Page 1

AN2846

Application note

SCLT3-8 - guidelines for use in industrial automation applications

Introduction

The serial current limited termination device SCLT3-8 provides 8 inputs and supports the

data transfer of the input states through a limited opto-transistor count thanks to the digital

SPI (serial peripheral interface).

The purpose of this document is to:

■ Help designers to use the SCLT3-8 in basic operations and to allow them to use it easily

in their own applications by describing the SCLT3-8 behavior in detail (Refer also to the

SCLT3-8 device datasheet and to the User guide for the evaluation board

STEVAL-IFP000V1.)

■ Provide basic schematic diagrams

■ Provide information on the thermal behavior of the SCLT3-8 device

■ Offer recommendations to achieve robust SCLT3-8 designs to optimize EMI protection in

accordance with industry standards (IEC 61000-4-2, 4-4, 4-5 and 4-6)

February 2010 Doc ID 15130 Rev 1 1/35

www.st.com

Page 2

Contents AN2846

Contents

1 Application guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Features of the SCLT3-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Current-limited inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.1 Maximum input current setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.2 Input characteristics (IEC 61131-2 standard) . . . . . . . . . . . . . . . . . . . . . 6

1.2.3 Digital input filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2.4 Input signal frequency limitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.2.5 Input state monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3 Monitoring functions and regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3.1 VCC monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3.2 Power loss detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.3.3 Overtemperature detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.3.4 Internal voltage regulator 5 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.4 SPI functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.4.1 Input state register and parity bit generator . . . . . . . . . . . . . . . . . . . . . 14

1.4.2 Data shift register and control shift register . . . . . . . . . . . . . . . . . . . . . . 15

1.4.3 Digital inputs and outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.4.4 SPI functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.4.5 SPI timing definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2 Thermal dissipation calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.1 Forward inputs polarity case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.2 Reverse polarity on a single input case . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.3 Temperature gradient on the SCLT3 and on the board . . . . . . . . . . . . . . 20

3 Application circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.1 Basic SCLT3-8 board description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.2 Component definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.2.1 Footprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4 Isolation management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.1 Opto-coupler isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2 Magnetic digital isolator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2/35 Doc ID 15130 Rev 1

Page 3

AN2846 Contents

5 SCLT3-8 link configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6 Electromagnetic compatibility (EMC) requirements . . . . . . . . . . . . . . 29

6.1 IEC 61000 4-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.2 IEC 61000 4-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.3 IEC 61000 4-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.3.1 Results on input pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.3.2 Results on VC pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.4 IEC 61000 4-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Doc ID 15130 Rev 1 3/35

Page 4

Application guidelines AN2846

V

CS

V

DD

Input

state

register

Data

Transfer

logic

shift

register

Parity

bits

gen.

4 lines

8 lines

8

lines

8 lines

Prog.

digital

filters

8 Lines

Current

reference

Oscillator

Undervoltage

alarm

Power

reset

Power

supply

/CS

SPM

SCK

MOSI

/MISO

COM

S

MISO

V

C

DVR

OSC

REF

IN

1

LD

1

IN

8

LD

8

COM

P

V

DD

Overtemperature

alarm

Write

V

DD

Shift

Ctrl

shift

register

8/16

Bits

Shift

Input

protection

and

input current

limiters

MOSI

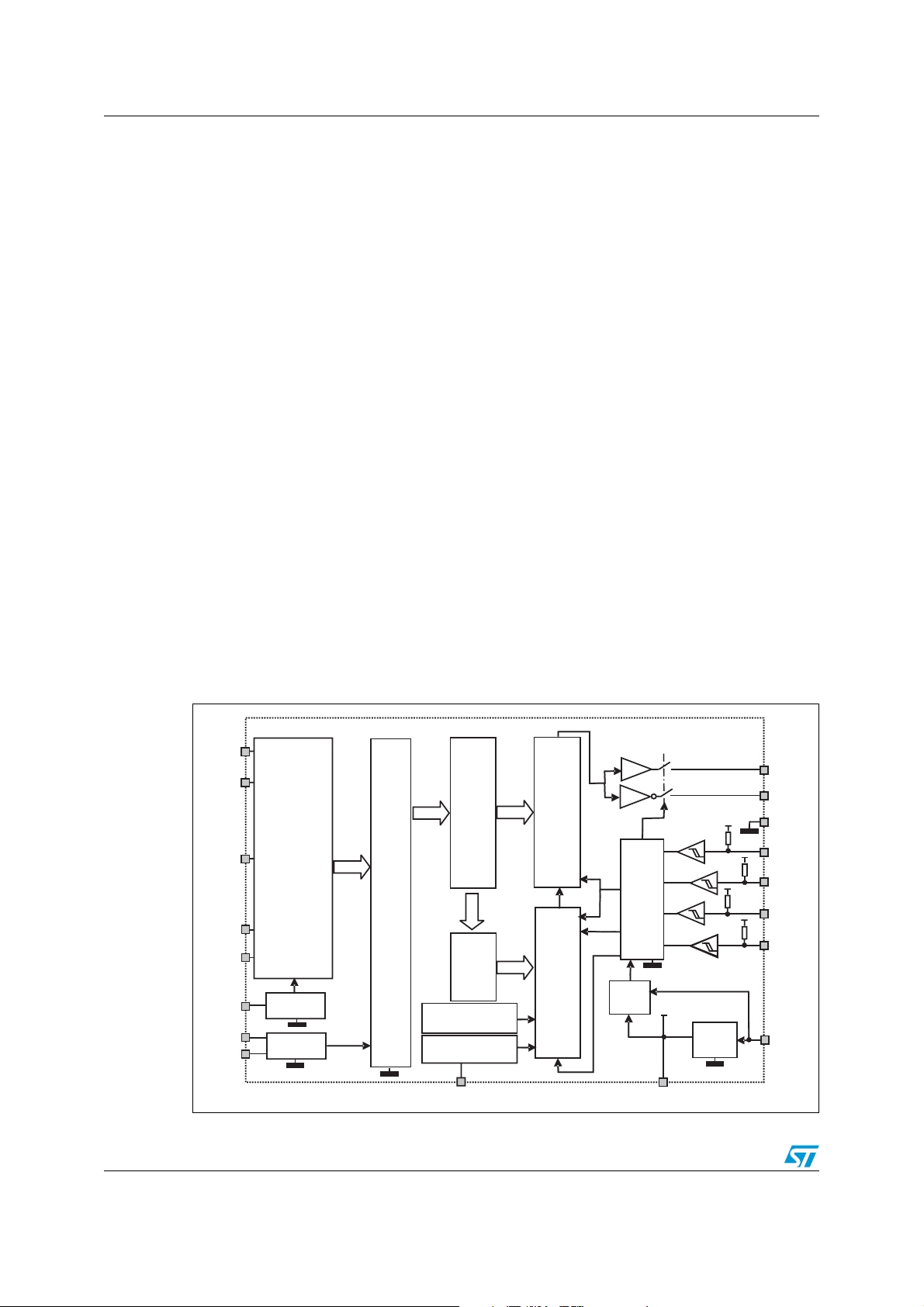

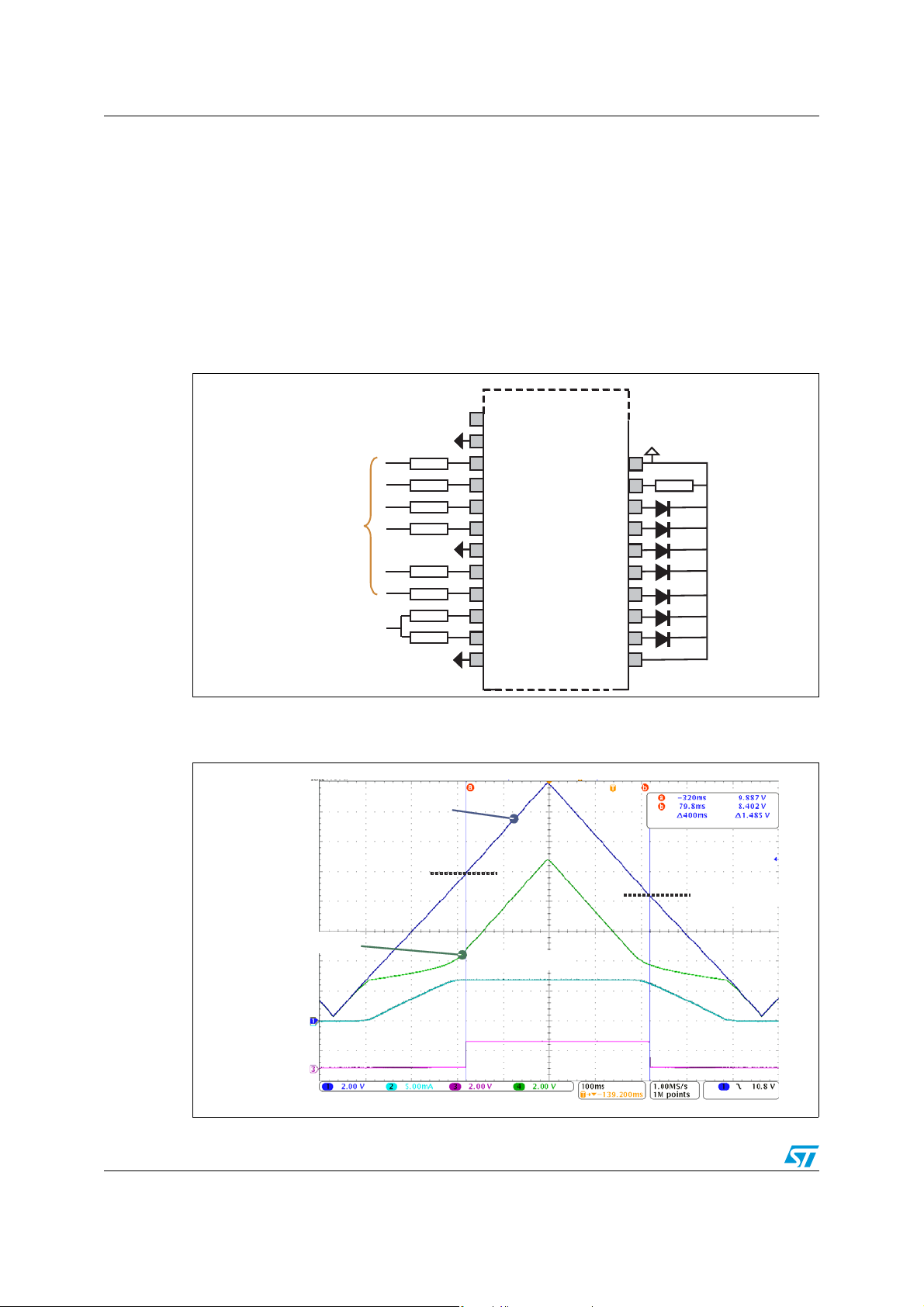

1 Application guidelines

1.1 Features of the SCLT3-8

The SCLT is an octal input active termination device designed for 24 V DC high density input

modules used in industrial automation. Each channel circuit terminates the connection

between a high side proximity sensor and the I/O module.

The advanced features of the SCLT3-8 compared to the basic CLT3-4BT6 device are:

● SPI for digital output count reduction

● Doubling of input terminations: 8 inputs compared to 4

● Input state monitoring by LEDs from the process section

● Undervoltage alarm detection of the power bus

● Power bus loss detection

● 5 V supply source available for external driving circuits like opto-couplers or magnetic

isolators

● Overtemperature detection

● Checksum data transmission through SPI for better data transfer integrity

The SCLT3-8 also features an input overvoltage protection. This input protection makes this

device robust against electromagnetic interference as defined in IEC 61000-4-x standards:

ESD, fast transient bursts, and voltage surges.

It is housed in a very low R

exposed pad, surface mount, HTSS0P38 package to reduce

TH

the circuit board size and the cooling pad.

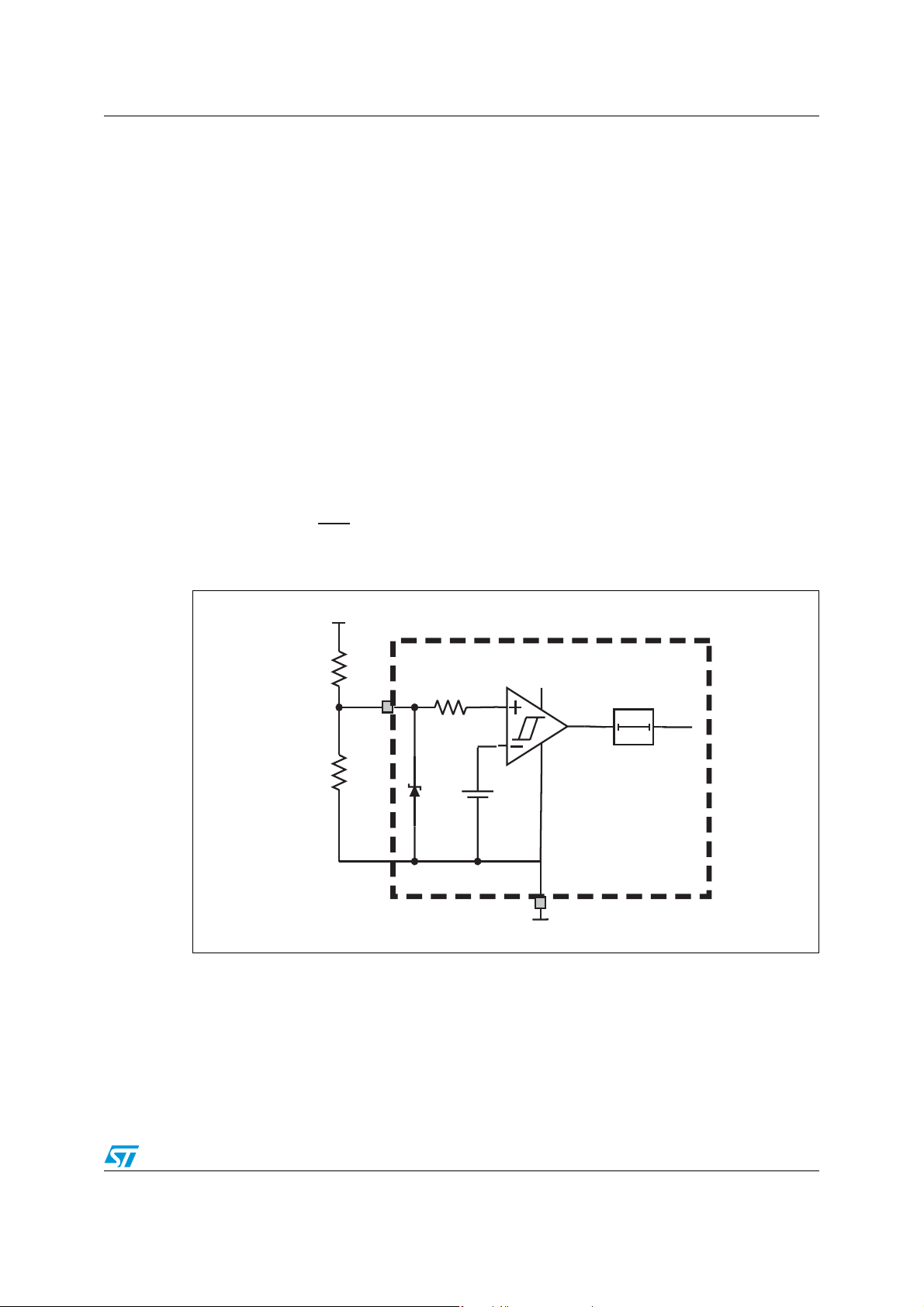

Figure 1 shows the schematic block diagram for the device.

Figure 1. Schematic block diagram

Transfer

logic

Bits

4/35 Doc ID 15130 Rev 1

Page 5

AN2846 Application guidelines

The SCLT3-8 has been designed to run with SPI protocol C

format is 16 bits or 8 bits long according to SPM pin level. When SPM is grounded, 16 bits

are transmitted - 8 input data bits and 8 control bits. When SPM is connected to V

the 8 input data bits are transmitted.

Ta bl e 1 defines the significance of the16 bits. Bit 15 is the most significant bit. Detailed SPI

functionality is described in Section 1.4.

Table 1. 16-bit frame definition

Bit15 Bit14 Bit13 Bit12 Bit11 Bit10 Bit09 Bit08

Data bits

IN

8

IN

7

Bit07 Bit06 Bit05 Bit04 Bit03 Bit02 Bit01 Bit00

Control Bits

/UVA /OTA PC1 PC2 PC3 PC4 0 1

1.2 Current-limited inputs

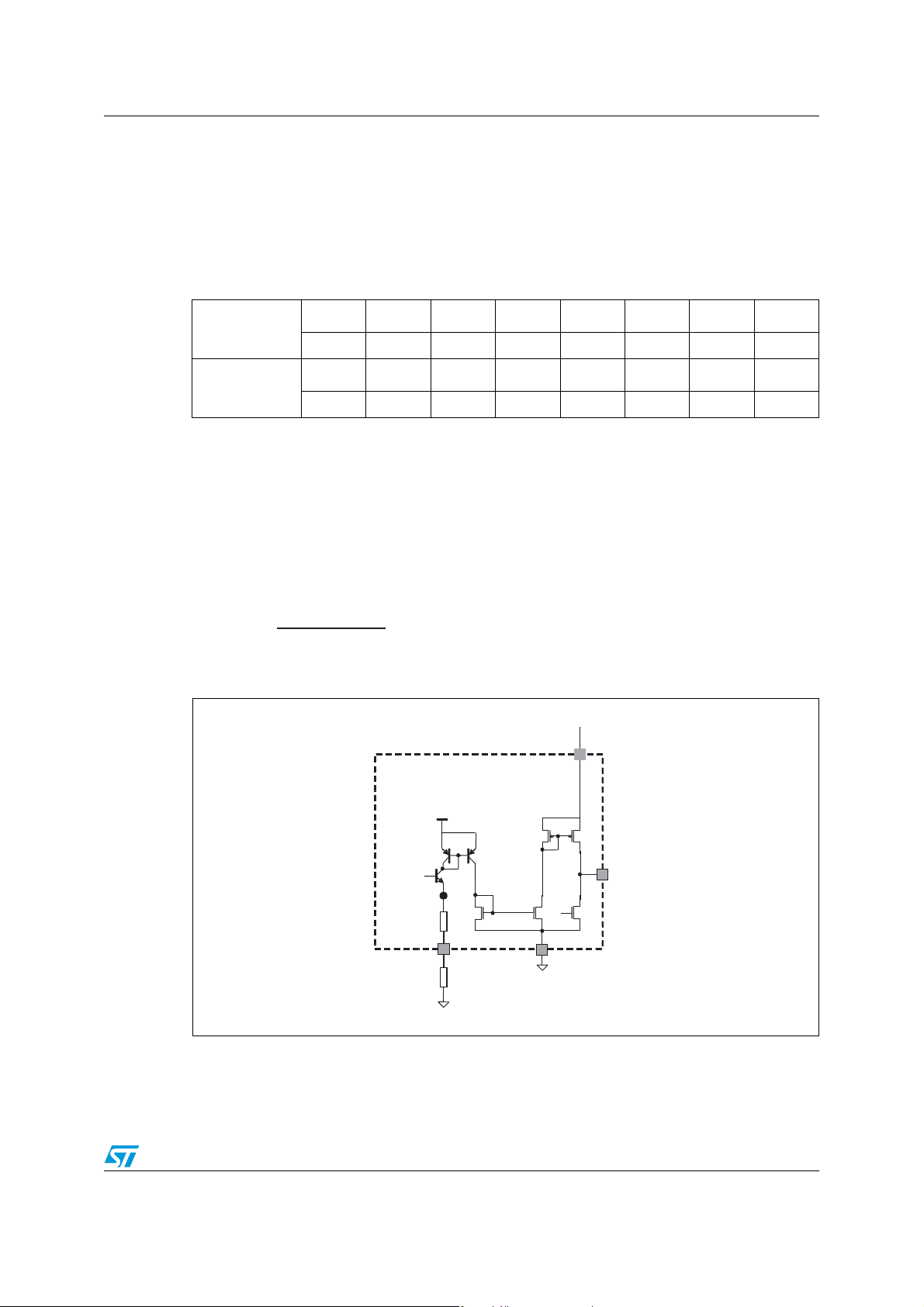

1.2.1 Maximum input current setting

All internal bias currents sources and particularly the input current limiter are defined by the

reference resistor connected to pin REF. A 15 kΩ resistor will assure a typical input limited

current of 2.35 mA (see Figure 2). The typical limited input current I

formula:

V

REF

BG

kR

5.1

+

I

LIM

30

·=

()

IN

= 0 and C

PHA

BG

IN

5

25.1Vcalwith typi

=

6

IN

4

IN

3

LIM

V

= 0. The frame

POL

DD

IN

2

is given by the

only

IN

1

Figure 2. Current limiter diagram

I

LIM

1 : 20

1 : 1

LED

VBG=1.25V

1.5k

REF

R

=15k

REF

2 : 3

LED_ON

COMs

The technology used allows a very low current dispersion according to the different

channels (less than 10%). The reference voltage V

is also compensated over the junction

BG

temperature range from -25 °C to 150 °C enabling a good stability of the limited current (see

Figure 3).

Doc ID 15130 Rev 1 5/35

Page 6

Application guidelines AN2846

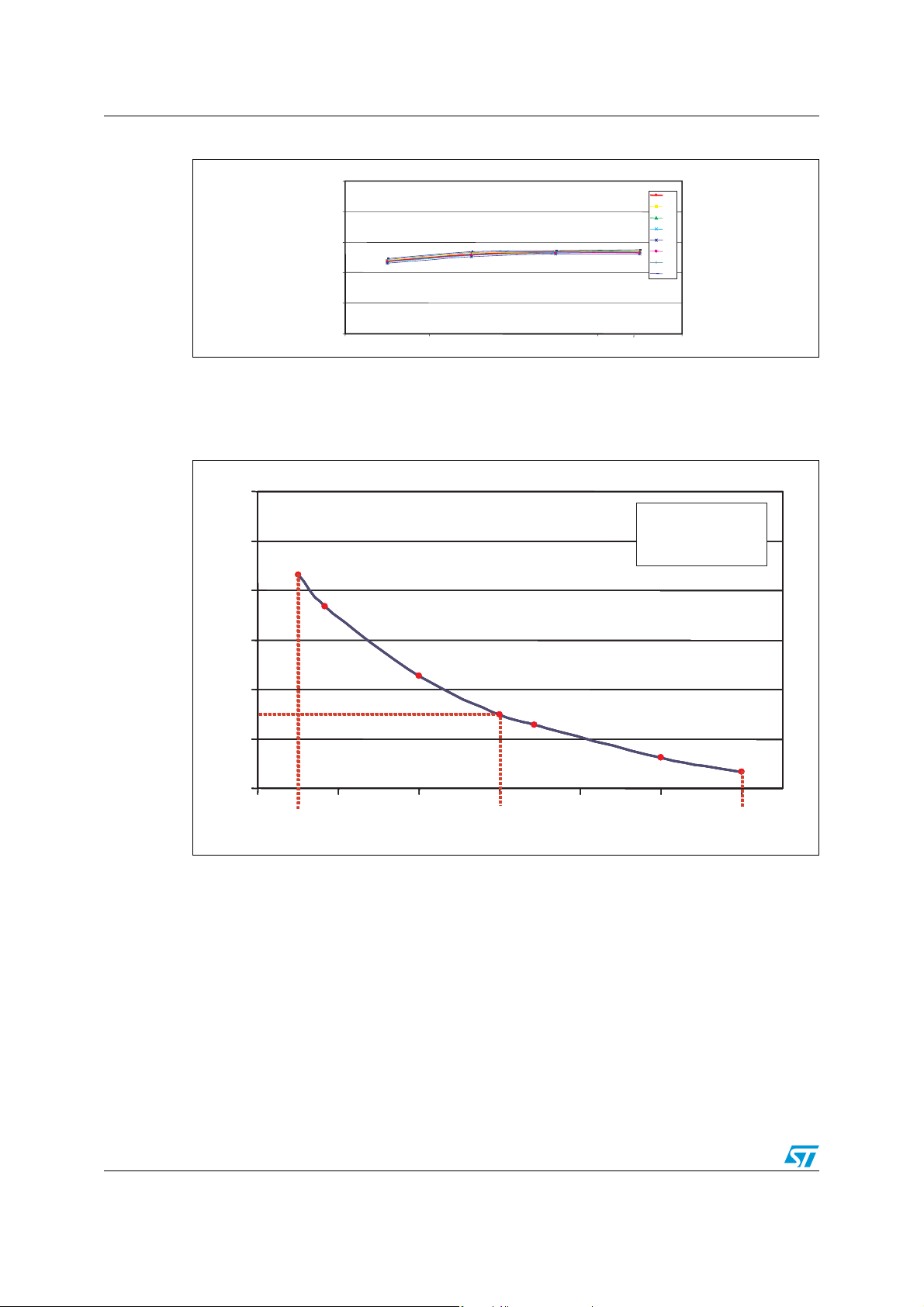

Figure 3. Limited current versus junction temperature

I (mA)

lim

2.6

2.5

2.4

2.3

2.2

2.1

-25°C 25°C 125°C 150°C

Vcc = 24 V, Vi = 11 V

Junction temp (°C)

IN1

IN2

IN3

IN4

IN5

IN6

IN7

IN8

Figure 4 shows the I

trend versus R

LIM

. according to the input current setting and

REF

therefore the dissipated power, the SCLT3-8 should be cooled with a sufficient copper heat

sink area (see Section 2)

Figure 4. Typical limiting input current versus R

I (mA)

lim

8.0

7.0

6.0

5.0

4.0

3.0

2.0

3 5 7 9 11 13 15

9.13.9

REF

Test conditions:

I versus R

LIM REF

V = 24 V, V = 24 V

CC I

R (k)

REF

15

1.2.2 Input characteristics (IEC 61131-2 standard)

According to the IEC 61131-2 standard and referring to type 3, when the input current is less

than 1.5 mA the output circuit passes all the input current, keeping the monitoring LED off

and transmits a low level state to the input state register.

When the module input voltage V

than 11 V (that is, the SCLT3-8 input voltage V

on and the circuit transmits a high level state to the input state register.

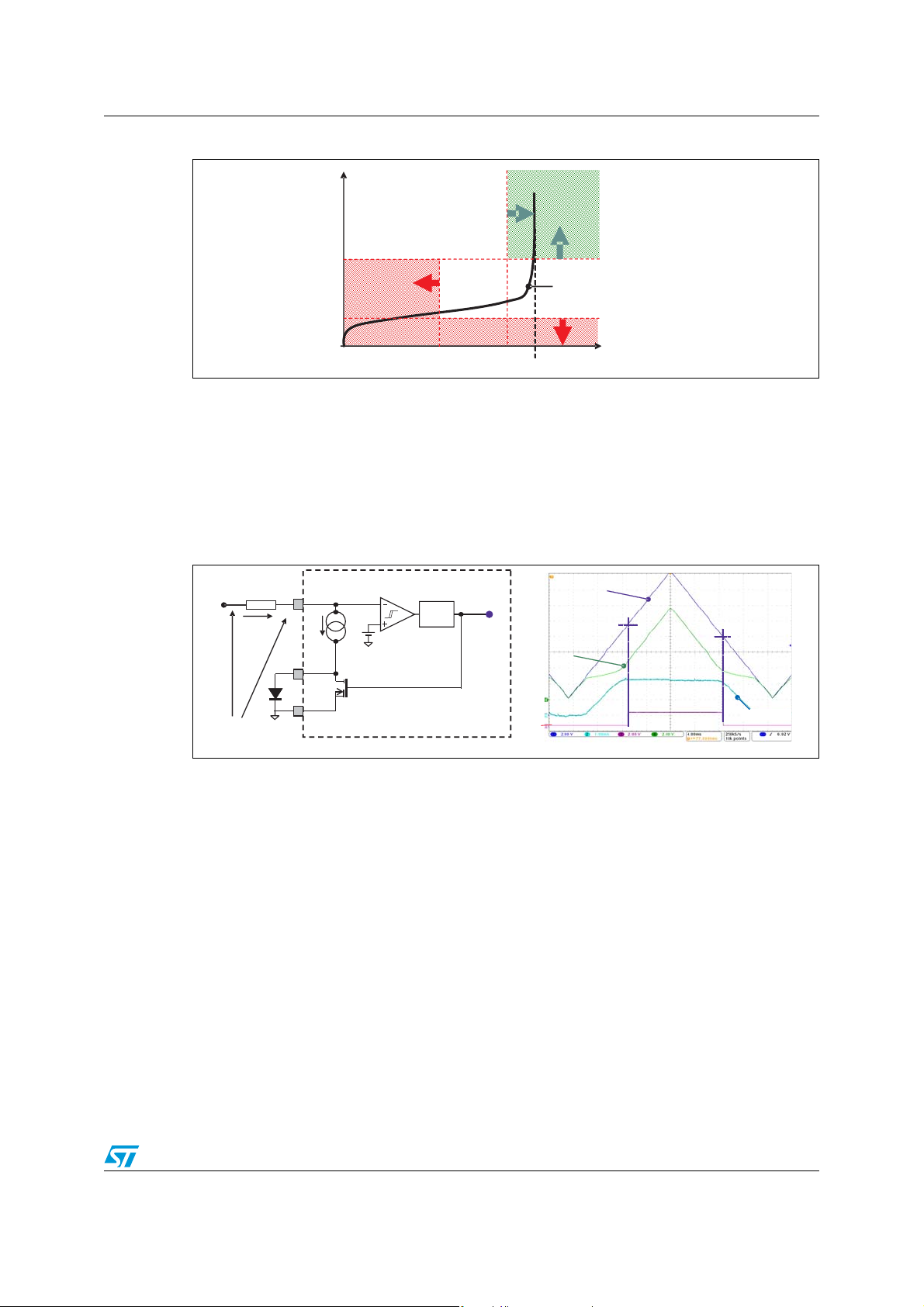

Figure 5 gives the input characteristics and operating regions of type 3, defined in the

IEC 61131-2 standard, and the typical SCLT3-8 input characteristic.

6/35 Doc ID 15130 Rev 1

, taking into account the 2.2 kΩ input resistor, is higher

I

is higher than 5 V) the monitoring LED is

IN

Page 7

AN2846 Application guidelines

INPUT STATUS

Figure 5. Input characteristic according to IEC 61131-2 type 3

(V)

IN

V

11V

OFF Region

5V

0.1

Transition Region

OFF

OFF

ON Region

ON

ON

11V

SCLT3-8 (including RIN)

input characteristic

5V

OFF

I

2.01.5

I

LIMIT

(mA)

IN

Current limited inputs allow reduced power dissipation into the device as well as reduced

power needed by the external supplies. A typical application circuit schematic is shown in

Figure 31 in the application section.

Figure 6 displays the SCLT3-8 input stage configuration and its typical input threshold

voltages. Low frequency triangular waveform as the input voltage has been used to better

highlight the voltage thresholds. Input current (I

displayed in Figure 6. The V

wave shape shows clearly the on-off states of the SCLT3-8.

LED

) and voltage across the LEDs are also

IN

Figure 6. Input stage

VIN:

2V/div

VI: 2V/div

V

IN_ON

= 9.5 V

I

LIM

= 2.35 mA

V

IN_OFF

IIN: 1mA/div

=8.0 V

R

IN

V

I

IN

V

I

IN

V

LED

TH

2.35 mA

DIGITAL

FILTER

V

LED

Input stage configuration Typical input voltage thresholds

With R

= 2.2 kΩ, the typical V

IN

I_ON

and V

threshold voltages are respectively 9.5 V

I_OFF

and 8.5 V, consistent with the 11 V min. and 5 V max specified in the IEC 61131-2 standard.

The hysteresis (1 V) improves the input noise immunity.

The module input thresholds are the results of drop voltage across the input resistor R

into which flows the input current I

V

TH_OFF

.

The input current limiter is activated typically when V

, and the SCLT3-8 input thresholds V

IN

= 3.7 V, before the V

IN

TH_ON

TH_ON

and

threshold

,

IN

is reached.

In all cases the following formula can be applied:

VIRV+×=

INININI

When the input current limiter is activated, the formula becomes:

VIRV+×=

The typical module input threshold voltage can be calculated as follow:

VIRV

Math Composer 1.1.5

+×=

ONVTHILIMINONIN

__

Doc ID 15130 Rev 1 7/35

Page 8

Application guidelines AN2846

The proposed RIN value of 2.2 kΩ has been calculated to meet the IEC 61131-2 threshold

requirements. Users can set their own particular application threshold voltages by applying,

in the formula given above, the V

value. Take note, the higher the R

they want to achieve and find the corresponding RIN

IN

, the better will be the immunity against voltage surges.

IN

A particular useful application is when an input type 2 is needed. Figure 7 shows the

solution of connecting R

R

= 9.1 kΩ to get 3.5 mA (see Figure 4) in each input branch. Of course corresponding

REF

and input R

IN7

= 1.5 kΩ in parallel and tuning the I

IN8

LIM

with

bits (B14, B15) will be set together at the right state according to the level applied at the

common input. Unused LED outputs must be grounded to maintain the flow of the

current in its corresponding chanel.

Figure 7. IN

The different threshold voltages and the I

and IN8 parallel wired for type 2

7

RIN= 1.5k Ω

Type 3 inputs

Type 2 inputs

R

IN

1

IN

2

IN

3

IN

4

IN

5

IN

6

IN

7

IN

8

= 7.0 mA are shown in Figure 8 below.

LIMIT

R

REF

LED

LED

LED

LED

LED

LED

LED

LED

1

2

3

4

5

6

7

8

REF

= 9.1kΩ

Figure 8. Threshold voltages - type 2 configuration using two inputs in parallel

VI(2V/div)

V

= 9.9 V

I_ON

V

(2V/div)

(5mA/div)

I

IN

V

IN

LED

I

LIMIT

8/35 Doc ID 15130 Rev 1

= 7.0mA

V

I_OFF

= 8.4 V

Page 9

AN2846 Application guidelines

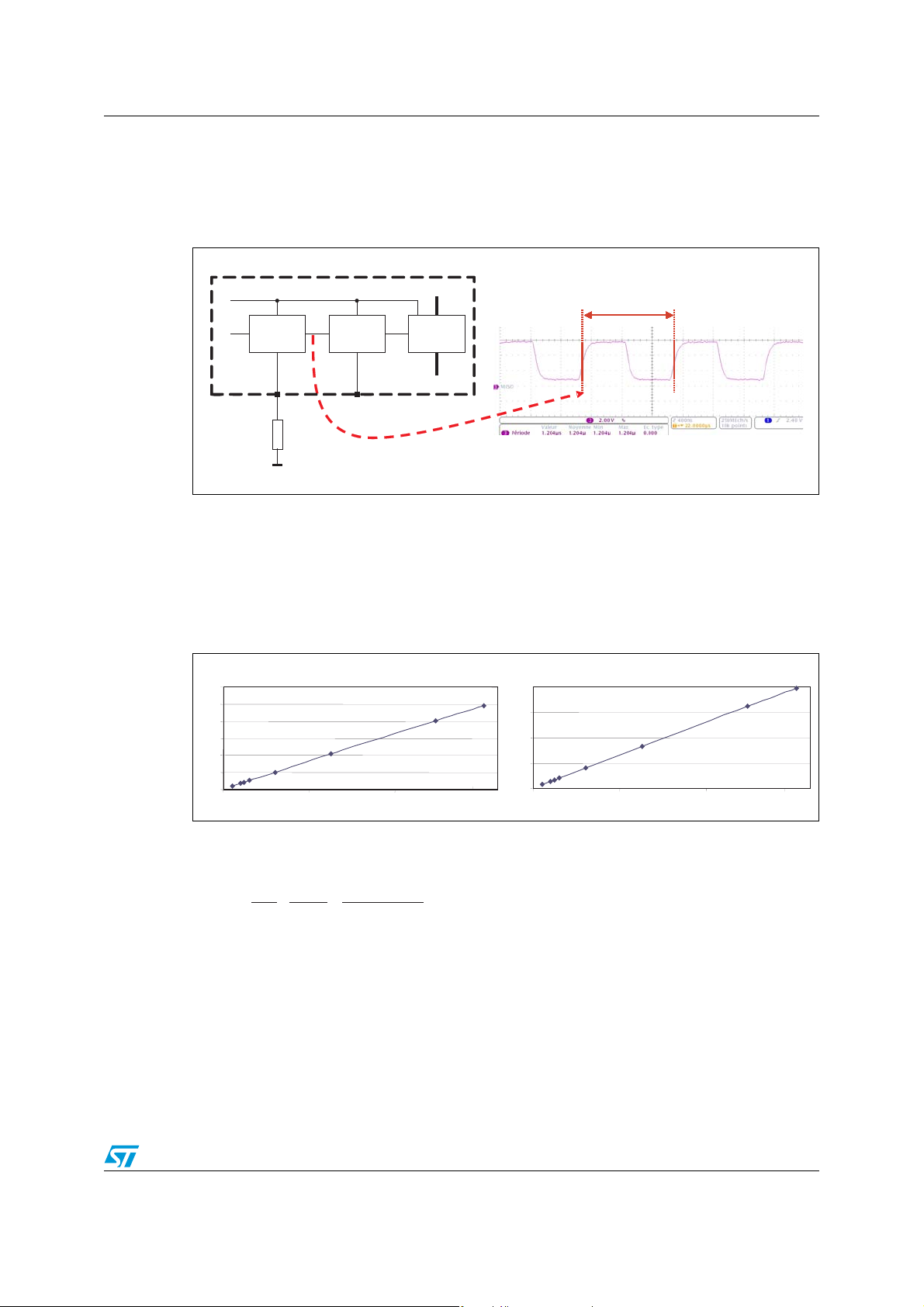

1.2.3 Digital input filter

Input parasitic disturbances can be removed by the programmable input digital filter. It is

based on an RC oscillator, a divider and a two step filter (see Figure 9).

Figure 9. Digital input filter.

CKF

IN<1:8>

OUT<1:8>

OSC period = 1.2 µ s

POR

REF1V

R

OSC

Oscillator

= 51 k

OSC

OSCR DVR

Divider filter_2step

The internal capacitor value is typically 10 pF. The oscillator resistor is connected externally

on pin R

when it is connected to V

least three rising edges as shown in Figure 9. The delay time is between 2 · t

3·t

OSC

. The clock divider is set at 8 when the pin DVR is connected to GND or at 64

OSC

. A wide filter time range, tFT, can be set by using the couple R

. The two step filter validates the input voltage when it sees at

DD

OSC

and DVR as

OSC

and

shown in below in Figure 10.

Figure 10. Minimum t

t (µS)

FT

600

500

400

300

200

100

0

0 500 1000 1500

FT

DVR=8

versus R

OSC

Rosc(k )Ω

t (µS)

FT

4000

3000

2000

1000

0

0 500 1000 1500

DVR=64

Rosc

(K )Ω

The user can also choose a particular typical filter time, tFT, by calculating the corresponding

R

value from the formula:

OSC

Math Composer 1.1.5

t

R

OSC

FT

2

××=

DVR

11

-

12

105.23

×

Doc ID 15130 Rev 1 9/35

Page 10

Application guidelines AN2846

1.2.4 Input signal frequency limitation

The maximum frequency transmitted trough the current limited inputs is limited by 3 factors:

1. The input digital filter, which cuts undesirable frequencies. R

DVR connected to GND ensures that the input signal has to be at a stable level for

more than 20 µs to be taken into account. This allows a maximum input frequency of

25 kHz. It can be reduced to 130 Hz using the combination of R

connected to V

2. The input capacitors C

signal. R

= 2.2 kΩ and CIN = 22 nF ensures a 3.2 kHz low pass filter.

IN

DD

.

are used to increase the EMI immunity filter of the input

IN

3. The SPI sampling effect - the input states are taken into account at each /CS fall (see

Section 1.4.4). This achieves a sampling of inputs at the /CS frequency, as shown in

Figure 11. The input states will be correctly transmitted if the sampling mode meets the

Shannon equation:

F2F

•=

InputCS/

Fwith

/CS

Input

1

=

t

/CS

=

/CS

frequencyinputmaxFwith

/CSthetwith:

periodsignal

Figure 11. Sampling effect

t

INPUT

set to 51 kΩ and

OSC

= 1.5 MΩ and DVR

OSC

Low level capture

missed

Current limited Input signal

/CS

High level capture

missed

t

/CS

As the /CS period is dependant on the frame length, Tab le 2 below gives some useful

combinations of SCK frequency signal, frame length and current limited input frequency.

Table 2. Input frequency versus SCK and length frame

F

SCK

Frame length 8 16 32 64 8 16 32 64 8 16 32 64 bits

t

/CS

F

current limited input

0.1 1.0 2.0 MHz

80 160 320 640 8 16 32 64 4 8 16 32 µs

6.25 3.125 1.56 0.78 62.5 31.25 15.6 7.8 125 62.5 31.25 15.6 kHz

10/35 Doc ID 15130 Rev 1

Page 11

AN2846 Application guidelines

1.2.5 Input state monitoring

The state of each of the 8 monitoring LEDs is an image of the 8 filtered input states. All the

monitoring LED cathodes have to be connected to ground. In the on state a current of I

reduced by 0.15 mA is available for each LED. In case of a LED not being used, the LED

output pin must be connected to the ground COM

to allow the input current to flow back to

P

the ground.

LIM

The LEDs must be chosen with a V

voltage less then 2.7 V (at minimum operating

F

temperature -25 °C).

1.3 Monitoring functions and regulator

1.3.1 VCC monitoring

The power bus voltage connected to VCC is sensed by the VCS pin through a resistor bridge.

The V

easily set their own alarm detection voltage by an appropriate resistor bridge (see

Figure 12) using the formula:

Figure 12. UVA comparator

threshold voltage is typically 1.25 V with a hysteresis of 100 mV. Designers can

CS

R

VV+=

min_

CSCC

S

)1(

R

PD

V

CC

R

S

V

CS

V

DD

UVA

R

PD

VBG=1.25V

For example, the resistor bridge consisting of R

activation when V

drops below 17 V. The UVA activation has no effect on SCLT3-8

CC

COM

= 1.5 MΩ and R

S

1ms delay

= 120 kΩ produces UVA

PD

behavior but the information is transmitted trough the SPI bus by setting bit 7 to low state in

the control bits register (see Figure 13 and Figure 14).

To eliminate any short voltage disturbances that could trigger the UVA, a 1 ms delay circuit

has been inserted in the output line of the UVA comparator.

Doc ID 15130 Rev 1 11/35

Page 12

Application guidelines AN2846

Figure 13. V

MISO

MISO

SCK

SCK

/CS

/CS

= 24 V, UVA bit not activated Figure 14. VCC = 16 V, UVA bit activated

CC

VCC= 24 V

MISO

MISO

SCK

SCK

/CS

/CS

VCC= 16 V

1.3.2 Power loss detection

For a greater voltage drop on VC, a power supply loss detection has been added. This

immediately sets MISO output at low level state when V

Figure 15 and Figure 16. The MCU can then interpret that if all bits are equal to 0, this

means that V

is too low.

C

Figure 15. Communication stops for VC < 8 V Figure 16. Communication resumes for

is below 8 V, as shown in

C

V

> 8.1 V

C

V

C

/CS

SCK

MISO

8.0 V

MISO goes to L

1.3.3 Overtemperature detection

When the junction temperature exceeds 150 °C an overtemperature alarm sets the MISO

bit 6 at low state in the control bits register. The SCLT3-8 remains operational. The MCU

receiving the alarm has to take the corrective actions. The alarm will be reset when the

junction temperature falls below 135 °C.

1.3.4 Internal voltage regulator 5 V

The input of this voltage regulator is internally connected to the VC pin. The voltage

regulator supplies the digital part of the SCLT3-8 and therefore it defines the high digital

level. It also supplies the sourced current available at pin MISO. It can also supply

application needs (such as opto-couplers and micro transformers) through pin V

current capability is 9 mA for a 3% voltage drop on V

/CS

SCK

MISO

(see Figure 17).

DD

8.1 V

. Its total

DD

12/35 Doc ID 15130 Rev 1

Page 13

AN2846 Application guidelines

Figure 17. Regulator output voltage

V versus I

5.1

5.0

4.9

4.8

4.7

4.6

4.5

V (V)

dd

dd dd

V -3%

dd

I (mA)

dd

9.0

Figure 18 shows the schematic diagram of a solution for applications where greater current

is needed. The bypass transistor allows extra current while maintaining a 5 V regulated

voltage (see Figure 19).

Figure 18. V

V

CC

SMAJ30A

booster schematic Figure 19. Load regulation with V

DD

R

2N2907A

E

R

C

I

RC

V

C

V

CS

IN

1

IN

2

IN

3

IN

4

SCLT3

R

LED

LED

LED

V

REF

DD

1

2

3

I

DD

VV

DD

V (V)

DD

5.100

5.050

5.000

4.950

4.900

4.850

4.800

0.00 5.00 10.00 15.00 20.00 25.00

0.00 5.00 10.00 15.00 20.00 25.00

V

booster

DD

DD

I (mA)

DD

The proposed circuit allows a 25 mA current load capability with a VDD regulation <2%. An

additional input protection device, like SMAJ30A, is needed to comply with voltage surges

because R

has to be reduced to limit the voltage drop across it.

C

The dissipated power in the bypass transistor PZT2N2907A is 550 mW.

Components used:

● PZT2N2907A (SOT223 with 1 cm

● R

= 330 Ω (1/8 W), RE = 51 Ω (1/8 W)

C

1.4 SPI functional description

Three registers (refer to Figure 1) are used to transfer input data and control data to the

16-bit data frame. The data frames are transmitted through four interface signals: /CS, SCK,

MOSI, and MISO.

Doc ID 15130 Rev 1 13/35

2

copper area)

Page 14

Application guidelines AN2846

∑

1N8 1N7 1N6 1N5 1N4 1N3 1N2 1N1

1

0 0

1 1

0 0

1

From

input

state

filter

1.4.1 Input state register and parity bit generator

After filtering, the 8 input termination states are stored in an 8-bit input state register. Its

content is an image of the filtered input states in real time.

Figure 20. Input state register and parity bit generator.

Filtered

Input

states

The SCLT3-8 has been designed to help diagnose incorrect data transmission. The four

parity bits generated by the parity bit generator are computed according to the input states

register content. They are updated each time the input state register content changes.

8 lines

Input state register

Parity

bits gen.

The parity bit 5 of PC1 register controls the 1 to 8 input data states; PC2-bit 4 controls inputs

5 to 8: PC3-bit 3 controls inputs 1 to 4;PC4-bit 2 controls inputs 3 to 6 according to the logic

equation:.

http://www.mathcomposer.com

n

INPUTstate

== odd.if0even,if1PC

See example in Figure 21.

The decoding of all the parity bit results will help the microcontroller detect the possible

corrupted pair of bits occurring during the transmission.

Figure 21. Parity bit generation example.

From

input

8 lines

state

filter

Input state register

8 lines

Parity

Bbits gen.

PC1

PC2

1

2

PC3

3

PC4

4

14/35 Doc ID 15130 Rev 1

Page 15

AN2846 Application guidelines

1.4.2 Data shift register and control shift register

Data and control shift registers are each 8 bits long. At each /CS falling edge all the data is

frozen and the 8 bits of the input states register are transferred to the data shift register (bits

8 to 15) while the control bits, consisting of four parity bits, overtemperature alarm bit,

undervoltage alarm bit and the stop bit, are transferred to the control shift register (bit 0 to

7).

The two last bits (bit 1 and bit 0) are always set respectively to 0 and 1 indicating the end of

data frame except in power loss case where all bits are set to 0.

Bit 15 will be the MSB and Bit 0 the LSB.

Figure 22. Data and control data shift registers.

8 Lines

Overtemperature

alarm

1.4.3 Digital inputs and outputs

These digital pins are involved with the SPI:

● /CS: Chip select input

● SCK: Serial clock input

● MISO: Master-in slave-out output

● /MISO: complementary MISO state

● MOSI: Master-out slave-in input (connected to ground when not used)

To improve the immunity of the digital inputs against noise, the digital inputs /CS, SCK and

MOSI have been designed to use a Schmitt trigger configuration. Each input is connected to

V

through a high impedance pull up resistor to set the input at high level state when no

DD

input signal is applied. Protection diodes are inserted with these pull-up resistors to prevent

the ESD reaching the V

. The digital input diagram is given in Figure 23.

DD

Input state register

8 lines

4 lines

Parity

bits gen.

Data shift register

Control shift register

Undervoltage

alarm

Doc ID 15130 Rev 1 15/35

Page 16

Application guidelines AN2846

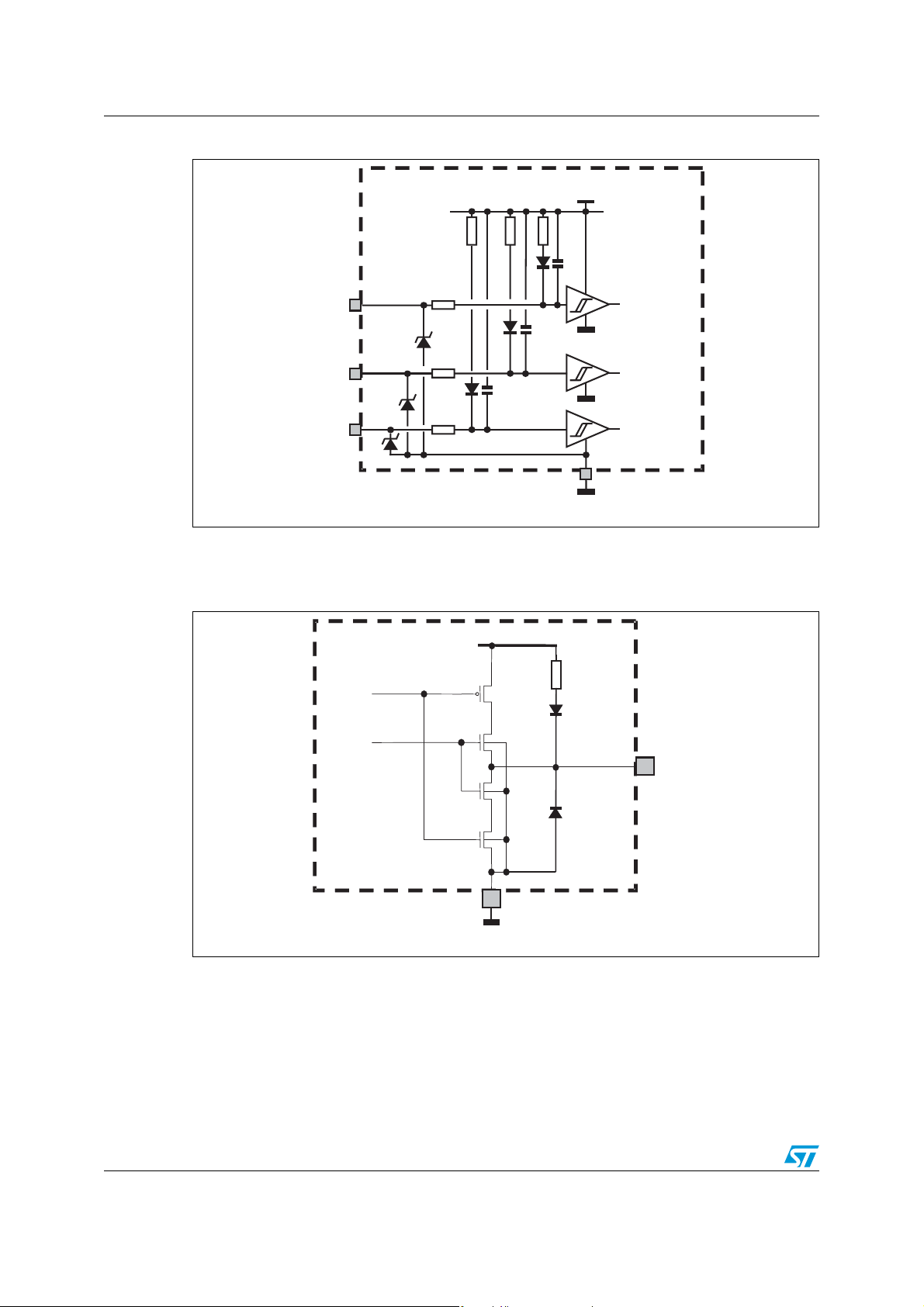

Figure 23. Digital inputs diagram.

V

DD

/CS

SCK

MOSI

COM

S

The digital output signal MISO is delivered through a high-Z impedance buffer able to

source or sink 3 mA.

Figure 24. Digital output MOSI

UVA

EN

M1

M2

V

DD

COMCOM

MOSI

S

16/35 Doc ID 15130 Rev 1

Page 17

AN2846 Application guidelines

1.4.4 SPI functionality

At the /CS falling edge the following operations are done:

● The input data states, parity and control bits are frozen and stored in the data and

control shift registers.

● The MSB (Bit 15) is shifted out first to MISO.

The SCLT3-8 data transfer uses SPI protocol with C

POL

= 0, C

= 0 conditions. This

PHA

means the SCK signal must be at low level state when the /CS is falling (communication

starts). In this case the MSB (bit15) is transferred first from MISO as soon as /CS falls, and

all the remaining bits are transferred at each SCK falling edge.

Figure 25. SCK and /CS synchronization security

/CS

/CS

SCK

SCK

MISO

MISO

Bit14

SCK is low when /CS falls

/CS

SCK

MISO

Bit14

SCK is high when /CS falls

For more flexibility the SPI protocol has been enhanced and takes into account the case

where SCK signal is at high level when /CS falls to low level. In this case, as previously the

MSB will be present at MISO pin at the /CS falling edge but the following bit will be available

only at the second SCK falling edge.

In both cases the rule is: a rising SCK edge must occur after the falling /CS edge to validate

the first SCK falling edge. Otherwise the state change duration of MISO may be too short to

correctly trigger the transmission of the MSB (bit 15) (see Figure 25).

In normal operation the two last bits are 0 and 1 indicating the end of the transmission.

The data transmission runs as long as the /CS is at low state. As soon as /CS returns to

high level, the data transfer is disabled and the MISO output is in high impedance - hi-Z.

When MOSI input is used in daisy chain operation, the inputs are captured at each SCK

rising edge and loaded into the shift register. Loaded data has no effect on the SCLT3-8.

Figure 26. 16-bit transmission example

/CS

SCK

MISO

10 1 01111111 0110110 1 01111111 01101

B15 B8 B7 B0

Input data bits Control bits

Doc ID 15130 Rev 1 17/35

Page 18

Application guidelines AN2846

Figure 26 shows a 16-bit transmission example when the application is running in good

conditions:

● Application is correctly supplied: /UVA, Bit 7 not activated

● SCLT3-8 junction temperature less than 150 °C: /OTA, bit 6 not activated

● Correct transmission: parity bits in accordance with input states

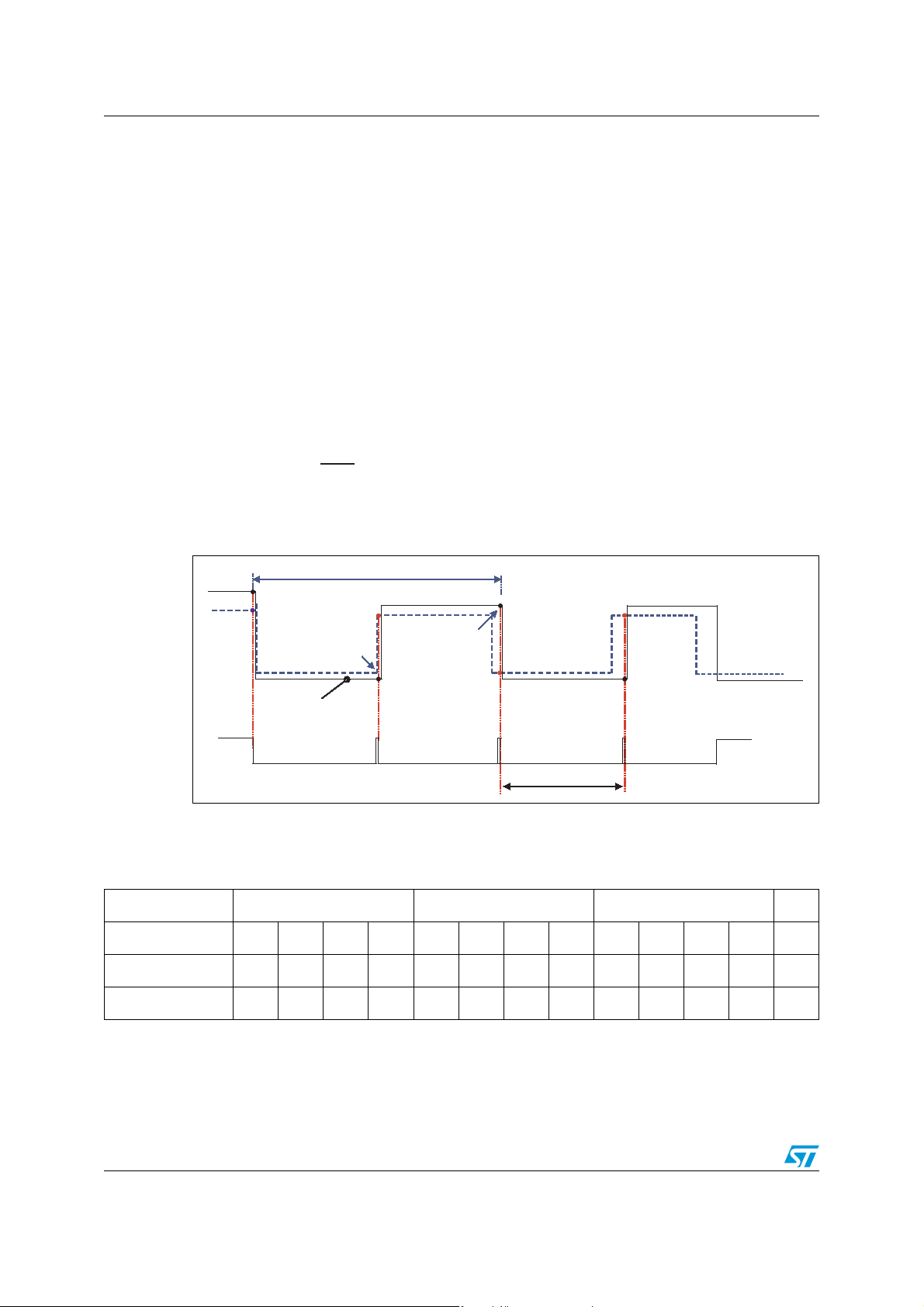

1.4.5 SPI timing definition

The four SPI signals involved: /CS, SCK, MOSI, MISO are described in Figure 27. A fifth

/MISO pin output signal is also present.

The typical SCK frequency is 1 MHz, but the SCLT3 can run at up to 2 MHz. The other more

important timing parameters are:

● t

: Delay time. This is the delay time of MISO between SCK falling edge and MISO

D

change.

● t

: Set up time. This is the minimum holding time of MOSI input data for its capture

S

before the SCK rising edge.

● t

: Holding time. This is the minimum holding time of MOSI input data after the SCK

H

rising edge for its correct capture.

The most important rules to meet to perform a correct data transmission are:

● t

● t

> tD + tS

CL

> tH.

CH

Figure 27. SPI timing definition.

/CS

SCK

MISO

MOSI

t

LD

t

A

12 16

t

t

D

MSB

S

t

C

t

DT

t

CL

CH t

t

t

S

H

LSB

HC

t

DIS

S

MSB

M

18/35 Doc ID 15130 Rev 1

Page 19

AN2846 Thermal dissipation calculation

2 Thermal dissipation calculation

2.1 Forward inputs polarity case

In reference to the application schematic defined in Figure 31, the dissipated power into the

SCLT3-8 P

Consider the worst case where all inputs are connected to 30 V.

P

= P1 - P2

SCLT

where:

P1 is the total power delivered by the supplies

P2 is the total power dissipated by the external components

can be calculated as following:

SCLT

P1 = V

External components are: R

Power dissipated by input resistors = 8 · R

· (IC + IDD + 8 · I

CC

)

LIM

, RC, LEDs, regulator load

IN

IN ·ILIM

2

Power dissipated by supply resistor = RC · (IC + IDD)2

Power dissipated by LEDs = 8 · V

Power supplied by the VDD linear regulator = V

The P

= 560 mW

SCLT

LED

· I

LED

REG

· I

DD

Assuming:

V

= 30 V, I

CC

= 2.35 mA, RIN = 2.2 kΩ, RC = 1.0 kΩ, V

LIM

LED

Note: The current flowing through the LED is almost the same as I

125 µA used to bias the input circuit device.

With the above mentioned conditions and using copper area of 1cm

SCLT3-8 junction temperature will be around 120 °C with an ambient temperature of 85 °C.

Figure 28 below shows the R

variations versus the heat sink area on a 35 µm FR4

TH_JA

epoxy single side board.

Figure 28. R

versus copper area

TH_JA

R (°C/W)

th(j-a)

120

HTSSOP38

= 2 V, VDD = 5 V, IDD = 7MA.

. The difference is about

LIMIT

2

as heat sink, the

SCLT

100

80

60

40

20

0

0 20 40 60 80 100 120 140 160 180

S (mm²)

Doc ID 15130 Rev 1 19/35

CU

Page 20

Thermal dissipation calculation AN2846

2.2 Reverse polarity on a single input case

Each input resistor can be connected to a reverse polarity down to -30 V. This case

corresponds to a connection mistake or a reverse biasing that is generated by the

demagnetization of a monitored inductive solenoid. The involved input can withstand a high

reverse current up to 20 mA. The corresponding state transmitted is low level. The other

inputs remain operational.

The power dissipated into a reverse polarized input is low, but attention has to be paid to

power dissipation into the input resistor which sustains almost all the reverse voltage.

2

P

dis_RIN

dis_RIN

()

=

7.0

-

V

I

R

IN

30

VP

ININ

Ω=-==

k2.2RandVformW390

2.3 Temperature gradient on the SCLT3 and on the board

Figure 29 shows the case top temperature when SCLT3-8 dissipates 600 mW, which

corresponds to maximum supply case with V

is 100 mm

2

, and the ambient temperature is 25 °C. In this example the maximum case top

temperature reaches 68 °C. The case top temperature is a good indication of the junction

temperature, which can be estimated using thermal analysis techniques.

and all module inputs at 32 V. The heat sink

CC

Figure 29. Case top temperature

R = 1.1 k

R = 2.2 k

Lens: G1

(Board paint in black)

Ω

C

IN

Ω

20/35 Doc ID 15130 Rev 1

Page 21

AN2846 Thermal dissipation calculation

Figure 30 shows the temperature gradient of the SCLT3-8 board with the same supply

conditions as above. Almost the totality of the power is concentrated around the SCLT3-8

and its heatsink. No particular temperature hot spot can be detected on the board.

Figure 30. Temperature gradient of the board

Profil 1Profil 1

Profil 1Profil 1

Doc ID 15130 Rev 1 21/35

Page 22

Application circuit AN2846

3 Application circuit

3.1 Basic SCLT3-8 board description

The basic electrical schematic diagram using a single SCLT3-8 fulfills the requirements

defined in the IEC 6131-2 standard. It is easy to duplicate this configuration to meet more

complex applications using many inputs and several SCLT3-8s.

The major settings are:

● Type 3 configuration

● 16-bit frame (SPM grounded)

● 16 µs digital input filtering (R

Figure 31. Type 3 application diagram

51k

33n

1.0k

1.5M

120k

22n

2.2k

22n

2.2k

22n

2.2k

J1

2.2k

2.2k

2.2k

2.2k

2.2k

22n

22n

22n

22n

DVR

OSC

SPM

COM

V

C

V

CS

COM

IN

IN

IN

IN

COM

IN

IN

IN

IN

COM

SCLT3-8

= 51 kΩ, DVR grounded)

OSC

V

DD

P

/CS

SCK

MOSI

P

1

2

3

4

P

5

6

7

8

P

/MISO

MISO

COM

R

REF

LED

LED

LED

LED

LED

LED

LED

LED

S

1

2

3

4

5

6

7

8

33n

10n10n

15k

220

220

470p

470p

J2

22/35 Doc ID 15130 Rev 1

Page 23

AN2846 Application circuit

3.2 Component definitions

The reference resistor R

tolerance gives the accuracy of the input limiters. 1% accuracy

REF

is suggested.

The typical type 3 SCLT3-8 application uses R

= 15 kΩ and RIN = 2.2 kΩ. Type 2 can be

REF

also achieved as shown in Tab le 3 .

The input MELF resistors are used to sustain high voltages occurring during surge tests.

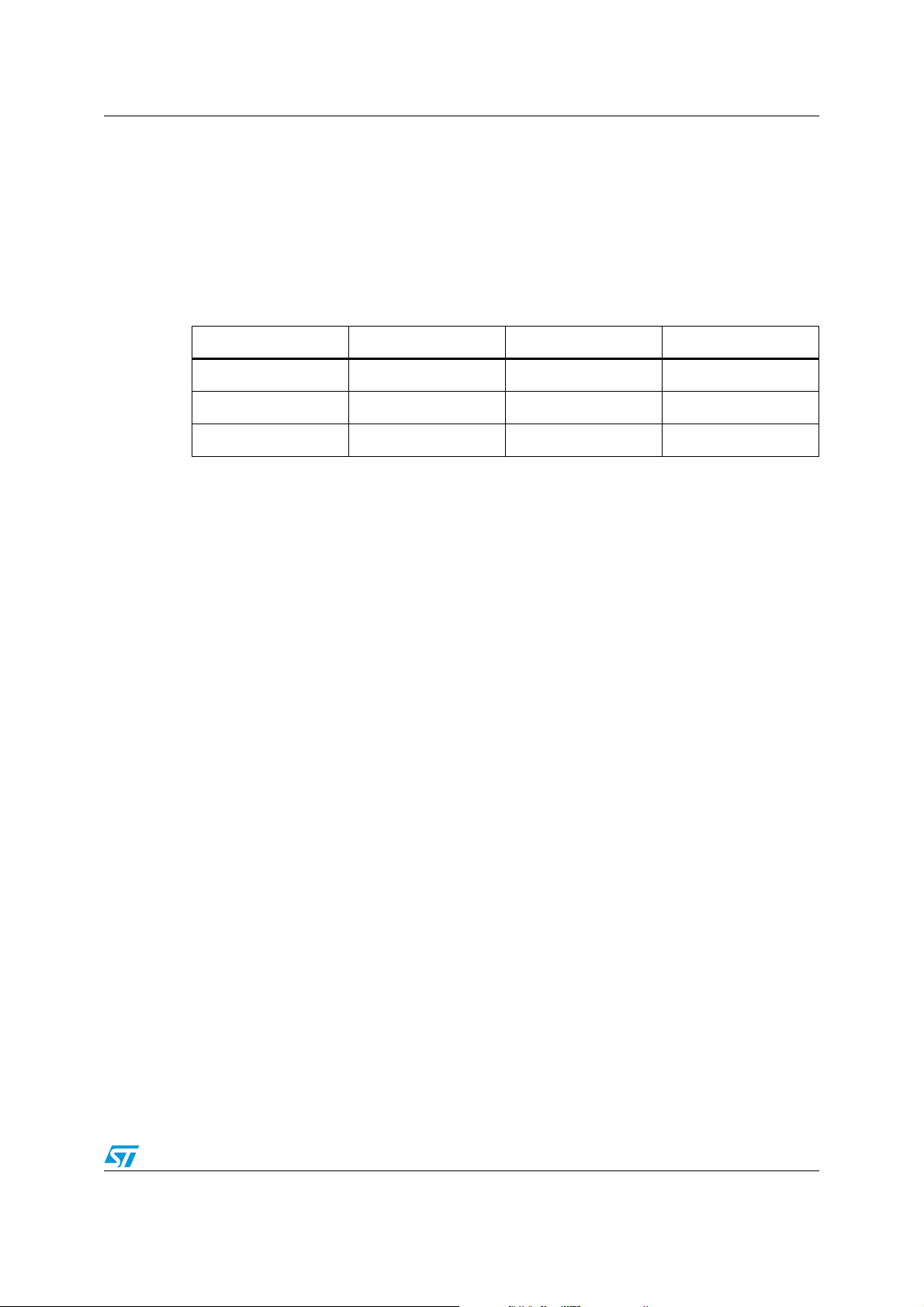

Table 3. Type 2 and 3 configurations

Typ e 3 Type 2 Un it

R

REF

R

IN

Typical I

LIMIT

Using type 2, the power dissipated by the SCLT3-8 reaches 1W with VI = VCC = 24 V. A

copper heat sink area of 1 cm

The R

value has to be chosen with attention. The voltage drop across this resistor is the

C

15 3.9 kΩ

2.2 0.75 kΩ

2.3 6.5 mA

2

will set TJ at 150 °C with an ambient temperature of 65 °C.

product of SCLT3-8 supply current and any load current supplied by VDD: regulator output

current and sourced MISO current. The resulting voltage V

must be in any case above the

C

8 V activation threshold to avoid a spurious power loss detection. 1 kΩ meets this

requirement and allows 2 kV of voltage surge.

The 22 nF input capacitors are used to improve the noise immunity of the whole module.

Their function is to filter the high frequency electrical noise, and to secure the off state of the

module.

Adding a 33 nF capacitor on V

pin ensures high immunity against electrical noise such as

C

that described in the IEC 61131-2 standard.

R

= 51 kΩ and pin DVR grounded set the input digital filter to eliminate pulse widths

OSC

below 20 µs.

A 33 nF capacitor connected on V

output ensures a good output of the voltage regulator.

DD

The LEDs must be chosen according to their input diode drop voltage. LED outputs can

drive LEDs with forward voltage up to 2.7 V.

Low pass RC filters have been inserted into digital inputs /CS and SCK to improve the

immunity against fast transient bursts. R = 220 Ω and C = 470 pF give a good compromise

between immunity result and SCLT-3 speed which can run up to 1 MHz.

Doc ID 15130 Rev 1 23/35

Page 24

Application circuit AN2846

3.2.1 Footprint

The footprint given in Figure 32 allows ground connection optimization of COMP and

COMP

Figure 32. Foot print (not to scale)

. The 1 cm2 heat sink area defines an R

S

TH-JA

of 80 °C/W.

8.80

0.65

1.35

0.6

Pin 1

Package footprint

2.575

6.10

0.4

5.00

11.35

0.25

3.425

1.30

S

= 100 mm

COPPER

Copper thickness : 35

3.50

0.6

Additional copper for extra-cooling

²

µm

24/35 Doc ID 15130 Rev 1

Page 25

AN2846 Isolation management

4 Isolation management

There are two solutions proposed for galvanic isolation between the SCLT3-8 and the

microcontroller.

● Opto-coupler isolation

● Magnetic digital isolation

4.1 Opto-coupler isolation

The first solution is given by opto-couplers which must run at a bit rate compatible with the

SCK frequency and meet SCLT3-8 requirements in terms of consumption.

HCPL4506 or HCPL0466 can be a solution to drive a single SCLT3-8 for a 1 MHz

application.

Figure 33. Single SCLT3-8 and HCPL4506 or 0466

V

DD

Ω

3k

V

CC

V

C

/CS

SCK

MOSI

/MISO

MISO

1 k

If several SCLT3-8s are used, more current is available through V

couplers. The different outputs V

can be tied together but, low serial resistors (22 Ω) must

DD

Ω

3k

Ω

HCPL4506

or 0466

750

750

V

DD2

3 k

DD

Ω

/CS

Ω

SCK

Ω

MISO

pins to supply the opto-

be inserted to balance the different regulated output voltages. The load current is shared

between the two SCLT3s and allows the voltage drop reduction across each R

resistor.

C

Doc ID 15130 Rev 1 25/35

Page 26

Isolation management AN2846

Figure 34 shows two SCLT3s in daisy chain configuration using ACPL-K73L (dual) and

ACPL-W70L (single).

Figure 34. Two daisy-chained SCLT3-8s and ACPL/K73L/W70L

V

V

DD

22

ACPL-K73L

750

750

ΩΩ

/CS

Ω

SCK

/CS

V

V

CC

V

V

CC

V

V

C

V

V

C

/CS

SCK

SCK

MOSI

MOSI

/MISO

/MISO

MISO

MISO

V

V

DD

/CS

/CS

SCK

SCK

MOSI

MOSI

/MISO

/MISO

MISO

MISO

22

1 k

Ω

V

DD2

Ω

MISO

HCPLK73L

HCPW70L

26/35 Doc ID 15130 Rev 1

ACPL-W70L

Page 27

AN2846 Isolation management

4.2 Magnetic digital isolator

The second solution is given by digital isolators. The triple-channel digital isolator

ADUM1301 is convenient for such an SCLT3-8 application. The sending channels V

V

are used for /CS and SCK signals while receiving channel VIC is used for MISO signal.

IB

The V

pin of SCLT3-8 can easily deliver the typical supply current needed by V

DD

is around 2.7 mA at 2 MHz as shown in Figure 35.

Figure 35. Digital isolator

V

V

DD

/CS

V

V

CC

V

V

C

/CS

SCK

SCK

MOSI

MOSI

/MISO

/MISO

MISO

MISO

V

DD

GND

VOA

VOB

VIC

NC

VE

GND

V

2

2

DD

GND

VIA

VIB

VOC

NC

2

2

VE

GND

DD2

1

1

1

1

and

IA

, which

SCLT3 -8

SCLT3 -8

ADuM1301

Doc ID 15130 Rev 1 27/35

Page 28

SCLT3-8 link configurations AN2846

5 SCLT3-8 link configurations

Parallel and daisy chain configurations can be implemented using SCLT3-8 or other devices

compatible with a serial peripheral interface.

In parallel mode the microcontroller selects the SCLT-8 with which it wants to communicate

by setting the corresponding /CS to low state as long as the communication lasts. The

microcontroller should be able to control as many /CS pins as SCLT-8s it wants to address.

While in daisy chain configuration the microcontroller commands at the same time all the

SCLT3-8s connected in series. The data must transit from SCLT3-8 to SCLT3-8 going out

from the MISO pin, going in through MOSI pin till reaching the last one connected to the

microcontroller. Considering n SCLT3-8s connected in daisy chain, the microcontroller has

to read n times 16 bits and the communication time is proportional to n times 16 bits.

Figure 36. Daisy-chain configuration Figure 37. Parallel configuration

MASTER SPI

SCK

MISO

MOSI

/CS

SCLT

SCK

MISO

MOSI

/CS

SCLT

SCK

MISO

MOSI

/CS

1

2

MASTER SPI

SCK

MISO

MOSI

/CS1

/CS2

SCLT

SCK

MISO

MOSI

/CS1

SCLT

SCK

MISO

MOSI

/CS2

1

2

28/35 Doc ID 15130 Rev 1

Page 29

AN2846 Electromagnetic compatibility (EMC) requirements

6 Electromagnetic compatibility (EMC) requirements

The SCLT3-8 has been designed to withstand electromagnetic interference as specified in

the IEC 61131-2 standard. This international standard gives all the requirements and

conditions for tests that must be performed on the programmable logic controllers (PLC) and

their associated peripherals. IEC 61000 4-2, 4-4, 4-5 and 4-6 standards define test

methods.

The current limited inputs and supply pins of SCLT3-8 are protected against high voltage

disturbances by a clamping circuits that are grounded to the common pin COM

with serial input resistances R

or RC (see Figure 38). These clamping circuits are effective

IN

against ESD (±8 kV contact), fast transient burt (±2.5 kV), and voltage surge (±1 kV).

Figure 38. Protection clamping circuits

R

IN

IN

1

IN

V

CC

V

C

Supply

39V

circuit

COM

P

COM

S

IN

IN

IN

IN

IN

IN

39V

2

39V

3

39V

4

39V

5

39V

6

39V

7

39V

8

39V

. Combined

P

Input

circuit

6.1 IEC 61000 4-2

This standard specifies the behavior of the device when subjected to electrostatic

discharges. The discharges must be applied to operator accessible parts. This means that

these tests have to be performed on each connector pin. The required levels are: air

discharge: ±15 kV, contact discharge: ±8 kV.

The system must continue to operate as intended after the discharge. Temporary

degradation of the performance is acceptable during the test, but the system must recover

by itself after the test (B criterion).

All SCLT3-8 pins are ESD protected.

COM

P

COM

S

Doc ID 15130 Rev 1 29/35

Page 30

Electromagnetic compatibility (EMC) requirements AN2846

6.2 IEC 61000 4-4

This standard specifies the behavior of the device when subjected to a fast transient burst.

The fast transient burst must be applied on all the input pins of the system. A capacitive

clamp-coupling device is used as described in the IEC 61000-4-4 standard. The required

sustainable burst voltage level is 2.5 kV. The system must continue to operate as intended.

No temporary degradation of the performance is acceptable during the test (A criterion).

New test methodology has been set up to check the frame integrity against fast transient

bursts. The need to monitor each bit level leads to using a scope isolated from the test

bench through optic fibers. The generation of /CS and SCK input signals are also isolated

through the same way as shown in Figure 39. Current and voltage level adaptation is done

through an optical fiber interface (OFI).

Long frames history can be stored in the monitoring scope for an easier detection of

disrupted bits.

The SCLT3-8 immunity has been increased by adding RC filter networks connected on /CS

and SCK input pins. But these RC filters act as low pass filters and limit the maxim data

transfer speed. For example the filter made of R = 220 Ω, C = 470 pF allows a 1 MHz

transmission frequency and ensures device FTB immunity up to 4 kV.

Table 4. Speed - FTB immunity compromise

RC Values SCK speed FTB immunity

220 Ω - 220 p

F 2 MHz 3 kV

220 Ω – 470 pF 1 MHz 4 kV

The test configuration is shown in Figure 39.

Figure 39. Two supplies configuration

Bat

FTB

generator

Bat

2

Capacitive clamp

SCLT3-8

1

/CS

SCK

MISO

OFI

/CS

SCK

MISO

Fiber optic cable

OFI

Generator

/CS

SCK

MISO

Scope

30/35 Doc ID 15130 Rev 1

Page 31

AN2846 Electromagnetic compatibility (EMC) requirements

Figure 40 shows the output MISO behavior is not disturbed during fast transient bursts. The

FTB signal has been captured through an antenna to observe where the bursts act.

Figure 40. Output MISO behavior during fast transient bursts

+ 4.0 kV

CS

/SCK

FTB

MISO

FTB 200 µs = 5 kHz

=

Figure 41. Test bench

HAEFELY

Bat2

FTB generator

Capacitive cl amp

SCLT3 board

Bat1

SCLT3 inputs, Gnd

OFI

Fiber

optic

cable

Doc ID 15130 Rev 1 31/35

Page 32

Electromagnetic compatibility (EMC) requirements AN2846

6.3 IEC 61000 4-5

This standard specifies the behavior of the device when subjected to voltage surges applied

on all input pins of the system. For all analog inputs, the coupling method is a 42 Ω serial

resistance and a 0.5 µF capacitor. For the DC power line, the coupling is 2 Ω resistor, and

18 µF capacitor. The required voltage surge levels are:

● 1 kV for the input pins with R

● 2.5 kV for the pin V

when RC = 2.2 kΩ or 1 kV when RC = 500 Ω.

C

The system must continue to operate as intended. Temporary degradation of the

performance is acceptable during the test, but the system must recover by itself after the

test (B criterion).

6.3.1 Results on input pins

When a positive surge voltage of 1 kV is applied on the input resistor RIN, the input active

clamp protects the SCLT3-8 input and limits the input voltage at 40 V. The input current

reaches 0.45 A.

When a negative voltage surge is applied the input diode is biased in forward mode and the

current is 0.45 mA (see Figure 42)

= 2.2 kΩ,

IN

Figure 42. V

+ 1.0 kV

V

surge

0.2kV/div

I

IN

0.2A/div

V

IN

20V/div

Positive voltage surge

and IIN behavior

IN

0.45A

40V

V

surge

0.5kV/div

I

0.2A/div

V

1V/div

-1.0 kV

C

0.45A

1V

C

Negative voltage surge

32/35 Doc ID 15130 Rev 1

Page 33

AN2846 Electromagnetic compatibility (EMC) requirements

6.3.2 Results on VC pin

When a positive or negative surge voltage of 1 kV is applied on the supply resistor RC, the

V

active clamp protects the SCLT3-8 input and limits the input voltage at 40 V. The current

C

reaches 0.45 A.

The wave shapes are similar to the previous ones as shown in Figure 43.

Figure 43. V

behavior with RC = 2.2 kΩ

C

+1kV

V

surge

0.5kV/div

I

C

0.2A/div

0.45A

40V

V

C

20V/div

Positive voltage surge

6.4 IEC 61000 4-6

This standard specifies the behavior of the device when subjected to conducted radio

frequency interference in the range 150 kHz to 80 MHz. The RF signal, 80% modulated by

1 kHz sinusoidal waveform, is injected at the inputs I

network (CDN). The required level defined into IEC 61131-2 is 3 V rms. With these stress

conditions, the system must continue to operate with no loss of function (A criterion).

V

surge

-

0.5kV/div

I

C

0.2A/div

V

C

1V/div

-1kV-1kV

0.45A

1V

Negative voltage surge

and VCC through a coupling device

IN

The test configuration used is shown in Figure 44.

Figure 44. RF test configuration

V

CWS500C

-6 dB

V

CC

Vi

CDN-AF2

IN

GND

CC

1-8

DUT

Scope

Reference plane

SCLT3-8 meets IEC 61000 4-6 and IEC 61311-2 standards requirements. Better immunity

can be obtained by decoupling pin SCK with a 470 pF capacitor.

Doc ID 15130 Rev 1 33/35

Page 34

Conclusion AN2846

7 Conclusion

This application note illustrates how designers can maximize SCLT3-8 performances in their

applications especially in the fields of bus controller interface configurations, thermal

behavior and EMI robustness. They will find information that helps them to design new

system boards while saving time.

Designed for digital I/O module in factory automation, the SCLT3-8 is a low-loss EMI-proof

solution showing high usage flexibility. With the SCLT3-8, designers will be able to develop

highly integrated modules interfacing proximity sensors with the following benefits:

● Reduced pin count

● Saved space (only 3 isolation devices for SPI)

● Reduced dissipation

● No need for additional LED supply

● Common SPI availability

● EMI proof

To illustrate its performances and advantages, an evaluation board STEVAL-IFP000V1

using 2 SCLT3-8s configured in daisy chain is available with an optimized layout.

8 Revision history

Table 5. Document revision history

Date Revision Changes

22-Feb-2010 1 Initial release.

34/35 Doc ID 15130 Rev 1

Page 35

AN2846

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2010 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 15130 Rev 1 35/35

Loading...

Loading...