Page 1

AN2831

Application note

Using the STw4102 for Li-Ion battery charging and monitoring

Introduction

Many portable applications now use Li-Ion batteries for which a dedicated charging system

is required. Handheld devices such as mobile phones, music and video players, as well as

portable navigation devices tend to integrate ever more multimedia functions that each have

different power needs. As such, it has become difficult to manage the battery capacity and

predict the remaining operating time with no dedicated gas gauge support. The STw4102 is

a new innovative device that combines the charge control function and battery monitoring

features in the same package for reduced PCB area use and global cost optimization.

This application note is intended to assist product designers by taking advantage of using

the STw4102 in one-cell Li-Ion battery handheld applications to implement the charge and

battery monitoring functions. The document provides:

● a brief description of the STw4102 and typical applications.

● a general flow chart of the tasks needed to control the STw4102.

● information on how to use the STw4102 to charge a battery from a wall adapter or USB

cable.

● information on how to use the battery monitoring functions of the STw4102 to build a

gas gauge system.

October 2008 Rev 1 1/16

www.st.com

Page 2

About the STw4102 AN2831

1 About the STw4102

The STw4102 combines the charge and battery monitoring functions in the same package.

The charge function is a standalone constant-current constant-voltage (CCCV) linear

charger dedicated to the one-cell Li-Ion battery. The STw4102 offers a dual-charging

capability using separate inputs for a USB cable and a wall adapter, or a single input that

accepts both. The charge current can be programmed to a maximum of 100 or 500 mA for

use with a USB 2.0 port, or programmed to the value set by an external resistor for use with

a wall adapter or a dedicated USB charger.

The STw4102 battery monitoring function includes measurement of the battery voltage and

current, and computation of the battery charge variation (Coulomb counter). An external

sense resistor used in series with the battery adapts the current measurement to the

application requirements.

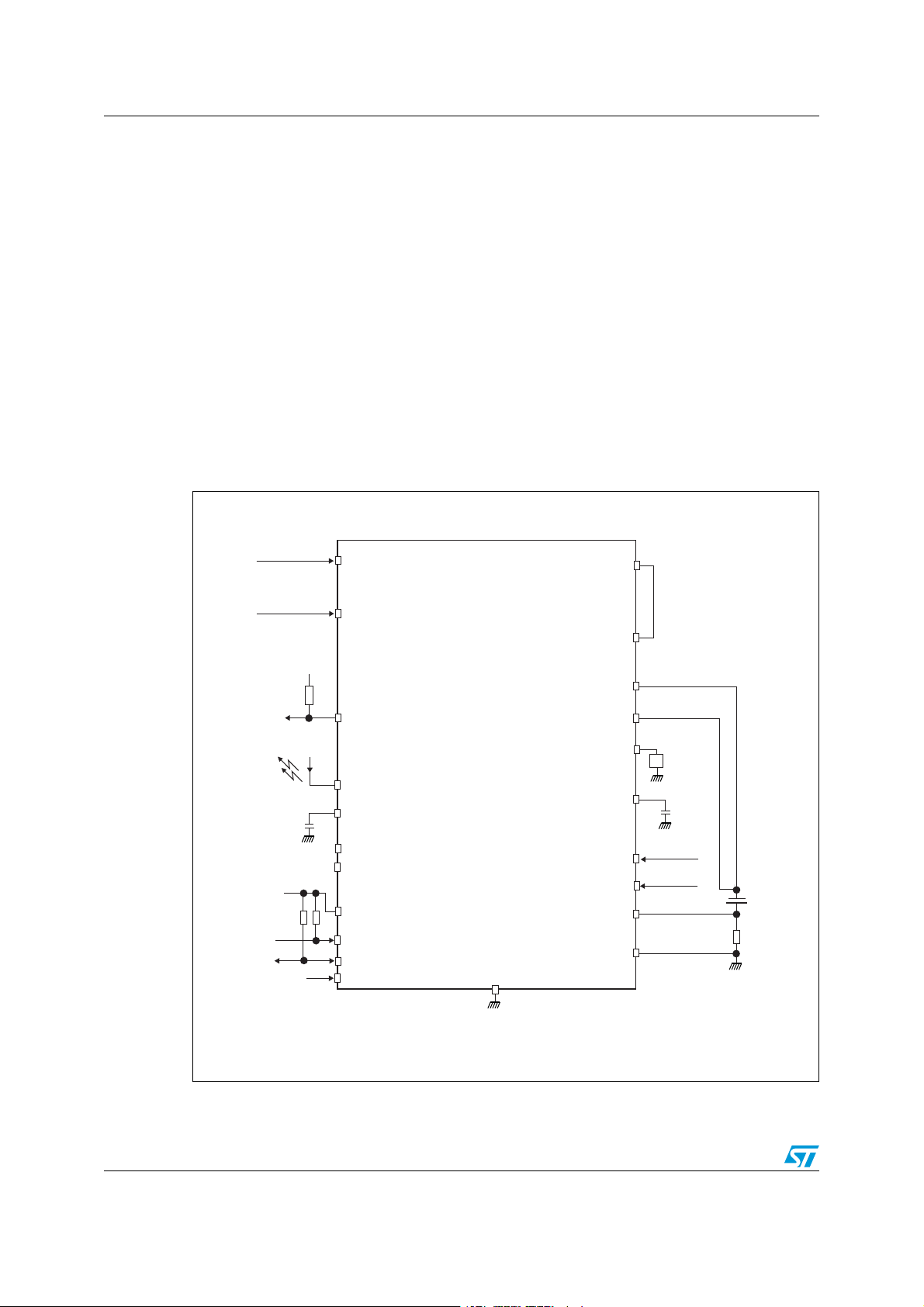

A typical application of the STw4102 is shown in Figure 1.

Figure 1. Typical application diagram for the STw4102

TO$""

)NDICATOR,%$

2ESET

)/VOLTAGE

#

)/VOLTAGE

-!).

53"072

072$%4%#4.

%/#('

#62%&

,$/$26

,$/&"

6)/

3#,

3$!

2%3%4.

34W

'.$

6/54

3%.3%

"!44

"!443%.3%

)3%4

#6)3

#+(:

34$"9

)#'

)#'

2

#

K(Z

3TAND"Y

2

2/16

!-

Page 3

AN2831 About the STw4102

The STw4102 mode and operation are controlled through an I2C interface. The VIO voltage

is the supply voltage for the digital I/Os.

● SCL and SDA are the clock and data signals of the I2C interface.

● RESETN is used to reset the STw4102 registers to their default value.

● C32KHZ is a 32,768 Hz clock signal used as a time base for the gas gauge.

● STDBY may be used to put the battery monitoring functions in standby mode by using

a hardware signal, the standby state is controlled by a combination of the STDBY

signal and the CG_ENA and ADPOWERON bits in the internal registers. If not used,

the STDBY pin must be connected to VIO.

Refer to the STw4102 datasheet for more detailed information

(a)

.

a. See Table 7: Document references.

3/16

Page 4

General control flow chart AN2831

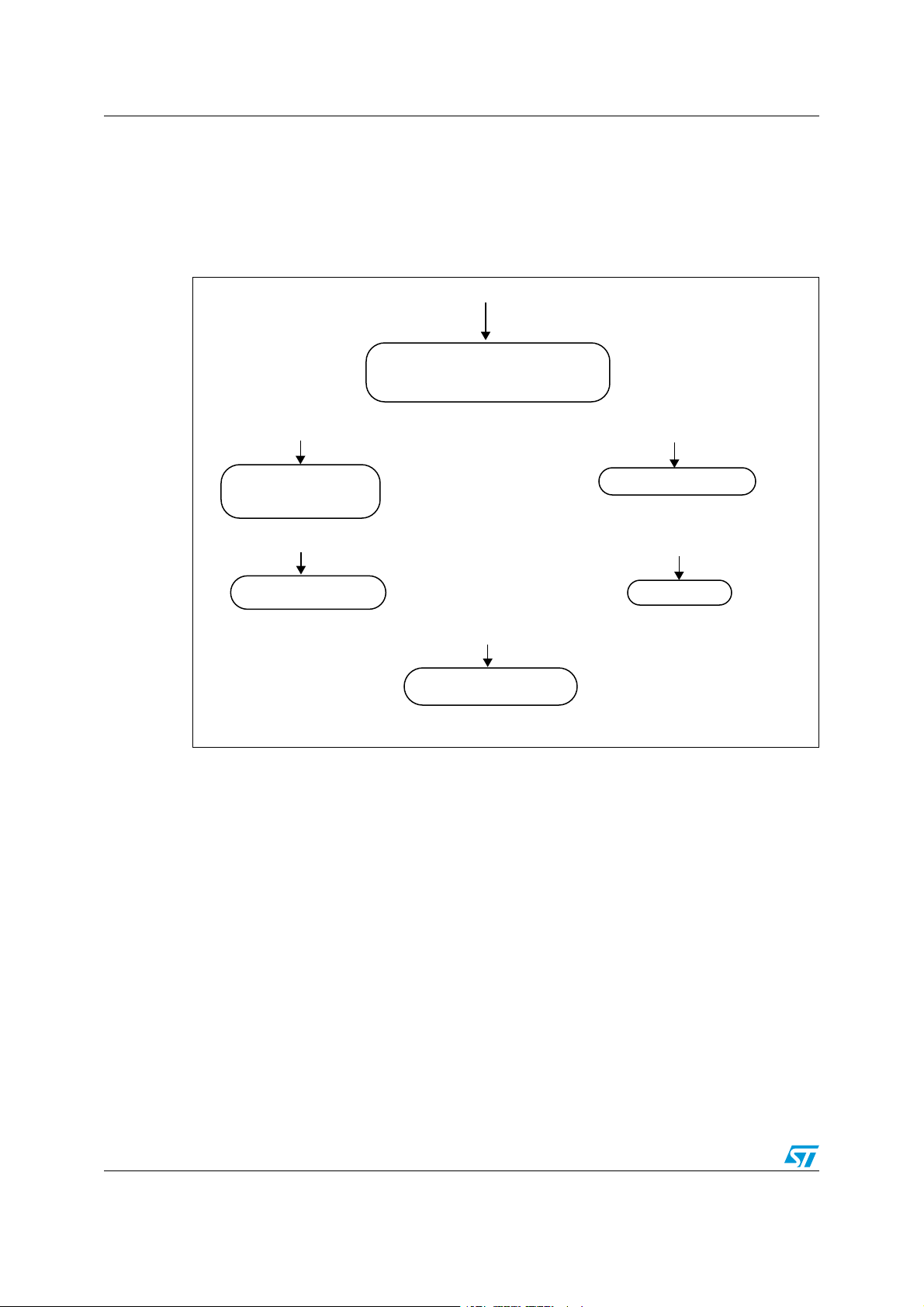

2 General control flow chart

Figure 2 depicts the general flow chart to control the charge and battery monitoring

functions of the STw4102.

Figure 2. General charge and battery monitoring flow chart

!PPLICATIONSTA

ZETHECHARGEPARAMETERS

)NITIALI

3TARTTHEGASGAUGESYSTEM

3ETUPAPE

RIODTASKh'AS'AUGEv

RTUP

0ERIODTASK@'AS'AUGE

2EADGASGAUGE

2EADBATTERYVOLTAGE

2EFRESHWATCHDOG

0/7%2$%4%#4.FALLINGEDGE

3TARTOFCHARGE

3ETUPTHECHARGETIMER

!PPLICATIONSHUTDOWN

)FCHARGINGSTOPCHARGING

3TOPGASGAUGE

53"STATUSCHANGE

5PDATECHARGECURRENT

0/7%2$%4%#4.RISINGEDGE

ORCHARGETIMERELAPSED

The controller tasks are described in detail in the following sections.

%NDOFCHARGE

!-

4/16

Page 5

AN2831 Charge function

3 Charge function

The STw4102 charge function is designed to be controlled by the application system

controller. However, if the controller is not active (for instance when the battery is fully

discharged) the STw4102 operates in standalone mode.

When the system is in the power-down state, the supplies are usually switched off and VIO

is not present. In this case, all the I/O lines, especially the RESETN signal, are low and the

control registers are automatically reset to the default values. The STw4102 starts charging

as soon as a power source is connected to the MAIN or USBPWR inputs.

3.1 Power-up conditions

The charge is enabled at power-up so as to be able to charge an empty battery when the

controller is unable to start due to the battery voltage being too low.

In the standard configuration, the power-up conditions are as follows.

● The charge voltage is set to 4.1 V to ensure maximum safety with all kinds of Li-Ion

batteries.

● The MAIN input is in the wall adapter mode, meaning that the charge current is set by

the external resistor; this corresponds to a configuration where the wall adapter and

USB cable use separate inputs.

● The USB charge current is set to 60 mA to comply with the USB 2.0 regulation.

● The watchdog is enabled and is set to one minute.

For special requirements (for instance, if the STw4102 is used in the common wall

adapter/USB input mode) and on request, some power-up values can be changed directly at

factory level.

● MAIN input mode: either wall adapter mode or USB mode.

● Watchdog enable or disabled: period = 1, 15, 30 or 60 minutes.

Refer to chapter 9 of the STw4102 datasheet for all factory options

(b)

.

When the system controller starts, it has to set the appropriate charge parameters.

● Charge voltage: usually 4.2 V for most batteries. The 4.1 V setting can be used to

extend battery lifetime but with reduced capacity. New high performance battery

generations may take benefit of the 4.30 and 4.35 V settings (consult battery

datasheets).

● MAIN input mode, if different from the power-up mode.

● USB current capability depending on the USB state: 0, 60 or 400 mA.

● Watchdog delay: it is recommended to keep the watchdog enabled and set to 1 minute

for maximum charge safety. If the watchdog is not used it must be disabled with

WDOG_EN=0 and cleared with WDOG_RST=1.

This is done by accessing the REG_CHG0 and REG_WDOG registers. The charge

parameters are kept in the STw4102 registers until the RESETN signal goes low.

b. See Table 7: Document references.

5/16

Page 6

Charge function AN2831

The open-drain PWRDETECTN output indicates that a power source is plugged in (wall

adapter or USB cable). This output can be used to wake up the system, or signal the event

by an interrupt mechanism. The MAINDETECT and USBDETECT bits in the REG_CHG0

register can be used to determine which power source is plugged in.

3.2 Controller tasks during the charge

While the application is active, the controller manages the following tasks.

● When a power source is detected, the controller starts a new charge cycle according to

the actual power source.

● When charging from a USB port, the controller sets the appropriate charge current

level or even disables the charge according to the current USB state.

● When the charge duration reaches the maximum charge time (usually 3 hours when

using fast charge from a wall adapter), the controller disables the STw4102 charge

function.

The watchdog must be refreshed periodically to keep the charge active. If the watchdog

period elapses, then the charge is disabled until the watchdog is refreshed again. Note that

if the watchdog elapses and then is disabled, the charge is still disabled. The suggested

method is to manage the watchdog as part of the battery monitoring and gas gauge task

(see Chapter 4: Battery monitoring functions).

Enabling and disabling the charge is done with the CHG_ENA bit in the REG_CHG1

register. When the charge is active, the EOCHG open-drain output indicates the charge

status: EOCHG is pulled down when the STw4102 is the fast charge phase and is open near

the end of charge when the charge current is less than 10% of the programmed charge

current. The same information is available with the CHARGERUN bit in the REG_CHG0

register. Note that an open EOCHG state does not necessarily mean that the charge is

finished, it just indicates to the user that the battery is almost fully charged, but the STw4102

continues to charge the battery to optimize the final stored energy (top-off or maintenance

phase). EOCHG can be forced low, for instance during the complete charge duration, by

writing to the FORCECHARGERUN bit in the REG_CHG1 register.

The system controller must stop the charge, usually 3 hours after the charge start. An

alternative method that does not involve the controller is to set the watchdog period to one

hour after EOCHG goes high and let the watchdog stop the charge. In all cases, it is not

recommended to keep the battery charging for long periods as this can reduce the battery’s

lifetime.

6/16

Page 7

AN2831 Charge function

3.3 Separate wall adapter/USB input configuration

Figure 3. STw4102 used in dual input mode

7ALLADAPTER

#

53"CABLE

#

-!).

53"072

34W

!-

In this configuration, the REG_CHG0 register must be programmed with SEL_DC_USB=0,

which is the standard power-up value. The STw4102 then automatically uses the MAIN or

USBPWR input according to the internal logic, which gives priority to the MAIN input if the

two inputs are connected to power sources.

There can be some cases where the USB charge must be disabled, like for instance when

the USB is used for OTG purposes. Two possibilities exist.

● If the USBPWR input standby current must be reduced to a minimum, then the charge

must be globally disabled for both MAIN and USBPWR inputs by setting the CHG_ENA

bit to 0. The USBPWR standby current is then reduced to 40 µA maximum.

● If a higher standby current on the USBWR input is acceptable, then the charge from the

MAIN input can still be enabled: CHG_ENA is set to 1, the USB current is set to 0 by

setting both USB_ICHG bits to 1 and the special SEL_IS bit in the REG_CHG1 register

is set to 1. In this case the USB standby input current is approximately 250 µA.

3.4 Common wall adapter/USB input configuration

Figure 4. STw4102 used in common input mode

7ALLADAPTER

-!).

#

53"CABLE

53"072

7/16

34W

!-

Page 8

Charge function AN2831

In this configuration, the MAIN input is used for charging from either a wall adapter, a

dedicated USB charger that allows more than 500 mA or a USB 2.0 cable limited to 500 mA.

In this case the SEL_DC_USB and USB_ICHG bits are used to set the charge current

according to the actual power source connected to the MAIN input:

● USB cable, 100 mA capability: set SEL_DC_USB=1, USB_ICHG=00.

● USB cable, 500 mA capability: set SEL_DC_USB=1, USB_ICHG=10.

● dedicated USB charger, wall adapter: SEL_DC_USB=0, the charge current is then set

by the external resistance.

In this configuration, when the charge is disabled with the CHG_ENA bit set to 0, the MAIN

input current is approximately 2 mA.

8/16

Page 9

AN2831 Battery monitoring functions

4 Battery monitoring functions

The STw4102’s battery monitoring functions include:

● a gas gauge for automatic computation of the battery charge variation: this is done by

integrating the battery current versus the time and accumulating the resulting charge

into charge and discharge registers. The last measurement of the current is available.

● measurement of the battery voltage.

The battery monitoring functions are disabled when the system is in power-down state (VIO

off, RESETN low). This ensures a low standby current from the battery.

The gas gauge function uses a 13-bit ADC and is enabled by the CG_ENA bit in the

REG_CG register. Once enabled, the gas gauge continuously updates the battery current

measurement and the charge/discharge internal registers.

4.1 Charge and discharge data reading

The charge and discharge data as well as the conversion count are read at the request of

the system controller by using the RD_REQ bit. The recommended procedure is:

● set RD_REQ.

● wait for 250 µs.

● read the locations REG_CHARGE (3 bytes), REG_DISCHARGE (3 bytes) and

REG_CONVNUMBER (2 bytes).

The charge/discharge values depend on the external resistance Rsense:

● Charge data (mA.h) = 0.00163 µV.h * REG_CHARGE / Rsense (mΩ).

● Discharge data (mA.h) = 0.00163 µV.h * REG_DISCHARGE / Rsense (mΩ).

When an accumulator reaches its maximum value (binary code = 2

stops accumulating. It is important to periodically reset the accumulators with the

RST_CHRG and RST_DCHG bits. The conversion counter does not stop when it reaches

12

2

-1 = 0xFFF, but wraps to 0 and continues counting. It may, however, be convenient to

reset it with the RST_COUNTER bit at the same time as the accumulators. Note that the

conversion counter is 12 bits wide and that the upper 4 bits of the high byte must be

discarded.

The CG_EOC bit in the REG_CG register can be used to check if at least one new

conversion has been made since the last reading of REG_CG.

4.2 Battery current reading

The last measured value of the current is available in the CONVDATA locations (2 bytes), is

updated at each conversion and is not synchronized with the I2C. To read it:

● read the CONVDATA (2 bytes) location once.

● read again the CONVDATA location.

● if the two results do not match, read the CONDATA location a third time.

The actual value of the current depends on the value of the external sense resistor:

Current (mA) = CONVDATA * 23.5 µV / Rsense (mΩ).

24

-1 = 0xFFFFFF), it

9/16

Page 10

Battery monitoring functions AN2831

4.3 Battery voltage reading

The voltage measurement uses a separate 7- or 12-bit analog-to-digital converter (ADC)

that operates independently of the current measurement and gas gauge. The 7-bit mode

gives the shortest conversion time (8 ms) whereas the 12-bit mode gives full resolution

(1.4 mV). The resolution is set by the ADRESOLUTION bits. Generally, the 12-bit mode

should be used, unless fast battery voltage variations have to be monitored.

The battery voltage measurement is made under control of the system controller: the ADC

must be enabled by setting the ADPOWERON bit and each conversion has to be triggered

by setting the ADSTART bit in the REG_ADCTRL register.

The recommended read procedure is:

● at power up, initialize the ADC by setting ADPOWERON, and trigger a first conversion

by setting the ADSTART bit.

● periodic task: read the battery voltage at the REG_ADDATA location (1 byte in 7-bit

resolution, 2 bytes in 12-bit resolution), then trigger the next conversion by setting again

the ADSTART bit.

In this way, the last voltage result is always available. The LSB value is 45.4 mV in 7-bit

resolution and 1.42 mV in 12-bit resolution.

4.4 Controller tasks

The gas gauge and voltage measurement functions are disabled at power-up or at each

STw4102 reset (RESETN input driven to low level).

The system controller does the following tasks.

● At start-up, it enables the gas gauge and the ADC for battery voltage measurement.

● It periodically reads the gas gauge and battery voltage, and if necessary resets the

accumulators.

● At power-down, it disables the gas gauge and battery voltage ADC.

Note: 1 The 32768 Hz clock signal must be present for both the gas gauge and battery voltage

measurement functions. When the gas gauge and battery voltage ADC are stopped with the

CG_ENA and ADPOWERON bits, the clock signal must still be present until the end of the

current conversion (this can take up to 250 ms).

2 If the battery voltage ADC is not used, the ADPOWERON bit must still be set at start-up and

cleared at power-down. This ensures correct operation of the standby mode of the STw4102

and minimum quiescent current from the battery.

10/16

Page 11

AN2831 STw4102 demonstration board

Appendix A STw4102 demonstration board

The STw4102 demonstration board is convenient to evaluate the charge and battery

monitoring functions and quickly obtain a working prototype or design reference.

Figure 5 describes the basic connections to use the STw4102 demonstration board.

Figure 5. STw4102 demonstration board usage

Power Detected

Power Detected

Charging

Charging

(if R1 removed)

(if R1 removed)

STw4102

STw4102

Vdc

Vdc

Gnd

Gnd

VBUS

VBUS

Gnd

Gnd

Adapter

Adapter

(5V DC)

(5V DC)

Vio

Vio

System

System

Controller

Controller

Gnd

Gnd

| Battery +

| Battery +

The EOCH and PWRDT pads are connected to the STw4102 EOCHG and

POWERDETECTN pins respectively. The PWRDT pad has a 10 kΩ pull-up resistor to BATT.

The demonstration board is configured for a charge current of 1 A from the MAIN wall

adapter set by the R1 resistor on the board. To change the charge current, remove the R1

resistor from the board and use an external resistor between the ISET pad and ground.

The gas gauge sense resistor is on the board and the resistance value is 33 mΩ.

The digital interface is made of VIO (I/O voltage to be externally provided, 1.45 to 3.0 V),

SDA, SCL (I2C bus signals), RST (STw4102 RESETN), STBY (STw4102 STDBY) and C32

(STw4102 C32KHZ). The RST pad has a 10 kΩ pull-up resistor to VIO.

11/16

Page 12

STw4102 register mapping AN2831

Appendix B STw4102 register mapping

The mapping of all registers is shown in Tab le 1 .

Table 1. Register map

Name

REG_CHG0 0 R/W Charge control and status

REG_CHG1 1 R/W Charge enable

REG_WDOG 2 R/W Watchdog control

REG_CG 3 R/W Gas gauge control

REG_CHARGE_LOW 4 R Gas gauge charge data, bits 0-7

REG_CHARGE_MID 5 R Gas gauge charge data, bits 8-15

REG_CHARGE_HIGH 6 R Gas gauge charge data, bits 16-23

REG_DISCHARGE_LOW 7 R Gas gauge discharge data, bits 0-7

REG_DISCHARGE_MID 8 R Gas gauge discharge data, bits 8-15

REG_DISCHARGE_HIGH 9 R Gas gauge discharge data, bits 16-23

REG_CONVDATA_LOW 16 R Gas gauge AD converter data, bits 0-7

REG_CONVDATA_HIGH 17 R Gas gauge AD converter data, bits 8-12

REG_CONVNUMBER_LOW 18 R Number of conversions, bits 0-7

REG_CONVNUMBER_HIGH 19 R

REG_ADCTRL 20 R/W Battery voltage monitor control

REG_ADDATA_LOW 21 R Battery voltage data, bits 0-7

REG_ADDATA_HIGH 22 R Battery voltage data, bits 8-11 in 12-bit mode

Address

(dec.)

Type Description

Number of conversions, bits 8-11,

bits 12-15 are undefined

The registers REG_CHG0, REG_CHG1, REG_WDOG, REG_CG and REG_ADCTRL are

described in detail in Ta bl e 2 to Tab le 6 . Power-up values are set at power startup or at reset

(RESETN pin at low level).

12/16

Page 13

AN2831 STw4102 register mapping

Table 2. REG_CHG0. address 0 (00h)

Name Pos. Type

CHARGERUN 0 R 0

Power-

up

Description

0: charge is below 10% of fast charge current.

1: charge is above 10% of fast charge current.

MAINDETECT 1 R 0 Main input voltage detection.

USBDETECT 2 R 0 USB input voltage detection.

VCHG [4,3] R/W 00

Charge voltage

00=4.1V, 01=4.2V, 10=4.3V, 11=4.35V.

Wall adapter/USB selection for MAIN input.

SEL_DC_USB 5 R/W 0

0: charge current set by Rset resistor.

1: charge current set by USB_ICHG bits.

USB_ICHG [7,6] R/W 00

Table 3. REG_CHG1. address 1 (01h)

Name Pos. Type

Power-

CHG_ENA 0 R/W 1

USB charge current

00 = 60 mA, 01 = 200 mA, 10 = 400 mA, 11 = off.

up

Description

0: charger disabled.

1: charger enabled.

Reserved [3,1] R/W 0 Reserved bits, to be set to zero.

FORCECHARGER

UN

4R/W0

0: no effect.

1: force EOCHG low independently of charge

state.

0: internal supply from Main or USB input when

SEL_IS 5 R/W 0

available and charge enabled.

1: internal supply always from battery.

Unused [7,6] R/W

Table 4. REG_WDOG. address 2 (02h)

Name Pos. Type

WDOG_EN 0 R/W 1

WDOG_TIME [2,1] R/W 00

Power-

up

Description

0: watchdog disabled.

1: watchdog enabled.

00 = 1 minute, 01 = 15 minutes, 10 = 30 minutes,

11 = 60 minutes.

0: no effect.

WDOG_RST 3 R/W 0

1: reset watchdog. Bit cleared after watchdog

reset.

Reserved [5,4] R/W 0 Reserved bits, to be set to zero.

WDOG_INT 6 R x 1: watchdog has elapsed.

Unused 7

13/16

Page 14

STw4102 register mapping AN2831

Table 5. REG_CG. address 3 (03h)

Name Pos. Type

Power-

up

CG_ENA 0 R/W 0

RST_CHRG 1 R/W 0

RST_DCHRG 2 R/W 0

RST_COUNTER 3 R/W 0

RD_REQ 4 R/W 0

CG_CAL 5 R/W 0

CG_EOC 6 R 0

Unused 7

Table 6. REG_ADCTRL. address 20 (14h)

Description

0: gas gauge disabled. Charge/discharge

accumulators are reset.

1: gas gauge enabled.

0: no effect.

1: resets the charge accumulator. This bit auto

clears after the charge register has been reset.

0: no effect.

1: resets the discharge accumulator. This bit auto

clears after the discharge register has been reset.

0: no effect.

1: resets the counter conversion. This bit auto

clears after the counter register has been reset.

0: no effect.

1: transfers the 24-bit charge/discharge

accumulators and the conversion counter to the

charge/discharge and conversion number

registers. This bit auto clears after the transfer.

0: no effect.

1: allows calibration of the AD converter.

Set to high at the end of a conversion. Cleared

after a read.

Name Pos. Type

Power-

up

ADPOWERON 0 R/W 0

ONSTATE 1 R 0

ADSTART 2 R/W 0

ADRUN 3 R 0

ADRESOLUTION 4 R/W 0

ADCAL 5 R/W 0

Unused [7,6]

Description

0: allows ADC shutdown.

1: enables ADC operation.

0: ADC is not ready for operation.

1: ADC is ready for operation.

0: no effect.

1: allows to start a conversion. Cleared upon

writing.

0: an AD conversion is not running.

1: an AD conversion is running.

0: 7 bits.

1: 12 bits.

0: no effect.

1: allows calibration of the AD converter.

14/16

Page 15

AN2831 References

References

Table 7. Document references

Document

STw4102 - Dual USB/wall adapter Li-Ion battery charger with gas gauge (stw4102.pdf).

Revision history

Table 8. Document revision history

Date Revision Changes

23-Oct-2008 1 Initial release.

15/16

Page 16

AN2831

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2008 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

16/16

Loading...

Loading...