AN2798

Application note

Complete DDR2/3 memory power supply

controller based on the PM6670AS

Introduction

The PM6670AS device is a complete DDR2/3 power supply regulator for portable

applications designed to meet JEDEC specifications . It int egr a tes a constant on-time ( COT)

buck controller, a 2 A peak sink/source low dropout regulator and a 15 mA low-noise

buffer ed reference.

The COT architecture assures fast transient response supporting both polymeric and

ceramic output capacitors. An embedded integrator control loop compensates the DC

voltage error due to the output ripple. The 2 A peak sink/source linear regulator pro vides the

memory termination voltage with fast load transient response.

The device is fully compliant with syst em sleep stat es S3 and S4/ S5, setting the LDO output

to high impedance in suspend-to-RAM state and performing the tracking discharge of all

outputs in suspend-to-disk state.

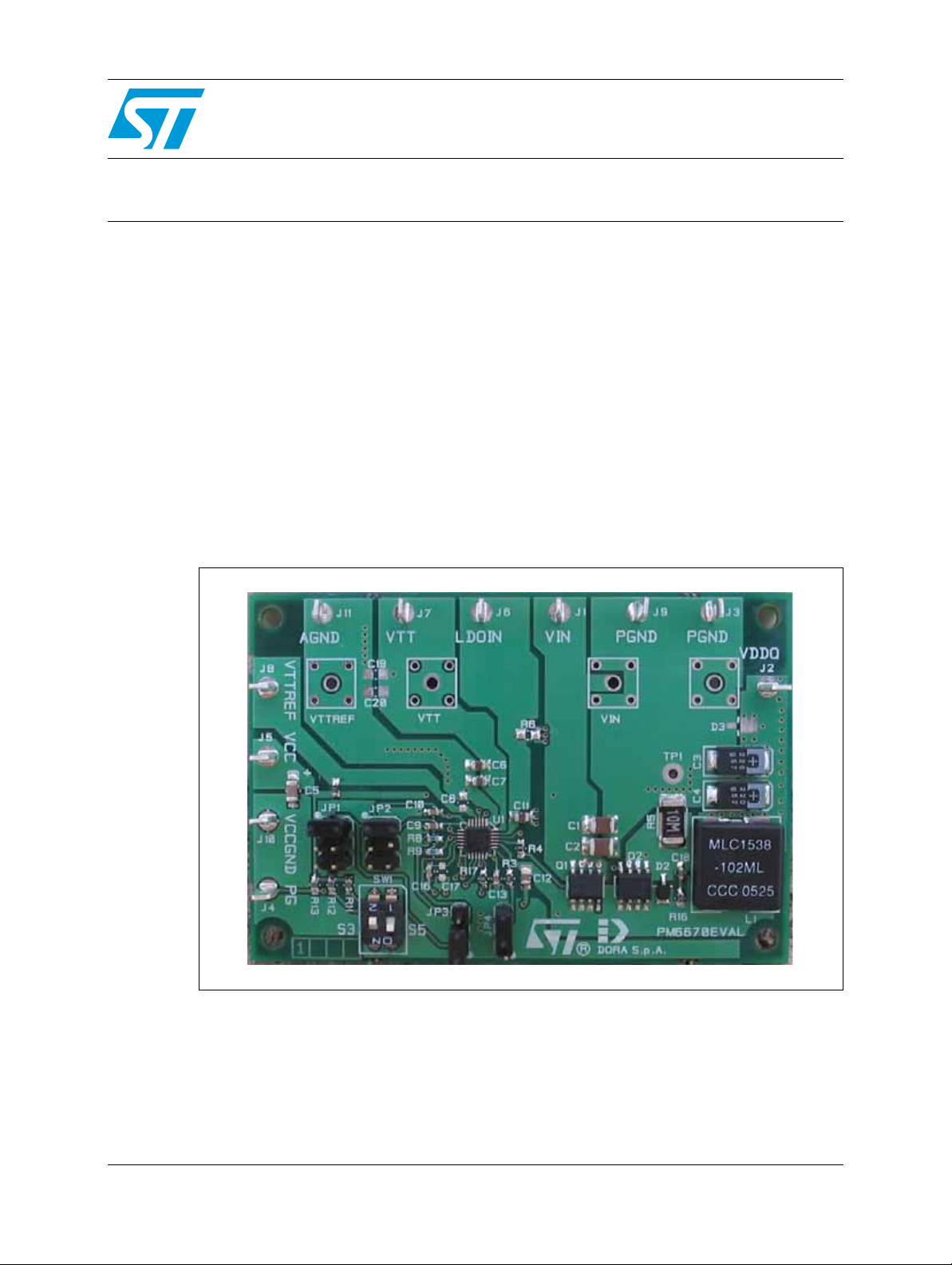

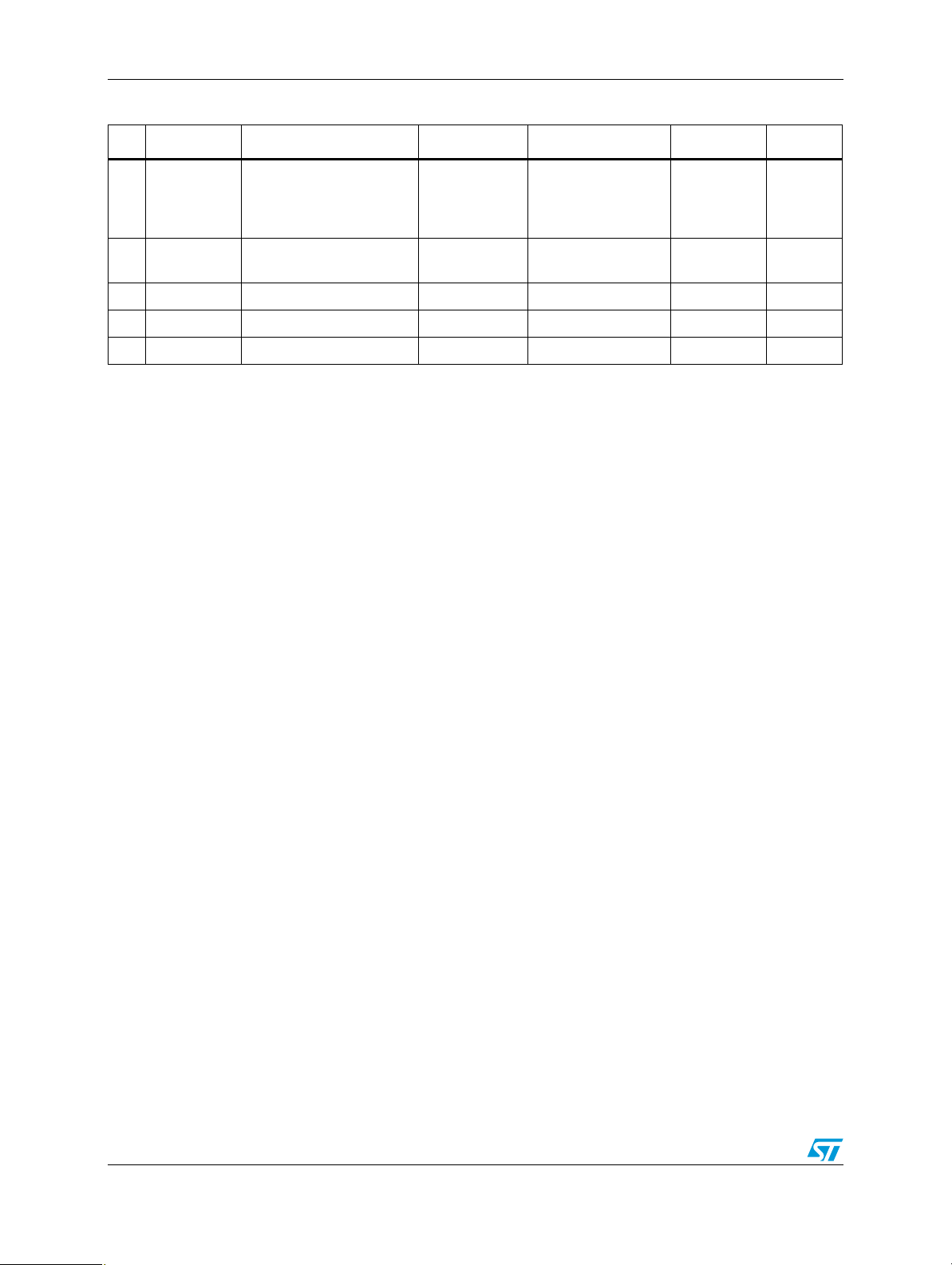

Figure 1. PM6670AS demonstration board

November 2008 Rev 1 1/38

www.st.com

38

Contents AN2798

Contents

1 Main features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Switching section (VDDQ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Reference and termination voltages (VTTREF and VTT) . . . . . . . . . . . . . 5

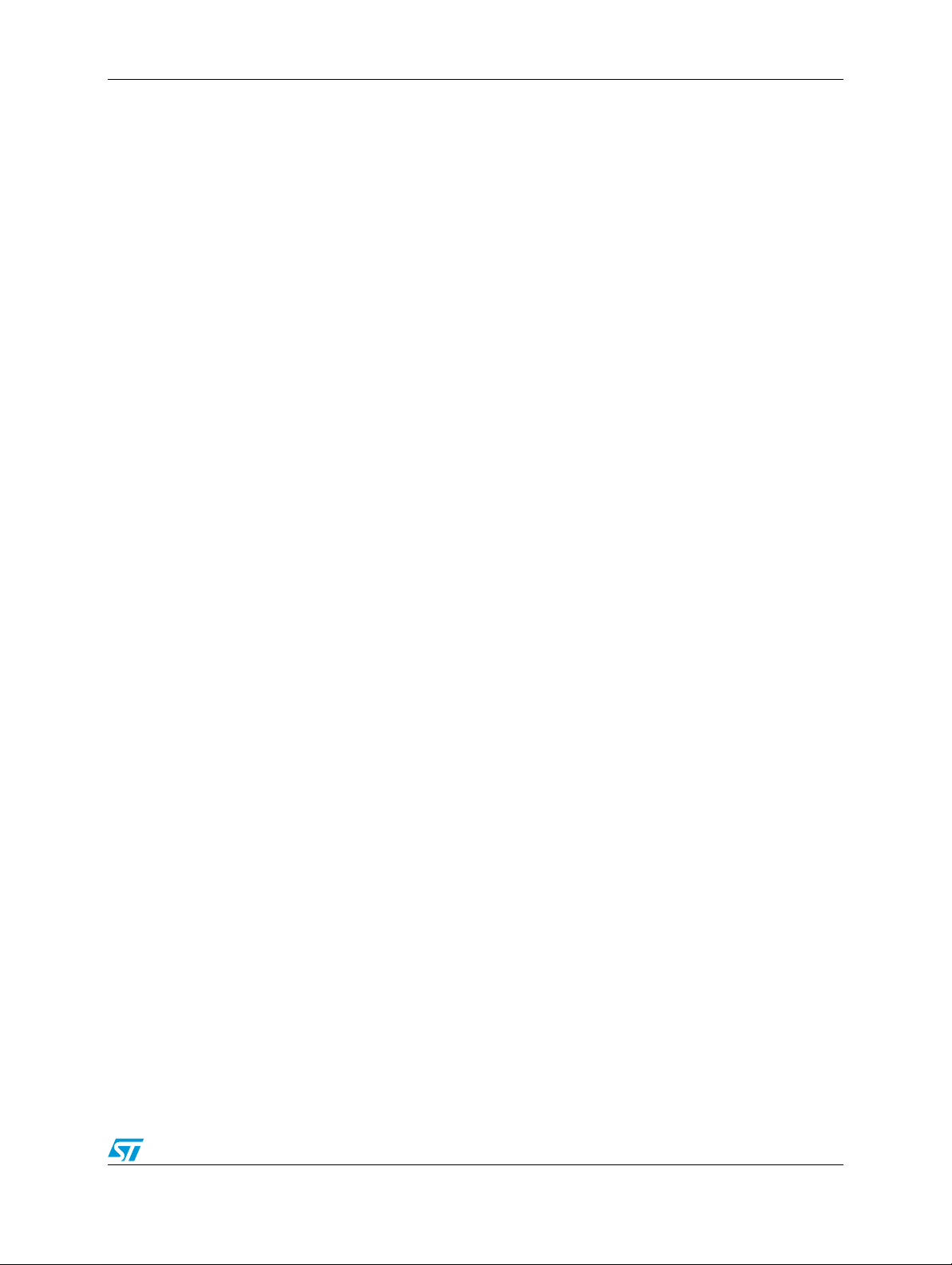

2 Demonstration kit schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Component list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Component assembly and layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 I/O interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 Recommended equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 JP3 fixed or adjustable output voltage (MODE pin) . . . . . . . . . . . . . . . . . 13

5.2 JP1 DDR2/DDR3 or power-saving mode (DDRSEL pin) . . . . . . . . . . . . . 13

5.3 JP2 output discharge (DSCG pin) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.4 JP5 compensation network (COMP pin) . . . . . . . . . . . . . . . . . . . . . . . . . 15

6 Test setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7 Getting started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7.1 Power-up sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7.2 Power-down sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8 PM6670AS evaluation tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.1 VDDQ, VTT and VTTREF turn-on (soft-start) . . . . . . . . . . . . . . . . . . . . . 18

8.2 VDDQ working modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.2.1 VDDQ forced PWM mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.2.2 VDDQ pulse-skip mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.2.3 VDDQ non-audible pulse-skip mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2/38

8.3 VDDQ, VTT and VTTREF load regulation . . . . . . . . . . . . . . . . . . . . . . . . 20

8.4 VDDQ and VTT load transient responses . . . . . . . . . . . . . . . . . . . . . . . . 22

8.5 VDDQ efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.6 VDDQ gate drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

AN2798 Contents

8.7 VDDQ, VTT and VTTREF turnoff (soft-end) . . . . . . . . . . . . . . . . . . . . . . 24

8.8 UV, OV and thermal protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.9 VDDQ current limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.10 VTT current limit (foldback) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.11 Switching frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.12 Thermal behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3/38

List of figures AN2798

List of figures

Figure 1. PM6670AS demonstration board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. PM6670AS demonstration board schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. Topside component placement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 4. Topside view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 5. Layer 2 view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 6. Layer 3 view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 7. Bottomside view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 8. Bottomside component placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 9. JP3 (MODE) setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 10. JP1 (DDRSEL) setting (change to “non-audible” in graphic) . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 11. JP2 (DSCG) setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 12. JP5 (COMP) setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 13. PM6670AS test setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 14. VDDQ soft-start at 180 mW load, pulse-skip mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 15. VTT turn-on (S0), pulse-skip mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 16. VDDQ = 1.8 V, VIN = 24 V, IVDDQ = 0 A, forced PWM mode. . . . . . . . . . . . . . . . . . . . . . 19

Figure 17. VDDQ = 1.8 V, VIN = 24 V, IVDDQ = 0 A, pulse-skip mode . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 18. VDDQ = 1.8 V, VIN = 24 V, no load, non-audible pulse-skip mode (33 kHz). . . . . . . . . . . 20

Figure 19. VDDQ load regulation - VIN = 24 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 20. VTT load regulation - LDOIN = VDDQ (VDDQ in forced PWM mode) . . . . . . . . . . . . . . . . 21

Figure 21. VTTREF load regulation (VDDQ in forced PWM mode). . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 22. VDDQ load transient (VIN = 24 V, LOAD = 0 A to 8 A at 2.5 A/µs) (pulse-skip mode). . . . 22

Figure 23. VTT load transient (VIN = 24 V, LOAD = – 2 A to 2 A at 2.5 A/µs) (pulse-skip mode). . . . 22

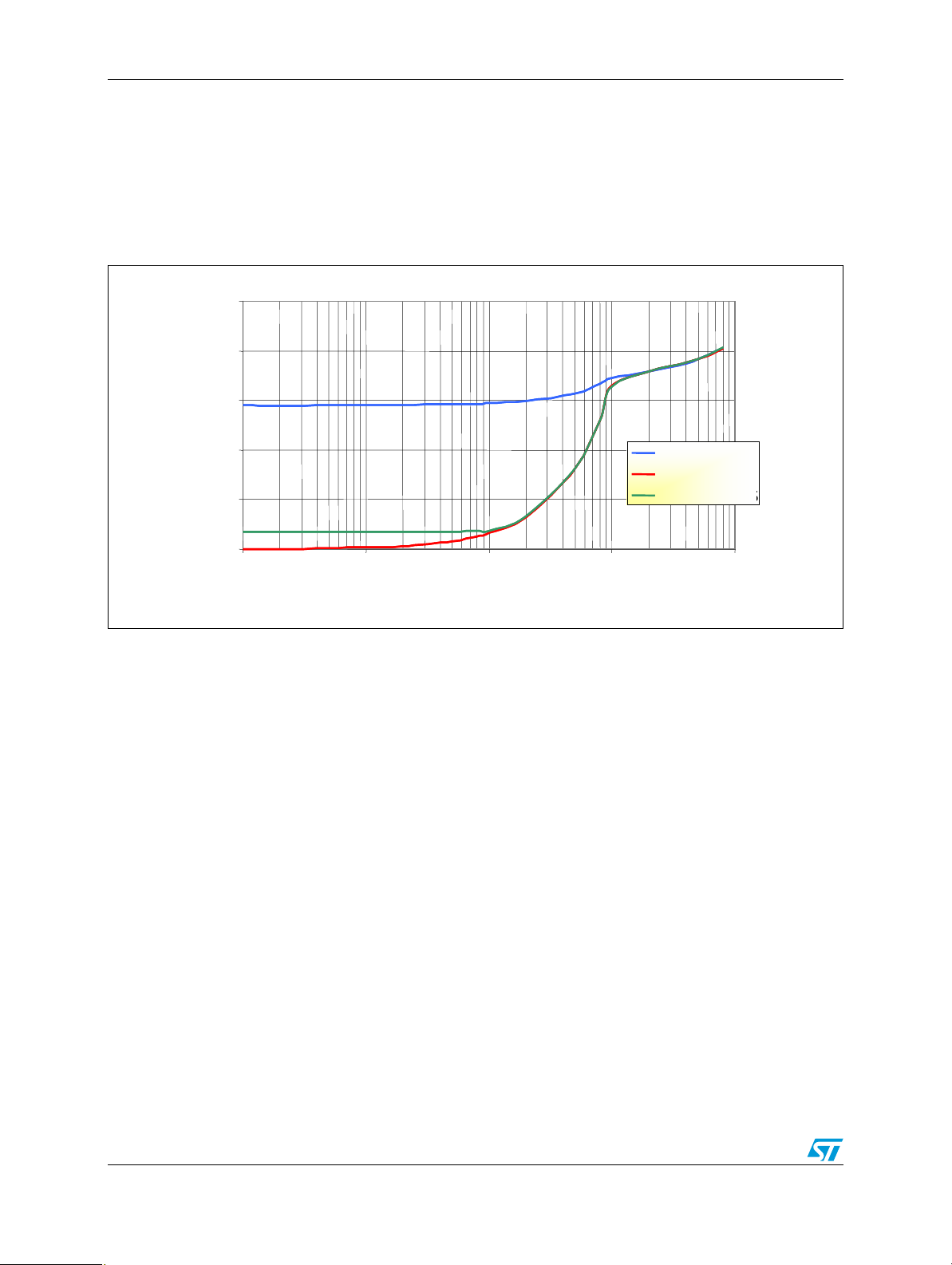

Figure 24. Forced PWM (blue), non-audible pulse-skip (green), pulse-skip (red) VDDQ efficiency vs. .

output current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 25. External MOS gate signals (VIN = 24 V, LOAD = 0 A) (pulse-skip mode) . . . . . . . . . . . . . 23

Figure 26. External MOS gate signals (VIN = 24 V, LOAD = 8 A) (pulse-skip mode) . . . . . . . . . . . . . 24

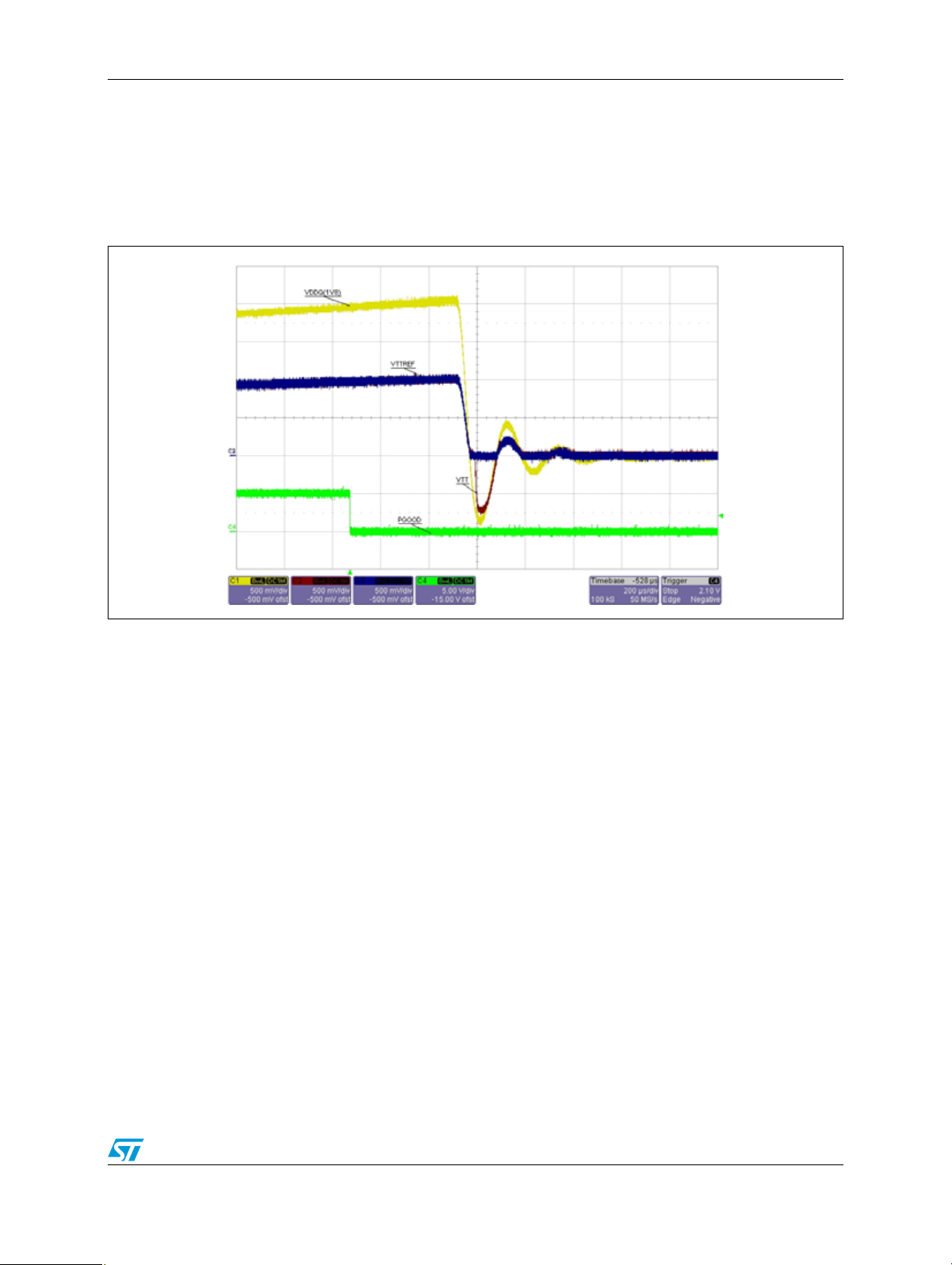

Figure 27. VDDQ, VTTREF, VTT output voltages and LDO input current, tracking discharge,

no load on any rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 28. VDDQ, VTTREF and VTT, non-tracking discharge, no load on any output . . . . . . . . . . . . 25

Figure 29. UV protection, pulse-skip mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 30. OV protection, pulse-skip mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 31. VDDQ, VTT, VTTREF and inductor current, thermal shutdown, pulse-skip mode . . . . . . . 28

Figure 32. VDDQ current limit protection during a load transient (0 A to 10 A at 2.5 A/µs) . . . . . . . . . 29

Figure 33. VTT current limit during an output short . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 34. Switching frequency vs. input voltage, VDDQ = 1.8 V, IVDDQ = 4 A, force d PWM mode. 31

Figure 35. Forced PWM (blue), non-audible pulse-skip (green) and pulse-skip (red), switching

frequency vs. output current, VDDQ = 1.8 V, VIN = 24 V. . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 36. IVTT = 0 A, average IC temperature = 37.5 °C, max internal IC temperature = 40.1 °C . . 33

Figure 37. IVTT = 0.5 A, average IC temperature = 48.8 °C, max internal IC temperature = 54.3 °C. 34

Figure 38. IVTT = 1 A, average IC temperature = 60.5 °C, max internal IC temperature = 72.7 °C . . 35

Figure 39. IVTT = 1.5 A, average IC temperature = 73.8 °C, max internal IC temperature = 95.6 °C. 36

4/38

AN2798 Main features

1 Main features

1.1 Switching section (VDDQ)

■ 4.5 V to 36 V input voltage range

■ 0.9 V, ± 1 % voltage reference

■ 1.8 V (DDR2) or 1.5 V (DDR3) fixed output voltages

■ 0.9 V to 2.6 V adjustable output voltage

■ 1.237 V ± 1 % reference voltage available

■ Very fast load transient response constant on-time loo p control

■ No-RSENSE current sensing using low-side MOSFETs' RDSON

■ Negative current limit

■ Latched OVP, UVP and thermal shutdown

■ Fixed 3 ms soft-start

■ Selectable pulse-skipping at light load

■ Selectable non-audible (33 kHz) pulse-skip mode

■ All ceramic output capacitor applications supported

■ Output voltage ripple compensation

1.2 Reference and termination voltages (VTTREF and VTT)

■ 2 A peak LDO with foldback for VTT

■ Remote VTT output sensing

■ High-Z VTT output in S3

■ All ceramic output capacitor applications supported

■ ±15 mA low-noise buffered reference for VTTREF

5/38

Demonstration kit schematic AN2798

0

0

1

J2

V

DDQ

1

J3

PGND

1

J11

AGND

1

J1

VIN

1

J5

VCC

JP3

MODE

0

0

0

VTT

24

LDOIN

23

BOOT

22

HGATE

21

PH

ASE

20

CSNS

19

VCC

18

LGATE

17

PGND

16

PG

15

S3

14

S5

13

DSCG

12

COMP

11

MODE

10

VSNS

9

VOSCSC

8

VREFEF

7

AVCC

6

SGND5VTTR

EF

4

DDR

SEL

3

VTTSNS

2

VTTGND

1

TH

PD

25

U1

PM

6670

AS

1

J9

V

CCGND

5

4

1

6

7

8

2

3

Q2

STS7NF60L

5

4

1

6

7

8

2

3

Q1

STS5NF

60L

1

J10

AGND

1

J6

LDOIN

21

D1BABAT41J

1 2

R4 3R3

0

1

2

R3 1k 5

1

2

R1

330k

12

R2

18k

1

2

L1 1u

2 1

D2

STPSPS1L1L60A

12

C1

10u

12

C2

10u

2 1

D3

STPSPS1L1L60A

12

C3

2

20u

12

C4

2

20u

12

C10

1

2

C9

100n

12

R7

3R9

0

1 2

C21

100p

12

C19

10u

1

2

C13

1

00n

12

C20

10u

1

2

4

3

SW1

1 2

R11

100k

1 2

R12

100k

1 2

C22

100p

0

R14 7.5k

R15 6.8k

1 2

C15 47n

1 2

C16 6

80p

12

C17

0

12

C6

10u

R17 0

VCC

VCC

VCC

VCC

12

C11

10u

0

12

C8

33n

12

C14

1

00n

TP1

G

ND_TP

1

J4

PG

12

R1310100k

0

12

C5

1u

JP5

INT_CER

1 2

3 4

5 6

J

P2

DSCG

1 2

3 4

5 6

JP1

D

DRSEL

0

0

0

12

C7

10u

0

0

R8

27k

R91818k

R6

0

R10

0

12

C12

100n

1

J7

VTT

1

J8

V

TTR

EF

12

C18

1n

R16

4R7

0 0

2 Demonstration kit schematic

Figure 2. PM6670AS demonstration board schematic

DD

20

20

PG

33

00

18

ND

80

60

00

ASE

PD

10

10

10

10

100

P2

PG

AS

VS

66

EF

SEL

DDR

10

27

DR

6/38

CC

EF

TT

AM00655v1

AN2798 Demonstration kit schematic

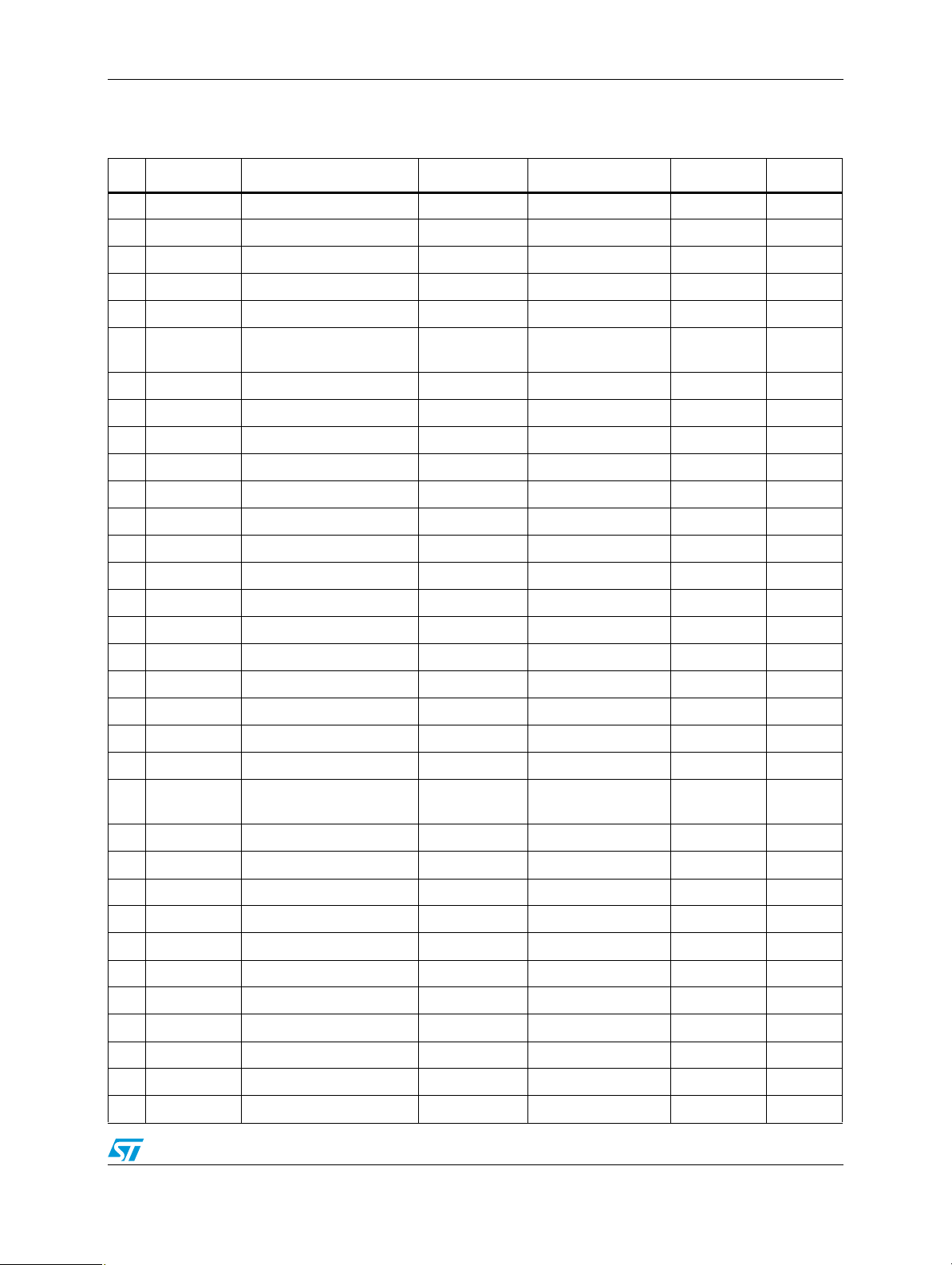

2.1 Component list

Table 1. PM6670AS demonstration board bill of materials

Qty Component Description Package Part number MFR Value

2 C1, C2 Ceramic, 50 V, X5R, 20% SMD 1210 UMK325BJ106KM-T Taiyo Yuden 10 µ

2 C3, C4 POSCAP, 4 V, 15 m, 20% SMD 7343 (D) 4TPE220MF Sanyo 220 µ

1 C5 Ceramic, 6.3 V, X5R, 10% SMD 3216-12 Standard 1 µ

3 C6, C7, C11 Ceramic, 6.3 V, X5R, 10% SMD 0805 JMK212BJ106KG-T Taiyo Yu den 10 µ

1 C8 Ceramic, 50 V,X7R, 20% SMD 0603 Standard 33 n

C9, C10,

4

C13, C14

1 C12 Ceramic, 50 V, X7R, 10% SMD 0805 Standard 100 n

1 C15 Ceramic, 50 V, X7R, 10% SMD 0603 Standard 6n8

1 C16 Ceramic, 50 V, X7R, 10% SMD 0603 Standard 680 p

1 C17 Ceramic, 20% SMD 0603 Standard N.M.

1 C18 Ceramic, 50 V, X7R, 10% SMD 0805 Standard 1 n

2 C19, C20 Ceramic, 6.3 V, X5R, 10% SMD 0805 JMK212BJ106KG-T Taiyo Yuden N.M.

1 R1 Chip Resistor, 0.1 W, 1% SMD 0603 Standard 330 k

Ceramic, 50 V, X7R, 20% SMD 0603 Standard 100 n

1 R2 Chip Resistor, 0.1 W, 1% SMD 0603 Standard 18 k

1 R3 Chip Resistor, 0.1 W, 1% SMD 0603 Standard 1.5 k

1 R4 Chip Resistor, 0.1 W, 1% SMD 0603 Standard 3R3

1 R6 Chip Resistor, 0.1 W, 1% SMD 0805 Standard 0

1 R7 Chip Resistor, 0.1 W, 1% SMD 0603 Standard 3R9

1 R8 Chip Resistor, 0.1 W, 1% SMD 0603 Standard 39 k

1 R9 Chip Resistor, 0.1 W, 1% SMD 0603 Standard 39 k

1 R10 Chip Resistor, 0.1 W, 1% SMD 0603 Standard 0

R11, R12,

3

1 R14 Chip Resistor, 0.1 W, 1% SMD 0805 Standard 7k5

1 R15 Chip Resistor, 0.1 W, 1% SMD 0603 Standard 6k8

1 R16 Chip Resistor, 0.1 W, 1% SMD 0805 Standard 4R7

1 R17 Chip Resistor, 0.1 W, 1% SMD 0603 Standard 0

1 L1 SMT, 10.6 Arms, 4.36 mΩ 13.8 x 13.2 mm MLC1538-152ML Coilcraft 1.5 µ

1 Q1 N-Channel, 60 V SO-8 STS7NF60L ST

1 Q2 N-Channel, 60 V SO-8 STS7NF60L ST

1 D1 Schottky, 100 V, 0.2 A SOD-323 BAT41J ST

1 D2 Schottky, 60 V, 1 A DO214-AC STPS1L60A ST

1D3 N.M.

R13

Chip Resistor, 0.1 W, 1% SMD 0603 Standard 100 k

1 U1 Controller VFQFPN-24 PM6670AS ST

7/38

Demonstration kit schematic AN2798

Table 1. PM6670AS demonstration board bill of materials (continued)

Qty Component Description Package Part number MFR Value

J1, J2, J3,

J4, J5, J6,

11

J7, J8, J9,

J10,J11

JP1, JP2,

3

1 JP5 PCB pads selector

1 TP6 Test point

1 SW1 Dip switch 2 DIP-2 Standard

JP3

Header, single pin

Jumper, 2 x 3, 100 mils

8/38

AN2798 Component assembly and layout

3 Component assembly and layout

Figure 3. Topside component placement

Figure 4. Topside view

9/38

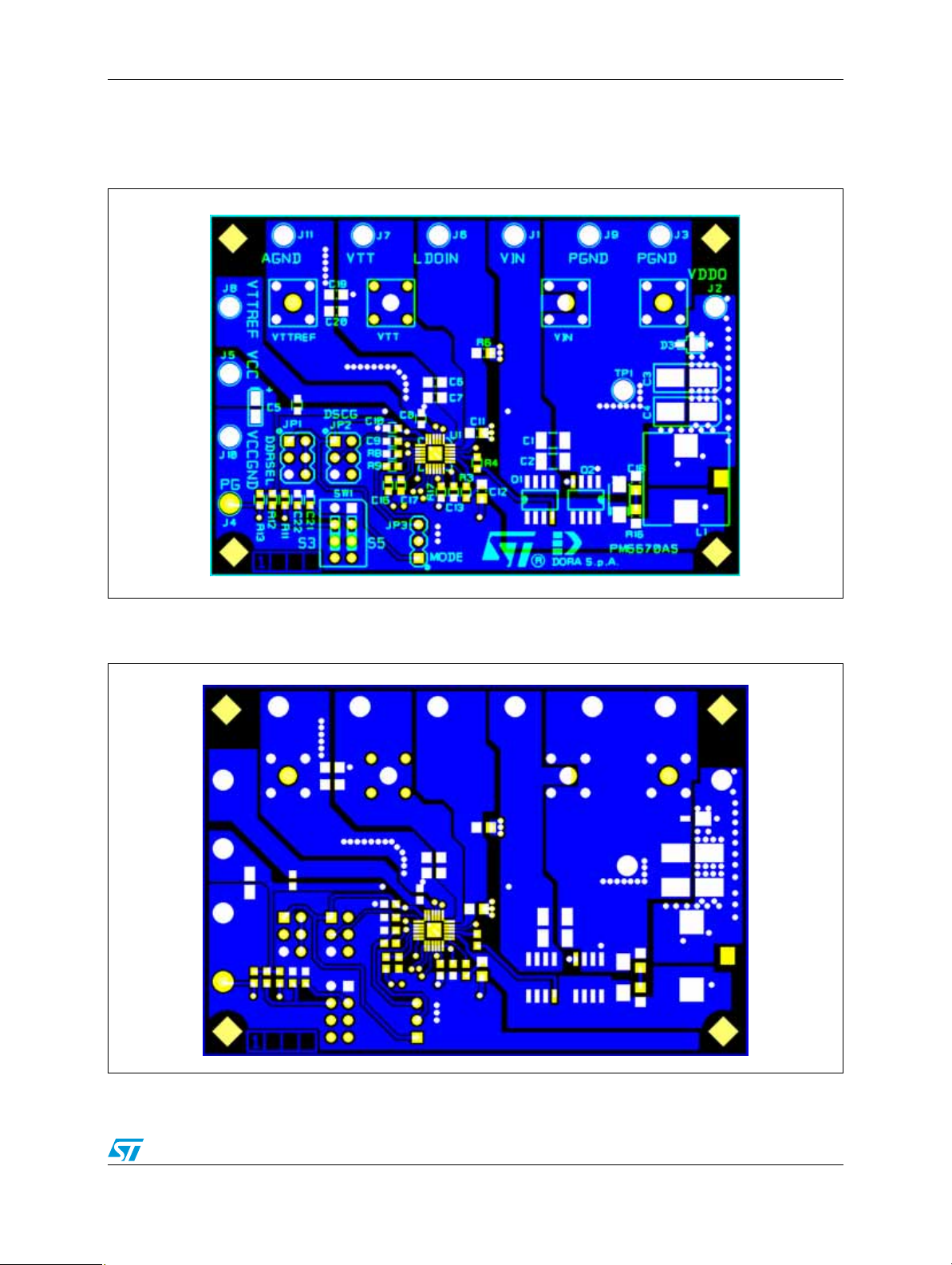

Component assembly and layout AN2798

Figure 5. Layer 2 view

Figure 6. Layer 3 view

10/38

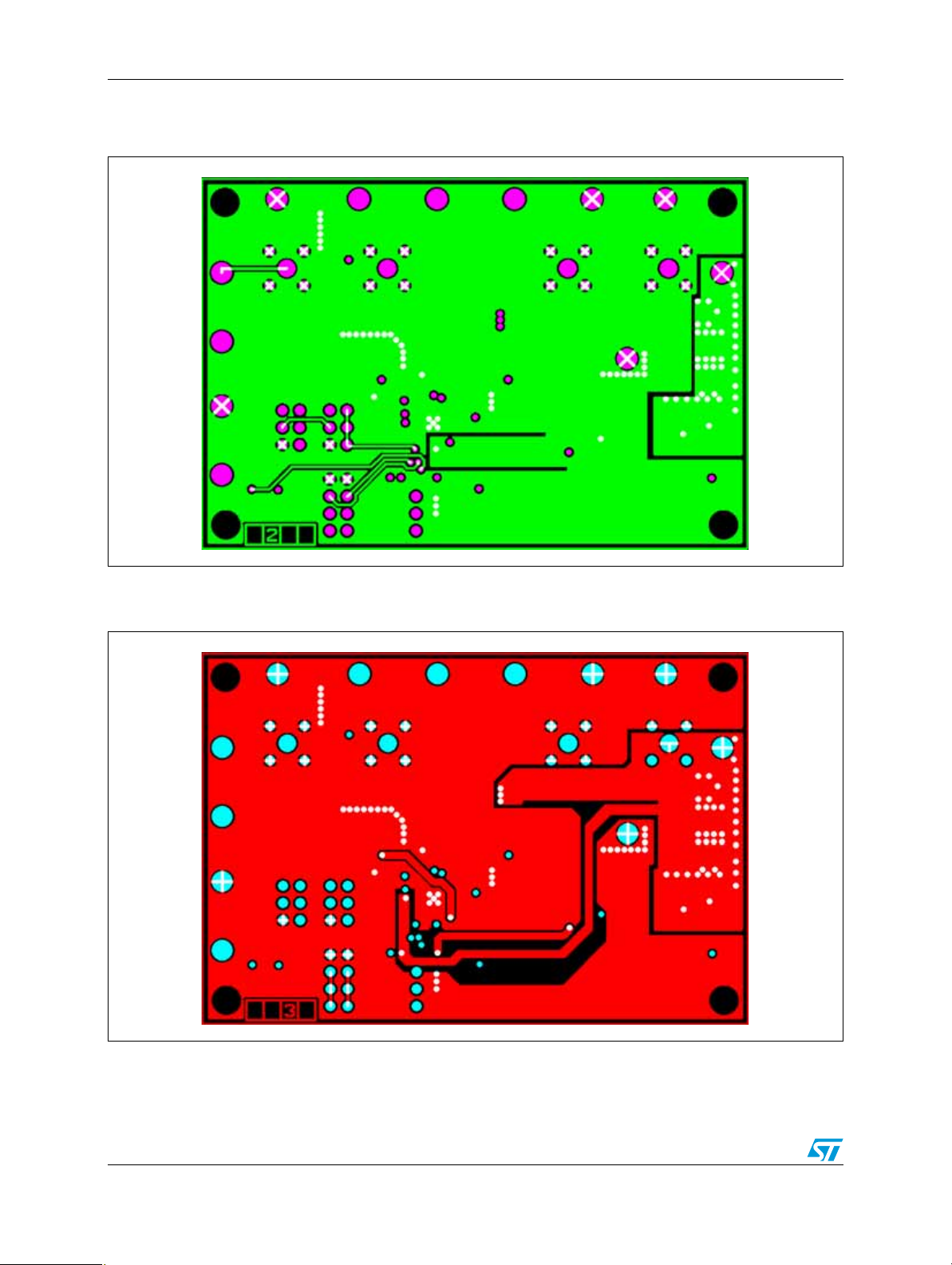

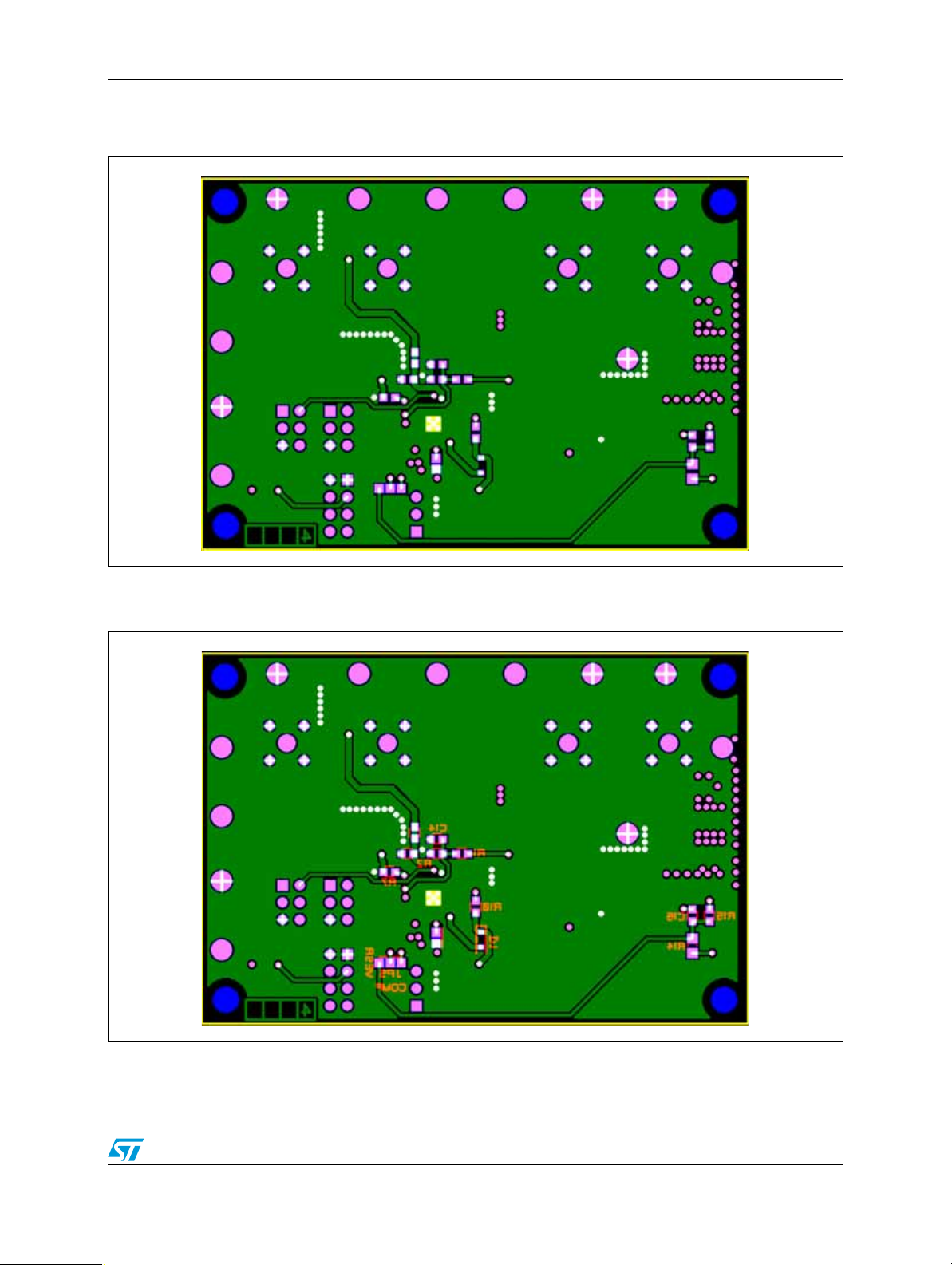

AN2798 Component assembly and layout

Figure 7. Bottomside view

Figure 8. Bottomside component placement

11/38

I/O interface AN2798

4 I/O interface

The PM6670AS demonstration board has the following test points as given in Table 2.

Table 2. PM6670AS demonstration board input and output interface

Test point Description

VIN Battery input voltage positive terminal

PGND Battery input and VDDQ output common return

VDDQ VDDQ output

LDOIN LDO linear regulator input

VTT VTT output (LDO)

AGND VTT and VTTREF outputs common return

VTTREF VTTREF output

VCC + 5 V supply, positive terminal

VCCGND Signal ground and VCC supply return

PG VDDQ output Power Good signal

TP1 Connection point between power and signal grounds

4.1 Recommended equipment

4 V to 36 V, 30 W power supply

Active loads

Digital multimeters

200 MHz four-trace oscilloscope

12/38

AN2798 Configuration

5 Configuration

The PM6670AS board allows the user to choose the desired mode of operation using four

jumpers (JP1, JP2, JP3 and JP5) and two resistors. Refer to the following configuration

description.

5.1 JP3 fixed or adjustable output voltage (MODE pin)

The JP3 jumper is used to choose between fixed output volta ge (1.5 V or 1.8 V) and a userdefined output voltage in the range 0.9 V to 2.6 V. When connected in the lower position, the

fixed output voltage is selected and the voltage depends on the setting of the DDRSEL pin

(see Section 5.2).

If JP3 is in the upper position, the output voltage is given by:

R8 + R9

R8 + R9

×=

×=

ADJ

ADJ

9.0

9.0

R8

R8

VDDQ

VDDQ

Figure 9. JP3 (MODE) setting

Adjustable Output Voltage

Adjustable Output Voltage

Fixed Output Voltage

Fixed Output Voltage

(default position)

(default position)

Both the R8 and R9 resistors are set to 39 kΩ (1.8 V by default) and can be changed by the

user.

5.2 JP1 DDR2/DDR3 or power-saving mode (DDRSEL pin)

The JP1 jumper allows differe nt options depending on the JP3 configuration. If the fixed

output voltage is selected (JP3 in the lower position), the user can choose between 1.8 V

(DDR2) or 1.5 V (DDR3), connecting JP1 as shown in Figure 10, and the pulse-skip mode is

set by default.

When the adjustable output v oltage is selected (JP3 in the up per position), the same jumper

allows choosing between forced PWM, pulse-skip and non-audible pulse-skip modes as

shown in Figure 10 on page 14.

13/38

Configuration AN2798

Figure 10. JP1 (DDRSEL) setting

Forced PWM

Forced PWM

1.8 V output voltage

1.8 V output voltage

1.8 V output voltage

(default position)

(default position)

(default position)

1.5 V output voltage

1.5 V output voltage

1.5 V output voltage

1.5 V output voltage

1.5 V output voltage

1.5 V output voltage

JP1 options when JP3 is in the lower position

JP1 options when JP3 is in the lower position

JP1 options when JP3 is in the lower position

JP1 options when JP3 is in the upper position

JP1 options when JP3 is in the upper position

JP1 options when JP3 is in the upper position

Forced PWM

(default position)

(default position)

(default position)

Non Audible Pulse-Skip

Non Audible Pulse-Skip

Non Audible Pulse-Skip

Pulse-Skip

Pulse-Skip

Pulse-Skip

5.3 JP2 output discharge (DSCG pin)

The JP2 jumper is used to select the desired output discharge when both S3 and S5 signals

are tied low. In the upper position the outputs are not discharg ed at all, while in the lower

position the outputs are independently discharged using the internal MOSFETs (22 Ω for

VDDQ and VTT, 1.5 kΩ for VTTREF).

The tracking discharge is pr ogr amme d by putting JP2 in th e ce ntr al po sition. This di scharge

mode relies on the connection of the LDOIN pin to the VDDQ output, see Section 6: Test

setup on page 16 for details. If an external rail is used to supply the LDO, the tracking

discharge cannot be used because the device can be damaged while attempting to sink 1 A

from the LDO input.

Figure 11. JP2 (DSCG) setting

No Discharge

No Discharge

(default position)

(default position)

Tracking Discharge

Tracking Discharge

Non-Tracking Discharge

Non-Tracking Discharge

14/38

AN2798 Configuration

5.4 JP5 compensation network (COMP pin)

The JP5 jumper is located on the bottom side of the PM6670AS board an d allows

connecting the integrator input (COMP pin) to the output through a simple capacitor

(integrative compensation) or using the "virtual ESR" network for very low ESR output

capacitor applications (e.g. all ceramic output capacitor applications). The integrative

compensation is set by default.

Refer to the PM6670AS datasheet for details about ceramic output capacitor applications

and the virtual ESR design.

Figure 12. JP5 (COMP) setting

Integrative Compensation

Integrative Compensation

(default position)

(default position)

Virtual ESR Network

Virtual ESR Network

15/38

Test setup AN2798

6 Test setup

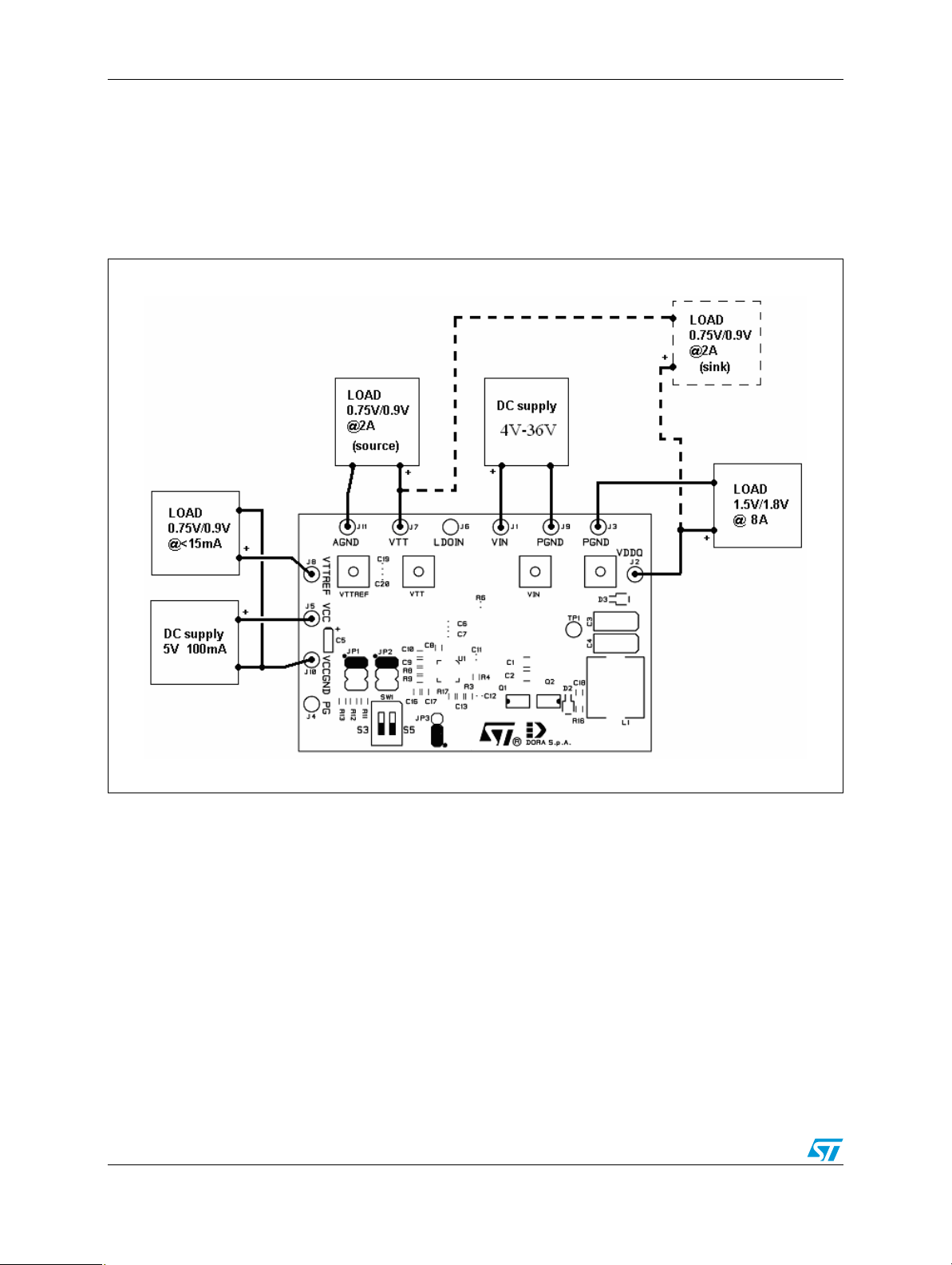

Figure 13 shows the suggested setup connections between the PM6670AS demonstration

board, the loads and the external supply. The LDO input (LDOIN) is connected to VDDQ by

default (R6 = 0 Ω).

Figure 13. PM6670AS test setup

16/38

AN2798 Getting started

7 Getting started

The following step-by-step power-up and power-down sequences are provided in order to

correctly evaluate the PM6670AS board performance.

7.1 Power-up sequence

Working in an ESD-protected environment is highly recommended. Check all wrist straps

and mat-earth connections before handling the PM6670AS board.

1. Connect power supplies as shown in the PM6670AS test setup (Figure13) and insert

the meters in order to perform the desired per formance evaluation. Conn ect the scopeprobes as desired.

2. Set the JP1 through JP5 jumpers in order to properly configure the PM6670AS board.

Set the S3-S5 switches to the on position (upper position). Do not change any of the

jumper settings when the board is po wered.

3. Set the VCC supply to 5 V ± 5 % and the current limit to 100 mA.

4. Set the VIN supply to a voltage in the range 4.5 V to 36 V. An initial test at 24 V and 3 A

current limit is suggested.

5. Set all loads to 0 A.

6. Turn on the VIN supply.

7. Turn on the VCC supply.

8. Vary the VDDQ load from 0 A to 8 A.

9. Vary the VTT load from 0 A to 2 A to test source capability. To test sink capability use

the dashed VTT load shown in Figure 13.

10. Vary the VTTREF load to test source capability.

11. Vary the VIN supply from 4.5 V to 36 V.

7.2 Power-down sequence

1. Decrease the VTTREF and VTT loads to 0 A.

2. Reduce the VDDQ load to 0.

3. Decrease the VCC supply from 5 V to 3.8 V in order to test the UVLO.

4. Increase the VCC supply from 3.8 V to 5 V to restart the device.

5. Use the S3-S5 s witches to enter/exit the S0-S3-S5 states.

6. Turn off the VDDQ load.

7. Turn off the VCC supply.

8. Turn off the VIN supply.

17/38

PM6670AS evaluation tests AN2798

8 PM6670AS evaluation tests

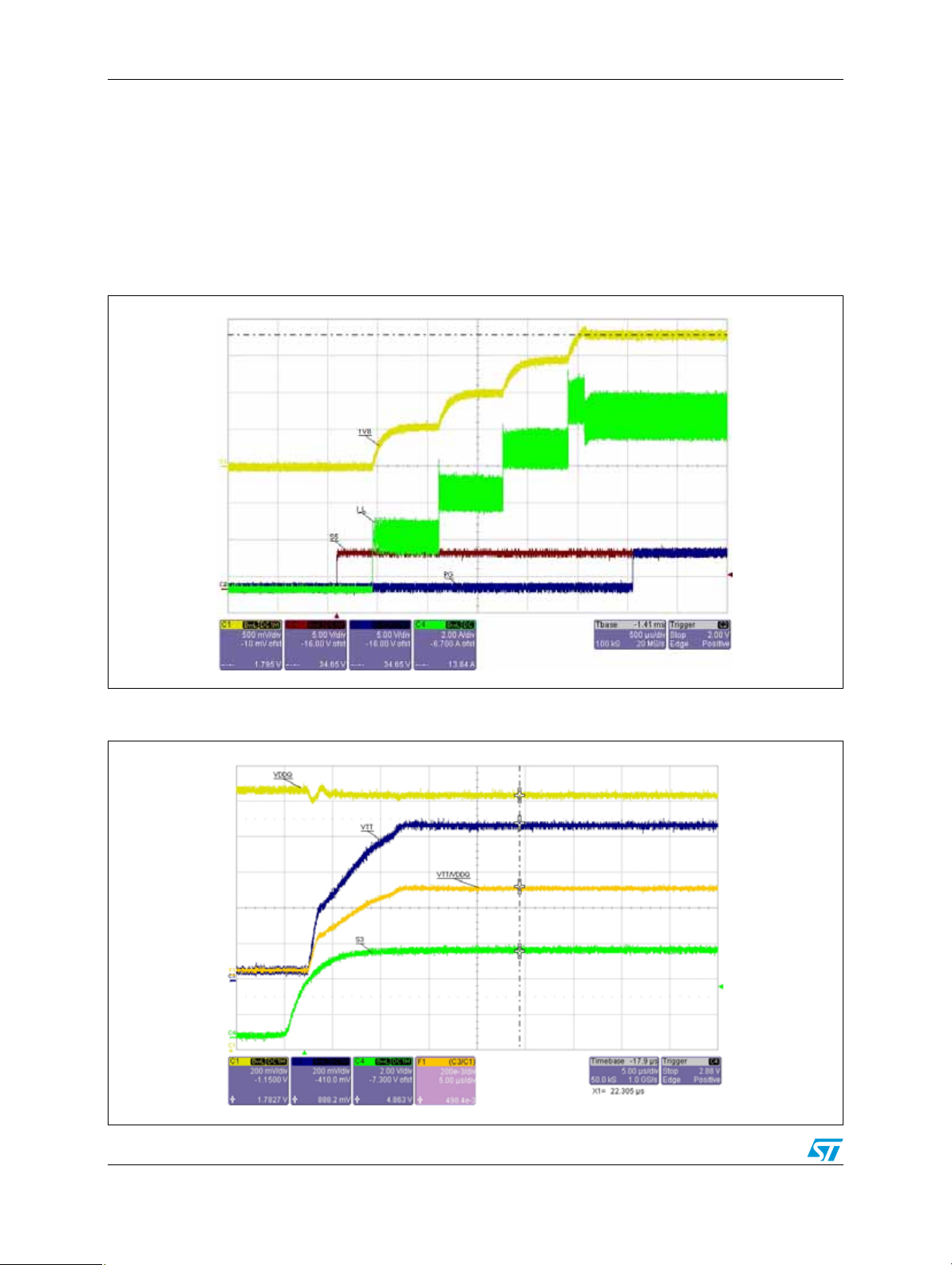

8.1 VDDQ, VTT and VTTREF turn-on (soft-start)

The VDDQ soft-start is divided in 4 steps. In each step the current limit is increased by ¼ of

the nominal value. This behavior is well understood by loading the rail, as performed in the

test. VTT and VTTREF soft-starts are performed at their maximum available current.

Figure 14. VDDQ soft-start at 180 mΩ load, pulse-skip mode

Figure 15. VTT turn-on (S0), pulse-s kip mode

18/38

AN2798 PM6670AS evaluation tests

8.2 VDDQ working modes

8.2.1 VDDQ forced PWM mode

When the forced PWM working mode is selected (JP3 and JP1 in the upper position), the

inductor current is allowed to become ne gative and the follo wing w avef orm can be captured.

Figure 16. VDDQ = 1.8 V, VIN = 24 V, IVDDQ = 0 A, forced PWM mode

8.2.2 VDDQ pulse-skip mode

The default working mode is the pulse-skip algorithm, in which the low-side MOSFET is

turned off when the inductor current becomes equal to zero. This behavior allows reaching

maximum efficiency.

Figure 17. VDDQ = 1.8 V, VIN = 24 V, IVDDQ = 0 A, pulse-skip mode

19/38

PM6670AS evaluation tests AN2798

8.2.3 VDDQ non-audible pulse-skip mode

In order to av oid an insufficient s witching frequency, the non-audible pulse-skip mode can be

selected (JP3 in the upper position and JP1 in the midd le). So doing, the minimum s witching

frequency allowed is 33 kHz as depicted in the following picture.

Figure 18. VDDQ = 1.8 V, VIN = 24 V, no load, non-audible pulse-skip mode (33 kHz)

8.3 VDDQ, VTT and VTTREF load regulation

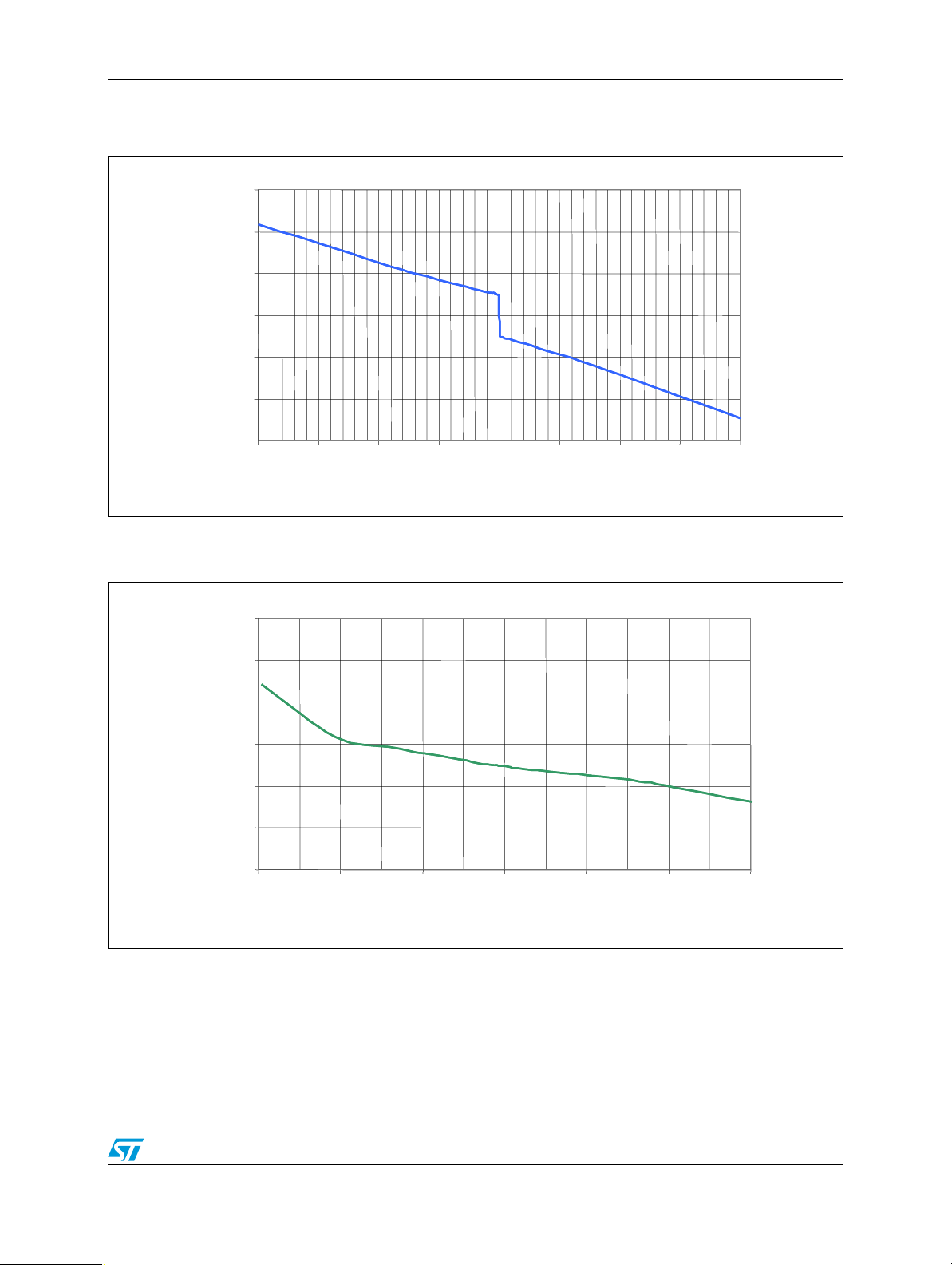

Figure 19 through 21 refer to VDDQ, VTT and VTTREF output voltage versus load current.

The switching section w orks in pulse-skip mode and directly supplies VTT LDO.

Figure 19. VDDQ load regulation - VIN = 24 V

1.840

1.840

1.830

1.830

1.820

1.820

1.810

1.810

Voltage [V]

Voltage [V]

1.800

1.800

1.790

1.790

0.001 0.010 0.100 1.000 10.000

0.001 0.010 0.100 1.000 10.000

Current [A]

Current [A]

Forced PWM

Forced PWM

Pulse Skip

Pulse Skip

Non Audible PS

Non Audible PS

20/38

AN2798 PM6670AS evaluation tests

Figure 20. VTT load regulation - LDOIN = VDDQ (VDDQ in forced PWM mode)

0.930

0.930

0.920

0.920

0.910

0.910

0.900

0.900

Voltage [V]

Voltage [V]

0.890

0.890

0.880

0.880

0.870

0.870

-2.000 -1.500 -1.000 -0.500 0.000 0.500 1.000 1.500 2.000

-2.000 -1.500 -1.000 -0.500 0.000 0.500 1.000 1.500 2.000

Current [A]

Current [A]

Figure 21. VTTREF load regulation (VDDQ in forced PWM mode)

0.920

0.920

0.915

0.915

0.910

0.910

0.905

0.905

Voltage [V]

Voltage [V]

0.900

0.900

0.895

0.895

0.890

0.890

-30 -20 -10 0 10 20 30

-30 -20 -10 0 10 20 30

Current [mA]

Current [mA]

21/38

PM6670AS evaluation tests AN2798

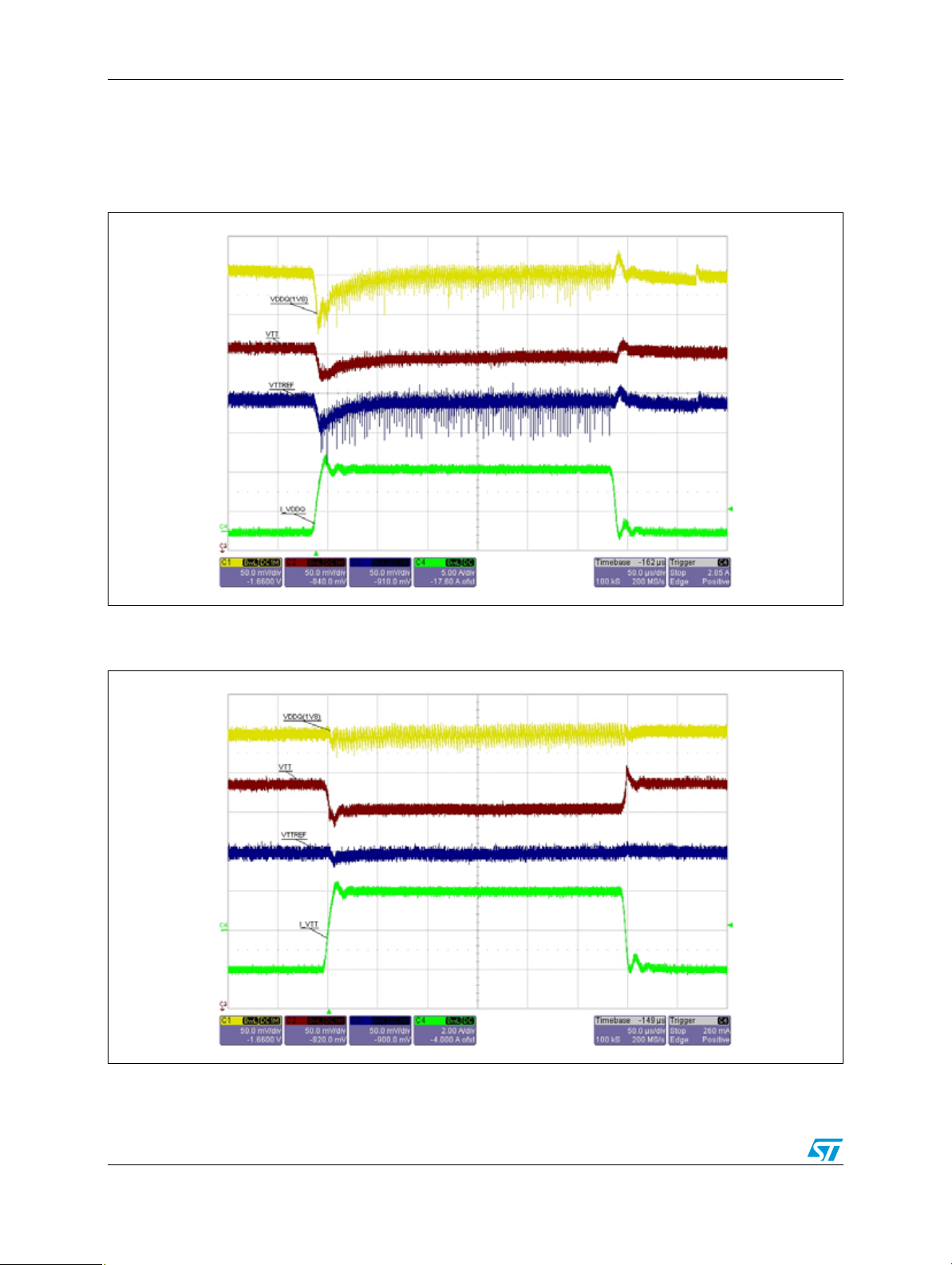

8.4 VDDQ and VTT load transient responses

Load transient responses are evaluated by loading VDDQ and VTT output rails with a

current slew rate of 2.5 A/µs.

Figure 22. VDDQ load transient (VIN = 24 V, LOAD = 0 A to 8 A at 2.5 A/µs) (pulse-skip mode)

Figure 23. VTT load transient (VIN = 24 V, LOAD = – 2 A to 2 A at 2.5 A/µs) (pulse-skip mode)

22/38

AN2798 PM6670AS evaluation tests

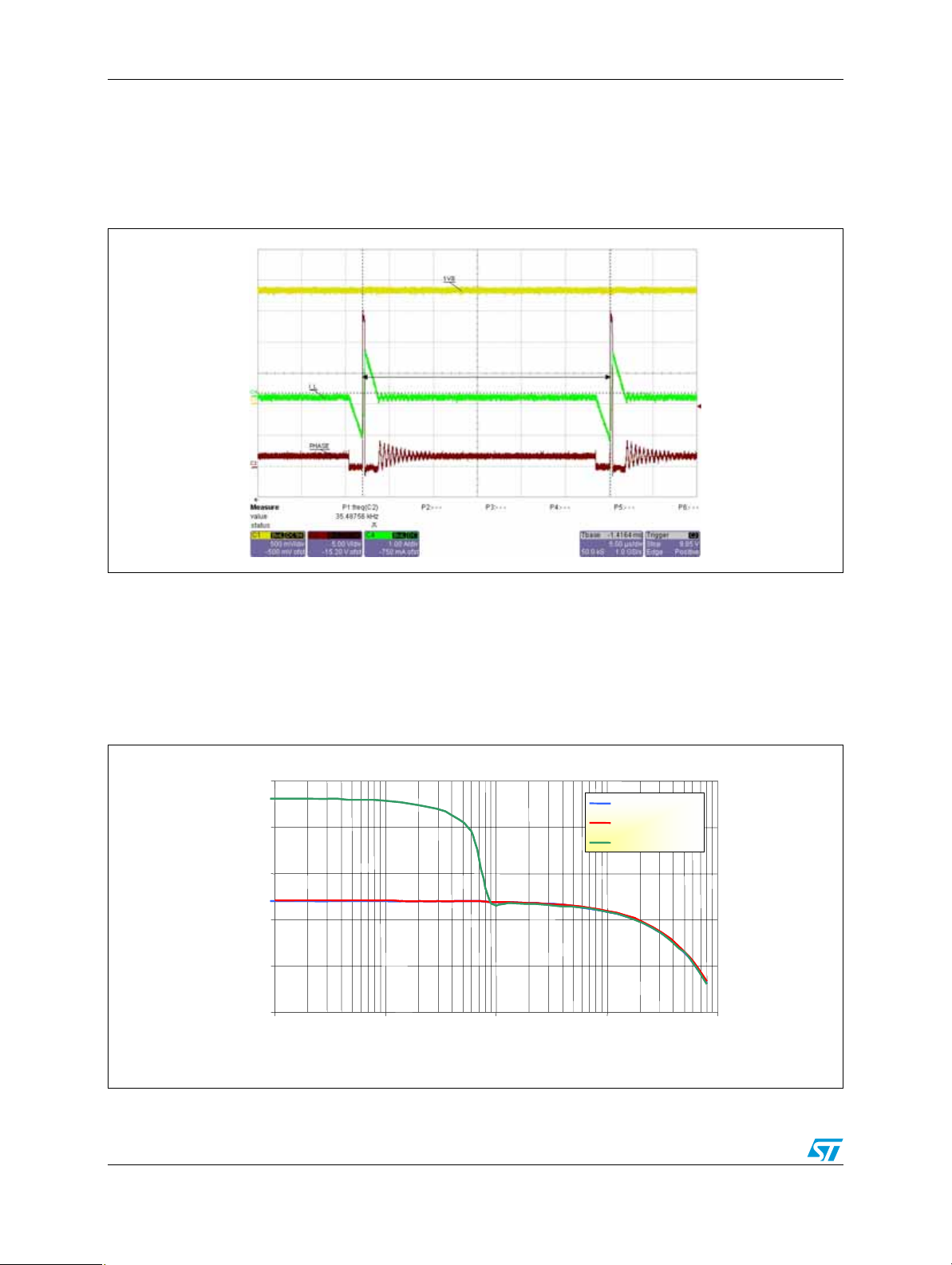

8.5 VDDQ efficiency

The three working modes lead to different power efficiency. The test setup is VIN = 24 V,

FSW = 330 kHz, VDDQ = 1.8 V. The following graph summarizes the results.

Figure 24. Forced PWM (blue), non-audible pulse-skip (green), pulse-skip (red) VDDQ efficiency

vs. output current

100

100

90

90

80

80

70

70

60

60

50

50

40

40

Efficiency [%]

Efficiency [%]

30

30

20

20

10

10

0

0

0.001 0.010 0.100 1.000 10.000

0.001 0.010 0.100 1.000 10.000

Current [A]

Current [A]

Forced PWM

Forced PWM

Pulse Skip

Pulse Skip

Non Audible PS

Non Audible PS

8.6 VDDQ gate drivers

The PM6670 internal MOS driver turns on and off the high-side and low-side external

MOSFET, avoiding cross-conduction. In Figure 24 and 25 the gates signals are depicted

without load and with load.

Figure 25. External MOS gate signals (VIN = 24 V, LOAD = 0 A) (pulse-skip mode)

23/38

PM6670AS evaluation tests AN2798

Figure 26. External MOS gate signals (VIN = 24 V, LOAD = 8 A) (pulse-skip mode)

8.7 VDDQ, VTT and VTTREF turnoff (soft-end)

Tracking discharge

The jumper JP2, if placed in the middle, a llows the output tracking discharge. When S3 and

S5 are pulled down, VTT discharges VDDQ b y sinking 1 A and, at the same ti me , tra c ks the

VDDQ remaining half. When VDDQ reaches abou t 400 mV, the output discharge MOSFETs

are all closed and each rail is finally discharged.

Figure 27. VDDQ, VTTREF, VTT output voltages and LDO input current, tracking discharge, no

load on any rail

24/38

AN2798 PM6670AS evaluation tests

Table 3. Measured discharge resistance in soft-discharge mode

VDDQ output VTTREF output VTT output

Measured N.T.D. discharge

MOSFET’s RDSon

25 Ω 1.5 kΩ 23 Ω

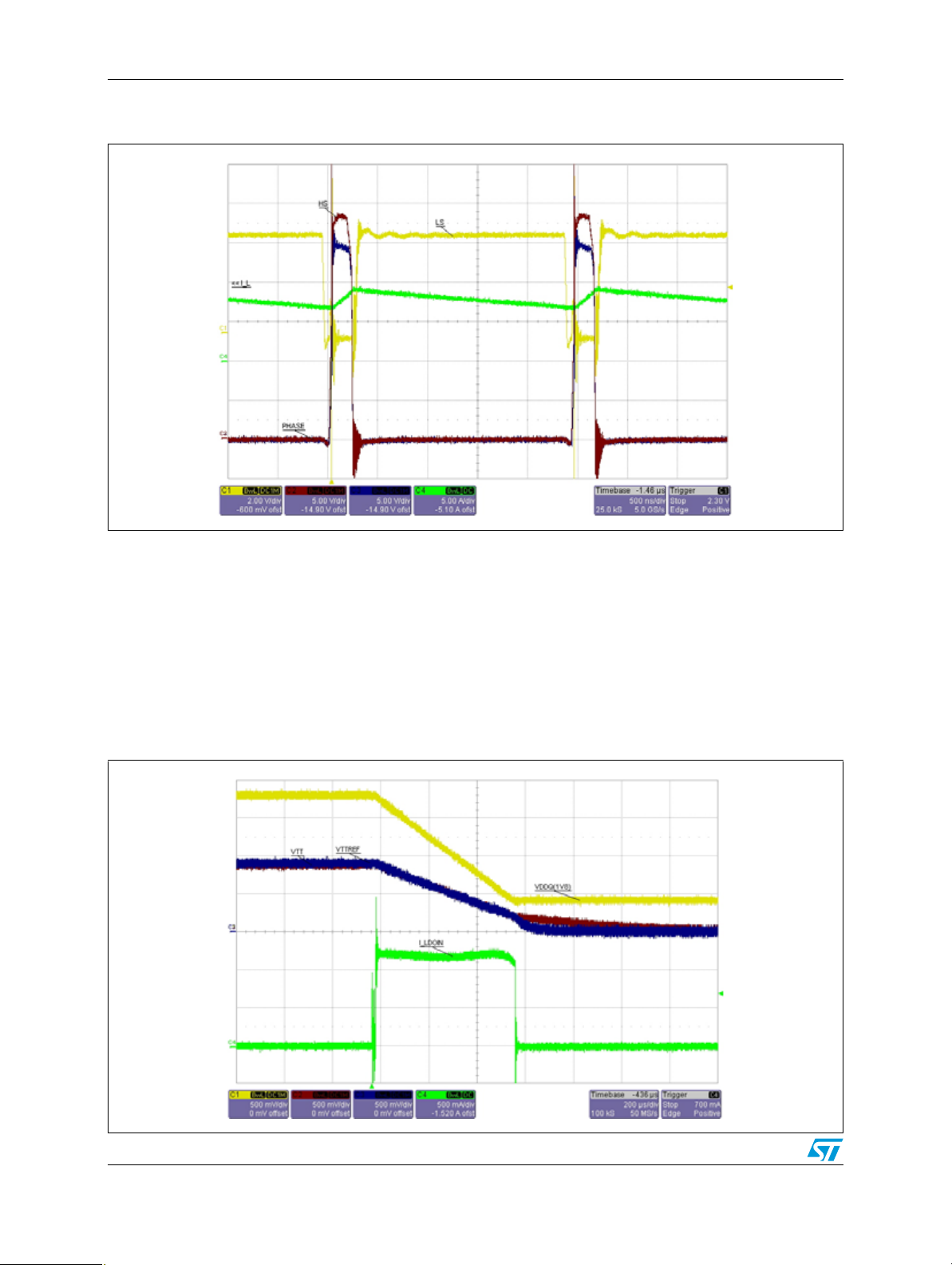

Non-tracking discharge

When the non-tracking discharge is programmed (JP2 in the lower position) and S3-S5 are

both tied to GND , each out put rail is discharged through its discharge MOSFET, as depicted

in the following picture.

Figure 28. VDDQ, VTTREF and VTT, non-tracking discharge, no load on any output

25/38

PM6670AS evaluation tests AN2798

8.8 UV, OV and thermal protections

Latched UV protection

If the output voltage is lower than the 70 % nominal value, the undervoltage sta te is ent ered

and the discharge MOSFETs are turned on (as in the non-tracking soft-end).

Figure 29. UV protection, pulse-skip mode

26/38

AN2798 PM6670AS evaluation tests

Latched OV protection

If the output voltage is hig her than the 115 % nomin al va lue, the o v ervoltage state is e ntered

and the low-side MOSFET is turned on. VTT and VTTREF are discharged through thei r

discharge MOSFETs.

Figure 30. OV protection, pulse-skip mode

27/38

PM6670AS evaluation tests AN2798

Latched thermal shutdown

If the junction temperature rises up to 150 deg, the thermal protection circuit turns off the

device and discharges the output rails by performing the non-tracking discharge soft-end.

Figure 31. VDDQ, VTT, VTTREF and inductor current, thermal shutdown, pulse-skip mode

8.9 VDDQ current limit

The valley current limit avoids any high side turning on if the inductor current is higher than

the programmed value. This current limit can be designed with the following equation:

The current sensing is performed by comparing the voltage drop in the low-side MOSFET,

during the TOFF period, with the voltage drop given by an injected current and the current

limit resistor.

I

I

CL

CL

100µA x

100µA x

=

=

R

R

R

R

ILIM

ILIM

DSonLS

,

DSonLS

,

28/38

AN2798 PM6670AS evaluation tests

Figure 32. VDDQ current limit protection during a load transient (0 A to 10 A at 2.5 A/µs)

29/38

PM6670AS evaluation tests AN2798

8.10 VTT current limit (foldback)

VTT LDO has a foldback pro tection feature which reduces the current limit to 1 A when the

VTT output voltage is outside the ± 10 % Power Good window. The current limit is restored

to 2 A when the output voltage re-enters the Power Good window.

Figure 33. VTT current limit during an output short

30/38

AN2798 PM6670AS evaluation tests

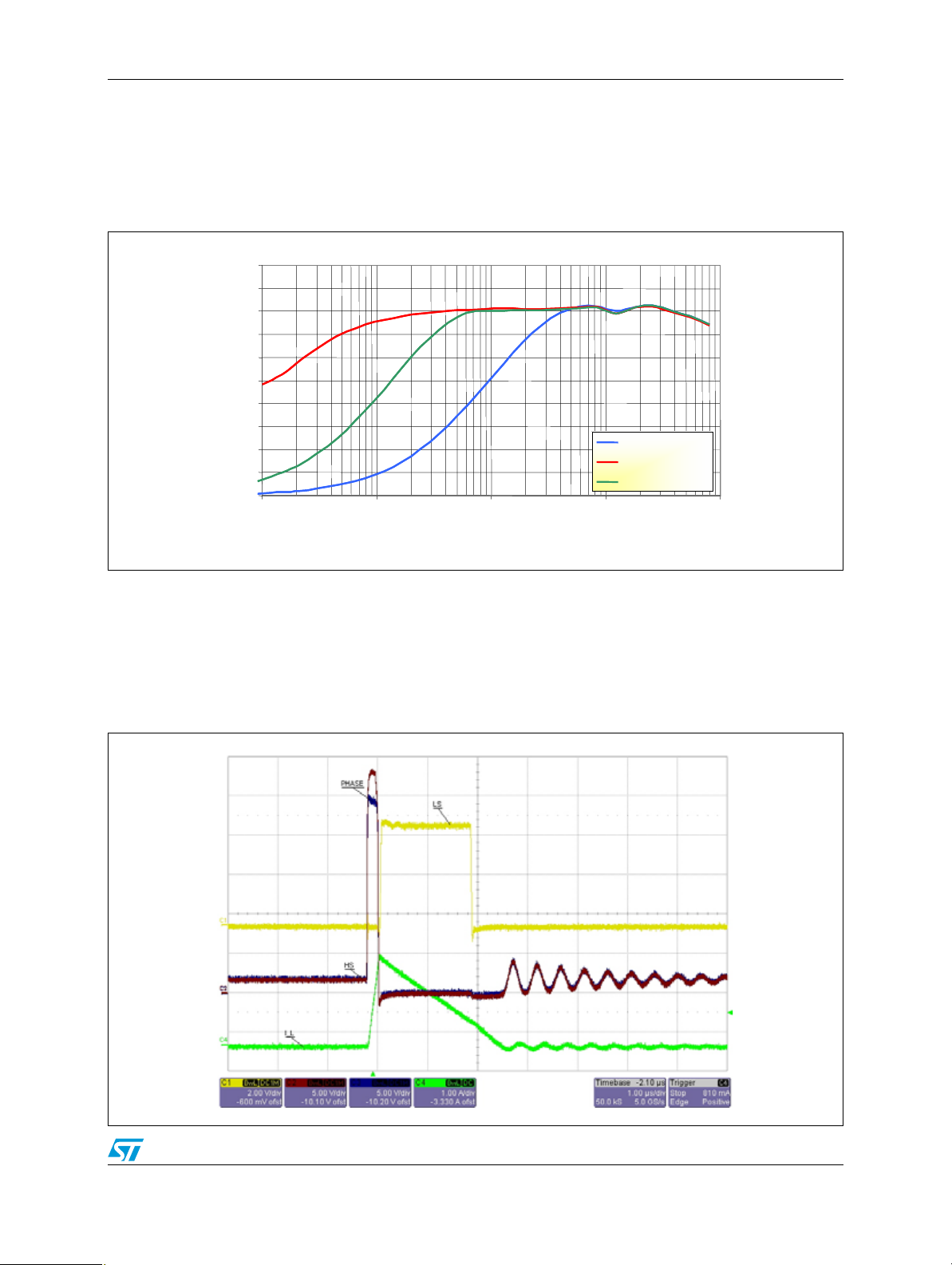

8.11 Switching frequency

Switching frequency vs. input voltage

The constant on-time controller leads to a quasi-constant switching frequency, slightly

following the input voltage.

Figure 34. Switching frequency vs. input voltage, VDDQ = 1.8 V, IVDDQ = 4 A, forced PWM mode

500

500

450

450

400

400

Frequency [kHz]

Frequency [kHz]

350

350

300

300

4142434

4142434

Voltage [V]

Voltage [V]

31/38

PM6670AS evaluation tests AN2798

Switching frequency vs. output current

The switching frequency can decrease to very low values in pu lse-skip mode instea d in nonaudible pulse-skip there is a lower limit (about 33 kHz). With increasing load, however, the

switching frequency increa ses a bit, as a consequence of conduction and switching losses.

Figure 35. Forced PWM (blue), non-audible pulse-skip (green) and pulse-skip (red), switching

frequency vs. output current, VDDQ = 1.8 V, VIN = 24 V

500

500

400

400

300

300

200

200

Frequency [kHz]

Frequency [kHz]

100

100

Forced PWM

Forced PWM

Pulse Skip

Pulse Skip

Non Audible PS

Non Audible PS

0

0

0.001 0.010 0.100 1.000 10.000

0.001 0.010 0.100 1.000 10.000

Current [A]

Current [A]

32/38

AN2798 PM6670AS evaluation tests

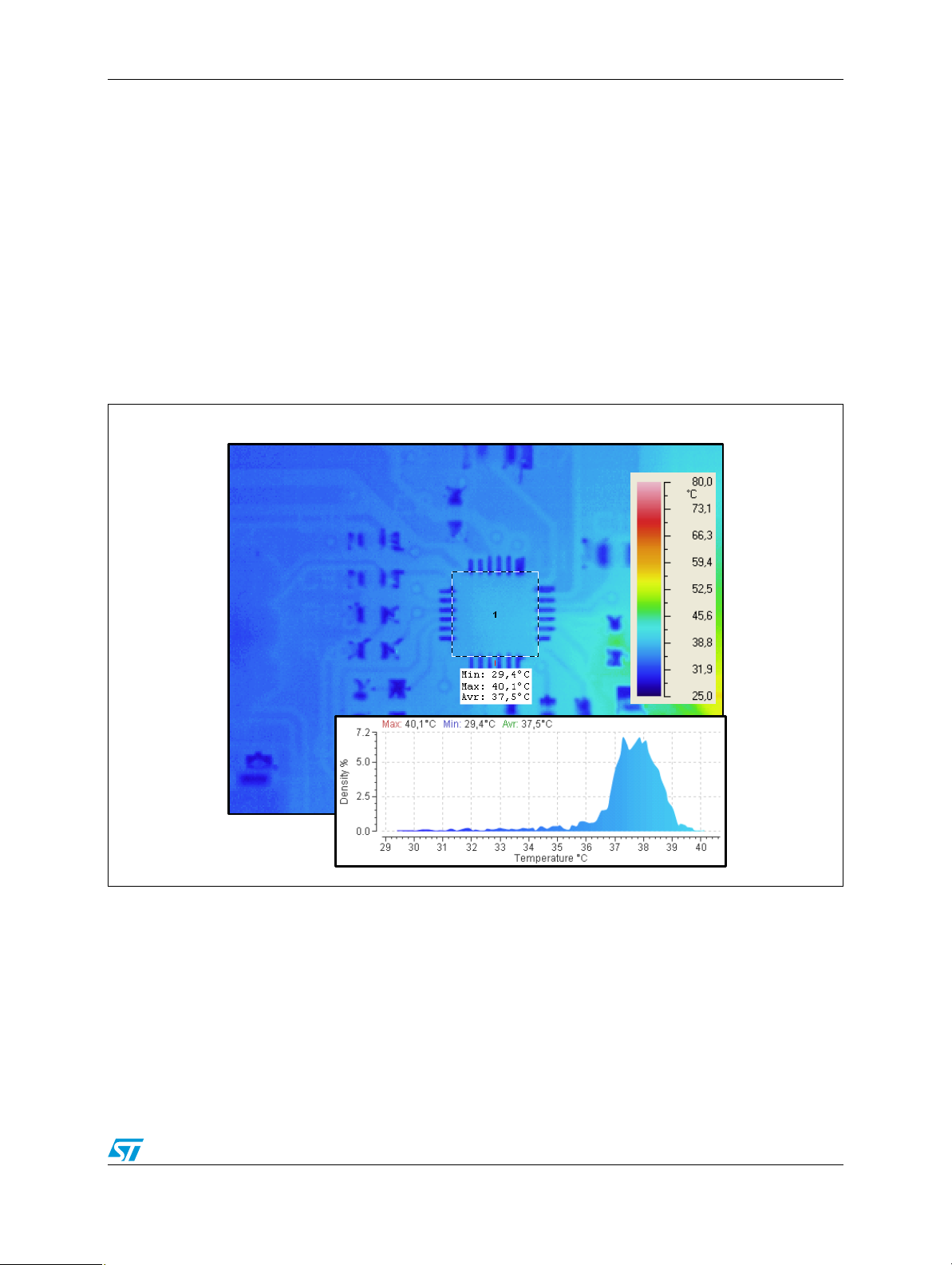

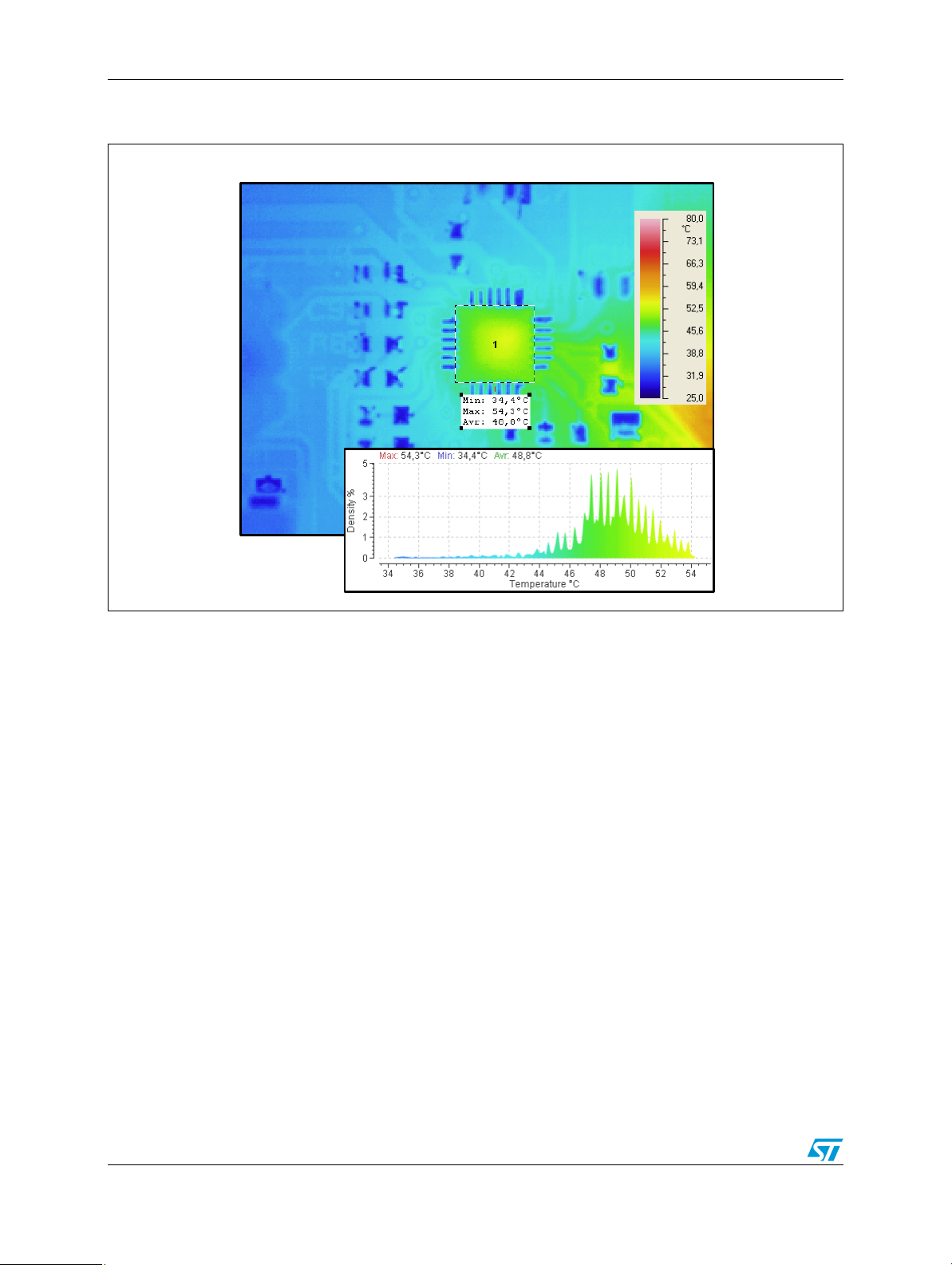

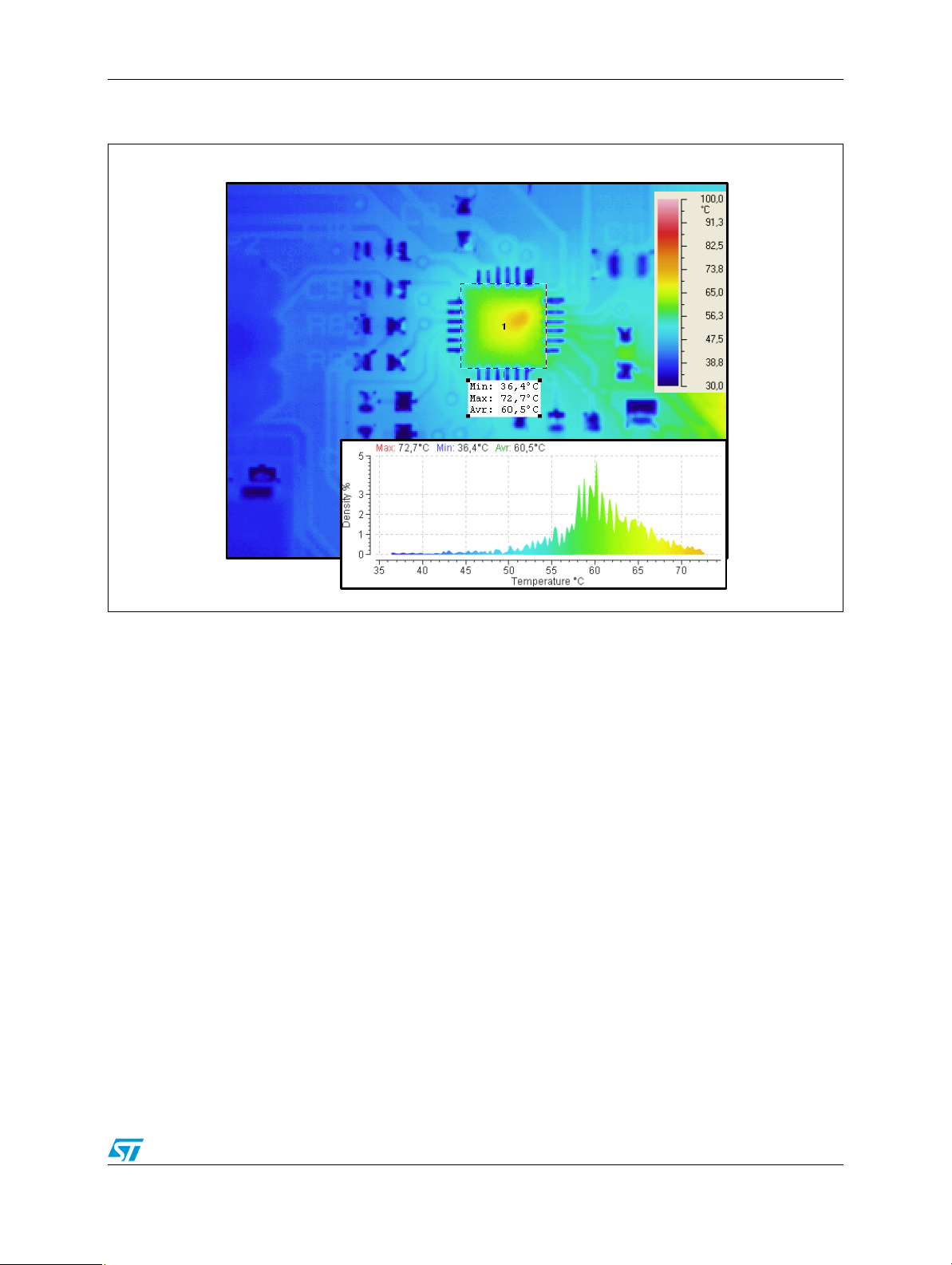

8.12 Thermal behavior

The IC internal maximum and average temperature can be monitored by an IR camera. For

the measurements in Figure 36 through 39 the test setup is:

● V

● F

● Pulse-skip mode

● I

● VTT rail powered by VDDQ

● T

By increasing the VTT current, the IC temperature changes as depicted in the following

pictures.

= 24 V

IN

= 360 kHz

SW

VDDQ

AMB

= 4 A

= 25 °C

Figure 36. I

= 0 A, average IC temperature = 37.5 °C, max internal IC temperature = 40.1 °C

VTT

33/38

PM6670AS evaluation tests AN2798

Figure 37. I

= 0.5 A, average IC temperature = 48.8 °C, max internal IC temperature = 54.3 °C

VTT

34/38

AN2798 PM6670AS evaluation tests

Figure 38. I

= 1 A, average IC temperature = 60.5 °C, max internal IC temperature = 72.7 °C

VTT

35/38

PM6670AS evaluation tests AN2798

Figure 39. I

= 1.5 A, average IC temperature = 73.8 °C, max internal IC temperature = 95.6 °C

VTT

36/38

AN2798 Revision history

9 Revision history

Table 4. Document revision history

Date Revision Changes

04-Nov-2008 1 Initial release.

37/38

AN2798

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely res ponsibl e fo r the c hoic e, se lecti on an d use o f the S T prod ucts and s ervi ces d escr ibed he rein , and ST as sumes no

liability whatsoever relati ng to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third pa rty p ro duc ts or se rv ices it sh all n ot be deem ed a lice ns e gr ant by ST fo r t he use of su ch thi r d party products

or services, or any intellectua l property c ontained the rein or consi dered as a warr anty coverin g the use in any manner whats oever of such

third party products or servi ces or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICUL AR PURPOS E (AND THEIR EQUIVALE NTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJ URY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST fo r the ST pro duct or serv ice describe d herein and shall not cr eate or exten d in any manne r whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document su persedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2008 STMicroelectronics - All rights reserved

STMicroelectronics group of compan ie s

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

38/38

Loading...

Loading...