Page 1

Super wide-range buck converter based on the VIPer16

1 Introduction

This document describes the STEVAL-ISA010V1 demonstration board, which is designed

as an example of a simple non-isolated auxiliary power supply for a range of input voltages

from 85 VAC to 500 VAC.

There is an ever-increasing demand for small power supplies capable of working without

voltage range limitations, even at nominal levels of 400 VAC and 415 VAC, respectively. The

real voltage levels can reach 500 VAC (415 V + 20%). The major markets for this type of

SMPS are home appliances and metering.

The new STMicroelectronics™ family of monolithic converters is well-suited for this range of

input voltages, thanks to the 800 V avalanche-rugged MOSFET integrated within the same

package with the control chip. This application note describes a low power SMPS with

a buck topology using STMicroelectronics’ VIPer16 fixed-frequency off-line converter as

a main circuit. The VIPer16 device includes an 800 V rugged power switch, a PWM

controller, programmable overcurrent, overvoltage, overload, a hysteretic thermal protection,

soft-start and safe auto-restart after any fault condition removal. Burst mode operation at

light load combined with the very low consumption of the device helps to meet standby

energy-saving regulations. The significant benefit of this new chip derives from the jitter of

the switching frequency and the possibility to supply the chip directly from the DC HV bus,

so auxiliary supply is not mandatory. The VIPer16 is suitable for flyback or buck topologies,

and thanks to an internal self-supply circuit it does not require an auxiliary supply.

AN2872

Application note

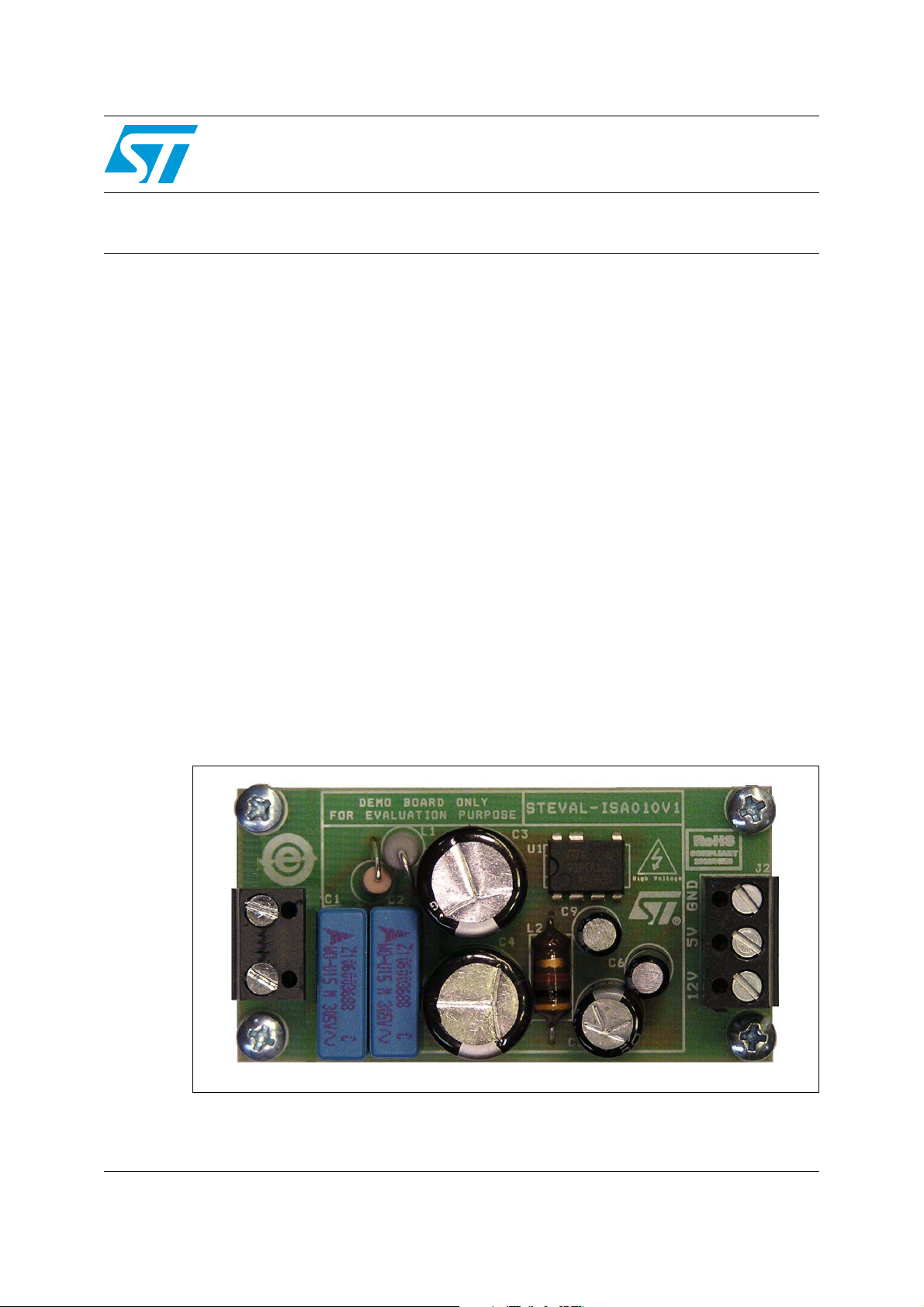

Figure 1. The STEVAL-ISA010V1 demonstration board

April 2009 Doc ID 15305 Rev 1 1/23

www.st.com

Page 2

Contents AN2872

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Main characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 Theory of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1.1 The basic principle of the buck converter . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1.2 Practical aspects of a buck converter dedicated for mains

and 3-phase input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Converter schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.4 Bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Experimental results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Load regulation and output voltage ripple . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Standby . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3 Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.4 MOSFET voltage stress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.5 Short-circuit behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.6 EMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.6.1 Surge - IEC 61000-4-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.6.2 Burst - IEC 61000-4-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.6.3 EMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.7 Thermal behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2/23 Doc ID 15305 Rev 1

Page 3

AN2872 List of tables

List of tables

Table 1. List of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 2. Temperature of the VIPer16 at full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 3. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Doc ID 15305 Rev 1 3/23

Page 4

List of figures AN2872

List of figures

Figure 1. The STEVAL-ISA010V1 demonstration board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. Buck converter schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. Standard implementation of a buck converter with a monolithic device . . . . . . . . . . . . . . . . 8

Figure 4. Schematic of the step-down converter based on the VIPer16L . . . . . . . . . . . . . . . . . . . . . . 9

Figure 5. PCB layout of the buck converter (top, bottom, bottom layout) . . . . . . . . . . . . . . . . . . . . . 11

Figure 6. 12 V output load regulation for different output loads and input voltage levels

(linear regulator U2 not assembled) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 7. Output voltage ripple for different input voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 8. Alternative schematic of the input part using balancing Zener diodes instead of

resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 9. Standby consumption for different input voltage levels . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 10. Efficiency of the converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 11. Drain voltage (CH1) and inductor current (CH4) at different input voltages . . . . . . . . . . . . 17

Figure 12. Indication of current (CH4) and drain voltage (CH1) during short-circuit . . . . . . . . . . . . . . 18

Figure 13. EMI measurements of the demonstration board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4/23 Doc ID 15305 Rev 1

Page 5

AN2872 Main characteristics

2 Main characteristics

The main characteristics of the SMPS are listed below:

●

Input:

–V

– f: 45 - 66 Hz

●

Output:

– 12 V ± 10%

–5 V ± 4%

– 150 mA total (5 V and 12 V output) output current for full input voltage range

●

Standby: 96 mW at 230 VAC

●

Short-circuit: protected

●

PCB type and size:

–FR4

– Single side 70 µm

– 27 x 45 mm

●

Isolation: non isolated - N connected to output GND

●

EMI: In accordance with EN55022 - class B

●

EMC: Surge - IEC 61000-4-5 - 2 kV

●

EMC: Burst - IEC 61000-4-4 - 8 kV

: 85 - 500 VAC

IN

Doc ID 15305 Rev 1 5/23

Page 6

Description AN2872

3 Description

3.1 Theory of operation

The detailed calculation and principles of the buck converter for mains voltage operating

range is described in Section 6: References:1. and References:2. The basic ideas and most

important behaviors of the buck converter for mains applications is described in the chapters

that follow.

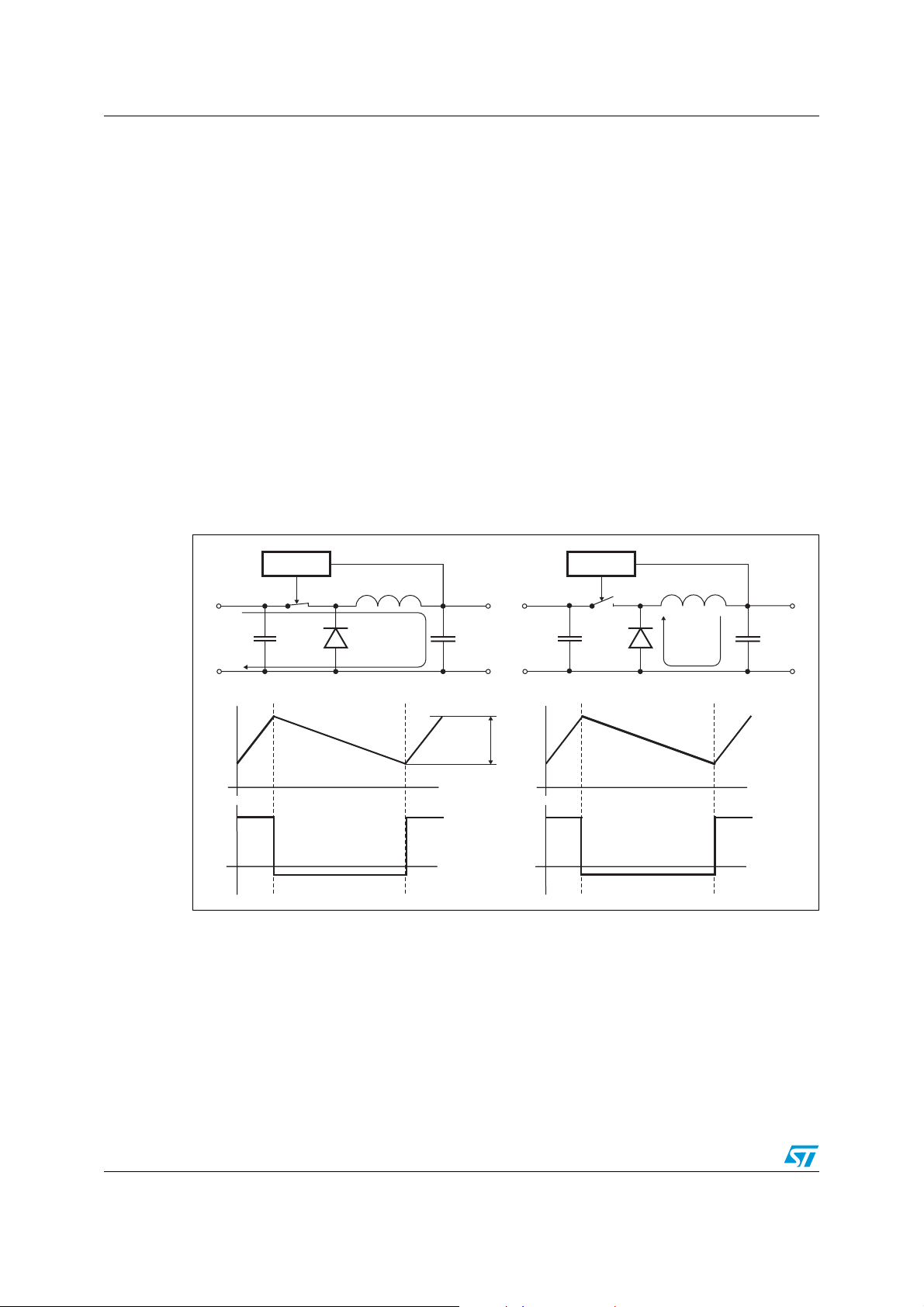

3.1.1 The basic principle of the buck converter

The schematic of the buck converter is shown in Figure 2. During the ON time, the control

circuit makes the high side switch T

output capacitor C

during the ON time. Assuming the voltage across C2 is constant and the

2

input voltage is constant, the voltage drop over L

over the inductor causes a linear increase in the current through inductor L

the inductor current is proportional to the inductance of the inductor and the level of voltage

drop over the inductor.

Figure 2. Buck converter schematic

conduct. The input DC voltage is connected to L1 and

1

is constant (V1 - V2). The constant voltage

1

. The slope of

1

Control

L

L

T1

C

V

1

1

1

+

+

D

1

–

I

L

C

2

V

V

1

2

Control

L

T

T

1

C

1

D

D

1

1

+

–

+

C

I

I

L

2

ON time OFF time

I

V

L

After T

L

t

t

is switched OFF, the low side switch (diode D1) conducts. If we assume, for

1

∆I

I

L

t

V

L

t

AM00359

simplification purposes, the voltage drop over the diode is zero, then the voltage drop over

inductor L

is equal to the output voltage (voltage drop over C2). Because the voltage across

1

the inductor is different (compare ON time), the slope of inductor current is also different.

The behavior of a buck converter can be expressed by Equation 1.

Equation 1

V

∆I

V2–()t

1

-------- --------- ---------- ------

ON

L

V2t

OFF

--------- ---------==

L

6/23 Doc ID 15305 Rev 1

Page 7

AN2872 Description

The regulator of the circuit measures the output voltage, compares it with the reference

voltage and modifies the duration of the ON time to keep the output voltage constant.

In cases where the inductor current is operating in the continuous mode (the current does

not cross zero at full load) the duty cycle can be obtained using Equation 2. This formula

follows from Equation 1. Another method to obtain Equation 2 is to consider the buck

converter as a low pass filter (L

, C2), connected to a rectangular signal and that the low

1

pass filter generates a mean value.

Equation 2

V

------=

V

2

1

δ

3.1.2 Practical aspects of a buck converter dedicated for mains and 3-phase

input

The application of a mains or 3-phase buck converter using a simple monolithic device

results in several special conditions. A few of the most important are described in the

following paragraphs.

The operation of a buck converter such as that of the diagram in Figure 2 requires an active

high side switch. Therefore, the monolithic device (with integrated N-channel MOSFET) is

also connected on the high side (between + of bulk capacitor and inductor). The GND of the

controller connected to the source of the MOSFET refers to the high side of the inductor

(see Figure 3). This wiring of circuit causes the feedback signal not to be directly sensed

from the output due to the shift of the GND of output voltage and controller. Basically, there

are two ways to move the information regarding the output voltage from the output to the

controller. The first way is to apply an optocoupler between the output and the converter.

The additional error amplifier and reference (typically TL431 or a simple Zener diode) must

be assembled to drive the LED of the optocoupler. This method gives high precision of the

output voltage level and low load regulation. However, it also increases the cost and space

requirements. The second principle is to use a replica of the output voltage stored in the

auxiliary capacitor during OFF time. The schematic in Figure 3 shows the principle

connection of the components. The auxiliary capacitor C

from inductor L

voltage drop over both capacitors (C

to the same voltage level as capacitor C2. It can be expected that the

1

and C3) must be equal. However, in real applications

2

the voltages are not exactly the same. This difference is caused by the difference in the

discharge current of capacitors, different capacitance and different voltage drop on diodes

D

and D2. An important effect of the variance of the voltage drop of C2 and C3 is the fact

1

that only C

is charged during ON time. Due to this behavior it is possible to see a

2

theoretically unlimited increase in the output voltage at light or no load, because the energy

delivered during the ON time is higher than the total energy required by the load. Therefore,

an additional load (resistor) or voltage limiter (Zener diode) is required on the output to

protect the output capacitor and the load against overvoltage at light load.

is charged during the OFF time

3

Doc ID 15305 Rev 1 7/23

Page 8

Description AN2872

Figure 3. Standard implementation of a buck converter with a monolithic device

Control

V

C

1

1

T1

FB

GND

C

3

D

1

D

2

L

1

C

V

2

2

AM00360

The second important behavior of a buck converter dedicated for mains applications follows

from the ratio between the input and output voltage. As derived from Equation 2 the duty

cycle is very low when the ratio between the input and output is very high. This also means

the ON time must be very short. It is possible for the ON time required for correct operation

to be shorter than the minimum ON time of the controller defined in the datasheet (the

maximum duration of the minimum ON time of the VIPer16 is 450 ns. see Section 6: 3). In

this case the SMPS delivers more energy than the controller, which is compensated by the

skipping of some pulses. This leads to higher ripple of the output voltage. This effect can be

compensated by applying a higher inductance value and a lower switching frequency.

The last technical point discussed in this paragraph concerns the input bulk capacitor in

applications dedicated to very high input AC voltage. In this case, the input voltage is up to

500 VAC. The DC voltage can reach voltage levels of up to 707 VDC. The input bulk

capacitor must be able to sustain such voltage levels. Unfortunately, there are no standard

aluminum capacitors on the market suitable for this voltage, so two capacitors connected in

series have been applied.

The series connection of two capacitors has two effects on the voltage drop over each

capacitor. The first is an influence over the tolerance of the capacitance and the second is

an influence over the leakage current.

Regarding the tolerance, the worst case is that one capacitor’s capacitance is at the

maximum upper limit and the second at the lower limit. Equation 3 defines the voltage

distribution on each capacitor for this configuration:

Equation 3

V

MAX

V

C1 C2,

------- -------

2

1 δ±()=

where

V

is the voltage across the capacitor with higher capacitance (the sign "–" in the brackets)

C1

is the voltage drop on the capacitor with lower capacitance (the sign "+" in the brackets)

V

C2

is the DC voltage bus

V

MAX

δ is the tolerance of the capacitors expressed as a percentage

If the voltage bus is 707 V and the tolerance is 20%, the highest possible voltage across the

capacitor is 424 VDC. Therefore, for this voltage range, the use of 450 V capacitors is

recommended.

The leakage current can cause additional unbalancing of the voltages and an increase in

the voltage drop of one capacitor over the allowed limit. If the leakage currents of both

8/23 Doc ID 15305 Rev 1

Page 9

AN2872 Description

capacitors are the same, no problem is presented. But in cases where there is a difference

in leakage currents (which is the case in practical applications) this difference will cause the

capacitor with lower leakage to be charged by this difference and the voltage over this

capacitor will rise, risking exceeding the voltage defined in the datasheet. To avoid this

effect, so-called balancing resistors are applied parallel to the electrolytic capacitors. The

correct value of the balancing resistors can be calculated from the difference in the leakage

currents and applied voltage. Unfortunately, the maximum difference in leakage currents is

not defined. It is possible, however, that the calculations for the balancing resistors are

available the technical documentation of some aluminum capacitor manufactures. An

examination of these documents reveals that there is not a single method and each

manufacturer uses different calculation methods, each of which unfortunately can give very

different values. Technical notes describing the calculations of balancing resistors can be

found in Section 6: References: 4, 5, 6, 7. Typically, the value of balancing resistors is in the

range of hundreds of kΩ to several MΩ.

The drawback of using balancing resistors is the constant input load. The additional

constant load caused by balancing resistors is mainly visible in the standby consumption

and reduction of efficiency at low power SMPS. It is recommended to set the value of the

balancing resistors to the maximum level, respecting the technical recommendations of the

manufacturer of the aluminum capacitors selected.

3.2 Converter schematic

The schematic of the converter is shown in Figure 4. It consists of three sections: an input,

a high voltage DC-DC converter and a linear regulator.

The input sections integrates a rectifier (D

C

, L1, C3, C4), protection (R1) and bulk capacitors (C3, C4) which store energy for the DC-

2

DC converter when the input voltage is low. Because there is 500 VAC applied, which

means a DC level over 700 V, the foil and electrolytic capacitors are connected in series.

This is due to the fact that the standard foil safety capacitors are produced for 440 VAC, and

the maximum DC voltage for standard electrolytic capacitors is 450 V. As the electrolytic

capacitors have different leakage current, the balancing resistors (R

applied to guarantee that the voltage of each capacitor does not exceed the maximum rating

even at maximum input voltage.

Figure 4. Schematic of the step-down converter based on the VIPer16L

D

D

1N4007

J

1

85 - 500 VAC

C

2

150 nF / X2

1

C

150 nF / X2

R122 Ω

4

3

1N4007

1

2

L12.2 mH

R

750 kΩ

2

10 µF / 450 V

R

5 750 kΩ

R6750 kΩ

R8750 kΩ

C

3

7

8

C

4

10 µF /

450 V

U1VIPer16

Drain

Drain

COMP5LIM

3

C

7 1.8 nF

, D4) of the input RMS voltage, an EMI filter (C1,

3

D11N4148

R

FB

V

DD

4

2

1

S

R7N.A.

R

C

9

10 µF

/ 35V

1 kΩ

9

3

24 kΩ

R

4

9.1 kΩ

D

5

STTH108

D

2

STTH108

C

8

100 nF

1 mH

L

2

D

15 V

, R5, R6, R8) must be

2

U2L78L05

3 1

V

V

OUT

IN

C

5

220 µF

/ 25 V

GND

2

6

C

6

10 µF

/ 35 V

J

2

1

2

3

Output

AM00361

The high voltage DC-DC section is a buck converter based on the VIPer16. It converts the

input high DC voltage stored in capacitors C

Doc ID 15305 Rev 1 9/23

and C4 to output. The high side switch is

3

Page 10

Description AN2872

a MOSFET integrated in the VIPer16. The low side switch of the buck converter is

freewheeling diode D

C

during the ON time, when the MOSFET is conducting. The ON time (and consequently

5

(800 V / 1 A). The energy is saved in inductor L2 and output capacitor

5

also the duty cycle) is very short (in the range several %) due to the high ratio between the

input and the output voltage. During the OFF time, the MOSFET is switched OFF and diode

D

conducts. Inductor L2 is discharged to the output and to capacitors C5 and C8 through

5

diodes D

voltage drop over C

Diode D

and D5. As the inductor L2 is, during OFF time, connected to C8 and C5 the

2

is also applied, though not mandatory for correct operation, to reduce the power

1

(used for feedback regulation) is similar to the output voltage level.

8

consumption of the VIPer16 and consequently the standby power.

The VIPer16 operates in current mode. The FB pin is connected to the input of the error

amplifier, the output of the error amplifier is visible on the COMP pin and is connected to the

input of the built-in comparator for comparing the value from the output of the error amplifier

to the drain current. The voltage level expected on the FB pin is 3.3 V. It is possible to see

a rise in the output voltage at low or almost no load for this type of buck converter. This

effect is caused by the capacitor C8 discharging faster than C5 at light or no load, and C5,

moreover, is charged at every ON time. Consequently, the voltage over C8 is constant while

the voltage over C5 rises. To protect the output capacitors and the load against overvoltage

at light load, Zener diode D

is included, limiting the output voltage to 15 V. It is possible to

6

use a simple resistive load instead of the Zener diode. The value of the minimum load

depends on the complete configuration of the components. If linear regulator U

is not used,

2

the value of the resistor is 12 kΩ (1 mA load), which could reduce the output voltage to

a similar level as the Zener diode.

Regarding current limitation, other features of VIPer16 can be activated by assembling

resistor R

, but it is not originally assembled to allow the delivery of maximum power.

7

A simple linear regulator is also assembled, generating 5 V on the output as an option to

complete the basic idea of generating 12 V and 5 V outputs. It should be highlighted that the

VIPer16 can also directly generate a 5V output (instead of 12 V). The 5 V can be set by

changing the value of resistor R

to 4.7 kΩ .

3

10/23 Doc ID 15305 Rev 1

Page 11

AN2872 Description

3.3 PCB

The converter is assembled on a single layer 65 x 33 mm, 70 µm, FR4 PCB. The PCB

layout, position of the components and silk screen are illustrated in Figure 5. The part of the

PCB dedicated to the converter itself is 43 x 27 mm in size.

Figure 5. PCB layout of the buck converter (top, bottom, bottom layout)

Doc ID 15305 Rev 1 11/23

Page 12

Description AN2872

3.4 Bill of material

The components assembled on the board are listed in the Table 1.

Table 1. List of components

Ref. Part type / value Description Size Supplier

R

1

R

2

R

3

R

4

R

5

R

6

R

7

R

8

R

9

C

1

C

2

C

3

C

4

C

5

22 Ω / 2 W Resistor

750 kΩ / 5% / 0.25 W Chip resistor 1206

24 kΩ / 1% / 0.1 W Chip resistor 0805

9.1 kΩ / 1% / 0.1 W Chip resistor 0805

750 kΩ / 5% / 0.25 W Chip resistor 1206

750 k Ω / 5% / 0.25 W Chip resistor 1206

N. A. Chip resistor 0805

750 kΩ / 5% / 0.25 W Chip resistor 1206

1 kΩ / 5% / 0.1 W Chip resistor 0805

150 nF / 305 VAC / X2 Foil capacitor 18 x 6 x RM15 Epcos - B32922C3154M

150 nF / 305 VAC / X2 Foil capacitor 18 x 6 x RM15 Epcos - B32922C3154M

10 µF / 450 V Aluminium capacitor R12.5 RM 10

10 µF / 450 V Aluminium capacitor R12.5 RM 10

220 µF / 25 V Aluminium capacitor R8 RM 3.8

C6 10 µF / 35 V Aluminium capacitor R5 RM2.5

C

7

C

8

C

9

L

1

L

2

D

1

D

2

D

3

D

4

D

5

D

6

1.8 nF / 50 V Chip capacitor 0805

100 nF / 50 V Chip capacitor 0805

10 µF / 35 V Aluminium capacitor R5 RM2.5

1 mH / 200 mA Inductor

1 mH / 300 mA Inductor

1N4148 Silicon diode SOD80

STTH108 Ultrafast diode SMA STMicroelectronics

1N4007 Silicon diode 1 A / 1 kV MELF

1N4007 Silicon diode 1 A / 1 kV MELF

STTH108 Ultrafast diode SMA STMicroelectronics

15 V Zener diode SOD80

U1 VIPer16L Converter DIP 7 STMicroelectronics

U

2

L78L05 Regulator SOT89 STMicroelectronics

12/23 Doc ID 15305 Rev 1

Page 13

AN2872 Experimental results

4 Experimental results

4.1 Load regulation and output voltage ripple

The 12 V output is affected by the load due to the effects described in Chapter 3.1.2 and

3.2. The real load regulation of the 12 V output (linear regulator U

different input voltages is visible in Figure 6.

Figure 6. 12 V output load regulation for different output loads and input voltage levels (linear

V

OUT

(V)

14.5

13.5

12.5

regulator U

15

500 V AC

14

400 V AC

13

230 V AC

120 V AC

90 V AC

12

not assembled)

2

is not assembled) for

2

11.5

11

10.5

10

-20 0 20 40 60 80 100 120 140 160

I

(mA)

OUT

AM00362

The flatness of the load characteristic can be influenced mainly at light load by setting

a fixed load (a resistor instead of Zener diode D

) or assembling a linear regulator to

2

represent light load. The behavior of the load characteristic can be influenced by the value

of the auxiliary capacitor C

and total value of resistance of R3 and R4.

8

The output voltage ripple is very low and presents a good opportunity to use smaller

capacitors with higher ESR and lower capacitance. The data measured with the

demonstration board are shown in Figure 7. It is possible to see the higher 100 Hz ripple at

90 VAC on the input. This ripple can be avoided by increasing the capacitance of the input

capacitors.

Doc ID 15305 Rev 1 13/23

Page 14

Experimental results AN2872

Figure 7. Output voltage ripple for different input voltages

4.2 Standby

The VIPer16 is designed to operate without any external power source. The device can be

supplied, thanks to its very low consumption, directly from an internal high voltage circuit

(see Section 6: References: 3). A major benefit of this feature is a reduction of the external

component count, as well as the possibility to generate output voltages that are below

voltage lockout. The buck converter based on the VIPer16 can directly generate, with

a simple inductor, 5 V (for example). On the other hand, as this method of self-supply is

based on the resistive principle, this method of supply increases power losses, which is

mainly visible in standby power losses. If low standby power losses is a priority, it is

suggested to apply an additional diode (D

higher than 12.5 V. Diode D

allows the VIPer16 to be supplied from reflected voltage (C8),

1

in Figure 4) in cases where the output voltage is

1

used for feedback and consequently to reduce standby consumption.

Another aspect which significantly influences standby consumption are the balancing

resistors. The value of the balancing resistor was set to 1.5 MΩ, respecting the fact that

there is no resolutely defined manufacturer of the capacitors, and consequently the worse

case is presented for calculation of the balancing resistors. The effect of these resistors on

standby consumption can be partly reduced (mainly for voltages below 400 VAC) using

Zener diodes instead of resistors (see Figure 8).

14/23 Doc ID 15305 Rev 1

Page 15

AN2872 Experimental results

Figure 8. Alternative schematic of the input part using balancing Zener diodes instead of

resistors

D

90 VAC - 500 VAC

D

3

1N4007

C

1

150 nF / X2

C

2

150 nF / X2

4

R

1N4007

1

22 Ω

200 V

200 V

200 V

200 V

Dz

Dz

Dz

Dz

1

2

3

4

L

1 mH

1

10 µF / 450 V

C

3

C

4

10 µF / 450 V

AM00363

The standby consumption of the demonstration board is displayed in Figure 9, measured

without linear regulator U

cases where diode D

converter itself with diode D

. The highest line represents the consumption of the converter in

2

was not assembled. The middle line is the consumption of the

1

, and the lowest line represents the consumption of input part

1

only, without the VIPer16 assembled. It is possible to observe that the contribution of the

VIPer16 on standby consumption is low even at high input voltage, and most of the

consumption is caused by the input stage of passive components - principally the balancing

resistors, leakage of aluminum capacitors and input foil capacitors.

Figure 9. Standby consumption for different input voltage levels

800

700

600

500

PIN (mW)

400

300

200

100

0

0 50 100 150 200 250 300 350 400 450 500

VIN AC (V)

Diode D1 not assembled

Diode D1 assembled

VIPer16 not

assembled

Contribution of balancing resistors

AM00364

Doc ID 15305 Rev 1 15/23

Page 16

Experimental results AN2872

90 VAC

4.3 Efficiency

The efficiency of the converter depends strictly on the input voltage. The efficiency of the

tested board is about 65% full load at nominal EU voltage. Complete measurement of the

efficiency is shown in Figure 10.

Figure 10. Efficiency of the converter

90.0

80.0

70.0

60.0

Eff. (%)

50.0

40.0

30.0

20.0

10.0

0.0

0 20 40 60 80 100 120 140 160

The efficiency can be slightly improved using inductors with reduced resistance and low

ESR input and output capacitors.

4.4 MOSFET voltage stress

A sufficient margin between the maximum drain voltage and the real maximum operating

voltage level guarantees good reliability of the converter. The drain voltage (CH1) and

inductor current (CH2) is displayed in Figure 11 at full load (150 mA). The maximum voltage

drop between the drain and source is 700 V. The margin is, at worst conditions, 100 V.

I

OUT

(mA)

120 VAC

230 VAC

400 VAC

500 VAC

AM00365

16/23 Doc ID 15305 Rev 1

Page 17

AN2872 Experimental results

Figure 11. Drain voltage (CH1) and inductor current (CH4) at different input voltages

The waveforms in Figure 10 show also the change of duty cycle (ON time) with input

voltage. The converter finally operates in burst mode for highest input voltage.

4.5 Short-circuit behavior

The short-circuit protection is integrated in the VIPer16. If the peak current is limited by the

internal threshold at maximum level for a duration of 50 ms (internally set), the Viper16

interprets this state as overload (short-circuit) and switches off the converter for 1 s. The

typical waveforms for different input voltages are displayed in Figure 12.

Doc ID 15305 Rev 1 17/23

Page 18

Experimental results AN2872

Figure 12. Indication of current (CH4) and drain voltage (CH1) during short-circuit

4.6 EMC

The following EMC tests of the board were performed:

●

EMI conducting disturbances test for 150 kHZ - 30 MHz (according to EN55022)

●

Surge immunity test (IEC 61000-4-5)

●

Burst immunity test (IEC 61000-4-4).

4.6.1 Surge - IEC 61000-4-5

Regulation IEC 61000-4-5 defines the so-called “Surge immunity test” (see Section 6:

References: 8) as high power spikes caused by large inductive devices in mains. The input

of the SMPS is charged by a short (20 - 50 µs) but high voltage (0.5 - 4 kV) pulse. The pulse

is applied between L-N and between L (N) - PE.

The surge pulse (typically) causes high inrush current, quickly charging the bulk capacitor in

a standard SMPS. The major risk is overvoltage for input components (capacitors, diodes)

and the main switch in the application. The inrush current can damage the components in

series in the input section of the SMPS (rectifier, fuse, inrush current limiter).

The effect of the surge pulse can be reduced in two ways. The first is to increase the

resistance of the input part (typically possible for low power applications) to reduce inrush

current. Higher input resistance reduces inrush current and consequently the amount of

energy charging the bulk capacitor; therefore the voltage rise over the bulk capacitor is

reduced. The second way is to apply components that reduce the voltage level. Typically it is

possible to use varistors or Transil™ connected to the input (to absorb part of the energy of

18/23 Doc ID 15305 Rev 1

Page 19

AN2872 Experimental results

pulse) or a bulk capacitor capable of storing enough energy from the surge pulse to reduce

the voltage peak level.

The 2 kV surge test was performed on the board with no failures.

4.6.2 Burst - IEC 61000-4-4

Regulation IEC 61000-4-4 defines the so-called “Burst immunity test” (see Section 6:

References: 9) as fast switching disturbance presented in the mains. This test means the

high frequency, high voltage (8 kV), very short pulses (50 ns) are applied between the input

lines and metal plate connected to PE at a defined distance from tested device

(100 mm).

This test typically does not cause any damage to the components applied for the SMPS, but

it produces high current pulses flowing through the board and causes voltage spikes

between different parts of PCB. These spikes can render unstable the applied integrated

circuits for the SMPS (mainly the controller). The possible impact typically seen in the SMPS

is unstable operation (restart of the SMPS could be allowed) or latching of the SMPS (not

allowed).

The typical protection against the effects of the burst pulses is application of small filters

(capacitance in the range of 100 pF to several nF) to the sensitive inputs.

The 8 kV burst test was performed on the board with no failures.

4.6.3 EMI

The EMI was tested at an input voltage of 230 VAC for full output load. Measurements are

listed for the different input connections and average and peak detector in Figure 13.

Doc ID 15305 Rev 1 19/23

Page 20

Experimental results AN2872

Figure 13. EMI measurements of the demonstration board

4.7 Thermal behavior

The temperature of the VIPer16 was measured for different input voltages at full load (12 V /

150 mA). The board was located in open area at an ambient temperature of 25 °C.

Table 2. Temperature of the VIPer16 at full load

T

amb

(VAC) T (°C) ∆T (°C)

V

IN

90 52 27

120 49 24

230 60 35

400 89 64

500 77 52

25 °C

20/23 Doc ID 15305 Rev 1

Page 21

AN2872 Conclusion

5 Conclusion

This document shows that it is possible to implement a low power, non-isolated SMPS

operating in a buck converter topology for super wide range (85 - 500 VAC), thanks to the

new advanced monolithic converter VIPer16.

6 References

1. Application note AN1357 - VIPower: LOW COST POWER SUPPLIES USING

VIPer12A IN NON ISOLATED APPLICATIONS - see www.st.com

2. Application note AN2300 - An alternative solution to Capacitive power supply using

Buck converter based on VIPer12A - see www.st.com

3. Datasheet of the VIPer16 - Fixed frequency VIPer™ plus family - see www.st.com

4. General technical information - Epcos - http://www.epcos.com/web/generator/

Web/Sections/ProductCatalog/Capacitors/AluminumElectrolytic/Photoflash/Page,

locale=en.html - General technical information.pdf

5. Series Connection - Rubycon

http://www.rubycon.co.jp/en/products/alumi/technote.html SeriesConnection.pdf

6. Engineering Notes - Vishay® (BC comp) - http://www.vishay.com/capacitors/aluminumradial/related#technt - Engineering Notes.pdf

7. Technical Notes on Aluminium Electrolytic Capacitors - Nichicon - http://nichiconus.com/english/products/pdf/aluminum.pdf

8. IEC 61000 - 4 -5 see www.iec.ch

9. IEC 61000 - 4 -4. see www.iec.ch

Doc ID 15305 Rev 1 21/23

Page 22

Revision history AN2872

7 Revision history

Table 3. Document revision history

Date Revision Changes

23-Apr-2009 1 Initial release.

22/23 Doc ID 15305 Rev 1

Page 23

AN2872

y

y

Please Read Carefully:

Informatio n in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at an

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, an

liability of ST.

ST and the ST logo a re trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2009 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finlan d - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 15305 Rev 1 23/23

Loading...

Loading...