 1 1/24

www.st.com

Page 2

Contents AN3255

Contents

1 Application description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Short-range contactless communication principles . . . . . . . . . . . . . . . . . . 6

1.2.1 CR14 contactless coupler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.2 I

1.2.3 Reader-tag protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2.4 Commands and tag states . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 Hardware requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4 Application schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2 STM8S-DISCOVERY configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.1 Power supply configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2

C polling using Ack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Option byte configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3 Software description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1 STM8S peripherals used by the application . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 Configuring the STM8S standard firmware library . . . . . . . . . . . . . . . . . . 15

3.3 Application principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Appendix A I2C memory addressing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Appendix B I2C Read and Write functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

B.1 I2C Page Write flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

B.2 I

2

C post polling buffer read flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2/24 Doc ID 17784 Rev 1

Page 3

AN3255 List of tables

List of tables

Table 1. CR14 control registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 2. List of PCB passive components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 3. List of PCB packaged components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 4. List of tag packaged components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 5. List of other passive components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 6. TAG commands used within this application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 7. Device Select code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 8. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Doc ID 17784 Rev 1 3/24

Page 4

List of figures AN3255

List of figures

Figure 1. Short range RFID reader solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2. Ack Polling flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 3. TAG state transition diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 4. Contactless RFID reader schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 5. Main application loop flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 6. I

Figure 7. I

2

C Page Write flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2

C post polling buffer read flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4/24 Doc ID 17784 Rev 1

Page 5

AN3255 Application description

1 Application description

1.1 Overview

This application is built around a short range RFID reader PCB developed by

STMicroelectronics. The PCB Gerber files and the user manual "CR14 and CRX14

reference design PCB Gerber files" (UM0672) are available from http://www.st.com.

This board is designed to be connected to a digital host, in this case an STM8SDISCOVERY, which manages data transmission and reception through an I

(see Figure 1).

The tags supported by this application must be based on ST contactless memories

compliant with ISO 14443 part2 type-B standard for the radio-frequency power and signal

interface.

This application has been tested using a tag based on ST SRI2K short range contactless

EEPROM. Refer to application note AN2866 explaining how to design a 13.56 MHz tag

antenna.

Figure 1. Short range RFID reader solution

Resistors

TS1

GPIO's

LD1

Buzzer

USB

STLINK

SWIM

5V

3V3

STM8S105C6T6

SO16

footprint

2

C interface

RP1

RP2

I2C bus

J1

HE10

STMicroelectronics

CR14

STM8S-DISCOVERY

RFID reader PCB

Doc ID 17784 Rev 1 5/24

Page 6

Application description AN3255

1.2 Short-range contactless communication principles

1.2.1 CR14 contactless coupler

The CR14 is the main component of the RFID reader PCB. It interfaces with the following

components:

● The contactless tags

The data frames exchanged with the tags are compliant with ISO14443 type-B radio

frequency protocol. Data are stored in the CR14 input/output Frame registers (see

Table 1: CR14 control registers).

● The STM8S105C6T6 through the I

The CR14 is organized as 4 functional blocks:

● The I²C bus controller

It handles the serial connection with the STM8S105C6 application host, and controls

the read/write accesses to all CR14 registers. It is compliant with the 400 KHz I

specification.

● The RAM buffer

The RAM buffer is bidirectional. It stores all the request frame bytes to be transmitted to

the tag, plus all the received bytes sent back by the tag on the answer frame.

● The transmitter

It powers the tag by generating a 13,56 MHz signal on an external antenna. The

resulting field is 10% modulated using ASK (amplitude shift keying) modulation to

transmit data.

● The receiver

It demodulates the signal generated on the antenna by the load variation of the tag.

The resulting signal is decoded by an 847 KHz BPSK (binary phase shift keying) subcarrier decoder.

2

C bus.

2

C bus

The CR14 generates an electromagnetic field which is rectified to power the tag. The reader

transmits information to the tag by modulating the carrier wave. To transmit information back

to the reader, the tag backscatters the carrier wave by modifying its own impedance thereby

perturbing the field.

The CR14 chip contains six volatile registers of which three allow to configure the CR14 and

to transmit/receive frames to/from the tag (see Ta bl e 1 ):

● Parameter register

● Input/Output Frame register

● Slot Marker register

For details regarding registers description and CR14 I

datasheet.

Table 1. CR14 control registers

Address Description Access Purpose

00h Parameter register 1 byte

6/24 Doc ID 17784 Rev 1

2

C protocol, refer to the CR14

W Set parameter register

R Read parameter register

Page 7

AN3255 Application description

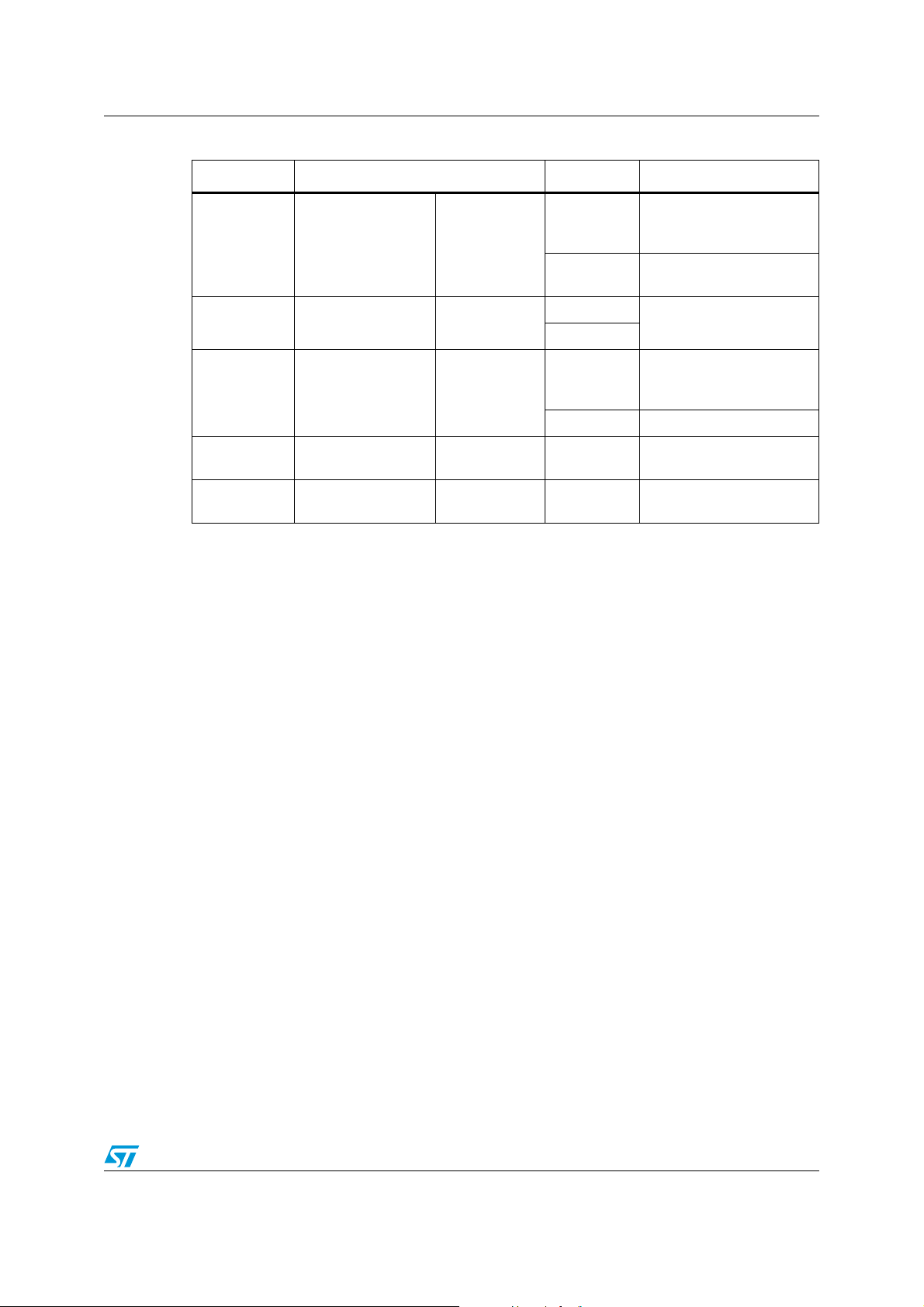

Table 1. CR14 control registers (continued)

Address Description Access Purpose

Store and send request

01h

02h ST reserved N/A

03h Slot Marker register 1 byte

04h ST reserved N/A R and W

Input/Output Frame

register

36 bytes

W

R

W

R

W

R Return FFh

frame to the tag. Wait for

tag answer frame

Transfer tag answered

frame data to host

ST reserved, must not be

used

Launch the automated anticollision process from

Slot_0 to Slot_15

ST reserved, must not be

used

05h ST reserved N/A R and W

1.2.2 I2C polling using Ack

During radio frequency data exchange, the CR14 disconnects itself from the I2C bus. The

time needed to complete the exchange is not fixed as it depends on the tag command

format. To know when the exchange is complete before starting reading the data in the

Input/Output Frame register, the bus master uses an Ack polling sequence that performs the

following actions:

1. Initial condition: a radio frequency data exchange is in progress.

2. Step 1: the master issues a START condition followed by the first byte of the new

instruction (Device Select Code plus R/W bit = 1) (see Appendix A: I2C memory

addressing).

3. Step 2: if the CR14 is busy, no Ack is returned and the master goes back to Step 1. If

the CR14 has completed the radio frequency data exchange, it responds by sending

back an ACK, thus indicating that it is ready to receive the second part of the next

instruction (the first byte of this instruction has been sent during Step 1).

Figure 2 shows the detailed I²C Ack polling flowchart.

ST reserved, must not be

used

Doc ID 17784 Rev 1 7/24

Page 8

Application description AN3255

2ADIO&REQUENCY

DATAEXCHANGE

INPROGRESS

3END

34!24CONDITION

3END#2

$EVICE3ELECT

#ODEWITH27

!#+

RETURNED

./

2EADDATABYTES

FROM#2

9%3

#2)£#

DISCONNECTED

AI

Figure 2. Ack Polling flowchart

1.2.3 Reader-tag protocol

Standard tag commands such as Read and Write are generated by the CR14 using its

Input/Output Frame register. To send a command to the tag, the STM8S105C6 host first

generates internally the complete frame containing the command code followed by the

command parameters (if required). Only the 2 CRC bytes must not be generated as the

CR14 automatically adds them during the RF transmission.

Once the frame is ready, the host writes it into the Input/Output Frame register using an I

Write command.

If the tag answers, the characters received are demodulated, decoded and stored into the

input/output frame buffer. During the entire RF transmission, the CR14 disconnects itself

from the I

the I

2

C bus. On reception of the tag EOF, the CR14 checks the CRC and reconnects to

2

C bus. The host can then get the tag answer frame by issuing an Input/Output Frame

Register Read command on the I

Refer to the CR14 datasheet for details on Read and Write commands.

1.2.4 Commands and tag states

The tag can be switched into different states (see Figure 3). The tag only answers specific

commands depending on its current state. These states are specified by the ISO 15693

standard. For details concerning these states, refers to one of ST short range contactless

EEPROM datasheet (for example SRI2K) available from http://www.st.com.

2

C bus.

2

C

8/24 Doc ID 17784 Rev 1

Page 9

AN3255 Application description

Power-off

Ready

Inventory

Selected

Deselected

Desactivated

Chip_ID

8bits = RND

Select(Chip_ID)

Read_block()

Write_block()

Get_UID()

Completion()

Select(Chip_ID)

Selct( != Chip_ID)

Select

(Chip_ID)

Reset_to_inventory()

Initiate() or Pcall16()

or Slot_marker(SN) or

Select(wrong Chip_ID)

Initiate()

On field

Out of

field

Out of

field

Out of

field

Out of

field

Out of

field

ai18400

Figure 3. TAG state transition diagram

1.3 Hardware requirements

The following STM8S-DISCOVERY on-board resources are used:

● LED LD1

Refer Ta bl e 2 , Tab le 3 , Tab le 4 , and Tab le 5 for the list of additional hardware required to

make this application software run on the STM8S-DISCOVERY.

Table 2. List of PCB passive components

Component description Value Comment

R1 N/A

R2 0 Ω

R3 N/A

R4 0 Ω

R5 N/A

R6 0 Ω

R7 0 Ω -

Doc ID 17784 Rev 1 9/24

Resistors

Hardwired addressing of the

CR14 (bits b3, b2, and b1 of the

7-bit I2C Device Select Code.

Allow up to 7 CR14 readers to

be addressed on the same I

2

C

bus

Page 10

Application description AN3255

Table 2. List of PCB passive components (continued)

Component description Value Comment

Serial resistor allowing to fine

R8 0 Ω

Capacitor

C1, C2 7 pF crystal oscillator capacitors

C3 22 nF -

C4 22 μF-

C5 5pF (50V) -

C6 100 nF -

C7, C7’ 220 pF (50 V), 56 pF (50 V)

C8, C8’ 82 pF (50 V), 22 pF (50 V)

Diode

D1 (N4148) Optional

tune the quality factor of the

reader antenna

Capacitors allowing to fine tune

the RLC resonant frequency

impedance adaptation of the

RLC resonant circuit.

Ferrite

L3,L4,L5,L6, L7 multilayer SMD

ferrites

Table 3. List of PCB packaged components

Removal of parasites for tag

data reception and I

Part name Component name Description Package

Contactless coupler

CR14/CRX14

Short-range RFID

couplers

compliant with short-

range ISO14443 type-B

standard

13.56 MHz crystal Crystal

Table 4. List of tag packaged components

Generates a 13.56 MHz

carrier frequency

Part name Component name Description Package

13,56 MHZ short-range

SRI2K

contactless memory

chip

Table 5. List of other passive components

Short-range contactless

memory used to build a

tag

SO16

XTALCMS

SBN18

2

C

Component description Value Comment

Resistor

RP1, RP2 resistors 4,7 KΩ Pull-up for I2C open-drain

10/24 Doc ID 17784 Rev 1

Page 11

AN3255 Application description

Table 5. List of other passive components (continued)

Component description Value Comment

Other

Piezo buzzer 5 V operating voltage Supports 4 KHz input frequency

1.4 Application schematics

Figure 4 shows the contactless reader implementation schematics. The reader is made of

two parts:

● STMicroelectronics RFID reader PCB based on the CR14 short range contactless

coupler (see Section 1.2.1).

● The STM8S-DISCOVERY which STM8S105C6T6 microcontroller controls the

bidirectional communications with the CR14 through the I

CR14 datasheet).

2

C serial bus (refer to the

Doc ID 17784 Rev 1 11/24

Page 12

Application description AN3255

Vref1RF IN2E03E14E25GND6GND7GND

8

SDA

9

SCL

10

GND

11

OSC212OSC1

13

GND_RF

14

RF OUT

15

VCC

16

U1

CRX14

X1

C1C3

22nF50V

C8

C8'

C7 C7'

VCC

VCC

C6

+

C4

L4

WURTH 742-792-042

L5

WURTH 742-792-042L6WURTH 742-792-042

L7

WURTH 742-79 2-042

R7

R8

R1

OPT ANT1

ANT2

E0

E1

E2

SCL

SDA

123

4

J1

R2

R3

OPT

R4

R5

OPT

R6

VCC

D1

1N4148 (OPTIONA L)

C5

L3

WURTH 742-792-042

Vref1RF IN2E03E14E25GND6GND7GND

8

SDA

9

SCL

10

GND

11

OSC212OSC1

13

GND_RF

14

RF OUT

15

VCC

16

U1

X1

13.56 MHz

C1 7 pF 50 V

C2

7 pF 50 V

C3

22nF50V

C8

82 pF 50 V

C8'

22 pF 50 V

C7

220 pF 50 V

C7'

56 pF 50 V

VCCant

VCCant

C6

100 nF 50 V

+

C4

22 μF 10V

L4

WURTH 742-792-042

L5

WURTH 742-792-042L6WURTH 742-792-042

L7

WURTH 742-79 2-042

R7

R8

R1

OPT ANT1

ANT2

E0

E1

E2

SCL

SDA

123

4

R2

0 ΩR

R3

OPT

R4

R5

OPT

R6

VCCant

D1

1N4148 (OPTIONA L)

C5

10 pF 50 V

L3

WURTH 742-792-042

STM8S

I²C

PD0

VCCVCC

Buzzer

Piezo

PD4

PE1/SCL

PE2/SDA

VCCVCC

BEEP

Rp1

Rp2

GNDant

GNDant

GNDant

GNDant

GNDant

GNDant

GNDant

GNDant

LD1

(green)

0 ΩR

0 ΩR

0 ΩR

0 ΩR

AI

4,7Ω

4,7Ω

RFID reader PCB

Figure 4. Contactless RFID reader schematics

12/24 Doc ID 17784 Rev 1

Page 13

AN3255 Application description

The efficiency of data transfers between the RFID reader and tag depends on the tuning of

their respective antenna. This is done by adjusting the following components:

● C

is the serial capacitance used to adapt the impedance of the reader antenna RLC

S

equivalent circuit:

C

= C8 + C8’

S

● C

is the parallel capacitance used to tune the resonant frequency of the reader RLC

P

equivalent circuit:

C

= C7 + C7’

P

● R

is the serial resistor used to fine tune the quality factor of the reader RLC resonant

S

equivalent circuit:

R

= R8

S

Refer to application note AN1806 for details on how to design a reader antenna and infer the

values of C

, CS and RS. This document is associated with a software tool using the Grover

P

method to calculate the inductance of rectangular planar antennas.

Warning: The values of CS, CP, and RS are dependant. Tuning one of

them impacts the 2 others. The best compromise must be

found to achieve a good tuning for the reader antenna (refer

to AN1806).

Doc ID 17784 Rev 1 13/24

Page 14

STM8S-DISCOVERY configuration AN3255

2 STM8S-DISCOVERY configuration

2.1 Power supply configuration

The CR14 of the RFID reader PCB must be supplied from 5 V± 500 mV. This board being

powered from STM8S-DISCOVERY V

be set to V

= 5 V (see UM0817).

DD

2.2 Option byte configuration

The STM8S105C6T6 Beeper output is enabled through the alternate function remapping

option (AFR7) of the OPT2 option byte:

AFR7 = 0: port D4 alternate function is TIM2_CH1 (default)

AFR7 = 1: port D4 alternate function is BEEP (required)

For details on the option byte and alternate function remapping, refer to UM0834 and to the

STM8S105xx datasheet, respectively.

, the jumper JP1 of the STM8S-DISCOVERY must

DD

14/24 Doc ID 17784 Rev 1

Page 15

AN3255 Software description

3 Software description

3.1 STM8S peripherals used by the application

The application software uses STM8S standard firmware library to control general purpose

functions. These peripheral functions are the following:

● Clock (CLK)

The clock control enables and delivers the correct clock frequency to the CPU and

peripherals. It configures the HSI prescaler division factor to 4. The I

frequency is 4 MHz to be able to generate correct timings compliant with Fast mode.

● GPIOs

They drive the MCU I/Os to interface with external hardware. They configure PD0 port

as output push-pull high to drive LD1 and switch it off at initialization. PD4 port is

configured through alternate function remapping to enable the Beeper output pin.

2

● I

C

This peripheral handles the serial connection with the CR14 contactless coupler of the

RFID reader board. It controls the read/write access to the CR14 registers.

● Auto wake-up (AWU)

This peripheral is used to provide an internal wake-up timebase that is used when the

MCU goes into Active-halt power saving mode. It is configured to wake up the MCU

after 512 ms, which is a good trade-off between the time during which the

microcontroller remains in Active-halt power saving mode and the time required by the

RFID reader to identify the tag.

● Beeper

This peripheral drives the Beeper output pin with a signal of 4 KHz for sound

generation.

● TIM3

The TIM3 timer is used to measure the LSI frequency with Input Capture 1 to reach

with a better accuracy the standard Beeper frequency outputs.

2

C input clock

3.2 Configuring the STM8S standard firmware library

The stm8s_conf.h file of the STM8S standard firmware library is used to configure the

library by enabling the peripherals used by the application.

The following define statements must be present:

#define _CLK 1 enables the clock control (CLK),

#define _GPIO 1 enables the GPIOs,

#define _I2C 1 enables the I

#define _AWU 1 enables the Auto wake-up,

#define _BEEP 1 enables the beeper,

#define _TIM3 1 enables timer 3.

2

C interface,

Doc ID 17784 Rev 1 15/24

Page 16

Software description AN3255

3.3 Application principle

This application initiates communications with the tags present in the range of the

electromagnetic field generated by the reader antenna, and read the tag UIDs. If the

operation succeeds, the STM8S105C6T6 emits a beep and blinks LD1.

When running the code in debug mode from STVD development tool, the UID value can be

displayed in the Watch windows.

The application uses the I

board, and to transmit/receive frames to/from the tags (see Ta bl e 6 ). Communications with

the tags are managed by the state transition diagram shown in Figure 3.

A possible way to improve this application would be to use an LCD screen to display the tag

unique identifier (UID). Another improvement could be to implement the CR14 anti-collision

capability which allows the reader to select up to 16 tags (one at a time) during predefined

time slots.

Refer to Figure 5 for the flowchart of the application software main loop.

Table 6. TAG commands used within this application

Tag commands Description

Initiate() To detect if a tag in Ready state is present in the reader field range

Select(Chip_ID) Allow the tag to enter the Selected state

2

C protocol to configure the CR14 embedded on the RFID reader

Get_UID() On receiving this command, the tag returns its 8 UID bytes

16/24 Doc ID 17784 Rev 1

Page 17

AN3255 Software description

34!24

4AGDETECTED

9%3

./

)#7RITE@3ELECTED#HIP?)$

34-3ENTERS!CTIVEHALT

MODEFORMS

.EW#HIP?)$)#2EAD

4AG

SUCCESSFULLY

DETECTED

./TAGNOTSELECTED

9%3

-AKE,$BLINK

%MITABEEP

)#7RITE@'ET5)$

5)$)#2EAD

-AKE,$BLINK

FORS

)#7RITE@)NITIATE

2EADTAG#HIP?)$

INITIALIZATIONOF

ALLPERIPHERALS

2EADNEW#HIP?)$OFTHETAG

AIB

Figure 5. Main application loop flowchart

During peripheral initialization, the application first configures the CR14 parameter register

to generate the 13,56 MHz RF field on the reader antenna.

Prior to issuing a Read/Write command (such as Get_UID()) to the memory tag, the tag

state machine must be put in the Selected state by sending a Select(Chip_ID) command. All

commands sent to the tag before this command is issued are ignored.

Once the peripheral initialization has completed, the application code enters a loop in which

it checks if a tag is present in the RF field by writing periodically the Initiate() command in

the CR14 Input/Output Frame register (see Appendix A: I2C memory addressing). If no tag

is present in the electromagnetic field, the STM8S105C6T6 enters the Active-halt power

saving mode for 512 ms and automatically wakes up to issue a new Initiate() command.

As soon as a tag is present in the electromagnetic field, it automatically enters the Ready

state in which its 8-bit random Chip_ID is initialized. When receiving the Initiate() command,

the tag then switches to the Inventory state in which its new 8-bit Chip_ID random value is

set and returned to the CR14. Since this application software does not implement the anti-

Doc ID 17784 Rev 1 17/24

Page 18

Software description AN3255

collision mechanism, the Chip_ID is stored by the host and sent as parameter to the

Select(Chip_ID) command issued by the host to the tag. The tag then switches directly to

the Selected state.

The Get_UID() command is then sent to the tag that answers by returning its 8 UID bytes.

The host emits a beep and lights LD1 for about 1 s.

18/24 Doc ID 17784 Rev 1

Page 19

AN3255 I2C memory addressing

Appendix A I2C memory addressing

To start communicating with the CR14, the bus master initiates a START condition and

sends 8 bits (with Most Significant Bit first) on the serial data line SDA. These bits contain

the Device Select Code (7 bits) and the RWbar bit.

According to the I

Code are the Device Type Identifier. For the CR14 these bits definition is given in Tab le 7 .

Table 7. Device Select code

CR14

select

The 8th bit is the Read/Write bit (RWbar). It is set to ‘1’ for I2C read and to ‘0’ for I2C write

operations.

If the data sent by the bus master matches the Device Select Code of the CR14, it returns

an acknowledgement on the bus during the 9th bit time. The CR14 device generates a

NACK if its Device Select Code does not correspond to the data sent. It deselects himself

from the bus and goes in standby mode.

Refer to the CR14 datasheet for details regarding the CR14 I

reference manual for a functional description on I

2

C bus definition, the seven Most Significant Bits of the Device Select

Device Code Chip Enable RWbar

b7 b6 b5 b4 b3 b2 b1 b0

1 0 1 0 E2 E1 E0 RWbar

2

2

C peripheral.

C protocol, and to the STM8S

Doc ID 17784 Rev 1 19/24

Page 20

I2C Read and Write functions AN3255

Appendix B I2C Read and Write functions

This section gives an overview of the main functions controlling the read and write accesses

to the CR14.

20/24 Doc ID 17784 Rev 1

Page 21

AN3255 I2C Read and Write functions

Start

I²C bus busy ?

YES

NO

Send

START condition

START condition

generated ?

YES

NO

Send

CR14 Device Select Code

with R/W=0

END of Address

transmission ?

Send register

write address

Data byte transfer

succeeded ?

Number of data

to be written > 0 ?

Send Data byte

Data byte transfer

succeeded ?

Generate

STOP condition

END

NO

YES

NO

YES

YES

NO

Number of data

to be written --

ai18402

B.1 I2C Page Write flowchart

The Page Write function performs write accesses to the CR14 registers. Its parameters are

the buffer containing the bytes to be written to the CR14, the CR14 write address and the

number of bytes to be written.

Figure 6 shows the detailed flowchart of the I2C_Page_Write function.

Figure 6. I

2

C Page Write flowchart

Doc ID 17784 Rev 1 21/24

Page 22

I2C Read and Write functions AN3255

B.2 I2C post polling buffer read flowchart

This function has been implemented to be used together with the I2C polling function. Once

an ACK has been returned by I2C_CR14_EE_AckPolling, the

I2C_CR14_EE_PostPolling function reads one by one all the bytes that are available in

the Input/ Output Frame register of the CR14.

Figure 7 shows the detailed flowchart of the I2C_CR14_EE_PostPolling function.

Figure 7. I

.UM"YTE4O2EAD

2

C post polling buffer read flowchart

.UM"YTE4O2EAD

2EADONEBYTE

FROM#2

#2!CK0OLLING

INPROGRESS

9%3

.UM"YTE4O2EAD

9%3./

$ISABLETHE)£#

!CKNOLEDGEMENT

34/0CONDITION

2EADONEBYTE

FROM#2

./

%.$

3END

.UM"YTE4O2EAD

22/24 Doc ID 17784 Rev 1

AI

Page 23

AN3255 Revision history

Revision history

Table 8. Document revision history

Date Revision Changes

12-Oct-2010 1 Document migrated from UM0927 rev 1.

Doc ID 17784 Rev 1 23/24

Page 24

AN3255

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2010 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

24/24 Doc ID 17784 Rev 1

Loading...

Loading...