AN3233

Application note

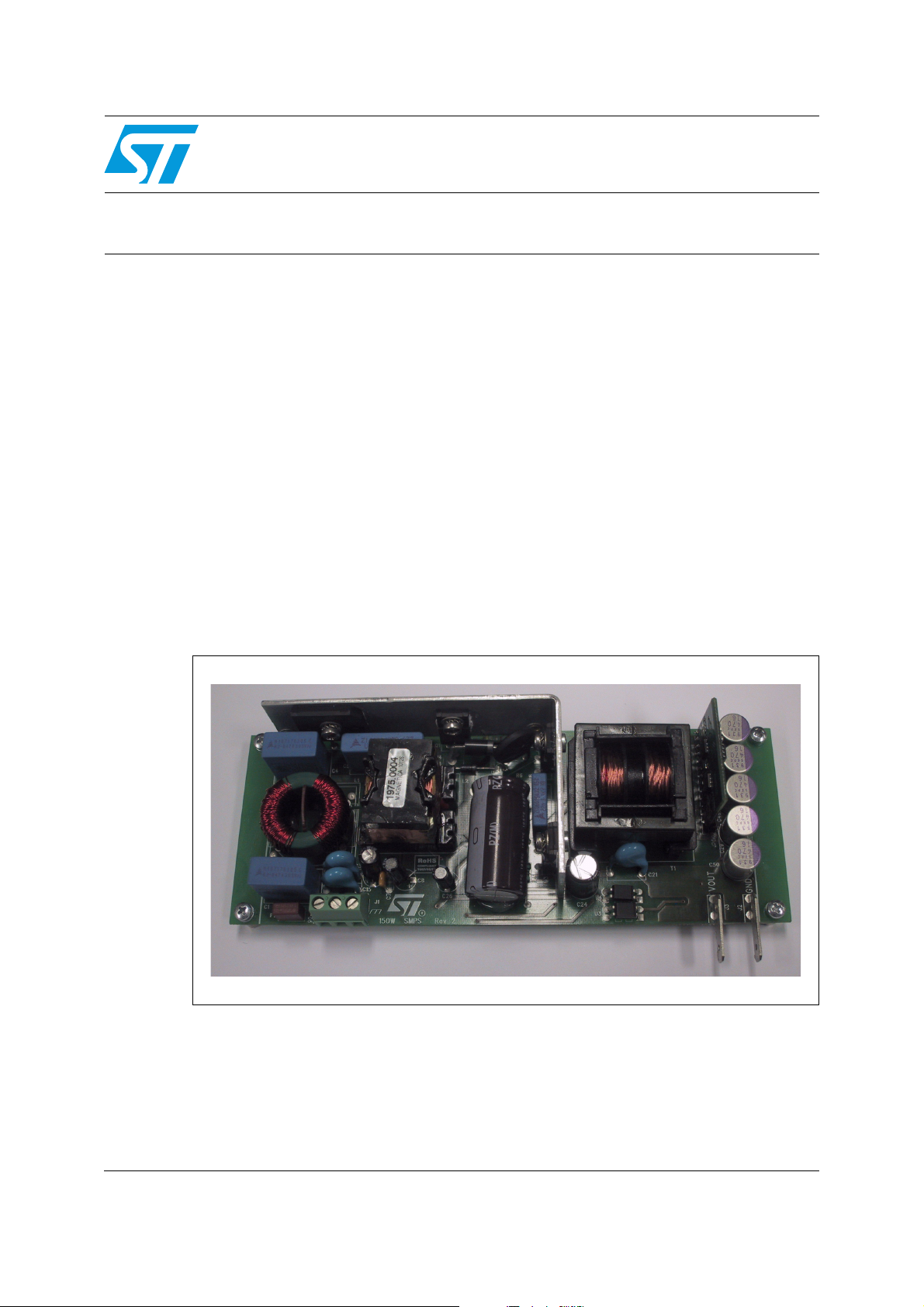

12 V - 150 W resonant converter with synchronous rectification

using the L6563H, L6599A, and SRK2000

Introduction

This application note describes the characteristics and features of a 150 W SMPS

demonstration board (EVL150W-ADP-SR), tailored to all-in-one computer power supply

(PS) specifications.

The characteristics of this design are the very high efficiency and low consumption at light

load which make it a viable solution for applications compliant with ENERGY STAR

eligibility criteria (EPA rev. 5.0 computer and EPA rev. 2.0 EPS). One of the key factors to

achieving high efficiency at heavy load is the SRK2000. This synchronous rectification (SR)

driver for LLC resonant converters allows a significant decrease in secondary side losses.

Standby consumption is very low thanks to the sleep function embedded in the SRK2000

and the high voltage start-up circuit integrated in the L6563H. The possibility of driving the

PFC burst mode via the L6599A PFC_STOP pin dramatically boosts light load efficiency.

Additionally, a secondary sensing circuit, dedicated to driving the primary controller into

burst mode, reduces deviation of light load efficiency against resonant circuit parameter

spread, improving the repeatability of design in production volumes.

Figure 1. EVL150W-ADP-SR: 150 W SMPS demonstration board

®

January 2011 Doc ID 17595 Rev 1 1/35

www.st.com

Contents AN3233

Contents

1 Main characteristics and circuit description . . . . . . . . . . . . . . . . . . . . . 5

2 Efficiency measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Harmonic content measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Functional check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Thermal map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6 Conducted emission pre-compliance test . . . . . . . . . . . . . . . . . . . . . . 21

7 Bill of materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8 PFC coil specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9 Transformer specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2/35 Doc ID 17595 Rev 1

AN3233 List of figures

List of figures

Figure 1. EVL150W-ADP-SR: 150 W SMPS demonstration board . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. Burst mode circuit block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 3. Electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 4. Light load efficiency diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 5. Compliance with EN61000-3-2 at 230 Vac – 50 Hz, full load . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 6. Compliance with JEITA-MITI at 100 Vac – 50 Hz, full load . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 7. Resonant stage waveforms at 115 V – 60 Hz – full load . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 8. SRK2000 key signals at 115 V – 60 Hz – full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 9. High-side MOSFET ZV turn-on at 115 V – 60 Hz – full load. . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 10. Low-side MOSFET ZV turn-on at 115 V – 60 Hz – full load . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 11. Converter startup at 115 Vac full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 12. Converter shutdown at 115 Vac full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 13. Startup resonant current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 14. Shutdown resonant current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 15. No-load operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 16. No-load operation – detail. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 17. Transition full load to no load at 115 Vac – 60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 18. Transition no load to full load at 115 Vac – 60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 19. Short-circuit at full load and 115 Vac – 60 Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 20. Thermal map at 115 Vac – 60 Hz - full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 21. Thermal map at 230 Vac – 50 Hz - full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 22. Thermal map SR daughterboard - full load. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 23. CE average measurement at 115 Vac and full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 24. CE average measurement at 230 Vac and full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 25. PFC coil electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 26. PFC coil mechanical aspect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 27. Transformer electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 28. Transformer overall drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Doc ID 17595 Rev 1 3/35

List of tables AN3233

List of tables

Table 1. Overall efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 2. Light load efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 3. Thermal maps reference points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 4. Daughterboard thermal map reference points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 5. EVL150W-ADP-SR demonstration board: motherboard bill of materials . . . . . . . . . . . . . . 21

Table 6. EVL150W-ADP-SR demonstration board: daughterboard bill of materials. . . . . . . . . . . . . 28

Table 7. PFC coil winding data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 8. Transformer winding data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 9. Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4/35 Doc ID 17595 Rev 1

AN3233 Main characteristics and circuit description

1 Main characteristics and circuit description

The main features of the SMPS are:

● Input mains range: 90 ÷ 264 Vac - frequency 45 ÷ 65 Hz

● Output voltage: 12 V at 12.5 A continuous operation

● Mains harmonics: Acc. to EN61000-3-2 Class-D or JEITA-MITI Class-D

● Standby mains consumption: <0.2 W at 230 Vac

● Efficiency at nominal load: > 91 % at 115 Vac

● EMI: according to EN55022-Class-B

● Safety: according to EN60950

● Dimensions: 65x154 mm, 28 mm component maximum height

● PCB: double side, 70 µm, FR-4, mixed PTH/SMT.

The circuit is composed of two stages: a front-end PFC using the L6563H and an LLC

resonant converter based on the L6599A and the SRK2000, controlling the SR MOSFETs

on the secondary side. The SR driver and the rectifier MOSFETs are mounted on a

daughterboard.

The L6563H is a current mode PFC controller operating in transition mode and implements

a high voltage start-up source to power on the converter.

The L6599A integrates all the functions necessary to properly control the resonant

converter with a 50 % fixed duty cycle and working with variable frequency.

The output rectification is managed by the SRK2000, an SR driver dedicated to LLC

resonant topology.

The PFC stage works as the pre-regulator and powers the resonant stage with a constant

voltage of 400 V. The downstream converter operates only if the PFC is on and regulating.

In this way, the resonant stage can be optimized for a narrow input voltage range.

The L6599A's LINE pin (pin 7) is dedicated to this function. It is used to prevent the resonant

converter from working with an input voltage that is too low which can cause incorrect

capacitive mode operation. If the bulk voltage (PFC output) is below 380 V, the resonant

start-up is not allowed. The L6599A LINE pin internal comparator has a hysteresis allowing

to set the turn-on and turn-off voltage independently. The turn-off threshold has been set to

300 V in order to avoid capacitive mode operation but allow the resonant stage to operate

even in the case of mains sag and consequent PFC output dip.

The transformer uses the integrated magnetic approach, incorporating the resonant series

inductance. Therefore, no external, additional coil is needed for the resonance. The

transformer configuration chosen for the secondary winding is center-tap.

On the secondary side, the SRK2000 core function is to switch on each synchronous

rectifier MOSFET whenever the corresponding transformer half-winding starts conducting

(i.e. when the MOSFET body diode starts conducting) and then switching it off when the

flowing current approaches zero. For this purpose, the IC is provided with two pins (DVS1

and DVS2) sensing the MOSFET drain voltage level.

One of the SRK2000’s main characteristics is the ability to automatically detect light load

operation and enter sleep mode, disabling MOSFET driving and decreasing its

consumption. This function allows great power saving at light load with respect to

benchmark SR solutions.

Doc ID 17595 Rev 1 5/35

Main characteristics and circuit description AN3233

In order to decrease the output capacitors size, aluminium solid capacitors with very low

ESR were preferred to standard electrolytic ones. Therefore, high frequency output voltage

ripple is limited and output LC filter is not required. This choice allows a saving of output

inductor power dissipation which can be significant in the case of high output current

applications like this.

Start-up sequence

The PFC acts as master and the resonant stage can operate only if the PFC output is

delivering the nominal output voltage. Therefore, the PFC starts first and then the

downstream converter turns on. At the beginning, the L6563H is supplied by the integrated

high voltage start-up circuit; as soon as the PFC starts switching, a charging pump

connected to the PFC inductor supplies both PFC and resonant controllers and the HV

internal current source is disabled. Once both stages have been activated, the controllers

are supplied also by the auxiliary winding of the resonant transformer, assuring correct

supply voltage even during standby operation.

As the L6563H integrated HV start-up circuit is turned off, and therefore is not dissipative

during the normal operation, it gives a significant contribution to power consumption

reduction when the power supply operates at light load, in accordance with worldwide

standby standards currently required.

Standby power saving

The board has a burst mode function implemented which allows power saving during light

load operation.

The L6599A's STBY pin (pin 5) senses the optocoupler’s collector voltage (U3), which is

related to the feedback control. This signal is compared to an internal reference (1.24 V). If

the voltage on the pin is lower than the reference, the IC enters an idle state and its

quiescent current is reduced. When the voltage exceeds the reference by 50 mV, the

controller restarts the switching.

The burst mode operation load threshold can be programmed by properly choosing the

resistor connecting the optocoupler to pin RFMIN (R34). Basically, R34 sets the switching

frequency at which the controller enters burst mode.

As the power at which the converter enters burst mode operation heavily influences

converter efficiency at light load, it must be properly set. Anyhow, despite this threshold

being well set, if its tolerance is too wide, the light load efficiency of mass production

converters has a considerable spread.

The main factors affecting the burst mode threshold tolerance are the control circuitry

tolerances and, even more influential, the tolerances of resonant inductance and the

resonant capacitor. Slight changes of resonance frequency can affect the switching

frequency and, consequently, notably change the burst mode threshold.

Typical production spread of these parameters, which fits the requirements of many

applications, are no longer acceptable if very low power consumption in standby must be

guaranteed.

As reducing production tolerance of resonant components causes cost increases, a new

cost-effective solution is required.

The key point of the proposed solution is to directly sense the output load to set the burst

mode threshold. In this way the resonant elements parameters no longer affect this

threshold. The implemented circuit block diagram is shown in Figure 2.

6/35 Doc ID 17595 Rev 1

AN3233 Main characteristics and circuit description

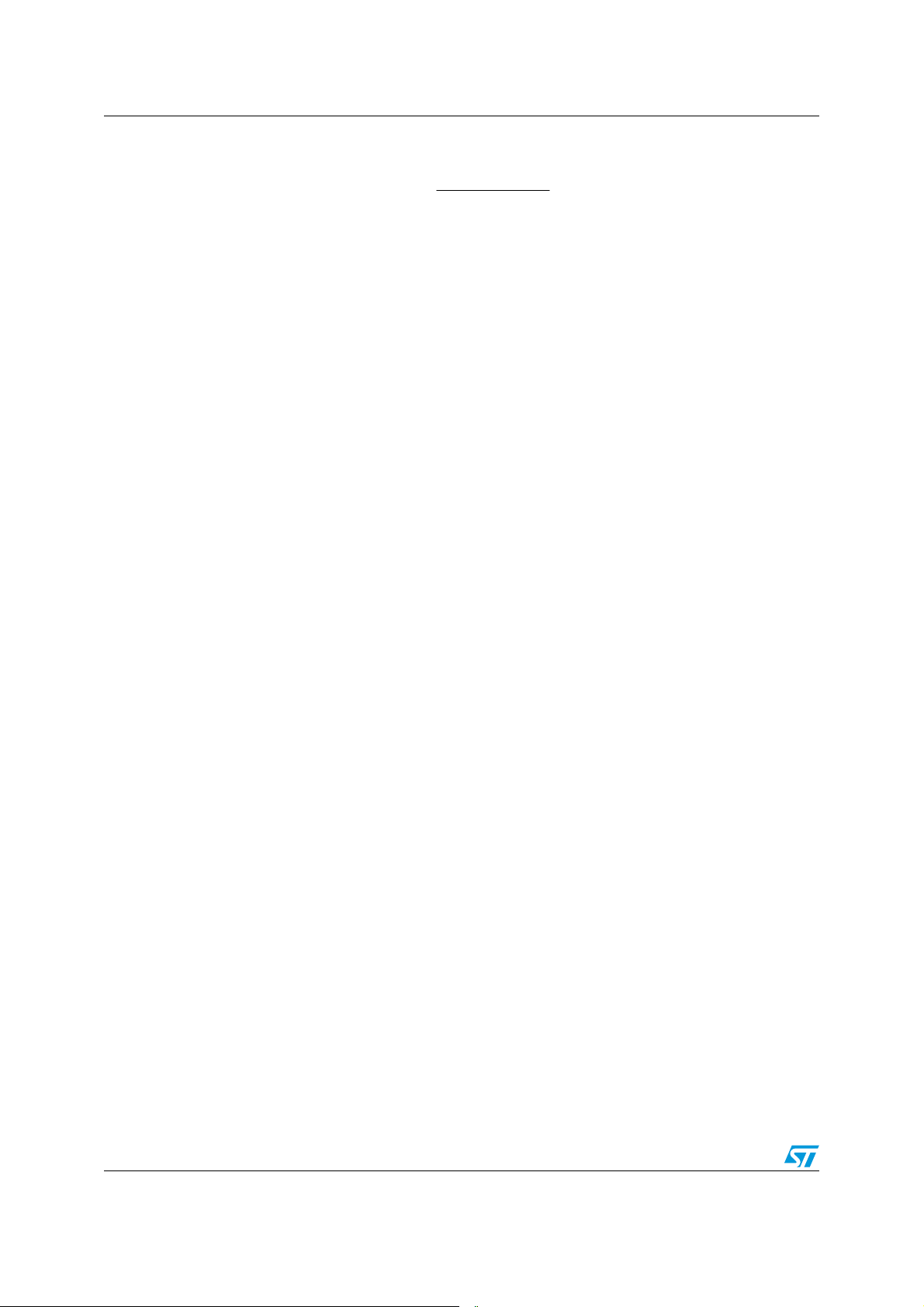

Figure 2. Burst mode circuit block diagram

to power transformer

R

CS

to FB optocoupler

to load

L6599A TSM1014

Standby

Comp.

1.24V

RFMIN

2V

R

FB

STBY

-

+

RBMR

BM

R

lim

CC_OUT

Comp.

R

Hts

-

+

The output current is sensed by a resistor (R

CC- OUT

V_REF

1.25V

CC+

); the voltage drop across this resistor is

CS

TSC101

VP

+

E/A.

R

H

R

L

100

VM

-

amplified by TSC101, a dedicated high side current sense amplifier; its output is compared

to a set reference by the TSM1014; if the output load is high, the signal fed into the CC- pin

is above the reference voltage, CC_OUT stays down and the optocoupler transistor pulls up

the L6599A’s STBY pin to the RFMIN voltage (2 V), setting continuous switching operation

(no burst mode); if load decreases, the voltage on CC- falls below the set threshold,

CC_OUT goes high opening the connection between RFMIN and STBY and so allowing

burst mode operation by the L6599A.

R

is dimensioned considering two constraints. The first is the maximum power dissipation

CS

allowed, based on the efficiency goal. The second limitation is imposed by the necessity to

feed a reasonable voltage signal into the TSM1014A inverting input. In fact, signals which

are too small would affect system accuracy.

On this board, the maximum acceptable power dissipation has been set to P

mW. R

maximum value is calculated as follows:

CS

loss,MAX

= 500

P

MAXloss,

R

MAXCS,

2

I

MAXout,

The burst mode threshold is set at 5 W corresponding to C

3.2mΩ

==

= 417 mA output current at 12

BM

V.

Choosing V

CC+,min

signal-to-noise ratio, the R

The actual value of the mounted resistor is 2 mΩ, corresponding to P

= 50 mV as the minimum reference of TSM1014A, which allows a good

minimum value is calculated as follows:

CS

R

V

=

minCS,

minCC+,

1.2mΩ

=

C 100

⋅

BM

= 312 mW power

loss

losses at full load. The actual resistor value at burst mode threshold current provides an

output voltage by TSC101 of 83 mV. The reference voltage of TSM1014 V

this level. The resistor divider setting the TSM1014 threshold R

range of kilo-ohms to minimize dissipation. By selecting R

and RL should be in the

H

= 22 kΩ, the right RH value is

L

must be set at

CC+

obtained as follows:

Doc ID 17595 Rev 1 7/35

Main characteristics and circuit description AN3233

(

)

V1.25VR

−

R

=

H

BML

309kΩ

V

BM

=

The value of the mounted resistor is 330 kΩ.

sets a small de-bouncing hysteresis and is in the range of mega-ohms. R

R

Hts

is in the

lim

range of tens of kilo-ohms and limits the current flowing through the optocoupler’s diode.

Both L6599A and L6563H implement their own burst mode function but, in order to improve

the overall power supply efficiency, at light load the L6599A drives the L6563H via the

PFC_STOP pin and enables the PFC burst mode: as soon as the L6599A stops switching

due to load drops, its PFC_STOP pin pulls down the L6563H’s PFC_OK pin disabling PFC

switching. Thanks to this simple circuit, the PFC is forced into idle state when the resonant

stage is not switching and rapidly wakes up when the downstream converter restarts

switching.

Fast voltage feed forward

The voltage on the L6563H VFF pin (pin 5) is the peak value of the voltage on the MULT pin

(pin 3). The RC network (R15+R26, C12) connected to VFF completes a peak-holding

circuit. This signal is necessary to derive information of the RMS input voltage to

compensate the loop gain that is mains voltage dependent.

Generally speaking, if the time constant is too small, the voltage generated is affected by a

considerable amount of ripple at twice the mains frequency causing distortion of the current

reference (resulting in higher THD and lower PF). If the time constant is too large, there is a

considerable delay in setting the right amount of feed-forward, resulting in excessive

overshoot or undershoot of the pre-regulator’s output voltage in response to large line

voltage changes.

To overcome this issue, the L6563H implements the fast voltage feed forward function. As

soon as the voltage on the VFF pin decreases by a set threshold (40 mV typically), a mains

dip is assumed and an internal switch rapidly discharges the VFF capacitor via a 10 k

resistor. Thanks to this feature, it is possible to set an RC circuit with a long time constant,

assuring a low THD, keeping a fast response to mains dip.

Ω

Brownout protection

Brownout protection prevents the circuit from working with abnormal mains levels. It is easily

achieved using the RUN pin (pin 12) of the L6563H: this pin is connected through a resistor

divider to the VFF pin (pin 5), which provides the information of the mains voltage peak

value. An internal comparator enables the IC operations if the mains level is correct, within

the nominal limits. At startup, if the input voltage is below 90 Vac (typ.)

inhibited

.

Output voltage feedback loop

The feedback loop is implemented by means of a typical circuit using the dedicated

operational amplifier of TSM1014A modulating the current in the optocoupler’s diode. The

second comparator embedded in the TSM1014A - usually dedicated to constant current

regulation - is here utilized for burst mode as previously described.

On the primary side, R34 and D17 connect the RFMIN pin (pin 4) to the optocoupler’s

phototransistor closing the feedback loop. R31, which connects the same pin to ground, sets

8/35 Doc ID 17595 Rev 1

, circuit operations are

AN3233 Main characteristics and circuit description

the minimum switching frequency. The R-C series R44 and C18 sets both soft-start

maximum frequency and duration.

L6599A overload and short-circuit protection

The current into the primary winding is sensed by the loss-less circuit R41, C27, D11, D10,

R39, and C25 and it is fed into the ISEN pin (pin 6). In the case of overcurrent, the voltage

on the pin overpasses an internal threshold (0.8 V) that triggers a protection sequence. The

capacitor (C45) connected to the DELAY pin (pin 2) is charged by an internal 150 µA current

generator and is slowly discharged by the external resistor (R24). If the voltage on the pin

reaches 2 V, the soft-start capacitor is completely discharged so that the switching

frequency is pushed to its maximum value. As the voltage on the pin exceeds 3.5 V the IC

stops switching and the internal generator is turned off, so that the voltage on the pin decays

because of the external resistor. The IC is soft-restarted as the voltage drops below 0.3 V. In

this way, under short-circuit conditions, the converter works intermittently with very low input

average power.

Open loop protection

Both circuit stages, PFC and resonant, are equipped with their own overvoltage protections.

The PFC controller L6563H monitors its output voltage via the resistor divider connected to

a dedicated pin (PFC_OK, pin 7) protecting the circuit in case of loop failures or

disconnection. If a fault condition is detected, the internal circuitry latches the L6563H

operations and, by means of the PWM_LATCH pin (pin 8), it also latches the L6599A via the

DIS pin (pin 8). The converter is kept latched by the L6563H internal HV start-up circuit that

supplies the IC by charging the Vcc capacitor periodically. To resume converter operation, a

mains restart is necessary.

The output voltage is monitored by sensing the Vcc voltage. If Vcc voltage overrides the D12

breakdown voltage, Q9 pulls down the L6563H INV pin latching the converter.

Doc ID 17595 Rev 1 9/35

Main characteristics and circuit description AN3233

~

~

~

~

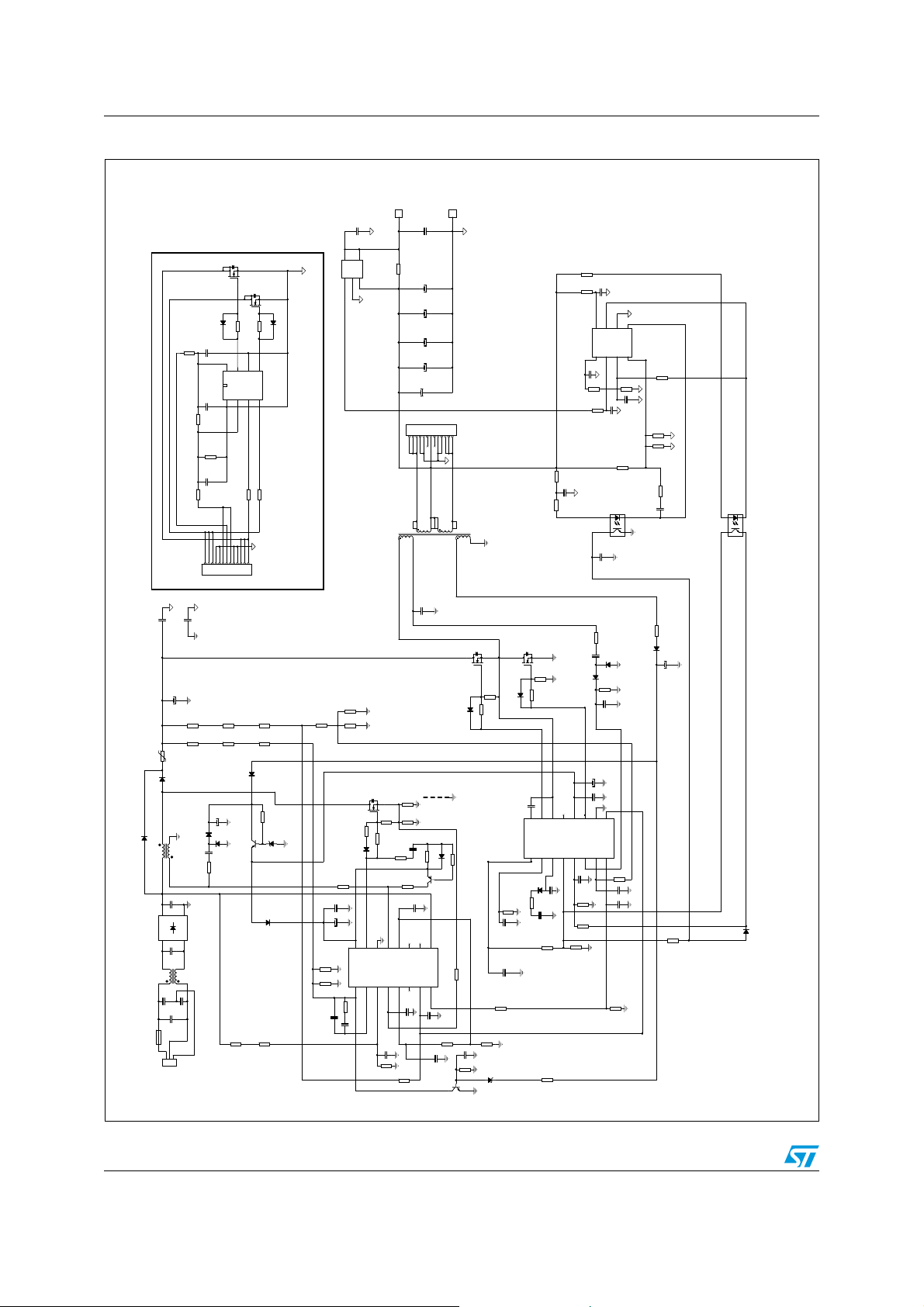

Figure 3. Electrical diagram

FASTONJ3FASTON

C38

100N

C38

100N

C37

470uF-16V

C37

470uF-16V

C50

470uF-16V

C50

470uF-16V

C49

470uF-16V

C49

470uF-16V

C30

C30

470uF-16V

470uF-16V

C29

C29

470uF-16V

470uF-16V

12345678910111213

91012138

4

R23

0R47

R23

0R47

R22

0R27

R22

0R27

C33

1NF

C33

1NF

R20

33R

R20

33R

R52

1K5

R52

1K5

R55

2K7

R55

2K7

C16

2N2

C16

2N2

10

11

NC

PWM-STOP

C22

220PF

C22

220PF

R37

220K

R37

220K

J2

FASTONJ2FASTON

R68

39K

R68

39K

C51

100N

C51

100N

R73

22R

R73

22R

6

8

5

7

VCC

GND

CV_OUT

CC_OUT

CV-

V_REF

CC+3CC-

U5

TSM1014AISTU5TSM1014AIST

4

1

2

C481NC48

1N

R72

330K

R72

330K

C32

1uF

C32

1uF

R711KR71

1K

R43

51R

R43

51R

C36

1uF - 50V

C36

1uF - 50V

R421KR42

Q4

STF8NM50NQ4STF8NM50N

213

R59

100K

R59

100K

R38

56R

R38

56R

D19

1N4148

D19

1N4148

1 2

C19

100N

C19

100N

16

15

HVG

VBOOT

CSS1DELAY2CF3RFMIN4STBY5ISEN6LINE

U2

L6599ADU2L6599AD

12

D16

D16

1N4148

1N4148

R16

4K7

R16

4K7

1M0

1M0

C18

4u7F

C18

4u7F

1K

14

OUT

C17

330PF

C17

330PF

C6

4N7C64N7

R44

6K2

R44

6K2

R77

1K0

R77

1K0

11

14

7

6

C28

22NF

C28

22NF

STF8NM50NQ3STF8NM50N

Q3

213

R58

100K

R58

100K

D18

1N4148

D18

1N4148

R25

56R

R25

56R

1 2

HS1

HEAT-SINK

HS1

HEAT-SINK

D6

1N4148D61N4148

23

R53

2K2

R53

2K2

1

Q2

BC857Q2BC857

9

HVS

R27

470R

R27

470R

8

C10

1N0

C10

1N0

R15

56K

R15

56K

C12

1uF

C12

1uF

1

32

BC847CQ9BC847C

R24

R24

C45

220NF

C45

220NF

R29

1K0

R29

1K0

R26

1M0

R26

1M0

1N

C521NC52

D12

BZV55-C43

D12

BZV55-C43

R76

R76

33K

33K

21

Q9

12

43

U3

SFH617A-2U3SFH617A-2

C41

22N

C41

22N

R41

100R

R41

100R

D11

D11

C27

C27

220PF-630V

220PF-630V

12

D10

1N4148

D10

1N4148

1 2

R39

160R

R39

160R

C25

2u2

C25

2u2

C26

C26

10uF-50V

10uF-50V

C40

100N

C40

100N

13

11

12

10

9

NC

LVG

VCC

GND

PFC-STOP

DIS

7

8

C44

470pF

C44

470pF

R36

1M8

R36

1M8

C23

C23

R32

47R

R32

47R

R31

12K

R31

12K

R60

10K

R60

10K

R64

10Meg

R64

10Meg

R70

22k

R70

22k

C471NC47

1N

R51

82K

R51

82K

R50

12K

R50

12K

R49

91K

R49

91K

R48

47K

R48

47K

C34

100N

C34

100N

R40

0R33

R40

0R33

D9

1 2

1N4148

1N4148

R30

R30

C43

C43

10N

10N

C24

220uF-50V

C24

220uF-50V

STPS1L60AD9STPS1L60A

10R

10R

4N7

4N7

R34

R34

6K2

6K2

12

43

U4

SFH617A-2U4SFH617A-2

12

D17

1N4148

D17

1N4148

J3

C42

100N

C42

100N

5

Vcc

U6

Out1GND2Vp

Q502

STL140N4LLF5

Q502

R502

R502

R501

10R

R501

10R

8

6

7

GD1

VCC

PGND

SGND1EN2DVS13DVS2

R506

330R

R506

330R

101112

13

R11

2M2

R11

2M2

R3

1M0R31M0

D21

1N4148

D21

1N4148

1 2

10uF-50VC810uF-50V

32

Q8

BC847CQ8BC847C

R1

3M3R13M3

STL140N4LLF5

10R

10R

D502

BAS316

D502

BAS316

5

GD2

4

R507

330R

R507

330R

EVLSRK2000-L-40

R13

8K2

R13

R12

2M2

R12

2M2

R8

1M0R81M0

R69

4K7

R69

4K7

D20

BZV55-B15

D20

BZV55-B15

1

D7

STPS140ZD7STPS140Z

1 2

R2

3M3R23M3

8K2

2 1

R19

R19

C39

100N

C39

100N

C15

47uF-50V

C15

47uF-50V

U1

L6563HU1L6563H

R10

27K

R10

27K

R9

62KR962K

C14

68N

C14

68N

Q501

STL140N4LLF5

Q501

STL140N4LLF5

D501

BAS316

D501

BAS316

R503

10R

R503

10R

C503

1uF

C503

1uF

U501

SRK2000

U501

SRK2000

C502

100nF

C502

100nF

R504

150k

R504

150k

R505

33k

R505

33k

C501

4nF7

C501

4nF7

RX1

0R0

RX1

0R0

123456789

JP501JP501

C20

2N2-Y1

C20

2N2-Y1

C21

2N2-Y1

C21

2N2-Y1

C9

100uF - 450VC9100uF - 450V

R17

2M2

R17

2M2

R7

1M0R71M0

R6

NTC 2R5-S237R6NTC 2R5-S237

12

D4

STTH5L06D4STTH5L06

D3

1N4005D31N4005

12

L2

1975.0004L21975.0004

D1

D1

GBU8J

GBU8J

L1

2019.0002L12019.0002

F1

FUSE T4AF1FUSE T4A

J1

MKDS 1,5/ 3-5,08J1MKDS 1,5/ 3-5,08

9 5

11 3

+

+

2 4

124

C2

2N2-Y1C22N2-Y1

123

C4

C1

C5

470N-X2C4470N-X2

470N-X2C1470N-X2

_

_

3 1

3

C3

2N2-Y1C32N2-Y1

90-264Vac

D5

C7

R5

470N - 520VC5470N - 520V

12

1N4148D51N4148

C8

12

D2

100NC7100N

1N4148D21N4148

10RR510R

12V-12.5A

4

Vm

R57

R002

R57

R002

TSC101U6TSC101

3

T1

1860.0034T11860.0034

2

R35

180K

R35

180K

R28

33K

R28

33K

Q1

STF19NM50NQ1STF19NM50N

213

R46

100K

R46

100K

R45

3R3

R45

3R3

R21

22R

R21

22R

D14

1N4148

D14

1N4148

1 2

56K

56K

16

14

15

13

12

GD

ZCD

VCC

RUN

GND

INV1COMP2MULT3CS4VFF5TBO6PFC-OK7PWM-LATCH

R18

82K

R18

82K

C13

680N

C13

680N

C11

2N2

C11

2N2

R14

51K

R14

51K

10/35 Doc ID 17595 Rev 1

AN3233 Efficiency measurement

2 Efficiency measurement

EPA rev. 2.0 external power supply compliance verification

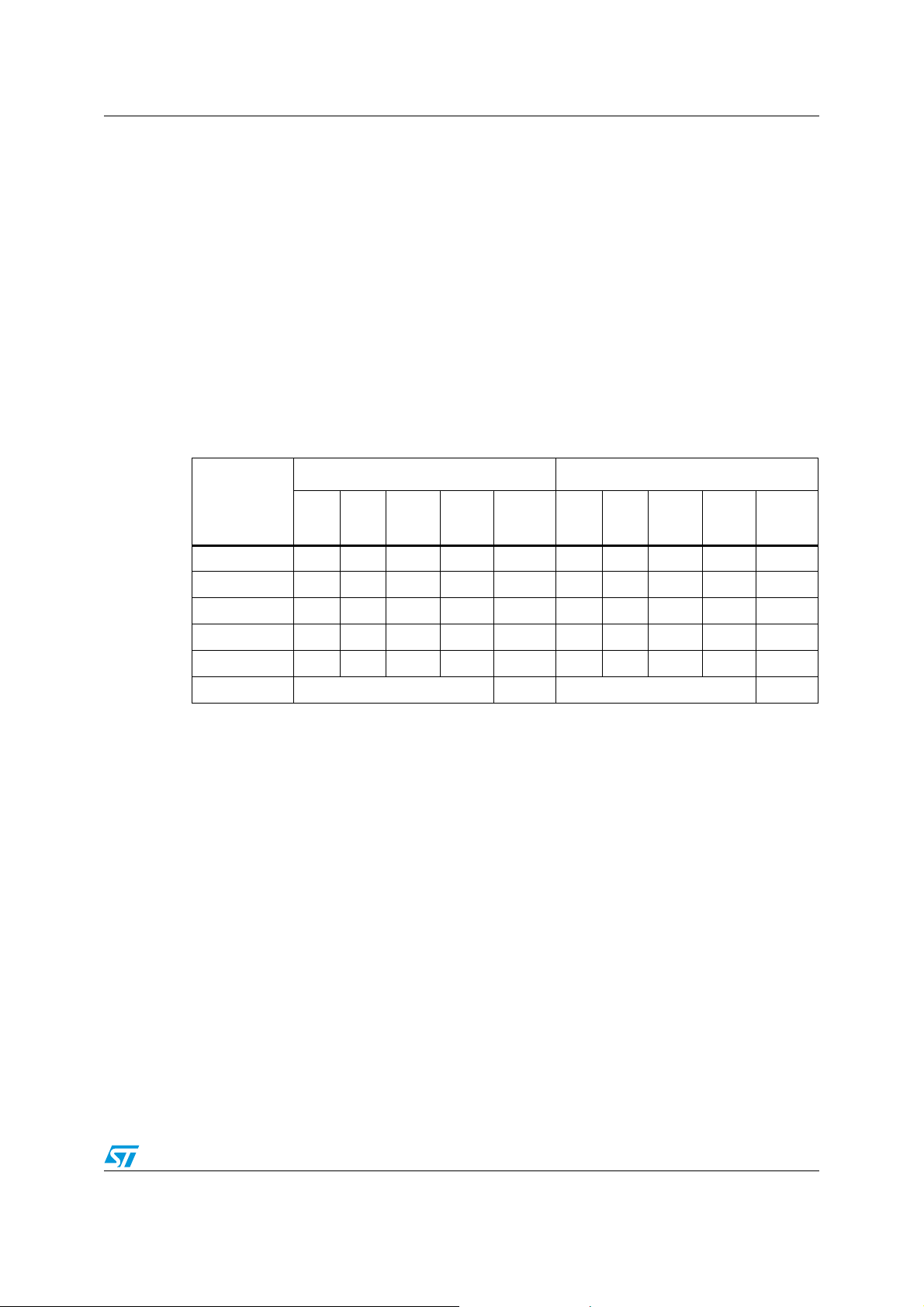

Tab l e 1 shows the no-load consumption and the overall efficiency, measured at the nominal

mains voltages. At 115 Vac the average efficiency is 90.6 %, while at 230 Vac it is 91.8 %.

Both values are much higher than the 87 % required by EPA rev 2.0 external power supply

(EPS) limits.

The efficiency at nominal load, 230 Vac, is 94 %, which is a very high efficiency for a double

stage converter and confirms the benefit of implemented SR.

Also at no load the board performances are superior: maximum no-load consumption at

nominal mains voltage is 200 mW; this value is significantly lower than the limit imposed by

the ENERGY STAR program which is 500 mW.

Table 1. Overall efficiency

230 V - 50 Hz 115 V - 60 Hz

Test

No load 12.10 0.00 0.00 0.20 ----------- 12.10 0.00 0.00 0.20 -----------

25 % load eff. 12.14 3.10 37.63 43.15 87.2 % 12.13 3.10 37.60 43.08 87.3 %

50 % load eff. 12.14 6.19 75.15 81.30 92.4 % 12.12 6.19 75.02 82.34 91.1 %

75 % load eff. 12.08 9.37 113.19 120.81 93.7 % 12.07 9.38 113.22 123.00 92.0 %

100 % load eff. 12.04 12.47 150.14 159.79 94.0 % 12.04 12.50 150.50 163.90 91.8 %

Average eff. 91.8 % 90.6 %

Vout

[V]

Iout

[A]

Pout

[W]

Pin

[W]

Eff.

[%]

Vou t

[V]

Iout

[A]

Pout

[W]

Pin

[W]

Eff.

[%]

Doc ID 17595 Rev 1 11/35

Loading...

Loading...