Page 1

AN3110

Application note

Using the STVM100

to automatically adjust VCOM voltage in e-paper

Introduction

The widespread use of multimedia electronic devices, coupled with environmental concerns

over the manufacturing and use of traditional paper products, provide the opportunity for the

utilization of electronic paper (e-paper).

Electronic paper is the best replacement for conventional paper. A high-quality image can

be displayed for weeks without power. Energy is consumed only during the short refresh

time. Unlike its counterpart, liquid crystal display (LCD) devices, e-paper does not require a

backlight, which not only saves energy, but also makes reading more comfortable.

Achieving high-quality images on e-paper requires the correct setting of the VCOM voltage

on the PC board. STMicroelectronics offers the STVM100 VCOM calibrator which is ideal

for e-paper applications and allows the VCOM voltage to be set automatically. In this

application note, the e-paper principle is briefly described so that the user can understand

the necessity of an accurate VCOM voltage setting and how the STVM100 can be used for

this purpose.

January 2010 Doc ID 16799 Rev 1 1/10

www.st.com

Page 2

General principle of e-paper AN3110

1 General principle of e-paper

Using Electrophoretic Display (EPD) technology, pre-charged particles within the capsules

can be either driven to the top plate (common electrode) of the e-paper which is white due to

the reflection of the light, or driven to the bottom plate (column electrodes) of the paper

which is dark. The particles are in a bi-stability state so that the position can be maintained

even though there is no power applied to the e-paper.

Similar to liquid crystal display (LCD) devices, some of the EPD devices are also formatted

by pixels with the active matrix controlled using TFT (Thin-Film Transistor) technology.

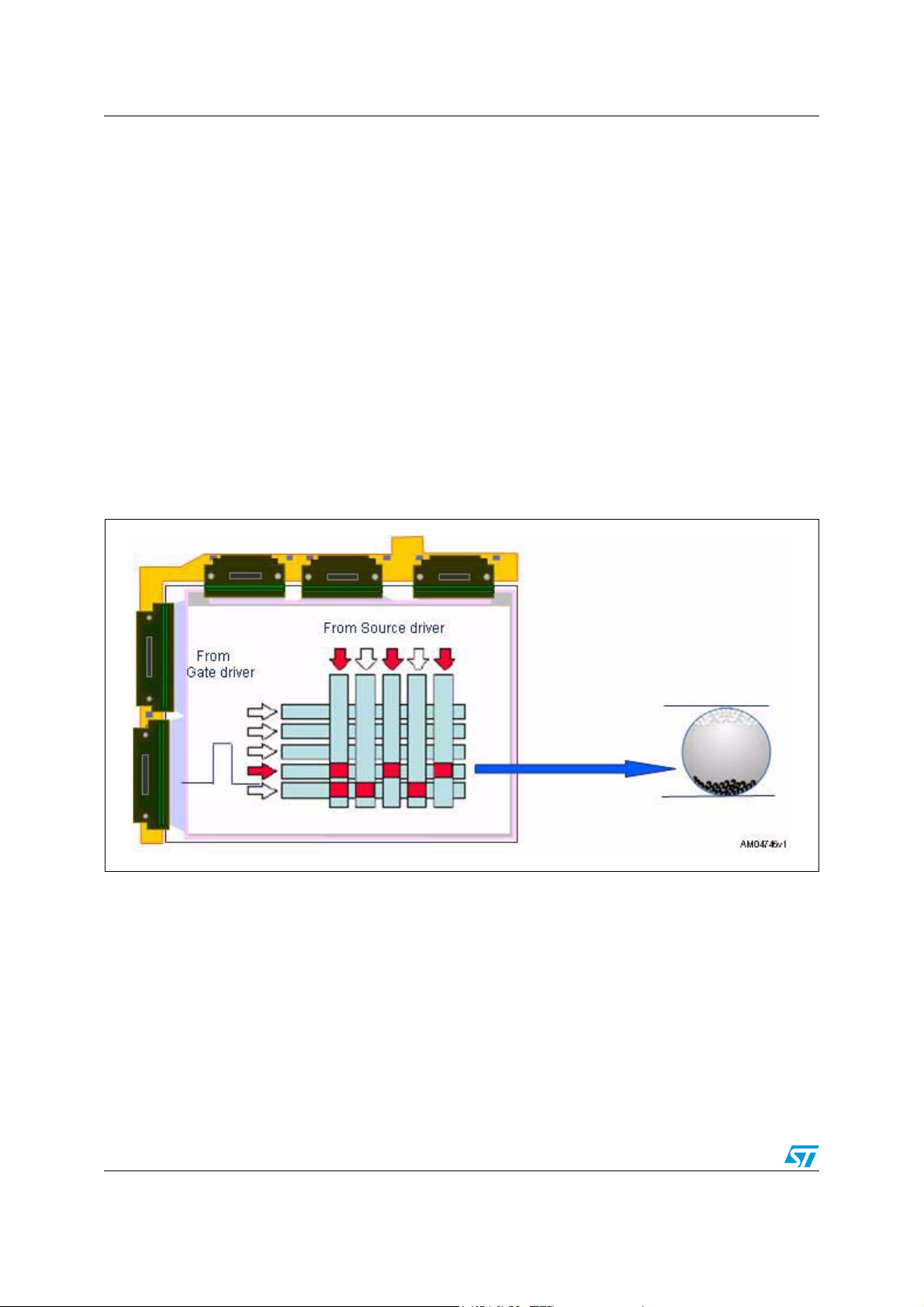

In Figure 1, the gate driver sends a line selection pulse to the top line and turns on the first

line TFT. The data (analog voltage) is transferred from the source driver to the pixels in the

first line. After the first line data is updated, the gate driver selects the second line and then

the third, and so on. Once the last line has been scanned, the entire picture on the screen

has been updated (whole e-paper refresh). Then the gate driver begins again from the first

line and starts the next refresh if required. The line selection pulse pattern is configurable in

the gate driver.

Figure 1. E-paper display layout

2/10 Doc ID 16799 Rev 1

Page 3

AN3110 General principle of e-paper

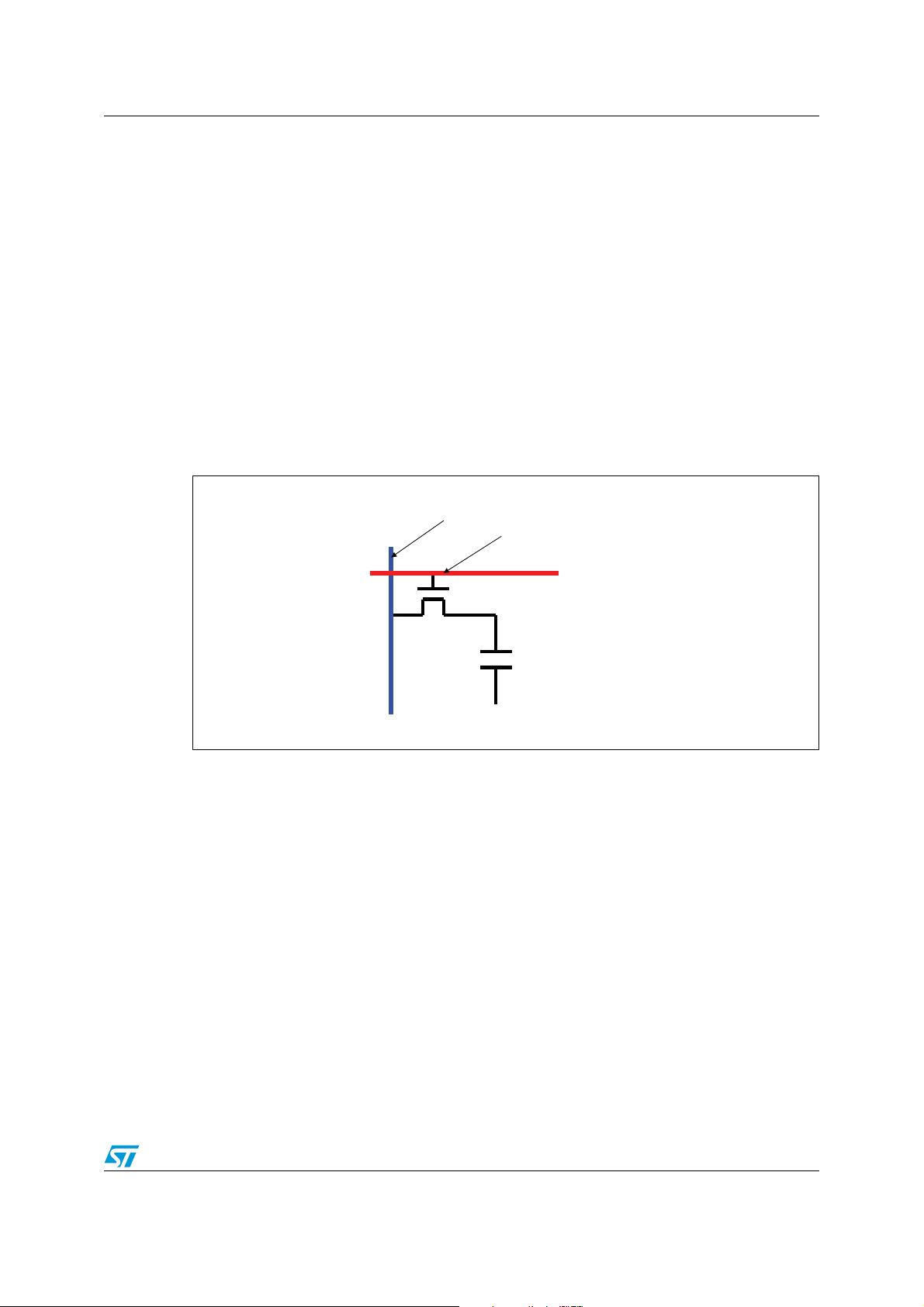

Figure 2 shows the detailed pixel schematic. The Cep is the equivalent capacitance of the e-

paper. The position of the pre-charged particles in the capsules between the two electrodes

depends on the absolute voltage applied on the electrodes.

The common electrodes of all the pixels are connected together and a constant Vcommon

voltage (VCOM) is required to drive this electrode. The VCOM voltage should be set

correctly panel-by-panel for the best performance. Residual pixels (“ghosting” effect) will

appear after content refresh if the VCOM voltage is not set correctly.

After the line is selected by the gate driver, the corresponding column electrode is

connected to the source driver by the TFT. When the source driver supplies positive voltage

to the column electrodes, the positively-charged particles are repelled by the positive

electric field and moved to the top plate of the capsule. The white particles are reflective and

reflect the ambient light to the viewer so that this pixel is viewed white. Otherwise, if

negative voltage is supplied to the column electrode, the positively-charged particles are

attracted to the negative electric field and moved towards the bottom side of the capsule

which then appears dark.

Figure 2. Basic e-paper pixel schematic

To source driver

To gate driver

TFT

Column electrode

C

ep

Common electrode

AM04747v1

Doc ID 16799 Rev 1 3/10

Page 4

E-paper VCOM calibration using the STVM100 AN3110

2 E-paper VCOM calibration using the STVM100

The VCOM values vary according to the type of e-paper. Each of the VCOM values is well

tested and provided by the e-paper manufacturer who normally labels the e-paper PC board

with a barcode and a decimal value. The common distribution range is from –0.5 V to

–2.5 V, but this range varies according to the technology.

The digital VCOM calibrator STVM100 (see datasheet at www.st.com) can completely

replace the mechanical potentiometer as an automatic, more accurate, and robust solution.

The STVM100 provides a digital I

output drives an external resistive voltage divider, which can then be applied to an external

VCOM buffer (TS512, precision dual operational amplifier). Four external resistors R1, R6,

R7 and R12 determine the highest and lowest value of the VCOM. An increase in the output

sink current lowers the voltage on the external divider so that the VCOM can be adjusted by

128 steps within this range. Once the desired VCOM setting is achieved, it can be stored in

the internal EEPROM that is automatically recalled during each power-up. Figure 3 shows

the basic connection of the STVM100 in e-paper applications.

Figure 3. STVM100 and VCOM buffer (TS512 from ST) on e-paper PC board

2

C interface to control the sink current output (I

+15V

OUT

). This

R7

14K

-15V

R1

80.6K

R6

28K

R12

100K

R9

0

R2

0

TP 8

TP 5

VCOM-

-15V

VCOM+

1

2

3

TP 6

VCOM- BUFVset

U2

1OUT

VDD+

1IN1IN +

VDD-42IN +

TS512

2OUT

2IN-

8

7

6

5

AM04748v1

+3V3

R15

0

R14

0

Not mounted

GND

+3V3

SDA

SCL

U1

6

7

3

STVM100

VDD5AVDD

Vout

SDA

Vset

SCL

GND

WP

2

1

8

4

GND

In this example, by choosing 1% accuracy resistors of R1, R6, R7 and R12 with a supply of

±15 V, a range of –0.5 V to – 2.5 V can be obtained at point VCOM– by writing 0 to 127 to

the STVM100 through the I

2

C bus. The VCOM– is buffered by the TS512 to VCOM– BUF

which is applied to the VCOM plate of the e-paper.

The advantages of this circuit are:

● The STVM100 replaces the conventional variable resistor (VR). The STVM100 is

robust, accurate, easily configurable, and provides automatic adjustment capability.

● The TS512 supports ±18 V (here ±15 V is used) which is necessary in e-paper

applications.

● No additional supply is required, making the power management circuit design easier.

+15V

4/10 Doc ID 16799 Rev 1

Page 5

AN3110 STVM100 auto-adjustment demonstration kit

3 STVM100 auto-adjustment demonstration kit

Since the target VCOM value is given by a decimal value or by a barcode on the

manufacturer’s e-paper PC board, ST has also developed an auto-adjustment

demonstration kit to facilitate calibration.

Only four single wires are needed to connect the e-paper PC board and the adjustment kit,

and the user can input the target VCOM value either manually or by a barcode reader in the

GUI as shown in Figure 4. After a single click on the "Run" button, no more than 1 second

later, the target VCOM is correctly adjusted and appears in the "Final VCOM" text box. In

this GUI, single-step up/down buttons are also available for the user to do a simple

comparison and confirmation of the VCOM value.

Figure 4. VCOM auto-adjustment kit GUI

AM04749v1

Doc ID 16799 Rev 1 5/10

Page 6

Auto-adjustment demonstration kit test results AN3110

4 Auto-adjustment demonstration kit test results

Tab l e 1 gives an example of the lab test results of the auto-adjustment kit.

It can be seen that this board has a maximum 11 mV difference between the target VCOM

write and the actual measured on VCOM– BUF. The results demonstrate its suitability for

the e-book VCOM application.

Please contact local ST sales office for the availability of the demonstration board hardware

and software.

Table 1. Test results of the auto-adjustment kit

Target voltage

for VCOM– BUF (V)

–0.65 –0.657 –0.007

–0.75 –0.757 –0.007

–0.85 –0.852 –0.002

–0.95 –0.95 0

–1 –0.998 0.002

–1.1 –1.096 0.004

–1.2 –1.193 0.007

–1.3 –1.29 0.01

–1.4 –1.404 –0.004

–1.5 –1.5 0

–1.51 –1.5 0.01

–1.52 –1.517 0.003

–1.53 –1.533 –0.003

–1.54 –1.533 0.007

–1.55 –1.549 0.001

–1.56 –1.565 –0.005

–1.57 –1.565 0.005

Measured voltage

on VCOM– BUF (V)

Delta between target and

measured voltage

on VCOM– BUF (V)

–1.58 –1.581 –0.001

–1.59 –1.581 0.009

–1.6 –1.597 0.003

–1.7 –1.694 0.006

–1.8 –1.792 0.008

–1.9 –1.889 0.011

–2 –2.003 –0.003

–2.1 –2.1 0

6/10 Doc ID 16799 Rev 1

Page 7

AN3110 Auto-adjustment demonstration kit test results

Table 1. Test results of the auto-adjustment kit (continued)

Target voltage

for VCOM– BUF (V)

–2.2 –2.198 0.002

–2.3 –2.295 0.005

–2.4 –2.393 0.007

–2.5 –2.491 0.009

–2.6 –2.589 0.011

–2.7 –2.691 0.009

Measured voltage

on VCOM– BUF (V)

Maximum error (V) 0.011

Delta between target and

measured voltage

on VCOM– BUF (V)

Note: VCOM– BUF is the point on the demonstration board which connects to the VCOM panel on

the e-book. Please refer to Figure 3 for a detailed description.

Doc ID 16799 Rev 1 7/10

Page 8

Conclusion AN3110

5 Conclusion

The STVM100 VCOM calibrator is ideally suited for the e-paper and e-book display

applications. By taking advantage of its 7-bit, non-volatile common voltage setting

capability, it allows easy and automated configuration of e-book display panels in a

manufacturing environment.

An STVM100 auto-adjustment kit is also available to demonstrate how VCOM accuracy of

better than ±16 mV is easily achievable.

8/10 Doc ID 16799 Rev 1

Page 9

AN3110 Revision history

6 Revision history

Table 2. Document revision history

Date Revision Changes

07-Jan-2010 1 Initial release.

Doc ID 16799 Rev 1 9/10

Page 10

AN3110

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2010 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

10/10 Doc ID 16799 Rev 1

Loading...

Loading...