Page 1

AN3203

Application note

EVL250W-ATX80PL: 250W ATX SMPS

demonstration board

Introduction

This application note describes the characteristics and performance of a 250 W wide range

input and power factor corrected power supply designed to be used in an ATX application.

Good electrical performance allows meeting the most demanding efficiency targets.

The converter consists of four main blocks:

■ A PFC front-end stage using the L6563S PFC controller which generates the +400 V bus

voltage.

■ An AHB (Asymmetrical half bridge) stage using the L6591 ZVS half bridge controller

which performs the conversion from the high voltage bus to the +12 V output providing

insulation.

■ Two DC-DC post-regulator stages using the L6727 which obtain the +5 V and +3.3 V

outputs from the +12 V bus.

■ An auxiliary power supply (STANDBY) stage using the VIPer27H in isolated flyback

configuration which provides the +5 V_SB output with 10 W power capability.

Figure 1. 250 W ATX SMPS demonstration board

January 2011 Doc ID 17402 Rev 2 1/49

www.st.com

Page 2

Contents AN3203

Contents

1 Main characteristics and circuit description . . . . . . . . . . . . . . . . . . . . . 5

2 Asymmetrical half bridge operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.1 AHB typical waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2 Short-circuit protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3 Complete system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1 Overvoltage protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2 Load transients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3 Standby operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4 Electrical performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1 Efficiency measurement and no-load consumption . . . . . . . . . . . . . . . . . 19

4.2 Thermal considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.3 Harmonic content measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.4 Single output configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5 Conducted noise measurements (pre-compliance test) . . . . . . . . . . . 30

6 Parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7 PFC coil specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.1 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8 AHB transformer specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.1 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.2 Mechanical aspect and pin numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9 AUX flyback transformer specification . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.1 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.2 Mechanical aspect and pin numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

10 PCB layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

11 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

2/49 Doc ID 17402 Rev 2

Page 3

AN3203 List of tables

List of tables

Table 1. Efficiency @ 115 Vrms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 2. Efficiency @ 230 Vrms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 3. 80 PLUS® program efficiency levels (115Vac). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 4. 80 PLUS® program efficiency levels (230 Vac) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 5. Climate Savers Computing Initiative (for multi-output PSU) . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 6. No-load consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 7. Low load efficiency @ 115 Vrms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 8. Low load efficiency @ 230 Vrms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 9. PF vs. load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 10. Single output efficiency @ 115 Vac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 11. Single output efficiency @ 230 Vac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 12. AHB efficiency with 400 Vdc input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 13. EVL250W-ATX80PL bill of materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 14. Winding characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 15. Winding characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 16. Winding characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 17. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Doc ID 17402 Rev 2 3/49

Page 4

List of figures AN3203

List of figures

Figure 1. 250 W ATX SMPS demonstration board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. Electrical diagram: input EMI filter and PFC stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 3. Electrical diagram: AHB stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

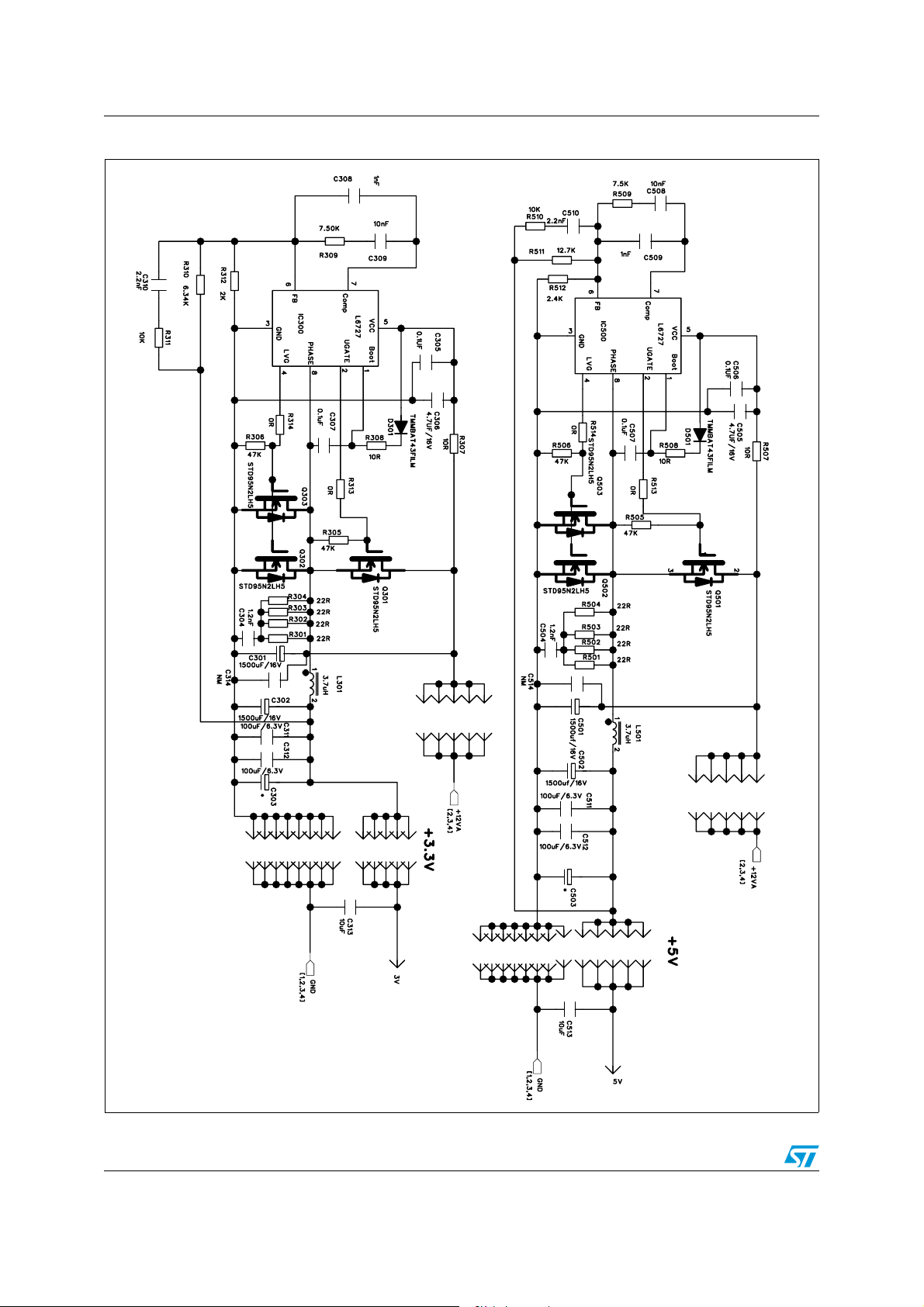

Figure 4. Electrical diagram: DC-DC stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

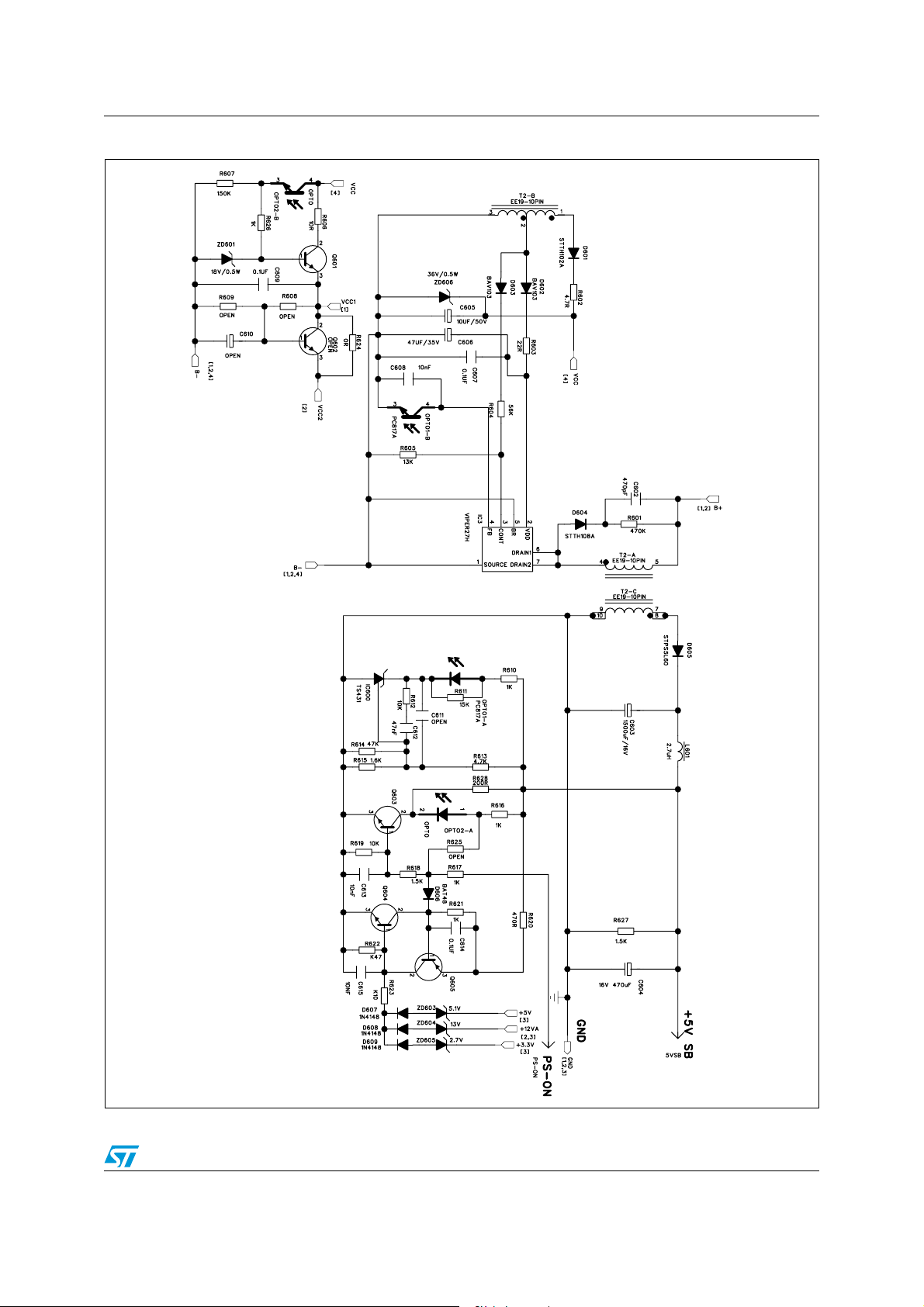

Figure 5. Electrical diagram: standby stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

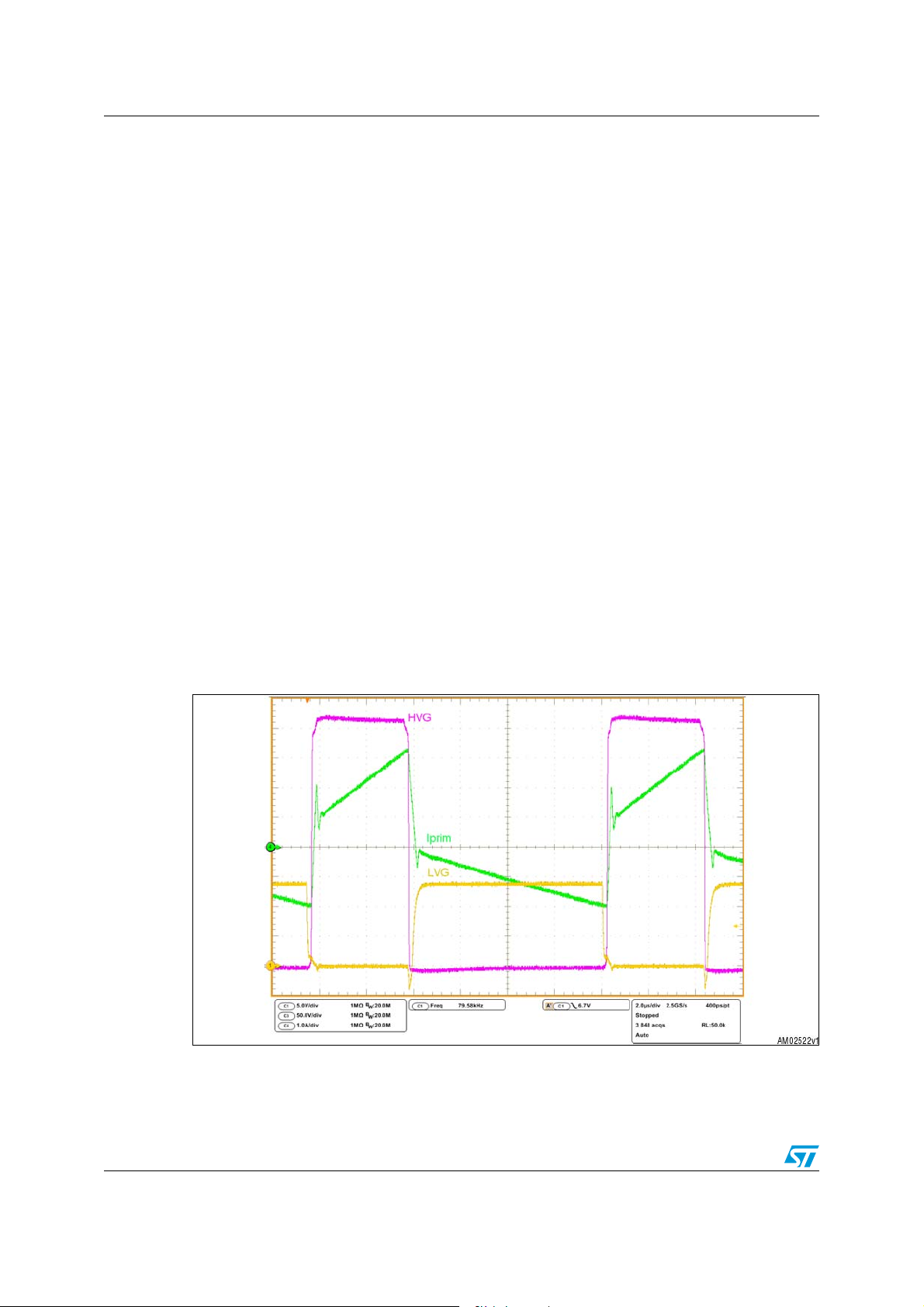

Figure 6. AHB primary side key waveforms @ full load. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 7. AHB zero voltage switching detail @ full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

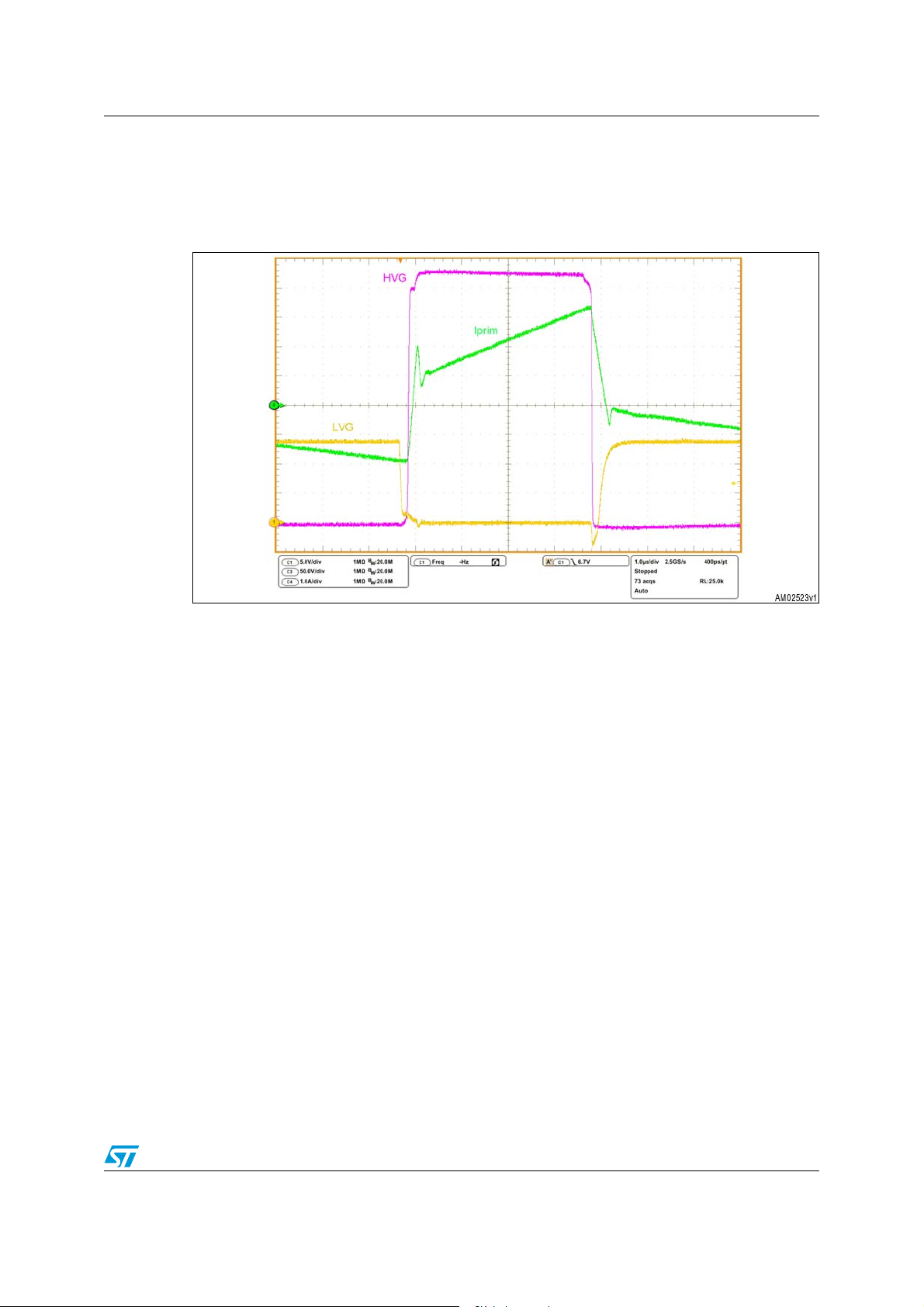

Figure 8. AHB transitions detail @ 20 % rated load. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 9. AHB secondary side key waveforms @ full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 10. Short-circuit behavior detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 11. Load transient on +12 V output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 12. Load transient on +5 V output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 13. Load transient on +3.3 V output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 14. Efficiency vs. O/P power @ 115 Vac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 15. Efficiency vs. O/P power @ 230 Vac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 16. No-load consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 17. Efficiency at low loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 18. Fanless board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 19. EN61000-3-2 and JEITA-MITI measurements @ full load . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 20. EN61000-3-2 and JEITA-MITI measurements @ 75 W in . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 21. PF vs. input voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 22. THD vs. input voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 23. Single output efficiency @ 115 Vac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 24. Single output efficiency @ 230 Vac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 25. AHB stage only efficiency (Vin = 400 Vdc) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 26. CE peak measurement@115 Vac and full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 27. CE peak measurement @ 230 Vac and full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 28. CE average measurement@115 Vac and full load. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 29. CE average measurement@230 Vac and full load. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 30. Electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 31. Mechanical drawing (unit: mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 32. Electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 33. Windings position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 34. Bottom view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 35. Electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 36. Windings position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 37. Bottom view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 38. Top side silk screen and copper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 39. Bottom side silk screen and copper (mirror view). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4/49 Doc ID 17402 Rev 2

Page 5

AN3203 Main characteristics and circuit description

1 Main characteristics and circuit description

Here are the main characteristics of the power supply:

● Input mains range:

– Vin: 88 ~ 264 Vrms

– f: 45 ~ 66 Hz

● Outputs:

– +12 Vdc ± 2 % - 13.5 A

– +5 Vdc ± 2 % - 12 A

– +3.3 Vdc ± 2 % - 8 A

– +5 V_SB ± 2 % - 2 A

● Standby consumption: < 0.2 W

● Protection:

– Short-circuit

–Overload

– Output overvoltage

– Brownout

● PCB type and size:

–FR4

– Double side CU 70 µm

– 148 x 120 mm

● Safety: according to EN60950

● EMI: according to EN55022 - class B

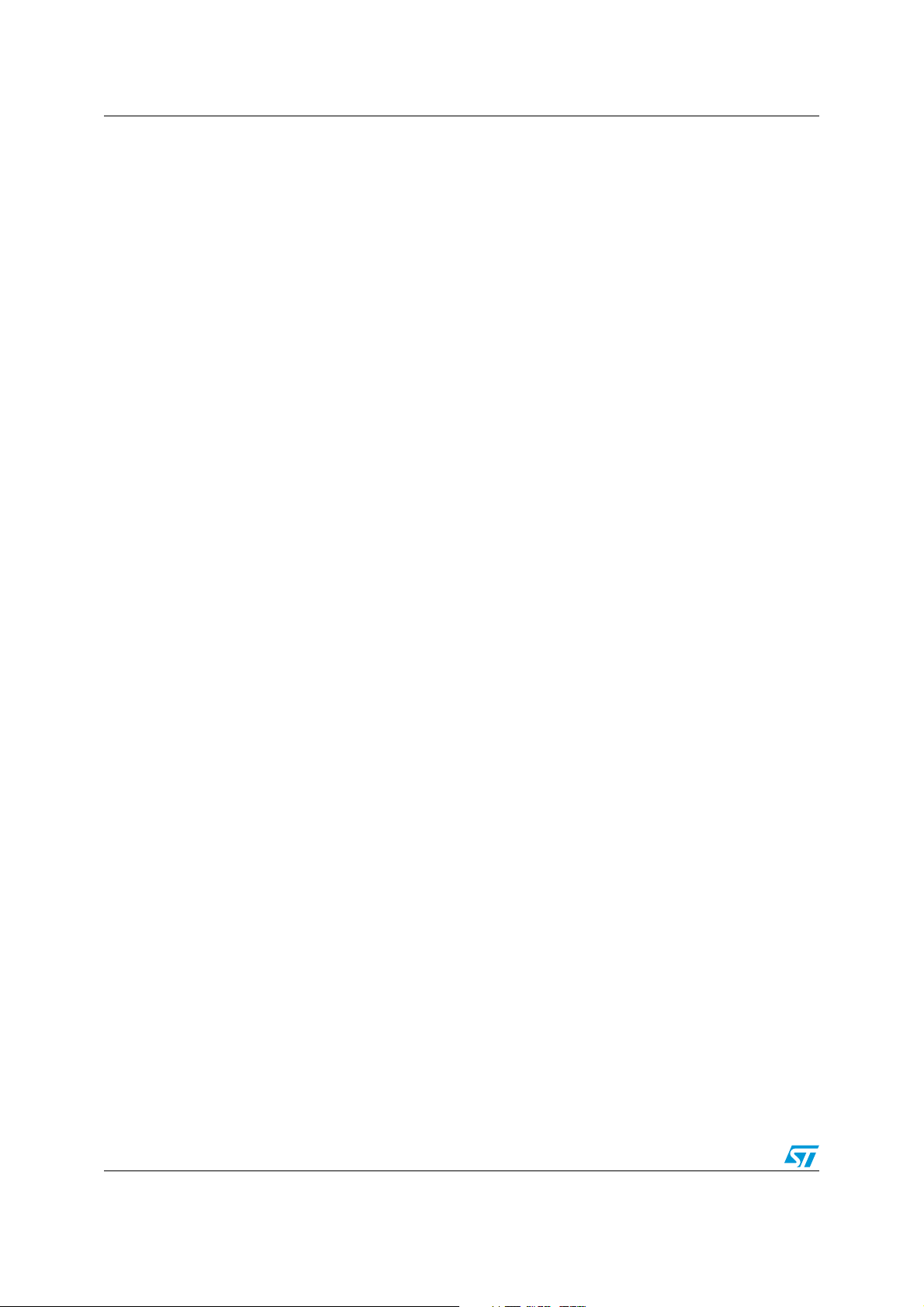

The EVL250W-ATX80PL demonstration board is made up of four main blocks, the

schematics are shown in Figure 2, 3, 4, and 5.

The front-end PFC stage is realized using a boost topology working in line modulated fixed

off time (LM-FOT) mode, described in STMicroelectronics’ application notes, AN1792;

Design of Fixed-Off-Time controlled PFC pre-regulators with the L6562 and AN3142;

Solution for designing a 400 W Fixed-Off-Time controlled PFC preregulator with the L6563S

and L6563H. The LM-FOT operation offers the advantage of having CCM operation (with

lower rms current with respect to TM mode) without the need to use a complex and

expensive controller. Therefore, it is possible to use the simple L6563S, enhanced TM PFC

controller, which integrates all the functions and protection, needed to control the stage, and

an interface with the downstream DC-DC converter.

The power stage of the PFC is realized with inductor L4, MOSFET Q1 and Q2, diode D3,

and capacitor C1. The LM-FOT operation is obtained with components D6, R15, C10, R14,

C9, R13, and Q3.

The PFC delivers a stable high voltage bus (+400 V nominal) to the downstream converters

(AHB and flyback) and provides for the reduction of the current harmonics drawn from the

mains, in order to meet the requirements of the European EN61000-3-2 norm and the

Japanese JEITA-MITI norm.

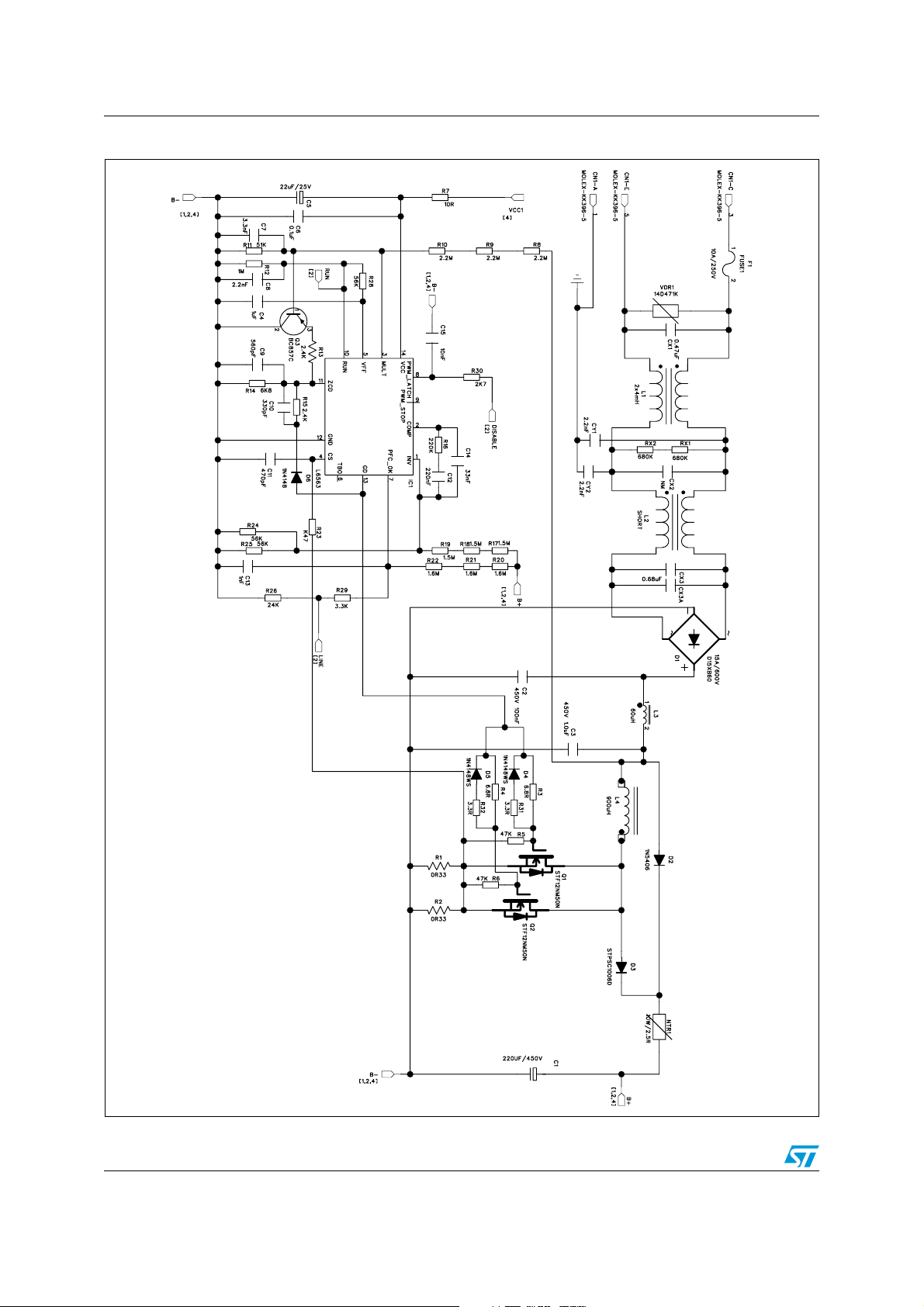

The second stage is an asymmetrical half bridge converter, driven by the L6591, a

STMicroelectronics controller dedicated to this topology. This IC integrates all the functions

Doc ID 17402 Rev 2 5/49

Page 6

Main characteristics and circuit description AN3203

and protection needed by the AHB stage and an interface for the PFC controller. The L6591

includes two gate drivers for the half bridge MOSFETs and a fixed frequency

complementary PWM logic with 50 % maximum duty cycle with programmable dead time

and current mode control technique.

Other features of this IC are pulse-by-pulse overcurrent protection, transformer saturation

detection, overload protection (latched or auto-restart), and programmable soft-start. There

is also a high voltage startup circuit, a burst mode logic for low load operation, and the

adaptive UVLO onboard, which are not used in this design as they are designed for adapter

applications (see AN2852).

The following is a description of the power circuit of this stage. The half bridge switches

Q101 and Q102 are connected to the output voltage of the PFC. The half bridge node drives

the series of C101 (DC blocking capacitor) and the primary side of the transformer T1. This

transformer has two secondary windings with a center tap connected to the secondary

ground. The other ends are connected to the sources of MOSFETs Q201 and Q202, which

replace output diodes in order to perform the synchronous rectification. Two extra windings

allow, with few external passive components, a self driven synchronous rectification to be

obtained. This solution allows efficiency to be increased without the extra cost of a

dedicated SR controller IC.

Q201 and Q202 drains are connected to the output inductor L201 that, together with output

capacitors C201 and C202, acts as a low pass filter. The signal +12 VA is then post filtered

(with L5 and C207) to obtain the +12 V output voltage.

The design of transformer T1 is a trade-off between ZVS operation and the required

electrical performance/efficiency. ZVS can be obtained acting on the magnetizing

inductance or on the primary side leakage inductance. In more detail, ZVS could be met by:

● Decreasing the magnetizing inductance

● Increasing the leakage inductance

Low values of magnetizing inductance generate high magnetizing current. This helps to

reach ZVS but it also increases the total primary side rms current and therefore the related

losses. In this design a value of 500 µH has been selected.

On the other hand, ZVS could be obtained by increasing the leakage inductance. If such a

parameter is increased, the primary side current takes more time before reversing its

direction and therefore ZVS is more easily met. A high leakage inductance value leads to

duty cycle losses, reducing the effective range of duty cycle usable. This creates problems

with hold-up requirements and makes it necessary to work with very narrow duty cycles with

nominal input voltage generating high rms currents in the circuit.

A value of 12 µH has been selected as the leakage inductance.

Because of these reasons, in this design ZVS is always met at low side MOSFET turn-on

while it is met only for medium-high loads at high side MOSFET turn-on. Even at mediumlow loads Q101 is turned on with a Vds well below the half bridge input voltage.

The L6591 LINE pin is used for startup sequencing. It shares with the L6563S the voltage

divider made up of R20, R21, R22, R29, and R26 that senses the PFC output voltage. The

AHB stage is activated when the bulk voltage reaches about 380 V.

The DISABLE pin (latched protection) is driven by the L6563S PWM_LATCH pin and stops

the AHB stage in case of PFC feedback disconnection.

The oscillator is programmed in order to have a switching frequency of about 80 KHz and to

use the minimum dead time (about 310 ns).

6/49 Doc ID 17402 Rev 2

Page 7

AN3203 Main characteristics and circuit description

The PFC_STOP pin is the interface for the PFC controller, it is connected to the L6563S

RUN pin through R104 and it stops the PFC operation (not latched) in case of overload,

output short-circuit or transformer saturation detection.

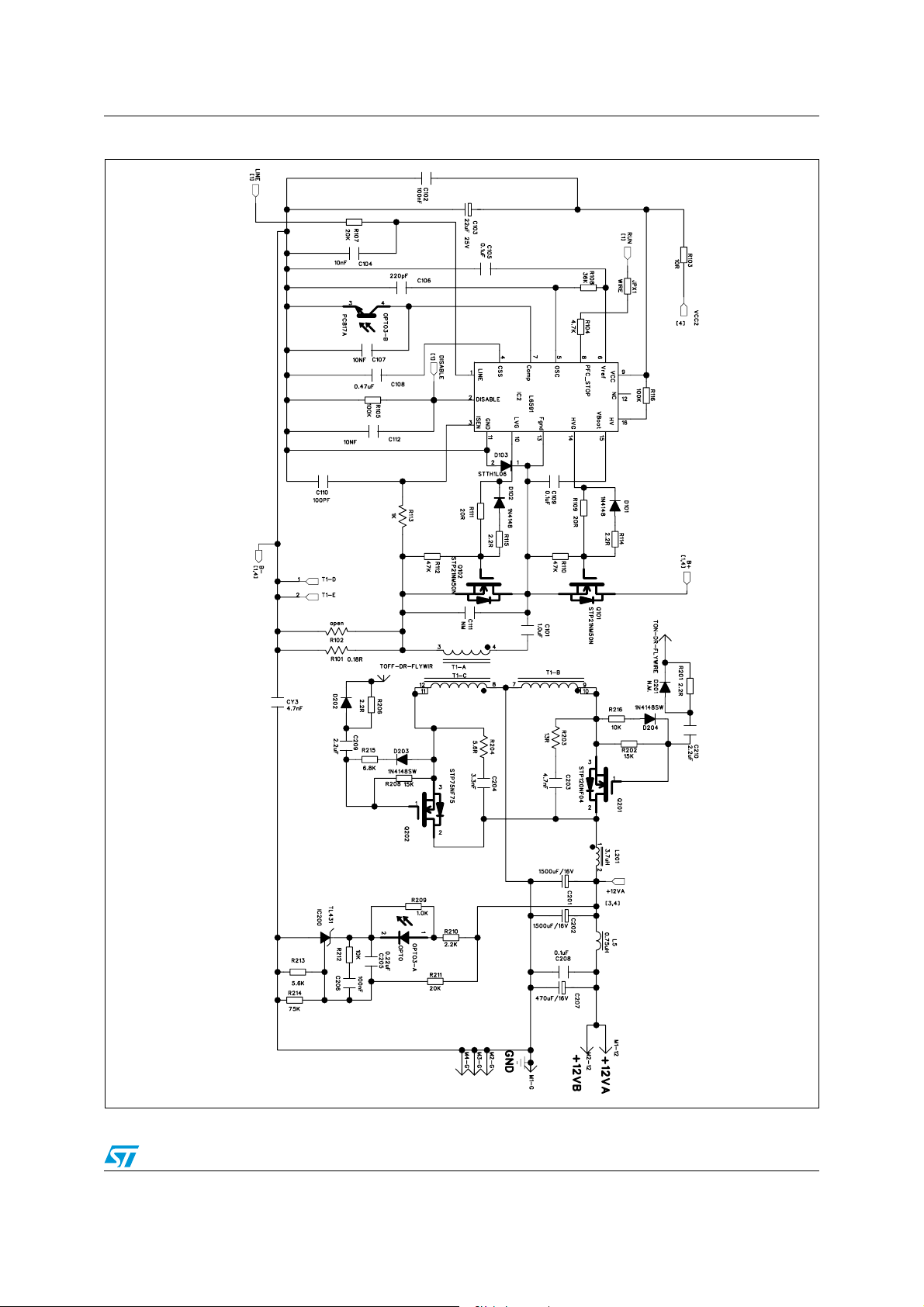

The +5 V and +3.3 V are obtained from the +12 VA bus (AHB output) thanks to two DC-DC

converters mounted on two daughter boards. These stages are driven by the L6727, single

phase PWM controller. The topology is a standard step down. For more information please

refer to the L6727; Single phase PWM controller datasheet.

The last stage is the auxiliary power supply that provides the +5 V_SB output (2A capability)

and the VCC supply for the L6563S and L6591. It is realized with a standard flyback

topology operating in CCM/DCM with fixed frequency using the VIPer27H. This stage takes

the PFC output voltage as input and is always working when the mains is plugged in. The

VIPer27H has all the protection needed to safely drive the standby stage. It protects the

circuitry in case of overload, output short-circuit, or output overvoltage.

All the other stages (and therefore the outputs +12 V, +5 V and +3.3 V) can be turned on /

off using the signal PS_ON. If it is disconnected or connected to GND, the OPTO2 current is

zero, Q601 is open and the VCC of the L6563S and L6591 is zero. If PS_ON is connected to

+5 V_SB, the OPTO2 current turns Q601 on. This BJT, together with the Zener diode

ZD601, acts as a linear regulator and provides the supply to the PFC and AHB controllers.

The same optocoupler is used to turn off the PFC and AHB stages in case of an overvoltage

on one of the three main outputs. Such protection is realized with three Zener diodes (one

for each output) that set the OVP thresholds. If one of the three output voltages goes over its

threshold, the Zener diode conducts and turns on the latch realized with Q604 and Q605.

The current in OPTO2 is reduced to zero (overriding the PS_ON information) and the

L6563S and L6591 are turned off.

Only the +5 V_SB stays on and continues to keep the protection latched.

Doc ID 17402 Rev 2 7/49

Page 8

Main characteristics and circuit description AN3203

Figure 2. Electrical diagram: input EMI filter and PFC stage

8/49 Doc ID 17402 Rev 2

Page 9

AN3203 Main characteristics and circuit description

Figure 3. Electrical diagram: AHB stage

!-V

Doc ID 17402 Rev 2 9/49

Page 10

Main characteristics and circuit description AN3203

Figure 4. Electrical diagram: DC-DC stage

10/49 Doc ID 17402 Rev 2

!-V

Page 11

AN3203 Main characteristics and circuit description

Figure 5. Electrical diagram: standby stage

!-V

Doc ID 17402 Rev 2 11/49

Page 12

Asymmetrical half bridge operation AN3203

2 Asymmetrical half bridge operation

2.1 AHB typical waveforms

In Figure 6 the primary side key waveforms during steady-state operation with full load

applied are shown. Figure 7 shows the detail of the two transitions during one switching

cycle.

The AHB stage has been designed to operate at about 80 kHz with a nominal input voltage

of 400 V (PFC output bus). The transformer design is the result of a trade-off between the

half bridge MOSFETs zero voltage switching (ZVS) operation requirements, the primary rms

current, and duty cycle losses. In fact, ZVS can be achieved by reducing the magnetizing

inductance or increasing the leakage inductance. With the output power of this board, the

first solution implies having very high rms primary current which leads to high losses. The

second solution introduces the so called “duty cycle losses”. When the leakage inductance

is de-magnetizing, the voltages on the secondary side windings are zero and therefore the

output mean value is reduced with respect to the same half bridge duty cycle and negligible

leakage inductance. Duty cycle losses limit the hold-up capability of the power supply

because they increase the minimum input voltage that guarantees output regulation.

In this design the system works with ZVS for both MOSFETs at full load. Because of the

intrinsic asymmetry of the topology the behavior of the two switches is different. When the

load is reduced the low side MOSFET always operates in ZVS while the high side one starts

loosing ZVS. The high side MOSFET never turns on with full bus voltage applied between its

drain and source. As shown in Figure 8, even at 20 % of rated load the Vds at turn-on is

about 100 V, definitely lower compared with the 400 V of a hard switching solution.

This design can therefore meet both efficiency and dynamic requirements.

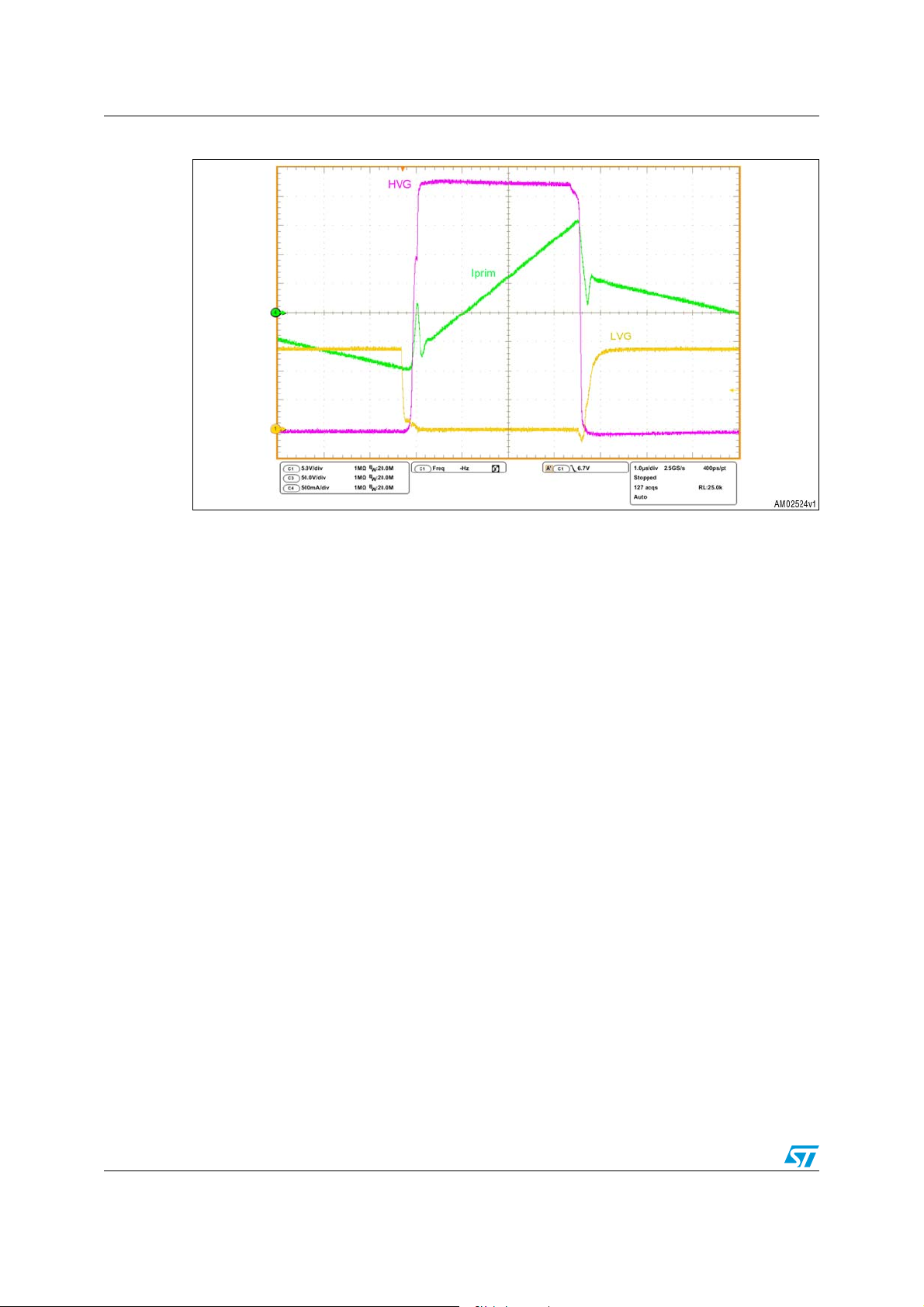

Figure 6. AHB primary side key waveforms @ full load

Ch1: LVG pin voltage (yellow)

Ch3: HVG pin voltage (purple)

Ch4: Primary winding current (green)

12/49 Doc ID 17402 Rev 2

Page 13

AN3203 Asymmetrical half bridge operation

The signal HVG is the sum of the half bridge node (FGND pin of L6591) and the high side

gate driver voltages. This peculiarity allows both waveforms and the ZVS operation for the

high side MOSFET to be checked. The driver activation is visible on the HVG signal when

there is a small voltage step on the high part of the waveform.

Figure 7. AHB zero voltage switching detail @ full load

Ch1: LVG pin voltage (yellow)

Ch3: HVG pin voltage (purple)

Ch4: Primary winding current (green)

Doc ID 17402 Rev 2 13/49

Page 14

Asymmetrical half bridge operation AN3203

Figure 8. AHB transitions detail @ 20 % rated load

Ch1: LVG pin voltage (yellow)

Ch3: HVG pin voltage (purple)

Ch4: Primary winding current (green)

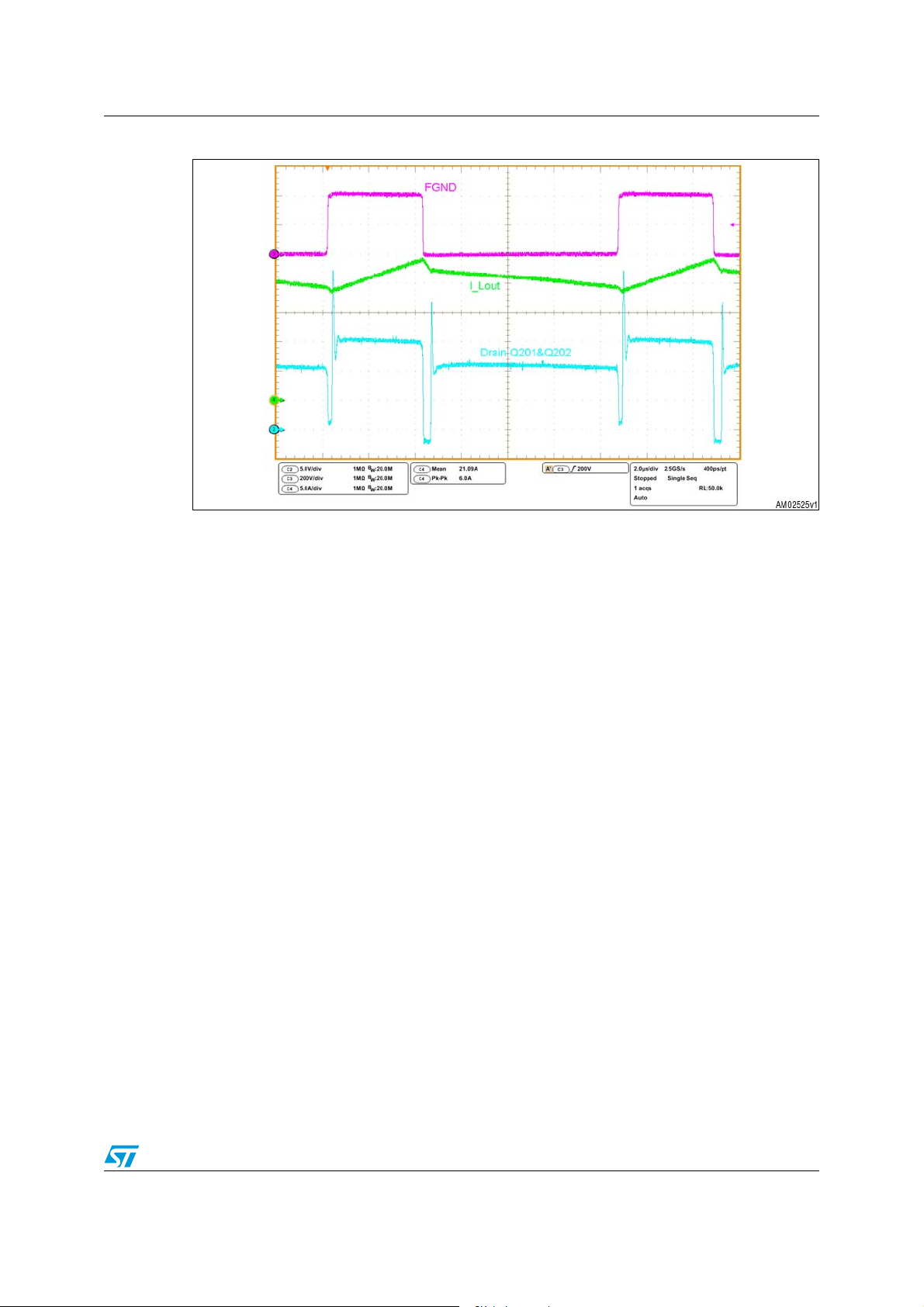

The key waveforms at the secondary side are shown in Figure 9. It is interesting to note that,

while the current is swapped between the two SR MOSFETs, the voltage at their drain is

nearly zero. The time required for current swap is directly proportional to the primary

leakage inductance. As mentioned before, the effect of this phenomenon is the duty cycle

losses.

14/49 Doc ID 17402 Rev 2

Page 15

AN3203 Asymmetrical half bridge operation

Figure 9. AHB secondary side key waveforms @ full load

Ch2: Q201 and Q202 drain pin (blue)

Ch3: FGND pin voltage (purple)

Ch4: Diode D13 current (green)

In order to improve the overall efficiency of the power supply, synchronous rectification has

been used. The two AHB output diodes have been replaced with two MOSFETs. A self

driven technique has been used to obtain a cheap solution. Two extra windings at the

secondary side generate the two square waves that, opportunely shifted, drive the two SR

MOSFETs gates directly. Referring to Q201, the extra winding (realized with just one turn)

starts from transformer pin 10 and ends in TON_DR_FLYWIRE. C210, D204, and R216 are

used to shift the voltage at the correct level to drive the MOSFET. R202 helps to keep the

MOSFET off if no driving signal is applied. A similar circuit drives the gate of Q202 starting

from the TOFF_DR_FLYWIRE signal.

Doc ID 17402 Rev 2 15/49

Page 16

Asymmetrical half bridge operation AN3203

2.2 Short-circuit protection

In case of a short-circuit at the AHB output the overload protection (OLP) is activated.

Figure 10 shows the pins involved in this function. When the short-circuit is applied, the

COMP pin saturates high. The IC detects this condition and starts charging the SS

capacitor. When the SS voltage reaches 5 V the system is shut down, when it reaches 6.4 V

the IC is latched. The PFC controller is also stopped: when the L6591 activates the

protection, the PFC_STOP signal pulls the L6563S RUN pin down to below the 0.8V

threshold. The latch is kept thanks to the auxiliary stage that remains active and provides

the VCC voltage.

In order to restart the system it is necessary to recycle the L6591 VCC voltage between the

UVLO thresholds. This can be done by removing the PS_ON signal in the auxiliary stage.

Figure 10. Short-circuit behavior detail

Ch1: SS pin voltage (yellow)

Ch2: COMP pin voltage (blue)

Ch3: FGND pin voltage, (purple)

Ch4: L6563S RUN pin voltage (green)

16/49 Doc ID 17402 Rev 2

Page 17

AN3203 Complete system

3 Complete system

3.1 Overvoltage protection

Every output is protected against overvoltage. The +12 V, +5 V and +3.3 V are monitored on

the auxiliary power supply schematic page. They use three Zener diodes to fix the three

overvoltage thresholds. In case one of the three voltages exceeds its threshold the latch

realized with Q604 and Q605 is turned on and the VCC for the L6591 and L6563S is

removed.

The two outputs +5 V and +3.3 V also have an overvoltage protection integrated into the

L6727 controller.

The +5 V_SB output is protected using the OVP protection of the VIPer27H that senses its

output voltage through the auxiliary winding. A threshold on the CONT pin detects the OVP

condition and stops the IC operation. This protection has an auto-restart behavior.

3.2 Load transients

The following figures show the behavior of the outputs during load transients. Each image

shows the transition from 20 % to 100 % of rated current and vice versa for a single output

voltage. The current slope is 0.5 A/µs for all the current variations.

Figure 11. Load transient on +12 V output

Doc ID 17402 Rev 2 17/49

Page 18

Complete system AN3203

Figure 12. Load transient on +5 V output

Figure 13. Load transient on +3.3 V output

3.3 Standby operation

When the PS_ON is not high, the system is in standby mode. Good performance is obtained

thanks to the VIPer27H high voltage converter. Efficiency and no-load consumption values

are shown in the next chapter.

18/49 Doc ID 17402 Rev 2

Page 19

AN3203 Electrical performance

4 Electrical performance

4.1 Efficiency measurement and no-load consumption

The efficiency measurements taken at the two nominal voltages are seen in the following

tables. The +5 V_SB output was unloaded during these measurements.

Table 1. Efficiency @ 115 Vrms

Load +12 V @load[A] +5 V @load[A] +3.3 V @load[A] Pout [W] Pin [W] Eff [%]

20 % 12.13 2.702 5.02 2.409 3.33 1.6 50.196 58.5 85.81 %

25 % 12.13 3.374 5.019 3.008 3.329 2.004 62.695 71.97 87.11 %

50 % 12.13 6.749 5.012 6.007 3.325 3.999 125.27 140.22 89.34 %

75 % 12.13 10.122 5.003 9.006 3.318 6.008 187.77 211.19 88.91 %

100 % 12.12 13.5 4.996 12.003 3.313 8.001 250.09 285.41 87.63 %

Table 2. Efficiency @ 230 Vrms

Load +12 V @load[A] +5 V @load[A] +3.3 V @load[A] Pout [W] Pin [W] Eff [%]

20 % 12.14 2.701 5.019 2.408 3.329 1.599 50.199 58.62 85.63 %

25 % 12.14 3.374 5.018 3.008 3.328 2.003 62.720 71.52 87.70 %

50 % 12.13 6.754 5.011 6.006 3.323 3.998 125.31 138.07 90.76 %

75 % 12.12 10.122 5.004 9.006 3.318 6.008 187.68 207.49 90.45 %

100 % 12.12 13.5 4.997 12.002 3.313 8.001 250.10 279.66 89.43 %

The 80 PLUS

®

program fixes several efficiency levels that describe how energy-efficient a

computer power supply is. The program defines the minimum efficiency requirements at 20

%, 50 %, 100 % of rated load and a minimum power factor requirement.

According to the program a power supply could be classified in 4 or 5 levels:

Table 3. 80 PLUS® program efficiency levels (115Vac)

Level Eff @ 20 % Eff @ 50 % Eff @ 100 % PF (@ load %)

80 PLUS > 80 % > 80 % > 80 % > 0.9 @ 100 %

80 PLUS Bronze > 82 % > 85 % > 82 % > 0.9 @ 50 %

80 PLUS Silver > 85 % > 88 % > 85 % > 0.9 @ 50 %

80 PLUS Gold > 87 % > 90 % > 87 % > 0.9 @ 50 %

80 PLUS Platinum > 90 % > 92 % > 89 % > 0.95 @ 50 %

Note: This table refers to power supplies for desktops, workstations, and non-redundant server

applications with 115 Vac mains

Doc ID 17402 Rev 2 19/49

Page 20

Electrical performance AN3203

®

Table 4. 80 PLUS

Level Eff @ 20% Eff @ 50% Eff @ 100% PF (@ load%)

80 PLUS Bronze > 81% > 85% > 81% > 0.9 @ 50%

80 PLUS Silver > 85% > 89% > 85% > 0.9 @ 50%

80 PLUS Gold > 88% > 92% > 88% > 0.9 @ 50%

80 PLUS Platinum > 90% > 94% > 91% > 0.95 @ 50%

program efficiency levels (230 Vac)

Note: This table refers to power supplies for redundant, data center applications with 230Vac

mains

This demonstration board is compliant with the 80 PLUS

please refer to Tab l e 9 ). Since this is basically a desktop PC power supply, the tests were

performed at 115 Vac. Certification report and other details can be found on the 80 PLUS

®

Silver specifications (for PF data

®

web site.

Similar levels of efficiency and power factor are defined also by the Climate Savers

Computing Initiative. According to the measurements carried out, the demonstration board

is compliant with “Climate Savers Computing Silver” level.

Table 5. Climate Savers Computing Initiative (for multi-output PSU)

Load

condition

20 % 82 % 0.8 85 % 0.8 87 % 0.8

50 % 85 % 0.9 88 % 0.9 90 % 0.9

100 % 82 % 0.95 85 % 0.95 87 % 0.95

Bronze Silver Gold

Efficiency PF Efficiency PF Efficiency PF

Ta bl e 6 shows the no-load consumption. These values are taken with the signal PS_ON

kept low, therefore only the auxiliary stage is active and only the +5 V_SB output is present.

The board showed very good values (below 200 mW over the whole input voltage range),

especially when considering that the inactive stages have a certain residual consumption

(only the voltage dividers in the input stage waste about 100 mW @ 230 Vac).

Table 6. No-load consumption

Vin [Vac] 90 115 135 180 230 264

Pin [mW] 59 70 82 113 161 199

Figure 14 and Figure 15 show the graph of the efficiency vs. output power at the two

nominal input voltages while Figure 16 shows the graph of the input power vs. input voltage

with no load applied. It is clearly visible that the power supply is compliant with the 80

®

PLUS

SILVER specification and it is very close to the GOLD one.

20/49 Doc ID 17402 Rev 2

Page 21

AN3203 Electrical performance

Figure 14. Efficiency vs. O/P power @ 115 Vac

Figure 15. Efficiency vs. O/P power @ 230 Vac

Figure 16. No-load consumption

Doc ID 17402 Rev 2 21/49

Page 22

Electrical performance AN3203

Some measurements with low output loads were also taken. They refer only to the operation

of the auxiliary stage, while the other stages are off. Results are shown in Table 7 and

Ta bl e 8 and plotted in Figure 17. The standby consumption allows the US Executive Order

13221 - “1-Watt Standby” to be met. To be more precise, when the output power is reduced

to 0.5 W, the input power is lower than 1 W (efficiency greater than 50 %). This is a very

common requirement for power supply manufacturers.

Table 7. Low load efficiency @ 115 Vrms

Vout [V] Iout [A] Pout [W] Pin [W] Eff [%]

4.993 0.1 0.499 0.688 72.6 %

4.993 0.2003 1.000 1.312 76.2 %

4.993 0.3007 1.501 1.933 77.7 %

4.993 0.3996 1.995 2.544 78.4 %

4.993 0.5 2.497 3.163 78.9 %

4.993 0.6002 2.997 3.812 78.6 %

4.993 0.7006 3.498 4.501 77.7 %

4.993 0.7994 3.991 5.114 78.0 %

4.993 0.8998 4.493 5.664 79.3 %

4.993 1.0001 4.993 6.209 80.4 %

Table 8. Low load efficiency @ 230 Vrms

Vout [V] Iout [A] Pout [W] Pin [W] Eff [%]

4.994 0.1 0.499 0.826 60.5 %

4.994 0.2002 1.000 1.471 68.0 %

4.994 0.3006 1.501 2.13 70.5 %

4.994 0.3995 1.995 2.798 71.3 %

4.994 0.4999 2.497 3.486 71.6 %

4.994 0.6001 2.997 4.161 72.0 %

4.994 0.7006 3.499 4.806 72.8 %

4.994 0.7994 3.992 5.304 75.3 %

4.994 0.8997 4.493 5.934 75.7 %

4.994 1 4.994 6.667 74.9 %

22/49 Doc ID 17402 Rev 2

Page 23

AN3203 Electrical performance

Figure 17. Efficiency at low loads

Low load eciency (AUX only)

85.0%

80.0%

75.0%

70.0%

65.0%

60.0%

55.0%

50.0%

0.0 1.0 2.0 3.0 4.0 5.0

115Vac

230Vac

Output power [W]

Doc ID 17402 Rev 2 23/49

Page 24

Electrical performance AN3203

4.2 Thermal considerations

This demonstration board has been designed for operation with forced air cooling, very

common in ATX power supply applications. As the component temperatures depend on the

type of fan used and on the airflow path inside the board housing, a thermal map of the

board isn’t significant and has not been taken. When the system works at 25 °C with full

load and no forced air, temperatures are not so high. If a heatsink with lower thermal

resistance for MOSFETs Q201 and Q202 is used, fanless operation may be achieved. For

example, the same shape of the heatsink used for D1, Q1, Q2, D3, Q101, and Q102 could

be used for fanless operation. A picture of this application is shown in Figure 18.

Figure 18. Fanless board

24/49 Doc ID 17402 Rev 2

Page 25

AN3203 Electrical performance

4.3 Harmonic content measurement

The front-end PFC stage provides the reduction of the mains harmonic, allowing European

EN61000-3-2 and Japanese JEITA–MITI standards for class D equipment to be met.

Figure 19 shows the harmonic contents of the mains current at full load.

A measurement has also been taken with a 75 W input power which is the lowest limit for

using harmonic reduction techniques.

Figure 19. EN61000-3-2 and JEITA-MITI measurements @ full load

Figure 20. EN61000-3-2 and JEITA-MITI measurements @ 75 W in

To evaluate the performance of the PFC stage the PF and THD vs. input voltage graphs are

also shown, in Figure 21 and Figure 22, at full load and 75 W input power load conditions.

Ta bl e 9 shows the PF values at the three different load amounts defined in the 80 PLUS

and climate savers computing requirements.

®

Doc ID 17402 Rev 2 25/49

Page 26

Electrical performance AN3203

Vin [Vrms]

Figure 21. PF vs. input voltage

1.000

0.975

0.950

0.925

0.900

PF

0.875

0.850

0.825

0.800

80

Figure 22. THD vs. input voltage

20.00

18.00

16.00

14.00

12.00

10.00

THD [%]

8.00

6.00

4.00

2.00

0.00

80

250W out 75W in

120

120

160 200

250W out 75W in

160

Vin [Vrms]

200

240

280

AM02539v1

240

280

AM02540v1

Table 9. PF vs. load

Load 115 Vac 230 Vac

20 % 0.972 0.857

50 % 0.984 0.954

100 % 0.992 0.981

26/49 Doc ID 17402 Rev 2

Page 27

AN3203 Electrical performance

4.4 Single output configuration

The power supply overall efficiency is given by the product of the efficiency of each stage. It

is interesting to take a look at the efficiency of the single +12 V output system. Such power

supply can be obtained from the complete system just removing the two daughter boards

that realize the DC-DC post regulation. The single output system can manage the same

power of the multi-output board, hence it is capable of sourcing about 21 A from the +12 V

output.

The system is now made up of input filter, PFC stage, AHB stage and Stand-by stage. The

latter is left unloaded for the following efficiency measurements:

Table 10. Single output efficiency @ 115 Vac

Load [%] Iout [A] Vout [V] Pout [W] Pin [W] Eff [%]

10 % 2.085 12.06 25.145 29.79 84.41%

20 % 4.17 12.06 50.290 56.27 89.37%

25 % 5.205 12.06 62.772 69.63 90.15%

50 % 10.421 12.05 125.573 137.4 91.39%

75 % 15.623 12.04 188.101 207.4 90.69%

100 % 20.829 12.03 250.573 279.8 89.55%

Table 11. Single output efficiency @ 230 Vac

Load [%] Iout [A] Vout [V] Pout [W] Pin [W] Eff [%]

10 % 2.084 12.06 25.133 31.02 81.02%

20 % 4.169 12.06 50.278 56.65 88.75%

25 % 5.204 12.06 62.760 69.39 90.45%

50 % 10.421 12.05 125.573 135.3 92.81%

75 % 15.622 12.04 188.089 203.9 92.25%

100 % 20.827 12.03 250.549 274.2 91.37%

It is interesting to compare the result obtained with the single output configuration with the

80 PLUS

®

levels (see Table 3 and Tab l e 4 ). The comparison is graphically shown in

Figure 23 and Figure 24.

Doc ID 17402 Rev 2 27/49

Page 28

Electrical performance AN3203

Figure 23. Single output efficiency @ 115 Vac

Figure 24. Single output efficiency @ 230 Vac

From the pictures it is immediately clear that the single output configuration is over

performing the 80 PLUS

®

GOLD efficiency targets and that it is close to the PLATINUM

ones.

Such performance has been achieved mainly thanks to the AHB stage, which is very

efficient. In Ta bl e 1 2 and Figure 25 efficiency data for the AHB stage only are given. These

measurements were taken by supplying the stage with a 400Vdc input voltage and with the

auxiliary operating without load.

28/49 Doc ID 17402 Rev 2

Page 29

AN3203 Electrical performance

Table 12. AHB efficiency with 400 Vdc input

Load [%] Iout [A] Vout [V] Pout [W] Pin [W] Eff [%]

10 % 2.078 12.06 25.061 28.61 87.59%

20 % 4.163 12.06 50.206 53.79 93.34%

25 % 5.213 12.06 62.869 66.6 94.40%

50 % 10.415 12.05 125.501 131.3 95.58%

75 % 15.616 12.04 188.017 197.9 95.01%

100 % 20.823 12.03 250.501 266.3 94.07%

Figure 25. AHB stage only efficiency (Vin = 400 Vdc)

When looking at these efficiency results we have also to keep in mind that the AHB stage is

a cost effective solution, thanks to a low count of components needed, no need of a

controller IC for the synchronous rectification and a small output choke.

Doc ID 17402 Rev 2 29/49

Page 30

Conducted noise measurements (pre-compliance test) AN3203

5 Conducted noise measurements (pre-compliance

test)

Figure 26, 27, 28, and 29 show the conducted noise measurements with peak and average

detection taken at both nominal voltages. All the measurements are performed with full load

output and only consider the worst phase. The average measurements show good margins

with respect to the mask limit (which is the EN55022 CLASS B).

Figure 26. CE peak measurement@115 Vac and full load

Figure 27. CE peak measurement @ 230 Vac and full load

30/49 Doc ID 17402 Rev 2

Page 31

AN3203 Conducted noise measurements (pre-compliance test)

Figure 28. CE average measurement@115 Vac and full load

Figure 29. CE average measurement@230 Vac and full load

Doc ID 17402 Rev 2 31/49

Page 32

Parts list AN3203

6 Parts list

Table 13. EVL250W-ATX80PL bill of materials

Ref Value Description Manufacturer

C1 220 µF Electrolytic capacitor VXG – 450 V Rubycon

C2 100 nF Polypropylene capacitor 450 V

C3 1.0 µF Polypropylene capacitor 450 V – ECWF2W105JA Panasonic

C4 1 µF SMD ceramic capacitor X7R – 16 V AVX

C5 22 µF Electrolytic capacitor 25 V – 105 °C

C6 0.1 µF SMD ceramic capacitor X7R – 25 V AVX

C7 3.3 nF SMD ceramic capacitor X7R – 50 V AVX

C8 2.2 nF SMD ceramic capacitor X7R – 50 V AVX

C9 560 pF SMD ceramic capacitor NP0 – 50 V AVX

C10 330 pF SMD ceramic capacitor NP0 – 50 V AVX

C11 470 pF SMD ceramic capacitor X7R – 50 V AVX

C12 220 nF SMD ceramic capacitor X7R – 25 V AVX

C13 1 nF SMD ceramic capacitor X7R – 50 V AVX

C14 33 nF SMD ceramic capacitor X7R – 25 V AVX

C15 10 nF SMD ceramic capacitor X7R – 25 V AVX

C101 1.0 µF Polypropylene capacitor 450 V – ECWF2W105JA Panasonic

C102 0.1 µF SMD ceramic capacitor X7R – 25 V AVX

C103 22 µF Electrolytic capacitor 25 V – 105 °C

C104 10 nF SMD ceramic capacitor X7R – 25 V AVX

C105 0.1 µF SMD ceramic capacitor X7R – 25 V AVX

C106 220 pF SMD ceramic capacitor NP0 – 50 V 1 % AVX

C107 10 nF SMD ceramic capacitor X7R – 25 V AVX

C108 470 nF SMD ceramic capacitor X7R – 16 V AVX

C109 0.1 µF SMD ceramic capacitor X7R – 25 V AVX

C110 100 pF SMD ceramic capacitor NP0 – 50 V AVX

C112 10 nF SMD ceramic capacitor X7R – 50 V AVX

C201 1500 µF Electrolytic capacitor HM – 16 V Nichicon

C202 1500 µF Electrolytic capacitor HM – 16 V Nichicon

C203 4.7 nF SMD ceramic capacitor X7R – 50 V AVX

C204 3.3 nF SMD ceramic capacitor X7R – 100 V AVX

C205 220 nF SMD ceramic capacitor X7R – 25 V AVX

C206 0.1 µF SMD ceramic capacitor X7R – 25 V AVX

32/49 Doc ID 17402 Rev 2

Page 33

AN3203 Parts list

Table 13. EVL250W-ATX80PL bill of materials (continued)

Ref Value Description Manufacturer

C207 470 µF Electrolytic capacitor ZLH – 16 V Rubycon

C208 0.1 µF SMD ceramic capacitor X7R – 25 V AVX

C209 2.2 µF SMD ceramic capacitor X7R – 25 V AVX

C210 2.2 µF SMD ceramic capacitor X7R – 25 V AVX

C301 1500 µF Electrolytic capacitor HM – 16 V Nichicon

C302 1500 µF Electrolytic capacitor HM – 16 V Nichicon

C303 1500 µF Electrolytic capacitor HM – 16 V Nichicon

C304 1.2 nF SMD ceramic capacitor X7R – 50 V AVX

C305 0.1 µF SMD ceramic capacitor X7R – 25 V AVX

C306 4.7 µF SMD ceramic capacitor X7R – 16 V AVX

C307 0.1 µF SMD ceramic capacitor X7R – 25 V AVX

C308 1 nF SMD ceramic capacitor X7R – 50 V AVX

C309 10 nF SMD ceramic capacitor X7R – 25 V AVX

C310 2.2 nF SMD ceramic capacitor X7R – 50 V AVX

C311 100 µF SMD ceramic cap 6.3 V – GRM32EF50J107ZE20K Murata

C312 100 µF SMD ceramic cap 6.3 V – GRM32EF50J107ZE20K Murata

C313 10 µF SMD ceramic capacitor X7R – 6.3 V AVX

C501 1500 µF Electrolytic capacitor HM – 16 V Nichicon

C502 1500 µF Electrolytic capacitor HM – 16 V Nichicon

C503 1500 µF Electrolytic capacitor HM – 16 V Nichicon

C504 1.2 nF SMD ceramic capacitor X7R – 50 V AVX

C505 4.7 µF SMD ceramic capacitor X7R – 16 V AVX

C506 0.1 µF SMD ceramic capacitor X7R – 25 V AVX

C507 0.1 µF SMD ceramic capacitor X7R – 25 V AVX

C508 10 nF SMD ceramic capacitor X7R – 25 V AVX

C509 1 nF SMD ceramic capacitor X7R – 50 V AVX

C510 2.2 nF SMD ceramic capacitor X7R – 50 V AVX

C511 100 µF SMD ceramic cap 6.3 V – GRM32EF50J107ZE20K Murata

C512 100 µF SMD ceramic cap 6.3 V – GRM32EF50J107ZE20K Murata

C513 10 µF SMD ceramic capacitor X7R – 10 V AVX

C602 470 pF Ceramic capacitor – 1 kV

C603 1500 µF Electrolytic capacitor HM – 16 V Nichicon

C604 470 µF Electrolytic capacitor ZLH – 16 V Rubycon

C605 10 µF Electrolytic capacitor 50V – 105 °C

C606 47 µF Electrolytic capacitor 35V – 105 °C

Doc ID 17402 Rev 2 33/49

Page 34

Parts list AN3203

Table 13. EVL250W-ATX80PL bill of materials (continued)

Ref Value Description Manufacturer

C607 0.1 µF SMD ceramic capacitor X7R – 25 V AVX

C608 10 nF SMD ceramic capacitor X7R – 25 V AVX

C609 0.1 µF SMD ceramic capacitor X7R – 25 V AVX

C611 220 nF SMD ceramic capacitor X7R – 25 V AVX

C612 47 nF SMD ceramic capacitor X7R – 25 V AVX

C613 10 nF SMD ceramic capacitor X7R – 25 V AVX

C614 0.1 µF SMD ceramic capacitor X7R – 25 V AVX

C615 10 nF SMD ceramic capacitor X7R – 25 V AVX

CN1 AC INLET 3.96 mm pitch KK series Molex

CX1 470 nF Polypropylene X2 capacitor R46 – 275 Vac Arcotronics

CX3 680 nF Polypropylene X2 capacitor R46 – 275 Vac Arcotronics

CY1 2N2 Ceramic Y1 capacitor – DE1E3KX222M Murata

CY2 2N2 Ceramic Y1 capacitor – DE1E3KX222M Murata

CY3 4N7 Ceramic Y1 capacitor – DE1E3KX472M Murata

D1 D15XB60 15A/600V bridge rectifier Shindengen

D2 1N5406 3A/600V rectifier

D3 STPSC1006D 10A/600V silicon carbide Schottky rectifier STMicroelectronics

D4 1N4148WS Fast switching diode

D5 1N4148WS Fast switching diode

D6 1N4148 Fast switching diode

D101 LL4148 Fast switching diode

D102 LL4148 Fast switching diode

D103 STTH1L06 1A/600V ultrafast high voltage rectifier STMicroelectronics

D203 LL4148 Fast switching diode

D204 LL4148 Fast switching diode

D301 TMMBAT43 Small signal Schottky diode STMicroelectronics

D501 TMMBAT43 Small signal Schottky diode STMicroelectronics

D601 STTH102A 1A/200V high efficiency ultrafast diode STMicroelectronics

D602 BAV103 Switching diode

D603 BAV103 Switching diode

D604 STTH108A 1A/800V high voltage ultrafast rectifier STMicroelectronics

D605 STPS5L60 5A/60V power Schottky diode STMicroelectronics

D606 BAT48 Small signal Schottky diode STMicroelectronics

D607 LL4148 Fast switching diode

D608 LL4148 Fast switching diode

34/49 Doc ID 17402 Rev 2

Page 35

AN3203 Parts list

Table 13. EVL250W-ATX80PL bill of materials (continued)

Ref Value Description Manufacturer

D609 LL4148 Fast switching diode

F1 FUSE - 10A Fuse T10A – time delay

IC1 L6563S Enhanced transition-mode PFC controller STMicroelectronics

IC2 L6591 PWM controller for ZVS half bridge STMicroelectronics

IC3 VIPER27HN Offline high voltage converters STMicroelectronics

IC200 TL431AIZ Programmable voltage reference STMicroelectronics

IC300 L6727 Single phase PWM controller STMicroelectronics

IC500 L6727 Single phase PWM controller STMicroelectronics

IC600 TS431AIZ Low voltage adjustable shunt reference STMicroelectronics

L1 2x4 mH Common mode choke 1606.0010 Magnetica

L2 2xJUMPER

L3 60 µH Differential mode choke 1119.0013 Magnetica

L4 870 µH PFC choke

L5 0.75 µH AHB post filter inductor 1019.0016 Magnetica

L201 3.7 µH AHB output choke 2029.0002 Magnetica

L301 3.7 µH DC-DC choke 2029.0001 Magnetica

L501 3.7 µH DC-DC choke 2029.0001 Magnetica

L601 2.7 µH AUX stage post filter inductor 1048.0010 Magnetica

NTR1 2R5 NTC inrush current limiter B57237S0259M000 EPCOS

OPTO1 PC817A Optocoupler SHARP

OPTO2 PC817A Optocoupler SHARP

OPTO3 PC817A Optocoupler SHARP

Q1 STF12NM50N 500 V MDmesh II Power MOSFET STMicroelectronics

Q2 STF12NM50N 500 V MDmesh II Power MOSFET STMicroelectronics

Q3 BC857C PNP small signal BJT

Q101 STF21NM50N 500 V MDmesh™ II Power MOSFET STMicroelectronics

Q102 STF21NM50N 500 V MDmesh™ II Power MOSFET STMicroelectronics

Q201 STP120NF04 40 V STripFET™ II Power MOSFET STMicroelectronics

Q202 STP75NF75FP 75 V STripFET™ II Power MOSFET STMicroelectronics

Q301 STD95N2LH5 25 V STripFET™ V Power MOSFET STMicroelectronics

Q302 STD95N2LH5 25 V STripFET™ V Power MOSFET STMicroelectronics

Q303 STD95N2LH5 25 V STripFET™ V Power MOSFET STMicroelectronics

Q501 STD95N2LH5 25 V STripFET™ V Power MOSFET STMicroelectronics

Q502 STD95N2LH5 25V STripFET™ V Power MOSFET STMicroelectronics

Q503 STD95N2LH5 25 V STripFET™ V Power MOSFET STMicroelectronics

Doc ID 17402 Rev 2 35/49

Page 36

Parts list AN3203

Table 13. EVL250W-ATX80PL bill of materials (continued)

Ref Value Description Manufacturer

Q601 MMBT3904 NPN small signal BJT

Q603 MMBT3904 NPN small signal BJT

Q604 MMBT3904 NPN small signal BJT

Q605 MMBT3906 PNP small signal BJT

R1 0R33 Metal film resistor – 5 % – 250 ppm/°C – 2 W

R2 0R33 Metal film resistor – 5 % – 250 ppm/°C – 2 W

R3 6.8 R SMD film resistor – 5 % – 250 ppm/°C – 0805

R4 6.8 R SMD film resistor – 5 % – 250 ppm/°C – 0805

R5 47 K SMD film resistor – 5 % – 250 ppm/°C – 0603

R6 47 K SMD film resistor – 5 % – 250 ppm/°C – 0603

R7 10 R SMD film resistor – 5 % – 250 ppm/°C – 0603

R8 2.2 Meg SMD film resistor – 1 % – 100 ppm/°C – 1206

R9 2.2 Meg SMD film resistor – 1 % – 100 ppm/°C – 1206

R10 2.2 Meg SMD film resistor – 1 % – 100 ppm/°C – 1206

R11 51 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R12 1 Meg SMD film resistor – 1 % – 100 ppm/°C – 0603

R13 2.4 K Metal film resistor – 1% – 100 ppm/°C – 0.16 W

R14 6.8 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R15 2.4 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R16 220 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R17 1.5 Meg SMD film resistor – 1 % – 100 ppm/°C – 1206

R18 1.5 Meg SMD film resistor – 1 % – 100 ppm/°C – 1206

R19 1.5 Meg SMD film resistor – 1 % – 100 ppm/°C – 1206

R20 1.6 Meg SMD film resistor – 1 % – 100 ppm/°C – 1206

R21 1.6 Meg SMD film resistor – 1% – 100 ppm/°C – 1206

R22 1.6 Meg SMD film resistor – 1 % – 100 ppm/°C – 1206

R23 470 R SMD film resistor – 5 % – 250 ppm/°C – 0603

R24 56 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R25 56 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R26 24 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R28 56 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R29 3.3 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R30 2.7 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R31 3.3 R SMD film resistor – 5 % – 250 ppm/°C – 0805

R32 3.3 R SMD film resistor – 5 % – 250 ppm/°C – 0805

36/49 Doc ID 17402 Rev 2

Page 37

AN3203 Parts list

Table 13. EVL250W-ATX80PL bill of materials (continued)

Ref Value Description Manufacturer

R101 0.18 R Metal film resistor – 5 % – 250 ppm/°C – 2 W

R103 10 R SMD film resistor – 5 % – 250 ppm/°C – 0603

R104 4.7 K SMD film resistor – 5 % – 250 ppm/°C – 0603

R105 100 K SMD film resistor – 5 % – 250 ppm/°C – 0603

R107 20 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R108 36 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R109 20 R SMD film resistor – 5 % – 250 ppm/°C – 0805

R110 47 K SMD film resistor – 5 % – 250 ppm/°C – 0603

R111 20 R SMD film resistor – 5 % – 250 ppm/°C – 0805

R112 47 K SMD film resistor – 5 % – 250 ppm/°C – 0603

R113 1 K Metal film resistor – 1 % – 100 ppm/°C – 0.16 W

R114 2.2 R SMD film resistor – 5 % – 250 ppm/°C – 0603

R115 2.2 R SMD film resistor – 5 % – 250 ppm/°C – 0603

R116 100 K SMD film resistor – 5 % – 250 ppm/°C – 0603

R201 2.2 R SMD film resistor – 5 % – 250 ppm/°C – 0805

R202 15 K SMD film resistor – 5 % – 250 ppm/°C – 0805

R203 13 R Metal film resistor – 5 % – 250 ppm/°C – 2 W

R204 5.6 R Metal film resistor – 5 % – 250 ppm/°C – 2 W

R206 2.2 R SMD film resistor – 5 % – 250 ppm/°C – 0805

R208 15 K SMD film resistor – 5 % – 250 ppm/°C – 0805

R209 1 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R210 2.2 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R211 20 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R212 10 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R213 5.6 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R214 75 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R215 6.8 K SMD film resistor – 5 % – 250 ppm/°C – SOD-80

R216 10 K SMD film resistor – 5 % – 250 ppm/°C – SOD-80

R301 22 R SMD film resistor – 5 % – 250 ppm/°C – 0805

R302 22 R SMD film resistor – 5 % – 250 ppm/°C – 0805

R303 22 R SMD film resistor – 5 % – 250 ppm/°C – 0805

R304 22 R SMD film resistor – 5 % – 250 ppm/°C – 0805

R305 47 K SMD film resistor – 5 % – 250 ppm/°C – 0603

R306 47 K SMD film resistor – 5 % – 250 ppm/°C – 0603

R307 10 R SMD film resistor – 5 % – 250 ppm/°C – 0603

Doc ID 17402 Rev 2 37/49

Page 38

Parts list AN3203

Table 13. EVL250W-ATX80PL bill of materials (continued)

Ref Value Description Manufacturer

R308 10 R SMD film resistor – 5 % – 250 ppm/°C – 0603

R309 7.5 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R310 6.34 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R311 10 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R312 2 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R313 0 R SMD film resistor – 0603

R314 0 R SMD film resistor – 0805

R501 22 R SMD film resistor – 5 % – 250 ppm/°C – 0805

R502 22 R SMD film resistor – 5 % – 250 ppm/°C – 0805

R503 22 R SMD film resistor – 5 % – 250 ppm/°C – 0805

R504 22 R SMD film resistor – 5 % – 250 ppm/°C – 0805

R505 47 K SMD film resistor – 5 % – 250 ppm/°C – 0603

R506 47 K SMD film resistor – 5 % – 250 ppm/°C – 0603

R507 10 R SMD film resistor – 5 % – 250 ppm/°C – 0603

R508 10 R SMD film resistor – 5 % – 250 ppm/°C – 0603

R509 7.5 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R510 10 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R511 12.7 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R512 2.4 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R513 0 R SMD film resistor – 0603

R514 0 R SMD film resistor – 0805

R601 470 K SMD film resistor – 5 % – 250 ppm/°C – 1206

R602 4.7 R SMD film resistor – 5 % – 250 ppm/°C – 0805

R603 15 R SMD film resistor – 5 % – 250 ppm/°C – 0805

R604 56 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R605 13 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R606 10 R SMD film resistor – 5 % – 250 ppm/°C – 0805

R607 150 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R610 1 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R611 15 K SMD film resistor – 5 % – 250 ppm/°C – 0603

R612 10 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R613 4.7 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R614 47 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R615 1.6 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R616 1 K SMD film resistor – 1 % – 100 ppm/°C – 0603

38/49 Doc ID 17402 Rev 2

Page 39

AN3203 Parts list

Table 13. EVL250W-ATX80PL bill of materials (continued)

Ref Value Description Manufacturer

R617 1 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R618 1.5 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R619 10 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R620 470 R SMD film resistor – 1 % – 100 ppm/°C – 0603

R621 1 K SMD film resistor – 1 % – 100 ppm/°C – 0603

R622 470 R SMD film resistor – 1 % – 100 ppm/°C – 0603

R623 100 R SMD film resistor – 1 % – 100 ppm/°C – 0603

R624 0 R SMD film resistor – 0603

R626 1 K SMD film resistor – 5 % – 250 ppm/°C – 0603

R627 1.5 K SMD film resistor – 5 % – 250 ppm/°C – 0805

R628 200 R SMD film resistor – 5 % – 250 ppm/°C – 0805

RX1 680 K SMD film resistor – 5 % – 250 ppm/°C – 1206

RX2 680 K SMD film resistor – 5 % – 250 ppm/°C – 1206

T1 Transformer AHB transformer 1965.0003 Magnetica

T2 Transformer AUX transformer 1031.0010 Magnetica

VDR1 Varistor 300 Vac – S14K300 – B72214S0301K101 EPCOS

ZD601 BZV55-B18 SMD Zener diode 18 V – 2 %

ZD603 BZX55B5V1 Zener diode 5V1 – 2 %

ZD604 BZX55-B13 Zener diode 13 V – 2 %

ZD605 BZX55B2V7 Zener diode 2V7 – 2 %

ZD606 BZV55-B36 SMD Zener diode 36 V – 2 %

Doc ID 17402 Rev 2 39/49

Page 40

PFC coil specification AN3203

7 PFC coil specification

● Application type: Consumer, IT

● Transformer type: Toroidal

● Coil former: none

● Max. temp. rise: 45 °C

● Max. operating ambient temp.: 60 °C

7.1 Electrical characteristics

● Converter topology: Boost, Fixed Off Time

● Core type: Dong Bu H106-093A

● Min. operating frequency: 20 kHz

● Primary inductance: 870 µH ±15 % @1 kHz - 0.25 V

● Max peak current: 5.3 A

●

Max RMS current: 3.37 A

Figure 30. Electrical diagram

pk

RMS

Table 14. Winding characteristics

Pins RMS current Nr. of turns Wire type

1 – 2 3.37 A

RMS

100.5 Ø 1.0mm – G2

Figure 31. Mechanical drawing (unit: mm)

40/49 Doc ID 17402 Rev 2

Page 41

AN3203 AHB transformer specification

8 AHB transformer specification

● Application type: Consumer, IT

● Transformer type: Open

● Coil former: vertical type, 6+6 pins

● Max. temp. rise: 45 °C

● Max. operating ambient temp.: 60 °C

● Mains insulation: Compliance with EN60950

8.1 Electrical characteristics

● Converter topology: Asymmetrical half bridge

● Core Type: PQ3230 – PC44 or equivalent

● Operating frequency: 80 kHz

(b)

(a)

● Primary inductance: 500 μH ±10 % @1 kHz – 0.25 V

● Air gap: 0.3 mm on central leg

● Leakage inductance: 12 μH typ. @100 kHz – 0.25 V

RMS

(c)

pk

● Primary capacitance: 6 pF typ.

● Max. peak primary current: 3.85 A

●

RMS primary current: 2 A

Figure 32. Electrical diagram

a. Measured between pins 2-4

b. Measured between pins 2-4 with secondaries and auxiliary windings shorted

c. Calculated considering primary inductance and resonance frequency

Doc ID 17402 Rev 2 41/49

Page 42

AHB transformer specification AN3203

3mm

Table 15. Winding characteristics

Pins Winding Current Nr. of turns Wire type

4 – 3 Primary 2.1 A

9,10 – 7,8 Secondary 1 15 A

7,8 – 11,12 Secondary 2 19.7 A

TonFW – 9,10 Sec.1 AUX 0.1 A

11,12 – ToffFW Sec.2 AUX 0.1 A

Note: Cover wire ends with silicon/teflon tube:

Use red tube for Ton-DR-Flyingwire

Use white tube for Toff-DR-Flyingwire

Figure 33. Windings position

SEC. AUX 1 & 2

SECONDARY 2

COIL FORMER

SECONDARY 1

RMS

RMS

RMS

RMS

RMS

PRIMARY

34

2 Copper foil 0.2 x 17 mm

3 Copper foil 0.2 x 17 mm

1 Ø 0.15 mm – G2

1 Ø 0.15 mm – G2

TIW – 2 x Ø0.4 mm

4 layers

INSULATING

TAPE

8.2 Mechanical aspect and pin numbering

● Maximum height from PCB: 33 mm

● Coil former type: vertical, 6+6 pins

● Pin distance: 5.08 mm

● Row distance: 30.5 mm

● Pin removed: # 5

● Manufacturer: Magnetica

● P/N: 1754.0004

3mm

42/49 Doc ID 17402 Rev 2

Page 43

AN3203 AHB transformer specification

Figure 34. Bottom view

Doc ID 17402 Rev 2 43/49

Page 44

AUX flyback transformer specification AN3203

9 AUX flyback transformer specification

● Application type: Consumer, IT

● Transformer type: Open

● Coil former: vertical type, 5+5 pins

● Max. temp. rise: 45 °C

● Max. operating ambient temp.: 60 °C

● Mains insulation: Compliance with EN60950

9.1 Electrical characteristics

● Converter topology: Flyback, CCM/DCM mode

● Core Type: E20/10/6 (EF20) - N87 or equivalent

● Operating frequency: 115 kHz

● Primary inductance: 1.7 mH 10 % @1 kHz - 0.25 V

Air gap: 1.24 mm on central leg

●

● Leakage inductance: 50 µH max. @100 kHz - 0.25 V

Max. peak primary current: 0.74 A

●

●

RMS primary current: 0.17 A

pk

RMS

(d)

(e)

Figure 35. Electrical diagram

d. Measured between pins 1-3

e. Measured between pins 1-3 with secondaries and auxiliary windings shorted

44/49 Doc ID 17402 Rev 2

Page 45

AN3203 AUX flyback transformer specification

Table 16. Winding characteristics

Pins Winding Current Nr. of turns Wire type

4 – A Primary – A 0.17 A

7,8 – 9,10 Secondary 2.8 A

1 – 2 AUX – A 0.05 A

2 – 3 AUX – B 0.05 A

A – 5 Primary – B 0.17 A

Note: Primaries A & B are in series

Cover wire ends with teflon tube

Figure 36. Windings position

RMS

RMS

RMS

RMS

RMS

90

11

11

28

90

G2 – Ø 0.2 mm

2 layers

TIW – Ø 0.8 mm

1 layer

G2 – Ø 0.15 mm

1 layer

G2 – Ø 0.2 mm

2 layers

Doc ID 17402 Rev 2 45/49

Page 46

AUX flyback transformer specification AN3203

9.2 Mechanical aspect and pin numbering

● Maximum height from PCB: 22 mm

● Coil former type: vertical, 5+5 pins (pin 6 removed)

● Pin distance: 3.81 mm

● Row distance: 10.16 mm

● Manufacturer: Magnetica

● P/N: 1031.0010

Figure 37. Bottom view

46/49 Doc ID 17402 Rev 2

Page 47

AN3203 PCB layout

10 PCB layout

Figure 38. Top side silk screen and copper

Figure 39. Bottom side silk screen and copper (mirror view)

Doc ID 17402 Rev 2 47/49

Page 48

Revision history AN3203

11 Revision history

Table 17. Document revision history

Date Revision Changes

24-Aug-2010 1 Initial release

28-Jan-2011 2

Added: Chapter 4.4 on page 27

Updated: Figure 1, Chapter 4.1, Figure 14

48/49 Doc ID 17402 Rev 2

Page 49

AN3203

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2011 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 17402 Rev 2 49/49

Loading...

Loading...