AN2960

Application note

LIS331DL: 3-axis - ±2 g /±8 g digital output

ultra compact linear accelerometer

Introduction

This document is intended to provide application information for the LIS331DL low-voltage

3-axis digital output linear MEMS accelerometer housed in an LGA package.

The LIS331DL is an ultra-compact low-power 3-axis linear accelerometer that includes a

sensing element and an IC interface capable taking information from the sensing element

and providing the measured acceleration data to external applications via an I

interface.

The sensing element used to detect acceleration is manufactured using a dedicated process

developed by ST to produce inertial sensors and actuators in silicon.

The IC interface is instead manufactured using a CMOS process that allows a high level of

integration to design a dedicated circuit which is factory trimmed to better match the sensing

element characteristics.

The LIS331DL has a user-selectable full scale of ±2 g and ±8 g and is capable of measuring

accelerations with an output data rate of 100 Hz or 400 Hz. A self-test capability allows the

user to check that the system is operating correctly.

2

C/SPI serial

The device features two independent, highly programmable interrupt sources that can be

configured either to generate an inertial wake-up interrupt signal when a programmable

acceleration threshold is exceeded along one of the three axes, to detect a free-fall or to

recognize single/double click events.

Two independent pins can be configured to provide interrupt signals to connected devices.

The LIS331DL is available in a plastic SMD package and is designed to operate over a

temperature range extending from -40 °C to +85 °C.

The ultra small size and weight of the SMD package make it an ideal choice for handheld

portable applications such as cell phones and PDAs, or any other application where

reduced package size and weight are required.

June 2009 Doc ID 15557 Rev 1 1/41

www.st.com

Contents AN2960

Contents

1 Theory of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Electrical connection and board layout hints . . . . . . . . . . . . . . . . . . . . . 7

2.1 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Soldering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Digital interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1 I2C bus interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1.1 I2C operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1.2 I2C subsequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 SPI bus interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2.1 Read & write protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2.2 SPI read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2.3 SPI write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2.4 SPI Read in 3-wires mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 Register description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1 Register address map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1.1 Reserved registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1.2 Registers loaded at boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6 About control registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1 CTRL_REG1 (20h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2 CTRL_REG2 (21h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.3 CTRL_REG3 (22h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7 Data and status registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.1 WHO_AM_I (0Fh) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.2 STATUS_REG (27h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.3 OUTX (29h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.4 OUTY (2Bh) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2/41 Doc ID 15557 Rev 1

AN2960 Contents

7.5 OUTZ (2Dh) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8 Free-fall and wake-up registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.1 HP_FILTER_RESET (23h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.2 FF_WU_CFG_1 (30h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.3 FF_WU_SRC_1 (31h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.4 FF_WU_THS_1 (32h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

8.5 FF_WU_DURATION_1 (33h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.6 FF_WU_CFG_2 (34h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.7 FF_WU_SRC_2 (35h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.8 FF_WU_THS_2 (36h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.9 FF_WU_DURATION_2 (37h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

9 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9.1 Start-up sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9.2 Reading acceleration data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9.2.1 Using the status register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9.2.2 Using the DataReady signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9.3 Understanding acceleration data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9.4 Interrupt generation description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

9.5 Inertial wake-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9.5.1 HP filter bypassed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9.5.2 Using the HP filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9.6 Free-fall detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.6.1 Roll function not used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.6.2 Roll function applied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.7 Output data rate selection and reading timing . . . . . . . . . . . . . . . . . . . . . 37

9.8 DataReady vs. interrupt signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

10 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Doc ID 15557 Rev 1 3/41

List of tables AN2960

List of tables

Table 1. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 2. Serial interface pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 3. Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 4. Registers address map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 5. Output data register content vs. acceleration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 6. Output data rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 7. Timing value to avoid data loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 8. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4/41 Doc ID 15557 Rev 1

AN2960 List of figures

List of figures

Figure 1. Device block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2. LIS331DL electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 3. I

Figure 4. Read & write protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 5. SPI read protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 6. Multiple byte SPI read protocol (example using 2 bytes) . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 7. SPI write protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 8. Multiple bytes SPI write protocol (example using 2 bytes) . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 9. SPI read protocol in 3-wires mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 10. Digital processing chain block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 11. FF_WU_CFG_1,2 high and low value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 12. DCRM bit function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 13. Interrupt generation block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 14. Free-fall, wake-up interrupt generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 15. Reading timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 16. Interrupt and DataReady signal generation block diagram. . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 17. DataReady signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2

C subsequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Doc ID 15557 Rev 1 5/41

Theory of operation AN2960

1 Theory of operation

The LIS331DL is an ultra compact, low-power, digital output 3-axis linear accelerometer

packaged in an LGA package. The complete device includes a sensing element and an IC

interface capable of taking information from the sensing element and providing a signal to

external applications through an I

A proprietary process is used to create a surface micro-machined accelerometer. The

technology allows the creation of suspended silicon structures which are attached to the

substrate at a few points, called “anchors”, and are free to move in the direction of the

sensed acceleration. To be compatible with traditional packaging techniques, a cap is

placed on top of the sensing element to avoid the blockage the moving parts during the

moulding phase of the plastic encapsulation.

When an acceleration is applied to the sensor, the proof mass displaces from its nominal

position, causing an imbalance in the capacitive half-bridge. This imbalance is measured

using charge integration in response to a voltage pulse applied to the sense capacitor.

In steady state, the nominal value of the capacitors are a few pico farads, and when an

acceleration is applied the maximum variation of the capacitive load is of a few femto farads.

The complete measurement chain is composed of a low-noise capacitive amplifier which

converts the capacitive unbalancing of the MEMS sensor into an analog voltage, and by

analog-to-digital converters.

The acceleration data may be accessed through an I

particularly suitable for direct interfacing with a microcontroller.

2

C/SPI serial interface (Figure 1).

2

C/SPI interface, making the device

Data synchronization in a digital system employing the device is made simpler through the

use of the DataReady signal (RDY), which indicates when a new set of measured

acceleration data is available, thus simplifying data synchronization in the digital system

employing the device.

The LIS331DL also features two independent, fully-programmable interrupt sources which

can be programmed to generate an interrupt signal when a programmable acceleration

threshold is exceeded along one of the three axes, or to detect a free-fall event.

The IC interface is factory calibrated for sensitivity (So) and zero-g level (Off).

The trimming values are stored in the device by a non-volatile structure. Any time the device

is turned on, the trimming parameters are loaded into the registers to be employed during

normal operation. This allows the user to use the device without further calibration.

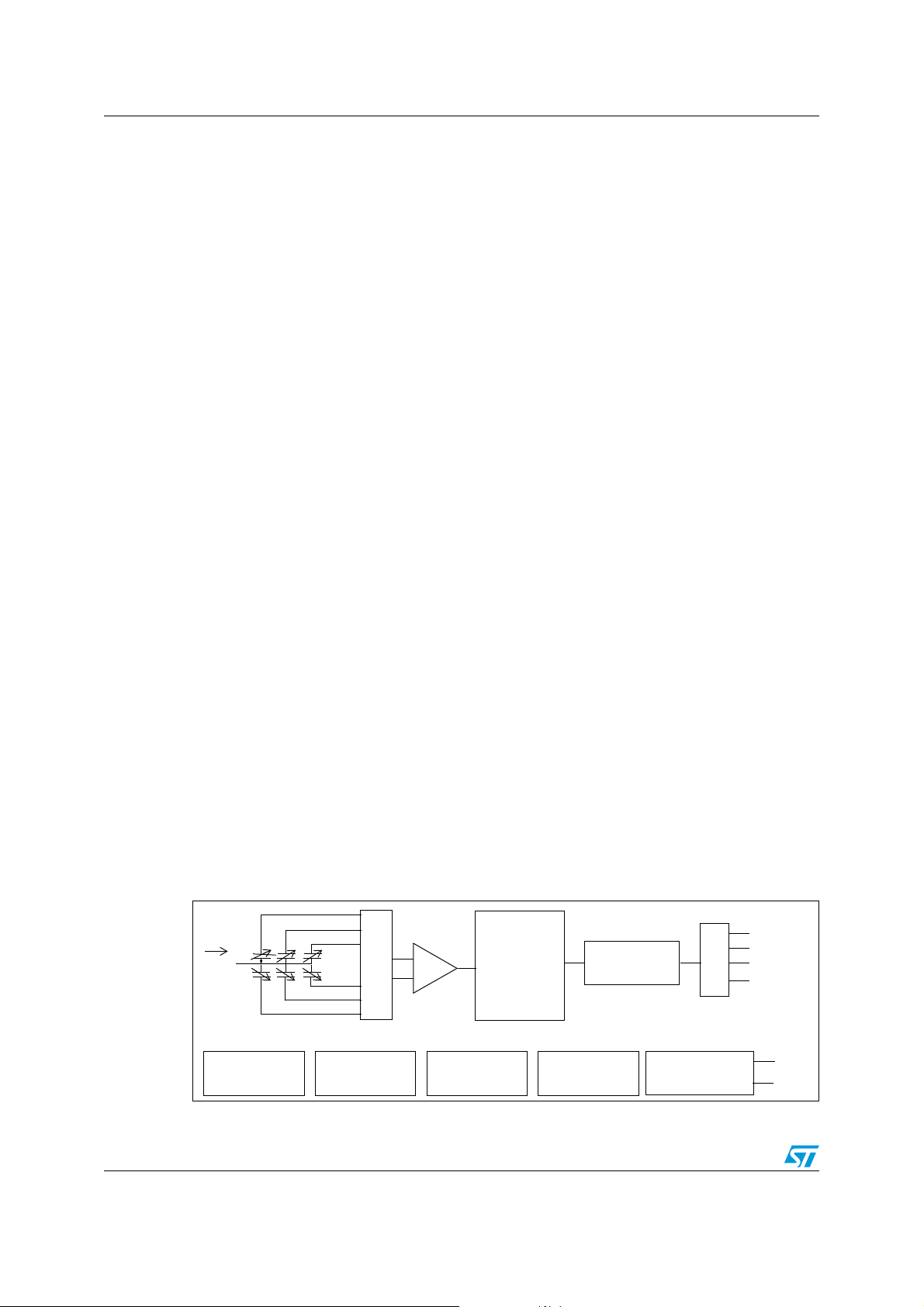

Figure 1. Device block diagram

X+

I2C

SPI

CS

SCL/SPC

SDA/SDO/SDI

SDO

INT 1

INT 2

Y+

Z+

a

MUX

Z-

Y-

X-

REFERENCESELF TEST

CHARGE

AMPLIFIER

TRIMMING

CIRCUITS

A/D

CONVERTER

CONTROL LOGIC

CLOCK

CONTROL LOGIC

&

INTERRUPT GEN.

6/41 Doc ID 15557 Rev 1

AN2960 Electrical connection and board layout hints

2 Electrical connection and board layout hints

2.1 Electrical connection

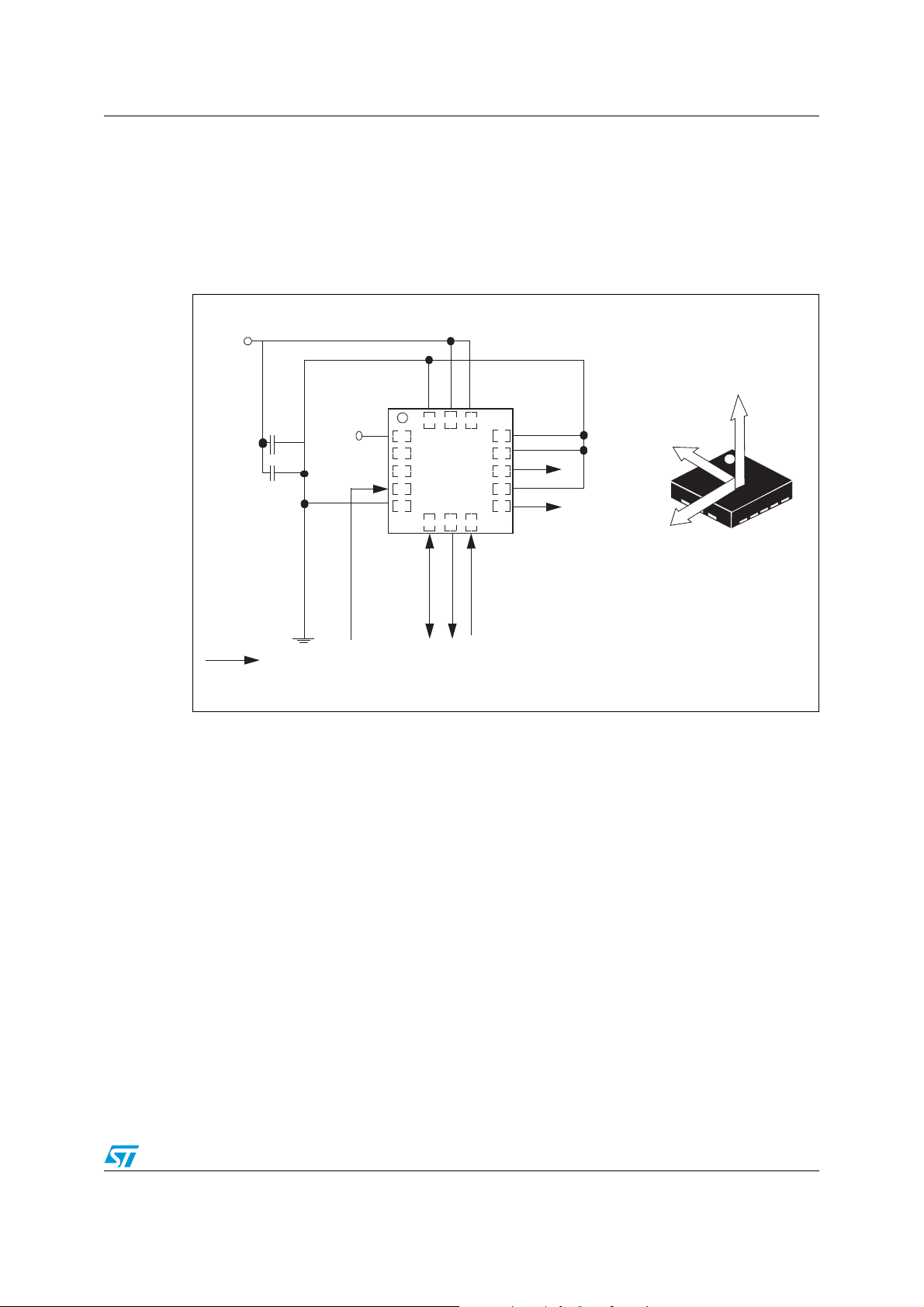

The typical electrical connection of the LIS331DL is shown in Figure 2.

Figure 2. LIS331DL electrical connection

Vdd

Z

10µF

100nF

GND

Vdd_IO

SCL/SPC

1

TOP VIEW

SDO/SA0

SDA/SDI/SDO

13

X

INT 1

INT 2

95

Y

1

(TOP VIEW)

DIRECTION OF THE

DETECTABLE

ACCELERATIONS

CS

Digital signal from/to signal controller.Signal’s levels are defined by proper selection of Vdd_IO

AM03707v1

The LIS331DL is designed to operate with a supply voltage spanning from 2.16 V up to 3.6

V, while the serial interface can function down to 1.8 V.

The device core is supplied through the Vdd line (Vdd typ=2.5 V) while the I/O pads are

supplied through the Vdd_IO line. The typical current consumption in normal mode at 2.5 V

is 400 µA.

Both voltage supplies must be present at the same time to ensure proper behavior of the IC.

It is possible to remove Vdd, maintaining Vdd_IO, without blocking the communication bus.

Adequate power supply decoupling is required to ensure IC performance. Optimum

decoupling is achieved by using two capacitors of different types that target different kinds of

noise on the power supply leads. To attenuate high frequency transients, spikes, or digital

hash on the line, the use of one 100 nF ceramic or polyester capacitor is recommended,

which must be placed as close as possible to the device Vdd lead. For filtering lowerfrequency noise signals, a larger aluminum capacitor of 10 µF or greater should be placed

near the device in parallel with the former capacitor. It is recommended to place these

capacitors as near as possible to pin 14 of the device.

The functionality of the device and the measured acceleration data are selectable and

accessible through the I

2

C/SPI interface. When using the I2C, the CS must be tied high

while the SDO allows the user to select between two device addresses in cases where two

Doc ID 15557 Rev 1 7/41

Electrical connection and board layout hints AN2960

sensors must be connected on the same bus. Whenever a single sensor is present on the

2

same I

C bus, it is recommended either to connect SDO to Vdd_IO, or to leave it floating.

2.2 Soldering information

The LGA-14 package is lead-free and green package qualified for soldering heat resistance

according to JEDEC J-STD-020C. Land pattern and soldering recommendations are

available upon request.

8/41 Doc ID 15557 Rev 1

AN2960 Absolute maximum ratings

3 Absolute maximum ratings

Stresses above those listed as “absolute maximum ratings” may cause permanent damage

to the device. These are stress ratings only and functional operation of the device under

these conditions is not implied. Exposure to maximum rating conditions for extended periods

may affect device reliability.

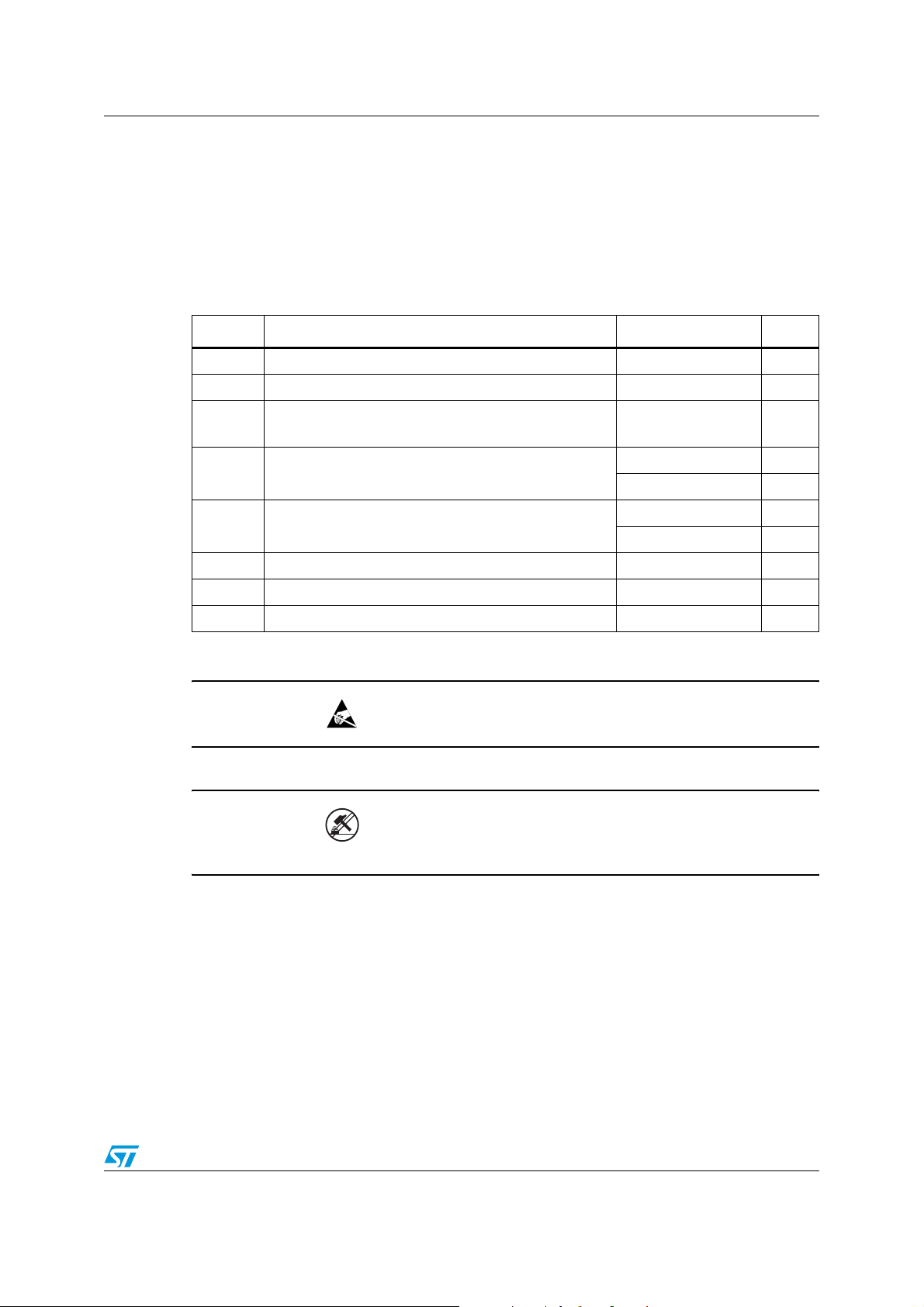

Table 1. Absolute maximum ratings

Symbol Ratings Maximum Value Unit

Vdd Supply voltage

Vdd_IO I/O pin supply voltage

(1)

(1)

-0.3 to 6 V

-0.3 to 6 V

Vin

Input voltage on any control pin

(CS, SCL/SPC, SDA/SDI/SDO, CK)

-0.3 to Vdd_IO +0.3 V

3000 g for 0.5 ms

A

POW

Acceleration (any axis, powered, Vdd=2.5V)

10000 g for 0.1 ms

3000 g for 0.5 ms

A

T

UNP

T

STG

Acceleration (any axis, unpowered)

10000 g for 0.1 ms

Operating temperature range -40 to +85 °C

OP

Storage temperature range -40 to +125 °C

ESD Electrostatic discharge protection Class 1: 0 - 2 kV HBM

1. Supply voltage on any pin should never exceed 6.0 V

Warning:This is an ESD sensitive device. Improper

handling can cause permanent damage to the part.

Warning:This is a mechanical shock-sensitive device,

improper handling can cause permanent damage to the

part.

Doc ID 15557 Rev 1 9/41

Digital interfaces AN2960

4 Digital interfaces

The registers embedded in the LIS331DL may be accessed through I2C and SPI serial

interfaces. The latter may be SW configured to operate in either 3-wire or 4-wire interface

mode.

The serial interfaces are mapped onto the same pads. To select/exploit the I

CS line must be tied high (i.e. connected to Vdd_IO).

Table 2. Serial interface pin description

Pin Name Pin description

2

C interface, the

CS

SCL/SPC

SDI/SDA/SDO

SPI chip select (CS)

I2C/SPI selector (1: I2C mode; 0: SPI enabled)

SPI CK line (SCL)

2

I

2

I

SPI data in (SDI)

SPI data out (SDO) -for 3-wire SPI mode

2

SDO

I

SPI data out (SDO) - for 4-wire SPI mode

4.1 I2C bus interface

The LIS331DL I2C is a bus slave. The I2C is employed to write/read the data to/from the

registers.

Relevant I

Table 3. Terminology

2

C terminology is provided in Ta b l e 3 :

Term Description

Transmitter The device which sends data to the bus

Receiver The device which receives data from the bus

C clock line (SPC)

C serial data (SDA)

C less significant bit of device address

Master

The device which initiates a transfer, generates clock signals and terminates

a transfer

Slave The device addressed by the master

There are two signals associated with the I2C bus: the serial clock line (SCL) and the serial

data line (SDA). The latter is a bidirectional line used for sending and receiving data to/from

the interface. Both lines are connected to Vdd_IO through a pull-up resistor embedded in

the LIS331DL. When the bus is free, both the lines are high.

2

The I

10/41 Doc ID 15557 Rev 1

C interface is compliant with fast mode (400 kHz) I2C standards as well as normal

mode.

AN2960 Digital interfaces

4.1.1 I2C operation

The transaction on the bus is started through a START (ST) condition, which is defined as a

HIGH to LOW transition on the data line, while the SCL line is held HIGH. After the START

condition has been generated by the master, the bus is considered busy. The next byte of

data transmitted contains the address of the slave in the first 7 bits and the 8th bit instructs

whether the master is receiving data from the slave or transmitting data to the slave (SAD

subsequence). When an address is sent, each device in the system compares the first

seven bits after a start condition with its own address. If they match, the device considers

itself addressed by the master.

The slave address (SAD) associated with the LIS331DL may be selected from the two

predefined values 0011100b or 0011101b depending on the logic level present on the SDO

pin. Specifically, if the SDO pin is either connected to Vdd_IO or left unconnected, the slave

address is 0011101b. Otherwise, when it is connected to GND, the slave address is

0011100b. When placing two sensors on the same bus is not required, it is recommended to

use slave address 0011101b by either connecting the SDO pin to Vdd_IO, or leaving it

floating.

Data transfer with acknowledge is mandatory. The transmitter must release the SDA line

during the acknowledge pulse. The receiver must then pull the data line LOW so that it

remains stable low during the HIGH period of the acknowledge clock pulse. A receiver that

has been addressed is obligated to generate an acknowledge after each byte of data has

been received.

2

The I

C embedded in the LIS331DL behaves as a slave device and the following protocol

must be adhered to. After the start condition (ST), a slave address is sent. Once a slave

acknowledge (SAK) has been returned, an 8-bit sub-address will be transmitted: the 7 LSb

represents the actual register address, while the MSB enables address auto-increment. If

the MSb of the SUB field is 1, the SUB (register address) will be automatically incremented

to allow multiple data read/write. Otherwise, if the MSB of the SUB field is ‘0’, the SUB will

remain unchanged and multiple read/write on the same address can be performed.

The slave address is completed with a read/write bit. If the bit is ‘1’ (read), a repeated

START (SR) condition must be issued after the two sub-address bytes; if the bit is ‘0’ (Write)

the master transmits to the slave with unchanged direction.

Transfer when master is writing one byte to slave

Master ST SAD + W SUB DATA SP

Slave SAK SAK SAK

Transfer when master is writing multiple bytes to slave:

Master ST SAD + W SUB DATA DATA SP

Slave SAK SAK SAK SAK

Transfer when master is receiving (reading) one byte of data from slave:

Master ST SAD + W SUB SR SAD + R NMAK SP

Slave SAK SAK SAK DATA

Doc ID 15557 Rev 1 11/41

Digital interfaces AN2960

Transfer when master is receiving (reading) multiple bytes of data from slave

Master ST SAD + W SUB SR SAD + R MAK

Slave SAK SAK SAK DATA

Master MAK NMAK SP

S la ve DATA DATA

Data are transmitted in byte format (DATA). Each data transfer contains 8 bits. The number

of bytes per transfer is unlimited. Data is transferred with the most significant bit (MSb) first.

If a receiver cannot receive another complete byte of data until it has performed some other

function, it can hold the clock line SCL low to force the transmitter into a wait state. Data

transfer continues only when the receiver is ready for another byte and releases the data

line. If a slave receiver does not acknowledge the slave address (i.e. it is not able to receive

because it is performing some other real-time function) the data line must be left high by the

slave. The master can then abort the transfer. A low to high transition on the SDA line while

the SCL line is HIGH is defined as a STOP condition. Each data transfer must be terminated

by the generation of a STOP (SP) condition.

In order to read multiple bytes, it is necessary to assert the most significant bit of the subaddress field. In other words, SUB(7) must be equal to 1 while SUB(6-0) represents the

address of the first register to read.

In the communication format presented, MAK signifies master acknowledge and NMAK is

no master acknowledge.

4.1.2 I2C subsequences

In order to better define subsequences and to clarify line SCL and SDA behavior, a

description containing the discrete values of SCL and SDA follow. These simple

subsequences are used to implement the complex commands described in the following

paragraph.

12/41 Doc ID 15557 Rev 1

AN2960 Digital interfaces

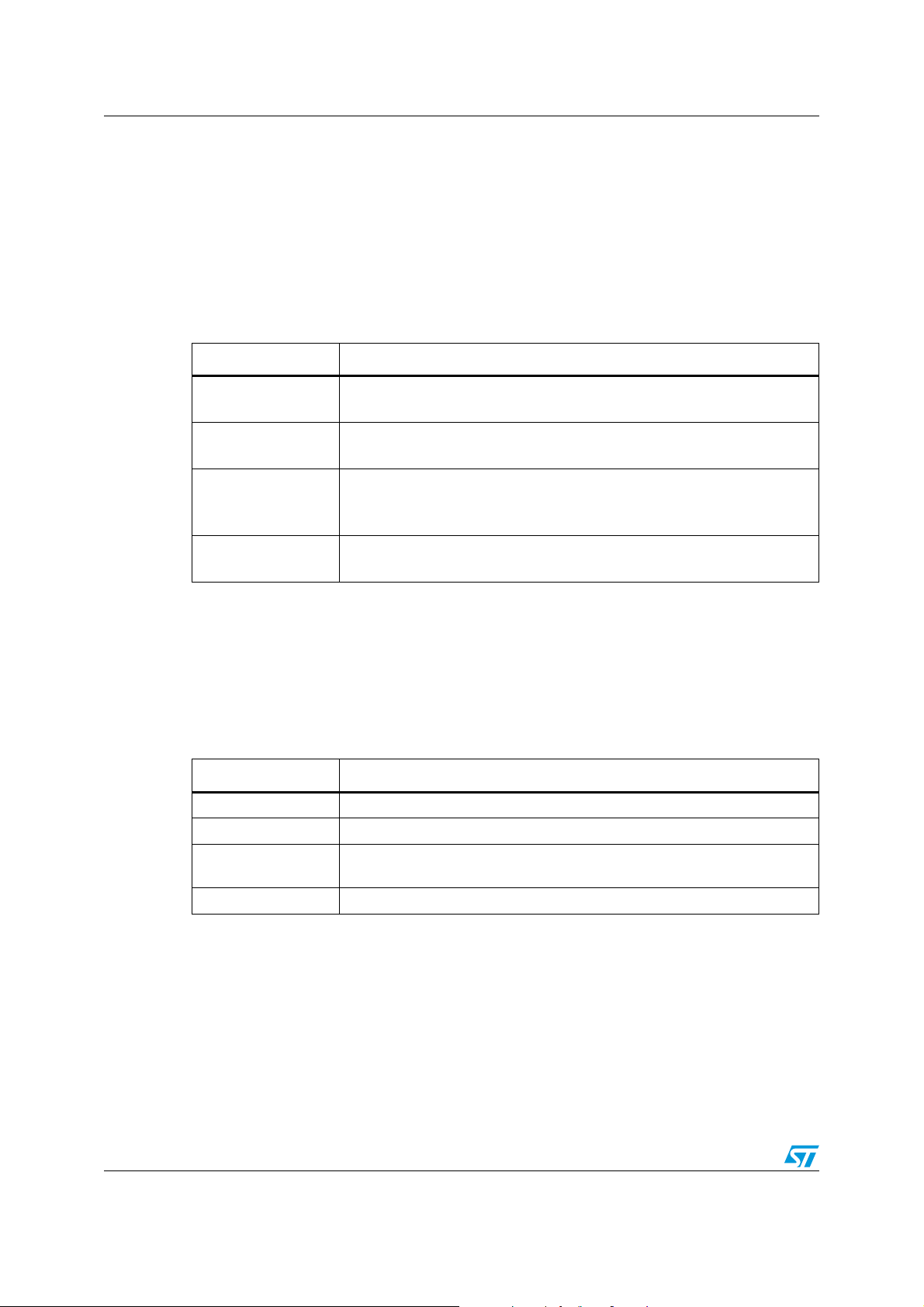

Figure 3. I2C subsequences

ST: START condition

SCL 1111

SDA 1100

SR: Repeated START condition

SCL 1111

SDA 1100

SAD: Slave address (binary address: abcdefgh. In LIS331DL “abcdef” = “001110”)

SCL 00110 0110 0110 0110 0110 0110 0110 0110

SDA 0aaaa bbbb cccc dddd eeee f f f f gggg hhhh

Bit g=0 if SDO connected to GND, g=1 if SDO pad connected to Vdd

Bit h=0 => write, h=1 => read

SAK: Slave acknowledge (Z means high impedance)

SCL 0011

SDA (force) ZZZZ Check that SDA is 0 after SCL=1

SDA (re ad) XX00

SUB: Sub a

DATA (M aster): send DATA byte (binary number: abcdefgh)

DATA (Slave): read DATA byte (binary number: abcdefgh)

ddress (binary address: a0cdefgh)

SCL 00110 0110 0110 0110 0110 0110 0110 0110

SDA 0aaaa 0000 cccc dddd eeee f f f f gggg hhhh

Bit a=0 => do not increment address in multiple mode

a=1 => increment address in multiple mode

SCL 00110 0110 0110 0110 0110 0110 0110 0110

Saaaabbbbcccc dddd eeee f f f f gggg hhhh

SCL 00110 0110 0110 0110 0110 0110 0110 0110

SDA (force) ZZZZ ZZZZ ZZZZ ZZZZ ZZZZ ZZZZ ZZZZ ZZZZ

SDA (re ad) a b c d e f g h

SP: STOP condition

SCL 1111

SDA 0011

MAK: Master Acknowledge

S

CL 0011

NMAK: No Master Acknowledge

SDA 0000

SCL 0011

SDA ZZZZ or 1111

Doc ID 15557 Rev 1 13/41

Digital interfaces AN2960

4.2 SPI bus interface

The LIS331DL SPI is a bus slave. The SPI allows writing and reading to the registers of the

device.

The serial interface interacts with the outside world through 4 wires: CS, SPC, SPDI and

SPDO.

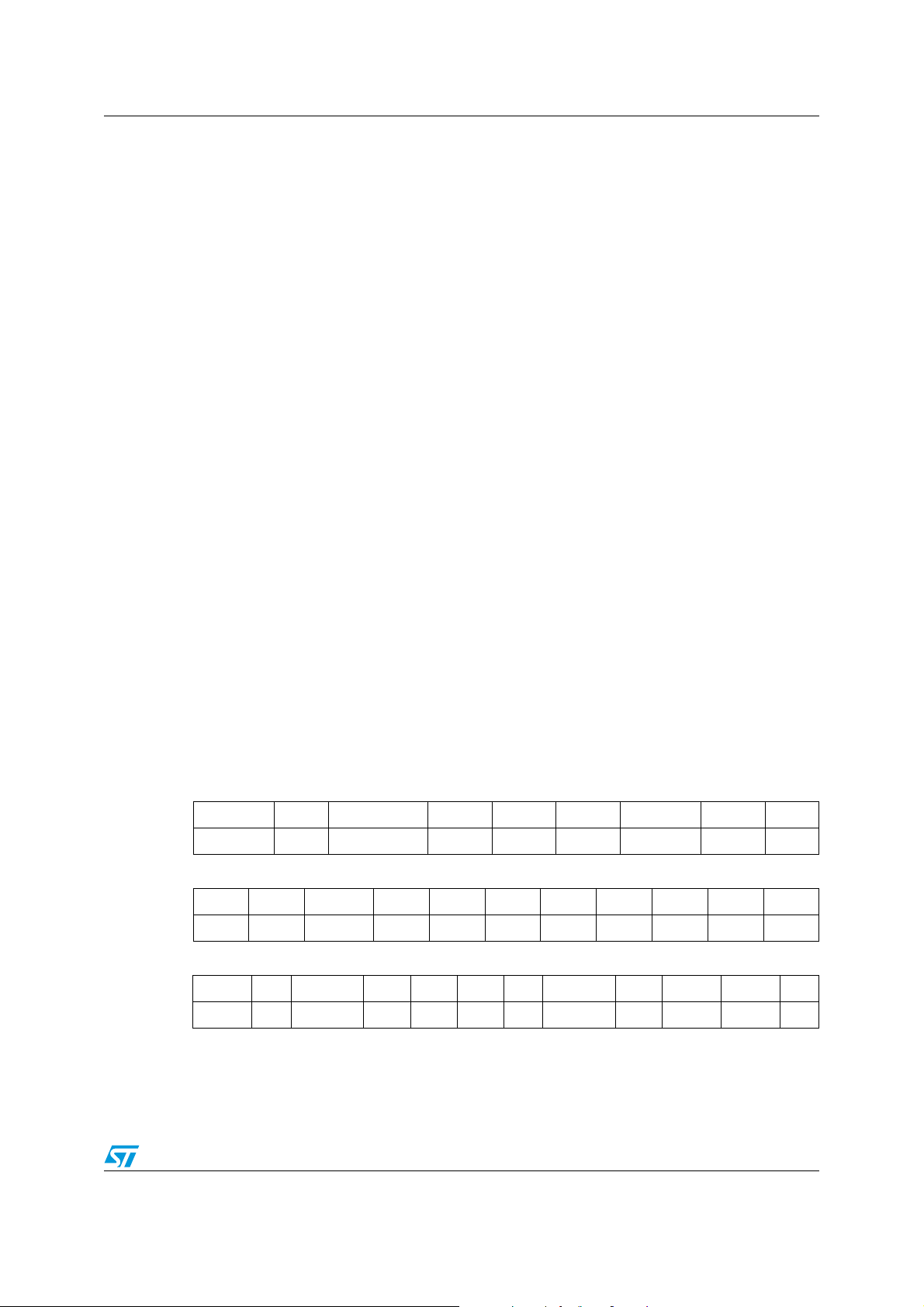

4.2.1 Read & write protocol

Figure 4. Read & write protocol

CS

SPC

SDI

DI7 DI6 DI5 DI4 DI3 DI2 DI1 DI0

DO7 DO6 DO5 DO4 DO3 DO2 DO1 DO0

SDO

RW

MS

AD5 AD4 AD3 AD2 AD1 AD0

CS is the chip select and is controlled by the SPI master. It goes low at the start of the

transmission and returns high at the end. SPC is the serial port clock and is controlled by

the SPI master. It is stopped high when CS is high (no transmission). SDI and SDO are,

respectively, the serial port data input and output. These lines are driven at the falling edge

of SPC and should be captured at the rising edge of SPC.

Both the read register and write register commands are completed in 16 clock pulses or in

multiples of 8 in cases of multiple byte read/write. Bit duration is the time between two falling

edges of SPC. The first bit (bit 0) starts at the first falling edge of SPC after the falling edge

of CS while the last bit (bit 15, bit 23, etc.) starts at the last falling edge of SPC just before

the rising edge of CS.

bit 0: RW

bit. When 0, the data DI(7:0) is written into the device. When 1, the data DO(7:0)

from the device is read. In the latter case, the chip drives SDO at the start of bit 8.

bit 1: MS

bit. When 0, the address remains unchanged in multiple read/write commands.

When 1, the address is auto-incremented in multiple read/write commands.

bit 2-7: address AD(5:0). This is the address field of the indexed register.

bit 8-15: data DI(7:0) (write mode). This is the data that is written to the device (MSb first).

bit 8-15: data DO(7:0) (read mode). This is the data that is read from the device (MSb first).

In multiple read/write commands, further blocks of 8 clock periods are added. When the MS

bit is 0, the address used to read/write data remains the same for every block. When the MS

bit is 1, the address used to read/write data is incremented at every block.

The function and the behavior of SDI and SDO remain unchanged.

14/41 Doc ID 15557 Rev 1

AN2960 Digital interfaces

4.2.2 SPI read

Figure 5. SPI read protocol

CS

SPC

SDI

RW

MS

AD5 AD4 AD3 AD2 AD1 AD0

SDO

DO7 DO6 DO5 DO4 DO3 DO2 DO1 DO0

The SPI Read command is performed with 16 clock pulses. A Multiple byte read command

is performed by adding blocks of 8 clocks pulses to the previous one.

bit 0: READ bit. The value is 1.

bit 1: MS

bit. When 0, do not increment the address. When 1, increment the address in

multiple readings.

bit 2-7: address AD(5:0). This is the address field of the indexed register.

bit 8-15: data DO(7:0) (read mode). This is the data that is read from the device (MSb first).

bit 16-... : data DO(...-8). Further data in multiple byte reading.

Figure 6. Multiple byte SPI read protocol (example using 2 bytes)

CS

SPC

SDI

SDO

4.2.3 SPI write

Figure 7. SPI write protocol

RW

AD5 AD4 AD3 AD2 AD1 AD0

MS

CS

DO7 DO6 DO5 DO4 DO3 DO2 DO1 DO0

DO15 DO14 DO13 DO12 DO11 DO10 DO9 DO8

SPC

SDI

RW

AD5 AD4 AD3 AD2 AD1 AD0MS

The SPI Write command is performed with 16 clocks pulses. A Multiple byte write command

DI7 DI6 DI5 DI4 DI3 DI2 DI1 DI0

is performed by adding blocks of 8 clocks pulses to the previous one.

Doc ID 15557 Rev 1 15/41

Digital interfaces AN2960

bit 0: Write bit. The value is 0.

bit 1: MS bit. When 0, do not increment the address. When 1, increment the address in

multiple writings.

bit 2 -7: address AD(5:0). This is the address field of the indexed register.

bit 8-15: data DI(7:0) (write mode). This is the data that is written to the device (MSb first).

bit 16-... : data DI(...-8). Further data in multiple byte writing.

Figure 8. Multiple bytes SPI write protocol (example using 2 bytes)

CS

SPC

SDI

RW

MS

AD5 AD4 AD3 AD2 AD1 AD0

DI7 DI6 DI5 DI4 DI3 DI2 DI1 DI0 DI1 5 DI14 DI13 DI12 DI11 DI10 DI9 DI8

4.2.4 SPI Read in 3-wires mode

3-wires mode is entered by setting the bit SIM (SPI serial interface mode selection) to 1 in

CTRL_REG2.

Figure 9. SPI read protocol in 3-wires mode

CS

SPC

SDI

RW

MS

AD5 AD4 AD3 AD2 AD1 AD0

DO7 DO6 DO5 DO4 DO3 DO2 DO1 DO0

The SPI Read command is performed with 16 clock pulses:

bit 0: READ bit. The value is 1.

bit 1: MS bit. When 0, do not increment the address. When 1, increment the address in

multiple readings.

bit 2-7: address AD(5:0). This is the address field of the indexed register.

bit 8-15: data DO(7:0) (read mode). This is the data that is read from the device (MSb first).

The Multiple read command is also available in 3-wires mode.

16/41 Doc ID 15557 Rev 1

AN2960 Register description

5 Register description

5.1 Register address map

The table below provides a listing of the registers embedded in the device.

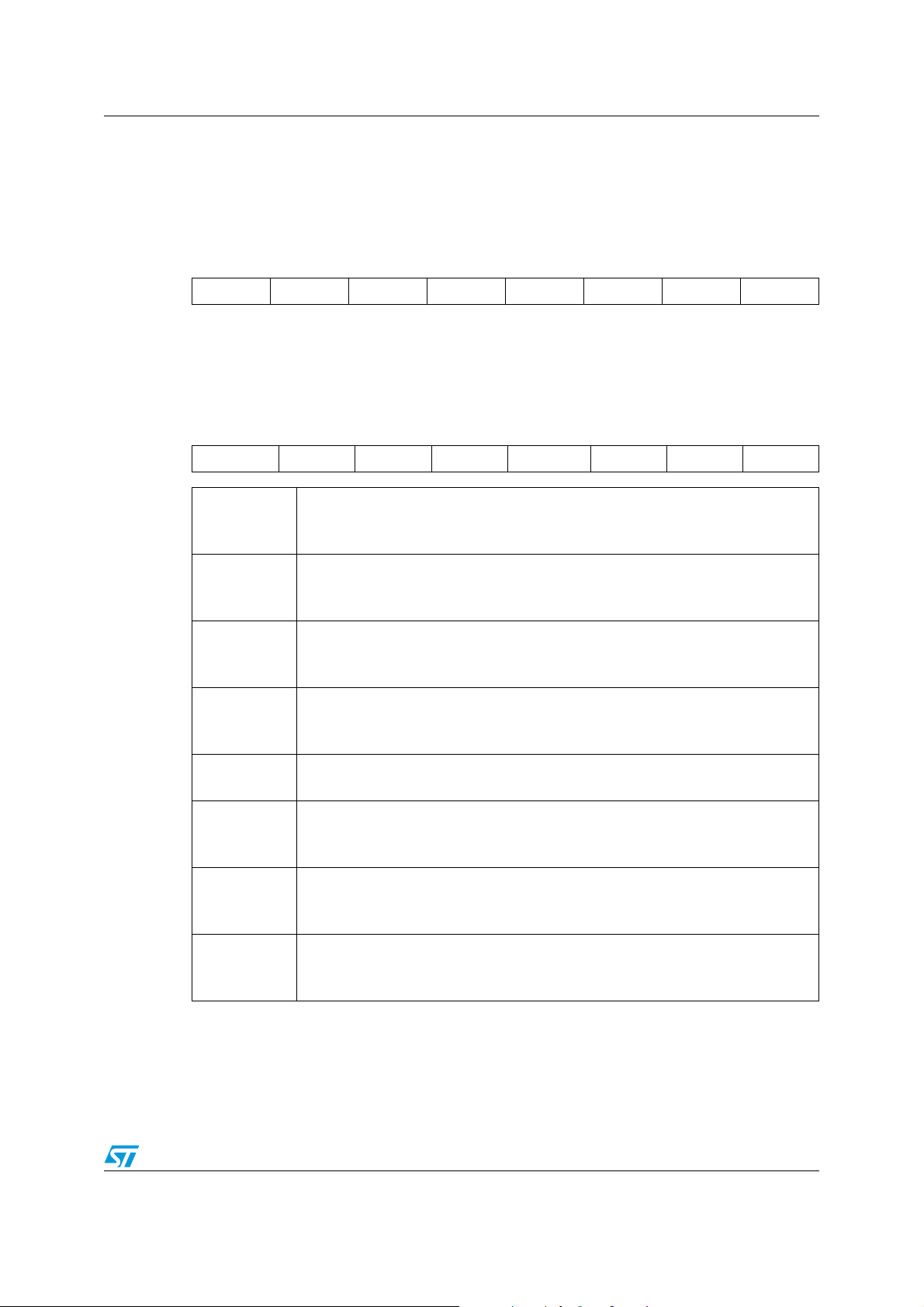

Table 4. Registers address map

Name Type

Register

address

Default Comment

Hex Binary

Reserved (do not modify) 00-0E Reserved

Who_Am_I r 0F 00 1111 00111011 Dummy register

Reserved (do not modify) 10-1F Reserved

CTRL_REG1 rw 20 10 0000 00000111

CTRL_REG2 rw 21 10 0001 00000000

CTRL_REG3 rw 22 10 0010 00000000

HP_filter_reset r 23 10 0011 dummy Dummy register

Reserved (do not modify) 24-26 Reserved

Status_Reg r 27 10 0111 00000000

-- r 28 10 1000 Not used

Out_X r 29 10 1001 output

-- r 2A 10 1010 Not used

Out_Y r 2B 10 1011 output

-- r 2C 10 1100 Not used

Out_Z r 2D 10 1101 output

Reserved (do not modify) 2E-2F Reserved

FF_WU_CFG_1 rw 30 11 0000 00000000

FF_WU_SRC_1(ack1) r 31 11 0001 00000000

FF_WU_THS_1 rw 32 11 0010 00000000

FF_WU_DURATION_1 rw 33 11 0011 00000000

FF_WU_CFG_2 rw 34 11 0100 00000000

FF_WU_SRC_2 (ack2) r 35 11 0101 00000000

FF_WU_THS_2 rw 36 11 0110 00000000

FF_WU_DURATION_2 rw 37 11 0111 00000000

Reserved (do not modify) 38-3F Reserved

Doc ID 15557 Rev 1 17/41

Register description AN2960

5.1.1 Reserved registers

Registers marked as reserved must not be changed. Random changes of the content of

these registers may cause permanent damage to the device.

5.1.2 Registers loaded at boot

The LIS331DL is factory-trimmed. The content of the registers loaded at boot must not be

changed. Their content is automatically restored when the device is powered up.

18/41 Doc ID 15557 Rev 1

AN2960 About control registers

6 About control registers

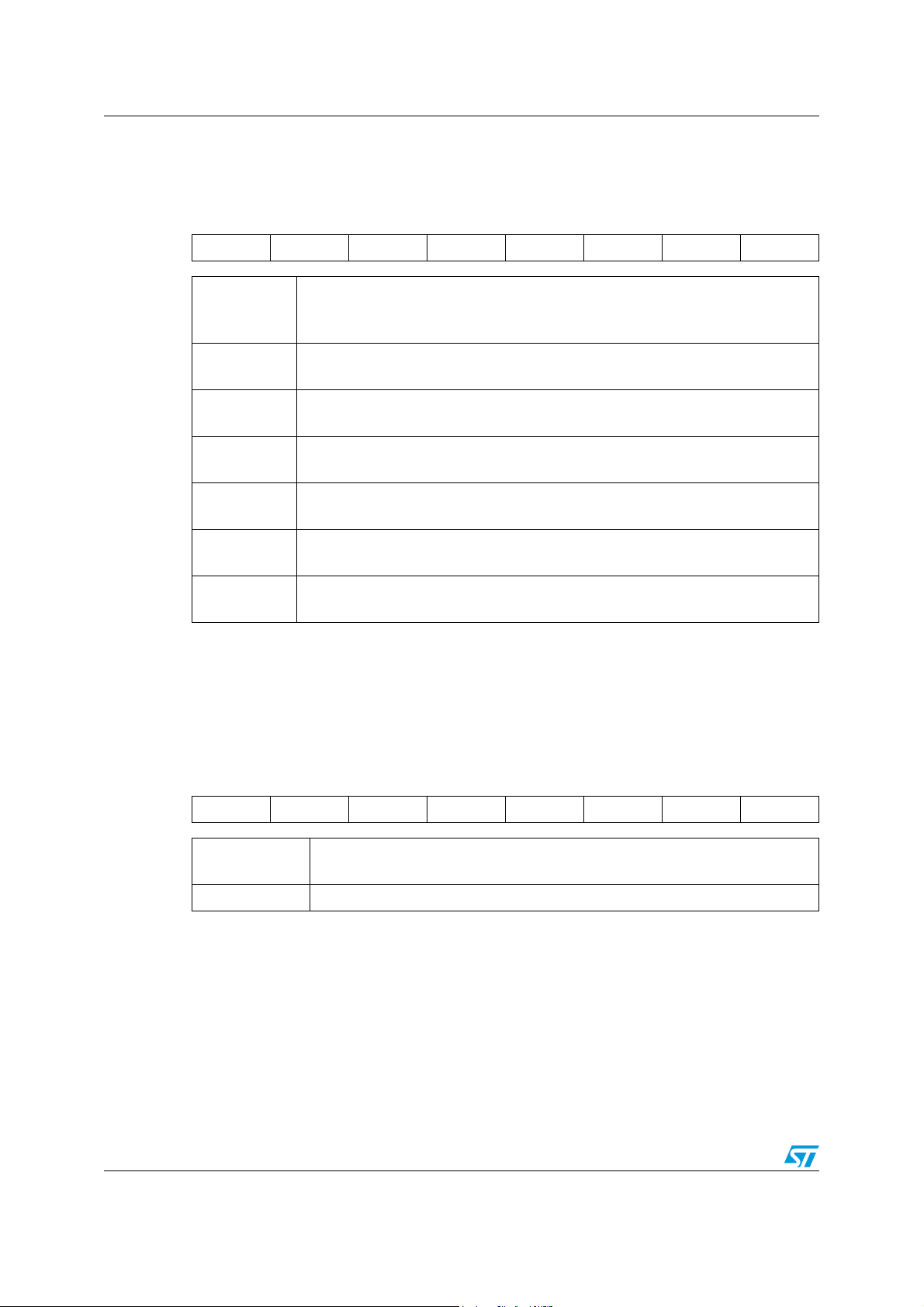

6.1 CTRL_REG1 (20h)

Control register #1.

DR PD FS ST P ST M Zen Yen Xen

DR

PD

FS

STP, STM

Zen

Ye n

Xen

Data rate selection. Default value: 0

(0: 100 Hz output data rate; 1: 400 Hz output data rate)

Power-down control. Default value: 0

(0: power-down mode; 1: active mode)

Full scale selection. Default value: 0

(0: +/- 2 g; 1: +/- 8 g)

Self test enable. Default value: 00

(00: normal mode; 10: self test P; 01 self test M; 11: forbidden)

Z-axis enable. Default value: 1

(0: Z-axis disabled; 1: Z-axis enabled)

Y-axis enable. Default value: 1

(0: Y-axis disabled; 1: Y-axis enabled)

X-axis enable. Default value: 1

(0: X-axis disabled; 1: X-axis enabled)

The DR bit allows the selection of the data rate at which acceleration samples are produced.

The default value is 0, which corresponds to a data rate of 100 Hz. By changing the content

of DR to 1, the selected data rate is set equal to 400 Hz.

The PD

bit allows the device to exit power-down mode. The device is in power-down mode when

PD= “0” (default value after boot). The device is in normal mode when PD is set to 1.

DR (Data rate) PD (Power-down) Status

0 0 Power-down (default)

0 1 Active (100 Hz output)

1 0 Power-down

1 1 Active (400 Hz output)

The STP and STM bits are used to activate the self-test function. When one of the bits is set

to 1, a change to the device outputs occurs (refer to datasheet for specification), allowing

checking of the functionality of the whole measurement chain. STP and STM move the

output in opposite directions.

The Zen bit enables the generation of a DataReady signal for the Z-axis measurement

channel when set to 1. The default value is 1.

The Yen bit enables the generation of a DataReady signal for the Y-axis measurement

channel when set to 1. The default value is 1.

The Xen bit enables the generation of a DataReady signal for the X-axis measurement

channel when set to 1. The default value is 1.

Doc ID 15557 Rev 1 19/41

About control registers AN2960

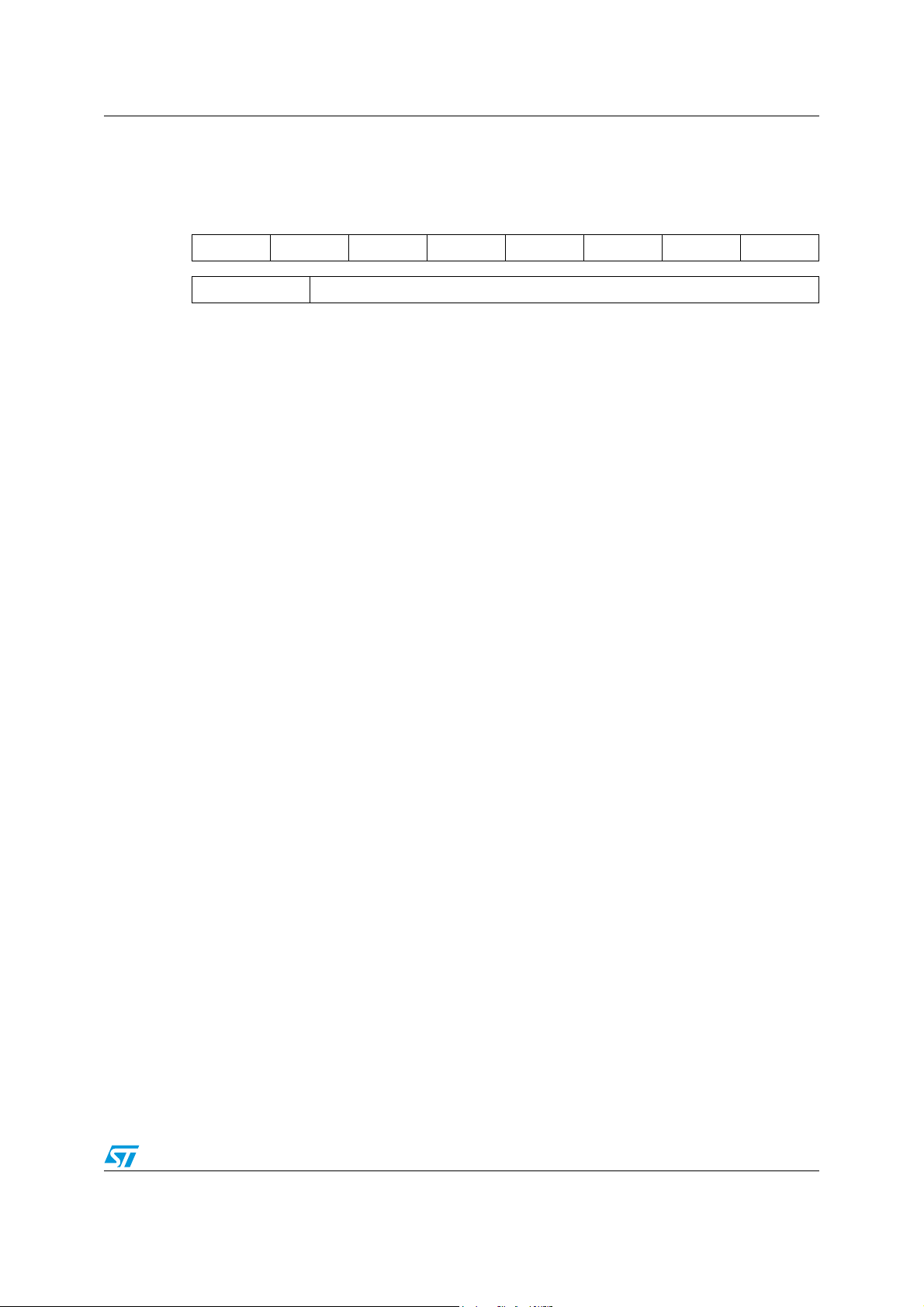

6.2 CTRL_REG2 (21h)

Control register #2.

SIM BOOT -- FDS

HP

FF_WU2

HP

FF_WU1

HP coeff2 HP coeff1

SIM

BOOT

FDS

HP FF_WU2

HP FF_WU1

HP coeff2

SPI serial interface mode selection. Default value: 0

(0: 4-wire interface; 1: 3-wire interface)

Reboot memory content. Default value: 0

(0: normal mode; 1: reboot memory content)

Filtered data selection. Default value: 0

(0: internal filter bypassed; 1: data from internal filter sent to output register)

High-pass filter enabled for free-fall/wakeup # 2. Default value: 0

(0: filter bypassed; 1: filter enabled)

High-pass filter enabled for free-fall/wake-up #1. Default value: 0

(0: filter bypassed; 1: filter enabled)

High-pass filter cut-off frequency configuration. Default value: 00

HP coeff1

The SIM bit selects the SPI serial interface mode. When SIM is ‘0’ (default value), the 4-wire

interface mode is selected. The data coming from the device are sent to the SDO pad. In 3wire interface mode, the output data are sent to the SDA/SDI pad.

The BOOT bit is used to refresh the content of internal registers stored in the Flash memory

block. At device power-up, the content of the Flash memory block is transferred to the

internal registers related to the trimming functions, to permit good device behavior. If for any

reason the content of the trimming registers is changed, this bit can be used to restore the

correct values. When the BOOT bit is set to ‘1’, the content of the internal Flash is copied to

the corresponding internal registers and used to calibrate the device. These values are

factory-trimmed, are different for every accelerometer and normally should not be changed.

At the end of the boot process, the BOOT bit is set again to ‘0’.

The FDS bit enables (FDS=1) or bypasses (FDS=0) the high-pass filter in the signal chain of

the sensor.

The HP FF_WU[2:1] bits enable (HP FF_WU=1) or bypass (HP FF_WU=0) the high-pass

filter in interrupt generation blocks.

The HP coeff[2:1] bits are used to configure the high-pass filter cut-off frequency ft,

accordingly to the following table:

HPcoeff2,1

00 2 8

01 1 4

10 0.5 2

11 0.25 1

20/41 Doc ID 15557 Rev 1

ft (Hz)

(DR=100 Hz)

ft (Hz)

(DR=400 Hz)

AN2960 About control registers

Figure 10 shows the block diagram of the digital processing chain and the related control

signals.

Figure 10. Digital processing chain block diagram

Regs Array

Offset

Adjustment

Block

Digital Processing Chain

6.3 CTRL_REG3 (22h)

Control register #3.

IHL PP_OD I2CFG2 I2CFG1 I2CFG0 I1CFG2 I1CFG1 I1CFG0

IHL

Interrupt active high, low. Default value 0.

(0: active high; 1: active low)

HP Filter

HP_FILTER_RESET

CTRL_REG3(FDS)

0

Interrupt Generator

(FF_WU 1)

1

CTRL_REG2(HP FF_WU1)

0

Interrupt Generator

(FF_WU 2)

1

CTRL_REG2(HP FF_WU2)

0

Output regs

1

SRC reg 1

SRC reg 2

PP_OD

2

I

CFG2,

2

CFG0

I

I1CFG2,

I1CFG0

Push-pull/open drain selection on interrupt pad. Default value 0.

(0: push-pull; 1: open drain)

Interrupt 2 configuration bits. Default value 000.

(see table below)

Interrupt 1 configuration bits. Default value 000.

(see table below)

Doc ID 15557 Rev 1 21/41

About control registers AN2960

The IHL bit selects the polarity of the interrupt signal. When IHL is ‘0’ (default value) any

interrupt event is signalled with a logical 1.

The PP_OD bit defines whether the interrupt pad should operate in Push-pull or in Open

Drain mode. The latter is specifically intended for wired-OR connection of multiple interrupt

signals on the same interrupt line. The default value is ‘0’ which corresponds to Push-pull

mode.

2

The I

CFG[2:0] and I1CFG[2:0] bits select which signal should be sent out from the INT2

and INT1 interrupt pads as described in the following table:

I2CFG2 I2CFG1 I2CFG0

I1CFG2 I1CFG1 I1CFG0 INT1 pin

0 0 0 GND

001 FF_WU 1

010 FF_WU 2

0 1 1 FF_WU1 or FF_WU2

100 DataReady

111 --

INT2 pin

Two completely independent interrupt blocks are available in the LIS331DL: FF_WU1 and

FF_WU2. They can be configured using the registers described in Section 8.

HP filtered data can be selected for further processing by the Interrupt Generator block by

setting the desired values for the HP FF_WU1 and HP FF_WU2 bits in CTRL_REG2. The

default value is '0' and corresponds to the use of non-filtered data. The output of the

Interrupt Generator block is used to load the FF_WU_SRC_1 and FF_WU_SRC_2

registers.

22/41 Doc ID 15557 Rev 1

AN2960 Data and status registers

7 Data and status registers

7.1 WHO_AM_I (0Fh)

Device identification register.

00111011

This register contains a device identifier which, for the LIS331DL, is set to 3Bh.

7.2 STATUS_REG (27h)

Data output status register.

ZYXOR ZOR YOR XOR ZYXDA ZDA YDA XDA

X, Y and Z axes data overrun. Default value: 0

ZYXOR

ZOR

(0: no overrun has occurred;

1: new data has overwritten the previous data before it was read)

Z-axis data overrun. Default value: 0

(0: no overrun has occurred;

1: new data for the Z-axis has overwritten the previous data)

Y-axis data overrun. Default value: 0

YOR

(0: no overrun has occurred;

1: new data for the Y-axis has overwritten the previous data)

X-axis data overrun. Default value: 0

XOR

(0: no overrun has occurred;

1: new data for the X-axis has overwritten the previous data)

ZYXDA

X, Y and Z-axis new data available. Default value: 0

(0: a new set of data is not yet available; 1: a new set of data is available)

Z-axis new data available. Default value: 0

ZDA

(0: new data for the Z-axis is not yet available;

1: new data for the Z-axis is available)

Y-axis new data available. Default value: 0

YDA

(0: new data for the Y-axis is not yet available;

1: new data for the Y-axis is available)

X-axis new data available. Default value: 0

XDA

(0: new data for the X-axis is not yet available;

1: new data for the X-axis is available)

ZYXOR is set to one whenever new acceleration data is produced before completing the

retrieval of the previous set. When this occurs, the content of at least one acceleration data

register (i.e. OUTX, OUTY, OUTZ) has been overwritten. ZYXOR is cleared when the

acceleration data (OUTX, OUTY, OUTZ) of all the active channels are read.

Doc ID 15557 Rev 1 23/41

Data and status registers AN2960

ZOR is set to 1 whenever a new acceleration sample related to the Z-axis is generated

before the retrieval of the previous sample. When this occurs, the previous sample is

overwritten. ZOR is cleared anytime the OUTZ register is read.

YOR is set to 1 whenever a new acceleration sample related to the Y-axis is generated

before the retrieval of the previous sample. When this occurs, the previous sample is

overwritten. YOR is cleared anytime the OUTY_H register is read.

XOR is set to 1 whenever a new acceleration sample related to the X-axis is generated

before the retrieval of the previous sample. When this occurs, the previous sample is

overwritten. XOR is cleared anytime the OUTX_H register is read.

The ZYXDA bit signals that a new sample for all the enabled channels is available. ZYXDA is

cleared when the acceleration data (OUTX, OUTY, OUTZ) of all the enabled channels are

read.

ZDA is set to 1 whenever a new acceleration sample related to the Z-axis is available. ZDA

is cleared anytime the OUTZ register is read. In order to trigger, the ZDA bit requires the Zaxis to be enabled (bit Zen=1 in CTRL_REG1).

YDA is set to 1 whenever a new acceleration sample related to the Y-axis is available. YDA

is cleared anytime the OUTY register is read. In order to trigger, the YDA bit requires the Yaxis to be enabled (bit Yen=1 in CTRL_REG1).

XDA is set to 1 whenever a new acceleration sample related to the X-axis is available. XDA

is cleared anytime the OUTX register is read. In order to trigger, the XDA bit requires the Xaxis to be enabled (bit Xen=1 in CTRL_REG1).

7.3 OUTX (29h)

X-axis output register.

XD7 XD6 XD5 XD4 XD3 XD2 XD1 XD0

7.4 OUTY (2Bh)

Y-axis output register.

.

YD7 YD6 YD5 YD4 YD3 YD2 YD1 YD0

7.5 OUTZ (2Dh)

Z-axis output register.

ZD7 ZD6 ZD5 ZD4 ZD3 ZD2 ZD1 ZD0

.

24/41 Doc ID 15557 Rev 1

AN2960 Free-fall and wake-up registers

8 Free-fall and wake-up registers

The following sections describe the registers that are involved in the generation of the

interrupt signals associated with inertial wake-up and free-fall events.

8.1 HP_FILTER_RESET (23h)

Dummy register. A reading at this address forces the high-pass filter to recover

instantaneously the dc level of the acceleration signal provided to its inputs. After the above

reading, the output of the high-pass filter is zero.

XXXXXXXX

8.2 FF_WU_CFG_1 (30h)

Free-fall and wake-up configuration register for interrupt source 1.

.

AOI LIR ZHIE ZLIE YHIE YLIE XHIE XLIE

AOI

And/Or combination of interrupt events. Default value: 0

(0: OR combination of interrupt events; 1: AND combination of interrupt events)

Latch interrupt request to FF_WU_SRC reg with the FF_WU_SRC reg cleared by

LIR

reading FF_WU_SRC_1 reg. Default value: 0

(0: interrupt request not latched; 1: interrupt request latched)

Enable interrupt generation on Z high event. Default value: 0

ZHIE

(0: disable interrupt request;

1: enable interrupt request on measured accel. value higher than preset threshold)

Enable interrupt generation on Z low event. Default value: 0

ZLIE

(0: disable interrupt request;

1: enable interrupt request on measured accel. value lower than preset threshold)

Enable interrupt generation on Y high event. Default value: 0

YHIE

(0: disable interrupt request;

1: enable interrupt request on measured accel. value higher than preset threshold)

Enable interrupt generation on Y low event. Default value: 0

YLIE

(0: disable interrupt request;

1: enable interrupt request on measured accel. value lower than preset threshold)

Enable interrupt generation on X high event. Default value: 0

XHIE

(0: disable interrupt request;

1: enable interrupt request on measured accel. value higher than preset threshold)

XLIE

Enable interrupt generation on X low event. Default value: 0

(0: disable interrupt request;

1: enable interrupt request on measured accel. value lower than preset threshold)

Doc ID 15557 Rev 1 25/41

Free-fall and wake-up registers AN2960

The AOI bit allows selection of wake-up (OR combination of interrupt events) or free-fall

(AND combination of interrupt events) detection

LIR defines whether the configured interrupt event should be latched by the device once it

has occurred. The interrupt request is cleared by reading the related source register

(FF_WU_SRC_1).

XHIE (YHIE, ZHIE) set an interrupt event to occur when the measured acceleration data on

the X (Y, Z) channel is higher than the threshold set in the FF_WU_THS_1 register.

XLIE (YLIE, ZLIE) set an interrupt event to occur when the measured acceleration data on

the X (Y, Z) channel is lower than the threshold set in the FF_WU_THS_1 register.

The threshold module used by the system to detect free-fall or inertial wake-up events is

defined by FF_WU_THS_1. The threshold value is expressed over 7 bits as an unsigned

number and X, (Y, Z) high is true when the unsigned acceleration value of the X (Y, Z)

channel is higher than or equal to FF_WU_THS_1. Similarly, X, (Y, Z) low is true when the

unsigned acceleration value of the X (Y, Z) channel is lower than FF_WU_THS_1. Refer to

Figure 11 for more details.

Figure 11. FF_WU_CFG_1,2 high and low value

+ Full Scale

X (Y, Z) high

Threshold module

Positive

acceleration

X (Y, Z) low

X (Y, Z) high

8.3 FF_WU_SRC_1 (31h)

Free-fall and wake-up source register for interrupt 1. Read only register.

.

x IA ZHZLYHYLXHXL

Interrupt active. Default value: 0

IA

ZH

ZL

YH

YL

XH

XL

(0: no interrupt has been generated;

1: one or more interrupt event has been generated)

Z high. Default value: 0

(0: no interrupt; 1: ZH event has occurred)

Z low. Default value: 0

(0: no interrupt; 1: ZL event has occurred)

Y high. Default value: 0

(0: no interrupt; 1: YH event has occurred)

Y low. Default value: 0

(0: no interrupt; 1: YL event has occurred)

X high. Default value: 0

(0: no interrupt; 1: XH event has occurred)

X low. Default value: 0

(0: no interrupt; 1: XL event has occurred)

0 g level

Threshold module

- Full Scale

Negative

acceleration

26/41 Doc ID 15557 Rev 1

AN2960 Free-fall and wake-up registers

This register keeps track of the acceleration event triggering (or that has triggered, if the LIR

bit in FF_WU_SRC_1 reg is set to 1) the interrupt signal. In particular, IA is equal to 1 when

the combination of acceleration events specified in FF_WU_CFG_1 register is true. This bit

is used for the generation of the interrupt signal associated with free-fall/wake-up events.

X, (Y, Z) high is true when the module of the acceleration value of the X (Y, Z) channel is

higher than the preset threshold which is defined as the concatenation of FF_WU_THS_1.

Similarly, X, (Y, Z) low is true when the module of the acceleration value of the X (Y, Z)

channel is lower than FF_WU_THS_1.

Reading at this address clears the FF_WU_SRC_1 register and the FF_WU1 interrupt and

allows the refreshment of data in the FF_WU_SRC_1 register itself, if the latched option was

chosen.

8.4 FF_WU_THS_1 (32h)

Free-fall, wake-up threshold for interrupt 1.

DCRM THS6 THS5 THS4 THS3 THS2 THS1 THS0

DCRM

Duration counter reset mode selection. Default value: 0

(0: counter reset; 1: counter decremented)

THS6, THS0 Free-fall / wake-up threshold: default value: 000 0000

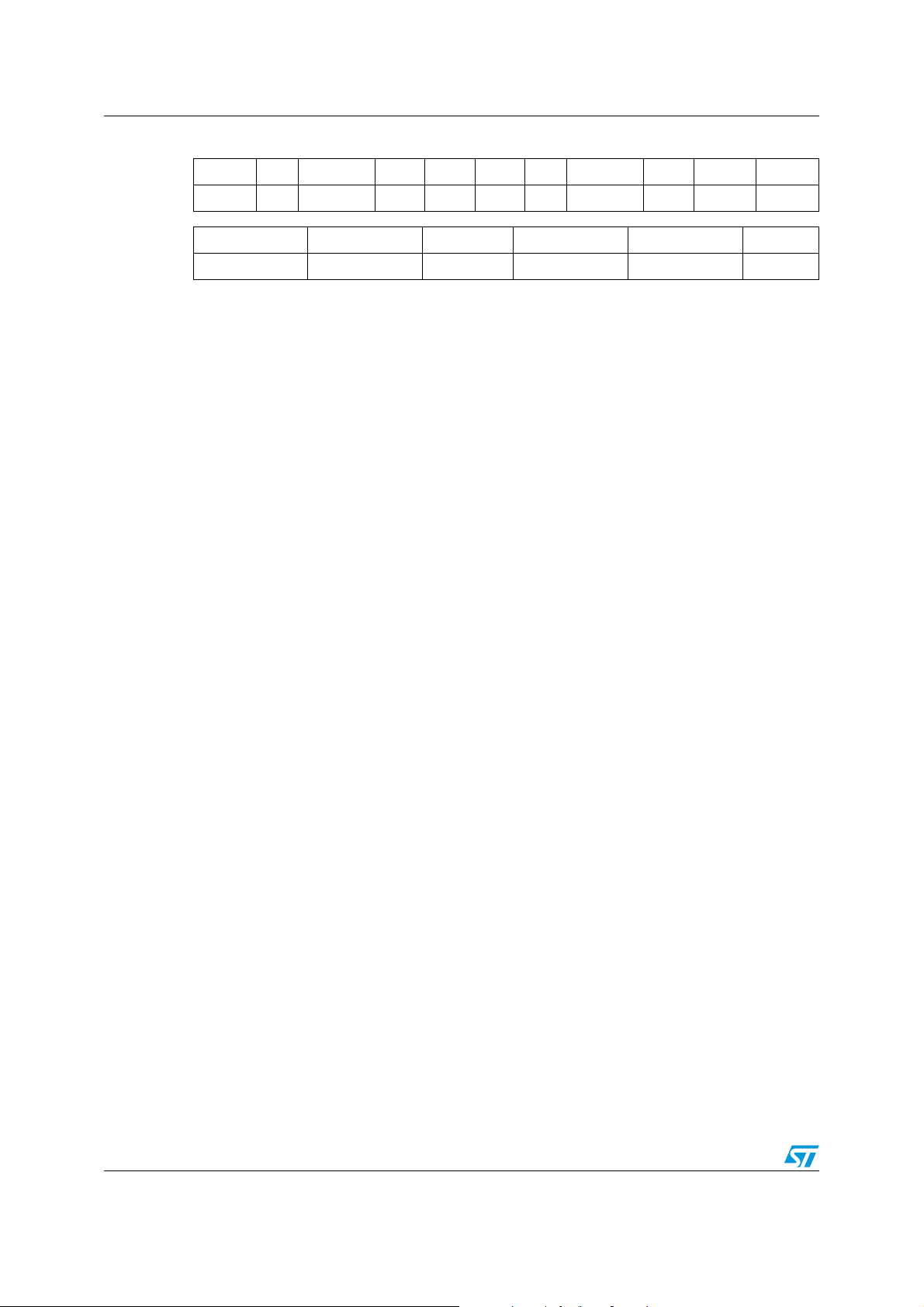

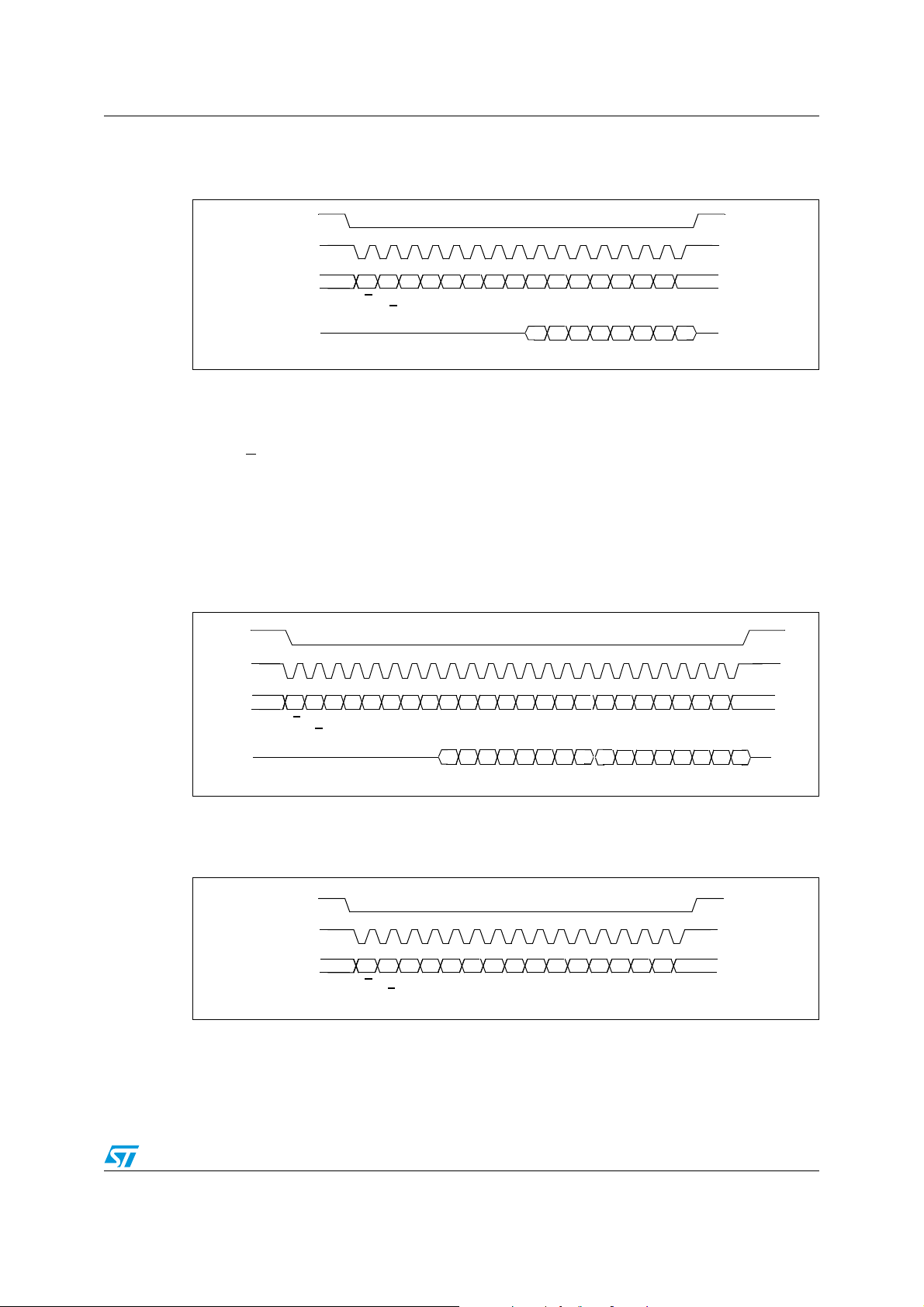

The DCRM bit allows selection of the way in which the duration counter is reset. When

DCRM is ‘0’, the duration counter is reset immediately whenever the internal inertial event

programmed by the user is not active (Figure 12 part B) while it is decremented when

DCRM is set to 1 (Figure 12 part C). The latter configuration allows the filtering out of

spurious spikes which might impair the recognition and validation of inertial events.

Doc ID 15557 Rev 1 27/41

Free-fall and wake-up registers AN2960

Figure 12. DCRM bit function

Duration

Free-fall event

Duration THS

Counter value

Free-fall interrupt

Duration

Free-fall event

Duration THS

B

Counter value

Free-fall interrupt

Duration

Free-fall event

Duration THS

Counter value

Free-fall interrupt

8.5 FF_WU_DURATION_1 (33h)

Set the minimum duration of the free-fall, wake-up event that must be recognized by the

LIS331DL.

D7 D6 D5 D4 D3 D2 D1 D0

D7, D0 Duration value. Default value: 0000 0000

D7, D0 define the minimum duration of the programmed inertial event such as free-fall and

wake-up that must be recognized by the device. Duration increments and maximum value

depend on the ODR chosen. For an output data rate of 400 Hz, the register allows setting a

duration spanning from 0 to 637.5 ms in increments of 2.5 ms. Conversely, when the output

data rate is set to 100 Hz, it is possible to define an event duration spanning from 0 to 2.55

seconds in increments of 10 ms. The counter used to implement the duration function is

blocked when the LIR bit in the configuration register is set to one and the interrupt event

has occurred.

C

28/41 Doc ID 15557 Rev 1

AN2960 Free-fall and wake-up registers

8.6 FF_WU_CFG_2 (34h)

Free-fall and wake-up configuration register for interrupt source 2.

AOI LIR ZHIE ZLIE YHIE YLIE XHIE XLIE

AOI

LIR

ZHIE

ZLIE

YHIE

YLIE

XHIE

XLIE

And/Or combination of interrupt events. Default value: 0

(0: OR combination of interrupt events; 1: AND combination of interrupt events)

Latch interrupt request to FF_WU_SRC reg with the FF_WU_SRC reg cleared by

reading FF_WU_SRC_1 reg. Default value: 0

(0: interrupt request not latched; 1: interrupt request latched)

Enable interrupt generation on Z high event. Default value: 0

(0: disable interrupt request;

1: enable interrupt request on measured accel. value higher than preset threshold)

Enable interrupt generation on Z low event. Default value: 0

(0: disable interrupt request;

1: enable interrupt request on measured accel. value lower than preset threshold)

Enable interrupt generation on Y high event. Default value: 0

(0: disable interrupt request;

1: enable interrupt request on measured accel. value higher than preset threshold)

Enable interrupt generation on Y low event. Default value: 0

(0: disable interrupt request;

1: enable interrupt request on measured accel. value lower than preset threshold)

Enable interrupt generation on X high event. Default value: 0

(0: disable interrupt request;

1: enable interrupt request on measured accel. value higher than preset threshold)

Enable interrupt generation on X low event. Default value: 0

(0: disable interrupt request;

1: enable interrupt request on measured accel. value lower than preset threshold)

Two structures can be used to generate interrupts. They have exactly the same

configuration capability and are completely independent.

The interrupt result of each structure can be sent with indifference to the INT1 or INT2 pins

using the CTRL_REG3 register.

Doc ID 15557 Rev 1 29/41

Free-fall and wake-up registers AN2960

8.7 FF_WU_SRC_2 (35h)

Free-fall and wake-up source register for interrupt 2. Read-only register. Refer to

FF_WU_SRC_1 for details.

x IA ZHZLYHYLXHXL

Interrupt active. Default value: 0

IA

ZH

ZL

YH

YL

XH

XL

(0: no interrupt has been generated;

1: one or more interrupt event has been generated)

Z high. Default value: 0

(0: no interrupt; 1: ZH event has occurred)

Z low. Default value: 0

(0: no interrupt; 1: ZL event has occurred)

Y high. Default value: 0

(0: no interrupt; 1: YH event has occurred)

Y low. Default value: 0

(0: no interrupt; 1: YL event has occurred)

X high. Default value: 0

(0: no interrupt; 1: XH event has occurred)

X low. Default value: 0

(0: no interrupt; 1: XL event has occurred)

Reading at this address clears the FF_WU_SRC_2 register and the FF_WU2 interrupt and

allows the refreshment of data in the FF_WU_SRC_2 register if the latched option was chosen.

8.8 FF_WU_THS_2 (36h)

Free-fall, wake-up threshold for interrupt source 2.

The

DCRM THS6 THS5 THS4 THS3 THS2 THS1 THS0

DCRM

THS6, THS0 Free-fall / wake-up threshold: default value: 000 0000

The DCRM bit and THS6 to THS0 behave exactly like the bit in FF_WU_THS_1 but they are

applied to interrupt source 2.

Duration counter reset mode selection. Default value: 0

(0: counter reset; 1: counter decremented)

30/41 Doc ID 15557 Rev 1

AN2960 Free-fall and wake-up registers

8.9 FF_WU_DURATION_2 (37h)

Set the minimum duration of the free-fall, wake-up event that must be recognized by the

LIS331DL.

D7 D6 D5 D4 D3 D2 D1 D0

D7, D0 Duration value. Default value: 0000 0000

Refer to FF_WU_DURATION_1 for details.

Doc ID 15557 Rev 1 31/41

Application information AN2960

9 Application information

9.1 Start-up sequence

Once the device is powered up, it automatically downloads the calibration coefficients from

the embedded Flash to the internal registers. When the boot procedure is complete (after

approximately 3 ms) the device automatically enters power-down mode.

To turn-on the device and gather acceleration data, it is necessary to write 47h in the

CTRL_REG1. With this command the three acceleration channels (i.e. X, Y and Z-axis) are

enabled and the output data rate is set to 100 Hz.

9.2 Reading acceleration data

9.2.1 Using the status register

The device is provided with a STATUS_REG which should be polled to check when a new

set of data is available. The reading procedure should be the following:

1 read STATUS_REG

2 if STATUS_REG(3)=0 then goto 1

3 if STATUS_REG(7)=1 then some data have been overwritten

4 read OUTX

5 read OUTY

6 read OUTZ

7 data processing

8 goto 1

The check performed at step 3 permits understanding of whether the reading rate is

adequate compared to the data production rate. In case one or more acceleration samples

have been overwritten by new data because of a too slow reading rate, the bit

STATUS_REG(7) is set to 1.

The overrun bits are automatically cleared when all the data present inside the device have

been read and new data have not been produced in the meantime.

9.2.2 Using the DataReady signal

The device may be configured to generate one HW signal (DataReady) on either pin 9 or 11,

to flag that a new set of measurement data is available for reading. This signal corresponds

to the ZYXDA bit present in the STATUS_REG. The polarity of the signal is defined through

the IHL bit present in CTRL_REG3 and is deasserted when the acceleration data of all the

enabled channels have been read. To enable the DataReady signal on pin 11

(corresponding to INT1), it is necessary to set the I1CFG[2:0] bit present in CTRL_REG3 to

100. Conversely, to enable the DataReady signal on pin 9 (corresponding to INT2) it is

necessary to set the I

2

CFG[2:0] bit present in the CTRL_REG3 to 100.

32/41 Doc ID 15557 Rev 1

AN2960 Application information

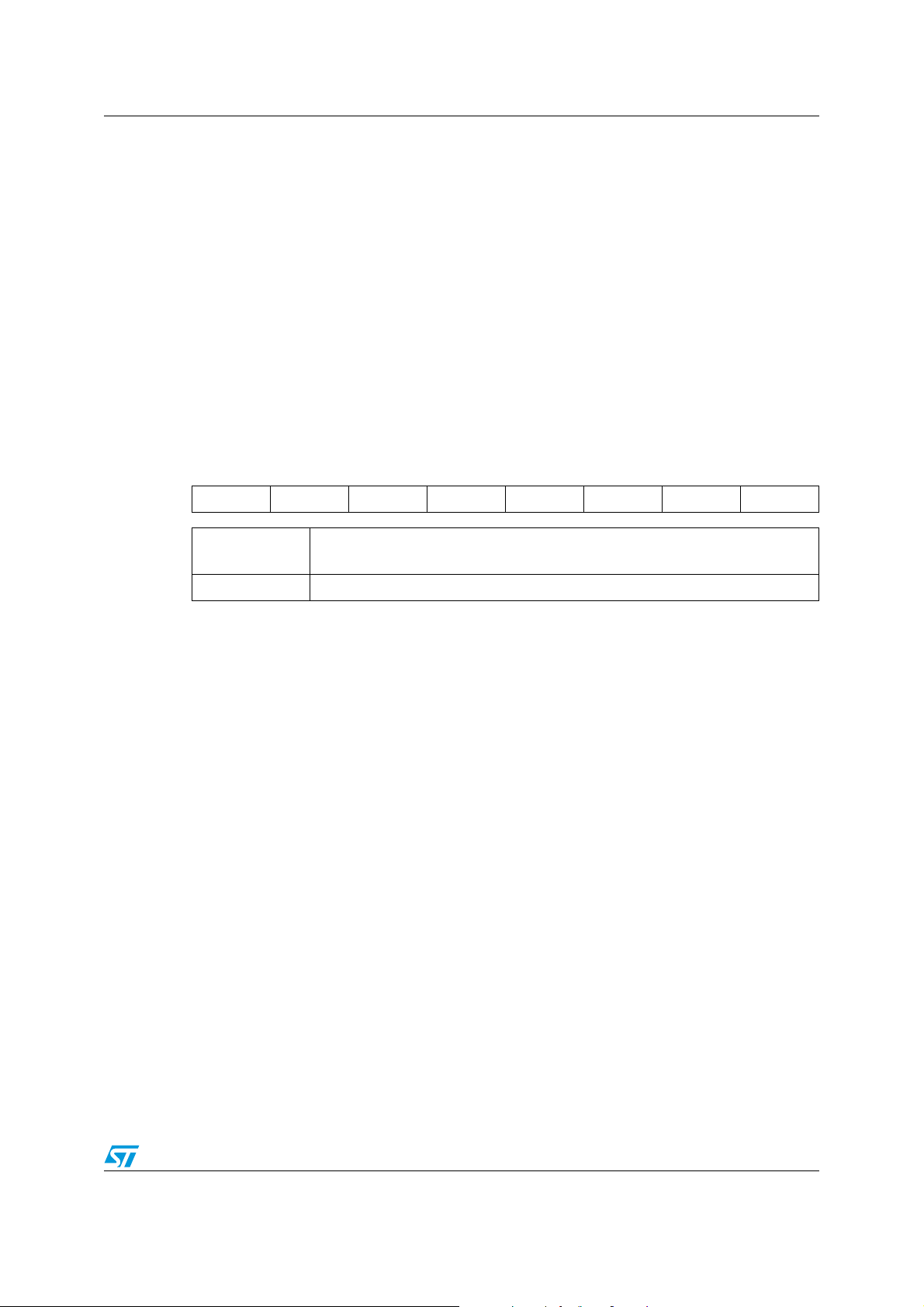

9.3 Understanding acceleration data

The measured acceleration data are sent to the OUTX, OUTY and OUTZ registers. The

acceleration values are expressed as a 2’s complement number. When the full-scale is set

to 2 g, each LSB corresponds to 18 mg.

The table below provides a few basic examples of the data that is read in the data registers

when the device is subject to a given acceleration. The values listed in the table are given

under the hypothesis of perfect device calibration (i.e. no offset, no gain error, etc.) and

rounded to the closest integer.

Table 5. Output data register content vs. acceleration

FS bit = 0 FS bit = 1

Acceleration values

Output register content

0 g 00h 00h

350 mg 14h 05h

1 g 38h 0Eh

2 g 6Fh 1Ch

-350 mg ECh FBh

-1 g C8h F2h

-2 g 91h E4h

Doc ID 15557 Rev 1 33/41

Application information AN2960

9.4 Interrupt generation description

The LIS331DL provides two fully-programmable interrupt sources which may be configured

to trigger different inertial events. Among them, it is worth mentioning, is the recognition of

free-fall and wake-up events. When an interrupt condition is verified, the interrupt signal is

asserted and by reading either the FF_WU_SRC_1 or FF_WU_SRC_2 registers, it is

possible to understand which condition has occurred.

The block diagram of the interrupt block is shown below.

Figure 13. Interrupt generation block diagram

CTRL_REG2(FDS)

ADC

HP filter

100/400Hz

Ph_Gen

0

1

0

FF_WU1

1

CTRL_REG2(HP FF_WU1)

CTRL_REG1(DR,PD)

0

FF_WU2

1

CTRL_REG2(HP FF_WU2)

Figure 14. Free-fall, wake-up interrupt generator

THS reg

Accel_X

Accel_Y

|b|>a?

X_en

|b|>a?

Y_en

Output Reg

SRC1

CFG 1

SRC2

CFG 2

WU

Serial

Interface

(SPI

2

C)

& I

0

1

|b|>a?

Accel_Z

FF or WU interrupt generation is selected for each interrupt generation channel through the

AOI bit in the corresponding FF_WU_CFG register. If the AOI bit is ‘0’, signals coming from

the comparators are put in logical OR. Depending on the values written in the

FF_WU_CFG_1 and FF_WU_CFG_2 registers, each time the value of at least one of the

enabled axes exceeds the threshold written in the module in the corresponding

FF_WU_THS_1 and FF_WU_THS_2 registers, a FF, WU interrupt is generated. Otherwise,

if the AOI bit is ‘1’, signals coming from the comparators go into a “NAND” port. In this case,

an interrupt signal is generated whenever the acceleration signal of all the enabled axes is

below the threshold written in the FF_WU_THS_1 or FF_WU_THS_2 registers.

34/41 Doc ID 15557 Rev 1

Z_en

FF

FF_WU_CFG(AOI)

AN2960 Application information

The FF_WU_CFG(LIR) bit permits the determination of whether or not the interrupt request

should be latched. If the LIR bit is ‘0’ (default value), the interrupt signal goes high when the

interrupt condition is satisfied and comes back low immediately if the interrupt condition is

no longer verified. Otherwise, if the LIR bit is ‘1’, whenever an interrupt condition is applied

the interrupt signal remains high even if the condition returns to a non-interrupt status, until

a reading to the FF_WU_SRC register is performed.

The remaining bits of the FF_WU_CFG register allow the decision as to which axis the

interrupt should be performed on and in which direction the threshold must be exceeded to

generate the interrupt request.

9.5 Inertial wake-up

9.5.1 HP filter bypassed

This paragraph provides a basic algorithm which shows the practical use of the inertial

wake-up feature. In particular, with the code below, the device is configured to recognize

when the absolute acceleration along either X or Y axis exceeds a preset threshold (180 mg

is used in the example). The event which triggers the interrupt is latched inside the device

using FF_WU interrupt source 1 and its occurrence is signalled through the use of the INT2

pin.

1 write C7h into CTRL_REG1 // Turn-on the sensor and set ODR=400Hz

2 write 00h into CTRL_REG2 // Default value: high-pass filter bypassed

3 write 08h into CTRL_REG3 // FF_WU1 interrupt sent to INT2 pin

4 write 0Ah into FF_WU_THS_1 reg // Set wake-up threshold = 180 mg

5 write 00h into FF_WU_DURATION_1 reg // No filtering/confirmation on the event

6 write 4Ah into FF_WU_CFG_1 // Configure desired wake-up event

7 poll INT2 pin; if INT2=0 then goto 7 // Poll INT2 pin waiting for the wake-up event

// Return the event that has triggered the

8 read FF_WU_SRC_1 reg

interrupt

// Clear interrupt request

(Wake-up event has occurred; insert your code

9

here)

// Event handling

10 goto 7

Doc ID 15557 Rev 1 35/41

Application information AN2960

9.5.2 Using the HP filter

The code provided below gives a basic routine which shows the practical use of the inertial

wake-up feature performed on high-pass filtered data. In particular, the device is configured

to recognize when the high-frequency component of the acceleration applied along either

the X, Y or Z axis exceeds a preset threshold (180 mg is used in the example). The event

which triggers the interrupt is latched inside the device using FF_WU interrupt source 1 and

its occurrence is signalled through the usage of the INT1 pin.

1 write C7h into CTRL_REG1 // Turn-on the sensor and set ODR=400 Hz

2 write 04h into CTRL_REG2

3 write 01h into CTRL_REG3 // FF_WU1 interrupt sent to INT1 pin

4 write 0Ah into FF_WU_THS_1 reg // Set wake-up threshold = 180 mg

5 write 00h into FF_WU_DURATION_1 reg // No filtering/confirmation on the event

6 read HP_FILTER_RESET register

7 write 6Ah into FF_WU_CFG_1 // Configure desired wake-up event

8 poll INT1 pin; if INT1=0 then goto 7 // Poll INT1 pin waiting for the wake-up event

// High-pass filter enabled on FF_WU1, fcutoff= 8Hz

// Dummy read to force the HP filter to

// actual acceleration value

// (i.e. set reference acceleration/tilt value)

(Wake-up event has occurred; insert your code

9

here)

// Event handling

// Return the event that has triggered the

10 read FF_WU_SRC_1 reg

interrupt

// Clear interrupt request

11 (Insert your code here) // Event handling

12 goto 8

At step 6, a dummy read at the HP_FILTER_RESET register is performed to set the

current/reference acceleration/tilt state against which the device performed the threshold

comparison.

This read may be performed any time required to set the orientation/tilt of the device as a

reference state without waiting for the filter to settle.

36/41 Doc ID 15557 Rev 1

AN2960 Application information

9.6 Free-fall detection

9.6.1 Roll function not used

This paragraph provides the basics for the use of the free-fall detection feature. The SW

routine that configures the device to detect free-fall events and to signal them is as follows:

1 write 47h into CTRL_REG1 // Turn-on the sensor and set ODR=100 Hz

2 write 00h into CTRL_REG2 // Default value: high-pass filter bypassed

3 write 08h into CTRL_REG3 // FF_WU1 interrupt sent to INT2 pin

4 write 14h into FF_WU_THS_1 reg // Set the free-fall threshold

5 write 09h into FF_WU_DURATION_1 reg // Set minimum event duration to 90 ms

6 write D5h into FF_WU_CFG_1

// Configure free-fall recognition and latch

// interrupt request

7 poll INT2 pad; if INT2=0 then goto 7 // Poll INT2 pin waiting for the free-fall event

(Free-fall event has occurred; insert your code

8

here)

// Event handling

9 read FF_WU_SRC_1 register // Clear interrupt request

10 goto 7

The code sample exploits a threshold set at 350 mg for free-fall recognition and the event is

notified by the hardware signal INT2 pin. At step 5, the FF_WU_DURATION_1 register is

configured to ignore events that are shorter than 9/ODR=9/100~90 ms (ODR=output data

rate) in order to avoid false detections.

Once the free-fall event has occurred, a dummy read at FF_WU_SRC_1 reg clears the

request and the device is ready to recognize other events.

9.6.2 Roll function applied

The roll function can be added to free-fall condition recognition using both interrupt sources.

Interrupt signals can be sent to two different pins (INT1, INT2) or can be sent to the same

pin so that the first condition verified controls the pin (logic “OR” of interrupt signals).

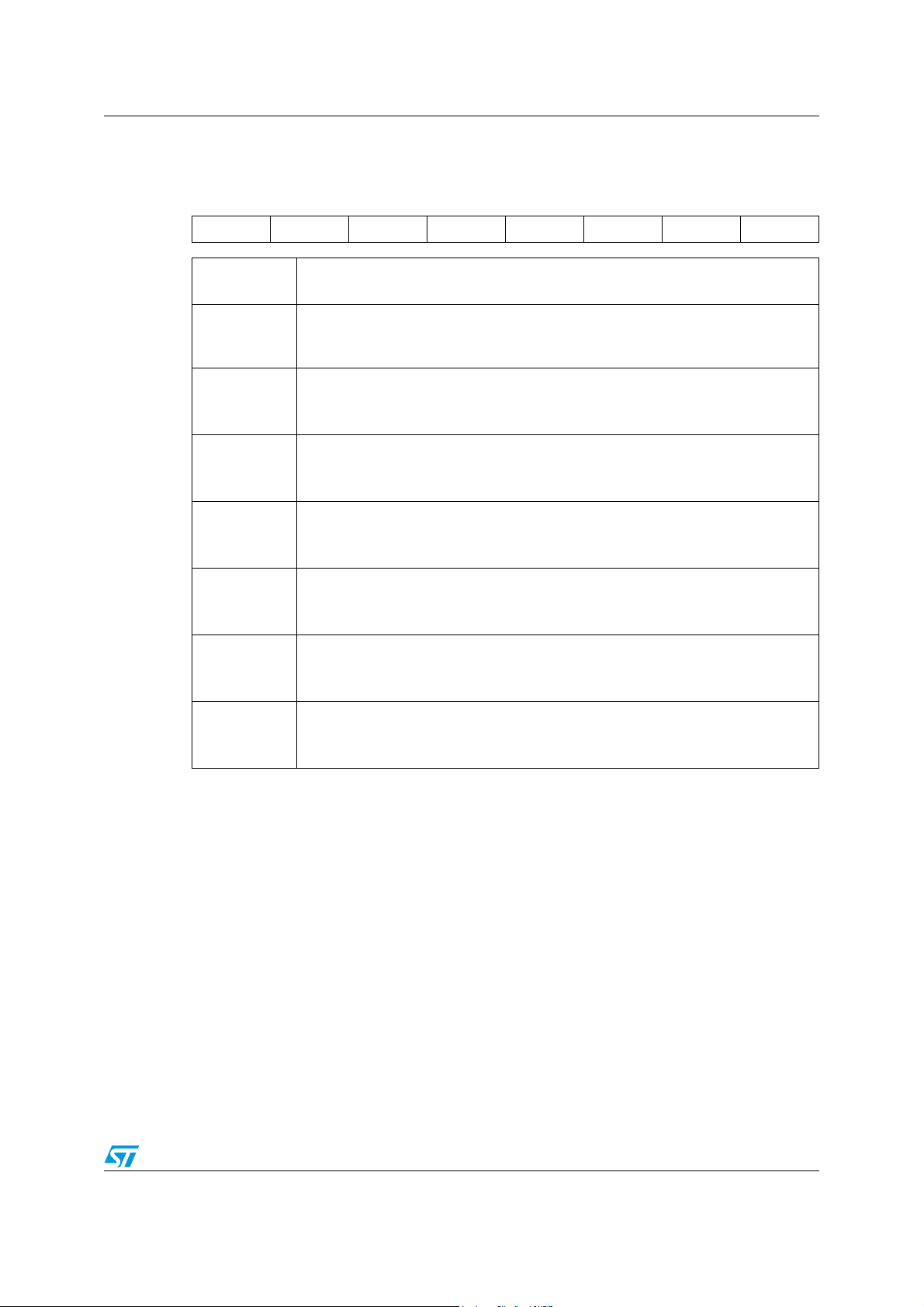

9.7 Output data rate selection and reading timing

The output data rate is user-selectable through the DR bit stored in the CTRL_REG1 (20h)

register. At power-on-reset, DR is reset to 0, thus providing a default output data rate set to

100 Hz.

The selectable output data rates are given in Tabl e 6 below:

Table 6. Output data rate

DR Output data rate

0 100 Hz

1 400 Hz

Doc ID 15557 Rev 1 37/41

Application information AN2960

The output data rate precision is related to internal oscillator or to external clock precision,

and an error of +/- 10% should be taken into account.

The output data rate precision is related to internal oscillator or to external clock precision,

and an error of +/- 10% should be taken into account.

A minimum reading period 150 µs shorter than the output data rate period is defined to

avoid the loss of any data produced. During this time period the reading of the data must be

performed and the DataReady signal can be used as a trigger to begin the reading

sequence. At the end of the complete sequence, the DataReady signal goes down and the

following rising edge advises that new data are available. If this minimum reading frequency

is not observed, it is possible to lose some data and the DataReady signal loses its function

as a trigger signal. The status register can be used to infer whether an overrun condition has

occurred.

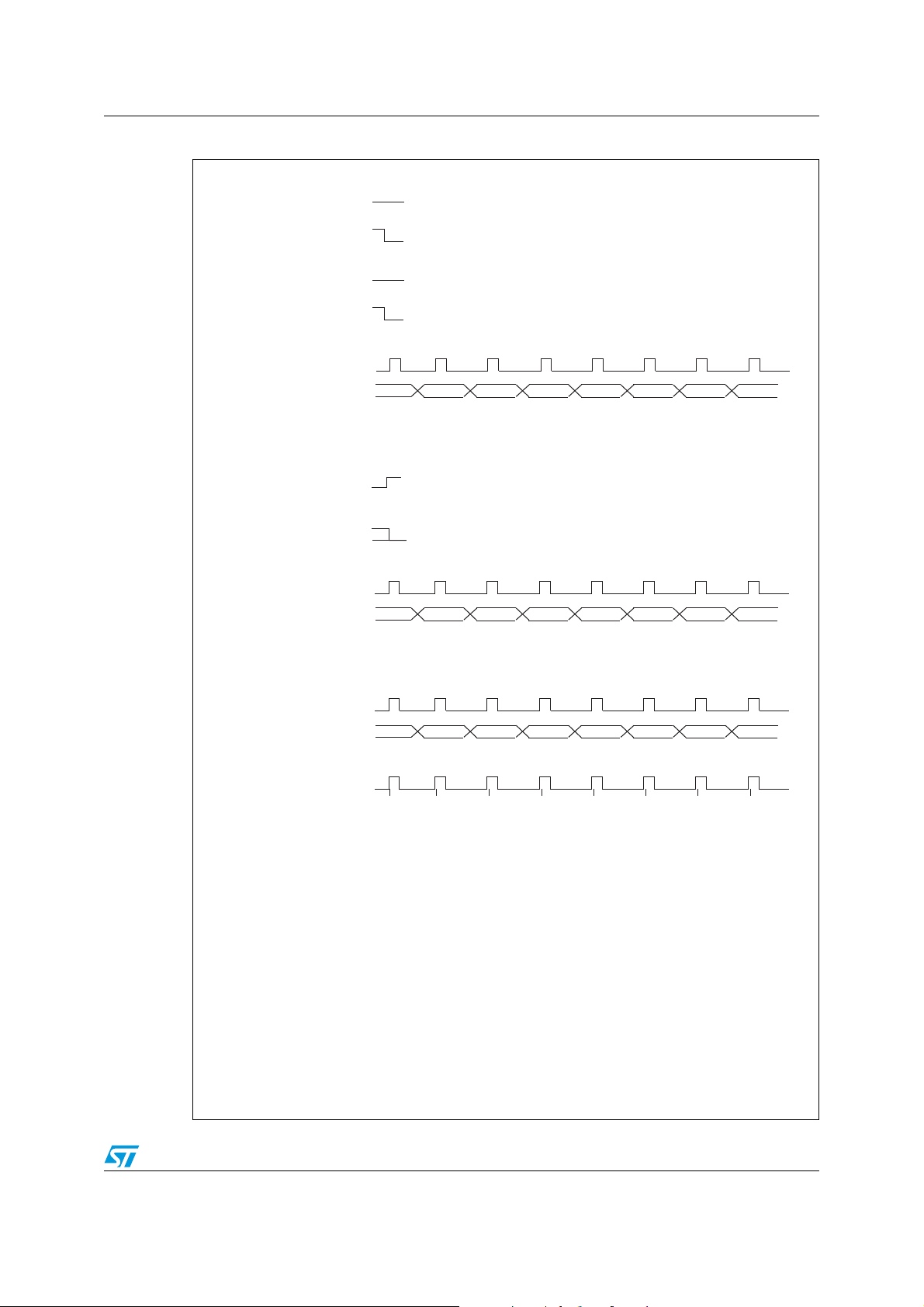

Figure 15. Reading timing

T0

T2T1

New data available

DataReady

Table 7. Timing value to avoid data loss

Time Description Min. Typ. Max.

T0 Data rate 2.5 ms - 10 ms

T1 Reading period - T0-T2

T2 New data generation 150 µs -

38/41 Doc ID 15557 Rev 1

AN2960 Application information

9.8 DataReady vs. interrupt signal

The device includes two pins which can be activated to generate either the DataReady or

the interrupt signal. The functionality of the pins is selected by setting the interrupt

configuration bits located in CTRL_REG3(2-0) for interrupt pin 1 (INT1) and in

CTRL_REG3(5-3) for interrupt pin 2 (INT2), in accordance with the block diagram given in

Figure 16.

The DataReady signal stored in STATUS_REG(3), which indicates when a new set of

acceleration data is ready, is made available by setting the cfg bit to 100. The interrupt

source 1 signal is sent to the pin when the cfg bit is set to 001 and the interrupt source 2

when the cfg bit is set to 010. A logic “OR” combination of interrupt source 1 and 2 can be

sent to an interrupt pin by writing 011 in the cfg bit.

Figure 16. Interrupt and DataReady signal generation block diagram

Interrupt Generator

(FF_WU_1, 2)

Free-Fall,

Wake-Up

Interrupt

Generator

Free-Fall,

Wake-Up

Interrupt

Generator

IA

(FF_WU_SRC_1)

IA

(FF_WU_SRC_2)

DataReady

Signal

Generator

Clock (100/400Hz)

Counter

ff_wu_duration

Clock (100/400Hz)

Counter

ff_wu_duration

1

2

DataReady signal

Latch

FF_WU_CFG1(LIR)

Latch

FF_WU_CFG2(LIR)

0

0 0 0

0 0 1

INT1 signal

0 1 0

0 1 1

0

1

0

1

1 0 0

1 1 1

CTRL_REG3(2,1,0)

0

0 0 0

0 0 1

0 1 0

0 1 1

1 0 0

1 1 1

CTRL_REG3(5,4,3)

INT2 signal

The DataReady signal rises to 1 when a new set of acceleration data has been generated

and is available for reading. The signal is reset after all the enabled channels are read

through the serial interface.

Figure 17. DataReady signal

ACCEL DATA Accel. Sample #(N) Accel. Sample #(N+1)

RDY

DATA READ

XYZXYZ

Doc ID 15557 Rev 1 39/41

Revision history AN2960

10 Revision history

Table 8. Document revision history

Date Revision Changes

12-Jun-2009 1 Initial release.

40/41 Doc ID 15557 Rev 1

AN2960

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2009 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 15557 Rev 1 41/41

Loading...

Loading...