Page 1

AN2835

Application note

70 W HID lamp ballast

based on the L6569, L6385E and L6562A

Introduction

This application note describes the electronic lamp ballast for 70 W high intensity discharge

(HID) metal halide lamps (MHL) used for general indoor applications. The ballast is

composed of a boost converter and an inverter. The inverter is realized by a full bridge driver

with a power control circuit.

The booster converter for power factor correction (PFC) is controlled by the L6562A

controller (U1). The inverter is a full bridge topology driven by two pairs of half bridge buck

converters, L6385E (U3) and L6569 (U4), with the constant power control circuit L6562A

(U2).

In this note the dual-buck converter is introduced. One works in high frequency and the

other works in complementarity with necessary dead time at a lower frequency.

Figure 1. The demonstration board

May 2010 Doc ID 15073 Rev 1 1/21

!-V

www.st.com

Page 2

Contents AN2835

Contents

1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 The selected solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 The dual-buck converter topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 The power control circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Ignition circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Description of demonstration board . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 The PCB layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Electrical schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.4 Bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Experimental results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1 Test with HID lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2/21 Doc ID 15073 Rev 1

Page 3

AN2835 List of figures

List of figures

Figure 1. The demonstration board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. The fundamental diagram for the HID lamp ballast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 3. The dual-buck converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 4. The timing chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 5. Input power, output voltage and input peak current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 6. Indirect constant power control circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 7. Average current sense circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 8. Ignition circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 9. Electrical characteristics of LIC01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 10. Demonstration board top-side view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 11. Demonstration board bottom-side view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 12. Schematic diagram of demonstration board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 13. Lamp current at warm-up state. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 14. Load with 30 W during warm-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 15. Load with 50 W during warm-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 16. Load with 100 W in steady-state. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 17. Load with 140 W in steady-state. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 18. Steady-state at 110 Vac input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 19. Steady-state at 220 Vac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 20. The timer circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 21. Lamp current during start up with HID lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 22. The lamp current in warm-up state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 23. The lamp current in steady-state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Doc ID 15073 Rev 1 3/21

Page 4

Safety instructions AN2835

1 Safety instructions

Warning: The demonstration board must be used in a suitable

laboratory by qualified personnel who are familiar with the

installation, use, and maintenance of electrical systems.

Intended use

The demonstration board is designed for demonstration purposes only, and must not be

used for domestic installations or for industrial installations. All technical data, including the

information concerning the power supply and working conditions, should only be taken from

the documentation included in the pack and must be strictly observed.

Installation

The installation instructions for the demonstration board must be taken from the present

document and strictly observed. The components must be protected against excessive

strain, and in particular, no components are to be bent, or isolating distances altered during

transportation, handling or use. The demonstration board contains electrostatically sensitive

components that are prone to damage through improper use. Electrical components must

not be mechanically damaged or destroyed (to avoid potential risk and personal injury).

Electrical connection

Applicable national accident prevention rules must be followed when working on the mains

power supply. The electrical installation must be carried out in accordance with the

appropriate requirements (e.g. cross-sectional areas of conductors, fusing, and PE

connections).

Board operation

A system architecture which supplies power to the demonstration board must be equipped

with additional control and protective devices in accordance with the applicable safety

requirements (e.g. compliance with technical equipment and accident prevention rules).

4/21 Doc ID 15073 Rev 1

Page 5

AN2835 The selected solution

2 The selected solution

2.1 The dual-buck converter topology

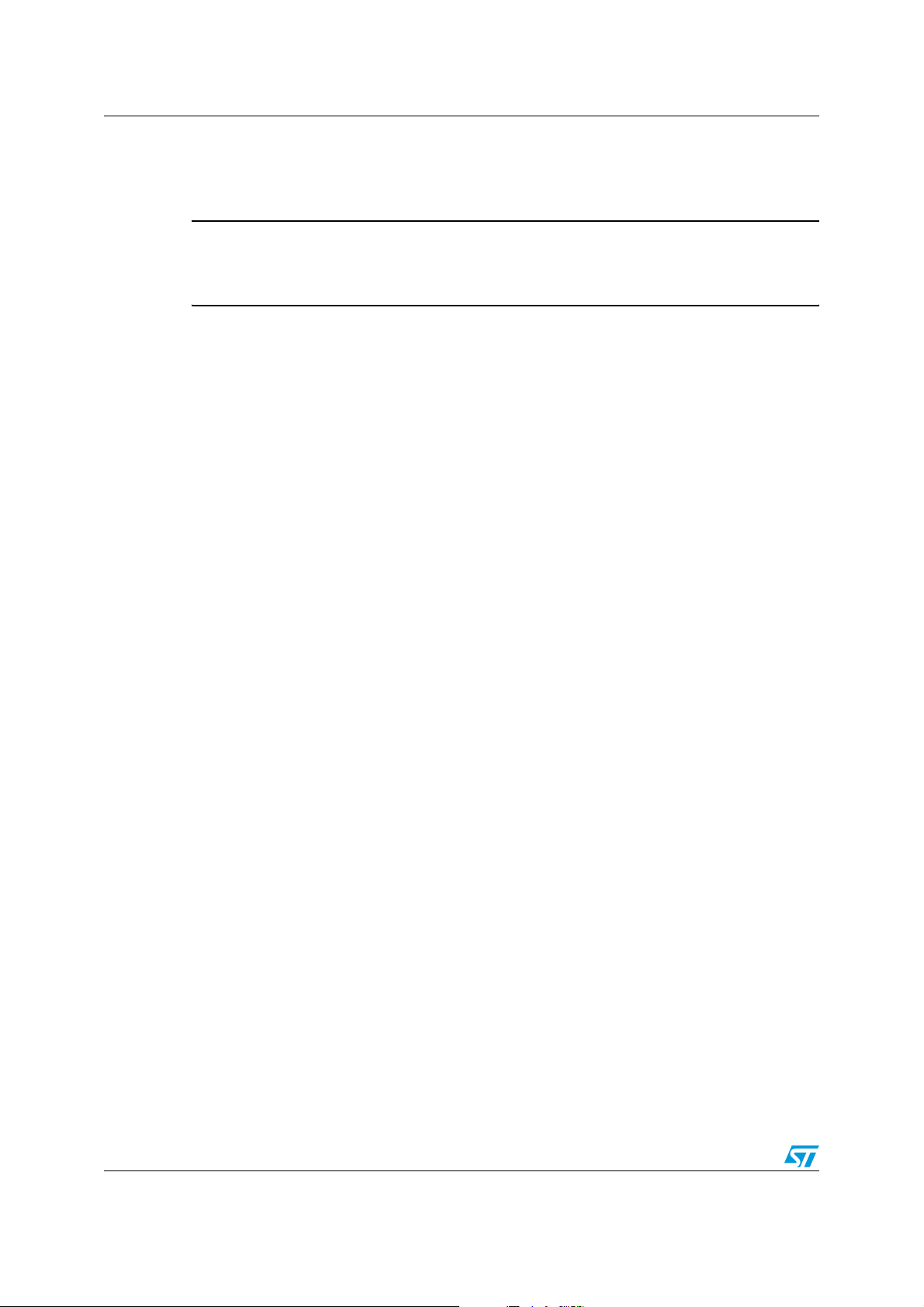

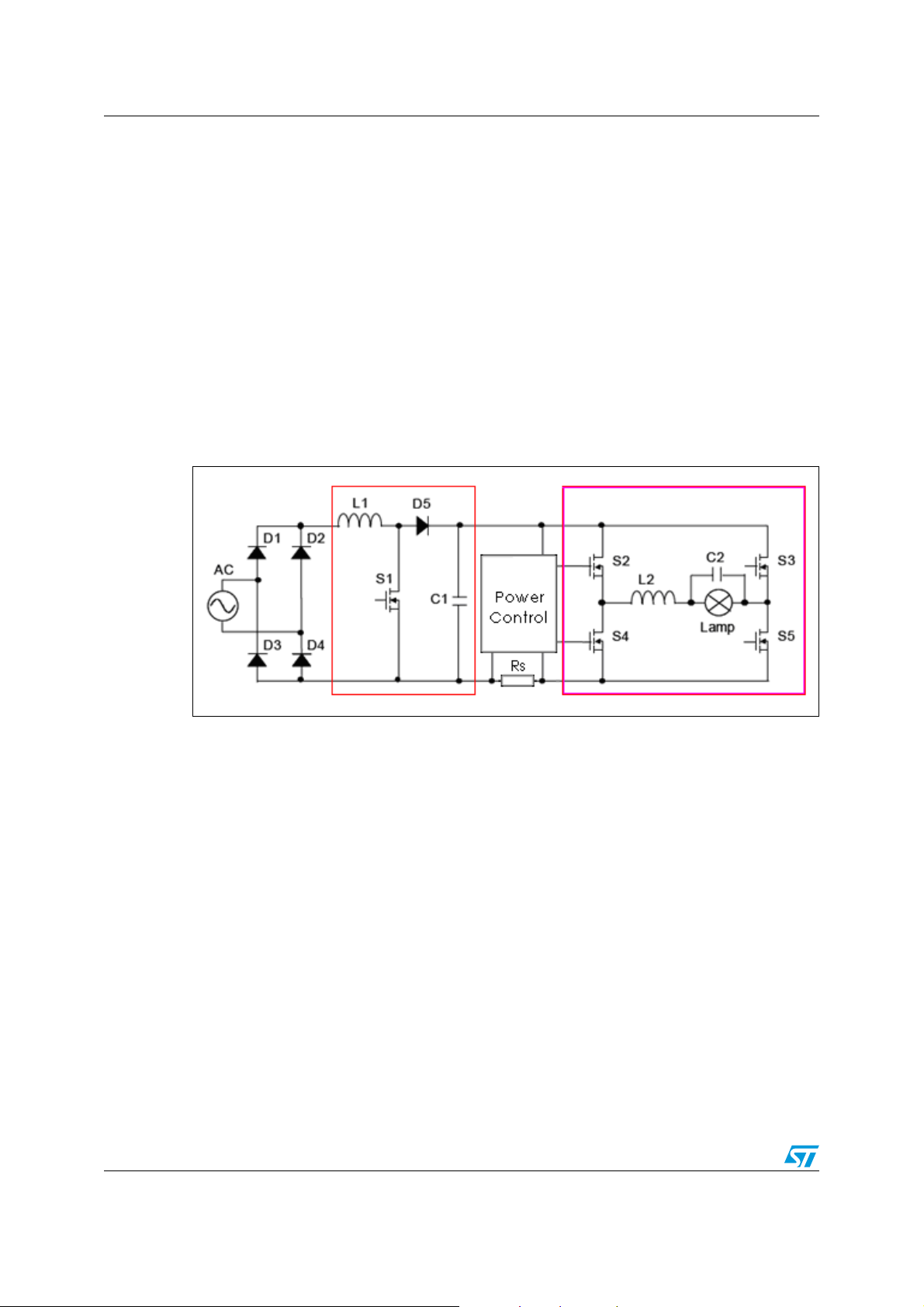

The fundamental application circuit in Figure 2 is composed of a PFC stage and a power

inversion stage. As the boost converter for power factor correction (PFC) is commonly used,

only the power inversion stage is introduced in this application note.

Figure 2. The fundamental diagram for the HID lamp ballast

!-V

The full bridge inverter consists of two half bridge buck converters. This is shown in

Figure 3. Both converters have the same L2 load, C2 and lamp. One of the buck converters

(S2 and S4) works in high frequency (several tens of kHz) and the second buck converter

(S3 and S5) works in complementarity with necessary dead time at a lower frequency (a few

hundred Hertz). This kind of full bridge stage is also called dual-buck converter.

Figure 3. The dual-buck converter

!-V

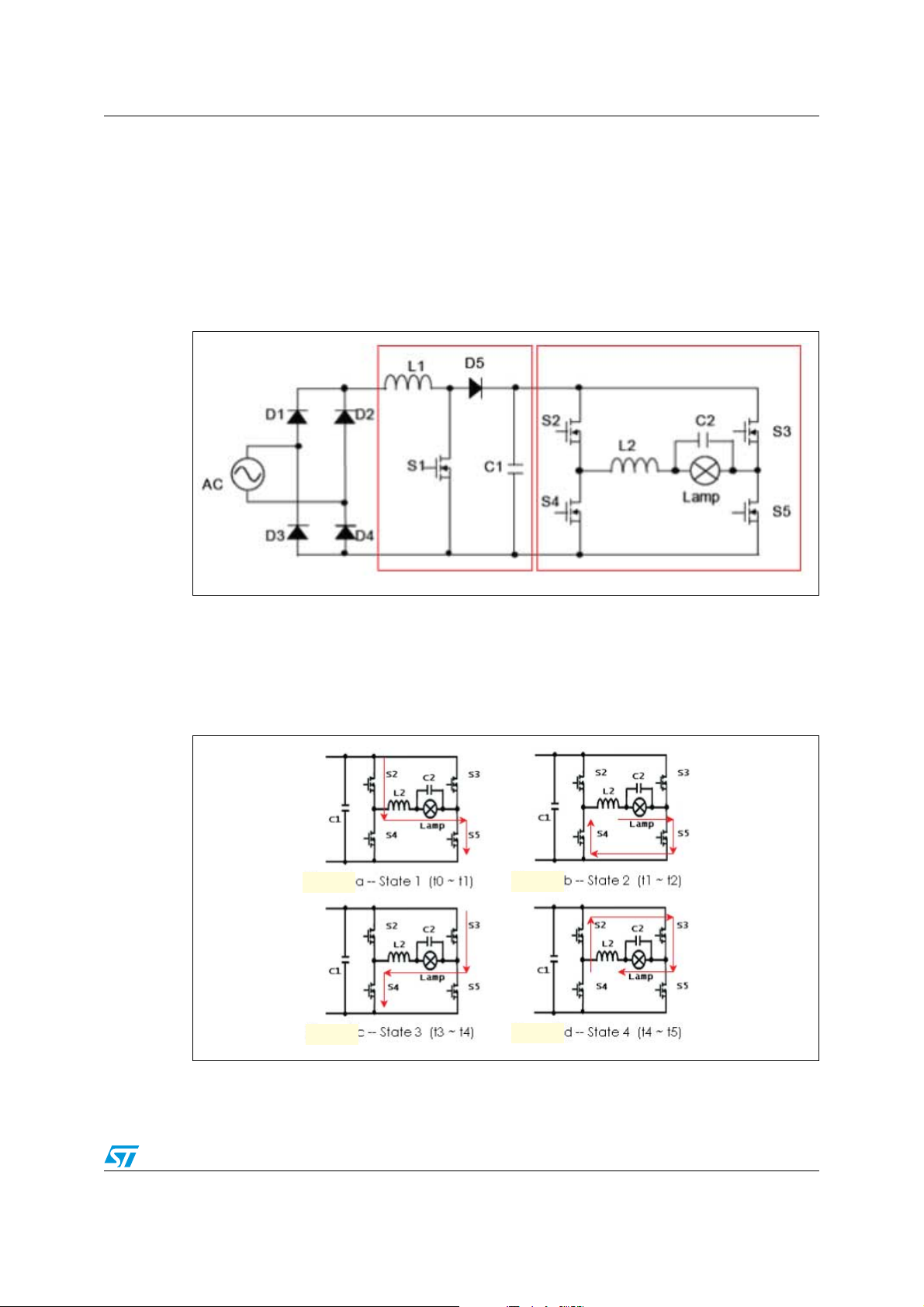

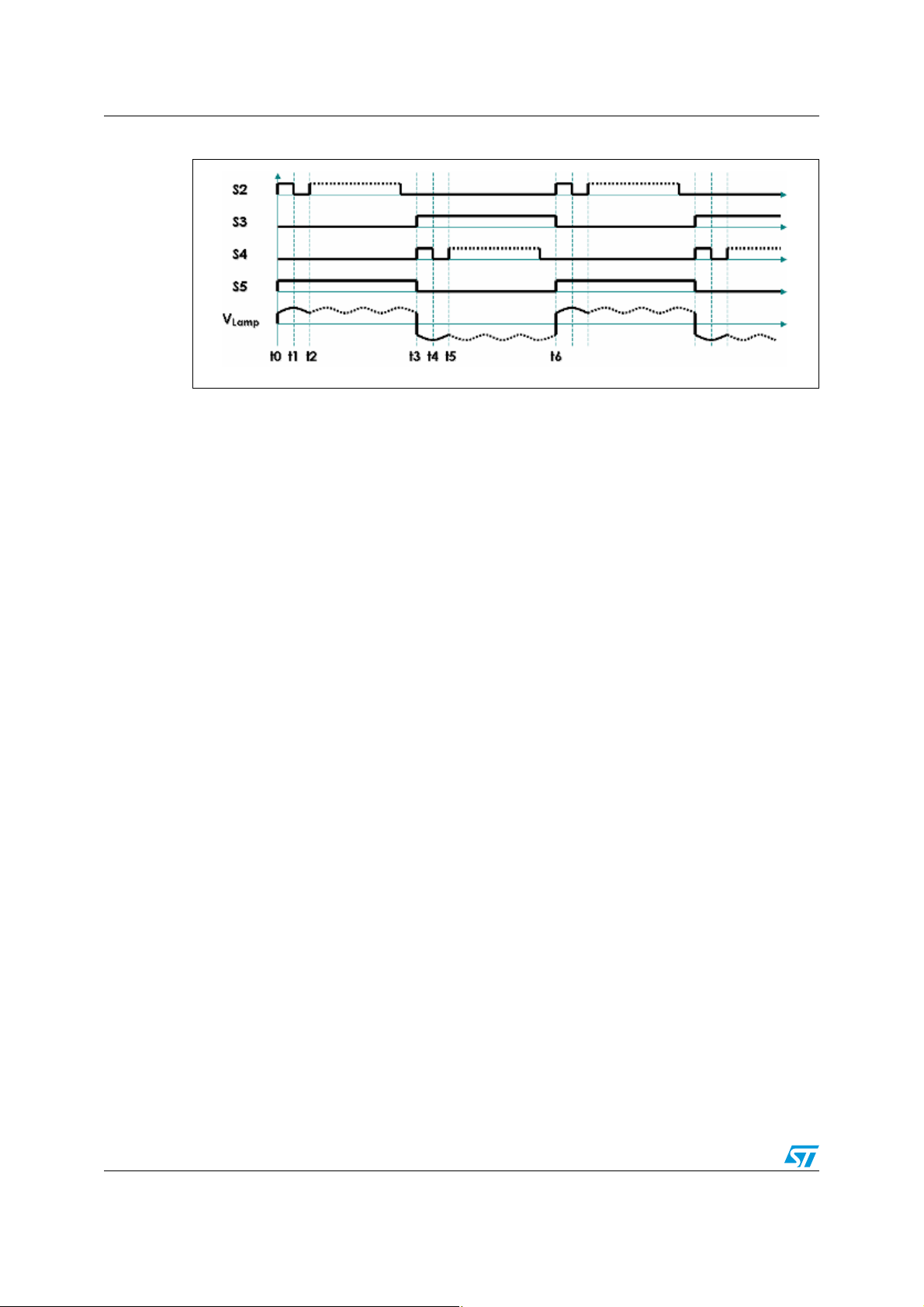

The timing diagram in Figure 4 indicates the relationship of a dual-buck converter and lamp

current.

Doc ID 15073 Rev 1 5/21

Page 6

The selected solution AN2835

Figure 4. The timing chart

!-V

Description of the four operating states

● State 1 in Figure 3a (from t0 to t1, see Figure 4):

– S3 and S4 in off-state, S2 and S5 are turned on, C1 discharges through S2, L2,

Lamp and S5. Certain energy stores to L2 and C2.

● State 2 in Figure 3b (from t1 to t2, see Figure 4):

– S3 and S4 remain in off-state. S2 is working in high frequency in off-state, and S5

is working in low frequency and remains in on-state. The energy of L2 and C2

keeps on releasing through Lamp, S5 and the reversed body diode of S4. As S2 is

working at a higher frequency, state 1 and state 2 is repetitive until the S5 is

turned-off at t3.

● State 3 in Figure 3c (from t3 to t4, see Figure 4):

– S2 and S5 in off-state, S3 and S4 are turned on, C1 discharges through S3, Lamp,

L2 and S4. Certain energy stores to L2 and C2.

● State 4 in Figure 3d (from t4 to t5, see Figure 4):

– S2 and S5 remain in off-state. S4 is working in high frequency in off-state, and S3

is working in low frequency and remains in on-state. The energy of L2 and C2

keeps on releasing through the reversed body diode of S2, then S3 and lamp. S4

is working at a high frequency from t3 to t6, therefore state 3 and state 4 is

repetitive until S3 is turned-off at t6. One full operating cycle is completed. Starting

from t6, the behavior of t0 is repeated again. From the above analysis, we realize

the lamp current flow to this dual-buck converter, and loads to the same L2

inductor, C2 output capacitor, and HID lamp. The lamp current at state 3 and state

4 is in the opposite direction.

2.2 The power control circuit

There are two main functions of the power control circuit. One is constant current control

during warm-up and the other is constant power control during steady-state operation.

● Constant current control

6/21 Doc ID 15073 Rev 1

Normally, the lamp current is higher during the warm-up stage than when working at

steady-state. But a warm-up current that is too high may cause the electrode to decay

and shorten the operating life of the lamp. If warm-up current is too low, the time to

steady-state is postponed. Therefore providing a value with 20% higher than the rate of

warm-up current during warm-up time is respected. The constant current control is

Page 7

AN2835 The selected solution

realized by controlling the peak inductor current of the dual-buck converter. Assume the

input voltage of the buck converter is V

input peak current is I

, as the buck converter is working at a critical discontinuous

in_pk

, the output voltage is Vbo, the duty cycle is D,

bi

mode, and the average input current is:

Equation 1

1

-- -

I

in

D⋅=

I

inpk

-

2

And the duty cycle is:

Equation 2

V

bo

D

---------=

V

bi

The input power becomes:

Equation 3

P

inVbiIin

⋅=

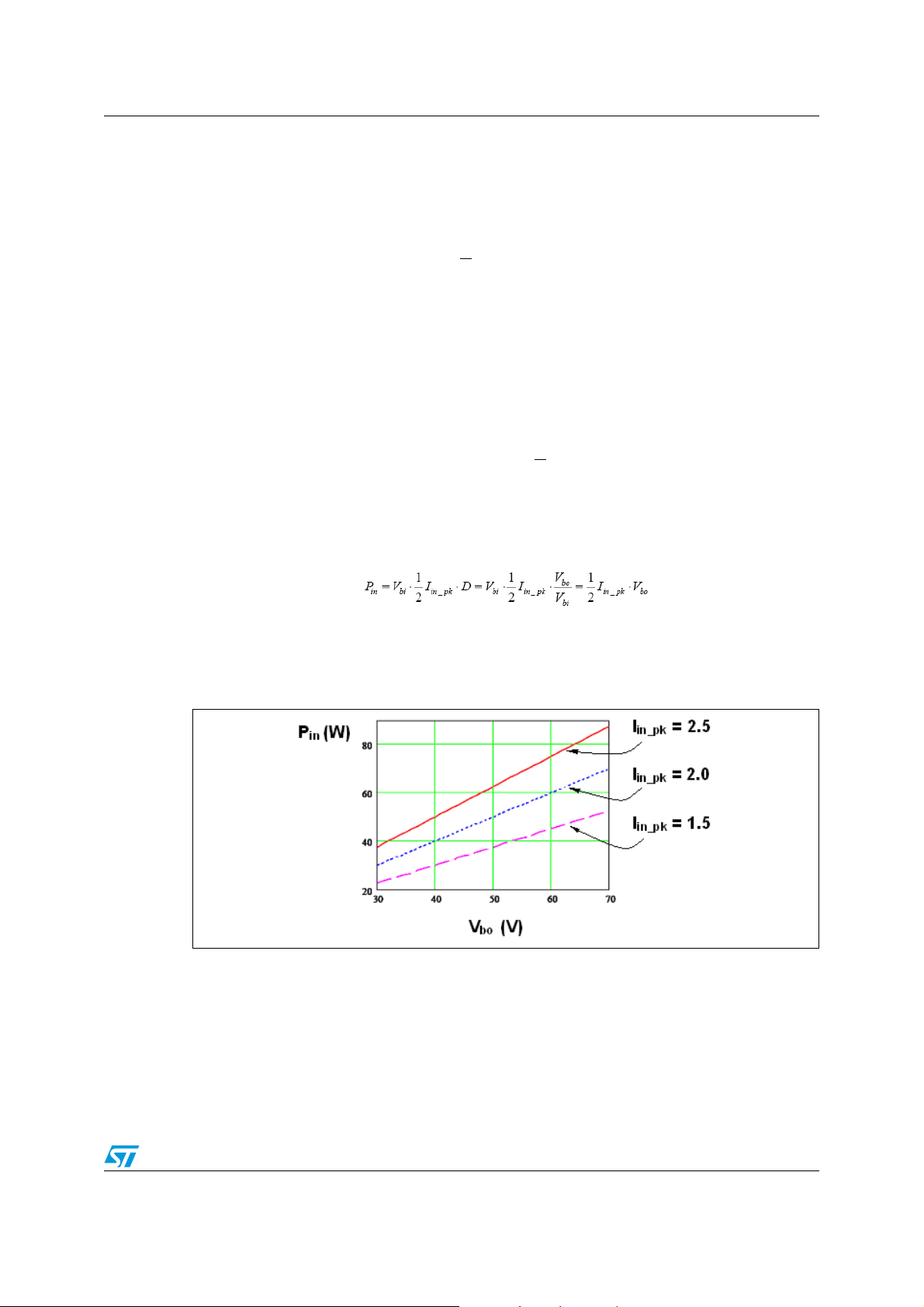

Thus the relationship between the input power (P

voltage (V

bo

) is:

), input peak current (I

in

) and output

in_pk

Equation 4

If the lamp is operating with a constant current source, once input peak current (I

selected, we observe the input power (P

) is proportional to the output voltage (Vbo).

in

in_pk

Despite the power losses, the output power is also proportional to the output voltage.

Figure 5. Input power, output voltage and input peak current

) is

!-V

In Figure 5, there are three different I

curves, this helps to choose the proper input peak

in_pk

current according to the different types of lamp. After warming-up, the lamp voltage

increases slowly to the minimum value of the rated power, the duty cycle increases

accordingly. And then the input peak current decreases. In order to power up the lamp in

steady-state, the circuit changes from constant current control function to constant power

control.

Doc ID 15073 Rev 1 7/21

Page 8

The selected solution AN2835

● Constant power control circuit

In this solution, the voltage on pin 3 of U2 (L6562A) is fixed, therefore, during the warmup time, pin 2 of U2 is clamped at its upper threshold, so the input peak current

detected by pin 4 is also fixed. Once the lamp power increases with the lamp voltage

increase, pin 2 decreases accordingly, the lamp works at a constant power state.

Constant power control assures the output power is constant and stabilizes lamp

luminosity without flicker. The lamp operates at the best rated lamp power. Here is an

indirect method to perform the constant power control for the lamp. As shown in

Figure 6, an Rs resistor is connected between the PFC stage and the full bridge stage.

If the output voltage of the PFC stage is constant, it means the current of Rs is

constant. With the proper controlling of the average current flow through Rs, the current

sources from the boost converter (PFC stage) become constant, and the output power

in full bridge stage is also constant, assume the power losses of the dual-buck

converter (full bridge stage) is constant. Therefore the lamp power has constant control

indirectly.

Figure 6. Indirect constant power control circuit

!-V

The average current sense circuit is shown as Figure 7. R1 and C3 is the filter used to

obtain the average voltage on Rs. The Vf feedback signal is generated to control the on-time

of the dual-buck converter. In practice, the operating lamp voltage and current change

according to the age of the lamp, but the change in power loss to the dual-buck converter is

very small and therefore negligible. This indirect method achieves good performances in a

low power application.

8/21 Doc ID 15073 Rev 1

Page 9

AN2835 The selected solution

Figure 7. Average current sense circuit

!-V

2.3 Ignition circuit

A high voltage is required to ignite the HID lamp. The ignition voltage depends on the type of

HID lamp. For a MHL (metal halide lamp) it is about 3-5 kV. For a hot lamp re-striking needs

about 20 kV. Immediate re-ignition of a hot lamp is not advised. Therefore, a cooling down

period for hot lamps is recommended. The ignition circuit is shown in Figure 8. The pulse

transformer (T1) is used to give the ignition pulse. The LIC01 is specially designed for high

voltage pulse generation purposes. At the beginning of turn-on S, with LIC01 in off-state,

bus voltage Vdc charges to C1 through R1 until it reaches the breakdown voltage (V

Figure 9) of LIC01. Once LIC01 breaksdown, C1 discharges and the crowbar current

occurs. LIC01 is latched to on-state. The LIC01 is turned off when discharging a current

lower than the holding current (IH). Then LIC01 returns to the off-state. In such a case, a

voltage pulse is generated on Lp. With the turn ratio 1:n of T1, the high voltage across C2 is

generated and remains constant for a very short time. Therefore the lamp obtains a high

voltage pulse to ignite. LIC01 returns to the off-state after C1 discharges and another

charging to C1 is restarted. After the lamp is ignited, S is turned off and there is no more

voltage pulse generation on Lp.

BO

in

Figure 8. Ignition circuit Figure 9. Electrical characteristics of LIC01

!-V

Doc ID 15073 Rev 1 9/21

!-V

Page 10

Description of demonstration board AN2835

3 Description of demonstration board

3.1 Specifications

The demonstration board is designed with open-lamp protection, specifications are shown in

Tab le 1 .

Table 1. Specifications

Parameter Value Unit

Line voltage range 88 to 264 Volt

Line frequency 50 or 60 Hz

Load with HID lamp 70 Watt

Lamp rate voltage 85 Vrms

Power factor 0.98 minimum -

Efficiency 0.88 minimum %

3.2 The PCB layout

Figure 10. Demonstration board top-side view

Figure 11. Demonstration board bottom-side view

!-V

10/21 Doc ID 15073 Rev 1

!-V

Page 11

AN2835 Description of demonstration board

3.3 Electrical schematic

Figure 12. Schematic diagram of demonstration board

VBB

R29

680

Q9

MMBT2 22 2

R28

C23

1u

132

LIN

HIN

Vcc

VCC1

Vboot

8

7

1.5u

C24

R31

1

VS1

CT

Q2

STP12NM5 0FD

L6385ED

U3

4

GND

LVG

OUT

HVG

6

5

20

VS2

CT2

3

4

3

4

2

1

2

1

R26

VBB

R30 20

C19

Q3

STP12NM5 0FD

VCC1

1.1mH

L4

ZCD

Vig 2

C12400V 0.47u

Vig 1

C13400V 0.47u

LAMP

Q5

STP9NK5 0Z

Z

Q4

R16

200

STP9NK5 0

C15 1u

VCC1

C16

R14

450V 47u

Vbu s

D2

STTH2L06

C11

R9

82k

R8

1M

0.47

R12

0.47

FD

3

2

L3

1

Q1

R7

3

2

1

4

20

STP12NM50

4

C3

0.47u

D1

Bridge

C4

C2

0.22u

100

R5

L2

D4

C1

L1

0.22u

VCC

Fuse

FUSE1

10K

10K

Q8

MMBT2 22 2

680

R27

VCC1

R21

24k

1u

1

2

3

6

7

L6562A

4

8

5

U2

*

1u

C18

R20

20K

D10

R24

D9

1N4148

C21

R18

2V

4.7k

4.7k

R25

5.1k

R22

R23

1.8k

1n

C22

100n

R19

1K

910

R35

150K

2k

68K

R33

R34

R32

2

3

U5A

36K

VCC1

8

A

1

Start

4

LM35 8D

C20 100n

360

ZCD

Q11

D14

200

VS2

D13

VBB

R17

VCC1

6

5

7

U4

8

Vboo t

1

Vcc

1u

C7

R11

62K

VCC

1u

R132

R4 100

1N4148

D6

L6569A

LVG

HVG

OUT

4

GND

Cf

Rf

3

2

C17

100n

R15

36K

6.8K

R10

680n

4

1

12k

330n

C8

R6

D3

R3

330K

R1

R133

270K

270K

R13

270K

VCC

1N4148

D5

C5

50V 47u

2

87

1N4148

C9

33u

1.5M

D7

1N4148

VCC1

65L6562A

3

C10

15V

D8

15V

2N7002

1N4148

1N4148

Q10

R36

2k

R37

VBB

U1

C6

10n

VCC1

10K

R2

20V 33u

R39

Q12

D12

1N4148

2N7002

D11

1N4148

VS1

2N7002

200

R38

200

Vig 2

Vig 1

2

1

2

1

4

3

T1

Tran s

4

3

2

2

1

Q13

*

1

10K

R49

Vbu s

2k

R41

D15

1N4148

R40

10k

Q6

STQ3NK50ZR-AP

C29

630V 0.1u

R48

100

7

LM358D

U5B

1u

C25

R42

4

8

B

6

5

R43

Start

1k

10k

VAC

INPUT

AM01613v1

Doc ID 15073 Rev 1 11/21

Page 12

Description of demonstration board AN2835

3.4 Bill of material

Table 2. Bill of material

Name Value Rated Type

C1, C2 0.22 µF 275 V

Panasonic

ECQU2A224KL

C3, C12, C13 o.47 µF 400 V Falatronic CL21

C4 1 µF

C5, C9, C10 47 µF 50 V

C6 10 nF SMD (0805)

C7 680 nF SMD (0805)

C8 330 nF SMD (0805)

C9, C10 33 µF 20 V Tantalum

C11 47 µF 450 V

C15, C16, C18,

C19, C23, C25

1 µF SMD (0805)

Panasonic

EEUEE2W470S

C17, C20, C22 100 nF SMD (0805)

C14, C21 1 nF SMD (0805)

C24 1.5 µF SMD (0805)

C29 0.1 µF 630 V Falatronic CBB21

R1 1.5 mΩ SMD (0805)

R2, R26, R40, R42 10 kΩ SMD (0805)

R3 330 kΩ SMD (1206)

R4, R5 100 Ω 1 W

R6 12 kΩ SMD (0805)

R7 20 Ω SMD (0805)

R8 1 MΩ SMD (0805)

R9 82 kΩ SMD (0805)

R10 6.8 kΩ SMD (0805)

R11 62 kΩ SMD (1206)

R12, R14 0.47 Ω 1 W

R13, R132, R133 270 kΩ SMD (1206)

R15 36 kΩ SMD (0805)

R16, R17, R37, R38 200 Ω SMD (0805)

R18 910 Ω SMD (0805)

R19, R43 1 kΩ SMD (0805)

R20 20 kΩ SMD (0805)

12/21 Doc ID 15073 Rev 1

Page 13

AN2835 Description of demonstration board

Table 2. Bill of material (continued)

Name Value Rated Type

R21 24 kΩ SMD (0805)

R22 5.1 kΩ SMD (0805)

R23 1.8 kΩ 1% ¼ W SMD (0805)

R24, R25 4.7 kΩ SMD (0805)

R27, R29 680 Ω SMD (0805)

R28 10 kΩ SMD (0805)

R30, R31 20 Ω SMD (0805)

R32 2 kΩ 1%

R33 68 kΩ 1%

R34 36 kΩ 1%

R35 150 kΩ 1%

R36, R41 2 kΩ

R39 360 Ω

R44, R45, R46, R47 N.C.

R48 100 Ω

R49 10 kΩ 1 W

D1 2KBP06 2 A, 600 V Bridge rectifier

D2 STTH2L06 Ultra-fast diode STMicroelectronics

D3, D7, D9, D11, D12, D13, D14, D15 1N4148 Mini MELF

D4, D5 1N4148 DO-35

D6, D8 15 V Zener diode 15 V Mini MELF

D10 2 V Zener diode 2 V Mini MELF

D16 N.C.

Q1, Q2, Q3 STP15NM60ND Power MOSFET STMicroelectronics

Q4, Q5 STP9NK50Z

Q6 STQ3NK50ZR

Zener protected

MOSFET

Zener protected

MOSFET

Q7 N.C.

Q8, Q9 MMBT2222 SOT-23

Q10, Q11, Q12 2N7002 Power MOSFET STMicroelectronics

Q13 LIC01-215H Light ignition circuit STMicroelectronics

U1, U2 L6562AD Power controller STMicroelectronics

U3 L6385ED HB driver STMicroelectronics

U4 L6569AD HB driver STMicroelectronics

STMicroelectronics

STMicroelectronics

Doc ID 15073 Rev 1 13/21

Page 14

Description of demonstration board AN2835

Table 2. Bill of material (continued)

Name Value Rated Type

U5 LM358D comparator STMicroelectronics

FUSE 1 500 mA

CT1, CT2 CT101 TDK CT101

L1 200 µH 2 A TDK SF-T8-60L-02-PF

L2 7.5 mH 1.5 A

L3

L4

T1

(1)

(2)

(3)

600 µH inductor

1.1 mH inductor

400 µH transformer

TDK HF2318-

A752Y1R5-01

1. Core: PC40EF25-Z or equivalent; bobbin: EF-25; winding: AWG30*4, 100 turns and AWG29*2,8 turns; air gap: about 1 mm

2. Core: PC40EF25-Z or equivalent; bobbin: EF-25; winding: AWG27*2, 150 turns; air gap: about 1.8 mm

3. Core: PC40EF25-Z or equivalent; bobbin: EF-25; winding: ~; air gap: about 1 mm

14/21 Doc ID 15073 Rev 1

Page 15

AN2835 Experimental results

4 Experimental results

Figure 13 shows the lamp current during start up. This warm-up current is higher than the

steady-state current. This current should be constant during the warm-up stage (the circled

area) before it enters the steady-state. During warm-up, the equivalent resistor for a 70 W

HID lamp can vary from 20 Ω to 70 Ω.

Figure 13. Lamp current at warm-up state

Since the HID lamp needs constant current control during the warm-up state and constant

power control during steady-state, designers, therefore, used a 30 Ω and 50 Ω dummy load

to evaluate the performance of the warm-up state. Figure 14 is the test with a 30 Ω dummy

load and Figure 15 is the test with a 50 Ω dummy load. Obviously the current values during

warm-up equal 1.1 A constantly, and therefore the constant current control is well achieved.

Figure 14. Load with 30 Ω during warm-up Figure 15. Load with 50 Ω during warm-up

!-V

Upper: Output voltage 50 V/div

Lower: Output current 1.0 A/div

Upper: Output voltage 50 V/div

Lower: Output current 1.0 A/div

!-V

!-V

For constant power control to the 70 W HID lamp, the rated voltage of the lamp is 85 V and

the rated current is 0.82 A. Therefore, the equivalent resistor for the lamp equals 103.6 Ω.

As the equivalent resistor for a new or old lamp varies, the typically varied range can have a

Doc ID 15073 Rev 1 15/21

Page 16

Experimental results AN2835

!-V

!-V

20% difference to the rated value. Therefore a 100 Ω and 140 Ω dummy load is chosen for

constant power evaluation on bench. Please refer to Figure 16 and 17 for test results of the

lamp voltage and lamp current.

Figure 16. Load with 100 Ω in steady-state Figure 17. Load with 140 Ω in steady-state

!-V

Upper: Output voltage 100 V/div

Lower: Output current 500 mA/div

Upper: Output voltage 200 V/div

Lower: Output current 500 mA/div

Figure 18 shows the input line voltage and current waveforms at 110 Vac and Figure 19 for

220 Vac, both bench measurements show the AC input simultaneous waveform, the input

current plot is very good and has extreme low distortion.

Figure 18. Steady-state at 110 Vac input Figure 19. Steady-state at 220 Vac

!-V

Upper: Output voltage 200 V/div

Lower: Output current 1.0 A/div

In steady-state, the input power (Pin), output power (Pout), operating efficiency and power

Upper: Input voltage 200 V/div

Lower: Input current 500 mA/div

factor under 110 Vac and 220 Vac is shown in Tab l e 3. Obviously the efficiency is over 88%

and the power factor is higher than 98%.

16/21 Doc ID 15073 Rev 1

Page 17

AN2835 Experimental results

Table 3. Test results of power factor and efficiency

Pin Pout

Conditions

Efficiency

(Pout/Pin)

PF

Watts Watts % ∼

At 110 Vac 77.8 68.9 88.5 0.99

At 220 Vac 76.9 68.9 89.6 0.98

From Section 2.3, we know that high voltage pulse generates continuously before it steps

into steady-state. Once the HID lamp is in open-circuit or absent from the system board,

there is no chance to step into steady-state. In such a condition, the ignition circuit is not

only continuously generating high pulse voltage, but also the full bridge circuit is working at

low frequency (about 200 Hz) as the output of U2 stays high before pin 4 of U2 detects a

current signal.

To avoid a hazard from 3~5 kV on the system board while the HID lamp is in open-circuit or

the HID lamp is absent from the system, the building of a timer to abort this high voltage

pulse generation may be important.

If it is necessary to abort the high voltage pulse generation, a NE555 timer (see Figure 20)

is used to set up a limited time (normally 5 minutes) to turn-off the circuit at the scheduled

time, or apply an MCU in digital solutions. The microcontroller gives more flexible and

precise time control compared to one with a simple hardware solution.

Figure 20. The timer circuit

!-V

Doc ID 15073 Rev 1 17/21

Page 18

Experimental results AN2835

!-V

4.1 Test with HID lamp

The test was done at 220 Vac line input with a HID lamp at room temperature. The test lamp

is a powerball HCI-T 70W/830 WDL from OSRAM. Tabl e 4 shows the test results. The input

power for the 70 W HID lamp is 76.4 W and the power factor achieved is 0.98.

Table 4. Test results of power factor

Results

Conditions

T

= 25 °C 220 0.347 76.4 0.98

AMB

Vin Iin Pin PF

Volts A mperes Wa t t s ~

The lamp current during start up is shown in Figure 21. The detail of warm-up current is

shown in Figure 22 and the steady-state current is shown in Figure 23.

Figure 21. Lamp current during start up with HID lamp

!-V

Figure 22. The lamp current in warm-up state Figure 23. The lamp current in steady-state

!-V

Vertical: lamp current 1 A/div

Horizontal: time 2 ms/div

18/21 Doc ID 15073 Rev 1

Vertical: lamp current 1 A/div

Horizontal: time 2 ms/div

Page 19

AN2835 References

5 References

1. AN2747

2. L6562A datasheet

3. L6569 datasheet

4. L6385E datasheet

5. LIC01 datasheet

6. LM358 datasheet

7. STTH2L06 datasheet

8. STQ3NK50ZR datasheet

9. STP9NK50Z datasheet

10. STP15NM60ND datasheet

11. 2N7002 datasheet.

Doc ID 15073 Rev 1 19/21

Page 20

Revision history AN2835

6 Revision history

Table 5. Document revision history

Date Revision Changes

13-May-2010 1 Initial release

20/21 Doc ID 15073 Rev 1

Page 21

AN2835

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2010 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 15073 Rev 1 21/21

Loading...

Loading...