Page 1

AN3029

Application note

Getting started with STM8L

Introduction

This application note complements the information in the STM8L datasheets by describing

the minimum hardware and software environment required to build an application around an

STM8L 8-bit microcontroller device.

It applies to low density STM8L101x, medium and medium+ density STM8L15x, and high

density STM8L15x/16x devices.

A brief description of the principal hardware components is given. The power supply,

analog-to-digital converter (ADC), clock management, and reset control are described in

some detail. In addition, some hardware recommendations are given. This application note

also contains detailed reference design schematics with descriptions of the main

components. The STM8L uses the same toolchain The STM8 development tools and

software toolchain are common to STM8L, STM8S and STM8A and are presented in

Section 8, and 9. Section 10 describes how to set up the STM8 development environment.

Finally, Section 11 provides a list of relevant documentation and online support resources.

March 2011 Doc ID 16139 Rev 3 1/42

www.st.com

Page 2

Contents AN3029

Contents

1 Hardware requirements summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Power supply overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Main operating voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Power-on/power-down reset (POR/PDR) . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Analog-to-digital converter (ADC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Analog power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Analog input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Clock management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 Clock management overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Internal clocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.3 External clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.3.1 HSE clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.3.2 LSE clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Reset control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1 Reset management overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.1 Output characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.1.2 Input characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2 Hardware reset implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1 Printed circuit board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2 Component position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.3 Ground and power supply (V

6.4 Decoupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.5 Other signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

, VDD) . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SS

6.6 Unused I/Os and features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.7 User options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.8 Bootloader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2/42 Doc ID 16139 Rev 3

Page 3

AN3029 Contents

7 Reference design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.1 Component references . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.2 Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

8 STM8 development tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8.1 Single wire interface module (SWIM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8.1.1 SWIM overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8.1.2 SWIM connector pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.1.3 Hardware connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.2 STice emulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.2.1 STice overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.2.2 STice in emulation configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.2.3 In-circuit programming and debugging . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.3 RLink and STLink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

9 STM8 software toolchain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9.1 Integrated development environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9.2 Compiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9.3 Firmware library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

10 Setting up the STM8 development environment . . . . . . . . . . . . . . . . . 29

10.1 Installing the tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10.2 Using the tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

10.2.1 Project editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

10.2.2 Online help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10.3 Running the demonstration software . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10.3.1 Compiling the project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10.3.2 Selecting the correct debug instrument . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.3.3 Connecting the hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.3.4 Starting the debug session . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

10.3.5 Running the software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

10.3.6 Follow up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

11 Documentation and online support . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

12 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Doc ID 16139 Rev 3 3/42

Page 4

List of tables AN3029

List of tables

Table 1. Component list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 2. SWIM connector pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 3. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4/42 Doc ID 16139 Rev 3

Page 5

AN3029 List of figures

List of figures

Figure 1. Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 2. Typical layout of V

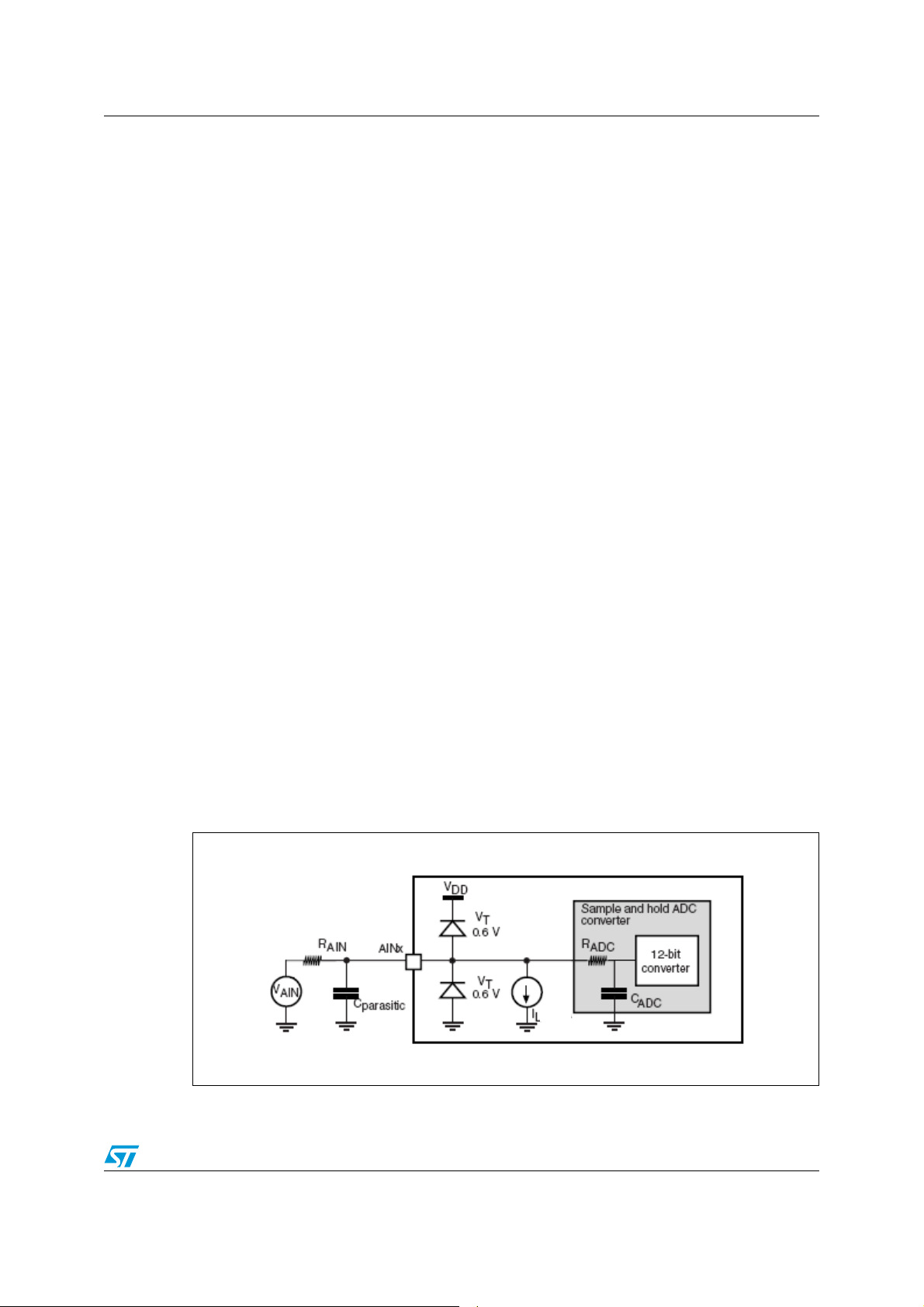

Figure 3. Analog input interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

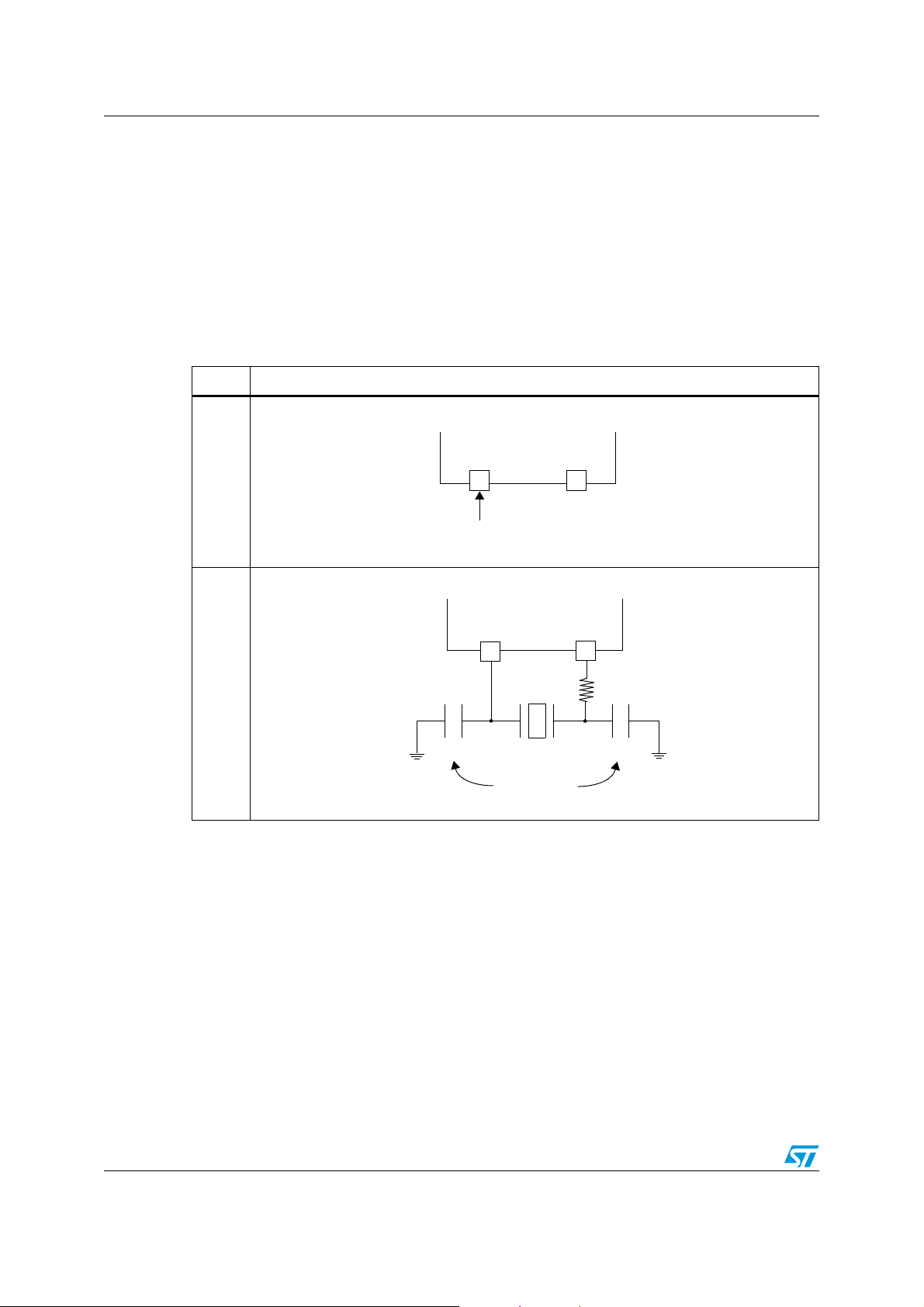

Figure 4. HSE clock sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

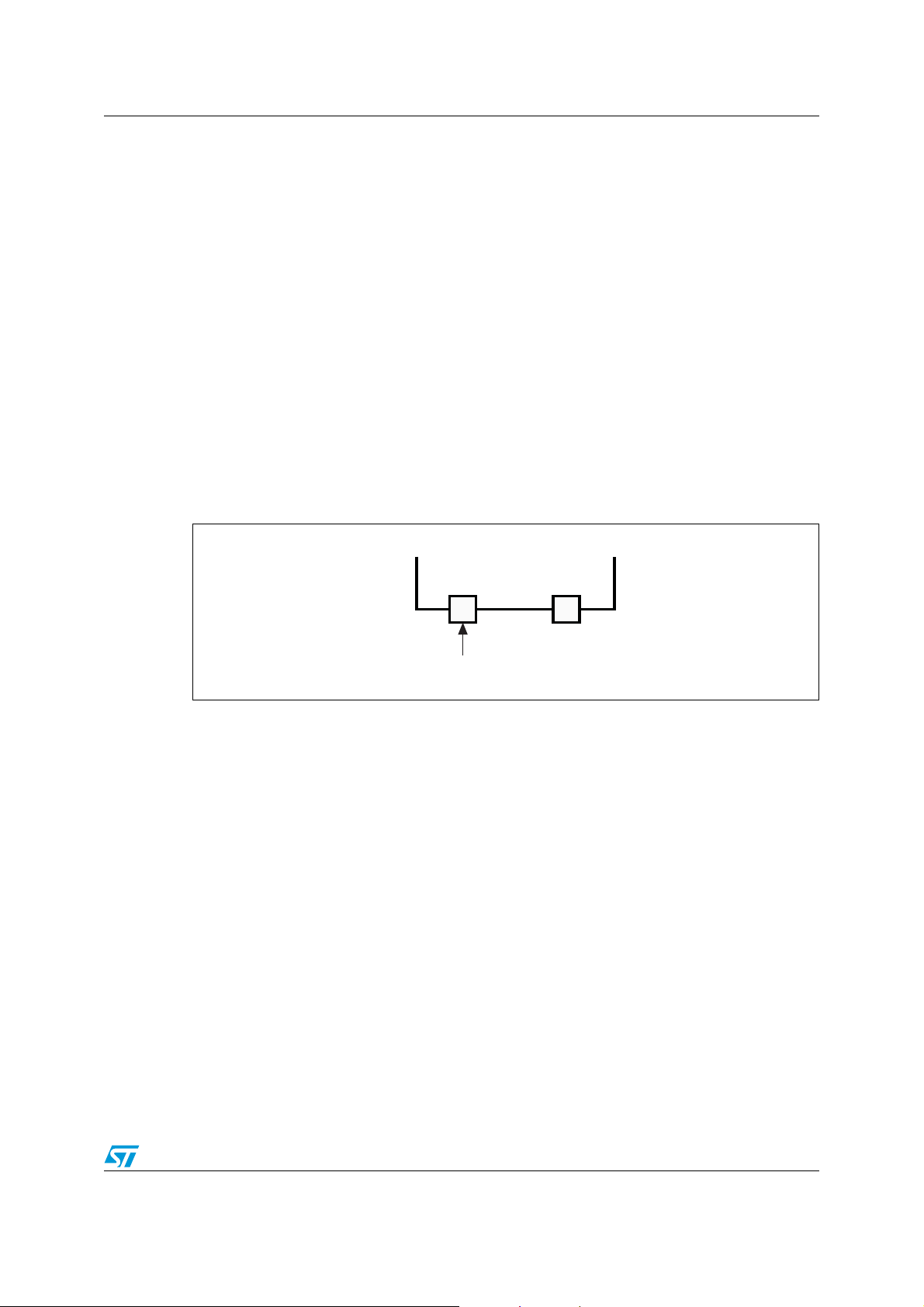

Figure 5. External clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 6. Crystal/ceramic resonators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 7. Reset management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 8. Output characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 9. Output characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 10. Input characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 11. Reference design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

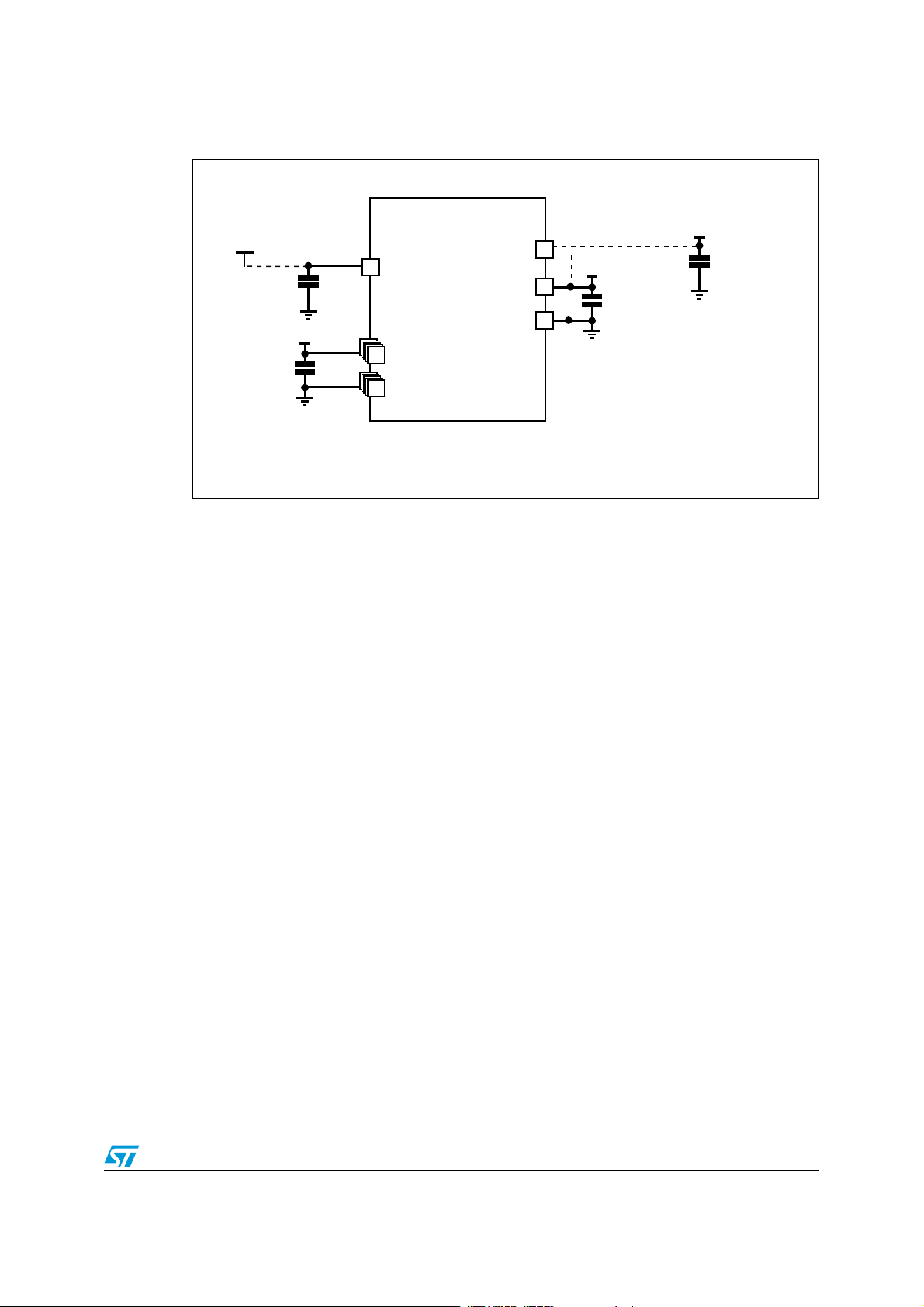

Figure 12. Debug system block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 13. Hardware connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 14. Connection description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 15. STice in emulation configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 16. In-circuit programming and debugging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 17. STM8 software toolchain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 18. STVD open example workspace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 19. STVD MCU edit mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 20. STM8 firmware library online help manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 21. STVD: Building the project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 22. STVD: Selecting the debug instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 23. Connecting the debug instrument to the STM8L101-EVAL evaluation board . . . . . . . . . . 35

Figure 24. Connecting the debug instrument to the STM8L152x-EVAL evaluation board . . . . . . . . . 36

Figure 25. STVD: Starting the debug session . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 26. STVD: Run the software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 27. STM8 evaluation board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

DD/VSS

pair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Doc ID 16139 Rev 3 5/42

Page 6

Hardware requirements summary AN3029

1 Hardware requirements summary

To build an application around an STM8L device, the application board should provide the

following features:

● Power supply (mandatory)

● Clock management (optional)

● Reset management (optional)

● Debugging tool support: Single wire interface module (SWIM) connector (optional)

2 Power supply

2.1 Power supply overview

The STM8L can be supplied through a 1.65 V to 3.6 V external source. For medium density

STM8L15x and high density STM8L15x/STM8L16x with BOR, the power supply must be

above 1.8 V at power-on and can go below 1.65 V at power-down.

An on-chip power management system provides the constant digital supply to the core logic,

both in normal and low power modes. This garantees that the logic consumes a constant

current over the voltage range. It is also capable of detecting voltage drops and generate

reset to avoid heratic behaviour.

The STM8L device provides:

● Depending on packages, one pair of pads (V

(V

DDx/VSSx

All V

connected to V

for each V

) from 1.65 V or 1.8 V to 3.6 V.

DDx

and V

DDx

must be at the same potential respectively. The V

SSx

with external decoupling capacitors: one 100 nF Ceramic capacitor

DD

pin and one single 1 µF Tantalum or Ceramic capacitor.

DD/VSS

), or several pairs of pads

pins must be

DDx

The STM8L15x and STM8L16x devices also provide in some packages:

● One pair of pads, V

DDA/VSSA

the same potential respectively as V

converter (ADC) for more details. The V

, dedicated to analog functions. V

and VSS. Refer to Section 3: Analog-to-digital

DD

pin must be connected to two external

DDA

DDA

and V

must be at

SSA

decoupling capacitors (one 100 nF Ceramic capacitor and one single 1 µF Tantalum or

Ceramic capacitor). Additional precautions can be taken to filter analog noise: V

can be connected to V

through a ferrite bead.

DD

DDA

The STM8L152/STM8L162 device manages the supply voltage needed by the LCD in three

different ways (see Figure 1):

1. If the LCD feature is not used, connect the VLCD pin to V

DD

.

2. Apply to VLCD the voltage to be applied to the LCD.

3. Leave the STM8L152/STM8L162 to provide the correct voltage, via its programmable

LCD booster, by connecting the VLCD pin to a 1µF capacitor.

6/42 Doc ID 16139 Rev 3

Page 7

AN3029 Power supply

6

,#$

34-,

.§N&

6

$$

§&

N&&

N&&

NOTE

6

,#$

6

2%&

6

$$!

6

33!

6

$$.

6

33.

6

2%&

6

$$

AIE

&

OPTIONAL

NOTE

NOTE

Figure 1. Power supply

1. Optional: if a separate, external reference voltage is connected on V

µF) must be connected. V

2. N is the number of V

DD

is either connected to V

REF+

and VSS inputs.

DDA

or V

REF.

, the two capacitors (100 nF and 1

REF+

Note: The capacitors must be connected as close as possible to the device supplies.

Placing a crystal/resonator on OSCIN/OSCOUT is optional. The resonator must be

connected as close as possible to the OSCIN and OSCOUT pins. The loading capacitance

ground must be connected as close as possible to V

SS

.

2.2 Main operating voltages

STM8L devices are processed in 0.13 µm technology. The STM8L core and I/O peripherals

need different power supplies. In fact, STM8L devices have an internal regulator with a

nominal target output of 1.8 V.

Doc ID 16139 Rev 3 7/42

Page 8

Power supply AN3029

Via to V

SS

Via to V

DD

Cap.

VDDV

SS

STM8

2.3 Power-on/power-down reset (POR/PDR)

The input supply to the main and low power regulators is monitored by a power-on/powerdown reset circuit. The monitoring voltage begins at 0.7 V.

During power-on, the POR/PDR keeps the device under reset until the supply voltages (V

and V

) reach their specified working area. This internal reset is maintained during ~1ms

DDA

DD

in order to wait for supply stabilization.

At power-on, a defined reset should be maintained below 0.7 V. The upper threshold for a

reset release is defined in the electrical characteristics section of the product datasheets.

A hysteresis is implemented (POR > PDR) to ensure clean detection of voltage rise and fall.

The POR/PDR also generates a reset when the supply voltage drops below the V

POR/PDR

threshold (isolated and repetitive events).

For better power monitoring, the STM8L15x and STM8L16x provide a programmable power

voltage detection (PVD) and a brown out reset (BOR) for an earlier detection of voltage

drop.

Recommendations

All pins need to be properly connected to the power supplies. These connections, including

pads, tracks and vias should have the lowest possible impedance. This is typically achieved

with thick track widths and preferably dedicated power supply planes in multi-layer printed

circuit boards (PCBs).

In addition, each power supply pair should be decoupled with filtering ceramic capacitors (C)

at 100 nF with one chemical C (1..2 µF) in parallel on the STM8L device. The ceramic

capacitors should be placed as close as possible to the appropriate pins, or below the

appropriate pins, on the opposite side of the PCB. Typical values are 10 nF to 100 nF, but

exact values depend on the application needs. Figure 2 shows the typical layout of such a

V

DD/VSS

pair.

Figure 2. Typical layout of V

8/42 Doc ID 16139 Rev 3

DD/VSS

pair

Page 9

AN3029 Analog-to-digital converter (ADC)

STM8L15x/STM8L16x

3 Analog-to-digital converter (ADC)

This section is unique for the STM8L15x and STM8L16x.

3.1 Analog power

For some packages, the ADC unit has an independent, analog supply voltage, isolated on

input pin V

voltage, V

noise, a ferrite bead can be added between V

choosen according to the frequencies to be filtered.

Some packages also provide a separate external analog reference voltage input for the ADC

unit on the V

● The V

external reference voltage is applied on V

connected on this pin. To compensate for peak consumption on V

capacitor may be increased to 10 µF when the sampling speed is low. In all cases,

V

REF+

equal to V

internal V

● V

REF-

internally bonded to V

, which allows the ADC to accept a very clean voltage source. This analog

DDA

, should be identical to the digital voltage supply on pin VDD. To filter some

DDA

pin. This gives better accuracy on low voltage input as follows:

REF+

pin can be connected to the V

REF+

must be kept between 2.4 V and V

. This input is internally bonded to V

DDA

pin.

REF+

and V

DD

external power supply. If a separate,

DDA

, a 100 nF and a 1 µF capacitor must be

REF+

. If V

DDA

. This ferrite bead should be

DDA

, the 1 µF

REF

is below 2.4, V

DDA

in the devices that have no

DDA

REF+

must be

(input, analog reference negative): The lower/negative reference voltage is

.

SSA

3.2 Analog input

STM8L15x and STM8L16x devices have up to 28 analog input channels (including four fast

channels), each multiplexed with an I/O, which are converted by the ADC one at a time.

The external input impedance (R

at maximum speed (1 MHz) if R

Please refer to Figure 3.

Figure 3. Analog input interface

) max value is 50 kΩ.The four fast channels can convert

AIN

is less than 0.5 kΩ.

AIN

Doc ID 16139 Rev 3 9/42

Page 10

Analog-to-digital converter (ADC) AN3029

Please refer to the STM8L15x and STM8L16x datasheets and reference manuals for more

details.

10/42 Doc ID 16139 Rev 3

Page 11

AN3029 Clock management

4 Clock management

The STM8L101 has no external clock so no precautionary measures are needed.

4.1 Clock management overview

STM8L15x and STM8L16x devices offer a flexible way of selecting the core and peripheral

clocks (ADC, memory, and digital peripherals). The devices have internal and external clock

source inputs, both of which have a high speed and a low speed version. Any of those four

clocks can be use for the CPU and most of the peripherals through a programable prescaler.

An I/O can be programmed as output clock (CCO) to reflect one of the four clocks (with or

without prescaling).

The signal which leaves the I/O represents an output clock (CCO) divided by a division

factor.

4.2 Internal clocks

STM8L devices have two kinds of internal clock: A high speed internal clock (HSI) running at

16 MHz and a low speed internal clock (LSI) running at 38 kHz.

After reset, the CPU starts with the internal RC (HSI clock signal) divided by 8, i.e. 2 MHz.

4.3 External clock

STM8L15x and STM8L16x devices have two kinds of external clock: A high speed external

clock (HSE) running at up to 16 MHz and a low speed external clock (LSE) running at

32.768 kHz.

4.3.1 HSE clock

STM8L15x and STM8L16x devices can connect to an external crystal or an external

oscillator.

Note: When no external clock is used, OSCIN and OSCOUT can be used as general purpose

I/Os.

Figure 4 describes the external clock connections.

External clock

● Frequency: 0 kHz … 16 MHz

● Input hysteresis: 100 mV

Caution: Without prescaler, a duty cycle of 45/55 % maximum must be respected at high speed

Doc ID 16139 Rev 3 11/42

Page 12

Clock management AN3029

OSC

IN

OSC

OUT

External source

STM8

(I/O available)

Load capacitors

STM8

C

L2

C

L1

Q1

OSC

IN

OSC

OUT

R

EXT

(1)

Crystal/ceramic resonator

● Frequency range: 1 to 16 MHz

● Stabilisation time: Programable from 1 to 4096 cycles

● Oscillation mode: Preferred fundamental

● Output duty cycle: Max 55/45%

● I/O’s: Standard I/O pins multiplexed with OSC

●

Cload: 10 to 20 pF

● Drive level maximum: at least 100 µW

Figure 4. HSE clock sources

Hardware configuration

External clock

and OSC

IN

OUT

(1)

Crystal/ceramic resonators

1. The value of R

but, it is not optimal. A typical value is in the range 5 to 6 RS (resonator series resistance). To fine-tune the

R

value, refer to AN2867 (Oscillator design guide for ST microcontrollers).

EXT

The values of the load capacitors C

depends on the crystal characteristics. A 0 resistor works well with most oscillators

EXT

and CL2 are heavily dependent on the crystal type and

L1

frequency. Refer to the datasheet of the crystal manufacturer to select the capacitances. For

best oscillation stability, C

and CL2 normally have the same value. Typical values are in the

L1

range from below 20 pF up to 40 pF (cload: 10 to 20 pF). The parasitic capacitance of the

board layout also needs to be considered and typically adds a few pF to the component

values (refer to AN2867).

A clock security system prevents any CPU fatal error from a HSE failure, as it safely

switches to HSI.

12/42 Doc ID 16139 Rev 3

Page 13

AN3029 Clock management

OSC32_OUTOSC32_IN

External source

(Hi-Z)

ai15765

Microcontroller

Recommendations

In the PCB layout all connections should be as short as possible. Any additional signals,

especially those that could interfere with the oscillator, should be locally separated from the

PCB area around the oscillation circuit using suitable shielding.

4.3.2 LSE clock

The low-speed external clock signal (LSE) can be generated from two possible clock

sources:

● LSE external crystal/ceramic resonator (see Figure 6)

● LSE user external clock (see Figure 6)

External source (LSE bypass)

In this mode, an external clock source must be provided. It must have a frequency of

32.768 kHz. The external clock signal (square, sine or triangle) with a duty cycle of about

50% has to drive the OSC32_IN pin while the OSC32_OUT pin must be left high impedance

(see Figure 6 and Figure 6).

Figure 5. External clock

1. OSC32_IN and OSC32_OUT pins can be used also as GPIO but, it is recommended not to use them as

both RTC and GPIO pins in the same application.

External crystal/ceramic resonator (LSE crystal)

The LSE crystal is a 32.768 kHz low-speed external crystal or ceramic resonator. It has the

advantage of providing a low-power, but highly accurate clock source to the real-time clock

peripheral (RTC) for clock/calendar or other timing functions.

The resonator and the load capacitors have to be connected as close as possible to the

oscillator pins in order to minimize output distortion and start-up stabilization time. The load

capacitance values must be adjusted according to the selected oscillator.

Doc ID 16139 Rev 3 13/42

Page 14

Clock management AN3029

OSC32_OUTOSC32_IN

ai15764

C

L1

C

L2

Microcontroller

R

EXT

(3)

Figure 6. Crystal/ceramic resonators

1. To avoid exceeding the maximum value of CL1 and CL2 (15 pF), it is strongly recommended to use a

resonator with a load capacitance C

AN2867 (Oscillator design guide for ST microcontrollers).

2. OSC32_IN and OSC32_OUT pins can be used also as GPIO, but it is recommended not to use them as

both RTC and GPIO pins in the same application.

3. The value of R

typical value is in the range 5 to 6 RS. To fine-tune the R

for ST microcontrollers).

depends on the crystal characteristics. A 0 resistor works with most oscillators. A

EXT

= 7 pF. To fine-tune the choice, refer to the g

L

value refer to AN2867 (Oscillator design guide

EXT

calculation in

mcrit

14/42 Doc ID 16139 Rev 3

Page 15

AN3029 Reset control

2

05

6

$$?)/

0ULSE

GENERATOR

MINS

3YSTEMRESE

T

&ILTER

N&

%XTERNAL

RESETCIRCUIT

.234

AIC

*MMFHBMPQDPEFSFTFU

4XJNSFTFU

103#03SFTFU

*8%(88%(TPGUXBSFSFTFU

$ELAY

34-

5 Reset control

5.1 Reset management overview

The reset pin is a 3.3 V bidirectional I/O. After startup it can be programmed by software to

be used as a general purpose I/O.

Its output buffer driving capability is fixed to Iol

= 2 mA @ 0.45 V in the 1.8 V to 3.6 V

MIN

range which includes a ~45 k pull-up. Output buffer is reduced to the n-channel MOSFET

(NMOS). The receiver includes a glitch filter, whereas the output buffer includes a 20 µs

delay.

There are many reset sources, including:

● External reset through the NRST pin

● Power-on reset (POR) and brown-out reset (BOR): During power-on, the POR keeps

the device under reset until the supply voltage (V

DD

and V

) reach the voltage level

DDx

at which level the BOR starts to function. STM8L101 has only a POR.

● Independent watchdog reset (IWDG)

● Window watchdog reset (WWDG), featuring also software reset: only for STM8L15x

and STM8L16x.

● SWIM reset: An external device connected to the SWIM interface can request the

SWIM block to generate a microcontroller reset.

● Illegal opcode reset: If a code to be executed does not correspond to any opcode or

prebyte value, a reset is generated.

Figure 7 shows a simplified functional I/O reset schematic.

Figure 7. Reset management

Doc ID 16139 Rev 3 15/42

Page 16

Reset control AN3029

20 n

20 µs pulse stretch min

A

Pad

Reset requested

Pad

System reset

>5 ns >5 ns

<50 ns <50 ns <50 ns

300 ns

Valid Reset requestedNegative train of glitch filtered

5.1.1 Output characteristics

● A valid pulse on the pin is guaranteed with a 20 ns pulse duration on the internal

output buffer.

● After a valid pulse is recognized, a pulse on the pin of at least 20 µs is guaranteed

starting from the falling edge of A.

Figure 8. Output characteristics

Figure 9. Output characteristics

5.1.2 Input characteristics

● All pulses with a duration less than 50 ns are filtered

● All train/burst spikes with a ratio of 1/10 must be filtered. This means that a negative

spike of up to 50 ns is always filtered, when a 5 ns interval between spikes occurs (ratio

1/10).

● All pulses with duration more than 300 ns are recognized as valid pulses

Figure 10. Input characteristics

16/42 Doc ID 16139 Rev 3

Page 17

AN3029 Reset control

5.2 Hardware reset implementation

The STM8L does not require an external reset circuit to power-up correctly. Only a pulldown capacitor is recommended (see Figure 7). However, charging/discharging the pulldown capacitor through an internal resistor has a negative influence on the device power

consumption. Therefore, the recommended capacitor value of 100 nF can be reduced down

to 10 nF to limit such power consumption.

The STM8L101 reset state is released 1 ms after the POR value (1.35 V to 1.65 V) is

reached. At this time, V

For medium density devices and medium+ and high density devices operating from 1.8 V at

power-on: the reset state is released 1 ms after the BOR minimum value (~1.75 V) is

reached.

should be in the 1.65 V to 3.6 V range.

DD

Doc ID 16139 Rev 3 17/42

Page 18

Recommendations AN3029

6 Recommendations

6.1 Printed circuit board

For technical reasons, it is best to use a multi-layer PCB with a separate layer dedicated to

the V

good shielding effect. For many applications, economical requirements prohibit the use of

this type of board. In this case, the most important feature is to ensure a good structure for

the V

6.2 Component position

A preliminary layout of the PCB must separate the different circuits according to their

electromagnetic interference (EMI) contribution. This reduces cross-coupling on the PCB,

for instance, noisy, high-current circuits, low voltage circuits, and digital components.

6.3 Ground and power supply (VSS, VDD)

The VSS should be distributed individually to every block (noisy, low level sensitive, and

digital) with a single point for gathering all ground returns. Loops must be avoided or have a

minimum surface. The power supply should be implemented close to the ground line to

minimize the surface of the supply loop. This is due to the fact that the supply loop acts as

an antenna, and is therefore the main emitter and receiver of EMI. All component-free

surfaces of the PCB must be filled with additional grounding to create a kind of shield

(especially when using single-layer PCBs).

and another layer to the VDD supply. This results in a good decoupling, as well as a

SS

and power supply.

SS

6.4 Decoupling

The standard decoupler for the external power is a 1 µF pool capacitor. Supplementary 100

nF capacitors must be placed as close as possible to the V

microcontroller to reduce the area of the current loop.

As a general rule, decoupling all sensitive or noisy signals improves electromagnetic compatibility (EMC) performances.

There are two types of decouplers:

● Capacitors close to components. Inductive characteristics, which apply to all capacitors

beyond a certain frequency, must be taken into account. If possible, parallel capacitors

with decreasing values (0.1, 0.01,... µF) should be used.

● Inductors. Although often ignored, ferrite beads, for example, are excellent inductors

due to their good dissipation of EMI energy and there is no loss of DC voltage (which is

not the case when simple resistors are used).

SS/VDD

pins of the

18/42 Doc ID 16139 Rev 3

Page 19

AN3029 Recommendations

6.5 Other signals

When designing an application, the following areas should be closely studied to improve

EMC performances:

● Noisy signals (clock)

● Sensitive signals (high impedance)

● Signals for which a temporary disturbance permanently affects operation of the

application, for example, interrupts and handshaking strobe signals (but not LED

commands).

A surrounding V

length or absence of noisy and sensitive traces (crosstalk effect).

For digital signals, the best possible electrical margin must be reached for the two logical

states. Slow Schmitt triggers are recommended for eliminating parasitic states.

trace for such signals increases EMC performances, as does a shorter

SS

6.6 Unused I/Os and features

Microcontrollers are designed for a variety of applications, where often a particular

application does not use 100 % of the microcontroller resources.

To avoid unnecessary power consumption (especially important for battery powered

applications) and also to improve EMC performance, unused clocks, counters, or I/Os,

should not be left free, I/Os should be forced externally (pull-up or pull-down to the unused

I/O pins), and unused functions should be ‘frozen’ or disabled.

Alternatively, unused I/Os can be programmed as push-pull ‘low’ to keep them at a defined

level without using external components. However in this case, the I/O is not driven during

the power up phase, until the I/O is configured. This can add a little extra power

consumption, and may be undesirable in very power sensitive applications.

6.7 User options

STM8L devices have user option features that can be used for remapping or

enabling/disabling an automatic reset or low speed watchdog. For more details, please refer

to the product datasheets.

6.8 Bootloader

STM8L15x and STM8L16x devices have a bootloader embedded in a ROM memory.

Through this firmware the device memory can be re-programmed via:

● USART communication interface for medium density devices

● USART1, USART2, USART3, SPI1, and SPI2 communication interfaces for medium+

and high density devices.

Doc ID 16139 Rev 3 19/42

Page 20

Reference design AN3029

7 Reference design

7.1 Component references

Table 1. Component list

ID Component name Reference Quantity Comments

Refer to the ‘pinouts and pin description’

1 Microcontroller STM8L 1

2 Battery 1.65 V to 3.6 V 1 Min 1.8 V when BOR is enabled

3 Capacitor 1 µF n Decoupling capacitor

4 Capacitor 100 nF n Ceramic capacitor (decoupling capacitor)

Components below are optional

5 Capacitor 10 µF 1 Ceramic capacitor (decoupling capacitor)

6 Crystal 1 to 16 MHz 1

7 Capacitor 20 to 40 pF 2 Used for crystal

and ‘package characteristics’ sections of

the STM8L datasheets, to choose the right

package

Crystal 32 kHz 1

8 Capacitor 5 to 20 pF 2 Used for crystal

Ferrite bead Depends on noise to be filtered

9 SWIM connector 4 pins 1

20/42 Doc ID 16139 Rev 3

Page 21

AN3029 Reference design

6

$$

6

$$!

6

2%&

6

33.

6

,#$

.234

/3#?) .

/3#?/54

/3#?).

/3#?/54

"IGGESTPACKAGE

P&

-(Z

/HM

P&

K(Z

P&

P&

(

"%!$

U&

U&

/NLYIF ACCURATE (IGH 3PEED

/SCILLATOR ISNEEDED

U&

/2 /2

6

33

66

6

/HM

0OMZJGBDDVSBUFMPXTQFFE

PTDJMMBUPSJTOFFEFE

*G-$%JTVOVTFE

0OMZJGJOUFSOBM

CPPTUFSJTVTFEUP

QPXFS-$%

SEENOTE

%XTERNALRESETCIRCUIT

4O POWER ,#$

SPECIFICALLY

AIB

SEENOTE

6

$$

6

$$

6

$$

N

&

N

&

N

&

N

&

SEENOTE

N

&

N

&

6

2%&

U&

N

&

6

$$

6

33

6

33

6

$$

6

$$

6

33

66

,#$

6

7.2 Schematics

Figure 11. Reference design

&OR NOISY

ENVIRONMENT

1. If these components are removed, they have to be replaced by a short connection.

2. Optional: if a separate, external reference voltage is connected on V

connected. V

3. One 100 nF Ceramic capacitor for each VDDx pin and one single 1 µF Tantalum or Ceramic capacitor.

is either connected to V

REF+

DDA

or V

REF.

Doc ID 16139 Rev 3 21/42

, the two capacitors (100 nF and 1 µF) must be

REF+

Page 22

STM8 development tools AN3029

SWIM entry

100

kHz Osc

Internal RC

Comm

layer

CMD

decode

DM

STM8

core

Peripheral

NVM

RAM

DBG

8 STM8 development tools

Typically, the following tools are needed to get started:

● STVD for integrated development environment

● STM8 C compiler (from Cosmic, Raisonance, or IAR)

● ST toolset and STM8 firmware library from STMicroelectronics

(STM8L10x_StdPeriph_Lib for STM8L101 or STM8L15x_StdPeriph_Lib for STM8L15x

and STM8L16x).

● STM8 evaluation board from STMicroelectronics (STM8L101-EVAL for STM8L101,

STM8L1526-EVAL for medium density STM8L15x and STM8L1528-EVAL for high

density STM8L15x/STM8L16x).

● If you use STM8L101-EVAL, you also need the HW SWIM debug interface "Rlink" from

Raisonance and ST-Link or STice-SWIM. The debug interface ST-LINK is included in

STM8L1526-EVAL and STM8L1528-EVAL.

8.1 Single wire interface module (SWIM)

8.1.1 SWIM overview

In-circuit debugging mode or in-circuit programming mode are managed through a single

wire hardware interface based on an open-drain line, featuring ultra fast memory

programming. Coupled with an in-circuit debugging module, the SWIM also offers a nonintrusive read/write to RAM and peripherals. This makes the in-circuit debugger extremely

powerful and close in performance to a full-featured emulator.

The SWIM pin can be used as a standard I/O (with 8 mA capability) which has some

restrictions if the user wants to use it for debugging. The most secure way to use it is to

provide a strap option on the PCB. Please refer to the STM8 SWIM communication protocol

and debug module user manual (UM0470) for more SWIM protocol details.

Figure 12. Debug system block diagram

22/42 Doc ID 16139 Rev 3

Page 23

AN3029 STM8 development tools

4

4

1

1

2

3

2

3

AD/ICC SWIM adapter

Application board

STM8

SWIM cable

V

DD

V

DD

SWIM connector

8.1.2 SWIM connector pins

The SWIM connector pins consist of four pins as described in Ta bl e 2 .

Table 2. SWIM connector pins

Pin number Pin name

Pin 1 V

DD

Pin 2 SWIM pin

Pin 3 V

SS

Pin 4 Reset

8.1.3 Hardware connection

Figure 13. Hardware connection

Caution: It is recommended to place the SWIM header as close as possible to the STM8L device, as

this minimizes any possible signal degradation caused by long PCB tracks.

Doc ID 16139 Rev 3 23/42

Page 24

STM8 development tools AN3029

Connection flex

Connection adapter

Adapter socket

Emulation system

8.2 STice emulator

8.2.1 STice overview

The STice is a modular, high-end emulator system which connects to the PC via a USB

interface, and to the application board in place of the target microcontroller.

It is supported by the free STM8 toolset: IDE ST visual develop (STVD) programmer, ST

visual programmer (STVP) and STM8 assembler. Please refer to the STice emulator for

STM8 for more details.

STice has two distinct modes of operation which are described further in this section:

● Emulation mode

● In-circuit mode

It can also be used instead of RLink for SWIM connection.

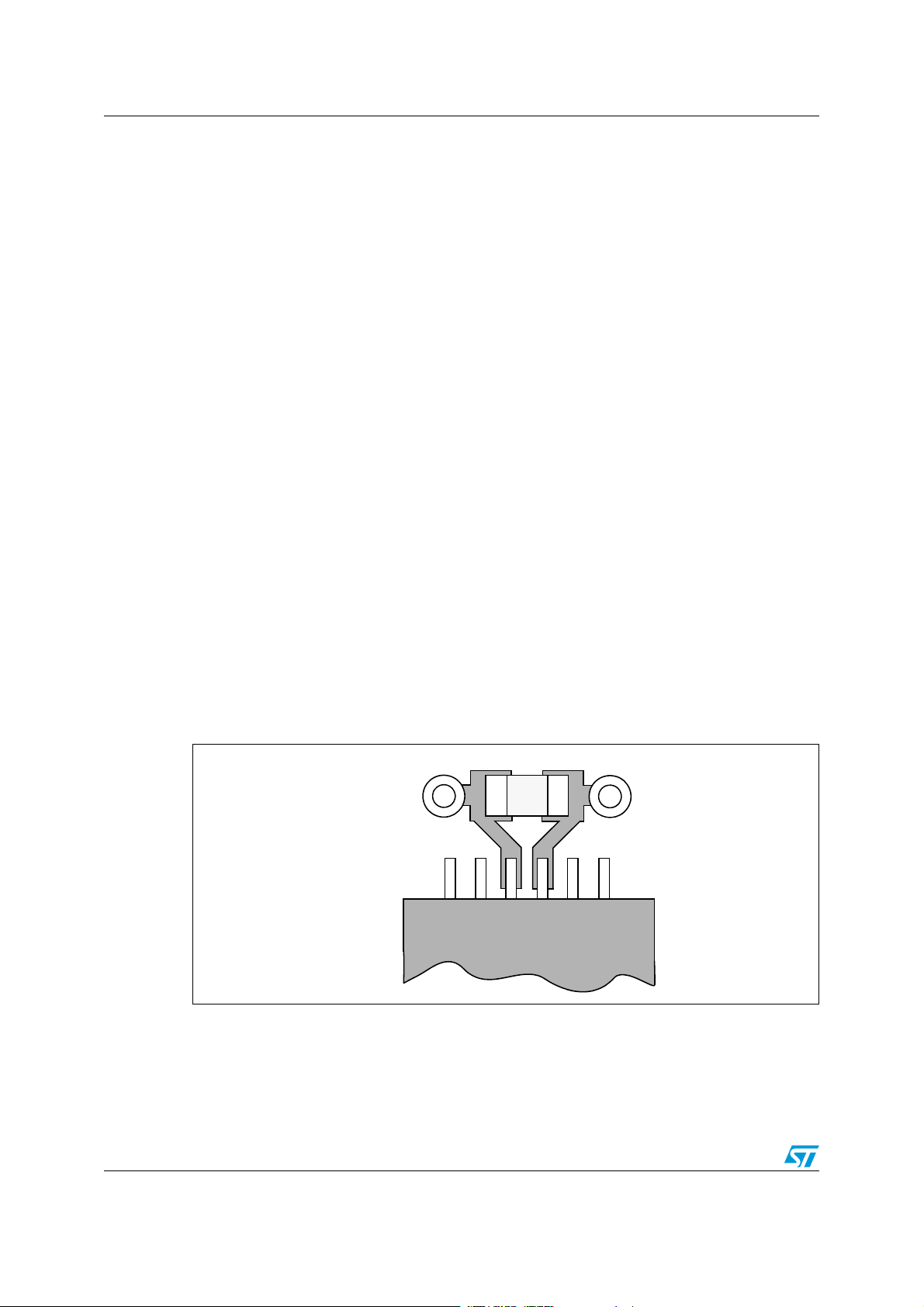

Figure 14. Connection description

Emulation system: STice

● Emulator box

● Cables for USB, power supply, trigger, and analyzer input

Connection flex

● 60-pin or 120-pin cable for connection to the application board

Connection adapter

● Links the connection flex to the footprint of the STM8L microcontroller

Adapter socket

● Package-specific socket for connection adapter and STM8L microcontroller

24/42 Doc ID 16139 Rev 3

Page 25

AN3029 STM8 development tools

8.2.2 STice in emulation configuration

In emulation configuration, the STice is connected to the PC via a USB interface and to the

application board in place of the target microcontroller being used.

● Connection flex: Flexible cable (60-pin or 120-pin depending on the target

microcontroller) that relays signals from the STice to the application board.

● Connection adapter: Links the connection flex to the footprint of the target

microcontroller on the users application board.

● Adapter socket: Socket that solders to the application board in place of the

microcontroller and receives the connection adapter.

The above accessories are not included with the STice system. To determine exactly what

is required for any supported microcontroller, refer to the online product selector on

www.st.com.

Figure 15. STice in emulation configuration

Doc ID 16139 Rev 3 25/42

Page 26

STM8 development tools AN3029

8.2.3 In-circuit programming and debugging

In the in-circuit debugging/programming configuration, STice allows the application to be

programmed in the microcontroller and for the application to be debugged while it runs on

the microcontroller on the application board. STice supports the SWIM protocol, making it

possible to in-circuit program and debug the microcontroller using only one general purpose

I/O.

In both the emulation and the in-circuit programming/debugging configuration, STice is

driven by the ST visual develop (STVD) or ST visual programmer (STVP) integrated

development environment running on the host PC. This provides total control of advanced

application building, debugging and programming features from a single easy-to-use

interface.

Figure 16. In-circuit programming and debugging

8.3 RLink and STLink

RLink and STLink are debug tools that allow the STM8L evaluation board or any user

application board with the SWIM interface to be connected to a host PC via USB for

debugging and programming. See Section 10.3.3: Connecting the hardware on page 35.

26/42 Doc ID 16139 Rev 3

Page 27

AN3029 STM8 software toolchain

9 STM8 software toolchain

To write, compile and run the first software on an STM8L device, the following components

of the software toolchain are required (see Figure 17):

● Integrated development environment

● Compiler

● Firmware library (optional, used to ease the startup)

Figure 17. STM8 software toolchain

Doc ID 16139 Rev 3 27/42

Page 28

STM8 software toolchain AN3029

9.1 Integrated development environment

The integrated development environment ST visual develop (STVD) provides an easy-touse, efficient environment for start-to-finish control of application development, from building

and debugging the application code to programming the microcontroller. STVD is delivered

as part of the free ST toolset, which also includes the ST visual programmer (STVP)

programming interface and the ST assembler linker.

To build applications, STVD provides seamless integration of C and assembly tool chains for

ST including the Cosmic and Raisonance C compilers and the ST assembler linker. When

debugging, STVD provides an integrated simulator (software) and supports a complete

range of hardware tools including the low-cost RLink in-circuit debugger/programmer, the

high-end STice emulator, and the low-cost ST-LINK tool.

To program applications to an STM8L, the STVD also provides an interface for reading from

the microcontroller memories, writing to them and verifying them. This interface is based on

the ST visual programmer (STVP), and supports all the target devices and programming

tools supported by STVP.

The free ST toolset for STM8 is available from STMicroelectronics homepage (see

www.st.com).

9.2 Compiler

STM8L devices can be programmed by a free assembler toolchain which is included in the

ST toolset.

As the core is designed for optimized high-level-language support, use of a C compiler is

recommended!

C compilers for STM8 are offered by the third party companies Cosmic, Raisonance, and

IAR.

A free version of the C compiler with up to 32 Kbytes of generated code is available at:

www.cosmic-software.com and www.raisonance.com.

9.3 Firmware library

The STM8 firmware library is a complete set of source code examples for each STM8

peripheral. It is written in strict ANSI-C and it is fully MISRA C 2004 compliant.

All examples can be used with four workspace and project definition files, one for STVD and

Cosmic C compiler, one for STVD and raisonance Compiler, one for Raisonance integrated

debugging environment and compiler (RIDE7 IDE), and one for IAR embedded workbench

for STM8 (EWSTM8). This enables the user to load and compile them easily into their

preferred development environment.

The examples run on the STMicroelectronics STM8L evaluation board and can be tailored

easily to other types of hardware.

For additional information and download of the STM8L firmware library connect to

www.st.com/mcu.

28/42 Doc ID 16139 Rev 3

Page 29

AN3029 Setting up the STM8 development environment

10 Setting up the STM8 development environment

10.1 Installing the tools

All software tools are delivered with a setup wizard which guides the user through the

installation process. It is recommended to install the tools in the following order:

1. C compiler

2. ST toolset

3. STM8 firmware library

ST-LINK does not need any dedicated software installation in the STM8 development

environment because the necessary drivers are delivered with the ST toolset.

The R-link drivers must be launched separately as follows:

Start/Programs/STtoolset/Setup/Install Rlink driver.

Doc ID 16139 Rev 3 29/42

Page 30

Setting up the STM8 development environment AN3029

10.2 Using the tools

Once the tools installation is complete, the ST visual develop (STVD) integrated

development environment can be launched.

The user then has the choice to generate either a new workspace with a new project or to

open an existing workspace. If using the STVD for the first time, it is recommended to open

an existing project from the STM8 firmware library.

Note: Even if you are not intending to use the library, an existing library project can be used as a

template to configure all the compiler options. Enter your own code after main().

The STM8 firmware library includes several examples for each peripheral plus one

workspace containing a blank project which is ready to receive your C code. It is located in

the firmware subdirectory \Project\Template (see Figure 18). You can choose between

STVD\Cosmic, STVD\Raisonance, RIDE, or EWSTM8.

Figure 18. STVD open example workspace

30/42 Doc ID 16139 Rev 3

Page 31

AN3029 Setting up the STM8 development environment

10.2.1 Project editing

All project source files are visible and can be edited (see Figure 19).

Figure 19. STVD MCU edit mode

Doc ID 16139 Rev 3 31/42

Page 32

Setting up the STM8 development environment AN3029

10.2.2 Online help

An online help manual is available inside the firmware installation directory (see Figure 20)

to help the user understand the structure of the STM8 firmware library.

Figure 20. STM8 firmware library online help manual

32/42 Doc ID 16139 Rev 3

Page 33

AN3029 Setting up the STM8 development environment

10.3 Running the demonstration software

● Go to www.st.com/mcu and search for STM8L products

● Choose STM8L1x-EVAL, STM8L1526-EVAL, or STM8L1528-EVAL firmware

● Open the desired project workspace within the chosen demonstration firmware

package.

To run the demonstration software on the STM8 evaluation board, the project has to be

compiled and the correct HW tool must be selected before the debug session can be

started.

10.3.1 Compiling the project

The project can be compiled using the ‘Build’ function in the ‘Build’ menu (see Figure 21).

Figure 21. STVD: Building the project

Doc ID 16139 Rev 3 33/42

Page 34

Setting up the STM8 development environment AN3029

10.3.2 Selecting the correct debug instrument

In the example below, the Rlink tool is used for communicating via the SWIM interface with

the on-board debug module of the STM8.

The Rlink tool can be selected from the ‘Debug Instrument Selection’ list in the ‘Debug

Instrument Settings’ dialog (see Figure 22).

Figure 22. STVD: Selecting the debug instrument

34/42 Doc ID 16139 Rev 3

Page 35

AN3029 Setting up the STM8 development environment

10.3.3 Connecting the hardware

The debug tool, STLink, is included on the STM8L1526-EVAL and STM8L1528-EVAL

boards. You can connect the PC to the USB connector. This connection ensures the debug

connection and the power. If the jumpers on the boards are no longer in the default position,

please read the evaluation board user manuals to select power and debug support jumpers.

For the STM8L101-EVAL, the Rlink tool can be connected to the PC by a standard USB

connection. It is also powered by the USB interface. On the controller side, the connection to

the STM8 evaluation board is made using the SWIM interface cable. The STM8L101-EVAL,

evaluation board is powered by an external 5 V supply (see Figure 23).

Figure 23. Connecting the debug instrument to the STM8L101-EVAL evaluation

board

Doc ID 16139 Rev 3 35/42

Page 36

Setting up the STM8 development environment AN3029

Figure 24. Connecting the debug instrument to the STM8L152x-EVAL evaluation

board

Caution: On the Rlink adapter board for STM8, the “SWIM” jumper must be set. If there is no pull-up

on the application SWIM line, the “ADAPT” jumper is also set. The “PW-5V” and “12MHz”

jumpers must not be set.

36/42 Doc ID 16139 Rev 3

Page 37

AN3029 Setting up the STM8 development environment

10.3.4 Starting the debug session

Debug mode can be entered by the command ‘Debug Start Debugging’ (see Figure 25).

Figure 25. STVD: Starting the debug session

Doc ID 16139 Rev 3 37/42

Page 38

Setting up the STM8 development environment AN3029

10.3.5 Running the software

After entering debug mode, the software can be started by the run command in the menu ‘Debug Run’

(see Figure 26).

Figure 26. STVD: Run the software

38/42 Doc ID 16139 Rev 3

Page 39

AN3029 Setting up the STM8 development environment

The LCD display on the STM8 evaluation board indicates a successful debug session (see

Figure 27).

Figure 27. STM8 evaluation board

10.3.6 Follow up

Step by step, additional peripherals of STM8L devices can be run, following on from the

initial debug session described above.

Many features of STM8L devices are supported by dedicated hardware on the STM8

evaluation board. The necessary software drivers, including STM8L peripheral drivers

(USART, ADC, SPI) and drivers for the EVAL board modules (LCD, serial memory), are

delivered in the STM8L1x firmware library.

Doc ID 16139 Rev 3 39/42

Page 40

Documentation and online support AN3029

11 Documentation and online support

Documentation resources related to tool usage includes:

Application

● STM8L101, medium density STM8L15x, medium+ and high density STM8L15x and

STM8L16x datasheets.

● How to program Flash memory and data EEPROM on STM8L microcontrollers

(PM0054).

● STM8L101, STM8L15x and STM8L16x reference manuals

● STM8 CPU programming manual (PM0044)

Tools

● STM8L101, STM8L15x, and STM8L16x firmware library and release note (detailed

descriptions of the library are included as help files).

● STice advanced emulation system for ST microcontrollers data briefing

● STice user manual

● Cosmic, Raisonnance, or IAR C compiler user manual

● STM8L101-EVAL, STM8L1526-EVAL, or STM8L1528-EVAL evaluation board user

manual.

● STM8L1x-EVAL, STM8L1526-EVAL, or STM8L1528-EVAL firmware

● ST visual develop tutorial (included as help files in the ST-toolchain)

● ST visual develop (STVD) user manual

● STM8 SWIM communication protocol and debug module user manual (UM0470)

The microcontroller discussion forum on www.st.com can be used by developers to

exchange ideas. It is the best place to find different application ideas. In addition, the

website has a knowledge base of FAQs for microcontrollers, which provide answers to many

queries and solutions to many problems.

40/42 Doc ID 16139 Rev 3

Page 41

AN3029 Revision history

12 Revision history

Table 3. Document revision history

Date Revision Changes

09-Sep-2009 1 Initial release

Updated all sections and references for medium density, medium+

density and high density devices.

Added STM8L16x devices.

16-Sep-2010 2

07-Mar-2011 3

Replaced V

DDIO

and V

Replaced 48-pin package by “some packages”.

Added IAR C compiler.

Section 2.1: Power supply overview: updated text.

Figure 1: added note 2; removed the + sign on the VLCD cappa.

Crystal/ceramic resonator: added reference to AN2867.

Section 3.2: Analog input: updated text.

Section 4.3.2: LSE clock: re-arranged section.

Section 5.1: Reset management overview: removed bullet

“electromagnetic susceptibility (EMS) reset (present only on STM8S

family).

Figure 7: removed EMS reset; added external reset circuit.

Section 5.2: Hardware reset implementation: added text about the

pull-down capacitor.

Table 1: Component list: updated “comment” information for ID

number 2 (battery); added ID number 5 (ceramic capacitor).

Figure 11: added external reset circuit and note 1.

Section 9.2: Compiler: updated “16 Kbytes” with “32 Kbytes” of

generated code.

Section 9.3: Firmware library: updated text explaining the workspace

and project definition files.

Section 10: Setting up the STM8 development environment:

removed introductory text.

Section 10.2: Using the tools: added EWSTM8.

Figure 1: updated figure content and footnotes.

Section 2.1: Power supply overview: updated bullet points.

Section 3.1: Analog power: updated bullet point concerning V

Section 6.4: Decoupling: updated value of the pool capacitor to 1 µF

(instead of 100 µF).

Figure 11: updated figure content and footnotes.

Section 8: STM8 development tools: updated bullet point 5 regarding

STM8L101-EVAL.

Section 9.1: Integrated development environment: added the low-

cost ST-Link tool in the list of hardware tools supported by STVD.

SSIO

by V

DDx

and V

respectively.

SSx

REF+

.

Doc ID 16139 Rev 3 41/42

Page 42

AN3029

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2011 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

42/42 Doc ID 16139 Rev 3

Loading...

Loading...