Page 1

AN2822

Application note

STM8S and STM8A high speed internal oscillator calibration

Introduction

This application note describes how to take advantage of the 16 MHz internal RC oscillator

trimming feature on the STM8S and STM8A microcontroller to improve the frequency

accuracy of the system compensating voltage and temperature frequency drift. The

calibration technique, using the mains frequency as a timebase, is presented with an

example of both hardware and software solutions. The example source code can be

downloaded from the www.st.com.

To benefit fully from the information in this application note, the user should be familiar with

the STM8S and STM8A microcontroller architecture and with the basics of C language.

For further information on the STM8S and STM8A family features, pinout, electrical

characteristics, mechanical data and ordering information, please refer to the STM8S and

STM8A datasheets.

This document and its associated firmware, are written to accompany the STM8S and

STM8A firmware library. Please contact STMicroelectronics for information on the STM8S

and STM8A firmware library.

August 2011 Doc ID 14983 Rev 2 1/19

www.st.com

Page 2

Contents AN2822

Contents

1 High speed internal oscillator trimming . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Calibration principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Calibration routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 Measurement of HSI pulses per calibration period . . . . . . . . . . . . . . . . . . 9

1.5 Timing of calibration period measurement . . . . . . . . . . . . . . . . . . . . . . . . 11

1.6 Uncertainty of calibrated HSI frequency . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2 Power supply and calibration signal conditioning circuit . . . . . . . . . . 15

3 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2/19 Doc ID 14983 Rev 2

Page 3

AN2822 List of tables

List of tables

Table 1. CLK_HSITRIMR values and two’s-complement binary representation . . . . . . . . . . . . . . . . 6

Table 2. Value of used components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 3. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Doc ID 14983 Rev 2 3/19

Page 4

List of figures AN2822

List of figures

Figure 1. STM8S and STM8A HSI trimming principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2. HSI calibration set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. HSI calibration flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 4. Measurement of HSI pulses per calibration period flowchart . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 5. Timing diagram of calibration period measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 6. Example of calibration signal conditioning circuit and 5 V power supply . . . . . . . . . . . . . . 15

4/19 Doc ID 14983 Rev 2

Page 5

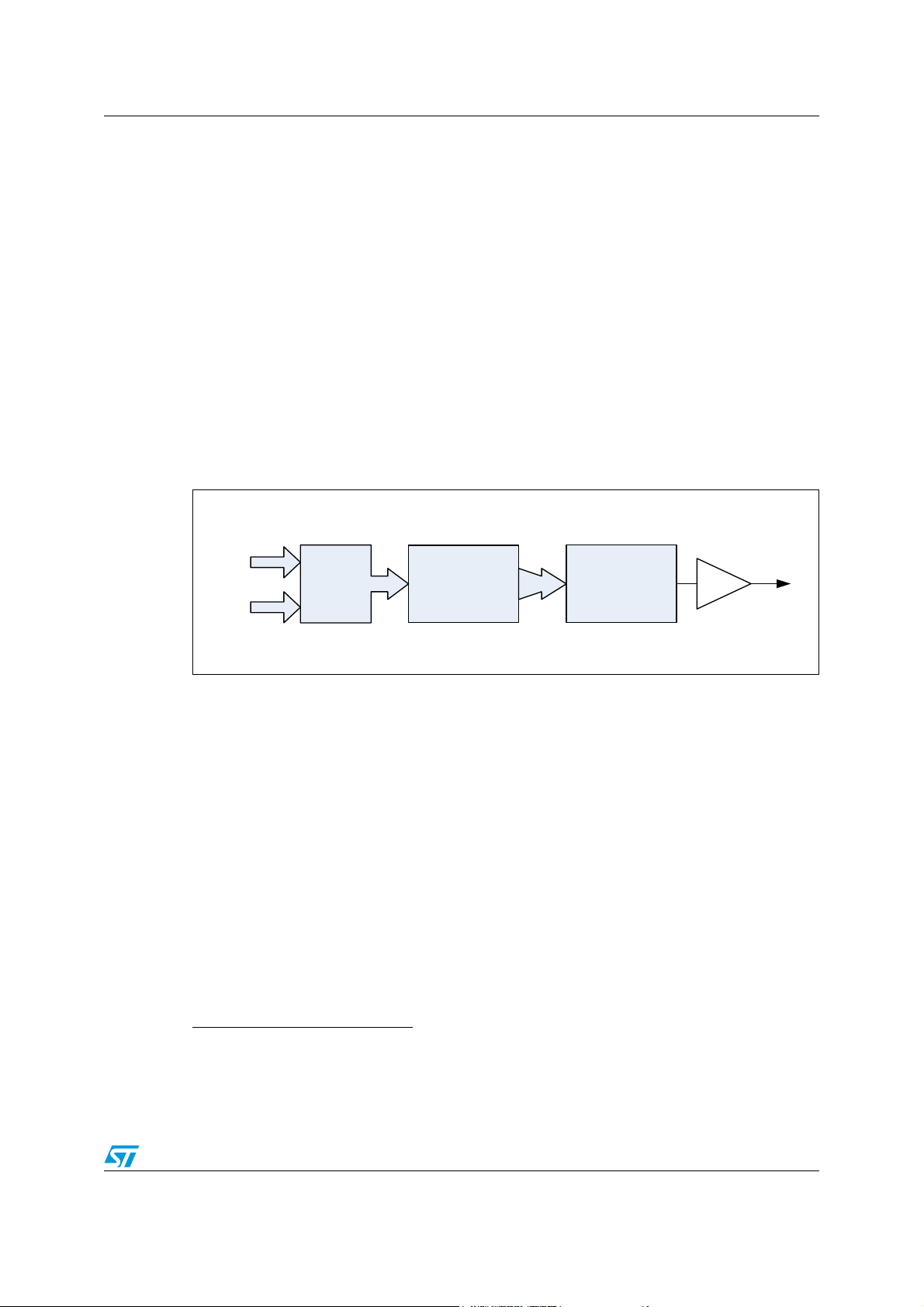

AN2822 High speed internal oscillator trimming

RC OSCILLATOR

DECODER

CLK_HSITRIM

HSI Clock Output

+

INIT_TR IM

1 High speed internal oscillator trimming

1.1 Introduction

The STM8S and STM8A 8-bit microcontrollers can use a high speed internal (HSI) RC

oscillator as a system clock source. This oscillator has a nominal frequency, f

16 MHz which is factory calibrated at an ambient temperature of T

voltage of V

= 5 V. This accuracy is specified in the datasheet for each device.

CC

= 25 °C and a supply

A

HSI nominal

The HSI frequency is calibrated to give reasonable accuracy for the vast majority of

applications. However, the output frequency of the RC oscillator is affected by temperature

and/or voltage drift, while, total accuracy of the HSI frequency is reduced a percentage

given in the datasheet. To compensate for such influences in the application, the STM8S

and STM8A HSI oscillator output frequency can be trimmed by the user runtime calibration

routine to improve frequency accuracy. This is especially important for communication

peripherals.

Figure 1. STM8S and STM8A HSI trimming principle

, of

Initial calibration data, INIT_TRIM, are stored in the protected part of the internal memory

and loaded onto the internal calibration register after reset.

The frequency of the HSI RC oscillator can be fine-tuned to achieve better accuracy with

wider temperature and supply voltage ranges. The lowest three bits of the CLK_HSITRIMR

register are reserved for this purpose. The number stored in these bits is processed as a

signed number with the two's-complement representation (see Ta bl e 1 ). The trimming

number

(a)

can vary from -4 (100b) to +3 (011b). This number is added to the factory

calibration value.

Note: An increase in this trimming value causes a decrease in HSI frequency.

The frequency change per step is approximately 1%

a. Some selected STM8S and STM8A devices can be set to 4-bit trimming mode by the HSITRIM option byte,

see device datasheet for details.

b. If the 4-bit trimming mode is set by the HSITRIM option byte, the frequency change between two steps in the

trimming value is approx. 0.5%

(b)

.

Doc ID 14983 Rev 2 5/19

Page 6

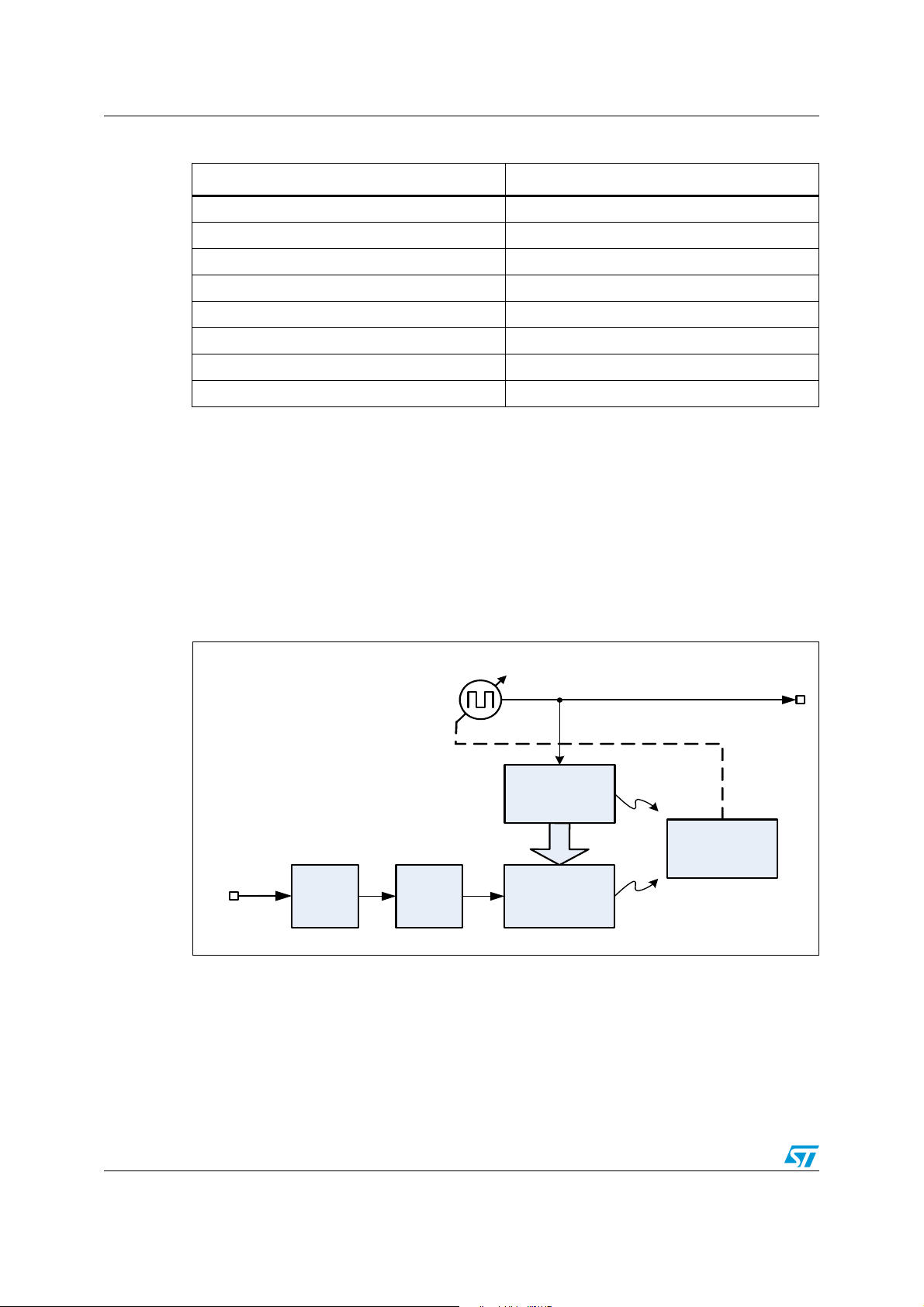

High speed internal oscillator trimming AN2822

TIM3_CC1

/1, /2, /4 or /8

Counter

Capture

f

MASTER

= f

HSI

Core

CCO

Overload

interrupt

Capture

interrupt

CLK_HSITRIMR

HSI 16 MHz

Prescaler

Calibration

signal

Input

Filter

TI1 TI1F IC1PS

Table 1. CLK_HSITRIMR values and two’s-complement binary representation

Decimal value Binary two’s-complement value

3011

2010

1001

0000

-1 111

-2 110

-3 101

-4 100

Note: The default value on the CLK_HSITRIMR register is zero (000b) after reset.

1.2 Calibration principle

To calibrate the HSI output frequency, a reference timebase is necessary. A simple

reference timebase can be used, such as the post-processed signal from the mains power

source (see Section 2). The final accuracy of the HSI frequency is strongly dependent on

the accuracy of the reference timebase. Better accuracy can be achieved with more

accurate timebases such as a signal generator.

Figure 2. HSI calibration set-up

The calibration signal, from the mains power supply, is connected to the TIM3_CC1 input pin

and is used as a timebase which allows the microcontroller to test if the HSI RC oscillator

frequency is above or below the nominal frequency. The HSI frequency is sequentially tuned

by the microcontroller until the optimum value is reached.

6/19 Doc ID 14983 Rev 2

Page 7

AN2822 High speed internal oscillator trimming

IdealCountedValue f

HSI nominalTcal

× L×=

The HSI frequency is evaluated from the number of pulses counted by timer TIM3 during

certain calibration signal periods. For noisy mains, where positive and negative half-periods

are not necessarily symmetrical, it is better to measure the whole period and not only the

time difference between the rising and falling edge of the calibration signal.

It is better to measure the number of HSI pulses for several sequential periods to reduce the

uncertainty of the measurement. This is also recommended when using a noisy mains as

the calibration signal. The input capture prescaler can be used for this purpose. It allows

every 1st, 2nd, 4th, or 8th rising edge of the calibration signal to be selected which is then

used to define the time interval for counting HSI pulses. In this way TIM3 is able to store

information about the number of HSI pulses in the capture register at the beginning and at

the end of a measurement.

If required (for example, for validation purposes), the frequency of the HSI oscillator can be

observed on the configurable clock output (CCO) pin.

See Section 2 for an example of a simple post-processing circuit which adapts a mains

signal to a square signal and converts the mains voltage to 5 V power supply voltage.

1.3 Calibration routine

The calibration routine is written in ANSI C. It takes advantage of the STM8S and STM8A

firmware library which is available from www.st.com. It can be simplified and optimized if

needed.

The software compares the number of HSI clock pulses during the certain number L of

calibration period, T

(20 ms), with the ideal value (see equation below).

cal

Using this equation, the calibration routine software compares the ideal HSI clock pulse

value (IdealCountedValue) with the nominal oscillator frequency, f

defined calibration period, T

(20 ms), for a known number of calibration signal periods (L).

cal

HSInominal

, during a

Note: For example, if the nominal HSI frequency is 16 MHz, the defined calibration period, T

20 ms (if the mains has a frequency of 50 Hz), and the known number of calibration signal

periods, L, is 8 then the ideal value captured by the timer is 2 560 000 (0x271000)

The calibration algorithm is described in Figure 3.

Calibration starts with initialization of TIM3. The lowest frequency is set by writing

MAX_TRIM_VAL to the CLK_HSITRIMR register. In this way, the trimming value is

decreased in the program loop. The difference between the number of counted HSI pulses

and the ideal value is compared with the previous difference, until either the current

difference becomes greater than the preceding difference, or, until the minimum value

MIN_TRIM_VAL is reached.

If the new difference is greater than the preceding difference, the trimming value is

incremented to the previous value, resulting in the optimum value for calibration.

cal

, is

Doc ID 14983 Rev 2 7/19

Page 8

High speed internal oscillator trimming AN2822

prevDiff

<

actDiff

Increment

CLK_HSITRIM

End of Calibration

Yes

No

Start of Calibration

CLK_HSITRIM = MAX_TRIM_VAL

Initialization of TIM3

Measure the HSI pulses,

Calculate abs (actual – ideal),

store it in prevDiff

CLK_HSITRIM

MIN_TRIM_VAL

Yes

No

Decrement

CLK_HSITRIM

Measure the HSI pulses

Calculate

1)

abs (actual – ideal)

Store it in actDiff

prevDiff = actDiff

Figure 3. HSI calibration flowchart

1. The ‘abs’ function calculates absolute value.

The measurement routine results are the sum of HSI pulses during the consequential

calibration period. The number of calibration signal periods, L, used for the measurement

are given by the constant, MAX_AVERAGED_PERIOD. The more periods used for the

measurement, the lower the uncertainty of period length due to the averaging effect. The

recommended value range is 4 or 8.

8/19 Doc ID 14983 Rev 2

Page 9

AN2822 High speed internal oscillator trimming

f

HSI

N

HSI

T

cal

L⋅

-------------------- -=

N

HSI

la stca p ture 0x 10000 overfl ows firstc aptur e–×+=

1.4 Measurement of HSI pulses per calibration period

The current HSI oscillator frequency, f

number of counted HSI clock pulses, N

, is not measured directly. It is evaluated from the

HSI

, during a defined calibration interval, T

HSI

cal

, for a

known number of calibration signal periods (L), using the following equation:

TIM3 timer counts the number of HSI pulses with minimum interaction from the software

routine. This helps to reduce measurement uncertainty caused by the software routine

reaction times. In addition, the MCU core is not occupied by the software and can continue

to execute user code.

The measurement of HSI pulses starts with the initialization of TIM3 timer. It is configured to

count the number of HSI pulses and to handle two interrupt events. The first interrupt occurs

when the timer overflows. The second interrupt is an input capture interrupt which occurs

every L

th

rising edge of the calibration period signal.

When the first rising edge of the calibration signal period occurs, the value in the

TIM3_CNTR register is stored in the input capture register, TIM3_CCR, and the content of

this register is saved during the input capture interrupt into the firstcapture variable.

The last input capture interrupt occurs when the L

th

rising edge of the calibration signal is

detected and the value in the input capture register TIM3_CCR is saved into the lastcapture

variable.

The number of overflows between the first and last capture events is increased at every

overflow interrupt and stored in the overflow variable.

When the last input capture event occurs the state MEASURE_COMPLETED is set and the

timer is stopped. Then the number of HSI pulses is evaluated using the equation below:

Figure 4 summarizes the measurement of HSI pulses for a known calibration signal period.

Doc ID 14983 Rev 2 9/19

Page 10

High speed internal oscillator trimming AN2822

Enter ‘overflow interrupt’

Exit interrupt

Increase the

number of

overflows

measureState

=

MEASURE_IN_

PROGRESS

YES

NO

measureState

?

Exit interrupt

Enter ‘input capture

interrupt’

MEASURE_START MEASURE_IN_PROGRESS

Disable interrupts

Stop the counter

Set measureState

to MEASURE_IN_

PROGRESS

Save Captured

value in

firstcapture

Set measureState

to MEASURE_

COMPLETED

Save Captured

value in

lastcapture

Initializing of

variables

Figure 4. Measurement of HSI pulses per calibration period flowchart

10/19 Doc ID 14983 Rev 2

Page 11

AN2822 High speed internal oscillator trimming

Counter

Register

Value

OVF

TI1

IC1PS

CC

OVL

OVL OVL

OVL

OVL

Filter Delay

L = 4

CC

OVL

1.5 Timing of calibration period measurement

This section describes the timing of the HSI oscillator frequency, f

measurement.

HSI

The ‘digital filtering technique’ is applied on the TI1 input from TIM3_CC1 (see Figure 2) to

further reduce period measurement uncertainty. This technique includes an event counter,

present on the input capture pin, in which a certain number of TI1 samples with the same

level are needed to validate a transition of the reference timebase. The number of such

pulses and the sampling frequency can be set by bits IC1F[3:0] in the TIM3_CCMR1

register. The sampling frequency can be set as an f

MASTER

eight equal consecutive samples with a time resolution of 1/f

divided by 1 to 32. By default,

MASTER

, are required for the

transition to be valid. This default value can be changed if needed. This digital filtering

technique causes a delay between TI1 and the IC1 signal. It does not affect the

measurement of HSI pulses per calibration interval (see Figure 5).

Figure 5. Timing diagram of calibration period measurement

Doc ID 14983 Rev 2 11/19

Page 12

High speed internal oscillator trimming AN2822

f

HSIm

N

HSI

L

------------ -

f

cal

=

uN

HSI

()

1

3

-------=

uf

cal

()

f

calδfcal

100 3

---------------------- -=

1.6 Uncertainty of calibrated HSI frequency

There are two sources of uncertainty

is caused by the finite resolution of the trimming value. The second is the uncertainty of the

HSI frequency measurement used to regulate HSI output frequency using the HSI trimming

register.

(c)

associated with this calibration method. The first one

The calibrated HSI oscillator frequency, f

, is not measured directly. We can start with

HSIm

the equation describing the estimated HSI frequency as a function of each of the factors that

can influence it to evaluate the uncertainty of the calibrated HSI output frequency given by

the calibration method

(d)

As L is a constant we can identify two uncertainty contributors. The first is a number of

counted HSI pulses, N

, the second is a calibration period, f

HSI

cal

.

These input parameters can be assumed as uncorrellated quantities.

The uncertainty of N

is caused by the nonsynchronous frequency of the calibration signal

HSI

and HSI oscillator frequency. The first rising edge of the L-series of calibration signal periods

can occur anywhere in the interval of one HSI signal period as well as the last rising edge

which close the counter gate, resulting in the uncertainty of counted HSI pulses equal to ±1.

Assuming uniform uncertainty distribution, the standard uncertainty of N

can be

HSI

evaluated using the following equation

To reduce this uncertainty, the calibration frequency should be well below the HSI frequency

(at least 1000 times lower). This is easily achieved when the mains frequency is used as a

calibration signal.

The uncertainty of the calibration signal frequency, f

mains frequency. Normally, the accuracy of the mains frequency, δf

, is given by the fluctuation of the

cal

, is better than ±1%.

cal

However, even better accuracy can be achieved by using a different frequency source, such

as a signal generator. To reduce uncertainty from this source to a minimum, the frequency

generator which gives the best accuracy should be used instead of the mains frequency.

The standard uncertainty of calibration frequency, f

, is expressed below assuming uniform

cal

uncertainty distribution.

From the equation describing the estimated HSI frequency, f

sensitivity coefficient associated with each of the input estimates.

c. This analysis of the HSI calibration method is based on ISO Guide to the Expression of Uncertainty in

Measurement and ANSI/NCSL Z540-2-1997. These standards offer a current international consensus of the

methods for estimating measurement uncertainty.

d. Estimates of uncertainty obtained in this way are usually called Type B.

12/19 Doc ID 14983 Rev 2

, we can calculate the

HSI

Page 13

AN2822 High speed internal oscillator trimming

c

N

HSI

N

HSI

∂

∂f

HSImfcal

L

--------==

c

f

cal

f

cal

∂

∂f

HSIm

N

HSI

L

------------ -==

u

c

2

f

HSIm

()c

i

2

ui()

2

i

∑

f

cal

L

--------

⎝⎠

⎛⎞

2

1

3

-------

⎝⎠

⎛⎞

2

N

HSI

L

------------ -

⎝⎠

⎛⎞

2

f

calδfcal

100 3

---------------------- -

⎝⎠

⎛⎞

2

+==

uf

trim

()

Δf

trim

23

--------------=

uf

HSI

() u2f

trim

()u

c

2

f

HSIm

()+=

uN

HSI

()

1

3

-------

1.732≅=

uf

cal

()

f

calδfcal

100 3

---------------------- -

50

100 3

-----------------

0.286≅==

c

N

HSI

N

HSI

∂

∂f

HSIm

f

cal

L

--------

12.5≅==

The combined standard uncertainty of the HSI frequency measurement can be calculated

by the equation bellow.

When the calibration is finished, the oscillator output frequency will be at maximum ±1/2 of

the frequency trimming step, Δf

steps causing additional uncertainty which can be expressed

, far from the desired frequency. This finite regulation

trim

(e)

by the following equation.

The total combined uncertainty of the HSI frequency can be expressed using the equation

below.

Example

Let’s consider as a calibration signal mains, f

δf

, in the range of ±1%, number of calibration signal periods L = 4 and a desired output

cal

, with a frequency of 50 Hz with accuracy,

cal

frequency 16 MHz. Evaluation of the uncertainty of input quantities and sensitivity

coefficients are the following.

e. Assuming a uniform distribution of the HSI output frequency uncertainty.

Doc ID 14983 Rev 2 13/19

Page 14

High speed internal oscillator trimming AN2822

c

f

cal

f

cal

∂

∂f

HSIm

N

HSI

L

------------ -

320 10⋅

3

468.7 8.376 109⋅()≅==

u

c

2

f

HSIm

()c

N

HSI

2u2

N

HSI

()c

f

cal

2u2

f

cal

()+ 468.7 8.376 109⋅+≅=

ucf

HSIm

()91.52 kHz≅

uf

trim

()

160 103⋅

23

--------------------------

46.19 kHz≅=

uf

HSI

() u2f

trim

()u

c

2

f

HSIm

()+ 102.5 kHz≅=

Ukuf

HSI

()⋅ 2 102.5 kHz 205 kHz≅⋅≅=

The combined standard uncertainty of the HSI frequency measurement is evaluated bellow.

Comparing the first and second terms we can find that a contribution caused by uncertainty,

u(N

), is negligible and can be omitted. This statement is valid if the calibration frequency

HSI

is well below the HSI frequency.

Let’s evaluate the uncertainty caused by the finite regulation steps.

Finally, the total combined uncertainty of the HSI frequency is evaluated bellow.

Assuming that the required confidence level is 95% using the coverage factor k=2, we can

express the extended uncertainty, U, as following.

14/19 Doc ID 14983 Rev 2

Page 15

AN2822 Power supply and calibration signal conditioning circuit

R2

C3

C1

+

R1

R4

V

DD

TIM3_CC1

STM8

N

L

AC Mains

~

D1

D2

C2

V

SS

R3

2 Power supply and calibration signal conditioning

circuit

Figure 6 shows the calibration signal conditioning circuit which also provides approximately

5 V of DC power supply to the microcontroller. Where power supply from the mains is not

needed, only a single resistor between power line and TIM3_CC1 input is adequate to

protect this pin from over current in normal operating conditions.

The calibration signal conditioning circuit contains a few passive components which convert

either the 230 V / 50 Hz of a European mains or the 110 V / 60 Hz of a US mains to a 5 V

DC power supply. An application with more current consumption should use a power

converter (see AN1357, VIPower: Low cost power supplies using VIPer12A in non isolated

applications).

Caution: The calibration signal conditioning and power supply circuits cannot be used if there are big

current variations.

Figure 6. Example of calibration signal conditioning circuit and 5 V power supply

If using a noisy mains, an input power line filter is recommended (see AN2326, Calibrating

the RC oscillator of the ST7ULTRALITE MCU using the mains).

Doc ID 14983 Rev 2 15/19

Page 16

Power supply and calibration signal conditioning circuit AN2822

Table 2. Value of used components

Component 230 V / 50 Hz value 110 V / 60 Hz value

R1 220 Ω / 0.5 W 110 Ω / 0.5 W

R2 220 Ω / 0.5 W 110 Ω / 0.5 W

R3 1 MΩ 1 MΩ

R4 5.6 kΩ 5.6 kΩ

D1 BZX85C5.6 BZX85C5.6

D2 1N4148 1N4148

C1 470 nF / ~275 V AC 330 nF / ~275 V AC

C2 100 nF 100 nF

C3 470 µF / 16 V 470 µF / 16 V

16/19 Doc ID 14983 Rev 2

Page 17

AN2822 Conclusion

3 Conclusion

The calibration method described in this application note, ensures that the high speed

internal clock of the STM8S and STM8A microcontrollers operates at its intended frequency

(16 MHz) in the target application, independently of the temperature and power supply

voltage drift.

The proposed solution uses the 16-bit timer TIM3 for measuring the internal RC oscillator

frequency and external calibration signal which can be easily adapted from the mains. An

implementation example with power supply and calibration signal conditioning circuit is

proposed.

The example source code written in ANSI C and using the STM8S and STM8A firmware

library can be download from www.st.com.

Doc ID 14983 Rev 2 17/19

Page 18

Revision history AN2822

4 Revision history

Table 3. Document revision history

Date Revision Changes

20-Jan-2009 1 Initial release

31-Aug-2011 2 Updated to refer to STM8S and STM8A products.

18/19 Doc ID 14983 Rev 2

Page 19

AN2822

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2011 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 14983 Rev 2 19/19

Loading...

Loading...