Page 1

AN3254

Application note

SPI protocol for the STPMC1 metering device

Introduction

The STPMC1 device is an ASSP designed for effective measurement in power line systems

utilizing the Rogowski coil, current transformer, and shunt or Hall current sensors. Used in

combination with one or more STPMSx ICs, it implements all the functions needed in a 1, 2,

or 3-phase energy meter. It can be coupled with a microprocessor for multifunction energy

meter or it can directly drive a stepper motor for a simple active energy meter.

All the data measured by the STPMC1 are accessible through the SPI port, which is also

used to configure and calibrate the device. The configuration and calibration data are

retained in a 112-bit OTP block; in any case, these data can be dynamically changed in

microprocessor based meters.

Measured data (like active and reactive energy, total and per phase, phase V

RMS

, I

RMS

and

instantaneous voltage and current, line frequency, phase status, etc.) should be read by the

microcontroller at a fixed time interval to be further processed.

This application note describes the SPI protocol to read measured data from the STPMC1

in a multiphase energy meter and how these readings should be processed by the

application.

For more details on the device please refer to the STPMC1; Programmable poly-phase

energy calculator IC, datasheet.

Figure 1. STPMC1 based application block diagram

N R S T

Current

Sensor

Voltage

Sensor

Current

Sensor

Voltage

Sensor

Current

Sensor

Voltage

Sensor

Current

Sensor

STPMS1

STPMS1

STPMS1

STPMS1

DAR

DAS

(

DAT

DAN

(

DAH

Ener gy

No Load

STPMC1

Tamper

Negative

powe r

LED indicators

Stepper CounterStepper Counter

4 wires

SPI

SPI

Appl ication S upp ort and

Appl ication S upp ort and

Application Support and

Application Support and

Peri phera l Control

Peri phera l Control

Perip heral Cont rol

Perip heral Cont rol

MCU

MCU

MCU

MCU

November 2010 Doc ID 17783 Rev 1 1/24

www.st.com

Page 2

Contents AN3254

Contents

1 SPI module description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Connection to microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 SPI interface timings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 SPI operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 Remote reset request . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Data registers writing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3 Data registers permanent writing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4 Reading data registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Data processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Reading process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1.1 Data register assembling example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2 Parity check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2.1 Parity check example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3 Unpacking data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5 Converting readings into measured values . . . . . . . . . . . . . . . . . . . . . 16

5.1 Energies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2 Other values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2.1 Voltage, current, and frequency calculation . . . . . . . . . . . . . . . . . . . . . . 18

5.2.2 Other values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2/24 Doc ID 17783 Rev 1

Page 3

AN3254 SPI module description

1 SPI module description

The STPMC1 SPI interface supports a simple serial protocol, which is implemented in order

to enable a communication between a host system (microcontroller or PC) and the device.

With this interface it is possible to perform the following tasks:

● remote reset of the device

● temporary and permanent programming of internal configuration/calibration data and

system signals

● reading of internal data registers (shown in Figure 5).

Four pins of the device are dedicated to this purpose: SCS, SYN, SCL, and SDA.

When the STPMC1 is in standalone mode, SYN, SCL, and SDA can provide information on

the meter status (see the STPMC1 datasheet for more information) and are not used for SPI

communication. In this document, the SYN, SCL, and SDA operation as part of the SPI

interface is described.

SCS, SYN, and SCL are all input pins while SDA can be input or output depending on

whether the SPI is in write or read mode.

The internal registers are not directly accessible, rather, a 32-bit of transmission latches are

used to pre-load the data before being read or written to the internal registers.

The condition in which SCS, SYN, and SCL inputs are set to a high level determines the idle

state of the SPI interface and no data transfer occurs. Any SPI operation should start from

this idle state. The exception to this rule is when the STPMC1 has been put into standalone

application mode. In such mode it is possible that pin states of the SCL, SDA, and SYN are

not high due to the states of corresponding internal status bits.

● SCS: enables SPI operation when low, both in standalone and in peripheral operating

mode. This means that the master can abort any task in any phase by deactivation of

SCS. In standalone mode SCS high enables SYN, SCL, and SDA to output the meter

status.

● SYN: when SCS is low, the SYN pin status selects if the SPI is in read (SYN=1) or write

mode (SYN=0). When SCS is high and SYN is also high, the results of the input or

output data are transferred to the transmission latches.

● SCL: is the clock pin of the SPI interface. This pin function is also controlled by the SCS

status. If SCS is low, SCL is the input of the serial bit synchronization clock signal.

When SCS is high, SCL is also high, determining the idle state of the SPI.

Configuration bit SCLP controls the polarity of the clock. SCLP=0 sets the clock idle

state SCL=1, while SCLP=1 sets the clock idle state SCL=0.

● SDA: is the data pin. If SCS is low, the operation of SDA is dependent on the status of

the SYN pin. If SYN is high, SDA is the output of serial bit data (read mode). If SYN is

low, SDA is the input of serial bit data signal (write mode). If SCS is high, SDA is idle.

When SCS is active (low), the signal SDA should change its state at the trailing edge of

signal SCL and the signal SDA should be stable at the next leading edge of signal SCL.

The first valid bit of SDA is always started with activation of signal SCL. This is valid if

SCLP=0, otherwise the polarity of the clock is inverted.

A high level signal for these pins means a voltage level higher than 0.75 x V

level signal means a voltage value lower than 0.25 x V

Doc ID 17783 Rev 1 3/24

CC

.

, while a low

CC

Page 4

SPI module description AN3254

1.1 Connection to microcontroller

The SPI master should be implemented by a host system, a PC, or a microcontroller.

The microcontroller’s SPI bus is usually a 4-wire bus with full duplex functionality, whose

signals are usually named as:

● SCLK: serial clock (output from master)

● MOSI: master output, slave input (output from master)

● MISO: master input, slave output (output from slave)

● SS: slave select (active low, output from master)

The best way to connect this standard SPI port to the STPMC1 SPI is to have SCS and SYN

driven from some general purpose I/O port and SCL and SDA driven from SPI pins.

The suggested connection between the microcontroller and the STPMC1 is the following:

● MISO connected to SDA

● MOSI not connected

● SCLK connected to SCL

● SS connected to SCS

● a general purpose I/O pin connected to SYN.

In this way, the SPI peripheral unit of the microprocessor should operate as 2-wire (simplex

synchronous transfers) SPI.

The microprocessor SPI peripheral can be used during STPMC1 device reading, while

during the writing process it is possible to implement the SPI protocol via firmware.

In fact, in real applications the meter is calibrated and configured during meter production,

so the main microcontroller task is to read from the device and, more rarely, to reset the

device.

Moreover the reading time is crucial for a correct evaluation of the device data, it is advisable

to emulate the writing procedure by firmware and to read using the SPI peripheral

functionality, therefore exploiting all the port performances to reach very fast reading.

4/24 Doc ID 17783 Rev 1

Page 5

AN3254 SPI interface timings

2 SPI interface timings

Table 1. SPI interface timings

Symbol Parameter Min. Typ. Max. Unit

F

SCLKr

F

SCLKw

t

t

t

t

OFF

t

SYN

Data read speed 32 MHz

Data write speed 100 kHz

DS

DH

ON

Data setup time 20 ns

Data hold time 0 ns

Data driver on time 20 ns

Data driver off time 20 ns

SYN active width 2/f

In Ta bl e 1 above, f

details).

XTAL1

is the oscillator clock frequency (see the STPMC1 datasheet for

XTAL1

s

Doc ID 17783 Rev 1 5/24

Page 6

SPI operations AN3254

3 SPI operations

3.1 Remote reset request

The STPMC1 has no reset pin. It is automatically reset by the power on reset (POR) circuit

when the V

giving a dedicated command, the timing diagram is shown in Figure 2.

The reset through SPI (remote reset request - RRR) is sent from the onboard

microprocessor when a malfunction of the metering device has been detected.

Unlike the POR, the RRR signal does not cause the 30 ms retarded restart of the analog

module and the 120 ms retarded restart of the digital module. This reset does not clear the

mode signals.

Figure 2. Remote reset request timing

SCS

crosses the 2.5 V value but it can be reset also through the SPI interface

CC

SYN

SCL

SDA

t2t

1

t4t

3

t6t

5

Note: All the time intervals must be longer than 30 ns. t

also be longer than 30 ns.

3.2 Data registers writing

Each writable bit (configuration and mode signals bits) of the STPMC1 has its own 7-bit

absolute address (see the STPMC1 datasheet for configuration bits map).

t

7

7 →t8

t

t

t

10

8

9

is the reset time, this interval must

In order to change the state of some pins, a byte of data via the SPI must be sent to the

device. This byte consists of 1-bit data to be written (MSB), followed by a 7-bit address of

the destination bit, which makes a command byte.

6/24 Doc ID 17783 Rev 1

Page 7

AN3254 SPI operations

For example, to set the STPMC1 configuration bit 47 (part of the R-phase current channel

calibrator) to 1, the decimal 47 must be converted to its 7-bit binary value: 0101111. The

byte command is then composed as:

1 bit DATA value+7 bits address = 10101111 (0xAF)

The same procedure should be applied for the mode signals, which also have their specific

address.

The LSB of the command is also called EXE bit because, instead of a data bit value, the

corresponding serial clock pulse is used to generate the necessary latching signal. In this

way, the writing mechanism does not need the measurement clock in order to operate,

which makes the operation of the SPI module of the STPMC1 completely independent from

the rest of the device logic, except from the signal POR.

The writing procedure timing is shown in Figure 3.

Figure 3. Timing for writing configuration bits and mode signals

SCS

SYN

SCL

SDA

t

t

2

1

t

→t2 (> 30 ns): SPI out of idle state

1

t

→t3 (> 30 ns): SPI enabled for write operation

2

t

: data value is placed in SDA

3

t

: SDA value is stable and shifted into the device

4

t

→t5 (> 10 µs): writing clock period

3

t

→t5: 1-bit data value

3

t

→t6: 6-bit address of the destination latch

5

t

→t7: 1-bit EXE command

6

t

: end of SPI writing

8

t

: SPI enters idle state

9

t4t

t

3

5

t

t

6

7

t

t

8

9

Doc ID 17783 Rev 1 7/24

Page 8

SPI operations AN3254

Commands for changing configuration bits and system signals should be sent during active

signals SCS and SYN, as it is shown in Figure 3.

The SYN must be put low in order to disable the SDA output driver of the device and to

make the SDA an input pin. A string of commands can be sent within one period of active

signals SCS and SYN or a command can be followed by reading the data record but, in this

case, the SYN should be deactivated in order to enable the SDA output driver and a SYN

pulse should be applied before activation of the SCS in order to latch the data.

Given the connection between the STPMC1 and a microcontroller, as shown in the previous

paragraph, it is possible to implement the writing procedure in the firmware through the

following steps:

1. disable the SPI peripheral

2. set MISO, SCLK, and SS to be output

3. set the pin which is connected to SYN to be output high

4. activate SCS first and then SYN

5. activate SCL

6. apply a bit value to SDA and deactivate SCL

7. repeat the last two steps seven times to complete one byte transfer

8. repeat the last three steps for any remaining byte transfer

9. deactivate SYN and the SCS

10. enable again the SPI module.

To temporarily set any bit, it is necessary to set the RD system signal before any other bit.

This bit determines the device functioning from OTP shadow latches and not from OTP

memory. The procedure to set this signal is that shown above.

In the case of a precharge command (0xFF), emulation of the above is not necessary, it can

be sent before any reading command. In fact, due to the pull up device on the SDA pin the

processor needs to perform the following steps:

1. activate SYN first in order to latch the results

2. after at least 1 µs activate SCS

3. write one byte to the transmitter of SPI this produces 8 pulses on the SCL with SDA=1

4. deactivate SYN

5. read the data records as shown in Section 3.4 (the sequence of reading is altered)

6. deactivate SCS.

3.3 Data registers permanent writing

In order to make a permanent set in OTP memory of some configuration bits, the following

procedure should be conducted:

8/24 Doc ID 17783 Rev 1

Page 9

AN3254 SPI operations

1. collect all addresses of bits to be permanently set into some list

2. clear all OTP shadow latches

3. set the system signal RD

4. connect a current source of at least +14 V, 1 mA to 3 mA to the V

5. wait until V

voltage is stable

OTP

OTP

pin

6. write one of the bits from the list (as the RD signal is set, the bit is written in the

corresponding OTP shadow latch)

7. set the system signal WE

8. wait for 300 µs

9. clear the system signal WE

10. clear the OTP shadow latch which was set in step 6

11. until all wanted bits are permanently set, repeat steps 5 to 10

12. disconnect the current source

13. wait until V

voltage is less than 3 V

OTP

14. clear the system signal RD

15. read all data records, in the last two there is read back of all configuration bits

16. if verification of CFG bits fails and there is still a chance to pass, repeat steps 1 to 16.

For the steps above which ask of set or clear, apply the timing shown in Figure 3 with proper

data on the SDA.

For step 15 apply the timing shown in Figure 4.

For a permanent set of the TSTD bit, which locks the device, the procedure above must be

conducted in such a way that steps 6 to 13 are performed in series during a single period of

active SCS because the idle state of SCS would make the signal TSTD immediately

effective.

This would abort the procedure, and it would possibly destroy the device.

In fact the clearing of system signal RD would connect all gates of 3 V NMOS sense

amplifiers of already permanently set bits to the V

3.4 Reading data registers

There are two phases of reading, called latching and shifting.

● Latching is used to sample results into transmission latches. This is done with the

active pulse on SYN when SCS is idle. The length of pulse on SYN must be longer than

2 periods of the measurement clock, i.e. more than 500 ns.

● Shifting starts when SCS becomes active. In the beginning of this phase another, but

much shorter pulse (30 ns) on SYN should be applied. An alternative way is to extend

the pulse on SYN into the second phase of reading. Latching and shifting finish at the

dotted line in the timing diagram shown in Figure 4.

OTP

source.

Doc ID 17783 Rev 1 9/24

Page 10

SPI operations AN3254

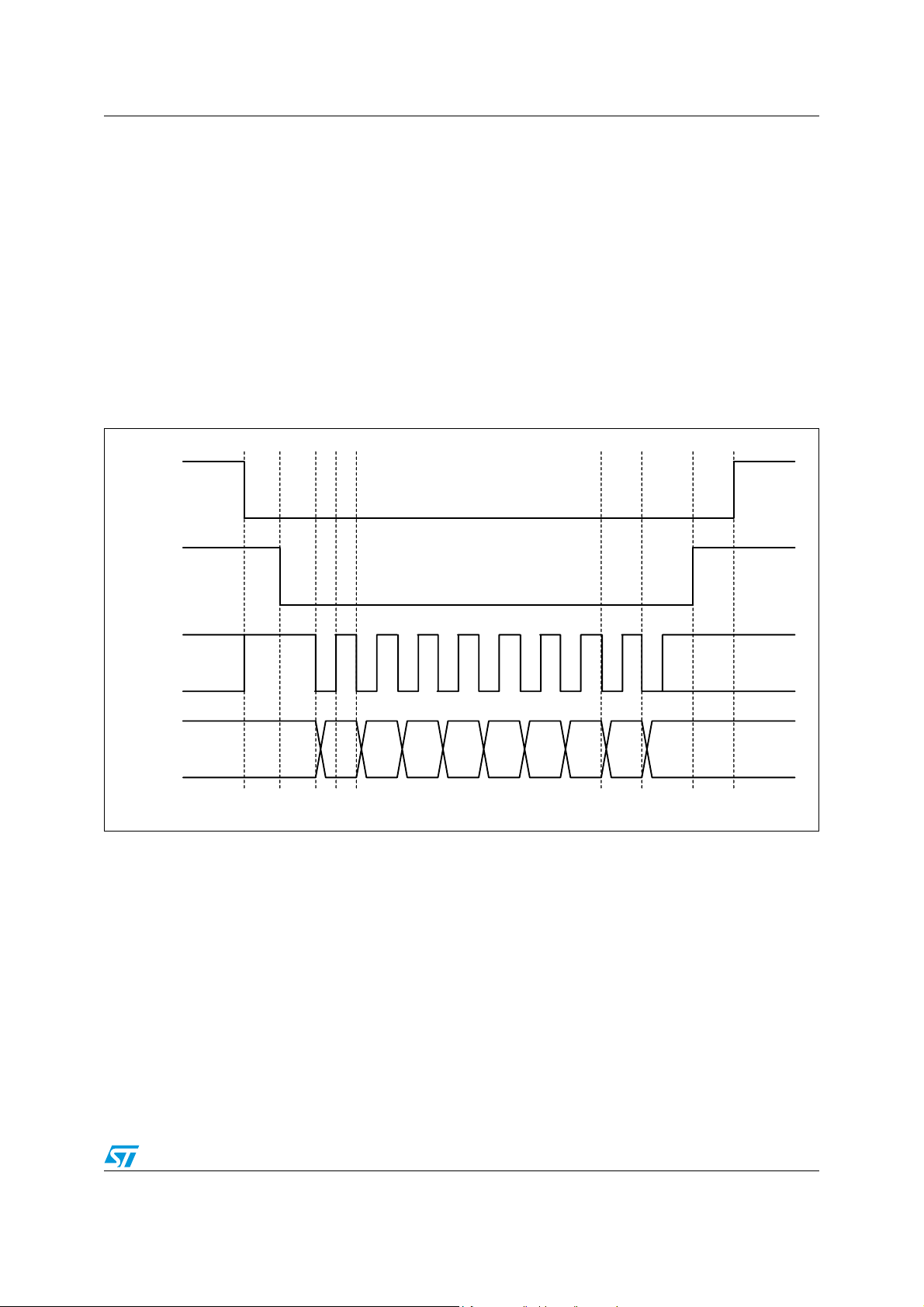

Figure 4. Timing for reading data registers

SCS

SYN

SCL

SDA

t

1

t1 → t2: latching phase. Interval value > 2 / f

t

t4t

2

t6t

3

5

t8t

7

last bit of 32ndbyte1stbyte1stbyte

XTAL1

t2 → t3: data latched, SPI idle. Interval value > 30 ns

t

→ t4: enable SPI for read operation. Interval value > 30 ns

3

t

→ t5: serial clock counter is reset. Interval value > 30 ns

4

t

→ t6: SPI reset and enabled for read operation. Interval value > 30 ns

5

t

: internal data transferred to SDA

7

t

: SDA data is stable and can be read

8

After the shifting phase, it is possible to read data, applying 32 serial clocks per data record.

Up to 28 data records can be read this way.

There are seven groups of four data records available, each consisting of a parity nibble

(see Section 3.2) and a 28-bit data field. Figure 5 and Figure 6 show the records structure

and the information they hold in the default sequence of reading.

The system which reads the data record from the STPMC1 should check the integrity of

each data record. If the check fails, the reading should be repeated, but this time only the

shifting phase should be applied otherwise a new data would be latched into the

transmission latches and the previous reading would be incorrectly lost.

Most of the registers contain the values of the electrical parameters and the status of the

signals, except the registers CF0, CF1, CF2, and CF3 which represent the configuration

bitmap.

The data records have a fixed position of reading. This means that no addressing of records

is necessary.

The sequence of data records during the reading operation is fixed. However, an application

may apply a precharge command prior to the reading phase. This command increases the

group pointer forcing the device to respond with the next group data records sequence. In

this way, a faster access to later groups is possible.

10/24 Doc ID 17783 Rev 1

Page 11

AN3254 SPI operations

Figure 5. STPMC1 data registers

DAP

DAP

parity

parity

20 bit

20 bit20 bit

3-phase active energy wide band

3-phase active energy wide band

4 bit

4 bit

lowe r status

lowe r status

8 bit4 bit

8 bit4 bit

4 bit

4 bit

DRP

DRP

DFP

DFP

PRD

PRD

DMR

DMR

DMS

DMS

DMT

DMT

DMN

DMN

DER

DER

DES

DES

DET

DET

DEN

DEN

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

3-phase reactive energy

3-phase reactive energy

3-phase active energ y fundamental

3-phase active energ y fundamental

period

period

12 bit 16 bit

12 bit 16 bit

DC uN

DC uN

iR MOMuRMOM

iR MOMuRMOM

iS MOMuS MOM

iS MOMuS MOM

iT M OMuT MOM

iT M OMuT MOM

iN MOMsI RMS

iN MOMsI RMS

iR RMSuR RMS

iR RMSuR RMS

iS R MSuS RMS

iS R MSuS RMS

iT RMSuT RMS

iT RMSuT RMS

iN RMSuN RMS

iN RMSuN RMS

upper status

upper status

system read back

system read back

TSG bits

TSG bits

Doc ID 17783 Rev 1 11/24

Page 12

SPI operations AN3254

Figure 6. STPMC1 data registers

DAR

DAR

parity

parity

20 bit

20 bit20 b it

R-phase active energy wide band R- p has e s tat us

R-phase active energy wide band R- p has e s tat us

28 bit

28 bit

8 bit4 bit

8 bit4 bit

DAS

DAS

DAT

DAT

CF0

CF0

DRR

DRR

DRS

DRS

DRT

DRT

CF1

CF1

DFR

DFR

DFS

DFS

DFT

DFT

CF2

CF2

ACR

ACR

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

parity

S-p h as e st atusS-phase active energy wide band

S-p h as e st atusS-phase active energy wide band

T-phase active energy wide band T-phase status

T-phase active energy wide band T-phase status

bits [27..0] of configurators

bits [27..0] of configurators

R-pha se reactive en erg y R- p has e s tat us

R-pha se reactive en erg y R- p has e s tat us

S-p h as e st atusS-phase reactive energy

S-p h as e st atusS-phase reactive energy

T- phas e reactive en erg y T-phase status

T- phas e reactive en erg y T-phase status

bits [55..28] of configurators

bits [55..28] of configurators

R- phas e a ctive en erg y fun dam e n ta l R- p has e s tat us

R- phas e a ctive en erg y fun dam e n ta l R- p has e s tat us

S-p h as e st atusS-phase active energy fundamental

S-p h as e st atusS-phase active energy fundamental

T-phase active energy fundamental T-phase status

T-phase active energy fundamental T-phase status

bits [83..56] of configurators

bits [83..56] of configurators

R- phas e e laps ed

iR RMS Ah accumulator if ba d uR

iR RMS Ah accumulator if ba d uR

R- phas e e laps ed

ACS

ACS

ACT

ACT

CF3

CF3

parity

parity

parity

parity

parity

iS RMS Ah accumulator if bad uS

iS RMS Ah accumulator if bad uS

iT RM S Ah accumulator if bad uT T-phase elapsed

iT RM S Ah accumulator if bad uT T-phase elapsed

bits [ 111..84] of configurators

bits [ 111..84] of configurators

parity

12/24 Doc ID 17783 Rev 1

S-p hase el a psed

S-p hase el a psed

Page 13

AN3254 Data processing

4 Data processing

4.1 Reading process

As previously mentioned, to start an SPI communication with the STPMC1 to read new

values of registers, it is necessary to apply a latching phase first. Then a shifting phase

starts, as described in Figure 4.

After that, 32 pulses of serial clocks need to be applied to pin SCL in order to read the DAP

register. If an additional 32 pulses are applied to pin SCL, the DRP register is read.

Reading can be continued by applying 32 clocks per register until all registers of interest are

read or a precharge command is applied first (8 pulses to pin SCLNLC while SYN=0 and

SDA=1) which moves ahead the internal group pointer to group 1 (register DMR) which

effectively skips DFP and PRD registers, and then reading may be continued.

The internal group pointer is incremented by 1 after each precharge command sent. If, for

example, in the previous case two precharge commands are sent, the pointer will be set to

group 2 (register DER).

It is up to an application to decide how many records should be read out from the device.

After all the registers are read, SCS can be returned to idle state which ends the shifting

phase.

The shifting phase can be repeated and it should read the same values. This repetition is

used to improve the reliability of successful reading in a strong EMI environment.

Every register is packed into 4 bytes where the most significant nibble (4 bits) is reserved for

parity code and the rest of the 28 bits are used for data. This means that every register is

protected by its own parity bit.

As shown in Figure 7, the first read out byte of the data record is the least significant byte

(LSB) of the data value and the fourth is the most significant byte (MSB) of the data value,

then it is necessary to re-order the four bytes after reading.

Figure 7. STPMC1 data register assembling

8 bit SPI reading order

1stbyte - LSB

msb lsb

7 07 0 7 07 0

7 07 0 7 07 0

msb lsb

7 07 015 815 823 1623 1600 2424

parity nibble 28 bit data

4thbyte - MSB

parity nibble

32 bits register assembling

Doc ID 17783 Rev 1 13/24

Page 14

Data processing AN3254

Normally, each byte is read out as the most significant bit (MSB) first. But this can be

changed by setting the MSBF configuration bit. If this is done, each byte is read out as the

least significant bit (LSB) first.

4.1.1 Data register assembling example

The following is an example of the reading and re-arranging of STPMC1 registers.

On the left there are the eight data records as they are read, represented as hexadecimal

bytes while MSBF was cleared, on the right is the corresponding register.

1. 65 7A 7C 82

2. 00 7A 0C E0

3. 00 00 8C 92

4. 00 06 6E 22 PRD = 22 6E 06 00

5. …

4.2 Parity check

Each bit of parity nibble is defined as odd parity of all seven corresponding bits of data

nibbles. In order to check the data record integrity, the application should execute something

similar to the following C code, given as an example:

int BadParity (unsigned char *bp)

{

register unsigned char prty = grp;

(0..6)*/

prty = *bp, /* take the 1st byte of data */

prty ^= *(bp+1), /* XOR it with the 2nd byte */

prty ^= *(bp+2), /* and with the 3rd byte */

DAP = 82 7C 7A 65

DRP = E0 0C 7A 00

DFP = 92 8C 0 00

/* temporary register set to group #

prty ^= *(bp+3), /* and with the 4th byte */

prty ^= prty<<4, prty &= 0xF0;/* combine and remove the lower

nibble */

return (prty != 0xF0); /* returns 1, if bad parity */

}

If the parity nibble check fails, the reading task should be repeated, but this time without the

request of latching, otherwise a new data would be latched and the previous reading would

be incorrectly lost.

In a very harsh EMI environment, it would be a good practice to read the data records twice

and then compare both readings. In this way, the probability of detecting bad readings would

be significantly improved. However, a single piece of bad data can be discarded because no

meaningful information is lost as long as the reading frequency is about 30 ms.

14/24 Doc ID 17783 Rev 1

Page 15

AN3254 Data processing

4.2.1 Parity check example

Let us calculate the parity of DMR, the first register of the second group:

DMR: 02 80 00 C8

prty = grp = 1 /* prty set to 1 - group #*/

prty = *bp = 3 /* xor it with 1st byte of data 02 */

prty ^= *(bp+1) = 83 /* xor it with the 2nd byte 80*/

prty ^= *(bp+2) = 83 /* and with the 3rd byte 00 */

prty ^= *(bp+3) = 4B /* and with the 4th byte C8 */

prty ^= prty<<4 = FB /* and with B0 */

prty &= 0xF0 = F0 /* parity is ok */

4.3 Unpacking data

After reading (and the following re-ordering of bytes read), each register should be

unpacked in order to obtain all individual values.

For this purpose it is necessary to mask the 28 bits according to the register map shown in

Figure 5 and Figure 6.

For example, the DAP register is unpacked into an 8-bit value of status (least significant

byte) and a 20-bit value of the 3-phase active energy counter (the remaining upper 3 bytes

with parity code masked out).

Doc ID 17783 Rev 1 15/24

Page 16

Converting readings into measured values AN3254

5 Converting readings into measured values

5.1 Energies

The first three registers contain 20-bit values of the internal 3-phase energy up/down

counters, and in the following groups there are the registers containing each phase energy

counter.

The value of the least significant bit of every energy counter is related to power meter

constant P, which is the number of pulses per kWh that the meter, through calibration, is

configured to provide to the LED pin.

This means that this value changes with the application and relative calibration.

Given P, the number of pulses per kWh provided, the energy registers LSB value is indicated

in Ta bl e 2 below:

Table 2. Energy registers LSB value

Register SYS = 0,1,2,4,5,6,7 SYS = 3

3-ph Active Energy Wide Band (P)

3-ph Reactive Energy Wide Band (Q)

3-ph Active Energy Fundamental (F)

3-ph Reactive Energy Fundamental (R)

For example, the energy registers LSB values for SYS

pulses/kWh = 17.7 Hz*kW are:

K

= KF = 15.258 *10-6 Wh

P

K

= KR = 15.258 *10-6 VArh

Q

The energy registers LSB values for SYS

1000

---------------- -

K

P

P2

---------------- -

K

Q

P2

K

F

---------------- -

K

R

P2

Wh[]= K

10

⋅

1000

VArh[]= K

10

⋅

1000

---------------- -

Wh[]= K

10

⋅

P2

1000

VArh[]= K

10

⋅

1000

---------------- -

P

P2

--------------

Q

P2

1000

--------------

F

P2

R

⋅

1000

⋅

⋅

1000

--------------

P2

⋅

Wh[]=

10

VArh[]=

9

Wh[]=

9

VArh[]=

9

= 0, 1, 2, 4, 5, 6, 7 when P = 64000

= 3 and the same P are:

K

= 15.258 *10-6 Wh

P

K

= 30.517 *10-6 Wh

F

K

= KR = 30.517 *10-6 VArh

Q

16/24 Doc ID 17783 Rev 1

Page 17

AN3254 Converting readings into measured values

This also means that the STPMC1 energy counters hold a very small energy value (in the

example above, when LSB represents 15.258 µWh, the whole register stores 16 Wh), and

further energy integration must be performed inside the application.

To accomplish this task, the procedure below should be followed.

Because all energy counters rollover in approximately 1 s when they are integrating maximal

power, the reading must be done frequently enough. It is suggested to read the registers at

least 32 times per second.

For each energy type, a variable e should be allocated, having the following structure (below

is the variable definition for an ST7 microcontroller):

typedef struct energ {

unsigned long old; /* previous energy value - 32 bits */

unsigned int quot; /* quant/16 - 16 bits */

signed int quant; /* new - old, measure of power - 16 bits */

signed long frac; /* fractional part of energy integrator -

32 bits */

signed long integ; /* integer part of energy integrator - 32

bits */

} ENERG;

The application should keep the previous value of each energy counter in order to evaluate

the difference of readings, from which also a direction of energy flow can be obtained. This

value should be stored in e

register reading should be stored in e

To calculate consummated energy the software should implement a 32-bit integrator. The

suggested integrator is two stages, with e

variables. Into e

old and e

value in order to enable a correct e

When e

(corresponding to a certain threshold value according to K

bit and the e

In this way, e

integ variable holds accumulated energy of which the least significant bit represents 10 Wh.

Considering an active energy meter where P = 64000 imp/kWh, for a step of 0.01 KWh = 10

Wh, as each bit of e

energy counter, because e

values), the threshold value is 10/K

In a microcontroller based application, a high priority timer interrupt should be set to perform

measuring tasks every 1/512 s. Within this interrupt service 16 different subtasks could be

established in order to break the whole meter task into 16 shorter consecutive subtasks

(reading of device register, checking the data read, and, if ok, computing the value of e

quant). In this way, the main program and other interrupt services are not blocked for more

than a few 100 us every 2 ms, and the meter task is completed in 16 steps - that is in 1/32 s.

→

→

frac is added the value e→ quant, obtained as the difference between e →

→

new energy values; then the e→ old value should be rewritten with the e→ new

frac collects a certain amount of energy, let’s say 10 Wh for active energy

→

frac should change by the threshold value.

→

frac stores 0.01 KWh, after which e→ integ is increased by one, and the e→

→

→

old before a reading. After the reading, the new energy

→

new.

→

frac and e→ integ 32-bit signed integer

→

quant computation next time.

), e→ integ should change for 1

P

quant represents KP Wh (it is the same resolution of the internal

→

quant is calculated as a difference of two energy counter

= 10/15.258*206 = 0xA0021.

P

→

Doc ID 17783 Rev 1 17/24

Page 18

Converting readings into measured values AN3254

The interrupt service should do the following:

● update e

● generate output pulses (if needed) from e

● call the next subtask

● perform other tasks (if needed)

→

frac and e→ integ of the energy variable using e→ quot = e→ quant / 16

→

frac

In this way the addition of e

→

quant is split in 16 times. This generates a microcontroller

output pulse that has a 16 times better accuracy of position in time, which would reduce the

jitter of an eventual LED output.

5.2 Other values

5.2.1 Voltage, current, and frequency calculation

The ratio between the register value and the actual voltage, current, or frequency value is a

function of the voltage and current sensor sensitivity and of the device internal parameters,

like analog amplification, reference voltage, measurement frequency, calibrator, attenuation

of each stage of decimation filter, and power meter constant.

Formulas to convert the readings into meaningful values are reported below.

For details on the device configuration bits mentioned below, please refer to the STPMC1

datasheet.

In any case, as the internal parameter values, here given as constants, are subject to

process drift, and the sensors sensitivity are subject to tolerance, even if these fluctuations

are compensated by the calibrators, the best way to obtain the proper parameters is to

measure known signals and calculate the ratio between the register value and actual value.

The device linearity ensures that the ratio remains constant.

Figure 8, 9, and 10 below show the signal processing chains for each phase current and

voltage.

Figure 8. Voltage signal path

18/24 Doc ID 17783 Rev 1

Page 19

AN3254 Converting readings into measured values

Figure 9. Current conditioning

Figure 10. Current signal path

Each block of the path contributes to the signal processing with the parameters shown

below.

Ta bl e 3 shows the variable parameters that must be considered as inputs for the following

calculation, while Ta bl e 4 shows the device internal constant parameters.

Table 3. Input parameters

Parameter Meaning

R1, R2 Voltage Divider Resistors Value [Ohm]

Ks Current Sensor Sensitivity Value [V/A]

x_i Current Register Value expressed as decimal

x_u Voltage Register Value expressed as decimal

x_period Period Register Value expressed as decimal

Ai Current Channel Gain

x_i can be one of the current readings in the registers from DMR to DEN (iR MOM, iS MOM,

etc., sI RMS, iR RMS, iS RMS, etc.), and x_u can be one of the voltage readings in the

registers from PRD to DEN (DC uN, uR MOM, uS MOM, etc., uR RMS, uS RMS, etc.).

x_period is the 12 bits value in the PRD register.

Doc ID 17783 Rev 1 19/24

Page 20

Converting readings into measured values AN3254

Table 4. STPMC1 internal parameters value

Parameter Value Meaning

Ku

0,875 Voltage calibrator ideal value if PM

0,9375 Voltage calibrator ideal value if PM = 1

0,875 Current calibrator ideal value if PM

Ki

0,9375 Current calibrator ideal value if PM

Kisum 0,875 Calibrator ideal value for sI RMS (sum of currents)

Au 4 Voltage channel gain

len_i 2

len_u 2

len_isum 2

16

12

12

Current register length

Voltage register length

sI RMS (sum of currents) register length

Kint_comp 1,004 Gain of decimation filter

= 0

= 0

= 1

(1)

(2)

π

Fm

3.14159

4 * 10

22

2

6

If oscillator frequency is 4.000 or 8.000 MHz

If oscillator frequency is 4.194 or 8.388 MHz

4915200 If oscillator frequency is 4.915 or 9.830 MHz

2 For CT/Shunt

Kut

1 For Rogowski coil

Vref 1.23 Internal voltage reference

1. PM is CFG 21, it sets the meter precision (Class 1 or Class 0.1)

2. 12 bits in DMN register

Line frequency is calculated as follows:

frequency = Fm /( x_period * 2

The integrator and differentiator gains are calculated as follows:

5

Kint = 2 * x_period * 2

/ (p * 2

Kdif = 1/ (2 * Kint)

Typical values for these gains are:

5

)

16)

Table 5. Kint and Kdif typical values

Kdif

Kint

20/24 Doc ID 17783 Rev 1

0,6135 Gain of differentiator @ line frequency = 50 Hz

0.7359 Gain of differentiator @ line frequency = 60 Hz

0,815 Gain of integrator @ line frequency = 50 Hz

0.679 Gain of integrator @ line frequency = 60 Hz

Page 21

AN3254 Converting readings into measured values

From these values the following scaling parameters are calculated for Rogowski Coil

sensor:

Kf = frequency / 50

Kdspu = 1

Kdspi = Kf

and for CT or Shunt current sensors:

Kdspu = Kdif * Kint

Kdspi = Kdif

The uN RMS value (12 bits in DEN register) conversion formula is:

u = x_u * 2 / len_u

For the sum of RMS currents sI RMS (12 bits in DMN register) the value is obtained as

follows:

si = x_i * Vref/(Ks * Kisum * Ai * len_isum * Kint * Kint_comp *

Kdspi)

For the data from the momentary registers, as the related momentary voltage and current

parameters are signed (they can be positive or negative), it is necessary to evaluate the sign

with the following task. This does not apply to the RMS values:

if (x_i & (len_i>>1)) // positive current

x_i = x_i & ((len_i>>1)-1);

else // negative current

{

x_i = (len_i>>1) - x_i;

x_i = x_i * (-1);

}

if (x_u & (len_u>>1)) // positive voltage

x_u = x_u & ((len_u>>1)-1);

else // negative voltage

{

x_u = (len_u>>1) - x_u;

x_u = x_u * (-1);

}

Both RMS and momentary current and voltage conversion formulas then are:

u = (1+R1/R2)* x_u * Vref /(Kut * Ku * Au * len_u * kint_comp*

Kdspu)

i = x_i * Vref/(Ks * Ki * Ai * len_i * Kint * Kint_comp * Kdspi)

Doc ID 17783 Rev 1 21/24

Page 22

Converting readings into measured values AN3254

For SYS configuration bits 2 or 3 (no neutral wire) the voltage value should be further

multiplied by 2:

u = u * 2

5.2.2 Other values

The ACR, ACS, and ACT registers hold the information needed for this calculation.

Concatenating ACT[7:0], ACS[7:0], and ACR[7:0] bytes, two 12-bit vectors, defined below,

are obtained:

ACT[7:0], ACS[7:0], ACR[7:0] = Asr[11, 10:0], Art[11, 10:0]

The delay times are calculated with the following formulas:

Table 6. f

where f

MCLK

f

XTAL1

time

time

depends upon the oscillator value according to Tab le 6 :

MCLK

Asr 10 0;[]211()

Asr

Art 10 0;[]211()

Art

Asr 11[]

– 1+()

Asr 11[]

– 1+()

value

MDIV f

---------------

⋅=

f

MCLK

---------------

⋅=

f

MCLK

8

8

MCLK

4.000 MHz 0 8.000 MHz

4.194 MHz 0 8.192 MHz

4.915 MHz 0 9.830 MHz

8.000 MHz 1 8.000 MHz

8.192 MHz 1 8.192 MHz

9.830 MHz 1 9.830 MHz

The phase delays in degrees can be calculated as follows:

time

----------- -

ϕ°

f

line

22/24 Doc ID 17783 Rev 1

360°⋅=

Page 23

AN3254 Revision history

6 Revision history

Table 7. Document revision history

Date Version Description

19-Nov-2010 1 First release

Doc ID 17783 Rev 1 23/24

Page 24

AN3254

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2010 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

24/24 Doc ID 17783 Rev 1

Loading...

Loading...