Page 1

AN3147

Application note

STM8L family power management

Introduction

This document is intended for application designers who require a hardware implementation

overview of low power modes in the STM8L product families. It shows how to use the

STM8L devices in these modes, explains differences between different modes and gives

several examples of how to select the best mode for your application needs.

This document is not intended to replace STM8L datasheets. All values given in this

document are for guidance only. Please, refer to the related datasheet to get guaranteed

values.

March 2010 Doc ID 17035 Rev 1 1/22

www.st.com

Page 2

Contents AN3147

Contents

1 Power consumption factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Internal supply structure for STM8L101xx devices . . . . . . . . . . . . . . . . . . 5

2.2 Internal supply structure for STM8L15x devices . . . . . . . . . . . . . . . . . . . . 6

2.2.1 Brownout detector (BOR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Clock management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 STM8L101xx clock system overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 STM8L15x clock system overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Clock configuration and power management . . . . . . . . . . . . . . . . . . . . . . . 9

3.4 Clock selection vs. power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Run and low power modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1 Flash memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2 Overview of low power modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2.1 STM8L101xx low power modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2.2 STM8L15x low power modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.3 Slowing down the clock frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.4 Peripheral clock gating (PCG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.5 Execution from RAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.6 Wait mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.6.1 Entering Wait mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.6.2 Exiting Wait for interrupt mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.6.3 Exiting Wait for event mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.7 Low power run mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.7.1 Entering Low power run mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.7.2 Exiting Low power run mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.8 Low power wait mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.9 Halt mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.9.1 Entering Halt mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.9.2 Exiting Halt mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.9.3 Active-halt mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2/22 Doc ID 17035 Rev 1

Page 3

AN3147 Contents

4.10 Activation level control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 Power management tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1 Choosing the optimal low-power mode for your application . . . . . . . . . . . 17

5.2 GPIO initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.3 Dynamic control of pull-up resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.4 Waiting loops / delays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.5 Minimizing power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Doc ID 17035 Rev 1 3/22

Page 4

Power consumption factors AN3147

IDD fI

DynamicRun

μA MHz⁄[]× I

Static

μA[]+=

1 Power consumption factors

The STM8L microcontrollers are digital logic devices using the complementary metal oxide

semiconductor (CMOS) technology. In this type of devices, power consumption is a sum of:

● Static power (mainly caused by transistor polarization and leakage)

● Dynamic power which depends on the supply voltage and the clock frequency. It is

calculated from the formula: Dynamic power = C x V²

– C is the CMOS load capacitance

– V is the supply voltage

– f is the clock frequency.

Static consumption is negligible compared to dynamic consumption when the clock is

running. In some low power modes, when no clock is running, static consumption is the

main consumption source.

● Total consumption is a sum of static and dynamic consumption

Consequently, power consumption depends on:

● The microcontroller unit (MCU) chip size: technology used, number of transistors,

analog features/peripherals embedded and used in the application.

● The MCU supply voltage: the amount of current used in CMOS logic is directly

proportional to the squared power supply voltage (V²). Thus, power consumption may

be reduced by lowering the MCU supply voltage. This is less critical for STM8L devices

than for other microcontrollers, as an internal voltage regulator is used but this could

have an influence for the remaining components on the board.

● The clock frequency: Power consumption may be reduced by decreasing the clock

frequency when fast processing is not required by the application.

● The number of active peripherals or used MCU features (CSS, BOR, PVD,...): the

greater the number of active peripherals or features, the greater the amount of

consumed power.

● The operating mode: Power consumption depends on which mode a particular

application is running (CPU on/off, oscillator on/off,...). For an application powered by a

battery, the consumption is very important. Usually, the average consumption should

be below a certain target value to ensure an optimum battery lifetime. This means that

an application can consume more for short periods of time and keep its average current

consumption below the target value.

x f, where:

4/10 Doc ID 17035 Rev 1

Page 5

AN3147 Power supply

Low Power voltage regulator

V

DD

Main voltage regulator

I/Os

1.8 V domain

1)

1.65 V-3.6 V

RAM

Flash

STM8 MCU Core

CPU

(MVR)

(LPVR)

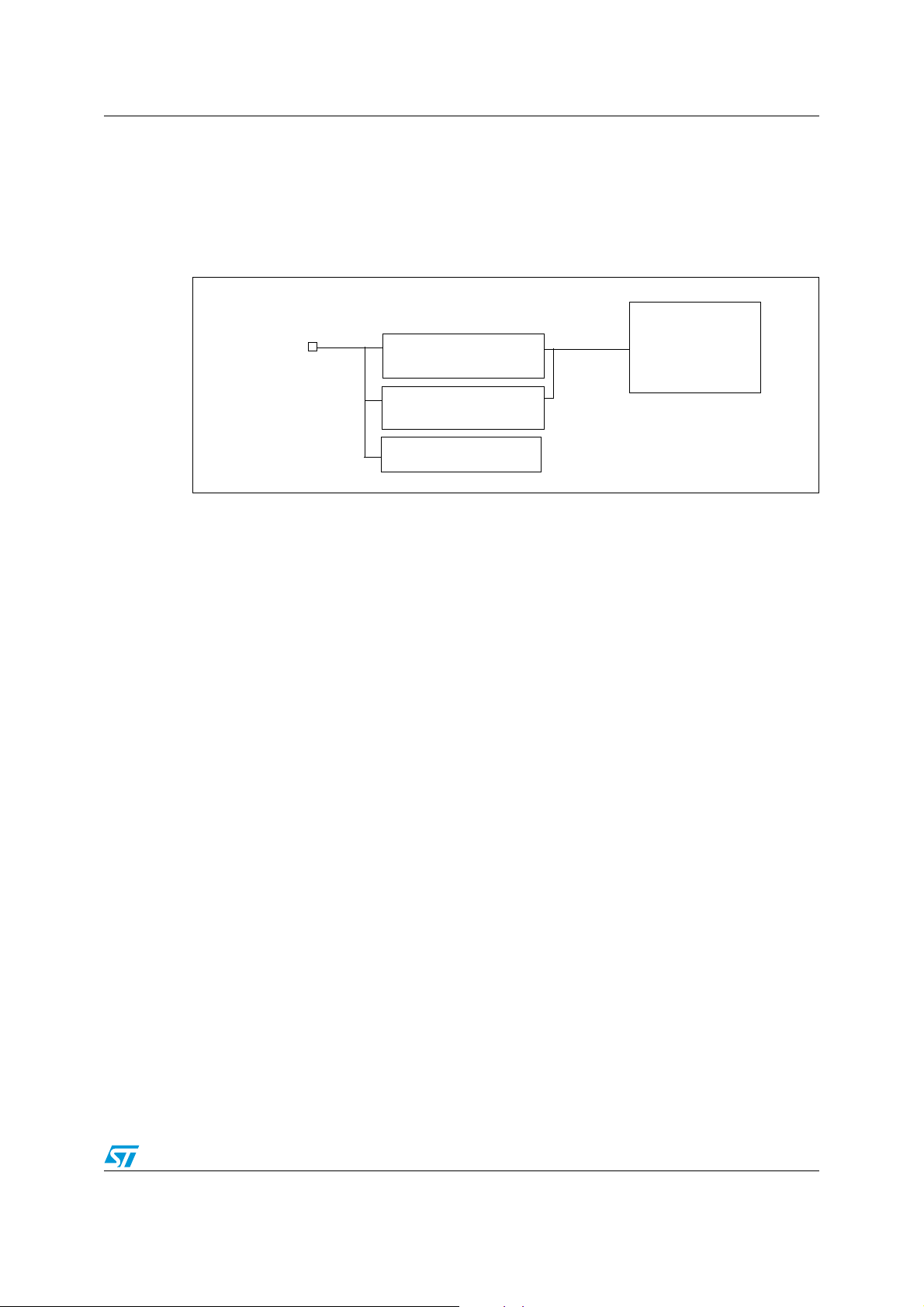

2 Power supply

The STM8L family embeds two regulators which provide a supply voltage (V

CORE

) for the

core and internal peripherals.

Figure 1. Power supply overview

1. If VDD is lower than 1.8 V, the 1.8 V domain is supplied by the voltage on the VDD input. For low power

modes where the LPVR is used, this domain is supplied by a 1.55 V voltage.

The main voltage regulator (MVR) provides a 1.8 V supply voltage. It has a high current

capability, as it can deliver up to 25 mA. However, the own consumption of this regulator is

higher than the own consumption of the LPVR. Consequently, the MVR is used during a

standard operation only.

The own consumption of the low power regulator (LPVR) is very low, as required for low

power modes. The LPVR can deliver up to 200 µA, providing 1.55 V to the digital part of the

MCU.

After reset, the MVR provides a supply voltage (V

) to the internal digital parts of the

CORE

microcontroller. Depending on the functional mode, the MVR can be switched off. In this

case, the LPVR continues to provide the V

CORE

voltage.

The power supply is monitored by the POR/PDR (power-on reset / power-down reset) and

and BOR (brown-out reset) system. This system ensures a proper startup and reset of the

MCU, while V

is rising above the POR threshold. It resets the MCU when VDD is falling

DD

below the PDR threshold.

Note: Analog peripherals require a power supply voltage above the PDR threshold (V

while V

= 1.5 V). In this case, it is recommended to use the BOR (Brownout reset) to

PDR

guarantee a proper functionality.

The BOR is available on STM8L15x devices only.

2.1 Internal supply structure for STM8L101xx devices

The STM8L101xx devices are able to operate from 1.65 V up to 3.6 V, connected to one pair

of supply pins.

There are no dedicated supply pins for the analog voltage domain. It is recommended to use

Doc ID 17035 Rev 1 5/10

> 1.8 V,

DD

Page 6

Power supply AN3147

a decoupling ceramic capacitor placed close to the supply pins.

● In Run and Wait modes, both MVR and LPVR provide the V

● In Halt / Active-halt modes, the LPVR is automatically used while the MVR is switched

CORE

.

off by the system in order to reduce current consumption.

2.2 Internal supply structure for STM8L15x devices

STM8L15x devices require a supply voltage of 1.8 V to 3.6 V. Once the supply voltage

reaches 1.8 V, the MCU can work down to 1.65 V with a limitation in the functionality of

analog peripherals.

The medium density STM8L15x devices have several supply pins, depending on the

package pincount. In addition to the main supply pair V

SS/VDD

could be present on the package.

It is recommended to use a decoupling ceramic capacitor, placed close to the supply pins.

● In Run and Wait modes, both MVR and LPVR provide the V

● In Low power run mode and Low power wait mode, the MVR has to be switched off.

Only the LPVR provides the V

● In Active-halt mode, during the Halt phase, either the MVR or the LPVR can provide the

V

. The user can select the regulator to be used.

CORE

● In Halt mode, the LPVR is automatically used, once MVR is switched off.

CORE

.

, another supply pin (V

.

CORE

DDA

)

2.2.1 Brownout detector (BOR)

The brownout detector is used to guarantee a proper functionality of all peripherals, mainly

analog ones. By default, this detector is enabled but the user can disable it through option

byte to decrease the MCU consumption by ~2.8 µA.

The BOR is mandatory to ensure a proper functionality of the product at power-down, to

cover a supply voltage area between V

Note: The BOR is available on STM8L15x devices only.

min. and V

DD

PDR

.

6/10 Doc ID 17035 Rev 1

Page 7

AN3147 Clock management

3 Clock management

3.1 STM8L101xx clock system overview

The 16 MHz high speed internal RC oscillator (HSI) is the only clock source that can be

used to drive the system clock.

The 38 kHz low speed internal RC oscillator (LSI) is only used to supply the auto-wakeup

unit (AWU) and watchdog.

Each peripheral clock can be switched on or off independently, in order to optimize power

consumption when the peripheral is not used. This is done by using the peripheral clock

gating (PCG) feature. See the “Clock control” section of the STM8L101xx reference manual

(RM0013) for more details.

3.2 STM8L15x clock system overview

Several different clock sources can be used to drive the system clock, depending on the

product and package you use:

● 1-16 MHz high speed external clock from the crystal oscillator (HSE crystal)

● Up to 16 MHz high speed external clock provided by the user (HSE bypass)

● 16 MHz high speed internal RC oscillator (HSI)

● 32.768 kHz low speed external crystal oscillator (LSE)

● 38 kHz low speed internal RC oscillator (LSI)

Each clock source can be switched on or off, depending on the actual needs of the

application. Each peripheral clock can be switched on or off independently, in order to

optimize power consumption when it is not used. This is done by using the peripheral clock

gating (PCG) feature. See the ‘Clock control’ section in the STM8L15x reference manual

(RM0031) for more details.

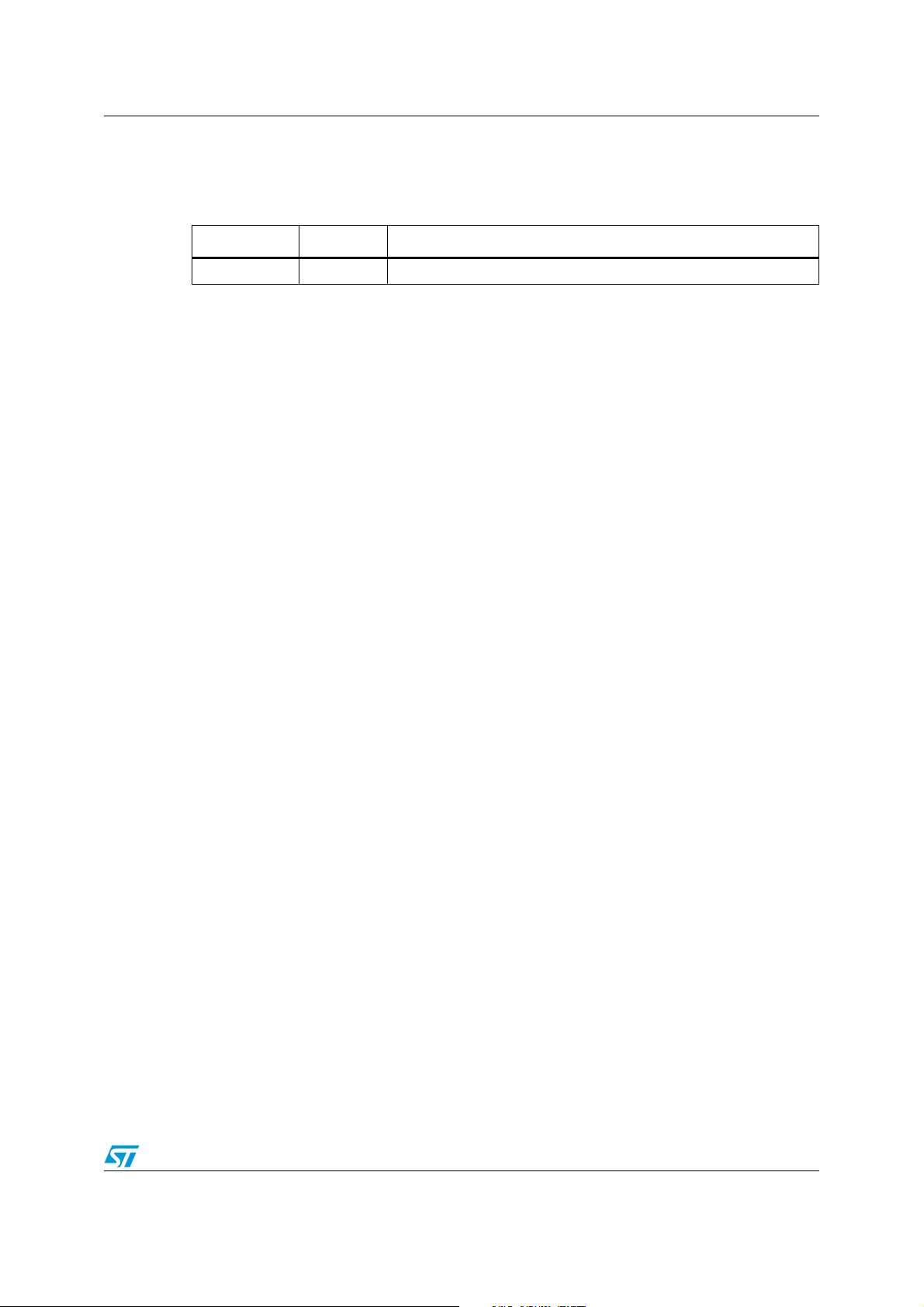

Several clock sources can be enabled in one time. The following table shows the main

features of each clock source. STM8L devices offer a complete range of clock sources to

meet customer application requirements in terms of cost, accuracy and consumption.

Doc ID 17035 Rev 1 7/10

Page 8

Clock management AN3147

Table 1. Clock sources

HSE oscillator external HSE HSI external LSE LSE crystal LSI

Cost Low to medium Low to high Free Low to medium

Accuracy ~ ppm / %

Consumption TBD High/medium

Start-up time 2 ms

Other

information

Crystal or

ceramic

resonator

depending on

external clock

depending on

external clock

Clock already

existing in the

system

~ %

100-200

µA

2 µs

depending on

external clock

depending on

external clock

Clock already

existing in the

system

The default clock source after reset is HSI / 8. The user can then switch the clock to different

frequencies and sources by using the following procedure:

● On the STM8L101xx devices:

– Choose the prescaler (/1, /2, /4 or /8) for an internal RC 16 MHz (HSI) clock

through the HSIDIV[1:0] bits in the CLK_CKDIVR register.

● On the STM8L15x devices

– Choose the prescaler (/1, /2 ... /128) for an internal RC 16 MHz (HSI) clock

through the CKM[2:0] bits in the CLK_CKDIVR register.

– Or change the system clock (to HSE, LSE or LSI ). Refer to the STM8L15x

reference manual (RM0031) for more details about the clock switching

mechanism.

Low to

medium

~ ppm ~ %

TBD

TBD TBD

Watch crystal

Free

100 - 400

nA

Before switching off a previous clock source when using automatic switching mode, the user

must ensure that the core is no longer running on the current clock. This means that the

previous clock must be turned off after the SWIF flag has been set. If the user tries to switch

off the clock and the SWIF flag has not been set by hardware, the current clock is not

switched off as the microcontroller is still running using this clock source.

Such clock switching can be combined with Wait mode (for example, if the HSE crystal is the

new clock) as clock switch execution interrupt can wake up the MCU from wait mode. This

enables the synchronization of the MCU wakeup with the new clock availability. The clock

switching feature can also be used at the beginning and the end of a regular or interrupt

routine to speed it up (for instance, if the clock master is LSI RC, but some parts of the code

have to be executed quickly with HSI RC).

8/10 Doc ID 17035 Rev 1

Page 9

AN3147 Clock management

IDD fI

DynamicRun

μAMHz⁄[]× I

Static

μA[]+=

IDD

STM8L101xx()

f 150 mA MHz⁄[]× 215 mA[]+=

3.3 Clock configuration and power management

In addition to the flexibility of the clock sources, different complementary clock

configurations and features are available to optimize the power consumption of the device:

● Each peripheral clock can be switched on/off through the CLK_PCKENRx registers.

● System clock divider from 1 to 8 (HSIDIV[1:0] bits in the CLK_CKDIVR register) is

available on STM8L101xx devices.

● System clock divider from 1 to 128 (CKM[2:0] bits in the CLK_CKDIVR register) is

available on STM8L15x devices.

Note: System clocks are used to supply both CPU and peripherals.

The STM8L is focused on low consumption. This is why all peripheral clocks are gated by

default. Before accessing any peripheral register, it is mandatory to enable the clock for the

given peripheral.

3.4 Clock selection vs. power consumption

The selected clock type and speed is one of the major factors influencing power

consumption of the MCU. In general, there are two parts in consumptions:

● A static part, depending on the number of enabled peripherals (mainly analog ones)

● A dynamic part, directly proportional to clock speed (increasing with higher clock

speed)

Note: The values given above are measured with all peripherals disabled.

Slowing down the clock decreases the immediate consumption but this is not the ideal

solution in many cases. By slowing down the clock, the CPU performance is also reduced.

Therefore, a longer time is required to perform an action or computation. If we consider the

average consumption, it might be better to use the highest available clock speed to perform

the required operation, and force the MCU to one of the low power modes (like Active-halt

mode) for the remaining time frame. This should be taken into account during the design of

application flowcharts.

Doc ID 17035 Rev 1 9/10

Page 10

Run and low power modes AN3147

4 Run and low power modes

By default, after a reset, the microcontroller is in Run mode. The default CPU clock is 2 MHz

(HSI / 8). Several low power modes are available to save power when the CPU is not used

for a standard operation (for instance: waiting for an external event). It is up to the user to

select the mode that gives the best compromise between low power consumption, short

startup time, good peripheral functionality, and availability of wakeup sources. Those power

modes are listed in Section 4.2.1 and Section 4.2.2.

Power consumption in Run and Wait modes can also be reduced by one of the following

means:

● Slowing down the system clocks

● Executing code from RAM

● Gating the clocks to the peripherals when they are not used.

4.1 Flash memory

On STM8L devices, the Flash memory supports a low power mode called I

mode, the Flash is switched off. It enters power-down mode (I

Active-halt, Low power wait or Low power run mode is entered.

By enabling the EEPM bit (available on STM8L15x and STM8L16x devices only) in the

FLASH_CR1 register, the Flash program memory automatically enters I

code is executed from RAM or when the device is in Wait mode. When the Flash program

memory is in I

mode, the recovery / wakeup time is longer (up to 2.8 µs) and depends

DDQ

on the supply voltage and temperature.

4.2 Overview of low power modes

The following table lists the STM8L low power modes and shows a basic behavior of STM8L

devices and the influence of different low power modes on CPU, peripherals and

consumption.

A detailed description of each mode is given in the following chapters.

In all low power modes, the general purpose I/Os continue to drive actively outputs (both

digital and analog - DAC).

The MCU can be woken up from these low power modes by specific interrupts, including

through comparators and incoming communications on SPI, I2C and/or USART. Refer to the

interrupt mapping table in the device datasheet.

. In this

) automatically when Halt,

DDQ

DDQ

mode when the

DDQ

10/10 Doc ID 17035 Rev 1

Page 11

AN3147 Run and low power modes

Table 2. Low power mode summary

Low power modes names

and consumptions

STM8L

typical

values

@ 3V / 25°C

Low power

modes

Low power

run

Low power

wait

Active-halt

w/ full RTC

Active-halt

w/ RTC

Entry

CPU Peripherals

Software

sequence

Software

sequence

+ WFE

ON

OFF

Can be

enabled

Can be

enabled

HALT OFF

Functions

High

speed

osc.

RTC

calendar

LSI

LSE

Flash RAM

OFF ON ON OFF ON 5.4 µA 6.8 µA

OFF ON ON OFF ON 3.3 µA 4.4 µA

ON ON OFF ON 1.0 µA

OFF ON OFF ON 0.8 µA

on LSI

Halt OFF OFF OFF ON 0.4 µA

1. Internal reference voltage and BOR off.

4.2.1 STM8L101xx low power modes

The STM8L101xx devices feature the following main low power modes:

● Wait mode: CPU stopped and peripherals kept running

● Active-halt mode: CPU stopped, AWU (auto-wakeup) and IWDG (independent

watchdog) kept running if enabled.

● Halt mode: CPU and peripheral clocks stopped

(1)

(1)

(1)

STM8L

typical

values

@ 3V / 85°C

1.4 µA

1.2 µA

1 µ A

4.2.2 STM8L15x low power modes

STM8L15x devices feature the following main low power modes:

● Wait mode: CPU clock stopped, peripherals kept running

● Low power run mode: executing code is done from RAM with a low speed oscillator

(LSI or LSE); selected peripherals remain active

● Low power wait mode: CPU clock stopped; selected peripherals remain active

● Active-halt mode: CPU clock stopped, AWU/RTC (auto wakeup/real-time clock) and

IWDG (independent watchdog) kept running if enabled

● Halt mode: everything is stopped.

Doc ID 17035 Rev 1 11/10

Page 12

Run and low power modes AN3147

4.3 Slowing down the clock frequency

In Run mode, choosing the clock frequency is very important to ensure the best compromise

between performance and consumption. The selection is done by programming the

prescaler registers. These prescalers can also be used to slow down peripherals before

entering low power modes.

Note: Keep in mind the recommendations given in Chapter 3.4 about performance and ratio

between Run mode and Halt mode operation.

4.4 Peripheral clock gating (PCG)

You can use peripheral clock gating (PCG) for additional power saving. This can be done at

any time by selectively enabling or disabling the clock connection to individual peripherals

through the CLK_PCKENRx registers. These settings are effective both in Run and Wait

modes.

Note: As all peripheral clocks are gated on STM8L devices after reset, it is mandatory to enable

the clock for a given peripheral before accessing any peripheral register.

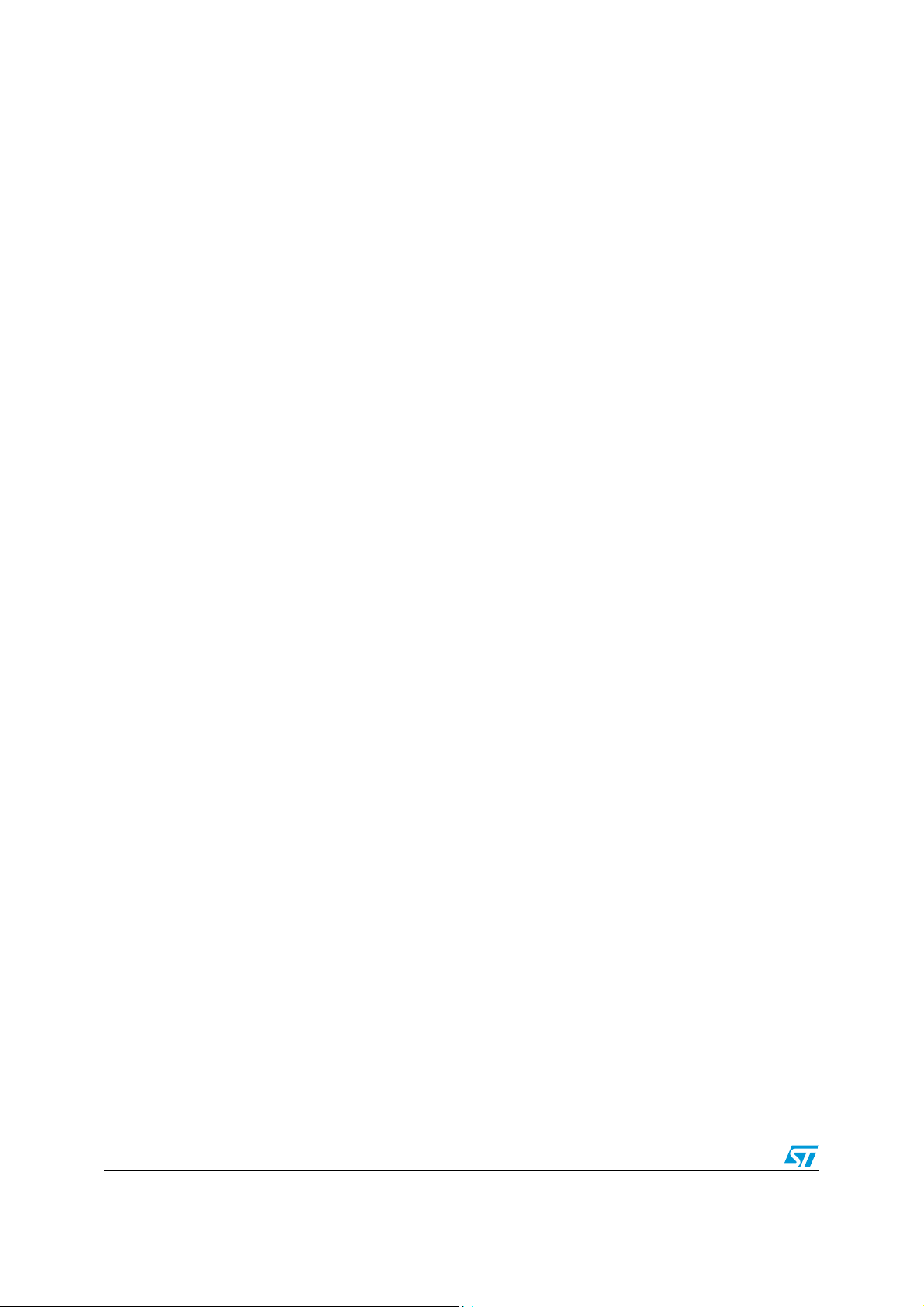

4.5 Execution from RAM

The code can be executed from RAM in order to save power consumption. However, due to

the difference between size of data & instruction bus from Flash (32-bit) and RAM (8-bit),

the performance is degraded when the execution is done from RAM. This is important to

take into account the performance and the ratio between Run/Halt operations.

In this mode, the Flash memory can be forced to I

DDQ

mode.

The following figure shows the different bus widths for Flash and RAM memories.

Figure 2. STM8L architecture

)NSTRUCTION

-EMORY

$ATA%

2!-

0ERIPHERALS

BIT

BIT

BIT

-EMORY

#ONTROLLER

)"US

$"US

$EBUG

37)-

34-

#/2%

)NTERRUPTCONTROL

)4#

37)-PROTOCOL

)NTERRUPT

$-!

BIT

12/10 Doc ID 17035 Rev 1

AI

Page 13

AN3147 Run and low power modes

4.6 Wait mode

The STM8L devices support two different Wait modes: WFI (Wait for interrupt) and WFE

(Wait for event). Both modes are designed to reduce STM8L device power consumption by

switching off the core when it is not used. Wait mode is mainly used when the STM8L is

waiting for an external or internal event so that the program execution can continue.

The device can be switched to Wait mode instead of waiting for an Event in Run mode with:

While( ! Event );

This mode can be used with PCG and with a low speed clock source to further reduce the

power consumption of the device.

This mode offers the lowest wakeup time.

4.6.1 Entering Wait mode

Wait mode is entered by executing the WFI or WFE assembly instruction. This stops the

CPU, but other peripherals and the interrupt controller can continue to run. When entering

Wait mode, the global interrupts are automatically enabled.

● Before entering WFI mode, at least one interrupt must be enabled.

● Before entering WFE mode, at least one event source must be enabled.

4.6.2 Exiting Wait for interrupt mode

When an internal or external interrupt request occurs, the CPU wakes up from Wait mode

and resumes processing.

The following list gives examples of peripherals or features with interrupts having exit-fromwait capability:

● I2C

● USART

● SPI

● ADC

● Comparator

● AWU/RTC

● External interrupt

● Timers

● Clock controller (clock switch execution)

Refer to the STM8L reference manuals for more details. Refer to the STM8L datasheets for

the availability of the above peripherals and features on your devices.

4.6.3 Exiting Wait for event mode

When an internal or external event request occurs, the CPU wakes up from Wait mode and

resumes processing.

Doc ID 17035 Rev 1 13/10

Page 14

Run and low power modes AN3147

The following list gives examples of peripherals or features with events having exit-from-wait

capability:

● I2C

● USART

● SPI

● ADC

● Comparator

● External interrupt

● Timers

If an interrupt occurs during Wait for event mode, the related interrupt service routine is

executed. After this routine, the MCU goes back to Wait for event mode.

Refer to the STM8L reference manuals for more details. Refer to the STM8L datasheets for

the availability of the above peripherals and features on your devices.

4.7 Low power run mode

This mode is based on code execution from RAM, using a low speed clock source. The main

voltage regulator (MVR) is switched off and the low power voltage regulator (LPVR) is used

to supply the voltage to internal structures. The Flash memory is configured by software in

I

mode.

DDQ

The ADC is not supported in this mode, as its clock source must have a minimum frequency

of 1 MHz.

No interrupt is allowed in this mode as the interrupt vectors are located in the Flash (which is

switched off). Consequently, all interrupts must be masked.

While using this mode, you have to switch from high speed clock sources to low speed clock

sources.

Note: This mode is available only on the STM8L15x family.

4.7.1 Entering Low power run mode

This mode is entered by executing the following software sequence:

1. Switch off all unused peripherals, oscillators (except LSI or LSE) and analog blocks

2. Mask all interrupts

3. Jump to RAM

4. Switch system clock to LSI or LSE clock sources

5. Configure the Flash memory in I

register

6. Add a software delay loop to make sure the Flash/Data EEPROM are off

7. Configure the ultralow power mode for the regulator by setting the REGOFF bit in the

CLK_REGCSR register (do not confuse with the ULP bit in the PWR_CSR2 which

configures the behaviour of the internal reference voltage).

Steps 1 to 4 can be performed in any order.

mode by setting the EEPM bit in the FLASH_CR1

DDQ

14/10 Doc ID 17035 Rev 1

Page 15

AN3147 Run and low power modes

4.7.2 Exiting Low power run mode

The only way to exit this mode is to follow these steps:

1. Switch on the main regulator by resetting the REGOFF bit in the CLK_REGCSR

register. The REGREADY flag in the CLK_REGCSR register is set when the regulator

is ready.

2. Switch on the Flash/Data EEPROM by resetting the EEPM bit in the FLASH_CR1

register. The EEREADY flag in the CLK_REGCSR register is set when the Flash/Data

EEPROM is ready.

3. Switch the clock to HSI (or HSE).

4. Reset interrupt mask.

5. Switch on what is necessary and jump to Flash/Data EEPROM if needed.

4.8 Low power wait mode

This mode is entered by executing a WFE instruction, while the MCU is in Low power run

mode. It can be exited only by means of an external or internal event, in this case the MCU

returns to Low power run mode. WFI instruction cannot be used, because interrupts have to

be disabled in Low power run mode.

4.9 Halt mode

In this mode the system clock is stopped. This means that the CPU and all the peripherals

requiring clocks are disabled, except for the following cases:

● The HSI clock is not stopped if used by the SWIM

● The system clock source is not stopped if a Flash/Data EEPROM write operation is in

progress

● The LSI clock is not stopped if used by the SWIM, by the IWDG or if the “IWDG_HALT”

option bit is disabled.

In Halt mode, none of the peripherals is clocked and the digital part of the MCU consumes

almost no power.

4.9.1 Entering Halt mode

The MCU enters Halt mode when a HALT instruction is executed. Before executing a HALT

instruction, the application must clear any pending peripheral interrupt by clearing the

interrupt pending bit in the corresponding peripheral configuration register. Otherwise, the

HALT instruction is executed but the MCU wakes up immediately and the program execution

continues.

However, the Halt procedure can be delayed if one of the following flags is set:

● SWBSY flag in the CLK_SWCR register

● EEBUSY flag in the CLK_REGCSR register

● RTCSWBSY flag in the CLK_CRTCR register

● BEEPSWBSY flag in the CLK_CBEEPR register when the Beep is enabled in Active-

halt mode.

Doc ID 17035 Rev 1 15/10

Page 16

Run and low power modes AN3147

If the SAHALT bit is set in the CLK_ICKCR register, the main regulator (MVR) is switched off

without taking into account that some high speed clocks may be used by the system.

4.9.2 Exiting Halt mode

Wakeup from Halt mode is triggered by an external interrupt, sourced by a general purpose

I/O port configured as interrupt input or by an alternate function pin capable of triggering a

peripheral interrupt.

The system clock is then restarted at a frequency depending on the FHW bit in the

CLK_ICKCR register. If the FHW bit is set, HSI/8 is the system clock. Otherwise, the system

clock is the last selected clock source before the system enters Halt mode.

Note: When the STM8L101xx microcontroller is woken up from Halt mode, the same clock source

as that used before entering this mode is always selected.

In an interrupt-based application, where most of the processing is done through the interrupt

routines, the main program may be suspended by setting the activation level bit (AL) in the

CFG_GCR register. Refer to Section 4.10: Activation level control on page 16.

4.9.3 Active-halt mode

In Active-halt mode, the main oscillator, the CPU and almost all peripherals are stopped.

Only the LSI RC oscillator or the LSE crystal is running to drive the SWIM, beep, IWDG,

RTC and LCD, if enabled. The user can enter this mode by a HALT instruction, once some

of the peripherals above have been enabled.

4.10 Activation level control

The STM8L devices support an automatic activation level control feature. Consequently, the

user can configure the MCU so that it directly returns to a low power mode after it has been

woken up from such a mode through interrupts.

In an interrupt-based application, where most of the processing is done through the interrupt

routines, the main program may be suspended by setting the activation level bit (AL) in the

CFG_GCR register. Setting this bit causes the CPU to return to low power mode after

exiting an interrupt service routine without restoring the main execution context when the

IRET instruction is executed. This saves power by removing both the save/restore context

activity and the need for a main software loop execution for power management (in order to

return to low power mode).

To return to the main loop, the AL bit has to be cleared by software. This must be done at

least two clock cycles before the IRET instruction is executed.

16/10 Doc ID 17035 Rev 1

Page 17

AN3147 Power management tips

5 Power management tips

5.1 Choosing the optimal low-power mode for your application

Different low power modes can be selected depending on your application:

● Application powered by a battery where the MCU is in sleep mode most of the time:

– If the MCU is woken up due to external events, no time tracking is necessary and

power consumption has to be as low as possible. Then, Halt mode is advised to

extend battery life as much as possible.

– Active-halt mode with AWU/RTC clocked by the LSI is advised if the application

does not only depend on external events, but needs a non accurate periodic

wakeup. The LSE can be used to achieve a high timing precision.

● Application powered by a battery where the MCU is awake most of the time:

– Active-halt mode is advised if the MCU has to perform a few periodic actions

during which no peripheral has to remain enabled.

– Wait mode is advised if at least one peripheral has to remain enabled all the time

and an interrupt or event can wake up the MCU.

● Application supplied by mains but where consumption is critical:

– Run mode, with a clock prescaler adapted to the application requirement, is

advised if the MCU has to run all the time and low power modes cannot be used.

5.2 GPIO initialization

By default, the I/Os are configured as floating input.

It is important to change the configuration of all I/Os that are not connected to defined logic

signals so as to obtain one of the following configurations:

● input configuration with pull-up,

● or output configuration with a low (or high) logic level.

Otherwise, an increased consumption is generated by noise, as the internal Schmitt triggers

detecting this noise are toggling.

Floating I/Os could generate additional consumption in the range of a few 10 µA.

There are also parts with some unbonded I/Os (typically different packages of the same

product). Those I/Os are connected to a defined level by factory option configuration, unless

otherwised specified in the datasheet.

5.3 Dynamic control of pull-up resistor

Many applications have buttons which are used as a user interface. Those buttons are

connected to I/Os that are connected to V

up is used in order to have a defined logic level on these I/Os when the button is off.

Once the button is pressed, the I/O is grounded and it generates an additional current of ~

40 – 70 µA, drawn from the power supply. This current is negligible if the application is in

Run mode, but becomes very important for applications mainly running in low power modes.

once the buttons are pressed. An internal pull-

SS

Doc ID 17035 Rev 1 17/10

Page 18

Power management tips AN3147

For this type of applications, you can control the pull-up dynamically. Once a button is

pressed, the related service routine is executed. This routine disables the pull-up and the

interrupt, in order to save consumption while the button is pressed.

As the application has to check the button status regulary, this pull-up is enabled again

before this check. If the button is still pressed, this process is repeated. Once a button

release is detected, the pull-up remains on.

For this task, an I/O can be left floating for a short time frame, given by a check period,

generating an extra consumption in the range of ~10 µA. Therefore, the total current

consumption for a button press operation is lower than without this dynamic control.

5.4 Waiting loops / delays

In some cases, the application has to wait for an input from the user, slow peripheral (ADC),

or another external unit.

If there is no useful code to execute in the meantime, instead of using:

● a typical delay loop:

(delay = 0; delay < 0xFFFF; delay++)

_asm ("nop");

●

or a polling loop like:

ADC_CR1 I= ADC_START; // start conversion

while (!( ADC_SR & ADC_SR_EOC)); // wait for EOC bit set

it is recommended to use a more advanced solution, using a Wait for event mode:

1. Configure the ADC as a source of event

2. Enable an event by allowing the related interrupt:

WFE_CR2 I= ADC_COMP_EV; // enable ADC as a source of event

ADC_CR1 = ADC_EOCIE; // enable interrupt for end of conversion

An event is then generated after each conversion. The conversion starts as follows:

ADC_CR1 = ADC_START; // start conversion

_asm ("wfe");

The sequence described above uses WFE mode to wait for an end of conversion. This can

also be used for other sources like communication lines, etc. In case of external sources

(like interrupt from an I/O port), you can also consider using Halt mode.

18/10 Doc ID 17035 Rev 1

Page 19

AN3147 Power management tips

5.5 Minimizing power consumption

The following recommendations can help you choose the right configurations to minimize

the power consumption of your device in your application:

● Switch off all unused peripherals (peripherals are switched off by default) and use the

PCG feature (through the CLK_PCKENRx registers) to disable the clock provided to

the unused peripherals (these clocks are disabled by default).

● All unused pins must be connected to a defined logic level. One of the option is to

configure them as output low level. Make sure there are no unused I/O pins configured

as a floating input. This needlessly leads to a high consumption.

● Use Wait mode if you need external wakeup capability in low power mode and if some

peripherals have to remain active.

● Use the appropriate V

consumed power.

Thanks to the internal regulator, which supplies internal structures of the MCU, there is

no major difference in the MCU consumption but the difference could be visible on an

application level, e.g. due to the current flowing through pull-up resistors out of the

MCU.

● Use Low power run mode and Halt modes as much as possible. To achieve this, you

need to shorten the time spent in the Run mode, for example by using the highest clock

speed in Run mode.

● When a low power mode cannot be used, use the minimum possible frequency for your

application. You can select the frequency value that meets your requirements.

● Use the dynamic control of pull-up configuration if possible. See Section 5.2: GPIO

initialization on page 17 for a the detailed description.

value for your application. The higher the VDD value, the more

DD

Doc ID 17035 Rev 1 19/10

Page 20

Conclusion AN3147

6 Conclusion

The STM8L family offers many possibilities for development of low consumption

applications. The user can take advantage of various low power modes like Wait, Low power

Run/Wait, or Halt and Active-halt modes. He can also reduce consumption by switching off

peripherals when they are not used. Another important point is the optimization of the ratio

between Run and Halt modes due to the good performance of the CPU itself.

The main important principles are described in this application note, including a few hints on

how and when to use it. Much more examples exist, depending on your exact needs. You

can find them on www.st.com.

20/10 Doc ID 17035 Rev 1

Page 21

AN3147 Revision history

7 Revision history

Table 3. Document revision history

Date Revision Changes

31-Mar-2010 1 Initial release

Doc ID 17035 Rev 1 21/10

Page 22

AN3147

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2010 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

22/22 Doc ID 17035 Rev 1

Loading...

Loading...