Page 1

AN2928

Applica t ion note

Modified buck converter for LED applications

Introduction

The use of high power LEDs in lighting applications is becoming increasingly popular due to

rapid improvements in lighting efficiency, longer life, higher reliability and overall cost

effectiveness. Dimming functions are more easily implemented in LEDs, and they are more

robust and offer wider design flexibility compared to other light sources.

Applications suitable for the use of LEDs include lighting for streets, stadiums, fairs and

exhibitions, shops, interiors, as well as for decorative lighting, outdoor wall lighting and

consumer lighting such as lamps and ballasts. Therefore, LED use for lighting is likely to

represent an increasingly large proportion of the lighting market in the future. To assist

engineers in their design approach, the STEVAL-ILL013V1 80 W offline PFC LED driver

demonstration board has been developed. This application note describes, step-by-step,

all the principles and calculations used for a modified buck converter intended for high

brightness LED applications.

The converter is designed as a constant current source to achieve the best lighting

performance from the LEDs. A “modified buck" topology was chosen because the power

switch is connected to ground rather than the high side switch, as in a standard buck

topology, so with this solution it is easier to control the switch. The design uses a fixed offtime (FOT) network operating in continuous conduction mode (CCM), rendering the overall

solution simple and cost-effective. The modified buck converter described in this document

can be used for lighting applications from low power and low voltage, to high power and high

voltage. This allows designers to cover a wide range of different LED systems using a single

topology.

Additionally, in lighting applications where the input active power is higher than 25 W and

a high power factor is required, the high PF converter can be connecte d as the first stage,

before the modified BUCK converter. The STEVAL-ILL013V1 shows this design concept.

The STEVAL-ILL013V1 demonstration board is an 80 W offline dimmable LED driver with

high power factor (PF) intended for 350 mA, 700 mA and 1 A LEDs, and is based on

STMicroelectronics’ L6562A transition-mode PFC controller. The design is complaint with

standard EN61000-3-2 (limits for harmonic current emissions). The order code is STEVALILL013V1 and the complete design, including schematic diagram, bill of material,

calculations, measurements, etc. is described in user manual UM0670 (see Section 3:

Reference and related materials).

March 2009 Rev 1 1/21

www.st.com

Page 2

Contents AN2928

Contents

1 Modified buck converter in constant current mode . . . . . . . . . . . . . . . . 4

2 Design equations for the modified buck converter . . . . . . . . . . . . . . . . 6

2.1 Basic equations for the modified buck converter . . . . . . . . . . . . . . . . . . . . 6

2.2 Fixed off-time network calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 LED current calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4 Power MOSFET calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5 Power diode selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.6 Inductor calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3 Reference and related materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2/21

Page 3

AN2928 List of figures

List of figures

Figure 1. Modified buck converter - tON time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 2. Modified buck converter - t

Figure 3. Modified buck converter - theory of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 4. Sawtooth signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 5. Real drain MOSFET current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 6. Real power diode current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

OFF

3/21

Page 4

Modified buck converter in constant curren t mode AN2928

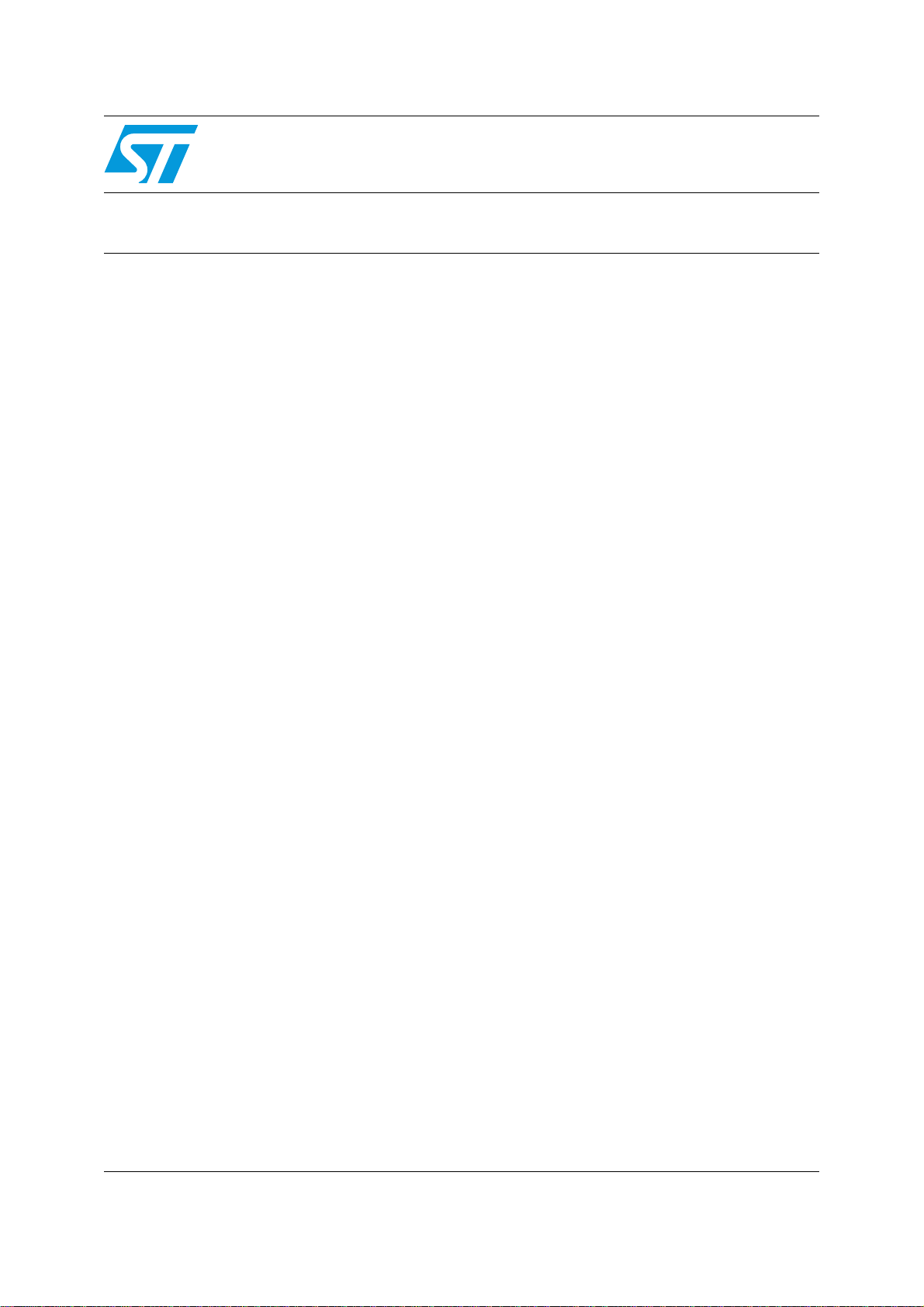

1 Modified buck converter in constant current mode

As stated in the introduction, the aim of this application note is to describe a modified buck

converter working in FOT and CCM. The basic principle of the design using the L6562A

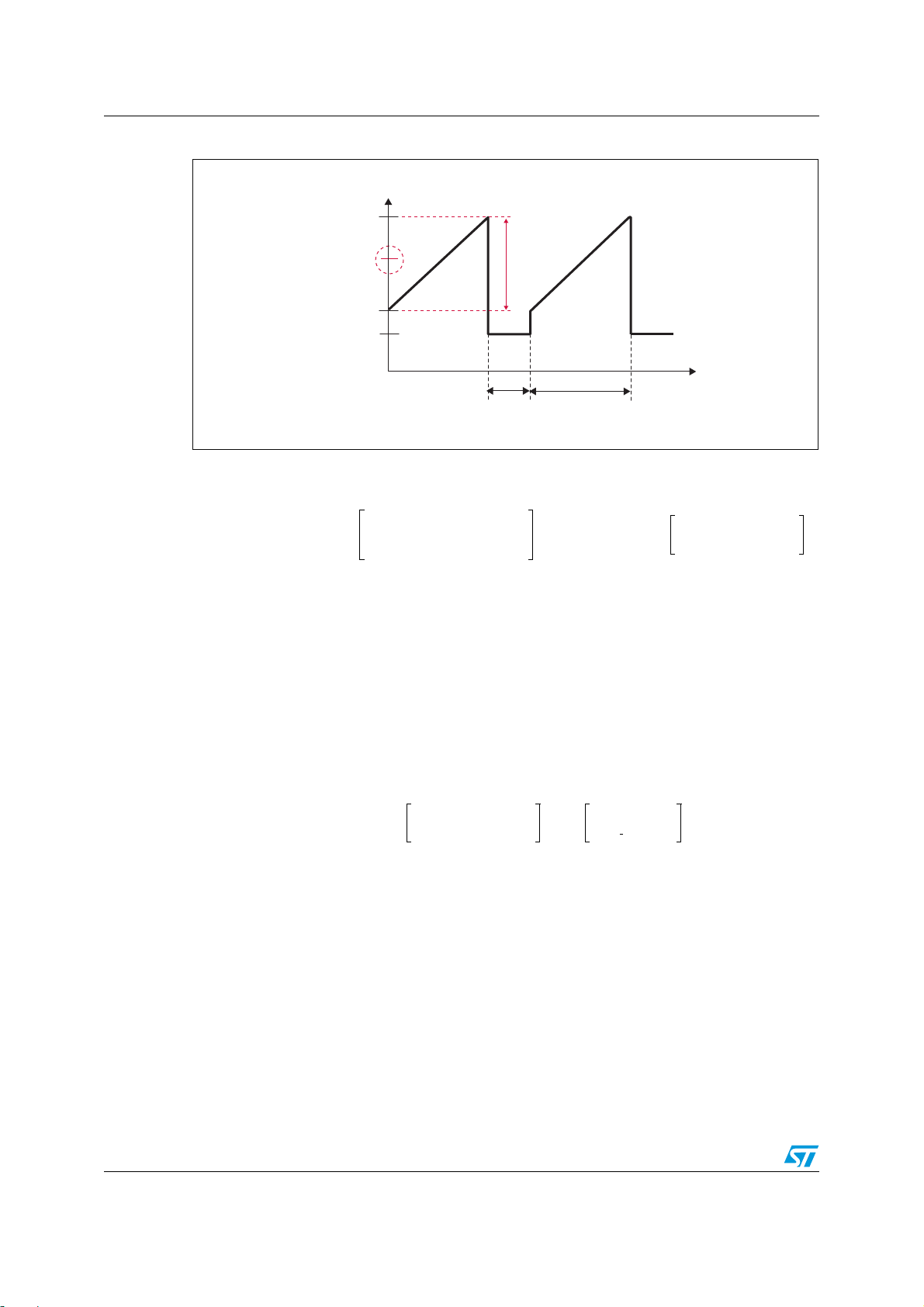

controller is shown in Figure 1 and Figure 2. Figure 1 represents the stage when the power

MOSFET Q

input (V

sensing resistor. Capacitor C

Q

is open and its gate voltage is around 10 V. During the tON time, the load current

1

increases and stops as soon as the voltage on the current sense resistor reaches the

internal threshold on the CS pin of the L6562A. The current sense of the L6562A is clamped

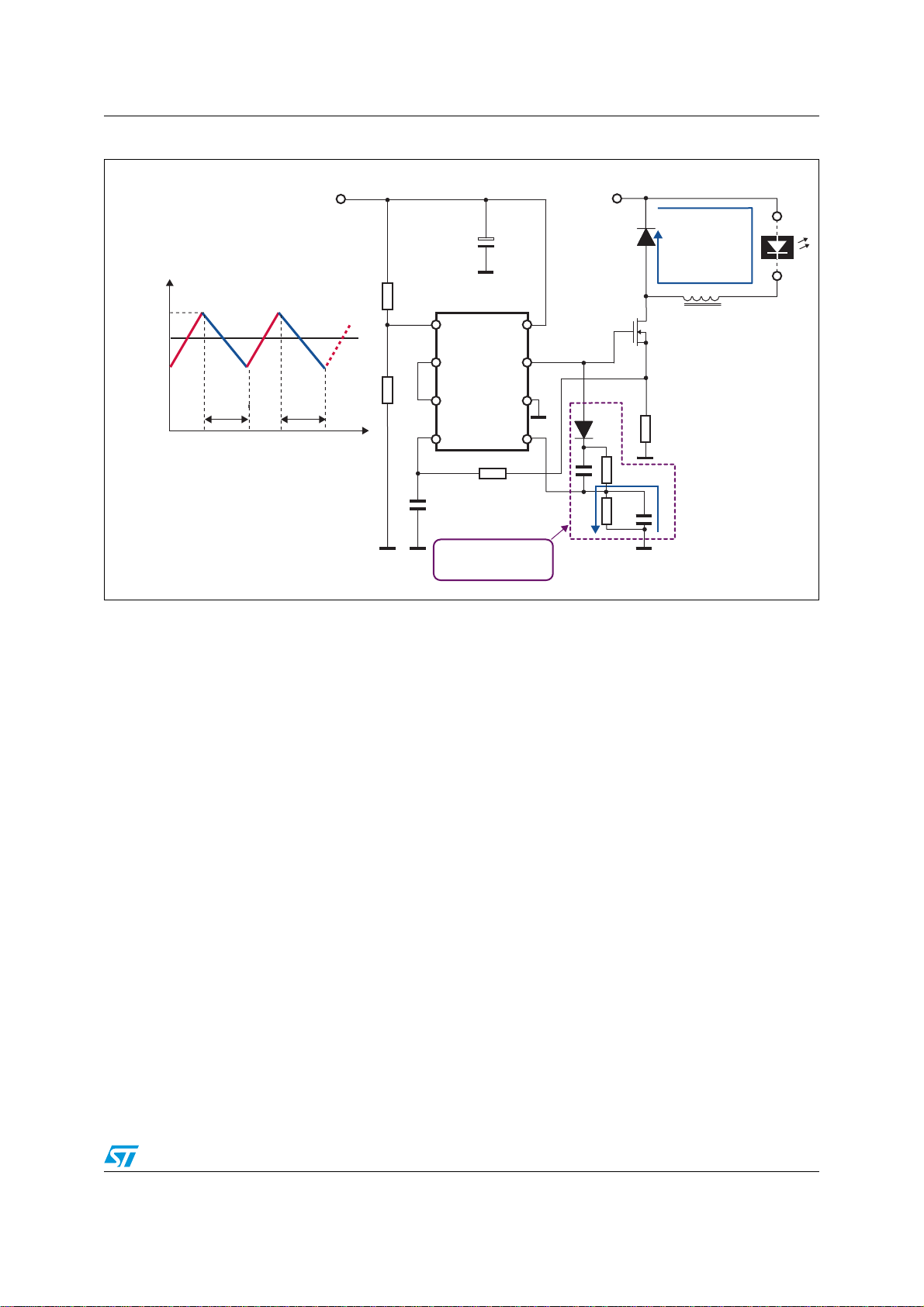

at 1.08 V (typ). Figure 2 shows the t

inductor keeps the current flowing in the same direction and the circuit is closed through

diode D

network (t

R

. The voltage on capacitor C4 is connected to the ZCD (zero current detector) pin of the

4

L6562A. As soon as the capacitor is discharged and its voltage falls below 0.7 V (the ZCD

threshold), the L6562A switches the power MOSFET again and the load current is

increased. This pr ocess repeat s cycle-b y-cycl e, as shown in the ti ming diag rams in Figure 1

and Figure 2.

is turned on. As shown by the red arrow, the current flows from the DC volt age

1

) through the load (LEDs), the inductor (L), the power MOSFET Q1 and the

IN

. The load current is decreasing and the minimum current is set by the fixed off-time

1

time is always constant), because capacitor C4 is discharged to the resistor

OFF

is charged via diode D2 and resistor R5, since the transistor

4

time, when the power MOSFET is switched off. The

OFF

Figure 1. Modified buck converter - t

V

C

I

LED

R

I

_MAX

I

_AVR

I

_MIN

R

FOT

t

t

ON

OFF

-

FOT- fixed off-time

-

t

ON

FOT

t

OFF

t

t

t

1

2

ON

time

C

1

VCC

INV

L6562A

GND

ZCD

R

3

GD

COMP

MULT

CS

C

2

Fixed off-time

network

V

IN

Q

R

LEDs

load

L

1

S

AM00366

D

1

t

ON

D

2

C

R

3

R

5

C

4

4

4/21

Page 5

AN2928 Modified buck converter in constant current mode

Figure 2. Modified buck converter - t

V

C

I

LED

R

I

_MAX

I

_AVR

I

_MIN

FOT

t

t

OFF

-

t

ON

ON

FOT-fixed off-time

FOT

t

OFF

1

R

2

t

OFF

time

C

1

INV

L6562A

COMP

MULT

CS

C

2

Fixed off-time

network

VCC

GND

ZCD

R

3

GD

V

IN

D

t

OFF

1

LEDs

load

L

Q

1

D

2

C

3

R

4

R

S

R

5

C

4

AM00367

5/21

Page 6

Design equations for the modified buck converter AN2928

2 Design equations for the modified buck converter

This section provides all the calculations required for a designer to develop an application

with the modified buck converter working in FOT and CCM. The equations are described

step-by-step, following an application design procedure. First, the basic equations for this

type of converter are shown, then the components for the t

proper power diode and power MOSFET is selected, and finally the power inductor

calculation is demonstrated.

2.1 Basic equations for the modif ied buck conver ter

time are calculated, the

OFF

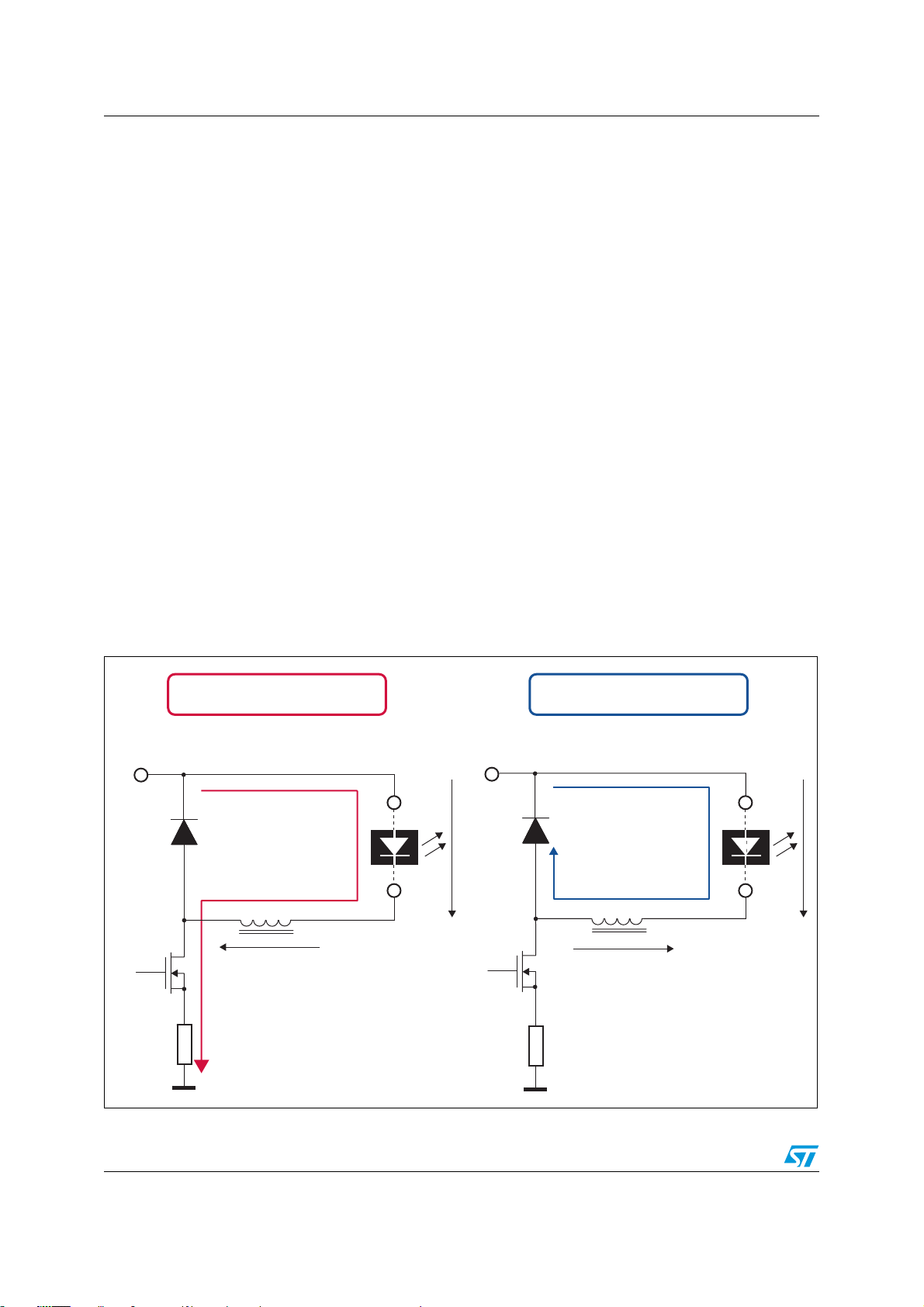

Figure 3 shows basic circuit stage during tON and t

component references used in the equations.

The voltage across the inductor L is calculated using the following equation:

Equation 1

VLL

= inductor voltage (V)

V

L

L = inductance (H)

= inductor current (A)

I

L

Figure 3. Modified buck convert er - the or y of operation

⋅=

tON time t

V

IN

LEDs

D

1

LEDs

load

V

LED

V

IN

D

1

time, with indicated voltage and

OFF

dI

L

--------

dt

time

OFF

LEDs

load

V

LED

L

t

ON

VL = VIN -V

Q

1

R

S

6/21

-

LED

t

OFF

Q

R

L

VL = V

LED

1

S

AM00368

Page 7

AN2928 Design equations for the modified buck converter

Using Equation 1, it is possible to calculate an inductor current change during tON and t

time:

Equation 2

t

ON

∆I

LON

V

------

∫

L

0

VINV

L

td

–()tON⋅

--------------------------------------------------==

LED

L

Equation 3

tONt

+

OFF

∆I

LOFF

∆I

= inductor current change during tON time (A)

L_ON

∆I

V

V

t

ON

t

OFF

= inductor current change during t

L_OFF

= input voltage (V)

IN

= LED (load) voltage (V)

LED

= turn-on time (s)

= turn-off time (s)

∫

t

ON

OFF

In CCM, the inductor current change during t

V

L

------

L

time (A)

ON

td

and t

V

⋅

LEDtOFF

---------------------------------–==

L

time is the same:

OFF

OFF

Equation 4

∆l

=

LON∆ILOFF

Using Equation 2 and Equation 3, it is possible to create following equations:

Equation 5

VINV

–()tON⋅

--------------------------------------------------

LED

L

V

–()

LEDtOFF

------------------------------------=

L

Equation 6

V

INtONVLEDtONVLEDtOFF

⋅=⋅–⋅

Equation 7

V

INtONVLEDtOFFtON

+()V

LED

T⋅=⋅=⋅

The duty cycle for the modified buck topology (also valid for a standard buck topology)

converter is calculated:

Equation 8

t

V

ON

---------

D

LED

------------- -==

T

V

IN

7/21

Page 8

Design equations for the modified buck converter AN2928

2.2 Fixed off-time network cal culation

The basic idea for this type of converter is to obtain a constant off-time when the power

MOSFET is turned off. This design approach is quite simple and cost-effective, because the

constant off-time is easily set by the RC network. Its calculation is described in this section.

The duty cycle is defined by the switching frequency and turn-off time:

Equation 9

t

---------

D

f = switching frequency in CCM (Hz)

T = period i n CCM (s)

D = duty cycle (-)

From Equation 8 and Equation 9, the turn off-time can be calculated (the switching

frequency is selected):

Equation 10

ON

T

–

Tt

OFF

---------------------

T

1ft

OFF

t

OFF

-----------

1

T

V

LED

------------- -=⋅–

V

IN

⋅–===

1=– ft

OFF

Equation 11

V

LED

⎛⎞

1

------------- -–

⎝⎠

V

IN

OFF

---------------------------- -=

f

t

As stated above, the modified buck converter uses a FOT network. The off-time is set by

resi stor R

the power MOSFET is high, diode D

clamped at V

MOSFET is low, diode D

and capacitor C4, as shown in Figure 2. During the on-time, the gate voltage of

4

ZCD_CLAMP

≈ 5.7 V. During the off-time, the gate voltage of the power

is closed and the voltage at the ZCD pin decreases based on an

2

is opened and the voltage at the ZCD pin is internally

2

exponential law:

Equation 12

1

⎛⎞

---------------- -----

⎝⎠

⋅

R

V

ZCDVZCD CL AMP

4C4

e

⋅=

The voltage at the ZCD pin decreases until it reaches the internal triggeri ng limit, which

causes switching to the turn-on stage. The trigger voltage for the L6562A is 0.7 V. The time

needed for the ZCD voltage to go from V

the off-time t

OFF

:

ZCD_CLAMP

to V

ZCD_TRIGGER

defines the duration of

Equation 13

V

⎛⎞

t

OFF

R4C

ZCD CL AMP

---------------------------------------- -

⎜⎟

4

V

⎝⎠

ZCD TRIGGER

R

4C4

5.7

⎛⎞

--------

ln R

⎝⎠

0.7

4C4

2.1⋅⋅=⋅⋅=ln⋅⋅=

8/21

Page 9

AN2928 Design equations for the modified buck converter

V

= voltage on the ZCD pin of the L6562A (V)

ZCD

V

ZCD_CLAMP

V

ZCD_TRIGGER =

Capacitor C

= clamp voltage on the ZCD pin of the L6562A (V)

trigger voltage on the ZCD pin of the L6562A (V)

can be selected, and the resistor is easily calculated using Equation 14, or the

4

inverse can be calculated with Equat ion 15 .

Equation 14

t

OFF

----------------------=

R

4

2.1 C4⋅

Equation 15

t

C

OFF

----------------------=

4

2.1 R4⋅

Resistor R

C

during the tON time, and must be within the following range (as described in application

4

(shown in Figure 2) is designed to limit the charge current flowing to capacitor

5

note AN1792. See Section 3: Reference and related materials).

Equation 16

V

GD MAXVZCD CLAMP

-------------------------------------------------------------------------------

l

V

= diode D2 forward voltage (V) (typically 0.7 V)

F

V

ZCD_CLAMP

V

GD_MAX

V

GD_MIN

I

ZCD_MAX

If the t

= clamp voltage on the ZCD pin of L6562A (V) (5.7 V)

= output high - maximum gate driver voltage (V) (15 V)

= output high - minimum gate driver voltage (V) (9.8 V)

= maximum sink capability for the ZCD pin (A) (0.01 A)

time is very short (light load or low output voltage), then capacitor C4 cannot be

ON

quickly charged via resistor R

parallel with resistor R

– VF–

ZCD MAX

⎛⎞

V

GD MINVZCD CLAMP

⎜⎟

5R4

⋅<<

----------------------------------------------------------------------------- -

⎜⎟

⎝⎠

V

ZCD CLAMP

---------------------------------- -+

R

4

. Therefore it is recommended to connect capacitor C3 in

5

. The maximum size of capacitor C3 can be calculated with the

5

R

– VF–

V

ZCD CL AMP

following equation:

Equation 17

C3C

<

V

------------------------------------------------------------------------------------

4

V

GD M AXVZCD CLAMP

ZCD CL AMP

– VF–()

9/21

Page 10

Design equations for the modified buck converter AN2928

2.3 LED current calculation

The preceding equations (Equation 12 through 17) are used to calculate the FOT network

using resistors R

circuit because the output LED current and inductor must be calculated. For the inductor

current change, the following equation is used:

Equation 18

and R5 and capacitors C3 and C4. At this point, focus shifts to the power

4

∆lLl

∆I

= inductor (LED) current change (A)

L

= maximum (LED) inductor current (A)

I

MAX

= minimum (LED) inductor current (A)

I

MIN

= average (LED) inductor current (A)

I

AVR

MAXlMIN

2l

MAXlAVR

–()⋅=–=

Combining Equat ion 18 and Equation 3, considering the current change as an absolute

value (i.e. positive), it is possible to derive:

Equation 19

V

⋅

LEDtOFF

where t

--------------------------------- 2l

∆l

L

is calculated using Equation 11.

OFF

L

–()⋅==

MAXlAVR

From Equation 11 and Equation 19 the equation for deriving the inductor size can be

formulated (maximum and average LED current is selected):

Equation 20

V

L

------------------------------------------------------

2l

1D–()⋅

LED

–()f⋅⋅

MAXlAVR

⋅

V

LEDtOFF

---------------------------------------------==

2l

–()⋅

MAXlAVR

Sense resist or R

can be easily calculated because the voltage threshold on the CS pin for

S

the L6562A is 1.08 V and therefore the resistor size is fol lowing:

Equation 21

R

S

V

= current sense threshold (V)

CS

Although the modified buck converter using the FOT network and working in CCM that is

described here works as a constant current source, a limitation is the current dependency

on the output voltage (number of LEDs). To understand this limitation it is necessary to

derive the average inductor current (which is the LED current) from Equation 20. The result

is shown in Equation 22, which provides the information listed.

10/21

V

CS

------------

l

MAX

1.08

----------- -==

l

MAX

Page 11

AN2928 Design equations for the modified buck converter

Equation 22

V

l

AVRlMAX

●

I

is constant and set by the resistor R

MAX

t

●

●

●

is constant and set by the FOT network

OFF

The average inductor (LED) current is independent of the input voltage

The average inductor (LED) current depends slightly on the voltage across the LEDs

--------------------------------------- l

LED

2Lf⋅⋅

1D–()⋅

S

MAX

V

⋅

LEDtOFF

---------------------------------–=–=

2L⋅

(i.e. number of LEDs) and therefore the design shows the best results using a fixed

number of LEDs. A variable number of LEDs results in less current precision.

2.4 Power MOSFET calculation

The power MOSFET is chosen based on maximum stress voltage, maximum peak

MOSFET current, total power losses, maximum allowed operating temperature and the

driver capability of the L6562A.

Maximum stress voltage on the power MOSFET (drain-source voltage) for this modified

buck converter is equal to the input voltage. The power MOSFET must be selected with

some voltage margin. For example, if the input voltage is maximally 400 V, then maximum

drain-source voltage should be 450 V or higher.

Maximum peak MOSFET current was selected in order to calculate the inductor size in

Equation 20. Also in this case, the power MOSFET must be chosen with some current

margin.

Total power losses on the power MOSFET must be calculated, due to the importance of

designing a proper heat sink to avoid temperature stress on the power MOSFET. Basically,

total power losses on the power MOSFET occur through conduction losses (depending on

the R

), switching losses and gate charge loss caused by charging up the gate

DS(ON)

capacitance and then discharging this capacitance to ground. The gate charge loss is very

small compared to the conduction and switching losses, so it is not used for further

calculations. For total power MOSFET loss, a valid equation is:

Equation 23

P

P

= total power losses on the power MOSFET (W)

TOT

= conduction losses on the power MOSFET (W)

P

CON

= switching losses on the power MOSFET (W)

P

SW

TOT

P

+=

CONPSW

The power MOSFET conduction loss is represented by the continuous conduction current

flowing through the MOSFET during the on-time stage. Therefore, the power loss depends

on its static drain- so ur ce resist ance (R

). In order to calculate conduction loss

DS(ON)

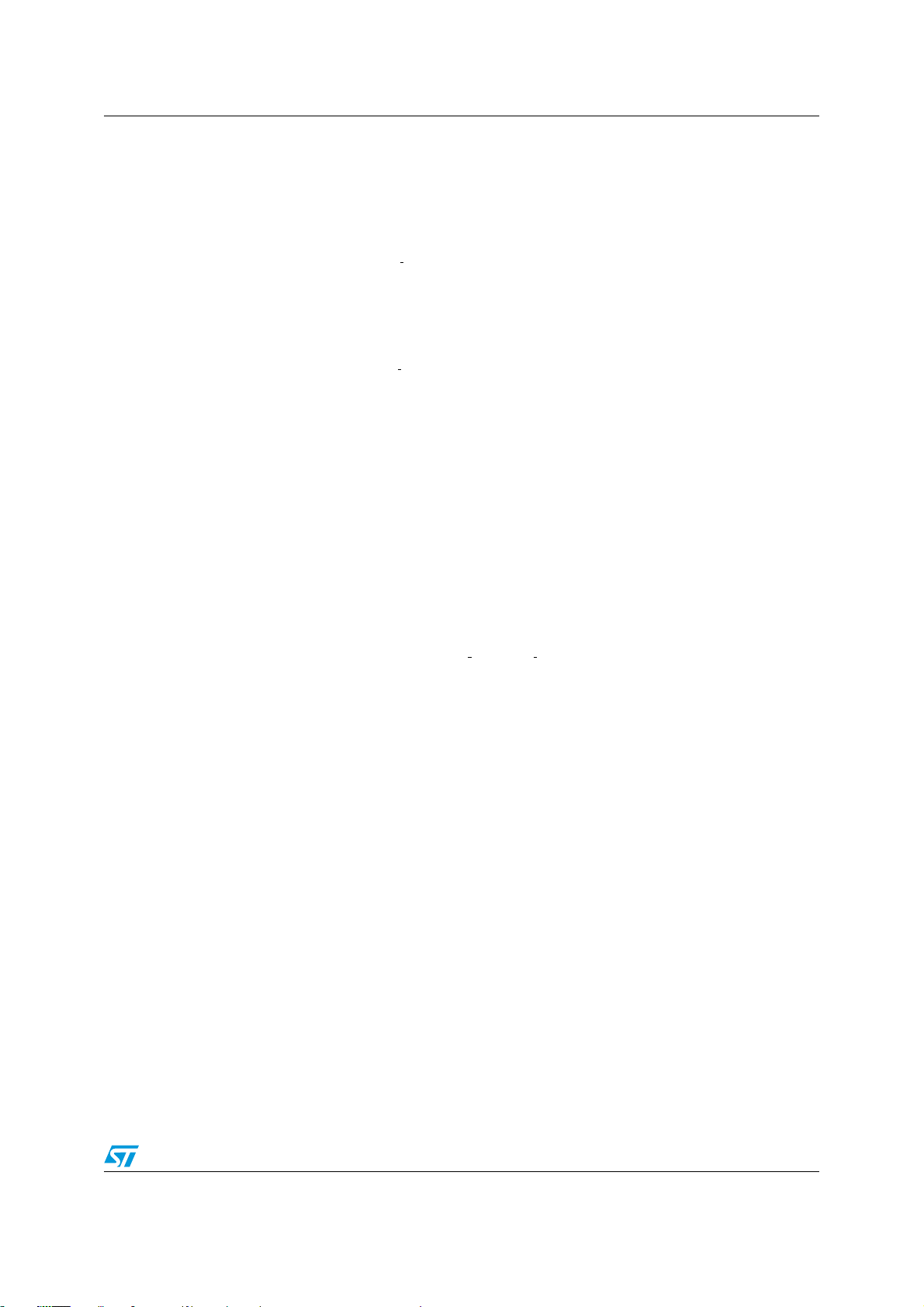

properly, it is necessar y to calculate the drain current RMS value. Figure 4 shows the

sawtooth signal for which the RMS value was calculated in Equation 24. Note that in this

case, average current I

((I

MAX+IMIN

)/2).

is defined as the average value of the sawtooth portion

AVR

11/21

Page 12

Design equations for the modified buck converter AN2928

Figure 4. Sawtooth signal

i(t)

l

MAX

t

ON

I

PP

t

OFF

l

AVG

l

MIN

I

0

t

DT (1- D)T

t

0

-

AM00369

Equation 24

t0T+

1

2

l

=

RMS

I

= root-mean squared drain current (A)

RMS

= peak-to-peak current (A) (difference between I

I

PP

2

-- -

T

t() t

i

∫

t

0

t0DT+

1

---

T

i2t() ti

∫

t

0

T+

t

0

2

+d

t0DT+

t() t··d

∫

D= l

_MAX

2

0

and I

1D–()⋅+⋅

_MIN

l

+

MAXlMIN

⎛⎞

-----------------------------

⎝⎠

2

)

2

2

l

PP

------- -+=d

12

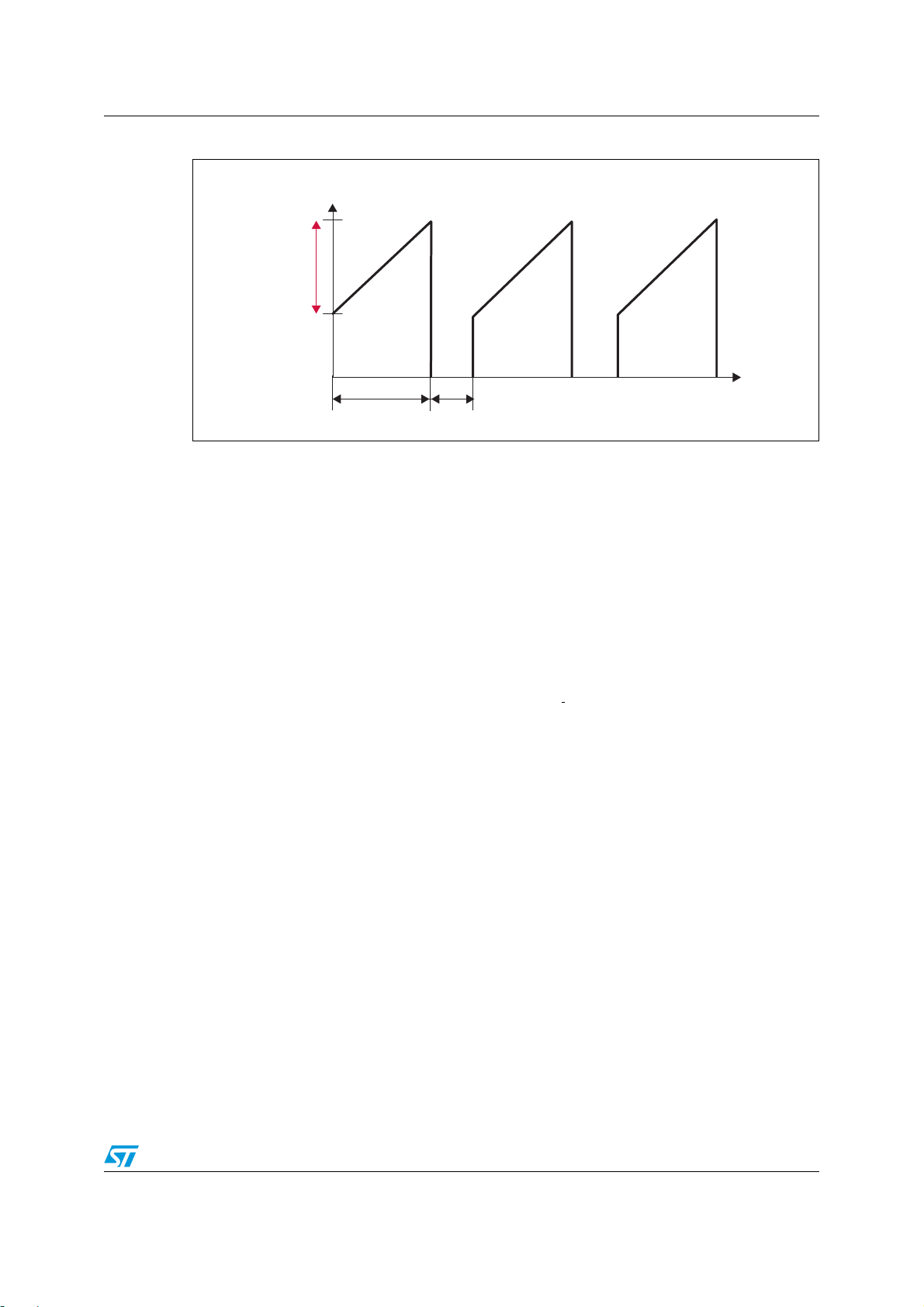

The real drain current waveform is given in Figure 5. As can be observed, the signal is quite

similar to the signal in Figure 4, except that there is no current during the off-time stage

= 0) and the on and off-times are reversed. Therefore, for real current Equation 24 is

(I

O

modified to become Equation 25.

Square RMS drain current is calculated using the equation:

Equation 25

l

+

MAXlMIN

⎛⎞

-----------------------------

⎝⎠

2

I

AVR_ON

2

l

RMS

D

= average current during tON time (A) (see Figure 5).

And finally it is possible to calculate the continuous conduction losses:

Equation 26

P

CONlRMS

R

12/21

= static drain-source on resistance for working MOSFET temperature (Ω).

DS(ON)

2

2

l

PP

------- -+ D= l

12

2

⋅=

R

DS ON()

2

AVR ON

l

------- -+⋅⋅=

12

2

PP

Page 13

AN2928 Design equations for the modified buck converter

Figure 5. Real drain MOSFET current

i

i(t)

I

MAX

I

PP

I

MIN

t

t

ON

t

OFF

AM00371

The second part of the MOSFET losses is switching losses, which depend on the (on and

off) switching time, drain MOSFET current, drain-source voltage and the switching

frequency . The s witching time, rise time and fall time is a function of the gate-to-drain “Miller”

charge of the MOSFE T (Q

(V

), and the minimum gate voltage which enables the current through the drain source

GS(TH)

), the internal resistance of the driver, the threshold voltage

_GD

of the MOSFET. As the correct calculation of switching power losses is complex due to non

linear behavior of the switch, it is not possible to obtain an exact equation for the calculation

of switching losses. Moreover, the s witching behavior is also influenced by the performance

of the driver and layout design (leakage inductance and parasitic capacitors). To arrive at an

estimation of the switching power losses, Equation 27 can be used.

Equation 27

t

OFF_SW

VINl

------------------------------------------------------------------- -=

MAXtOFF SW

P

SW

= switch off-time (s) (typically tens of ns).

2

f⋅⋅ ⋅

For example, switched off-time measured on the STEVAL-ILL013V1 using the STP9NM50N

power MOSFET (400 V input voltage) is 120 ns.

Total power (P

) is lost in the power MOSFET and its heat sink, so it is simple to

_TOT

calculate:

Equation 28

T

–

P

TOT

T

= maximum junction temperature (°C)

JMAX

= ambient temperature (°C)

T

A

= junction-to-case thermal resistance (°C/W)

R

thJC

= case-to-heat sink thermal resistance (°C/W) (usually between 0.35 and 0.8 for the

R

thCH

JMAXTA

------------------------------------------------------------=

R

++

thJCRthCHRthHA

insulating washer)

= heat sink-to-ambient thermal resistance (°C/W)

R

thHA

13/21

Page 14

Design equations for the modified buck converter AN2928

Finally, if the heat sink and its thermal resistance is known, it is possible to calculate

maximum static drain-source on resistance from Equation 26, Equation 27 and Equation 28

for easy power MOSFET selection.

Equation 29

R

DS ON()

------------------------------------------------------------------------------------ -

R

++()l

thJCRthCHRthHA

2.5 Power diode selection

The power diode (D1 from Figure 1) is chosen based on its maximum stress voltage, its

maximum peak current and total power losses. The power losses are lower for a larger duty

cycle and vice-versa, because the diode is opened (connected) during off-time.

Maximum voltage stress across the diode is equal to the input voltage V

power diode must be selected with some voltage ma rgin. For example, if the input voltage is

maximally 400 V, then maximum repetitive peak reverse voltage (V

higher.

Maximum peak diode current is selected in order to calculate the inductor size in

Equation 20. Also in this case, the power diode must be selected with some current margin.

Power losses are generally calculated with the following equation:

Equation 30

T

JMAXTA

P

LOSS D

–

⋅

T

1

---

i

=

D

∫

T

0

V

INlMAXtOFF SW

------------------------------------------------------------------- -–<

2

RMS

t() uD⋅ t()td

2

⋅

2l

RMS

RRM

f⋅⋅ ⋅

and therefore the

IN,

) should be 450 V or

P

LOSS_D

= power diode current (A)

i

D

u

D

= power diode losses (W)

= power diode voltage (V)

And assuming a constant voltage drop over the diode it is possible to approximately

calculate the power losses on the diode (switching losses are not included) with the

following equation:

Equation 31

P

LOSS DIAVR DVF

= power diode average current (A)

I

AVR_D

= power diode forward voltage for calculated average diode current (V)

V

F

14/21

⋅=

Page 15

AN2928 Design equations for the modified buck converter

where the average diode current is shown in Figure 6 and can be calculated using:

Equation 32

+

I

MAXIMIN

⎛⎞

I

AVR D

ID–()

------------------------------

⋅=

⎝⎠

2

And finally the junction diode temperature without using the heat sink can be calculated from

the following equation (ambient temperature is chosen):

Equation 33

TJP

T

= power diode junction temperature (°C)

J

= case-to-ambient thermal resistance (°C/W) (for example, the T O-220 package has a

R

thCA

LOSS D

R

+()TA+⋅=

thJCRthCA

typical thermal resistance of 60 °C/W)

The calculated power diode junction temperature must be lower then maximum diode

junction temperature T

. For proper design, it is recommended to keep the junction

JMAX

temperature much lower than its maximum in order to avoid temperature stress on the

power diode.

Equation 34

Figure 6. Real power diode current

i

i(t)

I

MAX

I

PP

I

MIN

t

ON

2.6 Inductor calculation

t

OFF

TJT

<

JMAX

t

AM00370

All components for the design are calculated, but the final step in the design procedure still

remains, since it is necessary to calculate the inductor (L). The calculations that follow are

valid for the inductor used in the STEVAL-ILL013V1 demonstration board, but for

applications with (for example) lower voltages, some standardized inductors for DC-DC can

als o be used.

15/21

Page 16

Design equations for the modified buck converter AN2928

First, the inductor core size must be selected, for which it may be helpful to calculate the

minimum area product using application parameters. The minimum required core area

product (AP), where the flux swing is limited by core saturation is:

Equation 35

4

-- -

LI

⋅⋅

PEAKIRMS

⎛⎞

AP

AP

= minimum area product (cm4)

MIN

= inductor peak current (A)

I

PEAK

= inductor RMS current (A)

I

RMS

= saturation limited flux density (T) (pow er ferrites like N27 or N67 have typically 0.3 T)

B

MAX

----------------------------------------------

=

MIN

⎝⎠

B

MAX

3

Cl⋅

Equation 36

Cl J

J

= maximum current density (A/cm2) (That commonly used for natural convection

MAX

cooling is 420 A/cm

= ratio of the total copper area to the window area (-)

C

R

The constant C

2

)

gives an estimation of how effectively the wires are placed on the core. For

R

⋅⋅=

MAXCR

10

4–

example, if the input vol tage of the modified buc k converter is 400 V (such as when a power

factor preregulator is used), then the wires must be well-isolated and the ratio between the

copper and window area is about 0.5, which in the end means that there is 50% of the wire

on the inductor core. The exact calculation using the equation listed here can be found in the

user manual UM0670 (see Section 3: Reference and related materials).

Once the minimum area product is calculated, the designer should then select the right

inductor core and ferrite material according to the higher AP value. The AP value is

calculated from the winding cross section and core cross section. For example, the ETD29

core with ferrite material N27 from EPCOS has a winding cross section of 97 mm

a core cross section of 71 mm

2

. Maximum flux density for the N27 is 0.3 T.

2

and

Equation 37

AP A

A

= winding cross section (mm2)

N

= minimum core cross section (mm2)

A

MIN

For a proper inductor core, the calculated area product must be higher than the AP

⋅=

NAMIN

MIN

calculated in Equation 35. If the condition derived from E quation 38 is no t f ulfi lle d, the

designer must select a bigger inductor core.

Equation 38

AP

MIN

AP<

A simple way how to calculate the number of inductor turns is shown in Equation 39, since

manufacturers also include the inductance factor A

which depends on air gap, in the

L,

product datasheets. For example, the ETD29 core with 1 mm gap and N27 ferrite material

has an inductance factor of 124 nH.

16/21

Page 17

AN2928 Design equations for the modified buck converter

Equation 39

LN2AL⋅=

= inductance factor (H)

A

L

N = inductor numb er of t urns (-)

The number of turns for the inductor is:

Equation 40

L

------=

N

A

L

After the number of turns is calculated, it is also necessary to calculate the wire diameter.

The maximum power loss can be calculated using the maximum inductor temperature and

core thermal resistance with the following equation:

Equation 41

T

–

P

MAX LOSS

MAXTA

---------------------------=

R

T

P

MAX_LOSS

T

MAX

= thermal resistance of the inductor core used (°C/W) (for example, thermal resistance

R

T

= maximum power loss in the inductor (W)

= maximum inductor temperature (°C)

for the E25 core used in the STEVAL-ILL013V1 design is 40 °C/W).

The loss in the core is:

Equation 42

P

COREPV

P

= loss in the inductor core (W)

CORE

= core loss defined in the datasheet (mW/g )

P

V

W10

⋅⋅=

3–

W = core weight (g) (for example, the ETD29 has a weight of 28 g)

Maximum powe r los s in the wire is simply:

Equation 43

= maximum power loss in the wire (W)

P

WIRE

P

WIRE

P

MAX LOSSPCORE

–=

The maximum wire resistance derives from the following equation:

Equation 44

P

R

MAX WIRE

-----------------=

I

WIRE

2

RMS

R

MAX_WIRE

= maximum wire resistance (Ω)

17/21

Page 18

Design equations for the modified buck converter AN2928

Winding resistance depends on the diameter, and is defined using the following formula:

Equation 45

I

Rp

l

--- -

p

S

⋅=⋅=

N

----------------

π d⋅

N⋅

R = wire resistance (Ω)

p = resistivity of the copper (Ω

S = conductor cross-section area (cm

•

cm) (1,76 • 10-6 for temperature 25 °C)

2

)

l = wire length (cm)

= average length of turn (cm)

l

N

d = wire diameter (cm)

The wire diameter is properly selected if the total wire resistance is lower than the maximum

wire resistance.

Equation 46

<

RR

MAX WIRE

18/21

Page 19

AN2928 Reference and related materials

3 Reference and related materials

1. STEVAL-ILL013V1, 80 W offline PFC and LED driver demonstration board with

dimming based on the L6562A; data brief

2. AN1792, Design of fixed-off-time-controlled PFC pre-regulators with the L6562;

application note

3. L6562A, Transition-mode PFC controller; datashe et

4. AN1059, Design equations of high-power-factor Flyback converters based on the

L6561; application note

5. UM0670, 80 W off-line LED driver with PFC; user manual

Note: The reference and related materials listed above are available on the STMicroelectronics

web site at www.st.com.

19/21

Page 20

Revision history AN2928

4 Revision history

Table 1. Document revision history

Date Revision Changes

24-Mar-2009 1 I nitial releas e.

20/21

Page 21

AN2928

y

y

Please Read Caref u ll y:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at an

time, with out notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchase rs are solely responsible for the ch oi ce, selec tion and use of the ST products and services d escribed herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party product s or servic es it shall n ot be deeme d a license grant by ST for the use of such third party products

or services , or any intel lec tual pro per ty cont aine d ther ein or consi dere d as a warra nty c overi ng th e use in any mann er w hats oever of such

third party products or services or any intellec tu al property c ont ai ned therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMM ENDED , AUTHO RIZED OR WARRANT ED FOR USE IN M ILITA RY, AIR CR AFT, SPA CE, LIF E SAVIN G, OR LIF E SUSTAI NING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY O R ENVI RONMEN T AL DAMA G E. S T PR ODUC TS W HIC H ARE NOT SPECIFIED AS "AU TO MOTI VE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warran ty gr anted by ST fo r the ST produc t or se rvice d es cribed he rein and shall not c reat e or ex tend in a ny mann er wha tsoe ver, an

liability of ST.

ST and the ST logo are trademarks or regis tered trade m arks of ST in vari ous countri es.

Information in this do cument super sedes and replaces all information pr eviously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2009 STM icroelectronics - All ri ght s reserved

STMicroelectron ics group of com panies

Austra l i a - Belgium - Brazil - Cana da - China - Czech Republic - F i nl and - Franc e - Germany - Ho ng K o ng - India - Isr ael - Italy - Japan -

Malaysi a - M al ta - Morocco - Singapore - Spain - Swe den - Switzerland - Uni ted Kingdom - Uni ted States of America

www.st.com

21/21

Loading...

Loading...