Page 1

AN3232

Application note

Mounting recommendations

for STAC

Introduction

RF power transistors are amongst the highest power density devices in the semiconductor

industry. It is crucial to the reliability and performance of such devices to consider

mechanical stress and thermal and electrical resistance within the application environment.

®

boltdown packages

The general purpose of this application note is to provide guidelines for mounting various

types of STAC

by soldering. Specific attention is paid to the STAC244B and STAC265B boltdown styles and

the STAC244F and STAC265F flangeless styles, which are used to encapsulate numerous

VDMOS and LDMOS technology products.

This application note is intended to provide mounting tips and design guidelines. For actual

data please refer to the relevant product datasheet.

STAC

is a registered trademarks of STMicroelectronics.

Figure 1. STAC boltdown packages

®

packages in amplifiers or application boards (PCB) by means of bolting or

August 2011 Doc ID 17594 Rev 3 1/26

www.st.com

Page 2

Contents AN3232

Contents

1 Epoxy sealed, non-hermetic RF power packages . . . . . . . . . . . . . . . . . 5

2 Exceptional thermal performance potential of the STAC package

concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Heatsink selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Core preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5 Mounting base surface conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6 Thermal interface material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7 Seating plane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8 Printed circuit board (PCB) considerations . . . . . . . . . . . . . . . . . . . . . 15

9 Package attachment to core by means of boltdown method . . . . . . . 16

9.1 Required hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

9.2 Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

9.3 Procedure summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

10 Package attachment to thermal base by means of soldering . . . . . . . 20

10.1 Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

10.2 Solder reflow equipment and methods . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

11 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

12 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

13 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2/26 Doc ID 17594 Rev 3

Page 3

AN3232 List of tables

List of tables

Table 1. Preferred copper core thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 2. Surface conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 3. Common TIMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 4. Recommended screw torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 5. Pb-free process - package classification reflow temperatures . . . . . . . . . . . . . . . . . . . . . . 21

Table 6. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Doc ID 17594 Rev 3 3/26

Page 4

List of figures AN3232

List of figures

Figure 1. STAC boltdown packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. Drying times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 3. Infrared imaging of a STAC package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 4. Pocket depth consideration (mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 5. Lead bending . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 6. Package cut and pads layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 7. Ideal screw-center spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 8. First boltdown mounting steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 9. SEHO FDS “MAXIPOWER” reflow oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 10. Component level temperature profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4/26 Doc ID 17594 Rev 3

Page 5

AN3232 Epoxy sealed, non-hermetic RF power packages

1 Epoxy sealed, non-hermetic RF power packages

Epoxy sealed products, such as the STAC package family, should be received in an N2backfilled, vacuum-sealed ESD bag containing a desiccant. This decreases the possibility of

moisture uptake by the package materials during transit and long-term storage. STAC

packages carry a moisture sensitivity rating of 3 (MSL3), but have demonstrated capabilities

of up to MSL1.

Even with such shipping methods, it is advised to store epoxy sealed packages in the

original containers, or in a dry box, until required for soldering. When the environmental

history of devices is not well-known, such as after a prolonged storage period, it is a wellpracticed safety measure to bake non-hermetic packages for 24 hrs at 125 °C prior to

soldering operations. These conditions can be accelerated or lengthened as a function of

temperature, up to the limits imposed by shipping containers, by trays, or by device

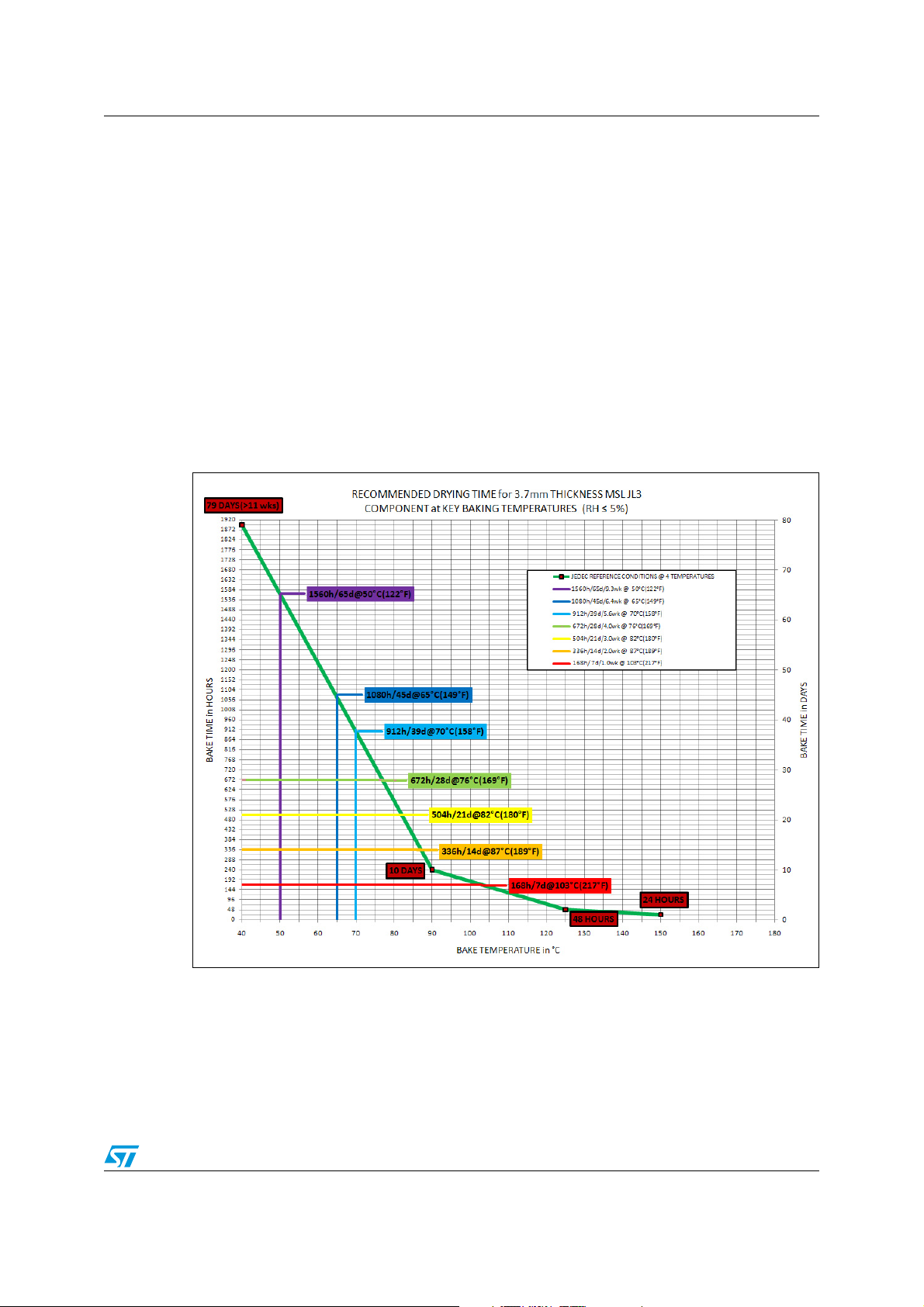

maximum ratings. Refer to Figure 2 for recommended baking conditions.

Figure 2. Drying times

Under no circumstances should any epoxy-sealed package be treated as a hermetically

sealed package, due to the fact that such sealing materials are not impervious to moisture

ingress. However, it is important to point out that RF Power packages are typically

constructed using engineering ceramics and polymers which, on their own, demonstrate

high resistance to moisture penetration, such as the proprietary liquid crystal polymer

materials upon which STAC packages are realized.

Doc ID 17594 Rev 3 5/26

Page 6

Epoxy sealed, non-hermetic RF power packages AN3232

Power RF packages typically require a reliable, low thermal resistance attachment to a

heatsink. In this respect, nothing out-performs a direct attachment of the device flange, or

thermal base, to the heatsink by means of soldering. This can be accomplished using any of

the PbSn or Pb-free soldering methods used throughout the electronic industry. The final

soldering step may be preceded by a hot-solder dip of the package base and/or leads, as

required for situations that require attention to Au content of the solder joint. Alternatively,

the packages may be inserted into an amplifier using a pick-and-place methodology, so that

complete soldering is accomplished in a single reflow.

Some amplifier assemblies require a manual approach for device positioning on a PCB

while soldering bases to copper core heatsinks. In such manual operations STAC boltdown

style packages have the unique possibility of serving as a built-in clamp to accomplish both

tasks expeditiously. These manual efforts are rewarded by an extremely low thermal

resistance, achieved by an ultra-thin solder joint case-to-heatsink, referred to as the Rth

. At the same time, the need to allocate valuable amplifier real estate to specialized

HS

C-

clamping fixtures is eliminated.

The approaches to soldering RF transistors in amplifier housings are as numerous as the

quantity of RF package outlines. While the traditional demand for high levels of ruggedness

in RF devices assures an intrinsic high tolerance to a wide variety of assembly methods, the

high-stress nature of any soldering operation requires careful consideration. Users

ultimately assume responsibility for developing and qualifying their soldering processes, and

therefore it is strongly recommended to fully evaluate temperature profiles at all steps in the

soldering procedure to avoid excessive peak temperatures and ramp rates.

When amplifier assemblies require cleaning after soldering operations, the use of a nonreactive cleaning agent is recommended. All residue from reactive flux should be removed

according to the flux supplier's recommendations.

If a non-aqueous cleaning method is employed, it must be followed by cleaning with DI water

to remove all ionic contamination. It is recommended to periodically check the conductivity

of the DI rinse to insure that levels of ionic contamination are as low as possible. In cases

where heavy ionic contamination is present, multiple DI rinses in isolated baths should be

used. Proceed from the most to the least contaminated rinsing system to maximize cleaning

effectiveness.

In general it is recommended to minimize the use of flux, to use no-clean flux, or to adopt

fluxless soldering techniques. When there is doubt as to the behavior of residual flux or flux

levels, consider a two-step solder approach. Since the PCB and other components may

involve flux, an initial soldering step of the majority of non-critical components can be done,

followed by a thorough cleaning. The second solder step, with greatly reduced flux content,

can be planned for more critical components such as epoxy sealed RF transistors. An

added benefit of a two-step operation is that non-solder thermal interface materials (TIMs),

such as thermal compounds, are not influenced by aggressive flux cleaning.

Following DI rinsing operations, the entire assembly should be baked, as determined by

user experimentation, before power is applied. It is suggested to perform this drying at 125

°C for 24 hrs, if all components are rated for this condition. A longer bake time is

recommended at lower temperatures. Refer to Figure 2 for some suggestions.

OEM equipment operating conditions should be specified for operation only in a “noncondensating” environment. If there is a question of humidity in ambient conditions in power

cycling, a heating/drying cycle is recommended before power is applied.

6/26 Doc ID 17594 Rev 3

Page 7

AN3232 Exceptional thermal performance potential of the STAC package concept

2 Exceptional thermal performance potential of the

STAC package concept

RF Power transistors are made up of hundreds of thousands of heat generating cells,

organized in an ultra-compact geometry at the silicon chip level. The necessity to generate

RF power at ever-increasing frequencies leads directly to the shrinking of silicon geometries

to ever-smaller portions of electrical wavelength. The result is unprecedented power density,

unmatched by most devices in the semiconductor industry. Indeed, such a power density

approaches those frequently encountered in the realm of high-energy physics.

The highest priority of the power transistor package is efficient evacuation of the incredible

thermal flux from the active regions of semiconductor chips to the external environment.

Great advances made to improve packaging systems and materials have enhanced this

effect, including the use of high thermal conductivity materials, the reduction of thermal path

length, and the improvement of thermal interfaces by way of superior flatness coupled with

enhanced TIMs.

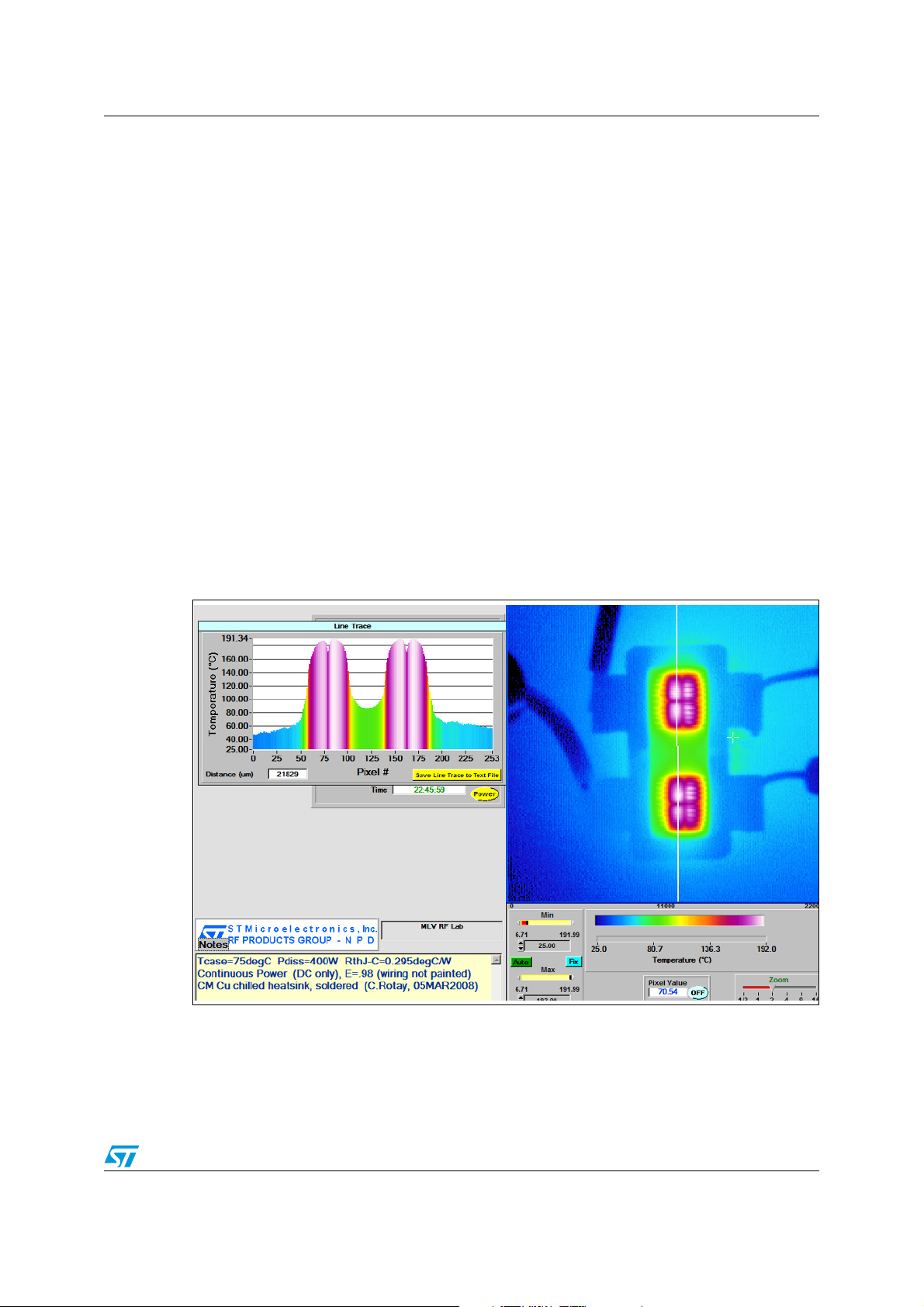

A demonstration of the high power density of one device in the STAC family is shown in

Figure 3 by way of infrared imaging. In this example, the junction temperature of the

semiconductor chips, dissipating a total of 400 W continuously, is maintained uniformly

below the maximum allowable temperature of 200 °C, while the case is elevated almost to

its maximum of 85 °C.

Figure 3. Infrared imaging of a STAC package

As is the case with many RF power devices, thermal resistance is dominated by the chips

themselves, as can be ascertained in Figure 3. In addition, the thermal conductivity of

silicon decreases with increasing temperature, therefore it is common practice to evaluate

power transistors near the maximum operating temperatures. Taking this into account, the

observed thermal resistance, or R

of approximately 0.30 °C/W for this STAC product, is

thJ-C

Doc ID 17594 Rev 3 7/26

Page 8

Exceptional thermal performance potential of the STAC package concept AN3232

approximately 30 % lower than it's ceramic package cousin, the ubiquitous GEMINI

package.

This situation affords amplifier designers extreme flexibility in terms of trade-offs between

power dissipated, output power, power density, and MTTF. For example, higher power can

be dissipated for a target junction temperature, or, on the other hand, increased MTTF can

be achieved for a target case temperature with equivalent power density.

While such flexibility often shifts the burden of cooling to system level, this decision is often

the more cost effective solution or easier to manage. Alternatively, such a solution could

translate into the ability to move an amplifier system from ground level to pole top. In the end

analysis, the choice of heatsinking system depends on the specific device and application

needs.

8/26 Doc ID 17594 Rev 3

Page 9

AN3232 Heatsink selection

3 Heatsink selection

The critical choice of a heatsinking system depends on the specific device and application

requirements. The decision results in the total power dissipation capability for the amplifier

assembly and greatly influences system performance and cost.

When the operating conditions of the device are such that the dissipated power is low, a

basic thermal core layer without fins may be all that is required for maintaining a low case

temperature, a high MTTF, or adherence to other maximum device ratings. Examples of

applications with low average power dissipation can include low duty-cycle pulsed

amplification or backed-off linear power amplifiers.

Most often, RF power devices are operated at the highest power levels possible, to extract

the most value for the cost. Combining the exceptional performance of recent silicon

improvements, having much higher power efficiency than in previous years, with the thermal

performances of STAC packages, allows the possibility for designers to specify relatively

simple systems like low-cost, extruded aluminum heatsinks with fins to provide sufficient

cooling. Such systems have good thermal and electrical properties for a majority of

applications and operating conditions.

One benefit of STAC packages is to enable designers to “push the envelope” in terms of

power density. First, high thermal flux is managed using a heat spreading copper core layer

between the transistor and a high performance heatsink. Second, for the most demanding

applications, system such as water cooling, heat pipes, and others can be coupled to the

first, affording a means of transferring heat very quickly to a more convenient location.

For a high performance package such as STAC, the preferred heatsink material interposed

between the package base and the heatsink is (UNS C10100) copper. Hereafter this

material layer is referred to as the core. Based on requirements for typical applications, the

thickness range for the core layer is listed in Ta bl e 1 .

Table 1. Preferred copper core thickness

Minimum Typical Maximum

0.12 in (3.0 mm) 0.22 in (5.6 mm) 0.32 in (8.1 mm)

Other copper grades and even aluminum may be used for the core layer based on

application needs. In these cases, it is advised to adjust core thickness appropriately to

control spreading of the heat.

Doc ID 17594 Rev 3 9/26

Page 10

Core preparation AN3232

4 Core preparation

By design, the STAC package family does not require complex core preparation, such as

channels, pockets, cavities, etc., assuming a typical PCB thickness is selected for the

application. However, because of the intended use of these packages, some aspects of core

preparation are appropriate. Holes for screws, solder wells, etc., should be slightly

countersunk and/or de-burred to achieve the best performance.

In soft materials such as copper, the tapping operation can lift material above the mounting

surfaces. This may occur on either side of the core layer, so both sides should be inspected.

It is sometimes helpful to fully thread test screws in the holes and tighten, to observe if the

core material is pushed or pulled above the mounting surfaces. If such a mushroom effect is

observed, it is an indication that additional countersinking of the tapped holes is warranted.

It is advised to drill and tap through the entire core layer, whenever possible.

In the case of boltdown mounting of STAC packages, the minimum tapped hole depth

should be 0.12 in (3.0 mm). Depending on the process used to fabricate the core layer, it is

common industry practice to recommend stress relieving the core material, such as an

annealing step before (and sometimes after) the heavy machining steps. This should be

considered whenever there are a large number of cuts, holes, and other machined features

in the core layer. The flatness of the core layer should be inspected after all machining steps

to insure that a buildup of stress has not caused it to become warped or otherwise

deformed.

10/26 Doc ID 17594 Rev 3

Page 11

AN3232 Mounting base surface conditions

5 Mounting base surface conditions

The mounting base, or the surface of the core to which the backside of the package is

mounted, must be flat, clean, and free of tool marks. Recommended specifications for the

surface conditions are shown in Ta bl e 2 .

Table 2. Surface conditions

Flatness Roughness, R

400 µin / in (0.4 µm/mm) < 30 µin (0.8 µm)

Flatness and roughness values can be achieved on the above mentioned materials with

standard machining processes, such as milling. Improved flatness and lower roughness

values reduce both electrical and thermal resistance.

a

Doc ID 17594 Rev 3 11/26

Page 12

Thermal interface material AN3232

6 Thermal interface material

Careful consideration must be paid to the actual interface layer between the backside of the

package and the mounting base. Cleanliness is key: particulates, grease, and oxidation

should be removed using standard practices.

A thermal interface material (TIM) of good thermal conductivity should be used in order to fill

any discontinuities between the package and mounting base surface. The decision of which

TIM material to use is based on many factors. Many types of TIMs are available with an

incredible range of thermal, electrical, and mechanical properties. A few are listed in

Ta bl e 3 .

Table 3. Common TIMs

Type Description Supplier

WPSII (silicone-free) Austerlitz Electronics

Paste or grease

Type 120(silicone based) Wakefield thermal solutions

Foil or film based Indium preform Indium

Solder based

Type 340 Dow Corning

Pb or Pb-free preform Various

Pb or Pb-free paste Various

In all cases, the chosen TIM should be no thicker than necessary and applied as evenly as

possible. For liquidus compounds, it is easiest to apply it to the backside of the package,

keeping in mind that excessive TIM thickness results in a higher thermal resistance than

using no TIM at all. Application of pressure displaces liquidus TIMs in regions of metal-tometal contact, and fills in any remaining air gaps, thus resulting in excellent electrical and

thermal contact.

For foils and soldering, it is best to specify an appropriately sized “preform”, with a thickness

of approximately 0.003 in(0.08 mm), and apply it to the core layer or heatsink.

In soldering of Au plated components which have not been pre-treated by HSD or tinning,

enough solder should be used so that the final Au content of the multi-eutectic alloy is less

than 4 % by weight, to avoid “gold embrittlement” issues. Excessive Au content in Pb and

Pb-free alloys can result in a brittle solder joint which degrades over time with continuous

power/temperature cycling.

12/26 Doc ID 17594 Rev 3

Page 13

AN3232 Seating plane

7 Seating plane

The seating plane refers to the plane determined by the bottom surface of the leads after the

package has been mounted. For design purposes, it is the distance between the bottom

surface of the package base and the bottom surface of the transistor leads. This important

dimension is specified on package outline drawings, and for through-the-board mounting of

high power packages, it indicates total depth of the pocket into which the transistor is

seated. To determine the depth of this pocket, the total thickness of the PCB, Cu traces,

solder layers, and the depth of any machined channel is considered. Some points to factor

into this calculation are shown in Figure 4.

Figure 4. Pocket depth consideration (mm)

Care should be taken to factor in the thickness of the TIM, which is equivalent to increasing

the seating plane dimension. Along similar lines, if the PCB is fused to the heatsink by

means of a bonding film, solder layer, etc., the corresponding thickness of this layer should

be factored into the PCB thickness.

The leads of the transistor should launch perpendicular to the package body onto the traces

of the PCB to reduce mechanical stress to the package and solder joints. In some cases, the

PCB fabrication tolerance is such that the leads extend above the plane defined by the top

of the PCB; this situation is best handled with a judicious selection of solder pad preform or

paste thickness, or by a slight downward bending of the transistor leads [no more than 0.01

in (0.25 mm)].

Figure 5. Lead bending

As with almost all power packages, in no case should the leads be bent higher than the

topside of the PCB, unless specific lead-forming techniques are applied, such as those

shown in Figure 5. Whenever non-coplanarity exists between the bottom of the device leads

and the top surface of the PCB, assembly mechanical stresses and cyclic life stresses

should be considered. Both lead-forming and a PCB pullback, such as that shown in

Doc ID 17594 Rev 3 13/26

Page 14

Seating plane AN3232

Figure 6, are effective methods to reduce shear stress. In applications where there is doubt

concerning lead stress, users can consult STMicroelectronics or it's resellers for analysis

and advice.

14/26 Doc ID 17594 Rev 3

Page 15

AN3232 Printed circuit board (PCB) considerations

8 Printed circuit board (PCB) considerations

A pocket feature through the PCB, with access to the core layer, is necessary for proper

mounting of the package. This pocket may be referred to as the “package-cut”, or an

oversized slot defined on an appropriate routed layer of the PCB stack. One such packagecut design is depicted in Figure 6. In this example, both performance optimization using

positioning notches and mechanical stress relief for the leads are achieved. The dimensions

for slots should be approximately 0.010 to 0.025 in (0.25 to 0.64 mm) greater than the

outside dimensions of the package body.

Figure 6. Package cut and pads layout

STAC244 and STAC265 packages were designed to be compatible with PCBs having

dielectric thicknesses in the range of 0.020 to 0.060 in (0.51 to 1.52 mm) - a wide range,

covering a large scope of applications. Generally, the more the typical PCB thickness

specification deviates from the typical seating plane dimension, the greater the offset

dimensions for the slots.

Often, the PCB traces are slightly pulled back from the edge of the slot. This “pullback”

technique is useful for situations in which the dimensions of the slot offset are constrained.

Among other benefits, trace pullbacks provide for reduced stress upon the leads and

package body.

Solder pad layouts for the transistor leads should be designed as large as the circuit

topology allows, but it is recommended that pad dimensions be at least the maximum width

and the remaining length of the leads (after the above pullbacks are considered). In most

cases a border around the leads of at least 0.01 in (0.25 mm) is advised, which allows for a

good solder fillet along three sides of each transistor lead.

Doc ID 17594 Rev 3 15/26

Page 16

Package attachment to core by means of boltdown method AN3232

9 Package attachment to core by means of boltdown

method

9.1 Required hardware

The recommended fastener system consists of:

● Printed circuit or wiring board (PCB or PWB)

● Core layer, normally copper

● Boltdown STAC package

● Choice of TIM

● 2 each of 4-40 UNC-2A (or M3) TORX, HEX, or PHILLIPS cap screws (one for each

end of the package body)

● 2 each of spring washers, ID=0.150"(3.81 mm) OD=0.275"(6.98 mm), t=0.015"(0.38

mm), h=0.025"(0.62mm)

● Means of measuring torque

9.2 Considerations

The ideal screw-center spacing for STAC244B and STAC265B packages is 1.1 inch (27.94

mm). This dimension is the same as recommended for legacy "GEMINI" package outlines

such as M244, M252, M265 as well as other familiar equivalents in the industry. Regardless

of the spacing, the key objective is to insure that long and short centerlines of the package

body are centered along and between the screws, respectively. This alignment procedure

insures that the clamping forces are correctly balanced, such that the STAC clamping

design directs pressure down and towards the center of the package body.

16/26 Doc ID 17594 Rev 3

Page 17

AN3232 Package attachment to core by means of boltdown method

Figure 7. Ideal screw-center spacing

The boltdown procedure begins with the application of the TIM to the back of the package,

followed by the insertion of the package into the application board. In the partially exploded

view shown in Figure 7, the washers are positioned between the screw head and the bolting

surfaces of the package. It is best to start the screws in both tapped holes as demonstrated

in Figure 8, continuing in an alternating fashion until finger tightness is achieved. This

method insures the package is properly seated and aligned before the final tightening

sequence.

Doc ID 17594 Rev 3 17/26

Page 18

Package attachment to core by means of boltdown method AN3232

Figure 8. First boltdown mounting steps

To further improve the distribution of pressure from the screw head/spring washer

combination, an optional flat washer, with an outer diameter no greater than 0.28 in(7.1

mm), may be inserted between the spring washer and the package bolting surfaces. Many

types of spring washer are available, such as split, conical, Belleville, and wave. The choice

of spring washer is left to the amplifier designer and choices may vary depending on the

application.

Finally, alternately tighten both screws in steps up to the recommended torque value using a

torque driver or equivalent. Depending on the choice of TIM, the final required screw torque

should be adjusted within the range listed in Tab l e 4.

Table 4. Recommended screw torque

Minimum Typical Maximum

3.5 in-lb 5.0 in-lb 6.5 in-lb

0.4 N-m 0.6 N-m 0.75 N-m

4 kg-cm 5.8 kg-cm 7.5 kg-cm

When the above procedure is properly applied, uniform pressure with tolerance for thermal

expansion is provided. The mechanical features designed in the STAC boltdown package

translate the force towards the center of the package at the prescribed screw torque. Along

with the material set featuring low creep and fatigue resistance, the STAC package and the

complete hardware system insure that pressure is maintained uniformly over time.

18/26 Doc ID 17594 Rev 3

Page 19

AN3232 Package attachment to core by means of boltdown method

9.3 Procedure summary

1. Tighten both fastener systems to each end of the package body to a “finger-tight”

condition, approximately 0.4 in-lb (0.05 N-m, 0.5 kg-cm).

2. Use a torque driver or equivalent means to tighten both screws to the recommended

torque of 5 in-lbs (0.6 N-m, 5.8 kg-cm).

Doc ID 17594 Rev 3 19/26

Page 20

Package attachment to thermal base by means of soldering AN3232

10 Package attachment to thermal base by means of

soldering

10.1 Hardware

● Printed circuit or wiring board (PCB or PWB)

● Solderable core layer, normally copper

● STAC package (can be flangeless or boltdown version)

● Pb or Pb-free Solder preform or similar solder paste

● Solder reflow equipment, such as an oven

● Optional mechanical hardware to locate the package

10.2 Solder reflow equipment and methods

There are many methods for soldering; which method to use is based on factors outside the

scope of this application note. For the STAC package comprising a material set in use for

decades, ST feels comfortable recommending a convection reflow oven, preferably with 5

zones plus a cooling strategy. For example, the SEHO FDS “MAXIPOWER” unit depicted in

Figure 9, with independent top and bottom heaters and a refrigerated cooling zone, has

been used in testing STAC packages for reflow soldering and is well-known throughout the

industry.

Figure 9. SEHO FDS “MAXIPOWER” reflow oven

An important consideration for reflowing power packages like the STAC is that the

temperature profile must be adjusted on a case-by-case application basis. No universal

profile can account for the large variation in thermal mass between various RF Power

Amplifier (RFPA) assemblies. An RFPA might consist of a relatively small PCB and thin core

layer, which can be soldered with a relatively fast conveyor speed. On the other hand, a

large area RFPA pallet, having a thick copper core layer, requires much slower movement

through the reflow oven to achieve good soldering. The PCB acts in insulating the top of the

core layer from topside heating, therefore a programming balance between top and bottom

20/26 Doc ID 17594 Rev 3

Page 21

AN3232 Package attachment to thermal base by means of soldering

heating zones may be required to optimize for uniform temperatures at the interface of the

STAC package and copper core layer.

Regardless of the amplifier assembly and choice of soldering method, the industry standard

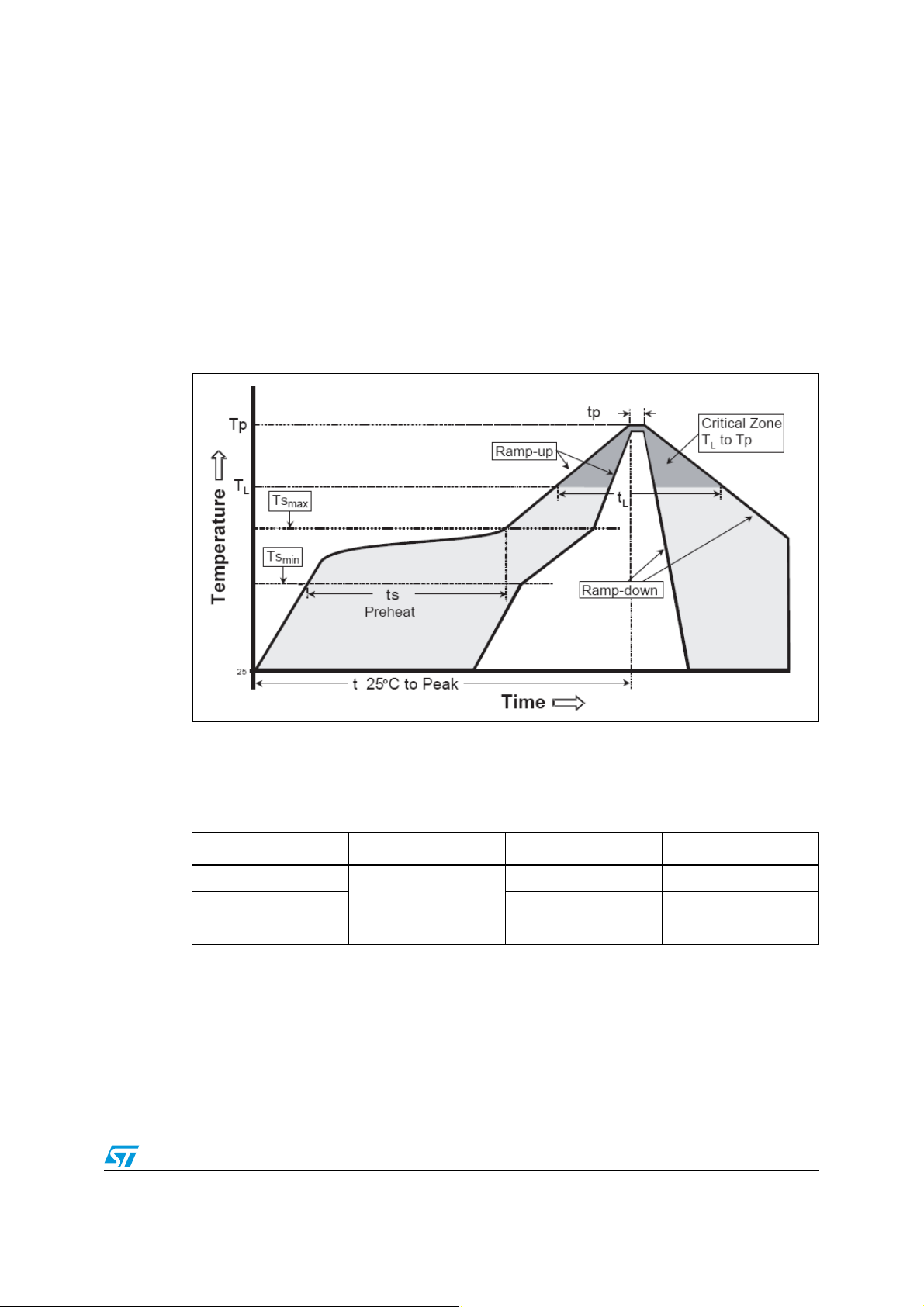

reflow profile recommended in J-STD-020D for solder reflow operations is acceptable for

STAC packages. It is important that this profile, as shown in Figure 10, is respected at the

component level. According to table 4-2 of the JEDEC reference, a max Tp of 245 °C is

advised, but STAC packages can survive many reflows at temperatures up to a body

temperature of 265 °C with no damage. However, such excursions up to this extreme

temperature are not recommended because many other board level components may not

survive such stressful conditions.

Figure 10. Component level temperature profile

Note: Tp= 20-40 sec, ramp-up = 3 °C/sec max, T

217 °C, T

= 200 °C, T

Smax

= 150 °C, TS= 60-180 sec, from t 25 °C to peak = 8 minutes

Smin

max, tp = Ta bl e 5 .

Table 5. Pb-free process - package classification reflow temperatures

Package thickness Volume mm3 < 350 Volume mm3 350-2000 Volume mm3 > 2000

< 1.6 mm

1.6 mm - 2.5 mm 250 + 0 °C

> 2.5 mm 250 + 0 °C 245 + 0 °C

1. Tolerance: the device manufacturer/supplier assures process compatibility up to and including the stated

classification temperature (this means peak reflow temperature + 0 °C. For example 260 °C + 0 °C) at the

rated MSL level.

260 + 0 °C

Doc ID 17594 Rev 3 21/26

= 60-150 sec, ramp-down = 6 °C/sec max, TL=

L

(1)

260 + 0 °C 260 + 0 °C

245 + 0 °C

Page 22

Package attachment to thermal base by means of soldering AN3232

Note: The profiling tolerance is + 0 °C, -X °C (based on the machine variation capability)

regardless of what is required to control the profile process, but at no time does it exceed -5

°C. The producer assures process compatibility at the peak reflow temperatures.

Package volume excludes external terminals (balls, bumps, lands, leads) and/or nonintegral heatsinks.

The maximum component temperature reached during reflow depends on package

thickness and volume. The use of convection reflow processes reduces the thermal

gradients between packages. However, thermal gradients due to differences on thermal

mass of SMD packages may still exist.

Ultimately, the most stressful aspect of soldering for packaging consisting of plastic or epoxy

layers is related to rapid transition between process steps. For this reason, it is

recommended to never exceed the ramping rates recommended in J-STD-020D at the

package level.

22/26 Doc ID 17594 Rev 3

Page 23

AN3232 Electrical connection

11 Electrical connection

Leads and/or flanges should be attached to the PCB and/or copper heatsinks using typical

Sn63Pb37 or Pb-free solders, in accordance with the supplier's recommendations.

However, the following guidelines with respect to the package should be considered:

● Avoid, as much as possible, the use of flux or flux solutions as it is a potential source of

contamination to the device.

● The leads of the transistor may be tinned prior to assembly on the PCB. This practice is

used in situations when it is undesirable to introduce even a small amount of gold into

the solder composition, forestalling the possibility of solder embrittlement issues. The

source of Au stems from the lead and/or backside surfaces, which are plated with 40 to

100 µin (1 to 2.5 µm) of Au.

● The amount of solder to be used depends on the type of solder and the amount of

allowable Au in the final solder composition. It is desirable to increase the amount of

solder when Au content is a concern, such as in Pb-free soldering applications.

● It is recommended to use either a solder preform or solder paste having a thickness of

0.001 to 0.010 in (0.03 to 0.3 mm), typically 0.006 in (.15 mm).

● Adjustment of the solder preform or paste thickness may be used advantageously to

account for thickness variations in the PCB manufacturing process.

● In cases where the backside of the flange is soldered to a copper core or heatsink, the

package design and previously discussed mechanical mounting procedure provide

sufficient downward pressure on the solder preform, resulting in a thin, high-quality

bondline after a typical solder reflow procedure. In such cases, solder-wells or a soldermoat around the perimeter of the flange should be considered, to provide a region for

excess solder to flow.

● A solder preform or other metallic foil may be used as both a TIM and electrical

interface between the backside of the package (source) and amplifier ground (normally

the core layer or the heatsink) even without soldering.

● Electrically insulative thermal pastes must be applied sufficiently thin, such that the

downward pressure is high enough to force metal-to-metal contact over a significant

area of the surfaces between the package (source) and amplifier ground.

Doc ID 17594 Rev 3 23/26

Page 24

Conclusion AN3232

12 Conclusion

This application note provides a set of guidelines to be considered for the proper attachment

of STAC packages. While these recommendations are intended to address the majority of

user applications, the flexibility afforded by this new generation of package technology

enables new approaches for amplifier assembly as well as novel system architectures. In

the search for constant improvement, ST continues to address customer needs by

improving the robustness of the STAC package line and by releasing additional outlines with

more functionality and versatility. For these reasons, it is expected that these guidelines are

to be revisited and updated over time. At present, these recommendations are expected to

result in reliable mechanical, electrical, and thermal performance.

Regarding the thermal expectations of STAC packages, this application note demonstrates

the exceptional performance that can be attained when utilizing the solder-down mounting

method; this can be viewed as the limiting case for lowest achievable thermal resistance.

While the STAC package concept embodies highly customizable thermal solutions by

means of chip carrier material substitution, the importance of an exceptionally low thermal

resistance between the transistor case and the heatsink (R

the case presented, this interface accounts for only 0.025 °C/W, roughly half of what is

achievable with industry standard flanged packages. In this regard, STAC packages afford

intrinsic flatness and the highest available thermal conductivity materials, further enhancing

cooling efficiency. Even without soldering, judicious selection of TIMS and respect to this set

of guidelines results in R

values on the order of 0.05 °C/W.

thC-HS

) cannot be overstated. In

thC-HS

24/26 Doc ID 17594 Rev 3

Page 25

AN3232 Revision history

13 Revision history

27-Jul

Table 6. Document revision history

Date Revision Changes

03-Aug-2010 1 Initial release.

08-Jun-2011 2

31-Aug-2011 3 Introduction on cover page has been updated.

Updated Figure 7: Ideal screw-center spacing and Section 9.2:

Considerations.

Doc ID 17594 Rev 3 25/26

Page 26

AN3232

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2011 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

26/26 Doc ID 17594 Rev 3

Loading...

Loading...