Page 1

AN2870

Application note

L6585DE combo IC

Introduction

The modern requirements for fluorescent lamp electronics ballast concerns both efficiency

of the drivers and safety aspects.

The L6585DE offers the designer a high performance PFC stage, high capability half bridge

high voltage drivers, a fully programmable control and an enhanced set of protections.

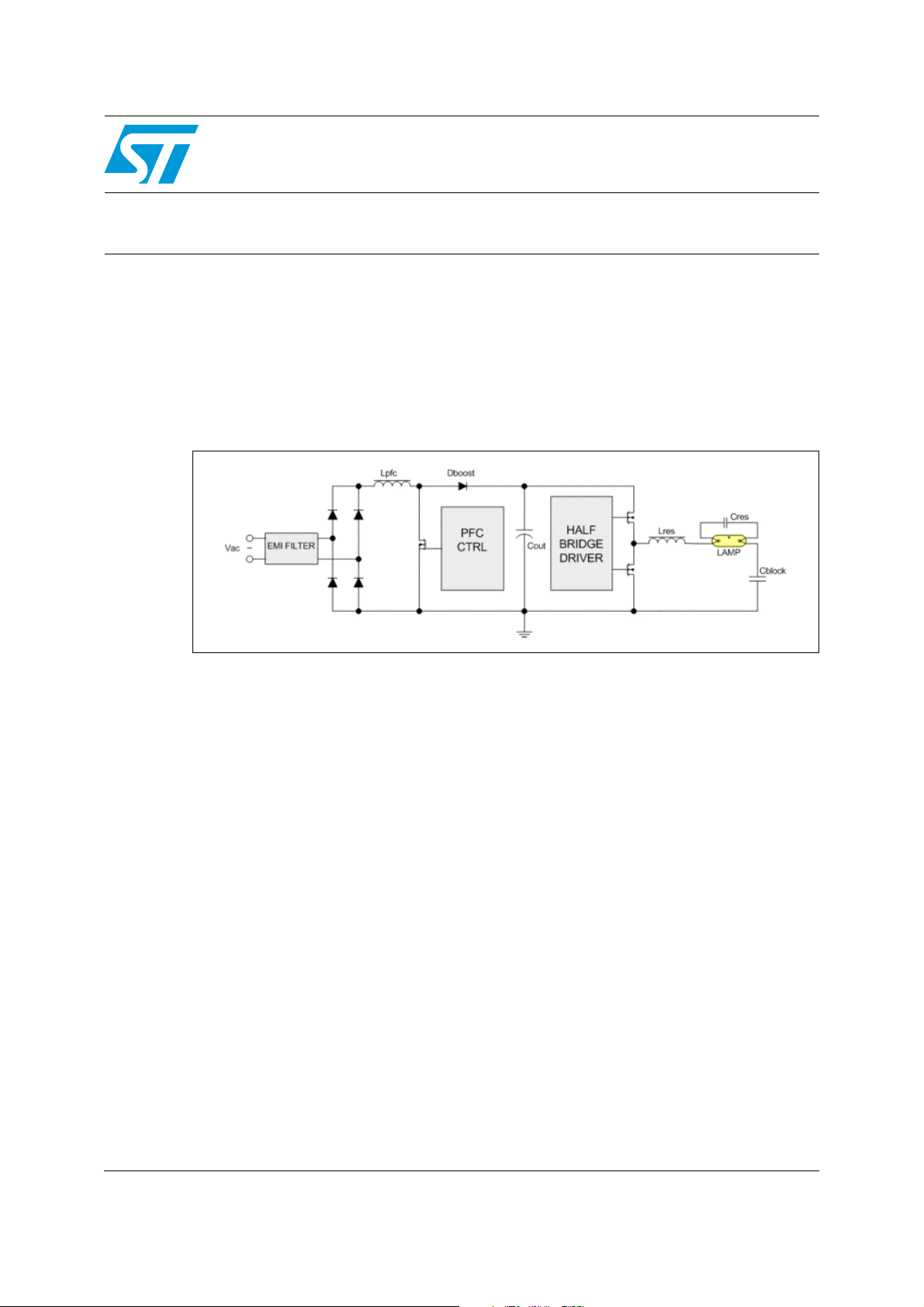

Figure 1. Typical electronic ballast block diagram

March 2009 Rev 1 1/41

www.st.com

Page 2

Contents AN2870

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Typical configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Lamp requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 L6585DE combo IC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Device blocks description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Start-up and shut-down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 PFC section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.1 Error amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.2 Multiplier block and THD optimizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.3 Current comparator and choke saturation detection . . . . . . . . . . . . . . . 11

3.2.4 Zero current detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2.5 Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2.6 PFC protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3 Ballast controller section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3.1 Oscillator and timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3.2 Overcurrent control and protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3.3 End of life detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3.4 Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4 Designing with L6585DE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1 PFC stage design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2 Ballast stage design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.3 PCB hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2/41

Page 3

AN2870 List of figures

List of figures

Figure 1. Typical electronic ballast block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 3. Start-up and shut-down waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 4. PFC section block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 5. PFCCS pin waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 6. Protections block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 7. Oscillator and starting sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 8. Current control sequence during ignition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 9. HBCS thresholds summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 10. Window comparator for rectifying effect detection (Cblock to GND). . . . . . . . . . . . . . . . . . 17

Figure 11. Window comparator for rectifying effect detection (lamp to GND) . . . . . . . . . . . . . . . . . . . 19

Figure 12. Typical application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 13. PFC MOSFET losses (example) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 14. Multiplier characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 15. (A) voltage frequency response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 15. (B) current frequency response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 16. Oscillator characteristic curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 17. (A) k parameter versus Cosc (pF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 17. (B) e parameter versus Cosc (pF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 18. EOL - Cblock to ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 19. EOL - lamp to ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 20. Current consumption vs PFC frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3/41

Page 4

Introduction AN2870

1 Introduction

1.1 Typical configuration

Typical fluorescent lamp electronic ballasts are composed by (Figure 1):

● An input PFC section, if input power is greater than 25 W, usually a TM PFC converter,

that generates a DC output voltage and absorbs power from mains with very high

Power Factor (typically 0.95 or grater) and very low THD (mandatory less than 10%).

● A high frequency half bridge driver, fed by the PFC output, with internal or external

oscillator, a timer and various protections in order to drive correctly the lamp, to avoid to

deliver an excessive power to the lamp and to detect any malfunction of the lamp

(broken lamp, broken cathode or lamp absence)

● An output resonant stage, realized by reactive components (capacitors and inductors),

that, together with the half bridge driver, optimizes the power delivered to the lamp (one

or more) during all working conditions (preheating, ignition and run mode).

1.2 Lamp requirements

Fluorescent lamp, during its normal operation, has to be supplied by means of alternative

and controlled current. In order to reduce the size of the ballast and increase the light

efficiency of the lamp a frequency greater than 20 kHz is typically used. A half bridge quasi

resonant inverter (series-parallel converter Figure 1) is used to obtain sinusoidal current into

the lamp and to reduce the power dissipation of the half bridge switches, in fact zero voltage

switching is achieved.

Lamp current and lamp voltage during normal operation are reported in lamp documentation

and are to be considered as design specification. Moreover, a well preheated lamp ignites at

a lower voltage; this implies a longer lamp life and a greater number of ignitions. The

efficiency of the preheating is mainly related with the total energy delivered to the cathode

(reported on lamp documentation), and then it depends on the time available for this

operation: keeping constant the preheating energy, longer is the preheating time, smaller is

the instantaneous power delivered to the cathode. During the preheating operation the

voltage across the lamp must be kept below a specified value in order to avoid unwanted

ignitions (when these happen, the lamp experiences multiple re-strike and dissipates large

amounts of power).

There are many ways to deliver power to the cathode, but the most used are two:

1. Current controlled preheating: the cathodes are interposed between the choke and the

resonant capacitor so they experience the same current of the resonant LC circuitry. An

efficient preheating is obtained controlling this current and the time of preheating. The

advantages of this method are the cheapness and easiness of design; it has also some

disadvantages, namely the difficulty of keeping low the lamp voltage during preheating

and the fact that during steady state the cathode experiences the sum of the lamp

current and of the resonant capacitor current.

2. Voltage controlled preheating: the current into the cathodes is generated by auxiliary

windings coupled with ballast choke or driven by an auxiliary oscillator. This implies

that, in any case, the design of the preheating circuitry is somewhat independent from

the design of the LC circuitry, even if it requires a lot of external components. This

method is then more efficient, but is cheaper and more difficult to design.

4/41

Page 5

AN2870 Introduction

After a good preheating, the voltage across the lamp is suddenly increased in order to

generate a strike inside the tube and ignite the lamp. This phase should last between 10 ms

and 100 ms.

The strike voltage depends on various parameters, many of which cannot be exactly

evaluated: preheating energy, remaining lamp life, number and efficiency of the past

ignitions. An insufficient preheating causes greater ignition voltage and a subsequent stress

of the cathodes that lose small amounts of material that darken the region of the tube near

to the cathode itself (sputtering).

Lamp ageing is related with the symmetrical or, more often, asymmetrical increasing of the

cathodes resistance. A symmetrically aged lamp absorbs more power causing hard

switching and over-current. Asymmetrically aged lamps experience a current that is more

intense in one direction than in the other. This implies that the current flowing into the lamp

has positive or negative mean value (DC component). This effect can be detected

measuring the mean values of the lamp voltage that should be zero in normal lamps. The

worst case of rectifying effect causes the current flowing only in one direction: the voltage

across the resonant capacitor can reach very high values and heavy hard switching is

detected.

When symmetrical or asymmetrical ageing of the lamp reaches a value indicated in

international norms, the lamp reaches its end of life (EOL).

5/41

Page 6

L6585DE combo IC AN2870

2 L6585DE combo IC

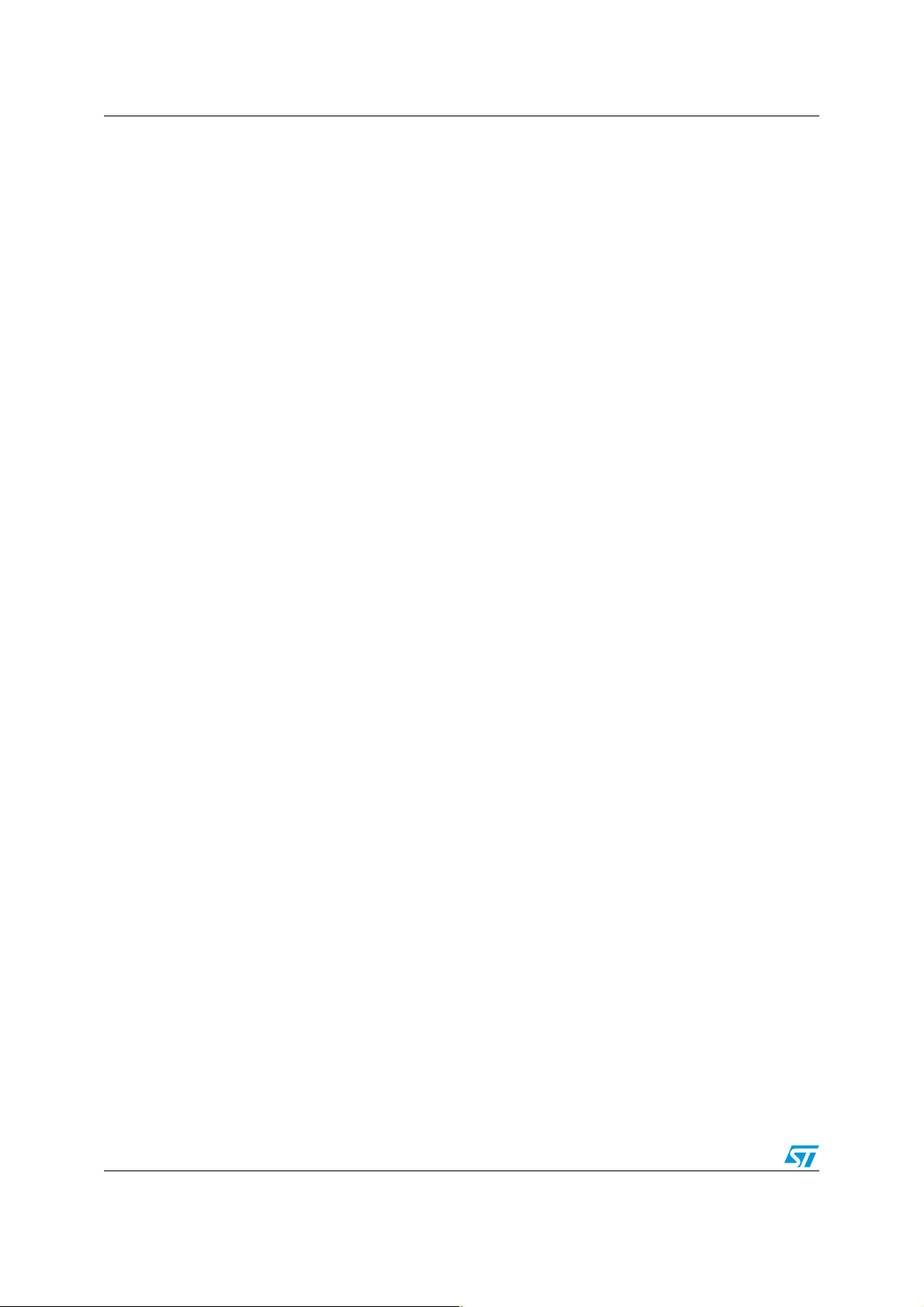

The L6585DE embeds both a PFC converter and a ballast regulator in a single SO20

package. It is intended to design complete high power electronic ballasts with a single chip.

● The most significant features of the L6585DE concern the following points:

● Transition mode PFC converter with over voltage and over current protection.

● Half-bridge controller with High voltage driver (600 Vdc) and integrated bootstrap

diode.

● 3% precise, fully programmable oscillator.

● Flexibility in programming preheating time and ignition time.

● Configurable EOL detection and over current protection.

● Hard switching detection.

The PFC section achieves current mode control operating in Transition Mode. The multiplier,

together with the internal THD optimizer, reduces input current distortion, and allows

reaching very high performances also in wide-range-mains operation and large load range.

The PFC output voltage is controlled by means of a voltage-mode error amplifier and a

precise internal voltage reference.

A static and dynamic OVP protects the IC from excessive output voltage and an over current

protection turns off the PFC gate driver in case of PFC choke saturation.

The PFC driver is able to provide 300 mA (source) and 600 mA (sink).

The half bridge section is driven by a current controlled oscillator (CCO) and the internal

control logic.

The steady state frequency, the preheating frequency, the pre-heating time, the over-current

protection time and the ignition time are independently set by means of six external

components (resistors and capacitors).

An over-current protection limits the voltage across the HBCS pin acting directly on the CCO

realizing a precise closed loop control. This control lasts for a time set by the Tch pin and,

after that, if the fault condition is still present, the IC is stopped in low consumption mode.

The HBCS voltage amplitude depends on actual operating mode, then this protection can

detect either a broken lamp during ignition (in this case the current regulation implies the

lamp voltage regulation) or the symmetrical ageing of the lamp during run mode.

An internal window comparator can be simply configured setting the window amplitude or

the comparator reference in order to detect the EOL status. The programmability of

comparator reference makes the L6585DE compliant with either “lamp-to-ground” (fixed

reference) or “block capacitor-to ground” (tracking with CTR) configurations.

The drivers of the half-bridge provide 290 mA source and 480 mA sink.

6/41

Page 7

AN2870 L6585DE combo IC

Figure 2. Block diagram

7/41

Page 8

Device blocks description AN2870

3 Device blocks description

3.1 Start-up and shut-down

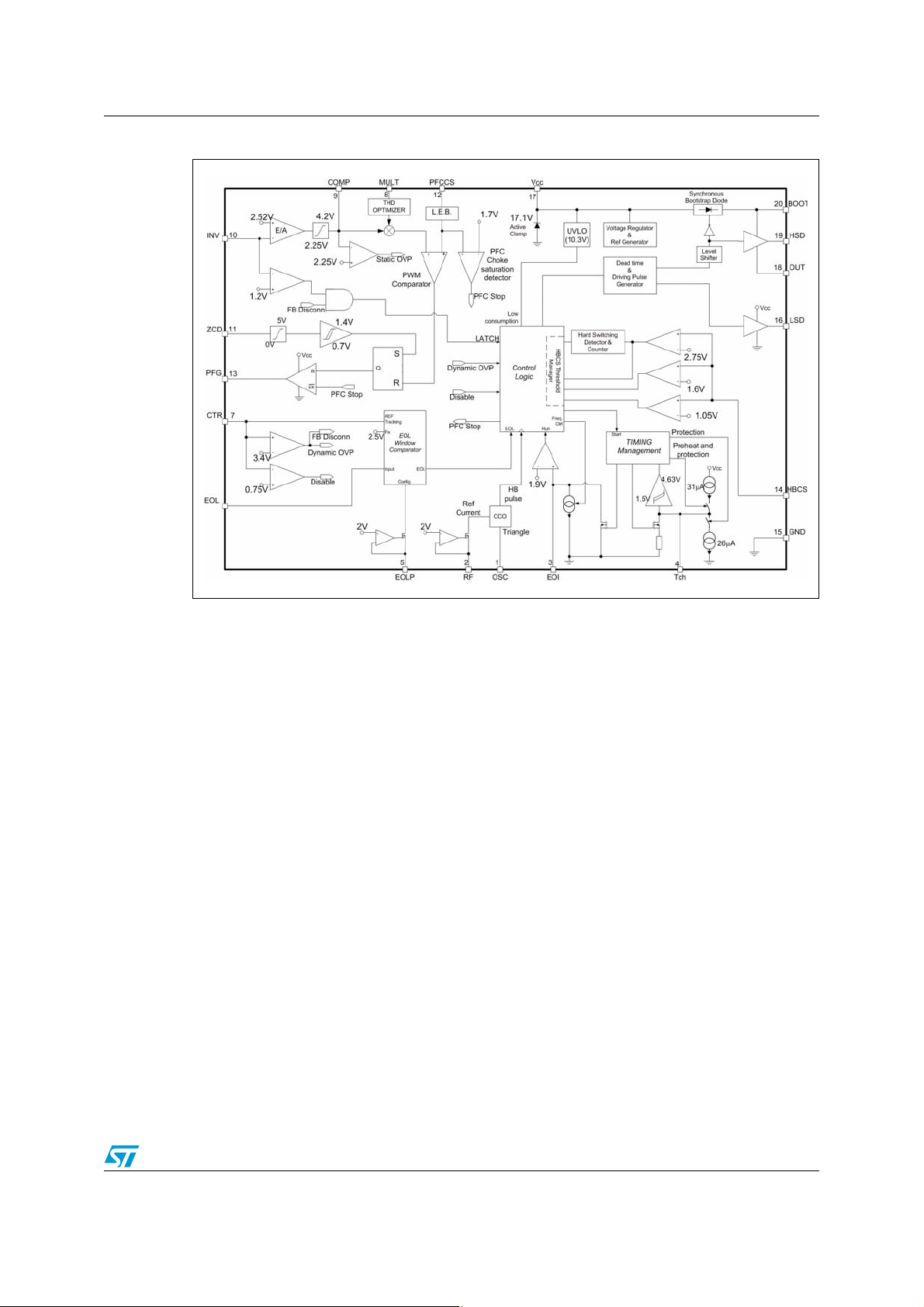

During start-up the chip is supplied through a resistive path from the rectified AC Mains

voltage whereas, during normal operation, a self-supply source is recommended: a charge

pump, an auxiliary winding coupled either with PFC choke or resonant choke, or an auxiliary

converter.

As the voltage at Vcc pin reaches the turn-on threshold (Vcc

, Figure 3-A), the chip is

ON

enabled and (unless a lamp absence is detected) the Half-Bridge and the PFC sections

start at the same time (independently):

● The PFC section, as the synchronization signal at pin ZCD is not yet generated by the

external ZCD circuit, is forced to switch by internal starter (f

= 6 kHz (typ)) for the

starter

first few switching cycles, until the control loop operates correctly at a frequency higher

than f

● The oscillator starts switching at a preheating frequency set by values of C

and R

At shut-down (Figure 3-B), when the V

starter

PRE

.

, R

OSC

RUN

.

decreases below the UVLO threshold (either in

CC

case of mains removal or in case of fault):

● All drivers are off;

● EOI pin is discharged (the internal switch is on);

● RF reference is disabled;

● Tch is discharged.

8/41

Page 9

AN2870 Device blocks description

Figure 3. Start-up and shut-down waveforms

A) Start-up

B) Shut down

9/41

Page 10

Device blocks description AN2870

3.2 PFC section

3.2.1 Error amplifier

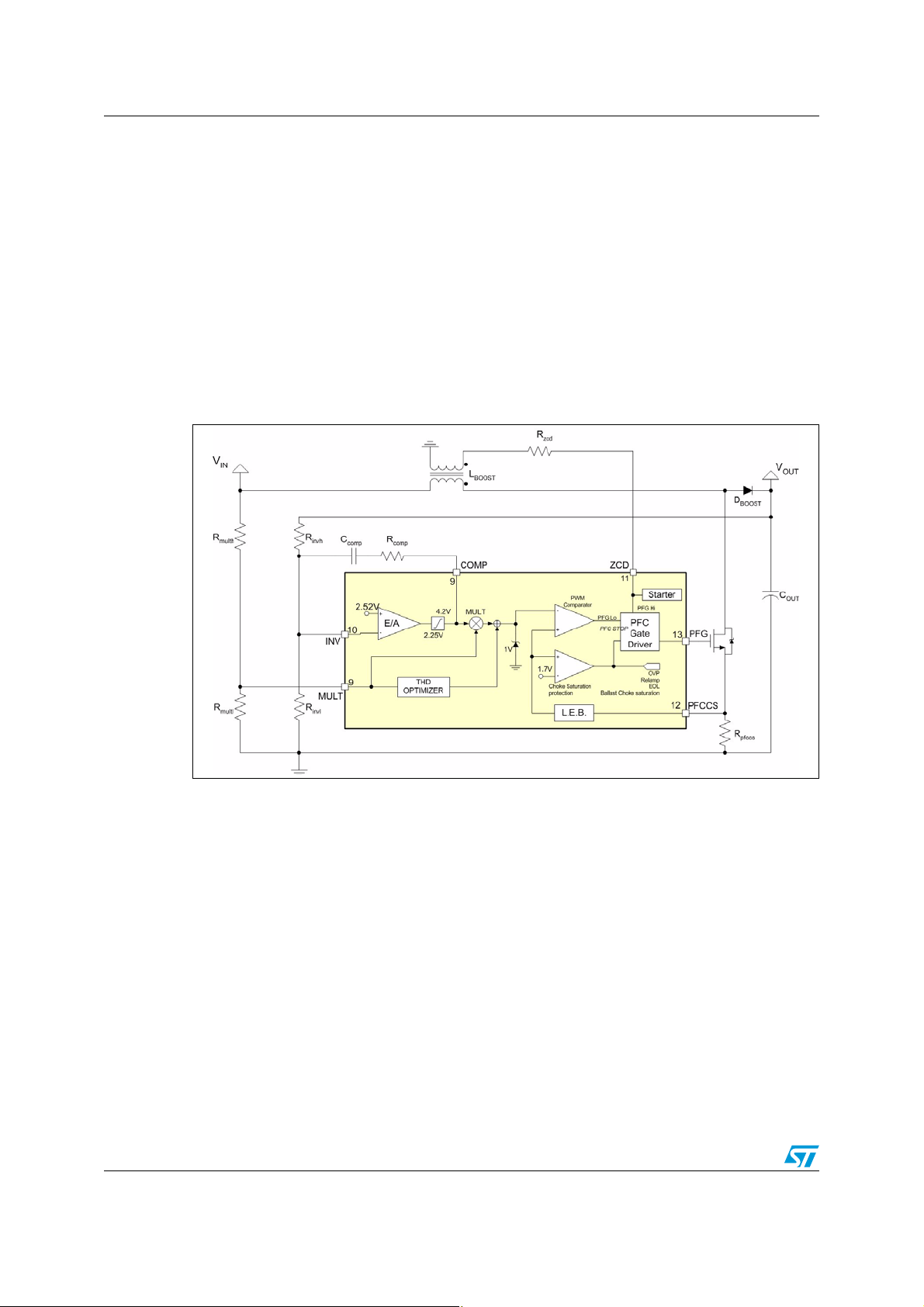

The error amplifier (E/A, Figure 4) is used to close the output voltage control loop. Its non

inverting input is connected to a precise voltage reference (2.52 V), the inverting input and

the output are externally available (pin 10 –INV; pin 9 – COMP).

The compensation network, placed between pins INV and COMP, is needed to reject the

mains ripple.

The E/A output dynamic is internally clamped: it can swing between 2.25 V and 4.2 V in

order to speed up the recovery after the E/A saturates low due to an over-voltage (static

OVP) or saturates high because of an over-current.

Figure 4. PFC section block

3.2.2 Multiplier block and THD optimizer

The multiplier (Figure 4) gives the sinusoidal voltage reference to the current sense in order

to absorb from the mains a sinusoidal current. This current will be function of both input

voltage and load current then this block has two inputs: the first one (Pin MULT – 8) takes a

partition of the instantaneous rectified line voltage and the second one (Pin COMP – 9) is

the output of the E/A.

An internal voltage clamp (1 V) sets the maximum allowed voltage of the multiplier output,

then it act as PFC current limiter.

When the rectified input voltage reaches 0 V the boost inductor cannot store enough energy

to discharge the input capacitor: this event increases the THD. In order to avoid this

additional distortion, a THD optimizer block is placed between the output of the multiplier

and the current sense comparator.

The characteristic curves of the multiplier block are reported in Figure 14.

10/41

Page 11

AN2870 Device blocks description

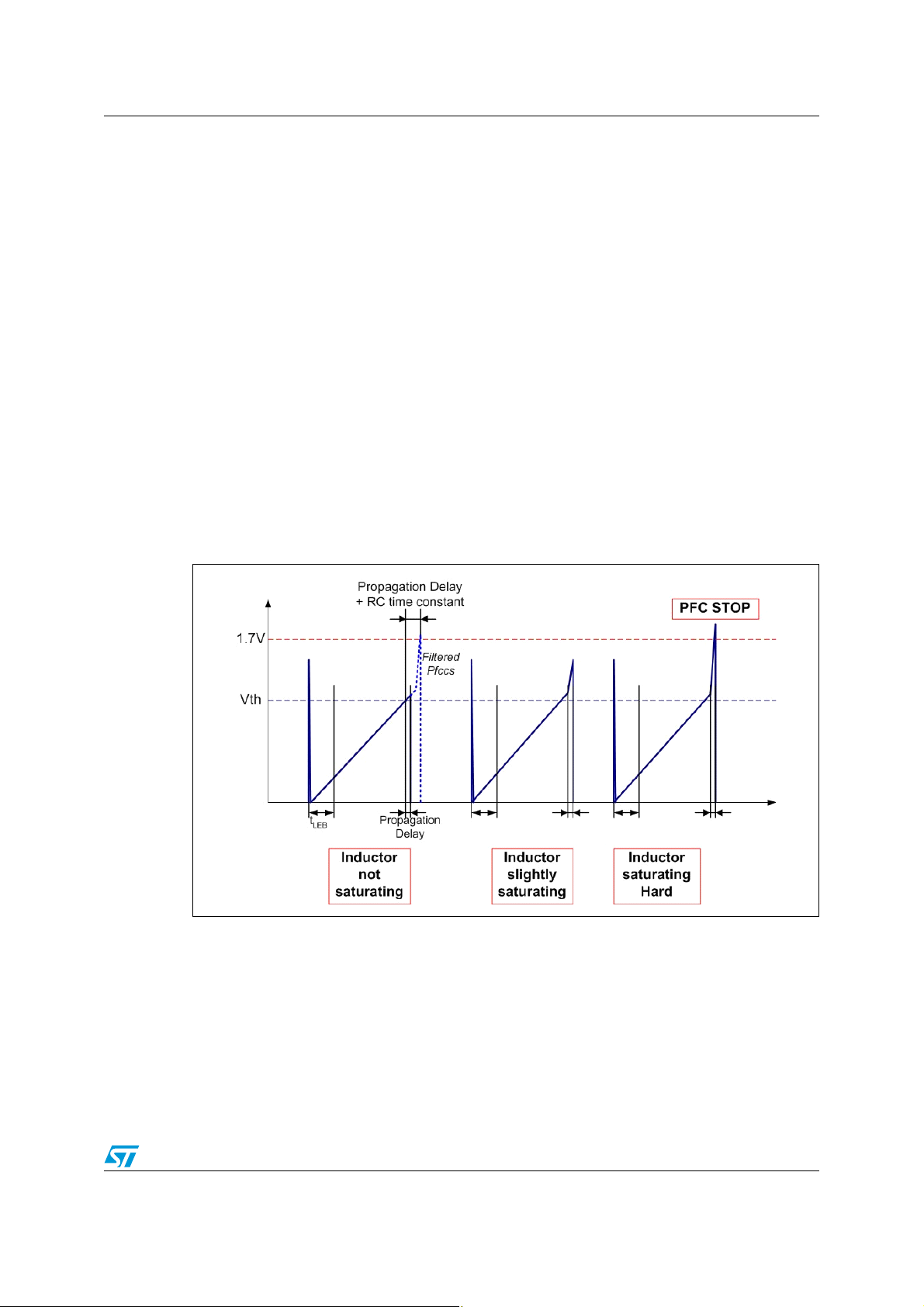

3.2.3 Current comparator and choke saturation detection

The current comparator senses the voltage across the current sense resistor (R

pfccs

) and,

by comparing it with the programming signal delivered by the multiplier, determines the

exact time when the external MOSFET has to be switched off.

When PFC MOSFET is turned on, parasitic drain capacitances are discharged and an

intense current spike can be seen by PFCCS (Figure 5). In past solutions, an RC filter

between sense resistor and current sense input was commonly used to reject these spikes,

but it introduced a delay between the instant the current crosses the threshold and the

actual activation of internal comparator. This delay may cause the inductor saturation, then

an over dimensioned inductor had to be used. In L6585DE, an internal leading edge

blanking structure (LEB) masks the first 200 ns of the PFC gate at the time current spikes

occurs; the filter is no longer necessary and the inductor can be smaller and lighter. On the

other hand this LEB limits the maximum available “ON time”.

Moreover, the device is provided with a second comparator on the PFC current sense pin

that turns off immediately the PFC MOSFET if the voltage on the pin, normally limited within

1.0 V, exceeds 1.7 V. A current peak limiting control is therefore achieved avoiding MOSFET

overheating in case of boost inductor’s hard saturation. In this case the current up-slope

becomes so large (50-100 times steeper) that during the current sense propagation delay

the current may reach abnormally high values.

Figure 5. PFCCS pin waveforms

11/41

Page 12

Device blocks description AN2870

3.2.4 Zero current detection

The zero current detection (ZCD) block switches on the external PFC MOSFET as the

current through the boost inductor has gone to zero. This feature allows TM operation.

When the circuit is running, the signal for ZCD is obtained with an auxiliary winding coupled

with the boost inductor. A Schmidt trigger prevents false activations and an internal clamp

limits the voltage across the pin during normal operation in 0 V-5 V range. As at start-up no

signal is coming from the ZCD, an internal starter is needed in order to turn on the external

MOSFET and to arm the ZCD trigger.

The repetition rate of the starter is ≅ 6 kHz and this maximum frequency must be taken into

account at design time.

3.2.5 Driver

A totem pole buffer, with 300 mA source and 600 mA sink capability, allows driving an

external MOSFET. A pull-down circuit holds the output low when the device is in UVLO

conditions, to ensure that the external MOSFET cannot be turned on accidentally.

3.2.6 PFC protections

The device is provided with a double over-voltage protection (OVP).

The first over voltage protection, also called dynamic OVP, is activated immediately when

CTR pin (pin 7) goes above 3.4 V. The maximum voltage allowed for the output voltage

(V

) is defined by a resistive divider connected between output voltage and CTR pin.

OVP

In case of over voltage, the output of the E/A will tend to saturate low with a long constant

time, because of the bandwidth of this stage (typ. 10 Hz).

If the over-voltage lasts so long that the output of E/A goes below 2.25 V, the PF gate driver

is stopped and Tch timer is started. If E/A output voltage doesn’t return above 2.25 V after

the timer finishes its count, the IC is stopped in latch condition. This protection prevents

damages due to the connection to an excessive input voltage.

An intense high voltage (e.g. a surge) may break the upper resistors (one or more than one)

of the voltage dividers connected to input voltage (MULT biasing) or to output voltage (INV

and CTR biasing). Losing of the bias on pin INV implies losing of the control of the loop: in

fact E/A output saturates high and causes an increased output voltage, eventually not seen

by OVP because of failure on CTR voltage divider. The feedback disconnection protection

prevents this failure stopping the PF gate if INV voltage falls below 1.2 V and CTR pin goes

above 3.4 V. CTR pin can be also used to disable the IC pulling its voltage below 0.8 V.

Figure 6. Protections block diagram

12/41

Page 13

AN2870 Device blocks description

3.3 Ballast controller section

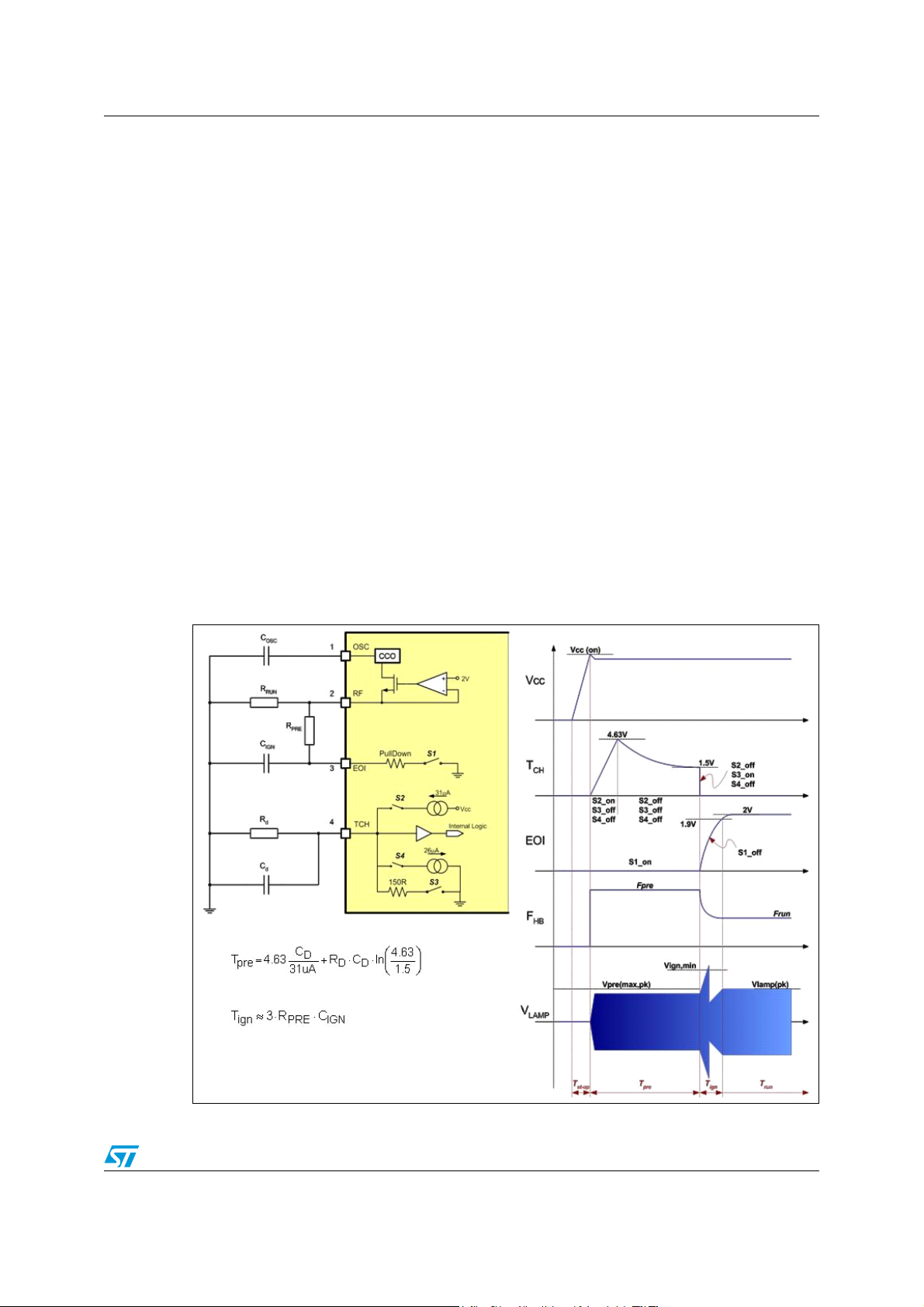

3.3.1 Oscillator and timer

The half bridge driver oscillation is regulated by a current controlled oscillator (CCO): it

needs a capacitor connected to OSC pin (pin 1) and uses the current flowing outside RF pin

(pin 2) as reference.

The RF pin has a 2 V precise voltage reference that let the designer fix the run mode

frequency simply connecting a resistor between RF pin and GND (Rrun).

The EOI pin (pin 3) is driven by the internal logic in order to set the frequency during the

preheating and to control the lamp current during an over-current event in the half bridge.

Preheating frequency is set by the parallel of Rrun and a resistor (Rpre) placed between RF

and EOI: in fact during the preheating the EOI pin is pulled to GND.

TCH pin is connected to the parallel of a resistor (R

) and a capacitor (CD) and is used in

D

order to define the preheating time and the protection time; its cycle (Tch cycle) is

composed by the following steps:

1. A 31 μA current generator charges the C

2. When TCH voltage reaches 4.63 V, the TCH pin is left in high impedance status and C

is discharged by R

,

D

causing TCH voltage to rise linearly,

D

D

3. When TCH voltage reaches 1.5 V the cycle finishes and an internal resistor pulls down

the TCH pin to GND.

Figure 7. Oscillator and starting sequence

13/41

Page 14

Device blocks description AN2870

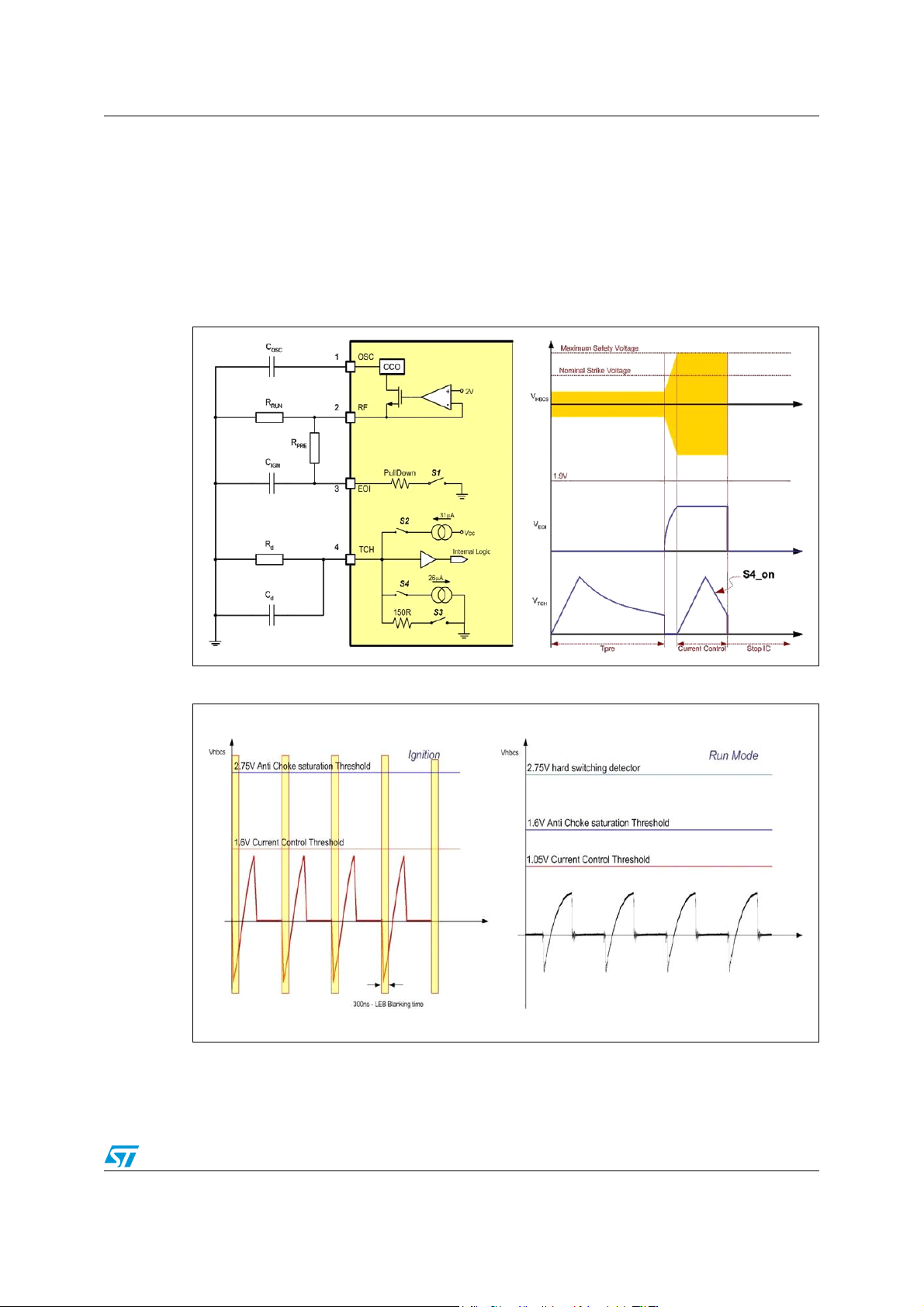

3.3.2 Overcurrent control and protections

Limiting the current flowing into the half bridge:

● The lamp voltage during the ignition phase is limited

● The power of the lamp during run mode is limited

Ignition phase: (see Figure 8) if the VHBCS high threshold (HBCSH = 1.6 V) is crossed

(because the lamp doesn’t ignite), the following actions are taken by L6585DE:

1. A current, whose amplitude is proportional to the time the V

sunk from EOI and consequently from RF pin. This results in a frequency increase that

reduces the resonant network current and therefore the lamp voltage.

2. A reduced time is calculated by Tch pin:

a) The 31µA generator charges C

b) Instead of leaving C

quickly C

to 1.5 V (S4 on)

D

to be discharged by RD, a 26 µA current generator discharge

D

to 4.63 V

D

c) The pull down switch S3 completes the reduced cycle

is above threshold, is

HBCS

The reduced Tch cycle depends only on C

value and is equal to:

D

Equation 1

⎛

63.4

⎜

CT ⋅≅

Dreduced,Tch

⎜

I

⎝

+=

I

⎞

5.163.4

−

⎟

⎟

snk,Tchsource,Tch

⎠

C269740

D

At the end of the Tch cycle, during the first subsequent low side on time, the HBCS voltage

is checked: if V

is higher than a threshold (HBCS

HBCS

) the IC is stopped in latched

H,test

condition, otherwise EOI pin is released in high impedance status. When EOI voltage

reaches 1.9 V the IC enters the run mode.

The sense resistor value defines the maximum current that can flow during ignition and then

the maximum allowed lamp voltage.

The linear growth of the lamp voltage, thanks to the exponential decrease of the operating

frequency during ignition allows a better control of the voltage thanks to a lower dV/dF

In case of choke saturation the intense current results in very high V

HBCS

. The 2.75

sw

.

threshold triggers this event and stops immediately the IC.

Run mode: During this phase, current control similar to the one present during ignition is

available in case of an over-current due to symmetrical ageing of the lamp. It follows the

same rules, but the threshold is equal to 1.05 V instead of 1.6 V.

Also during run mode the saturation protection is active: in case of choke saturation due to

lamp breaking, lamp removal and capacitive mode where V

experiences a spike whose

HBCS

amplitude is higher than 1.6 V and whose duration is longer than 300 ns. This kind of event

causes the IC turn-off in latched condition.

The lamp ageing causes the shift of peak of the resonance curve towards the run frequency.

This results in hard switching behavior: the half bridge doesn’t work at ZVS and spikes

appears at HBCS pin. These spikes have very high amplitude (up to 8 V) and short duration

(30 ns-50 ns).

14/41

Page 15

AN2870 Device blocks description

During hard switching the power dissipation of half bridge MOSFETs increases rapidly.

L6585DE detects these pulses and shuts down the half bridge after 350 (typ) subsequent

pulses.

The hard switching detection structure is masked during preheating and ignition: in fact

during this phase the frequency changes cause hard switching that is unavoidable but is not

dangerous.

In

Figure 9 a summary of the protection thresholds is reported:

Figure 8. Current control sequence during ignition

Figure 9. HBCS thresholds summary

15/41

Page 16

Device blocks description AN2870

3.3.3 End of life detection

When the lamp becomes older and approaches its end of life, its equivalent resistance

increases symmetrically or asymmetrically.

In symmetrical ageing a modification of the frequency response of the resonance network

can be seen and, consequently, an increasing of lamp current and the appearance of hard

switching events: in fact the resonance frequency is now closer to operating frequency.

In asymmetrical ageing the current flowing in one direction is greater than the current

flowing in the other; this means that lamp voltage and current waveforms have no longer

zero mean value.

lamp voltage that can be either positive or negative. The reference and the amplitude of this

comparator can be set choosing the value of a resistor connected between EOLP pin and

GND accordingly with the following table.

Table 1. Comparator amplitude

EOLP resistor Symbol Reference Half–window amplitude

R

EOLP > 620 kΩ RFH Fixed 2.5 V ± 720 mV

A window comparator measures the variation of the DC component of the

220 kΩ < R

75 kΩ < R

22 kΩ < R

EOLP < 270 kΩ RTL Tracking with CTR - 240 mV / + 250 mV

EOLP < 91 kΩ RFL Fixed 2.5 V ± 240 mV

EOLP < 27 kΩ RTL Tracking with CTR - 150 mV / + 160 mV

This comparator can be used in both the two most used ballast configurations: Blocking

capacitor to ground and lamp to ground.

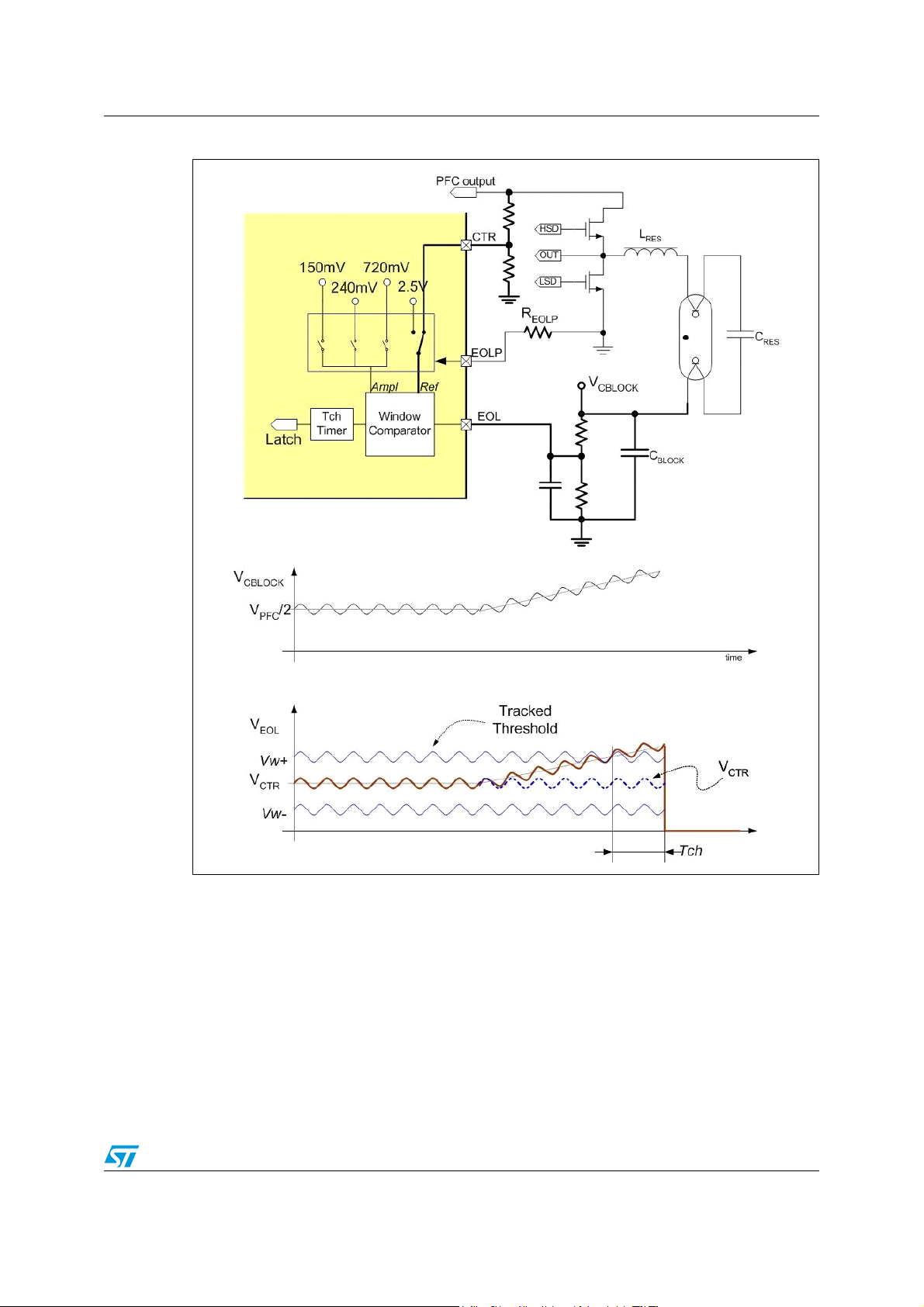

Block capacitor to ground (Figure 10): During normal operation the DC mean value

across Cblock is equal to the half of the output voltage of the PFC. A resistive divider is

placed across the block capacitor to sense its DC voltage: the asymmetric effect appears as

a shifting of this DC value.

Any voltage ripple or disturbance across the output voltage is present also on Blocking

Capacitor and may alter the correct detection of a lamp at the end of its life.

In order to reject all this disturbances, the reference of the window comparator is connected

to CTR pin (Tracking reference configurations): in fact this pin is connected directly to the

output voltage and experiences the same ripple voltage. The rejection of the PFC output

voltage low frequency ripple allows using a smaller bulk capacitance.

16/41

Page 17

AN2870 Device blocks description

Figure 10. Window comparator for rectifying effect detection (Cblock to GND)

17/41

Page 18

Device blocks description AN2870

Lamp to ground (Figure 11): the resistive divider senses the voltage across the lamp. As

the L6585DE doesn’t have a negative rail, it is necessary to shift the external signal; this can

be done (for example) using two Zener diodes connected back-to-back between the EOL

pin and the centre of the resistive divider.

The Zener voltages should differ by an amount as close as possible to the double of the

internal reference to have a symmetrical detection, in fact:

Let be V

Voltage divided by the divider factor K

Zener and V

● V

●

UP

V

DOWN

and V

UP

the forward voltage of the Zener (@ 5.5 μA)

F

= V

LAMP,MAX/KD

= V

LAMP,MIN/KD

the maximum allowed values of the DC component of the Lamp

DOWN

= V

REF

= V

, W the window amplitude, VZ the Zener voltage of a

D

+ W/2 + V

– W/2 – VZ2 – V

REF

Z1

+ V

F

F

It must be:

● V

UP

= - V

DOWN

therefore:

● 2 V

= VZ2 − V

REF

Z1

The biasing current available at pin EOL is equal to 5.5 μA then the VZ1 Voltage should be

greater than 8 V in order to have a more precise EOL threshold.

In this case the window comparator can be referenced to the 2.5 V internal reference as

external disturbances don’t influence the lamp voltage mean value (Fixed reference

configurations).

In the

Figure 11 is shown the case of asymmetric rectification with positive shifting.

To avoid an immediate intervention of the EOL protection, a filtering is introduced: as soon

as the voltage at pin EOL goes outside the window of the comparator a Tch cycle is started.

The IC is stopped if, at the end of the Tch cycle, the EOL voltage is again outside the limits.

18/41

Page 19

AN2870 Device blocks description

Figure 11. Window comparator for rectifying effect detection (lamp to GND)

3.3.4 Shutdown

A second comparator, with a threshold equal to 0.8 V, has been introduced on the pin CTR

in order to stop the IC if the CTR pin is pulled to ground. If IC is not in latched condition

when CTR is pulled down, a new starting sequence is performed as CTR pin voltage is

higher than the threshold; this behavior can be used for shutdown.

19/41

Page 20

Designing with L6585DE AN2870

4 Designing with L6585DE

Figure 12. Typical application

4.1 PFC stage design

Output voltage and dynamic OVP

Output voltage is set designing a voltage divider connected to INV pin:

Equation 2

The maximum output voltage is set designing a voltage divider connected to CTR pin:

Equation 3

Both R

series in order to increase the reliability of the application against over-voltages.

INV,Hi

and R

should be composed by a suitable number of resistors placed in

CTR,Lo

OUT

⎛

R

⎜

1V52.2V

+⋅=

⎜

R

⎝

⎛

⎜

1V4.3V

MAX,OUT

+⋅=

⎜

⎝

⎞

Hi,INV

⎟

⎟

Lo,INV

⎠

R

R

⎞

Hi,CTR

⎟

⎟

Lo,CTR

⎠

20/41

Page 21

AN2870 Designing with L6585DE

(

Boost choke design

PFC stage operates in transition mode; for a certain value of input voltage the on time (Ton)

is constant over the entire half period of the input voltage.

The frequency changes along the period of the input voltage: in particular the frequency is

the lowest when the input voltage reaches its maximum.

Moreover the frequency is higher if the output power is low and the frequency variation

changes if input voltage changes.

The internal starter requires a minimum PFC frequency equal to around15 kHz.

Equation 4

f

PFC

f

2

⎛

V

in

⎜

1

=

in

=

min,PFC

−⋅

⎜

LP2

⋅⋅

⎝

2

⎛

V

in

⎜

1

⎜

LP2

⋅⋅

in

⎝

V2

⋅

−⋅

in

V

out

mainsin

V

out

⎞

⎟

kHz15

≥

⎟

⎠

⎞

)

tf2sinV2

⋅⋅π⋅⋅

⎟

⎟

⎠

Using Eq.4 with both minimum and maximum value of Vin, the value of L can be selected as

the minimum obtained value. Even the maximum frequency should be checked to avoid to

absorb too much current from Vcc and to degrade the input performances due to excessive

frequency (> 450 kHz) in correspondence to zero input voltage.

The calculation of the maximum frequency is only a rough evaluation of the real frequency;

in fact the presence of the THD optimizer reduces the frequency near the crossover of the

input voltage.

The maximum current flowing into the choke can be evaluated as twice the maximum input

current:

Equation 5

P

in

max,L

22I ⋅⋅=

V

min,in

The ohmic power losses will be evaluated considering the RMS value of the current:

Equation 6

P

2

I =

RMS,L

in

V

3

min,in

The choke is realized around of a gapped ferrite core; the core shape has to be selected

considering the electrical parameters (Eq.4,5 and 6), the dimensions of the ballast and the

availability of the selected core. The core should be made by a material suitable for high

frequency operation.

21/41

Page 22

Designing with L6585DE AN2870

(

)

The number of turns and the length of the gap can be calculated as follows (L in uH, Bmax

in tesla, Ae in square millimeters and μ

=4π*10-7):

0

Equation 7

N

=

A

L

⎪

AB

⎪

emax

⎬

L

⎪

2

⎪

N

⎭

gap

2l

2

μ

AN

e

0

×=→

L

LI

⎫

max

=

Wire section is selected in order to fit the winding window of the coil former (preferred if

slotted).

In order to evaluate the actual copper losses the DC resistance of the winding must be

multiplied by a factor that depends on skin effect. Using a wire composed by multiple

conductors reduces this factor.

The copper losses can be evaluated as:

Equation 8

2

RIP ⋅=

RMS,L,L

Ω

HF,wire

Ferrite losses can be checked on ferrite manufacturer catalogs.

ZCD auxiliary winding must be able to develop the triggering pulse for ZCD pin

= 1.4 V). The voltage across the auxiliary winding will be:

(V

arm

Equation 9

V4.1mV2VV

⋅>⋅−=

inoutzcd,aux

The current flowing in ZCD pin must be limited by means of a resistor connected between

auxiliary winding and ZCD pin. Although the maximum ZCD pin current is around 5 mA, a

smaller value should be chosen in order to limit power dissipation and increase the

application reliability.

Equation 10

V2

⋅

R

=

ZCD

max,in

Im

⋅

ZCD

22/41

Page 23

AN2870 Designing with L6585DE

MOSFET selection

PFC MOSFET is to be selected considering the maximum current flowing into the switch,

the maximum voltage between drain and source and the maximum allowed losses.

Maximum allowed losses depend on maximum allowed junction temperature; an ambient

temperature equal to 70 °C – 80 °C is usually considered.

Power losses can be summarized as follows:

● Conduction losses: due to ohmic resistance of the MOSFET channel during its on

state; these losses are prevalent at minimum input voltage.

● Switching losses: experienced only during turn off transitions.

● Capacitive losses: experienced only during turn on transitions when the MOSFET has

to discharge the parasitic capacitance present at its drain. These losses are very high

at higher input voltages.

Conduction losses are related to R

and RMS value of the drain current:

DS(on)

Equation 11

2

⎛

2

RMS,MOS

P

⎜

=

8I

⎜

V

⎝

⎡

⎞

1

in

⎟

−

⎢

⎟

6

⎢

rms,in

⎠

⎣

Considering a maximum conduction losses less than P

24

9

π

COND,max

⎤

V

rms,in

⎥

V

⎥

OUT

⎦

, the maximum R

DS(on)

,

measured at 100 °C, can be found as follows:

Equation 12

P

(max)R <

ON,DS

max,COND

2

I

RMS,MOS

Switching losses are directly related to frequency, to output voltage, to input current and fall

time of drain of the MOSFET. The frequency should be averaged over the half period of the

mains and the fall time of the MOSFET can be found on MOSFET datasheet.

Equation 13

2

f

SW

V

=

⎛

RMS,in

⎜

−

1

⎜

⋅⋅

LP2

in

⎝

V

22

⋅

π

V

RMS,IN

OUT

⎞

⎟

⎟

⎠

Equation 14

P

VftIVftP ==

OUTswfrms,inOUTswfcross

in

V

rms,in

Capacitive losses are present only if instantaneous input voltage is greater than half the

output voltage. In fact when the inductor current becomes zero the parasitic capacitances

seen at the drain node starts to resonate with parasitic inductances causing a damped

oscillation whose peak to peak amplitude is equal to V

When V

in<VOUT

/2 the drain voltage at MOSFET turn on is almost zero.

OUT

- Vin.

23/41

Page 24

Designing with L6585DE AN2870

[

The time when input voltage is greater than V

/2 can be calculated as follows:

OUT

Equation 15

⎛

V

OUT

⎜

arcsin

⎜

1

f2

mains

⎝

=

t

1

t

2

⋅⋅

V22

π

f2

mains

−=

t

1

Within t2-t1 interval capacitive losses can be written as:

Equation 16

⎛

⎜

⎜

⎝

3

1

2

VC3.3fP

Drainossswcap

()

2

Where

Equation 17

t

2

∫

t

1

⎞

⎟

⎟

rms,in

⎠

()

⎞

2

+++=

VCCC

2

]

−ω⋅=

outrms,inmainsrms,Drain

⎟

Drainextossrss

⎟

⎠

dtVtsinV22f2V

These losses are greater at higher input voltage.

Figure 13 illustrates an example of calculation in wide range application

(Pin = 64 W, MOSFET STx7NM50).

Figure 13. PFC MOSFET losses (example)

24/41

Page 25

AN2870 Designing with L6585DE

Boost diode selection

Boost diode experiences a maximum current equal to maximum boost inductor current, an

average current equal to P

Equation 18

OUT/VOUT

and a RMS current equal to:

22

2

2

III

rms,Lrms,d

RMS,MOS

4

=−=

π

3

The maximum reverse voltage must be greater or equal to V

P

in

VV

rms,inOUT

and a fast Schottky diode is

OUT

suggested.

Diode power losses can be calculated using the formula reported in diode datasheet:

Equation 19

2

IKIK ⋅+⋅

rms,d2AV,d1

Bulk capacitor selection

Output voltage ripple is due to capacitance value and equivalent series resistor (ESR) of

bulk capacitor. ESR value is a function of frequency: higher the frequency, lower the ESR

value. The worst ESR will be measured in correspondence of the peak of the input voltage,

when the PFC frequency reaches the minimum frequency.

Equation 20

P

V ⋅+

=Δ

OUT

OUT

Rms value of the bulk capacitor current is:

CVf4

⋅⋅⋅π

outOUTmains

IESR

RMS,Cf@

outmin,PFC

Equation 21

2

⋅

I

OUT ⎟

=

RMS,C

232

π

9

P

⋅

in

⋅

VV

⎛

⎜

−

⎜

OUTrms,in

⎝

P

V

OUT

OUT

2

⎞

⎟

⎠

Multiplier biasing and PFC current sense resistor selection

The multiplier biasing proceeds as follows (Figure 14):

1. Calculate the range of the peak of the input voltage.

2. Consider the characteristic curve that exploits the maximum slope and the point that

guarantees, on this curve, a linear behavior. Indicate this point as (V

mult,1,VCS,1

)

25/41

Page 26

Designing with L6585DE AN2870

Figure 14. Multiplier characteristics

3. At minimum input voltage, Vmult had to be biased to V

by means of a voltage

mult,1

divider connected between the rectified input mains and ground. The divider factor is:

Equation 22

V

kp

1,mult

V

min,in

pk

4. PFC sense resistor is chosen in order to obtain V

R

==

lo,mult

RR

+

hi,multlo,mult

at maximum input current (i.e. at

CS,1

minimum input voltage):

Equation 23

R

PFCCS

V

1,CS

==

I

max,L

VV

⋅

min,in1,CS

P22

⋅⋅

in

5. Check Vmult when Vin assumes its maximum value: this new bias point should lie on

the linear segment of a characteristic curve.

The upper resistor value should be obtained using a suitable number of resistors in series in

order to increase the reliability of the application. Furthermore a capacitor placed in parallel

with lower resistor helps filtering the high frequency components of the signal; the cut

frequency of this filter can be placed at ten times the mains frequency, i.e. at 500 Hz.

Error amplifier compensation

Error amplifier compensation design proceeds as follows:

Direct gain of the PFC control loop can be written as (cfr AN966):

Equation 24

1

=

)s(G

26/41

V

4

2

Vkk

out

R

rms,inpM

R

PFCCS

out

1

CR

+

s1

outout

2

Page 27

AN2870 Designing with L6585DE

Where R

is the effective resistance of the load (i.e. V

out

(reported in datasheet) and C

is the bulk capacitor.

out

OUT

2

/P

), kM is the multiplier gain

OUT

In order to compensate the loop and reject the ripple superimposed to the output voltage,

the loop gain at 100 Hz should be less than -60 dB. The transfer function of the error

amplifier, compensated with a simple capacitor can be written as:

Equation 25

comp

()

sG =

1

RsC

invhcomp

and:

Equation 26

⎞

⎟

⎟

CR

⎟

outout

⎟

2

⎠

π=

001.0

=

Hz1002s

() () ()

comploop

=⋅=

sGsGsG

Using a high value for

⎛

⎜

⎜

⎝

R

the value of C

invh

⎛

⎜

⎞

1

RsC

invhcomp

1

⎟

⎜

⋅

⎟

⎜

4

⎠

⎜

⎝

comp

2

Vkk

rms,inpM

V

out

is reduced.

R

R

out

pfccs

1

s1

+

Input rectifier

This component is needed to supply the PFC stage with a rectified voltage.

The reverse voltage should be greater than twice V

, the forward current greater than

in,max

maximum input current and the power dissipation greater than:

Equation 27

P ==

4

2

F(max)rms,inB

P

in

22VI

V

V

F

(min)rms,in

Input capacitor

At this stage of design the current absorption is impulsive. The mean value of this current is

in phase with the input voltage, but the high frequency components have amplitude equal to

twice the amplitude of the mean value, therefore can create interferences with nearby

electronic equipment. An input filter capacitor must be placed between the rectifier and the

PFC stage in order to reduce the high frequency current ripple superimposed to the input

current.

Let be

current:

Equation 28

r the maximum allowed ratio between ripple amplitude and mean value of the input

I

sw

min

RMS,in

Vfr2

⋅⋅⋅π

=

(min)RMS,in

C

=

min,in

min

P

in

Vfr2

⋅⋅⋅π

2

(min)RMS,insw

27/41

Page 28

Designing with L6585DE AN2870

The mean value of the PFC frequency is calculated accordingly with Eq.13.

This capacitor may worsen the overall performance of the PFC stage: in fact the energy

stored in it may not be transferred to inductor when the input voltage is near zero. This is the

main reason of the introduction of the THD optimizer.

Other input circuitry

The EMI behavior of the circuit needs to be improved with a suitable EMI filter, a fuse with

inrush limiter can be introduced for improved reliability against burst and surge events and

finally also a surge suppressor (varistor) can be needed.

4.2 Ballast stage design

Resonant network and operating point design

The values of resonant inductor and resonant capacitor and the operating frequencies are

chosen in order to:

a) Supply the lamp with correct voltage and current during run mode

b) Maintain lamp voltage lower than Vpre during preheating mode

c) Develop a suitable high voltage across the lamp during the ignition

The resonant network when the lamp is off has a very high Q factor and the resonant

frequency is very close to the ideal resonant frequency of an LC resonator.

The relationship between lamp voltage and frequency can be easily found using the Fourier

transform and considering the fundamental harmonic of the square wave generated by the

half bridge.

Input voltage will be:

Equation 29

2

V

V

=

outpk,bal

π

Useful parameters are resonant frequency f0, characteristic impedance Z0 and Q factor:

Equation 30

⎧

f

=

0

⎪

⎪

⎪

⎪

Z

⎨

0

⎪

⎪

⎪

Q

⎪

⎩

1

CL2

π

=

R

lamp

Z

resres

L

res

C

res

V

run

==

ZI

0

0run

Where V

run

and I

are respectively the lamp voltage and lamp current.

run

The suitable frequencies to obtain the desired operating parameters can be calculated as

follows:

28/41

Page 29

AN2870 Designing with L6585DE

Equation 31

2

1

⎛

2

⎜

⎝

ff

=

0run

⎞

−

⎟

Q

⎠

⎡

V2

f

⎢

f

=

pre

2

0ign

out0

⎢

⎢

⎣

1ff

+=

+

IZ

⋅⋅π

pre0

V2

out

⋅⋅π

V2

ign

1

⎛

2

⎜

⎝

⎛

⎜

⎜

⎝

⎞

−+

⎟

22

Q

⎠

V2

out

IZ

⋅⋅π

⎛

⎜

4

+−

⎜

⎝

2

2

⎞

⎟

+

⎟

pre0

⎠

V4

out

⋅⋅⋅π

⎤

⎥

⎥

⎥

⎦

2

⎞

⎟

⎟

I2QZ

run0

⎠

V2

out

1f)OR(4

+==

0

V

π

pre

L and C are chosen in order to fit the following constraints:

● Preheating voltage has to be less than a value reported on lamp datasheet to avoid

early ignition.

Equation 32

V

=

V <⋅

pre

● In case of current controlled preheating, the Preheating current should be between two

pk,bal

⎛

f

f

pre

⎜

−

⎜

⎝

f

f

pre

0

f

res

V

2

f

pre

⎞

0

⎟

⎟

⎠

max,pre

values in order to obtain an effective preheating. These two values depend on the

preheating time, or, better, on the total energy delivered to the lamp during preheating.

Equation 33

V

=

I ∈

pre

Z

0

● Run frequency should be less than minimum ignition frequency. This frequency is the

pk,bal

⎛

f

f

pre

⎜

⎜

⎝

0

−

f

f

pre

0

[]

I..I

2

⎞

⎟

⎟

⎠

max,phmin,ph

frequency at which the voltage across the lamp reaches its maximum value (reported

on lamp datasheet).

Equation 34

V

=

V ⋅

ign

⎛

f

⎜

⎜

⎝

pk,bal

min,ign

f

0

f

0

−

f

min,ign

f

res

2

f

⎞

⎟

⎟

⎠

min,ign

29/41

Page 30

Designing with L6585DE AN2870

Equation 35

V

I

=

run

⎛

2

⎜

1QZ

0

⎜

⎝

pk,bal

2

2

⎞

⎞

⎛

f

⎟

run

⎟

⎜

−

⎜

f

0

⎝

+

⎟

⎟

⎠

⎠

2

⎞

⎛

f

run

⎟

⎜

⎟

⎜

f

0

⎠

⎝

An example of characteristic curves is reported in Figure 15-A and B

Figure 15. (A) voltage frequency response Figure 15. (B) current frequency response

Ballast inductor experiences the maximum current during ignition, when the operating point

is very close to the resonance frequency.

Equation 36

⎛

⎜

⎜

⎜

V

pk,bal

⎜

I

R

must be chosen in order to obtain the minimum ignition voltage across the lamp:

hbcs

=

ign,ballast

Z

⎜

0

⎜

⎜

⎜

⎝

⎡

⎛

2

⎢

⎜

−

1Q

⎜

⎢

⎝

⎣

f

⎞

⎛

ign

⎟

⎜

+

Q1

⎟

⎜

f

0

⎠

⎝

2

2

⎤

f

ign

f

0

⎛

⎞

⎥

⎜

⎟

+

⎜

⎟

⎥

⎝

⎠

⎦

⎞

⎟

⎟

⎟

⎟

2

⎟

f

⎞

ign

⎟

⎟

⎟

⎟

f

⎟

0

⎠

⎠

Equation 37

V

R =

HBCS

R

power rating can be calculated considering the RMS value of the low side current

hbcs

hbcsh

I

ign,ballast

during ignition.

In this case the bias point lies at a frequency close to the resonance frequency, therefore the

current flowing in resonant network is almost sinusoidal.

This allows the designer to approximate the RMS current to:

30/41

Page 31

AN2870 Designing with L6585DE

Equation 38

I

pk,lamp

I

≈

RMS,hbcs

2

And the power rating to:

Equation 39

2

IRP ⋅≈

hbcshbcs

RMS,hbcs

The real maximum inductor current and lamp voltage can be calculated considering the

maximum threshold value and the tolerances related with value of Rhbcs and Lres.

The design of the inductor proceeds as indicated in Eq 7.

The resonance capacitor is preferably a metallized polyester film capacitor. Blocking

capacitor is around ten times the resonant one: a value greater or equal to 100 nF for the

polyester capacitor is usually chosen.

Parameters setting

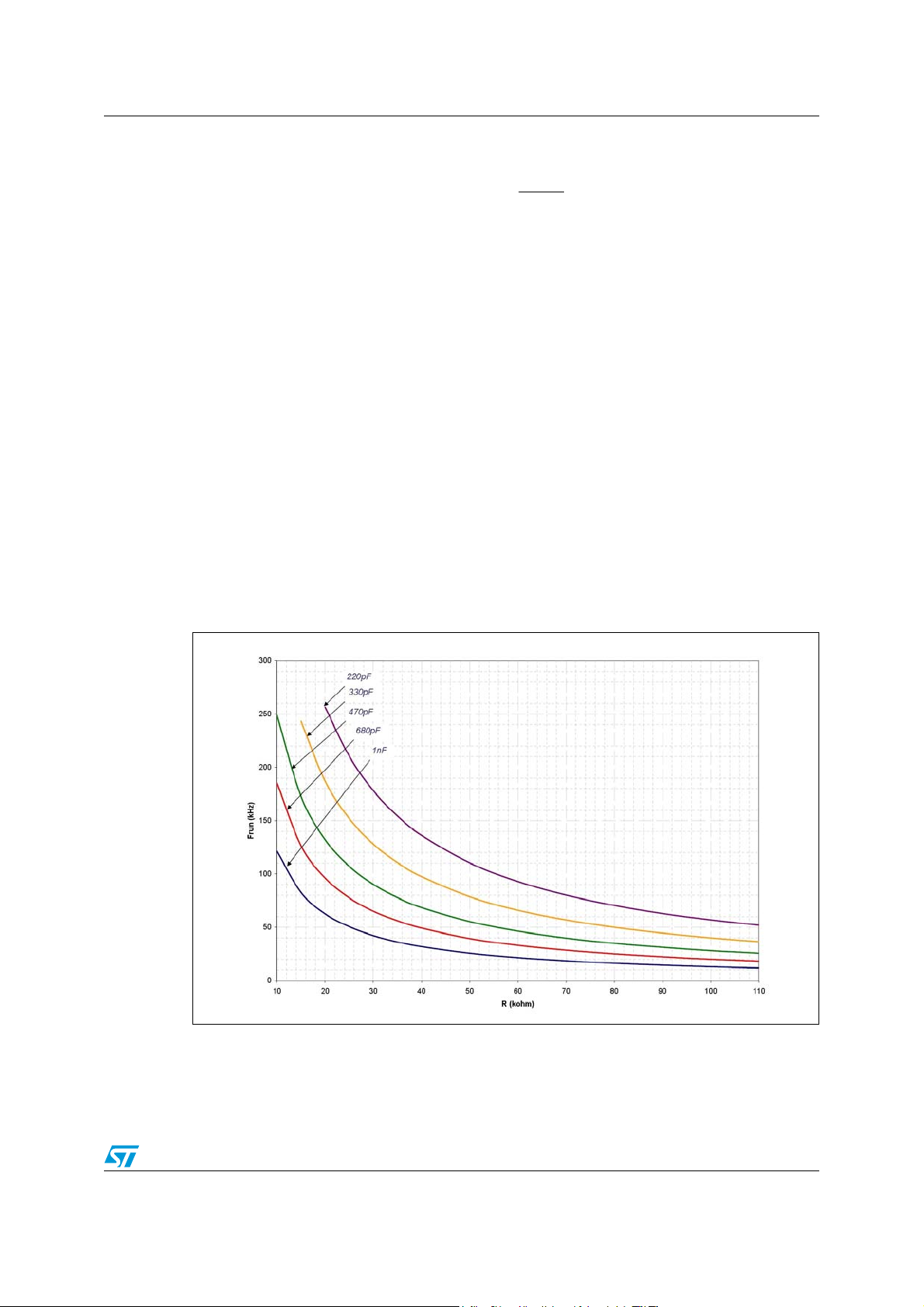

In order to fix the run frequency and the preheating frequency, the following curves can be

used. Each curve is related with a particular capacitor value, therefore a capacitor value

must be firstly chosen. The resistances corresponding Frun and Fpre can be graphically

found and are respectively Rrun and the parallel between Rrun and Rpre.

Figure 16. Oscillator characteristic curves

31/41

Page 32

Designing with L6585DE AN2870

A more accurate procedure can be followed considering that the reported curves can be

represented by the following equation (f in kHz and R in k

Ω):

Equation 40

k

f =

e

()

R

In particular the constant, k, and the exponent, e, can be calculated for a given Cosc

(expressed in pF) as follows:

Equation 41

3

C

OSC

106.499k⋅

872.0

=

()

Equation 42

1e −=

Figure 17. (A) k parameter versus Cosc (pF) Figure 17. (B) e parameter versus Cosc (pF)

33.1

OSC

581.0

()

C

Firstly k and e should be found and then R can be calculated as follows:

Equation 43

1

e

⎞

⎛

k

⎟

run

⎜

=

⎟

⎜

f

run

⎠

⎝

1

e

⎛

⎞

k

⎜

R//R

=

runpre

⎟

⎜

⎟

f

pre

⎝

⎠

R

32/41

Page 33

AN2870 Designing with L6585DE

⋅

=

(

⋅

=

The ignition time is equal to the time the capacitor Cign is charged by the RF current and the

EOI leakage current. A precise calculation of this parameter is not needed. It’s

approximately equal to:

Equation 44

CR3T =

ignpreign

Preheating time and protection time are related to Tch cycle:

Equation 45

pre

C

D

I

TCH

+=

63.4T

63.4

⎞

⎛

lnCR

DD

⎟

⎜

5.1

⎠

⎝

Equation 46

C269740T

Dprot

Half bridge design

When resonant network works in inductive region, half bridge MOSFETs switch at zero

voltage switching condition.

This implies that high side and low side MOSFETs experience mainly conduction losses

because of their on state resistance.

Equation 47

2

)

IRP ⋅=

rmson,dscond

I

can be considered as per Eq 38 or can be calculated considering that the waveform

rms

seen during an on time is a sinusoid having a frequency equal to resonance frequency.

From thermal consideration the maximum R

In order to drive correctly the high side MOSFET, a suitable boostrap capacitor is needed.

can be calculated.

ds,on

The size of the boostrap capacitor can be calculated considering the allowed V

total gate capacitance of the High side MOSFET and the R

of the integrated boostrap

on

drop, the

gs

diode.

In steady state, during the ON time of the low side transistor the bootstrap capacitor stores

charges:

Equation 48

VCQ

ccbootboot

During the ON time of the high side transistor, the charges stored in bootstrap capacitor are

shared with total gate capacitance, causing a voltage drop:

33/41

Page 34

Designing with L6585DE AN2870

Equation 49

Q

CC

bootgate

boot

=+

VV

Δ−

cc

These charges must be replaced during the subsequent ON time of the low side transistor:

Equation 50

⎛

⎡

−⋅−=

ln1CRT =

⎢

bootonboot

⎢

⎣

⎤

⎞

⎛

Δ

V

⎟

⎜

⎥

⎟

⎜

V

⎥

⎠

⎝

⎦

1

⎜

<

⎜

⎝

−

⋅

f2

precc

⎞

⎟

TT

⎟

⎠

min,onDeadTime

End of life detection

Blocking capacitor to GND configuration:

In case of blocking capacitor to ground configuration the tracking mode is suggested. In

order to set this mode a resistor placed between EOLP and GND is needed: its value has to

be chosen as follows:

● 220 kΩ < R

● 22 kΩ < R

EOL pin biasing proceeds as follows:

The blocking capacitor mean voltage is half of the PFC output voltage and the CTR pin

voltage is equal to:

Equation 51

Therefore the voltage divider connected between C

factor equal to:

< 270 kΩ → VW = 240 mV

eolp

< 27 kΩ → VW = 150 mV

eolp

CTR

V

out

4.3V ⋅=

V

OVP

and EOL pin should have a divider

block

Equation 52

k =

eol

A capacitor placed in parallel with the lower resistor and placed near the IC helps to keep

low the high frequency residual noise.

34/41

V2

⋅

CTR

=

V

8.6

V

OVPout

Page 35

AN2870 Designing with L6585DE

Figure 18. EOL - C

block

to ground

Lamp to GND configuration:

In case of lamp to ground configuration the fix reference mode is suggested.

In order to set this mode a resistor placed between EOLP and GND is needed: its value has

to be chosen as follows:

● 75 kΩ < R

● 620 kΩ < R

The EOL pin biasing proceeds as follows:

< 91kΩ → window amplitude = 240 mV

eolp

→ window amplitude = 720 mV

eolp

A voltage shift is needed in order to detect a null value with a positive referenced

comparator: two Zener diodes are requested.

The current capability of EOL pin is equal to 5.5 µA, therefore the minimum Zener voltage

that guarantees accuracy of the measurement is 8 V.

35/41

Page 36

Designing with L6585DE AN2870

Figure 19. EOL - lamp to ground

Consider the case of positive going lamp voltage mean value (VK): the maximum VK allowed

value is equal to:

Equation 53

VVV5.2V +++=

K

max

2F1zW

In the opposite case it will be:

Equation 54

VVV5.2V −−−=

K

min

1F2zW

In order to have a symmetrical behavior, the absolute values of the two voltages have to be

equal.

This brings to the following relation:

Equation 55

⎛

−=

V

K

max

V

⎜

⎝

V5.2

W

VV5.22

⎞

⎟

K

min

⎠

V

V

V

V

2z

2F

1z

V

−=⋅⇒

1z

V5.2

W

+++−=+++⇒

1F

2z

The difference of the Zener voltages has to be equal to 5V: twice the reference voltage.

36/41

Page 37

AN2870 Designing with L6585DE

(

⋅⋅=

The maximum deviation of the mean voltage of the lamp, V

lamp,EOL

, depends on the lamp

type (e.g. is 15 V for T5-54W lamp).

The following relation can be used to calculate the correct value of the divider's resistors

(R

Ehi

and R

Elo

)

Equation 56

)

IIRVV

+⋅−=

K

max

max

VV

K

−=

EOL,lamp

EOLREloEhiEOL,lamp

RV

⋅

EhiEOL,lamp

RR

+

EloEhi

Ehi

A5.5R

μ⋅−

The value of filtering capacitor should be calculated in order to have a cutoff frequency

equal to at least one hundreds of run frequency.

IC power supply design

L6585DE can be supplied by means of either external source, auxiliary winding on PFC

choke or charge pump connected to the middle point of half bridge. The most used method

is the charge pump connected to the middle point of the half bridge.

The charge pump must be able to deliver the correct current to the IC. I

half bridge and PFC driver switching activities. Typical values of I

CC

Figure 20.

The current is delivered by the capacitor during the edges of the middle point of the half

bridge. The slope of these edges is also related to the recovery time of the body diode of the

MOSFETs and to the capacitor itself. Assuming a linear slope the instantaneous current

delivered by the capacitor will be:

depends on both

CC

are reported on

Equation 57

V

OUT

CI =

cppk,cp

T

rise

Equation 58

IfTII ≥

ccrunrisepk,cpcp

The diode connected to ground is a Zener diode (15 V is the suggested value): it limits the

voltage across the Vcc pin avoiding an extra stress of the internal active clamp. In order to

limit the current flowing into this diode, when it is directly biased, a low value resistor is

placed in series with the capacitor.

A bigger capacitor (>1 µF) and a 100 nF ceramic capacitor placed near the IC are needed to

filter the Vcc voltage.

At start up the current is sunk from rectified mains and delivered to the IC through a resistor

path. This resistor is chosen in order to guarantee the minimum quiescent current required

by L6585DE (370 µA). Its value influences also the start-up time because it had to charge

the electrolytic capacitor connected to Vcc.

37/41

Page 38

Designing with L6585DE AN2870

Figure 20. Current consumption vs PFC frequency

38/41

Page 39

AN2870 Designing with L6585DE

4.3 PCB hints

The following rules, considered during the PCB design, help to optimize the performance of

the L6585DE.

1. In a board containing both PFC and Ballast section four different ground potentials are

present:

a) PFC signal ground,

b) PFC power ground

c) Ballast signal ground and

d) Ballast power ground.

These traces are usually kept separate and connected together in correspondence of a low

impedance node (the negative terminal of bulk capacitor). A similar rule has to be followed

in the L6585DE: power grounds are to be kept separate and connected to the negative

terminal of the bulk capacitor, signal grounds should be firstly routed to the pin GND (15)

and then the pin 15 is connected to the negative terminal of bulk capacitor. It is very

important that the ground trace relevant to C

GND pin as shortly as possible.

2. Ballast PCBs are usually long and narrow, therefore current loops are to be minimized

in order to reduce the electromagnetically induced interference between PFC stage

and Ballast Stage. This is very important when wide range application has to be

implemented.

3. Regions surrounding the gap of the chokes are usually very noisy therefore signal and

ground traces shouldn’t pass underneath these regions.

4. Traces that connect the gates of the MOSFETs, the OUT pin and the charge pump

components are affected by voltages that vary with very fast edges. They can

capacitively induce noise to closest traces. Therefore if a signal has to pass near these

nodes an increased distance between traces or, eventually, a ground shield has to be

considered.

5. Ground pin of shunt components should be placed as close as possible to star

connection point or, at least, close together, this avoids errors reading the voltage

across them and current sense traces has to be kept as short as possible in order to

avoid HF noise induction. In the second case is preferable to connect signal GND to the

ground of the shunts instead of the star point.

6. Bootstrap capacitor and Vcc ceramic capacitor have to be placed as close as possible

to relevant pins.

7. Error amplifier feedback network must be small and placed near the IC in order to

reduce any loop that can couple radio interference.

8. The drain of the PFC MOSFET, the anode of Boost Diode and the PFC choke are

connected together as close as possible. In fact this node experienced very fast edges

and also very high currents.

, RRF and C

OSC

is connected directly to the

PRE

39/41

Page 40

Revision history AN2870

5 Revision history

Table 2. Document revision history

Date Revision Changes

26-Mar-2009 1 Initial release

40/41

Page 41

AN2870

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2009 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

41/41

Loading...

Loading...