Page 1

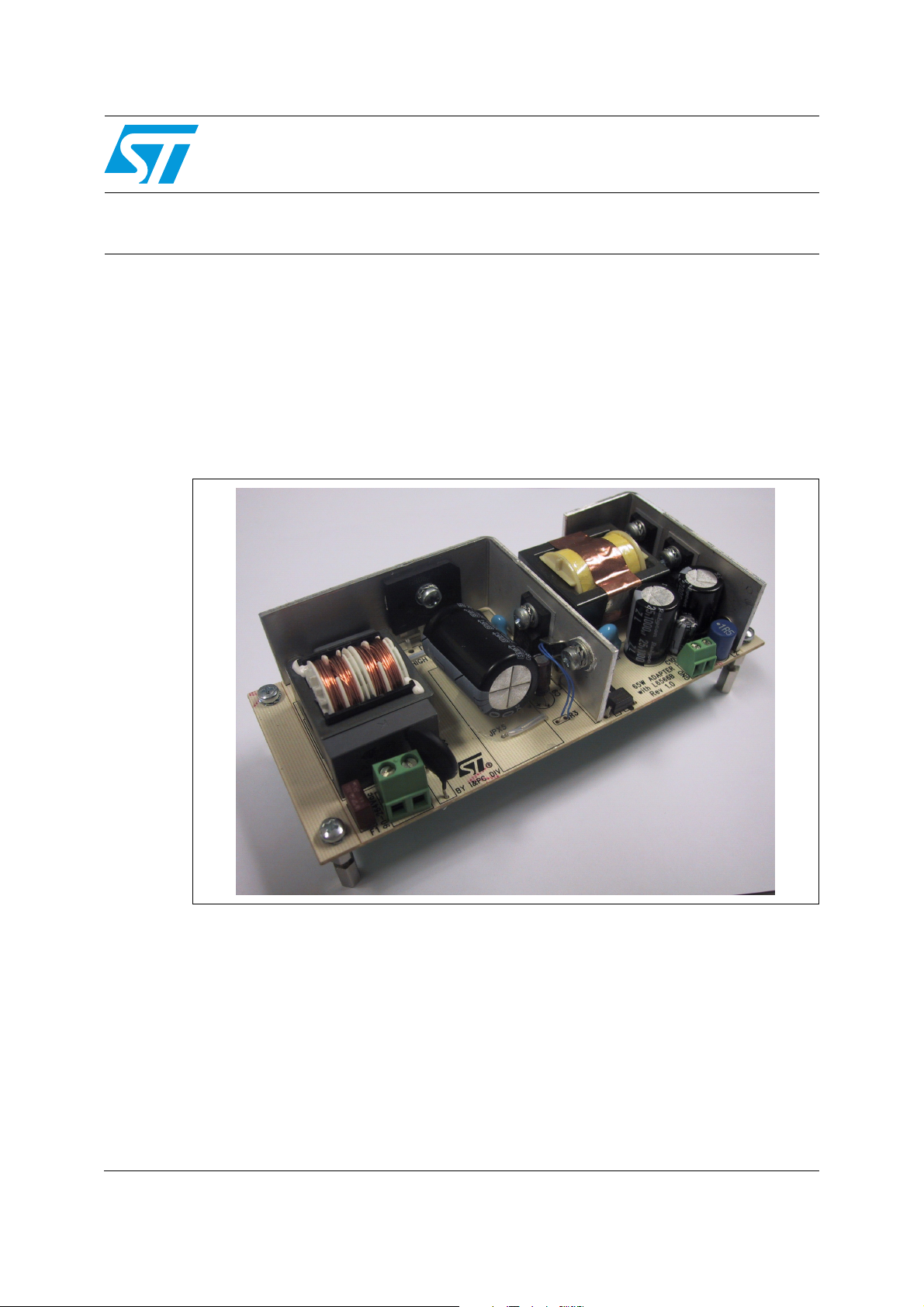

AN3089

Application note

19 V - 65 W quasi-resonant flyback adapter using

L6566B and TSM1014

Introduction

This application note describes the characteristics and features of a 65 W demonstration

board (EVL6566B-65W-QR), tailored to the specifications of a typical hi-end portable

computer power supply. The peculiarities of this design are the very high average efficiency

of about 90%, without synchronous rectification, and very low no-load consumption of 100

mW at 230 Vac. The result is that this converter is more than compliant with Energy Star

eligibility criteria (EPA rev. 2.0 EPS).

Figure 1. EVL6566B-65W-QR: 65 W adapter demonstration board

®

July 2010 Doc ID 16493 Rev 1 1/25

www.st.com

Page 2

Contents AN3089

Contents

1 Main characteristics and circuit description . . . . . . . . . . . . . . . . . . . . . 5

1.1 Power stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Brown-out protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Output regulation feedback loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 L6566B current mode control and voltage feed-forward function . . . . . . . . 7

1.6 L6566B short-circuit protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.7 Overvoltage protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.8 Overtemperature protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.9 Burst mode operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Efficiency measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Functional check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Standby and no-load operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 Overcurrent and short-circuit protection . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3 Overvoltage and open-loop protection . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4 Thermal map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 Conducted emission pre-compliance test . . . . . . . . . . . . . . . . . . . . . . 17

6 Bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7 Transformer specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

8 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2/25 Doc ID 16493 Rev 1

Page 3

AN3089 List of tables

List of tables

Table 1. Overall efficiency and no-load consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 2. Thermal map reference points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 3. EVL6566B-65W-QR demonstration board: bill of material . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 4. Transformer winding data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 5. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Doc ID 16493 Rev 1 3/25

Page 4

List of figures AN3089

List of figures

Figure 1. EVL6566B-65W-QR: 65 W adapter demonstration board . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. Electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 3. Light load efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 4. Flyback stage waveforms at 115 V -60 Hz – full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 5. Flyback stage waveforms at 230 V-50 Hz – full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 6. Flyback stage waveforms at 115 V -60 Hz – light load . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 7. Flyback stage waveforms at 230 V-50 Hz – light load . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 8. No-load operation at 90 V-50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 9. No-load operation at 265 V-50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 10. Transition full load to no-load at 265 Vac-50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 11. Transition no-load to full load at 265 Vac-50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 12. Short-circuit at full load and 230 Vac – 50 Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 13. Short-circuit detail at full load and 230 Vac – 50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 14. Flyback open-loop – detail at 230 V - 50 Hz - half load . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 15. Flyback open-loop at 230 V - 50 Hz - half load. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 16. Thermal map at 115 Vac – 60 Hz - Full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 17. Thermal map at 230 Vac – 50 Hz - Full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 18. CE average measurement at 115 Vac and full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 19. CE average measurement at 230 Vac and full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 20. Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 21. Transformer winding diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 22. Transformer mechanical diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4/25 Doc ID 16493 Rev 1

Page 5

AN3089 Main characteristics and circuit description

1 Main characteristics and circuit description

The main features of the SMPS are listed below:

● Universal input mains range: 90 ÷ 264 Vac - frequency 45 ÷ 65Hz

● Output voltage: 19 V @ 3.42 A continuous operation

● Mains harmonics: Acc. to EN61000-3-2 Class-D or JEITA-MITI Class-D

● Standby mains consumption: <100 mW @ 230 Vac

● Average efficiency: better than 89% without synchronous rectification

● EMI: according to EN55022-Class-B

● Safety: according to EN60950

● Dimensions: 58x121 mm, 25 mm maximum component height

● PCB: single side, 35 µm, CEM-1, Mixed PTH/SMT

1.1 Power stage

The Flyback converter implements the new ST dedicated current mode L6566B (U2)

controller operating in quasi-resonant mode and detecting the transformer demagnetization

through the ZCD (#11) pin.

R23 on the OSC (#13) pin sets the maximum switching frequency at about 165 kHz.

Because the maximum switching frequency is imposed, the converter operates in

discontinuous conduction mode during light load operation. The L6566B valley skipping

function is capable of turning-on the MOSFET in valley switching even in DCM, therefore

reducing switching losses.

The MOSFET is a standard 800 V, STF7NM80, housed in a TO-220FP package, needing

just a small heat sink. The transformer is a layer type, using a standard ferrite size EER28L,

designed according to EN60950 and manufactured by MAGNETICA.

The flyback reflected voltage is ~150 V, providing enough room for the leakage inductance

voltage spike with a still margin for reliability of the MOSFET. The D5 rectifier and the D4

Transil clamp the peak of the leakage inductance voltage spike at MOSFET turn-off. A small

capacitance in parallel with D4 smooth leakage inductance spikes, reducing EMI and Transil

dissipation.

The output rectifiers are two STPS20H100CFP dual centre tap Schottky diodes (D2 and D3)

in parallel, housed in TO-220FP. They have been selected according to the maximum

reverse voltage, forward voltage drop, and power dissipation. The snubber, made up of R5,

R7 and C12, dampens the oscillation produced by the diode capacitance and the leakage

inductance.

A small LC filter has been added on the output, filtering the high frequency ripple and

spikes.

D6, R4, R5, R8, R9, Q2 and Q3 implement an output voltage “fast discharge” circuit, quickly

discharging the output capacitors when the converter is turned off. It has been implemented

to quickly decrease the residual output voltage after the converter is turned off at no-load.

Doc ID 16493 Rev 1 5/25

Page 6

Main characteristics and circuit description AN3089

1.2 Startup

The L6566B flyback controller pin #1 (HV) is directly connected to the bulk capacitor, and at

startup an internal high voltage current source charges C9 until the L6566B turn-on voltage

threshold is reached, then the high voltage current source is automatically switched off. As

the IC starts switching it is initially supplied by the C9, then the transformer auxiliary winding

(pins 5-6) provides the voltage to power the IC.

Because the L6566B integrated HV startup circuit is turned off, and therefore not dissipative

during normal operation, it gives a significant contribution to power consumption reduction

when the power supply operates at light load.

1.3 Brown-out protection

Brown-out protection prevents the circuit from working with abnormal mains levels. It can be

easily achieved using the AC_OK controller pin (#16).

This feature is typically implemented sensing the bulk voltage through a resistor divider,

however on this board a different solution has been applied. The mains voltage is sensed

before the bridge rectifier. This has two main achievements: it is less dissipative and it

allows faster restart in case of latching, because there is no need to wait for the bulk

capacitor discharge.

If the input voltage is below 90 Vac, the startup of the circuit is inhibited, while the turn-off

voltage has been set at 80 Vac. The internal comparator has in fact a current hysteresis

allowing to set the converter turn-on and turn-off voltage independently. R19 sets the

relation between the comparator hysteresis and the actual voltage hysteresis.

C13, R20 and R21 set the discharging time constant of the AC_OK voltage. This value must

be dimensioned properly, taking two main points into account:

● The voltage must keep up during the mains missing cycle to avoid the converter

shutting down during mains dip.

● In the case of converter switch-off, the voltage must go down promptly to avoid an

operation with improper input voltage.

Basically, the ideal dimensioning would allow C13 to discharge slightly faster than the bulk

capacitor in the case of switch-off at nominal load.

1.4 Output regulation feedback loop

Output regulation is done by means of two control loops, voltage and current, working

alternatively. A dedicated control IC, the TSM1014 (U3), has been used. It integrates two

operational amplifiers (used as error amplifiers) and a precise voltage reference. The output

signal of the error amplifiers drives an SFH617A-4 (U1) optocoupler to achieve the required

insulation of the secondary side and modulate the COMP pin (#9) voltage of the L6566B.

6/25 Doc ID 16493 Rev 1

Page 7

AN3089 Main characteristics and circuit description

1.5 L6566B current mode control and voltage feed-forward function

R16 senses the flyback MOSFET current and the signal is fed into the CS pin (#7)

connected to the PWM comparator. This signal is compared with the COMP pin (#9) signal,

which comes from the optocoupler.

The maximum power that the converter can deliver is set by a comparator limiting the peak

of the primary current, comparing the CS and an internal threshold (V

signal exceeds the threshold, the comparator limits the MOSFET duty cycle, hence the

output power is limited too.

As the maximum transferable power depends on both the primary peak current and the

input voltage, in order to keep the overload set point almost constant, which changes

according to the flyback input voltage, the L6566B implements a voltage feed-forward

function via a dedicated pin. Therefore, V

(#15) sensing the mains voltage through a resistor divider. A higher voltage causes a

smaller V

voltage.

On this board, VFF is implemented via the same circuit of brown-out, saving components

and reducing consumption at light load.

CS,MAX

so that the maximum power can be kept almost constant at any input

is modulated by the voltage on the VFF pin

CSX

). If the current

CSX

1.6 L6566B short-circuit protection

An internal comparator senses the COMP pin after the soft-start time: in case of short, the

COMP pin goes high, and the said comparator activates a current source that restarts

charging the soft-start capacitor from the initial 2 V level. If the voltage on this pin reaches 5

V, the L6566B stops the operation and enters into the so-called “Hiccup mode”. The L6566B

restarts with a startup sequence when the Vcc voltage drops below the Vcc restart level (5

V). Because of the long time needed by the Vcc capacitor to drop to 5 V, it results in an

increase of the duration of the no-load operation, therefore decreasing the power dissipation

and the stress of the power components. This sequence is repeated until the short is

removed, after that normal operation of the converter is automatically resumed.

A second protection, dedicated to protecting the circuit in the case of MOSFETs or output

diode short or transformer saturation, is implemented by another comparator on the CS pin

(#7). If the voltage on this pin exceeds the 1.5 V threshold, the IC immediately shuts down.

In this way a hiccup mode operation is still obtained, avoiding consequent failures due to the

power components overheating. To prevent spurious activation of the protection in the case

of temporary disturbances, for example during immunity tests, the comparator must be

triggered two consecutive times.

1.7 Overvoltage protection

The ZCD pin (#11) is connected to the auxiliary winding by a resistor divider. It implements

the OVP against feedback network failures. When the ZCD pin voltage exceeds 5 V four

consecutive times, the IC is shut down. This protection can be set as latch or auto-restart by

the user with no additional components. On the board it is set as latched. Therefore the

operations can be resumed after a mains recycling.

Doc ID 16493 Rev 1 7/25

Page 8

Main characteristics and circuit description AN3089

1.8 Overtemperature protection

The R3 thermistor, connected to the L6566B DIS pin (#8), provides a thermal protection of

the flyback MOSFET (Q1). Therefore, in case of overheating, the flyback converter activity is

latched off. To maintain this state, an internal circuitry of the L6566B monitors the Vcc and

periodically reactivates the HV current source to supply the IC.

1.9 Burst mode operation

The L6566B implements a current mode control, thus it monitors the output power through

the COMP pin, which has a level proportional to the load. Therefore, when the voltage on

the COMP pin falls below an internal threshold, the controller is disabled and its

consumption reduced; normal operation restarts as soon as the COMP voltage rises again.

In this way a low consumption burst mode operation is obtained

8/25 Doc ID 16493 Rev 1

Page 9

AN3089 Main characteristics and circuit description

Figure 2. Electrical diagram

Doc ID 16493 Rev 1 9/25

Page 10

Efficiency measurement AN3089

2 Efficiency measurement

Ta bl e 1 shows the no-load consumption and the overall efficiency, measured at the nominal

mains voltages. Average efficiency is about 90% at both mains levels. This value is much

higher than the 87% required by EPA rev2.0 external power supply limits.

Thanks to the L6566B valley skipping feature it has been possible to dimension the power

transformer parameters, optimizing efficiency at different loads and achieving an

outstanding result even without synchronous rectification.

Also at no-load the board performances are superior: maximum no-load consumption at

nominal mains voltage is below 100 mW; this value is significantly lower than the limit

imposed by the Energy Star program which is 500 mW. This has been obtained thanks to

the embedded solutions of the L6566B that allow the minimization of consumption at light

load and avoid adding additional discrete circuits that generally increase overall

consumption and component count (HV start-up, latching circuit). In addition, the peculiar

solution implemented for brown-out protection has a very low consumption of about 5 mW.

Table 1. Overall efficiency and no-load consumption

230 V-50 Hz 115 V-60 Hz

Tes t

No-load 19.00 0.00 0.00 94 mW ----- 19.00 0.00 0.00 75 mW -----

Vout

[V]

Iout

[mA]

Pout

[W]

Pin

[W]

Eff.

[%]

Vout

[V]

Iout

[A]

Pout

[W]

Pin

[W]

Eff.

[%]

25% load eff. 18.97 0.86 16.37 18.53 88.3 18.97 0.86 16.32 18.03 90.5

50% load eff. 18.97 1.71 32.50 35.77 90.9 18.97 1.72 32.54 35.91 90.6

75% load eff. 18.98 2.57 48.74 53.44 91.2 18.97 2.57 48.82 54.39 89.8

100% load eff. 18.98 3.42 64.89 71.18 91.2 18.98 3.42 64.99 73.30 88.7

Average eff. 90.4 89.9

Light load efficiency measurement results are plotted in Figure 3. As shown, efficiency is

better than 60% even at half-watt input power.

Figure 3. Light load efficiency

90%

85%

80%

75%

70%

65%

Effi ci en cy [%]

60%

55%

50%

0.51.01.52.02.53.03.54.04.55.05.5

Pi n [ W]

230V-50 Hz

115V-60 Hz

10/25 Doc ID 16493 Rev 1

Page 11

AN3089 Functional check

3 Functional check

Some flyback waveforms during steady state operation are reported here.

At nominal load conditions, in Figure 4 and Figure 5, it is possible to note that the ZCD

negative-going edge triggers MOSFET’s turn-on, allowing quasi-resonant operation.

Figure 4. Flyback stage waveforms at 115 V -

60 Hz – full load

Figure 5. Flyback stage waveforms at 230 V-

50 Hz – full load

CH1: Drain voltage CH2: CS pin voltage CH1: Drain voltage CH2: CS pin voltage

CH3: ZCD pin CH4: Bulk voltage CH3: ZCD pin CH4: Bulk voltage

Doc ID 16493 Rev 1 11/25

Page 12

Functional check AN3089

Figure 6 and Figure 7 show operation at light load. As already indicated, maximum

switching frequency has been set at 165 kHz. For this reason, the L6566B skips the first

valley signal on ZCD and switches on the MOSFET at the second negative-going edge.

Figure 6. Flyback stage waveforms at 115 V -

60 Hz – light load

Figure 7. Flyback stage waveforms at 230 V-

50 Hz – light load

CH1: Drain voltage CH2: CS pin voltage CH1: Drain voltage CH2: CS pin voltage

CH3: ZCD pin CH4: Bulk voltage CH3: ZCD pin CH4: Bulk voltage

3.1 Standby and no-load operation

In Figure 8 and Figure 9, some no-load waveforms are captured. As shown, the L6566B

works in burst mode. When the feedback voltage at the COMP pin falls below 2.65 V

(typical), the IC is disabled and its consumption is reduced. The chip is re-enabled as the

voltage on the COMP pin rises over this threshold again. Therefore, the residual

consumption of the PFC control circuitry is minimized to a negligible level.

Figure 8. No-load operation at 90 V-50 Hz Figure 9. No-load operation at 265 V-50 Hz

CH1: Drain voltage CH2: COMP pin CH1: Drain voltage CH2: COMP pin

CH3: Output voltage CH4: Bulk voltage CH3: Output voltage CH4: Bulk voltage

12/25 Doc ID 16493 Rev 1

Page 13

AN3089 Functional check

In Figure 10 and Figure 11 the transitions from full load to no-load and vice versa, at

maximum input voltage, have been checked. The maximum input voltage has been chosen

because it is the most critical input voltage for transition: in fact, at no-load the burst pulses

have the lower repetition frequency and the Vcc may drop, causing restart cycles of the

controller. As shown, both transitions are clean and there isn’t any output voltage or Vcc dip.

Figure 10. Transition full load to no-load at

265 Vac-50 Hz

Figure 11. Transition no-load to full load at 265

Vac-50 Hz

CH1: Drain voltage CH2: Vcc CH1: Drain voltage CH2: Vcc

CH3: Output voltage CH4: Output current CH3: Output voltage CH4: Output current

3.2 Overcurrent and short-circuit protection

In this demonstration board the overcurrent is managed by the TSM1014 (U3), a CC/CV

controller. Inside the IC there is a voltage reference and two Or-ed operational amplifiers,

one dedicated to act as the error amplifier of the voltage loop, and the second dedicated to

act as the error amplifier of the current loop. During normal operation the voltage feedback

loop is working, while in the case where the output current exceeds the programmed value,

the current loop error amplifier takes over, therefore keeping the output current constant.

In case of a dead-short, the current cannot be limited effectively by U5 because the output

voltage drops, and so it is un-powered, therefore the primary controller must manage the

failure condition.

In case of output short, there are two different possible situations which the controller must

handle: if the coupling between the secondary winding and the auxiliary winding is good, as

soon as the output voltage drops, the auxiliary voltage drops as well and the IC supply

voltage falls below the under voltage lock-out threshold, causing the L6566B to stop

switching. It remains in the off-state until the voltage on the Vcc pin decreases below the

Vcc

threshold (5 V), then, the HV startup turns on and charges the Vcc capacitor; as

restart

soon as the turn-on threshold is reached, the circuit restarts. If the short is still there, the

circuit just attempts to restart but it stops after a few milliseconds. Restart attempts are

repeated indefinitely until the short is removed. This provides a very low frequency hiccup

working mode (for this board 1 Hz), limiting the current flowing at the secondary side (less

than 1 Arms) preventing the power supply from overheating, which could destroy it.

In the case where the coupling between the auxiliary and secondary winding is poor, some

spikes on the auxiliary voltage may keep Vcc above the UVLO threshold for a period long

enough to damage the converter. In this case the L6566B detects a short-circuit by

Doc ID 16493 Rev 1 13/25

Page 14

Functional check AN3089

monitoring the control pins: in the case of a short, the COMP pin goes high, and an internal

comparator activates a current source that restarts charging the soft-start capacitor from the

initial 2 V level. If the voltage on this pin reaches 5 V, the L6566B stops the operation and it

restarts with a startup sequence when the Vcc voltage drops below the V

entering into the so-called “Hiccup mode”.

CCrestart

level (5 V),

Figure 12. Short-circuit at full

load and 230 Vac – 50 Hz

CH1: Gate voltage CH2: Vcc CH1: Drain voltage CH2: Vcc

CH3: SS pin voltage CH4: Output current CH3: SS pin voltage CH4: Output current

In Figure 12 we can see that, in this case, the IC supply voltage drops to the UVLO

threshold (10 V), causing controller turn-off before the SS pin signal achieves the disable

threshold (5 V). This happens because the transformer leakage inductance is very low and

once the output voltage drops, the auxiliary voltage also immediately drops. Furthermore, in

the image we can note that during the SS voltage ramping up the transferred power is

limited.

Figure 13. Short-circuit detail at full

load and 230 Vac – 50 Hz

3.3 Overvoltage and open-loop protection

The L6566B OVP function monitors the voltage on the ZCD pin (#11) during the MOSFET’s

OFF-time, when the voltage generated by the auxiliary winding tracks the converter’s output

voltage. If the voltage on the pin exceeds an internal 5 V reference, an overvoltage condition

is assumed and the device is shut down. An internal current generator is activated which

sources 1 mA out of the VFF pin (#15). If the VFF voltage is allowed to reach 2 VBE over 5

V, the L6566B is latched off (Figure 14). As soon as the IC is latched, Vcc starts decreasing

until it reaches a value 0.5 V below the turn-on threshold. Then the HV startup circuit turns

on and begins to operate periodically in order to keep Vcc between VCCON and VCCON-

0.5V (Figure 15), maintaining the IC latched.

Additionally, to improve immunity against temporary disturbances (needed for example in

case of immunity tests), an internal logic activates the protection after the OVP has been

detected for 4 consecutive switching cycles.

14/25 Doc ID 16493 Rev 1

Page 15

AN3089 Functional check

Figure 14. Flyback open-loop – detail

at 230 V - 50 Hz - half load

CH1: V

voltage CH2: Vcc CH1: VFF voltage CH2: Vcc

FF

Figure 15. Flyback open-loop

at 230 V - 50 Hz - half load

CH3: ZCD voltage CH4: Output voltage CH3: ZCD voltage CH4: Output voltage

Doc ID 16493 Rev 1 15/25

Page 16

Thermal map AN3089

4 Thermal map

In order to check the design reliability, a thermal mapping by means of an IR camera was

done. In Figures 16 and 17 the thermal measurements of the board, component side, at

nominal input voltage are shown. Some pointers visible in the images have been placed

across key components or components showing high temperature. The ambient

temperature during both measurements was 27 °C.

Figure 16. Thermal map at 115 Vac – 60 Hz - Full load

Figure 17. Thermal map at 230 Vac – 50 Hz - Full load

Table 2. Thermal map reference points

Point Reference Description

A L1 EMI filtering common mode choke

B D1 Bridge rectifier

C D4 Clamping transil

D Q1 Flyback power MOSFET

E R2 Input NTC

F T1 Flyback power transformer

G D2 Output diode

16/25 Doc ID 16493 Rev 1

Page 17

AN3089 Conducted emission pre-compliance test

5 Conducted emission pre-compliance test

Figures 18 and 19 show the average measurement of the conducted noise at full load and

nominal mains voltages. The limits shown on the diagrams are EN55022 Class-Bs, which is

the most popular rule for domestic equipment and has more severe limits compared to

Class-A, dedicated to IT technology equipment. As shown in the diagrams, in all test

conditions the measurements are far below the limits.

Figure 18. CE average measurement at 115 Vac and full load

Figure 19. CE average measurement at 230 Vac and full load

Doc ID 16493 Rev 1 17/25

Page 18

Bill of material AN3089

6 Bill of material

Table 3. EVL6566B-65W-QR demonstration board: bill of material

Des. Part type/part value Description Supplier Case

C1 2N2 Y1 - safety cap. DE1E3KX222M Murata 12x4 mm p10 mm

C2 120 uF - 400 V 400V - aluminium elcap - KXW series Rubycon Dia. 18 mm

C3 330 pF - 2 kV 2kV - disc cercap Murata p8 mm

C4 100N X2 - flm cap - R46-I 3100--M1- Arcotronics 18x5 mm p15 mm

C5 2N2 Y1 - safety cap. DE1E3KX222M Murata 12x4 mm p10 mm

C6 150N X2 - flm cap - R46 KN 3150 - - 01 - Arcotronics

C7 1000 u - 25 V 25V - aluminium elcap - ZL SERIES Rubycon Dia. 13 mm

C8 1000 u - 25 V 25V - aluminium elcap - ZL SERIES Rubycon Dia. 13 mm

C9 22 u - 50 V 50V - aluminium elcap - YXF SERIES Rubycon Dia. 6 mm

C10 100 u - 25 V 25V - aluminium elcap - YXF SERIES Rubycon Dia. 6 mm

C11 47 u - 50 V 50V - aluminium elcap - YXF SERIES Rubycon Dia. 6 mm

C12 1N0 200V cercap - general purpose AVX 1206

C13 22N 50V cercap - general purpose AVX 0805

C14 2N2 50V cercap - general purpose AVX 0805

26x6 mm p22.5

mm

C16 2N2 50V cercap - general purpose AVX 0805

C17 100N 50V cercap - general purpose AVX 0805

C18 100N 50V cercap - general purpose AVX 1206

C19 100N 50V cercap - general purpose AVX 1206

C20 330 pF 50V cercap - general purpose AVX 1206

C21 470N 50V cercap - general purpose AVX 0805

C22 330 pF 50V cercap - general purpose AVX 1206

C23 2N2 50V cercap - general purpose AVX 1206

C26 1N0 50V cercap - general purpose AVX 1206

C27 100N 50V cercap - general purpose AVX 0805

C28 10N 50V cercap - general purpose AVX 1206

C29 100N 50V cercap - general purpose AVX 0805

C30 47 pF 50V cercap - general purpose AVX 1206

D1 GBU4J SIngle-phase bridge rectifier VISHAY GBU STYLE

D2 STPS20H100CFP HV power Schottky rectifier STMicroelectronics TO - 220 FP

D3 STPS20H100CFP HV power Schottky rectifier STMicroelectronics TO - 220 FP

D4 1.5 KE300A Transil STMicroelectronics DO-201

D5 S1M High voltage rectifier Vishay SMA

18/25 Doc ID 16493 Rev 1

Page 19

AN3089 Bill of material

Table 3. EVL6566B-65W-QR demonstration board: bill of material (continued)

Des. Part type/part value Description Supplier Case

D6 BZV55-B18 Zener diode Philips SOD-80

D7 S07M High voltage diode Vishay SMF DO-219AB

D10 LL4148 Fast switching diode Vishay SOD-80

D12 STTH102A Fast switching diode STMicroelectronics SMA

D13 S07M High voltage diode Vishay SMF D0-219AB

D14 LL4148 Fast switching diode Vishay SOD-80

F1 392/TE05 - 4A Fuse T4A - time delay Littelfuse DWG

HS1 Heatsink Bridge rect. and MOSFET heatsink - DWG

HS2 Heatsink Output rectifiers heatsink - DWG

J1 MKDS 1,5/ 2-5.08 Screw conn., pitch 5.08 mm - 2 w. Phoenix contact DWG

J2 MKDS 1,5/ 2-3.81 Screw conn., pitch 3.81 mm - 2 w. Phoenix contact DWG

L1 HF2826-203Y1R5-T01 Input EMI filter TDK DWG

L2 1071.0083 1.1uH-5A - radial inductor MAGNETICA Dia. 9mm p5mm

Q1 STF7NM80 N-channel power MOSFET STMicroelectronics TO-220FP

Q2 BC847C NPN small signal BJT ZETEX SOT-23

Q3 BC847C NPN small signal BJT ZETEX SOT-23

Q4 BC847C NPN small signal BJT ZETEX SOT-23

R2 NTC 1R-S237 NTC resistor P/N B57237S0100M000 EPCOS 12x4mm p10mm

R3 M57703 Thermistor - B57703M103G EPCOS DWG

R4 2K2 SMD film res - 1/4W - 5% - 250ppm/°C Vishay 1206

R5 100 K SMD film res - 1/8W - 5% - 250ppm/°C Vishay 0805

R6 3R9 SMD film res - 1/4W - 5% - 250ppm/°C Vishay 1206

R7 3R9 SMD film res - 1/4W - 5% - 250ppm/°C Vishay 1206

R8 4K7 SMD film res - 1/8W - 5% - 250ppm/°C Vishay 0805

R9 1K8 SMD film res - 1/8W - 5% - 250ppm/°C Vishay 0805

R10 3M9 SMD film res - 1/4W - 5% - 100ppm/°C Vishay 1206

R11 91 K SMD film res - 1/4W - 1% - 100ppm/°C Vishay 0805

R12 3M9 SMD film res - 1/4W - 1% - 100ppm/°C Vishay 1206

R14 33R SMD film res - 1/8W - 5% - 250ppm/°C Vishay 0805

R15 100 K SMD film res - 1/8W - 5% - 250ppm/°C Vishay 0805

R16 0R33 MSR1 SMD film res - 1W - 5% - 250ppm/°C MEGGIT 2512

R17 470 R SMD film res - 1/4W - 5% - 250ppm/°C Vishay 1206

R19 2K7 SMD film res - 1/4W - 1% - 100ppm/°C Vishay 1206

R20 680K SMD film res - 1/4W - 1% - 100ppm/°C Vishay 1206

R21 180K SMD film res - 1/8W - 1% - 100ppm/°C Vishay 0805

Doc ID 16493 Rev 1 19/25

Page 20

Bill of material AN3089

Table 3. EVL6566B-65W-QR demonstration board: bill of material (continued)

Des. Part type/part value Description Supplier Case

R23 12K SMD film res - 1/8 W - 1% - 100ppm/°C Vishay 0805

R24 6R8 SMD film res - 1/4 W - 5% - 250ppm/°C Vishay 1206

R25 10K SMD film res - 1/8 W - 5% - 250ppm/°C Vishay 0805

R26 15K SMD film res - 1/4 W - 5% - 250ppm/°C Vishay 1206

R28 1K0 SMD film res - 1/8 W - 5% - 250ppm/°C Vishay 0805

R29 22K SMD film res - 1/8 W - 5% - 250ppm/°C Vishay 0805

R30 1K0 SMD film res - 1/4 W - 5% - 250ppm/°C Vishay 1206

R31 R015 MSR1 SMD FILM RES - 1 W - 5% - 250ppm/°C MEGGIT 2512

R32 12K SMD film res - 1/8 W - 5% - 250ppm/°C Vishay 0805

R33 220K SMD film res - 1/4 W - 5% - 250ppm/°C Vishay 1206

R35 39K SMD film res - 1/4 W - 5% - 250ppm/°C Vishay 1206

R36 47K SMD film res - 1/8 W - 5% - 250ppm/°C Vishay 0805

R37 24K SMD film res - 1/8 W - 1% - 100ppm/°C Vishay 0805

R38 4K7 SMD film res - 1/8 W - 1% - 100ppm/°C Vishay 0805

R40 100K SMD film res - 1/4 W - 5% - 250ppm/°C Vishay 1206

R41 2K2 SMD film res - 1/8 W - 5% - 250ppm/°C Vishay 0805

R42 1K SMD film res - 1/4 W - 5% - 250ppm/°C Vishay 1206

R43 3K9 SMD film res - 1/8 W - 5% - 250ppm/°C Vishay 0805

R45 56K SMD film res - 1/4 W - 1% - 100ppm/°C Vishay 1206

R46 22R SMD film res - 1/8 W - 5% - 250ppm/°C Vishay 0805

T1 1972.0005 Power transformer MAGNETICA DWG

U1 SFH617A-4 Optocoupler Infineon DIP-4

U2 L6566B Multi-mode pwm controller STMicroelectronics SO-16

U3 TSM1014AIST Low consumption CC/CV controller STMicroelectronics MiniSO-8

20/25 Doc ID 16493 Rev 1

Page 21

AN3089 Transformer specification

7 Transformer specification

General description and characteristics

● Application type: consumer, home appliance

● Transformer type: open

● Coil former: horizontal type, 6+6 pins

● Max. temp. rise: 45 ºC

● Max. operating ambient temperature: 60 ºC

● Mains insulation: acc. with EN60950

Electrical characteristics

● Converter topology: QR flyback

● Core type: EER28L-PC44 or equivalent

● Typical operating frequency: 100 kHz

● Primary inductance: 500 µH±10% at 1 kHz-0.25 V

Leakage inductance: 5 µH Max at 100 kHz-0.25 V

●

(a)

(b)

Figure 20. Transformer

""

Table 4. Transformer winding data

Pins Winding RMS current

3-1 PRIMARY A

9-7 SEC - A

10-8 SEC - B

2-3 PRIMARY B

(1)

(2)

(2)

(1)

6-5 AUX 0.05 A

1. Secondary windings are wound between primary A and primary B layers

2. Secondary windings A and B are in parallel

0.84 A

2.9 A

2.9 A

0.84 A

RMS

RMS

RMS

RMS

RMS

Number of

turns

Wire type

27 G1 φ 30x0.1 mm

7 G1 φ 90x0.1 mm

7 G1 φ 90x0.1 mm

27 G1 φ 30x0.1 mm

6 spaced G2 φ 0.25 mm

a. Measured between pins 2-1

b. Measured between pins 2-1 with secondary windings shorted

Doc ID 16493 Rev 1 21/25

Page 22

Transformer specification AN3089

Figure 21. Transformer winding diagram

Mechanical aspect and pin numbering

● Maximum height from PCB: 26 mm

● Coil former type: horizontal, 6+6 pins (pins 4, 11 and 12 removed)

● Pin distance: 5.08 mm

● Row distance: 30 mm

● External copper shield: not insulated, wound around the ferrite core and including the

coil former. Height is 12 mm.

22/25 Doc ID 16493 Rev 1

Page 23

AN3089 Transformer specification

Figure 22. Transformer mechanical diagrams

Manufacturer

● MAGNETICA - Italy

● Transformer P/N: 1972.0005

Doc ID 16493 Rev 1 23/25

Page 24

Revision history AN3089

8 Revision history

Table 5. Document revision history

Date Revision Changes

01-Jul-2010 1 Initial release.

24/25 Doc ID 16493 Rev 1

Page 25

AN3089

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2010 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 16493 Rev 1 25/25

Loading...

Loading...