Page 1

AN2821

Application note

Clock/calendar implementation

on the STM32F10xxx microcontroller RTC

The internal RTC (real-time clock) of the 32-bit, ARM® Cortex™-M3-based medium-density

STM32F10xxx microcontroller is an independent timer. It provides a set of continuously

running counters, which, using suitable software, can be used to implement a clock/calendar

function. The RTC and backup registers are supplied through a switch that draws power

from either the V

when the main supply is switched off.

This application note gives an example of how to implement the clock/calendar functionality

using the medium-density STM32F10xxx microcontroller in low-power and standard

applications. The firmware example also performs leap year counting and tamper time

stamping. It provides a low-power mode demonstration and a basic RTC calibration routine

to compensate for crystal and temperature variations.

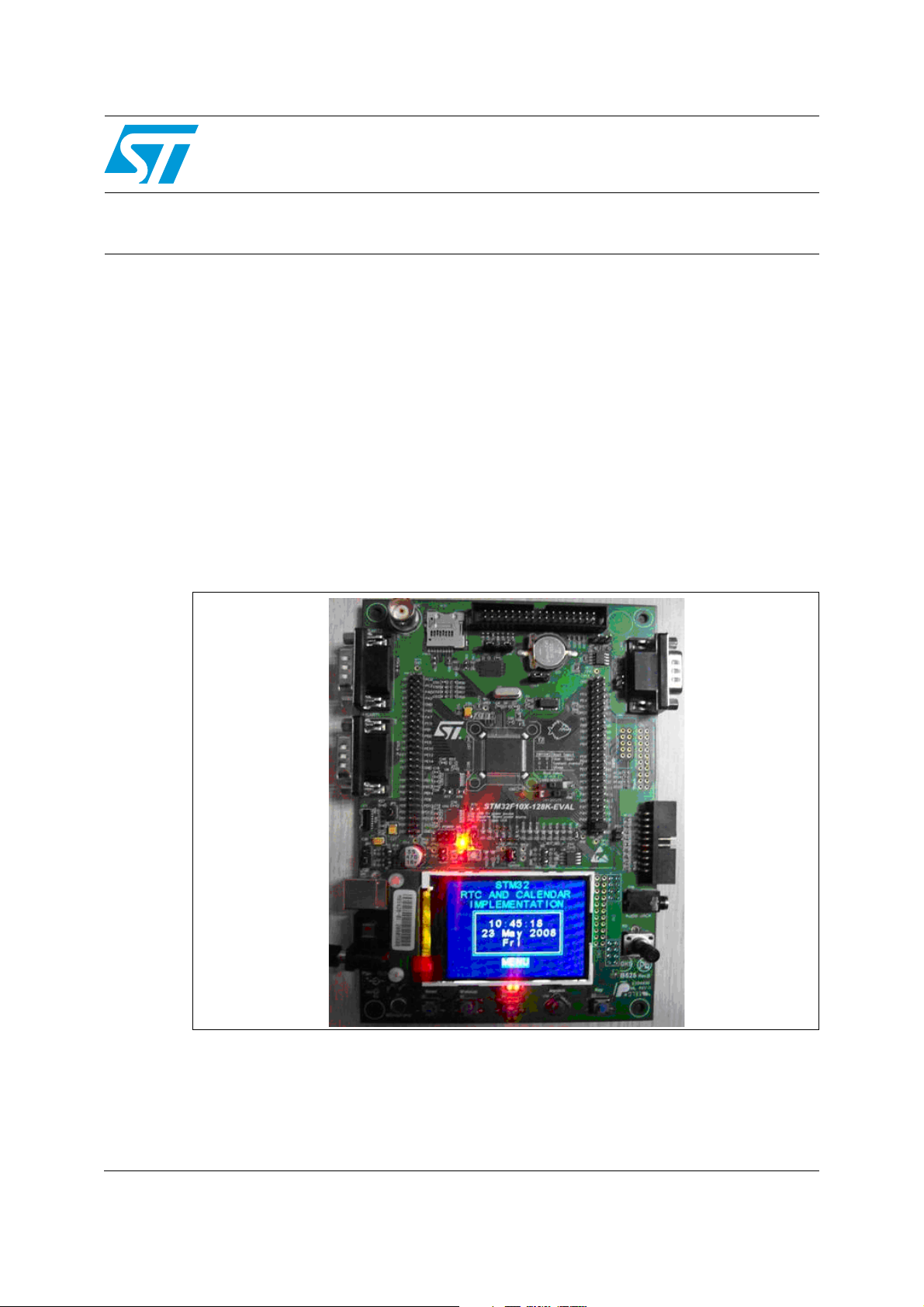

The STM3210B-EVAL board supports the firmware example described in this application

note without any modification to its hardware.

Figure 1. STM3210B-EVAL board

supply (when present) or the backup battery. Thus the RTC runs even

DD

April 2009 Doc ID 14949 Rev 2 1/28

www.st.com

Page 2

Contents AN2821

Contents

1 Overview of the medium-density STM32F10xxx backup domain . . . . . 6

1.1 Main backup domain features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Main RTC features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Configuring the RTC registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Clock/calendar functionality features . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Clock/calendar basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1.1 Implementing the clock function on the medium-density STM32F10xxx . 9

3.1.2 Implementing calendar function on the medium-density STM32F10xxx . 9

3.1.3 Summer time correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Clock source selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.4 Low-power modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4.1 Stop mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4.2 Standby mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.5 Tamper detection and time stamping . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.5.1 TAMPER-RTC pin functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.5.2 Tamper timestamping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.5.3 Battery tamper timestamping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 Firmware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 Hardware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 Running the demonstrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1 Clock/calendar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1.1 Setting the time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1.2 Setting the alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1.3 Setting the date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2 Low-power demonstration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1.4 Summer time correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2.1 Stop mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2.2 Standby mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2/28 Doc ID 14949 Rev 2

Page 3

AN2821 Contents

6.3 Timestamping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.3.1 Tamper events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.3.2 Battery removal and installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.4 Clock calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.5 Clock source selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.5.1 50 Hz time base selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.5.2 60 Hz time base selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Appendix A Calibration table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Appendix B Additional notes on calibration and clock accuracy . . . . . . . . . . . 25

7 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Doc ID 14949 Rev 2 3/28

Page 4

List of tables AN2821

List of tables

Table 1. Calibration lookup table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 2. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4/28 Doc ID 14949 Rev 2

Page 5

AN2821 List of figures

List of figures

Figure 1. STM3210B-EVAL board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. RTC block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. Time system flowchart

Figure 4. Calendar algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 5. Leap year flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 6. Calibration process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 7. Stop mode entry sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 8. Standby mode entry sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 9. STM3210B-EVAL board description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 10. RTC time base connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 11. Clock source selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

(1)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Doc ID 14949 Rev 2 5/28

Page 6

Overview of the medium-density STM32F10xxx backup domain AN2821

1 Overview of the medium-density STM32F10xxx

backup domain

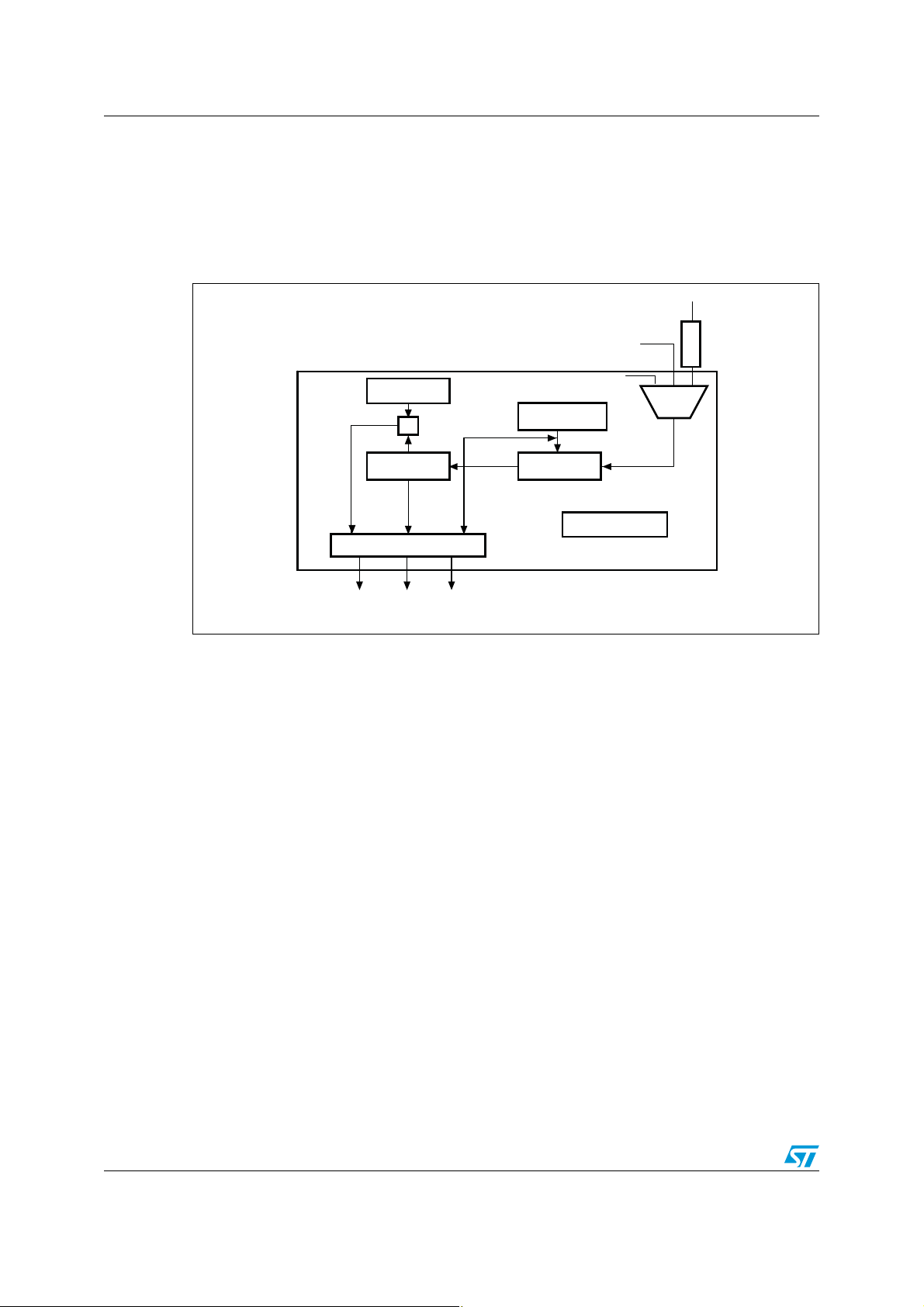

Figure 2 shows the RTC block diagram.

Figure 2. RTC block diagram

HSE OSC

RTC alarm

=

RTC counter

RTC control register

AlarmITOverflowITSecond

IT

1.1 Main backup domain features

The backup domain of the medium-density STM32F10xxx:

● includes ten 16-bit backup data registers, backup control/status registers and RTC

registers.

● is powered by V

● is not reset due to system reset, power reset or when the microcontroller wakes up

from the Standby mode.

● is protected from parasitic write access after reset (access to the backup domain is

disabled after reset)

● consists of two main units:

– an APB1 interface used to interface with the APB1 bus. The backup domain

registers are accessible through the APB1 bus in read/write access mode.

– an RTC core which is clocked by the RTC clock.

when the VDD main power is switched off.

BAT

LSE OSC/ EXT CLOCK

RTC prescaler

RTC divider

Backup registers

LSI RC

RTCSel

[1:0]

1/128

f

rtc

ai15437

6/28 Doc ID 14949 Rev 2

Page 7

AN2821 Overview of the medium-density STM32F10xxx backup domain

1.2 Main RTC features

The RTC:

● has three clock sources:

– LSE (low-speed external) clock that can also be bypassed by an external clock

– LSI (low-speed internal) RC oscillator

– HSE (high-speed external) clock divided by 128.

● has a 20-bit programmable prescaler that can be programmed to generate the RTC

time base. The prescaler load register contains the period counting value of the

prescaler.

● has three interrupt sources:

– second

–overflow

– alarm (also connected to EXTI Line 17 for auto-wakeup from Stop mode)

● its clock can be output on the TAMPER-RTC pin for calibration purposes.

Please refer to Figure 2 for an illustration of the medium-density STM32F10xxx RTC block

diagram.

All of the above mentioned features of the medium-density STM32F10xxx backup domain

can be used to develop a clock/calendar application equivalent to dedicated real-time

clocks.

Note: Be careful when choosing the 32.768 kHz crystal for your application. It is strongly

recommended to use a crystal with a load capacitance less than or equal to 7 pF. Never use

a crystal with a load capacitance of 12.5 pF.

Doc ID 14949 Rev 2 7/28

Page 8

Configuring the RTC registers AN2821

2 Configuring the RTC registers

On startup, follow the steps below to configure the RTC to generate an interrupt every

second:

● Enable the APB1 backup domain and power interface clocks by writing the BKPEN and

PWREN bits to ‘1’ in the RCC_APB1ENR register

● Enable access to backup domain by writing the DBP bit to ‘1’ in the PWR_CR register

● Enable the LSE clock by writing the LSEON bit to ‘1’ (also write LSEBYP to “1” when

the external clock has to be bypassed)

● Poll the LSERDY flag in the RCC_BDCR register until the LSE clock is ready (if the

external crystal is used as the clock source).

● Select LSE as the RTC clock source by writing ‘01’ to the RTCSEL bits in the

RCC_BDCR register.

● Enable the RTC clock by setting the RTCEN bit in the RCC_BDCR register

● Poll the RSF bit in the RTC_CRL register until the RTC registers are synchronized (if a

50/60 Hz external clock source is used this step may take up to a minute to complete)

● Poll the RTOFF bit in the RTC_CRL register until the last operation on the RTC

registers is over

● Enable the RTC second global interrupt by setting the SECIE bit in the RTC_CRH

register

● Wait for the last task to complete

● Set the RTC prescaler value using the following formula:

f

= f

TRCLK

–f

–f

RTCCLK

RTCCLK

TRCLK

For example, if an external 32.768 kHz (32 kHz) crystal oscillator is used, set the

prescaler to 32767. If an external 50 Hz supply is used set the prescaler value to 49.

/(PRL[19:0]+1), where:

is the input clock frequency

is the time base generated from the prescaler block

8/28 Doc ID 14949 Rev 2

Page 9

AN2821 Clock/calendar functionality features

Read RTC counter value

(TimeVar)

ai15438

Hours = TimeVar

3600

Minutes = TimeVar % 3600

60

Seconds =

(TimeVar % 3600) % 60

3 Clock/calendar functionality features

3.1 Clock/calendar basics

A real-time clock keeps track of the time (hours, minutes, seconds) and date (day, month,

year). It should also take into account leap years. A leap year is a year where an extra day is

added to the calendar in order to synchronize it to the seasons. Since the tropical year is

365.242190 days long, a leap day must be added roughly once every 4 years (4 × 0.242190

= 0.968760). Thus, every four years, the month of February counts 29 days instead of 28.

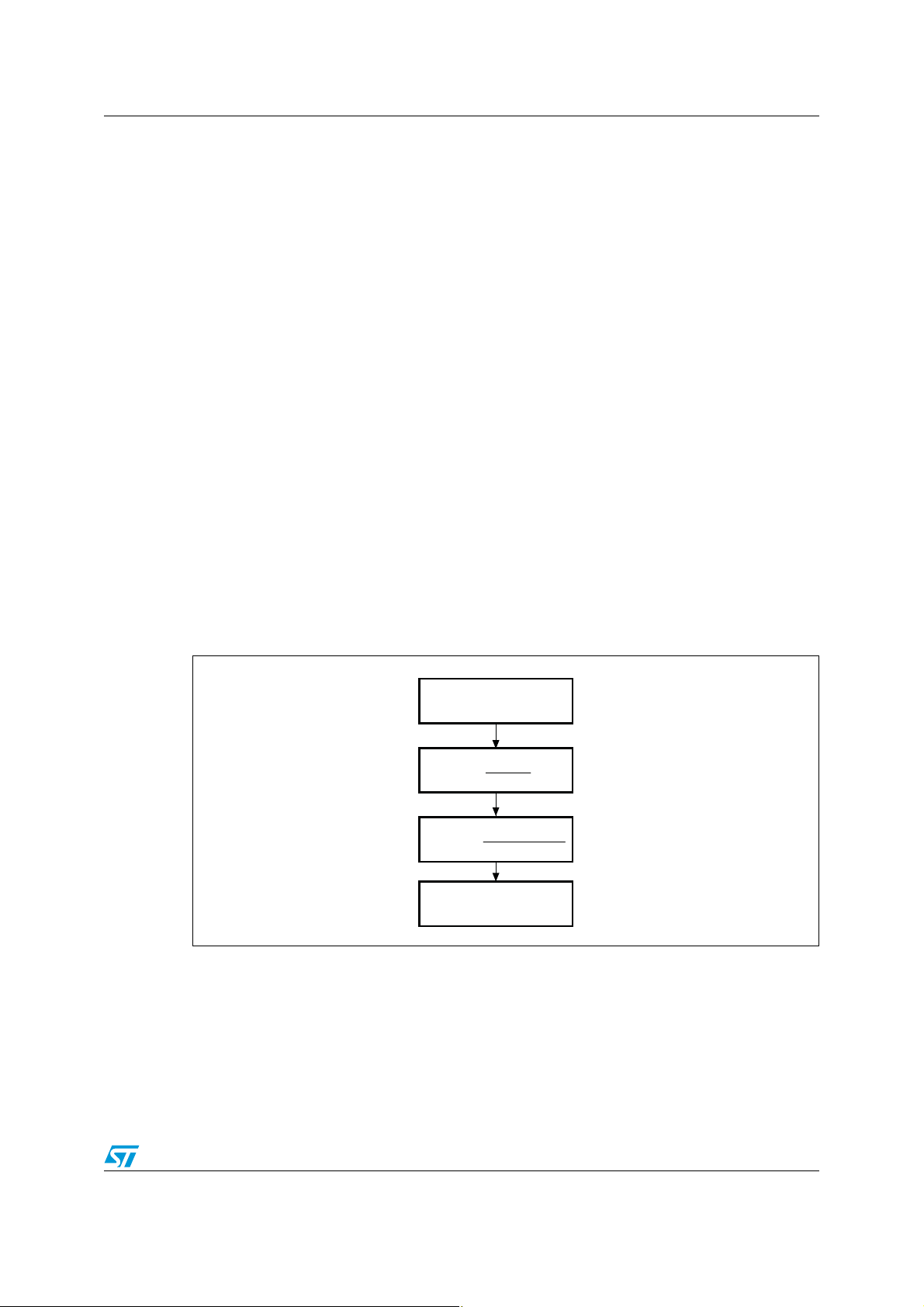

3.1.1 Implementing the clock function on the medium-density STM32F10xxx

The used registers are RTC registers: prescaler register, counter register and alarm register.

The medium-density STM32F10xxx RTC peripheral consists of a chain of programmable

counters consisting of two main units:

● the RTC prescaler block generates the RTC time base. Depending on the clock period

applied to the LSE input, this prescaler can be adjusted to generate a time base

(RTC_CLK) of 1 second by writing to the prescaler load register.

● the 32-bit programmable counter can be initialized to the current system time. The

system time is incremented at the RTC_CLK rate and compared with the alarm register

value. When it reaches the alarm register value, an interrupt is generated.

The current system time can be inferred from the value in the counter register by following

the steps shown in Figure 3 (“/” implies division, “%” implies modulus)

Figure 3. Time system flowchart

1. % is for modulo.

(1)

3.1.2 Implementing calendar function on the medium-density STM32F10xxx

The used registers are the 16-bit backup data registers.

When the 32-bit counter register value reaches 86399, this means that one day has

elapsed, and that the date has to be updated. The counter value is then reset. Whenever the

system date is updated, the new date is stored into the 16-bit backup data registers so that

Doc ID 14949 Rev 2 9/28

Page 10

Clock/calendar functionality features AN2821

No

Year divisible

by 400?

Year divisible

by 100?

Yes

Year divisible

by 4?

It is a leap year

Yes

No

No

Not a leap year

ai15440

Not a leap year

It is a leap year

Yes

the system remains at the current date even after system reset, power reset or wakeup from

the Standby mode.

The calendar algorithm given in Figure 4 can be used to develop the date update function.

Figure 4. Calendar algorithm

No

Month has

31 days ?

Yes

Day < 31

?

No

Month = 12

?

Yes

Month=1

Day=1

Year++

Month has

30 days ?

Yes

?

No

Month++

Day=1

Yes

No

No

Yes

Day++

Month++

Day=1

Day++Day < 31

Month = 2

?

Yes

Day < 28?

No

Day = = 28

?

Yes

Is it a

leap year?

No

Month++

Day=1

Day = = 29

?

Yes

Month++

Day=1

Yes

No

Yes

Day++

Day++

ai15439

Leap year correction: each time the date is updated, the possibility of a leap year also has to

be considered (please refer to Figure 5).

Figure 5. Leap year flowchart

10/28 Doc ID 14949 Rev 2

Page 11

AN2821 Clock/calendar functionality features

Caution: In the case of a device in low-power mode or whose external supply is off when the counter

reaches 86399, the counter cannot be reset and so the date is not updated. This is why, just

after power reset, it is necessary to check the counter value and update the date as many

times as the number of days during which the device remained in low-power mode or had its

external main supply switched off.

3.1.3 Summer time correction

This correction is also known as daylight saving and it is used in some countries to save

power. The principle is to increment the time of a given country by an hour in summer time

so that the sun rises an hour later in the morning and daylight is present longer in the

evening. Typically, an hour is added to all clocks near the start of spring and, likewise, an

hour is removed in autumn. Exact time and date for summer time correction differs from

location to location.

3.2 Clock source selection

The external LSE (low-speed external) crystal oscillator can be a crystal oscillator usually

with a frequency of 32.768 kHz (

clock source to the RTC peripheral for clock calendar applications. The external LSE can

also be bypassed by an external clock. Thus, in countries where the mains power line

frequency is significantly stable, a 50 Hz or 60 Hz clock can also be used to provide the RTC

clock. Assuming that there is already an isolating circuit and an overcurrent protection in the

system, all that is needed is to bypass the LSE crystal and adjust the prescaler load register

value so as to generate a time base of 1 second, and hence the second interrupt, if

configured.

32 kHz), which provides a low-power and highly accurate

This application only covers the case of an emulated 50/60 Hz clock source.

The RTC time base of 1 second is derived from the following formula:

● f

● f

50 Hz selection: the prescaler load register value is set to 49 (0x31)

60 Hz selection: the prescaler load register value is set to 59 (0x3B)

32.768 kHz selection: the prescaler load register value is set to 32767 (0x7FFF).

3.3 Calibration

Real-clock precision is a requirement in most embedded applications. The external crystal

oscillator used to provide the time base is subject to frequency variations due to external

conditions. It is therefore necessary to compensate for crystal and temperature variations.

The calibration routine used in this application is based on RTC calibration as described in

application note AN2604.

The medium-density STM32F10xxx RTC comes with a digital calibration circuit that gives

the user software control over the calibration process. The digital calibration circuit removes

0 to 127 cycles every 2

on the value loaded into the seven least significant bits of the RTC clock calibration register.

The calibration circuit can only subtract clock cycles, which means that only higher

f

TRCLK

TRCLK

RTCCLK

= f

RTCCLK

/(PRL[19:0]+1), where:

is the derived time base

is the clock frequency applied on the low-speed oscillator input

20

clock cycles. The number of times the pulses are blanked depends

Doc ID 14949 Rev 2 11/28

Page 12

Clock/calendar functionality features AN2821

Output RTC clock/64

on TAMPER-RTC pin

Calculate deviation

from 511.968 Hz

Find nearest

calibration value

Load the value into

calibration register

ai15441

Calculate error in ppm

(deviation/511.968)

× 1 million

frequencies can be compensated whereas lower frequencies cannot. The frequency range

that can be calibrated is [32772, 32768]. The workaround consists in setting the prescaler to

32766 (instead of 32767), in which case the frequency range that can be calibrated shifts

from [32772, 32768] to [32770, 32766].

The calibration process, illustrated in Figure 6, is the following:

First, the TAMPER-RTC pin functionality is disabled and the clock calibration register ASOS

and ASOE bits are cleared. The (RTC clock) /64) frequency is output on the TAMPER-RTC

pin by setting the CCO (clock calibration output) bit in the clock calibration register.

There are two modes of calibration: auto-calibration and manual calibration. Manual

calibration consists in actually measuring the LSE/64 value with an external calibrated

frequency counter, calculating and manually entering the calibration value via the joystick.

● Auto-calibration:

The frequency output on the TAMPER-RTC pin is fed to the timer input. The frequency

is calculated by using the PWM input mode of the medium-density STM32F10xxx

general-purpose timer peripheral. The calibration value to be entered in the calibration

register can be inferred on the basis of the deviation from 511.968 Hz (the calibration

table giving calibration values for various error values in ppm is given in Appendix A.)

● Manual calibration:

In this case, the frequency output on the TAMPER-RTC pin has to be measured by

using an external precision instrument. The calibration value has to be calculated, and

then entered manually using the joystick.

Note: 1 When the RTC clock/64 is output on the TAMPER-RTC pin, the tamper detection

functionality is not available.

2 When the auto-calibration feature is used, the obtained calibration accuracy depends on the

accuracy of the on-board HSE clock. This is because the HSE is used as the time base to

measure the LSE frequency. As a consequence, if a very accurate oscilloscope or

frequency counter is available, it is recommended to implement manual calibration.

Figure 6. Calibration process

12/28 Doc ID 14949 Rev 2

Page 13

AN2821 Clock/calendar functionality features

Select the regulator

state in Stop mode

Reset PDDS

Request _WFI()

or _WFE()

ai15442

Set the SLEEPDEEP

bit in the Cortex-M3

system control register

3.4 Low-power modes

After a system or power reset, the microcontroller is in Run mode. In this mode, the CPU is

clocked by HCLK, and the CPU and its peripherals are running. Several low-power modes

are available to save power when there is no need for the CPU to be running.

The medium-density STM32F10xxx low-power modes have no effect on the internal RTC,

whose counter values keep being updated. The RTC alarm can also be used to auto-wake

up the microprocessor from the low-power mode.

The Stop and Standby low-power modes are described in the following paragraphs.

3.4.1 Stop mode

In the Stop mode, the:

● CPU clock is off

● peripheral clocks, PLL, HSI, HSE are disabled

● SRAM and register contents are preserved

● RTC and IWDG are kept running

● voltage regulator can be on or in low-power mode

Any of the EXTI line source, RTC Alarm, PVD or USB Wakeup can be used to release the

microcontroller from the Stop mode. On exiting the Stop mode, the clock configuration

returns to its reset state (HSI used as the system clock).

Entering the Stop mode

The sequence used to enter the Stop mode is illustrated in Figure 7 and described below:

1. Select the regulator state in Stop mode through the LPDS bit in the PWR_CR register:

– LPDS = ‘0’, the regulator is ON

– LPDS = ‘1’, the regulator is in low-power mode

2. Reset the PDDS bit in PWR_CR

3. Set the SLEEPDEEP bit in the Cortex-M3 system control register

4. Request Wait for interrupt or Wait for event depending on how the Stop mode is

entered.

Figure 7. Stop mode entry sequence

Doc ID 14949 Rev 2 13/28

Page 14

Clock/calendar functionality features AN2821

Clear the WAKEUP flag

in PWR_CSR

Enable the WAKEUP

pin

Request _WFI()

ai15443

Set the SLEEPDEEP

bit in the Cortex-M3

system control register

Set the PDDS bit

After the microcontroller has exited the Stop mode, the basic reset and clock control circuitry

has to be reconfigured and access to the backup domain has to be re-enabled.

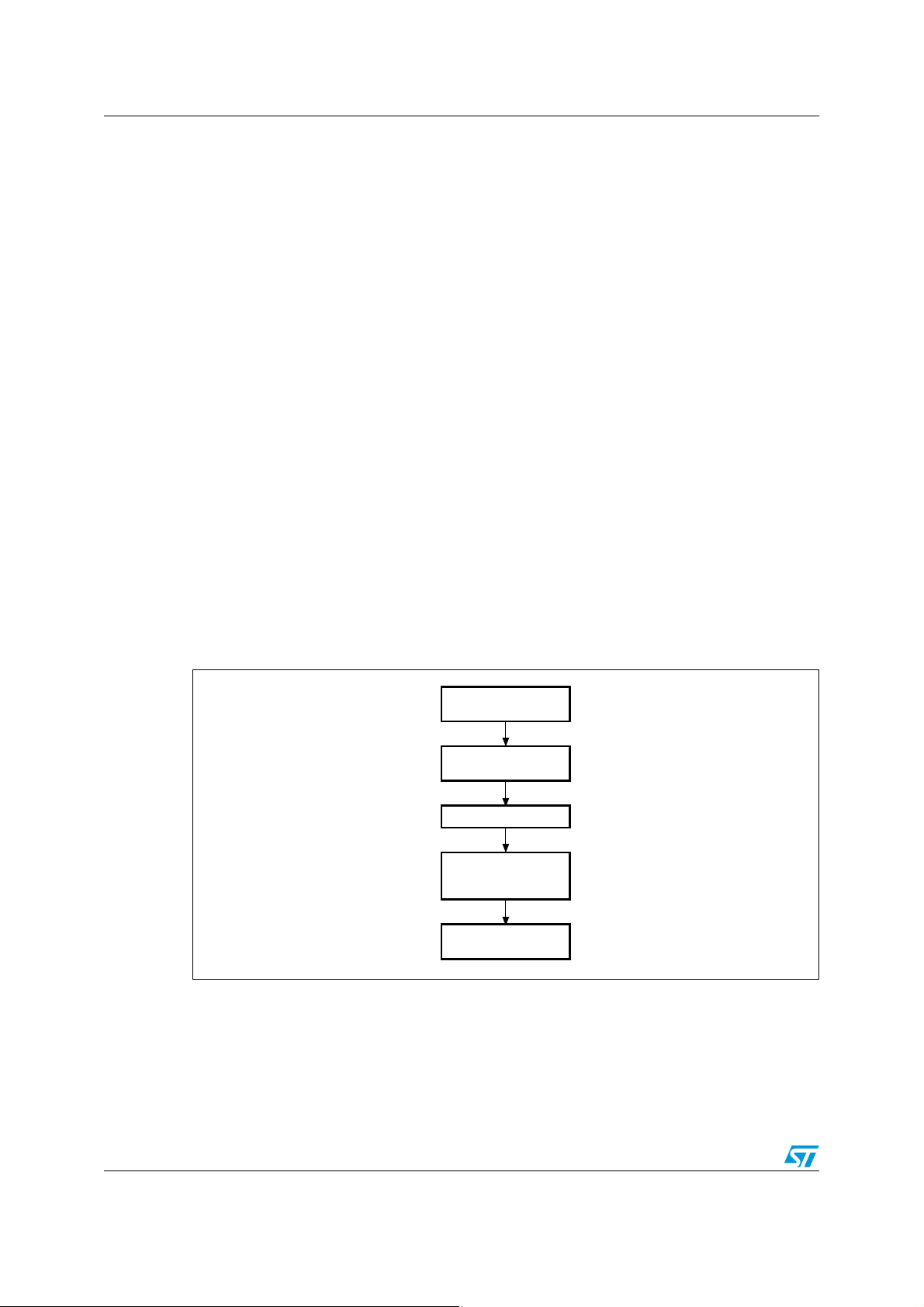

3.4.2 Standby mode

In the Standby mode, the:

● CPU clock is off

● SRAM and register contents are lost except for the backup domain

● RTC and IWDG keep running

● entire 1.8 V domain is off

● Exit through WAKEUP pin rising edge, RTC Alarm, external reset.

The Standby mode is exited on the WAKEUP signal’s rising edge, by external reset or by

triggering an RTC Alarm.

Entering the Standby mode

The sequence used to enter the Standby mode is illustrated in Figure 8 and described

below:

1. Clear the WAKEUP flag in the PWR_CSR register.

2. Enable the WAKEUP pin functionality by setting the EWUP bit in the PWR_CSR

register

3. Set the PDDS bit in PWR_CR

4. Set the SLEEPDEEP bit in the cortex system control register

5. Request Wait for interrupt

Figure 8. Standby mode entry sequence

The Standby mode is the lowest power consumption mode. After the microcontroller wakes

up from the Standby mode, program execution restarts in the same way as after a

system/power reset.

14/28 Doc ID 14949 Rev 2

Page 15

AN2821 Clock/calendar functionality features

3.5 Tamper detection and time stamping

The medium-density STM32F10xxx features an internal supervisor (in the backup domain)

that can be used to detect external tampering.

3.5.1 TAMPER-RTC pin functionality

The TAMPER-RTC pin generates a tamper detection event when the level applied to it

changes from ‘0’ to ‘1’ or from ‘1’ to ‘0’ depending on the TPAL bit in the backup control

register (BKP_CR). A tamper detection event resets all the backup data registers.

Configuring the TAMPER-RTC pin:

1. Set the TAMPER-RTC pin level by configuring the TPAL bit in the backup control

register

2. Enable the TAMPER-RTC pin interrupt by setting the TPIE bit in the backup

control/status register (BKP_CSR)

3. Enable the TAMPER-RTC pin by setting the TPE bit in the backup control register

(BKP_CR)

3.5.2 Tamper timestamping

The tamper detection feature and the RTC of the medium-density STM32F10xxx can be

used to timestamp the tamper events, that is, to store the exact time and date of each

tamper event. In this application note, the microprocessor’ s internal Flash memory was

emulated as an EEPROM. The last few pages of the Flash memory can be used to store

these timestamps. Every time a tamper event is detected, the backup data registers are

cleared, which means that after every tamper event the calendar information has to be

rewritten to the backup registers.

3.5.3 Battery tamper timestamping

Events like battery removal or battery installation can also be timestamped and stored into

the emulated EEPROM. For this purpose, the V

battery) can be connected to a general-purpose I/O. Configured in interrupt mode, this I/O

generates an interrupt on both the falling and rising edges of the V

battery removal and battery installation events. The exact times and dates of the events can

be stored into the memory.

pin (which is connected to the external

BAT

signal so as to detect

BAT

Doc ID 14949 Rev 2 15/28

Page 16

Firmware description AN2821

4 Firmware description

The example firmware consists of a clock/calendar driver that includes all the functions

needed to realize a clock and calendar application on the medium-density STM32F10xxx

RTC peripheral. Other features like RTC calibration, low-power mode demonstration,

timestamping for tamper detection and battery removal/installation and, clock source

selection (between external crystal and 50/60 Hz) are also supported by the clock/calendar

driver. The source code example is based on the STM32F10xxx standard peripheral library.

User include files:

● clock_calendar.h: contains the prototypes of the basic functions used to implement the

calendar function on the STM32F10xxx’s internal RTC. Also includes some macros for

summer-time correction, system start default time and date.

● application_rtc.h: contains the RCC_Configuration, GPIO_Configuration and

SystickConfig function prototypes.

● eeprom.h: contains the prototypes of the functions used to emulate EEPROM in the

STM32F10xxx’s internal Flash memory, and for the timestamping application.

● lcd.h: contains the prototypes of the functions used to drive the TFT LCD present on

the STM3210B-EVAL board.

● fonts.h: includes various LCD font size definitions.

● menu.h: contains the prototypes of the functions needed to implement the menu.

User source files:

● clock_calendar.c: contains the basic routines for calendar implementation and RTC

calibration.

● application_rtc.c: contains the routines for system clock, peripheral clock, GPIO and

Systick timer initialization.

● eeprom.c: contains the functions used to emulate EEPROM in the STM32F10xxx’s

internal Flash memory. The 1 Kbyte internal Flash memory page 124 (address

0x0801F000 – 0x0801F3FF) is used to store timestamping information. The page

address and size are defined in the eeprom.h header file.

● lcd.c: contains the functions used to drive the display on the STM3210B-EVAL board.

● menu.c: contains the functions used to implement the menu. Various features can be

accessed through the menu options displayed on the LCD screen.

16/28 Doc ID 14949 Rev 2

Page 17

AN2821 Hardware description

5 Hardware description

This application can be fully demonstrated on the STM3210B-EVAL board. The main

hardware sections used are:

● TFT LCD

● LED’s (LD1, LD2, LD3, LD4)

● Joystick

● Tamper switch

● Wakeup switch

● PA1, PC7, PC8, PC13 pads

Figure 9. STM3210B-EVAL board description

Doc ID 14949 Rev 2 17/28

Page 18

Running the demonstrator AN2821

6 Running the demonstrator

6.1 Clock/calendar

The home screen displays the clock, date and day on the LCD screen. The MENU provides

various options. When the application is run for the first time, some default settings are

applied. The current system time and date can be set using various MENU options.

Press joystick Sel to select, joystick right/left to move to the next/previous position and

joystick up/down to increment/decrement the value. If you want to exit the current menu, do

not press any key for eight seconds, the display will automatically return to the home screen.

6.1.1 Setting the time

To set the system time, go to MENU->Time, and use joystick up/down to

increment/decrement the value, joystick right/left to move to the next/previous position and

joystick Sel to set the time and return to the home screen. The clock will then start with the

newly set time.

6.1.2 Setting the alarm

To set the alarm, go to MENU->Alarm, use joystick left/right, and up/down to enter the alarm

time. Then, press Sel. The system will now prompt you to set the alarm date. Enter the

alarm date and press Sel. When the Alarm condition is reached, the LD1 LED (see Figure 9:

STM3210B-EVAL board description) lights up and ‘ALARM’ appears on the LCD screen.

After five seconds, LD1 turns off and the display returns to the home screen.

6.1.3 Setting the date

To set the system date, go to MENU->Date and enter the current date using the joystick.

After entering the date, press the joystick Sel button to set the current date and return to the

home screen. The updated date is then displayed on the screen.

If a wrong date is entered, an error message is displayed on the LCD screen.

6.1.4 Summer time correction

The clock is set ahead by 1 hour at 2 am on the last Sunday of March and it is delayed by 1

hour on the last Sunday of October. Assumedly, the correction for March has already been

done and the correction for October has to be done. This is a one-time assumption only,

further corrections being automatically handled. The date and time have to be after the

current system date and time, that is, for instance if the initial time and date were set to

12:00 hours, 1

but not earlier.

st

April, 2008, you can verify the time correction for October 2008 and beyond,

6.2 Low-power demonstration

6.2.1 Stop mode

To enter the Stop mode, go to MENU->LowPower->STOP and press Sel. The LD4 LED

(see Figure 9: STM3210B-EVAL board description) lights up and the MCU enters the Stop

18/28 Doc ID 14949 Rev 2

Page 19

AN2821 Running the demonstrator

mode. A confirmation message is displayed on the LCD screen. Press the joystick Sel

button to exit the Stop mode. LD4 turns off and the display returns to the home screen.

6.2.2 Standby mode

To enter the Standby mode, go to MENU->LowPower->STANDBY and press Sel. A

confirmation message is displayed on the screen. The Standby mode is exited by pressing

the Wakeup switch (see Figure 9: STM3210B-EVAL board description).

The RTC alarm can also be used to auto-wake up the microcontroller from the Stop or

Standby mode. For that purpose, first configure the RTC Alarm and then place the

microcontroller in a low-power mode. When the alarm sets off, the microprocessor wakes up

from the low-power mode.

6.3 Timestamping

6.3.1 Tamper events

To trigger a tamper event, press the B4 tamper switch on the STM3210B-EVAL board (see

Figure 9: STM3210B-EVAL board description).

6.3.2 Battery removal and installation

The battery removal and installation conditions are simulated on the STM3210B-EVAL

board. The “battery in place” condition is simulated by placing a jumper between PC7 and

PC8 whereas the “battery removed” condition is simulated by removing this jumper. PC7

and PC8 are available on the STM3210B-EVAL board (see Figure 9: STM3210B-EVAL

board description).

Viewing tamper events

To view the tamper log, go to MENU->Tamper->VIEW. If there is no tamper event stored,

the corresponding message is displayed on the LCD screen. A maximum of 64 events can

be stored. Each page shows up to 10 events. Subsequent pages can be displayed by

pressing the joystick SEL button. The tamper view screen is exited from the last page by

pressing the joystick SEL button once more.

Erasing the tamper log

The user can also erase the tamper log. To do so, go to MENU->Tamper->ERASE. This

erases the tamper log.

Since only a page (1 Kbyte) in Flash memory is used to store timestamps, a maximum of 64

timestamps can be stored. Whenever the 65

The LCD screen cannot display more than 10 events at a time. The difference between

timestamps created by pressing the tamper switch and battery tamper timestamps is that

the former type of timestamps shows a “seconds” field, whereas the others show “BI” or

“BO” (to mean “battery in” and “battery out”, respectively).

th

tamper occurs the memory page is erased.

Doc ID 14949 Rev 2 19/28

Page 20

Running the demonstrator AN2821

Note: The TAMPER-RTC pin functionality is not available:

●

when the user is navigating through the MENU options

●

when user is viewing the tamper log

●

during the calibration process

●

when the microprocessor is in a low-power mode

●

when the main VDD supply is off

6.4 Clock calibration

To calibrate the external oscillator in manual mode, do as follows:

● Go to MENU -> CALIBRATE-> MANUAL. A message appears on the LCD screen:

“LSE/64 is available on the PC13/TAMPER-RTC pin. Measure the frequency and press

Sel to proceed”.

The frequency output on the TAMPER-RTC pin can be measured by using a highprecision frequency counter. The PC13 pad is available on the STM3210B-EVAL

board. (Refer to Figure 9: STM3210B-EVAL board description.)

● Follow the steps of the procedure illustrated in Figure 6: Calibration process to

calculate the error in ppm. On the basis of this error, the calibration value can be

inferred from the Calibration lookup table in Appendix A.

Once this is done, press Sel. You will be prompted to enter the calibration value. To do

so, use the joystick up/down and left/right buttons, then press Sel again. If the entered

value is within the range (0-121), it is stored into the RTC clock/calibration register and

the application returns to the home screen. Otherwise, the value is invalid. This

generates an error message and the application returns to the home screen without

modifying the value in the RTC clock/calibration register.

To calibrate the external oscillator in auto-calibration mode, do as follows:

● First, connect a wire link from PC13 (RTC clock output on the TAMPER-RTC pin) to

PA1 (timer input). Both of these pads are available on the STM3210B-EVAL board.

(Refer to Figure 9: STM3210B-EVAL board description.)

● Select MENU->CALIBRATE->AUTO: the calibration value is automatically calculated

and fed into the calibration register. A confirmation message will appear on the LCD

screen.

● After the calibration process, the application returns to normal clock operation.

Note: For more details, please refer to Appendix B: Additional notes on calibration and clock

accuracy on page 25.

6.5 Clock source selection

By default, on startup the clock runs at the external crystal oscillator frequency of

32.768 kHz. This frequency is provided by the clock source of the STM3210B-EVAL board.

An external clock source can also be used to provide the time base for the RTC. Figure 10

shows how to realize the RTC time base circuit.

20/28 Doc ID 14949 Rev 2

Page 21

AN2821 Running the demonstrator

STM32F10xxx

50/60 Hz in

Resistive

divider

Source

switch

OSC in

OSC out

2 jumpers for source

selection, to GPIO

Jumper for anti-tamper

demonstration,

optional

display (part of main

system)

switches/joystick,

to set the time/date

(part of main system)

Backup battery

(part of main system)

32 kHz crystal

ai15444

Figure 10. RTC time base connection

In this application note, the clock source selection is demonstrated by emulating an external

50/60 Hz sinewave (as can be derived from the utility mains). The external 50/60 Hz can be

derived from a function generator and applied to the oscillator input using a connector probe

(see Figure 11: Clock source selection).

Caution: Make sure that the amplitude of the applied clock signal is less than 3 V peak-to-peak and

that the corresponding DC offset is about half the full-scale value.

Note: Since the time base selection is a one-time setting, the clock is initialized every time the time

base is changed.

6.5.1 50 Hz time base selection

To select an external 50 Hz clock source:

● Apply the external clock to the oscillator input. The clock will seem to stop running.

● Go to MENU->50Hz and press the joystick Sel button. This sets the prescaler

accordingly and the clock restarts from 09:24:00.

To return to the 32.768 kHz clock source selection:

● Go to MENU->32768Hz and press the joystick Sel button

● Remove the external clock source. The clock restarts from 09:24:00.

6.5.2 60 Hz time base selection

To select an external 60 Hz source:

● Apply the external clock to the oscillator input

● Go to MENU->60Hz and press the joystick Sel button. this sets the prescaler

accordingly and the clock restarts from 09:24:00.

To return to the 32.768 kHz clock source selection:

● Go to MENU->32768Hz and press the joystick Sel button

● Remove the external clock source. The clock restarts from 09:24:00.

Doc ID 14949 Rev 2 21/28

Page 22

Running the demonstrator AN2821

Figure 11. Clock source selection

22/28 Doc ID 14949 Rev 2

Page 23

AN2821 Calibration table

Appendix A Calibration table

Ta bl e 1 gives a list of calibration values.

Table 1. Calibration lookup table

Calibration

value

Value in ppm

rounded to the

nearest ppm

Value in seconds per

month (30 days) rounded

to the nearest second

Calibration

value

Value in ppm

rounded to the

nearest ppm

month (30 days) rounded

00 0 6461 158

11 2 6562 161

22 5 6663 163

33 7 6764 166

4 4 10 68 65 168

5 5 12 69 66 171

6 6 15 70 67 173

7 7 17 71 68 176

8 8 20 72 69 178

9 9 22 73 70 180

10 10 25 74 71 183

11 10 27 75 72 185

12 11 30 76 72 188

13 12 32 77 73 190

14 13 35 78 74 193

15 14 37 79 75 195

16 15 40 80 76 198

17 16 42 81 77 200

18 17 44 82 78 203

19 18 47 83 79 205

20 19 49 84 80 208

21 19 49 85 81 210

22 21 54 86 82 213

23 22 57 87 83 215

24 23 59 88 84 218

25 24 62 89 85 220

26 25 64 90 86 222

27 26 67 91 87 225

28 27 69 92 88 227

29 28 72 93 89 230

Value in seconds per

to the nearest second

Doc ID 14949 Rev 2 23/28

Page 24

Calibration table AN2821

Table 1. Calibration lookup table (continued)

Calibration

value

Value in ppm

rounded to the

nearest ppm

Value in seconds per

month (30 days) rounded

to the nearest second

Calibration

value

Value in ppm

rounded to the

nearest ppm

30 29 74 94 90 232

31 30 77 95 91 235

32 31 79 96 92 237

33 31 82 97 93 240

34 32 84 98 93 242

35 33 87 99 94 245

36 34 89 100 65 247

37 35 91 101 96 250

38 36 94 102 97 252

39 37 96 103 98 255

40 38 99 104 99 257

41 39 101 105 100 260

42 40 104 106 101 262

43 41 106 107 102 264

44 42 109 108 103 267

45 43 111 109 104 269

46 44 114 110 105 272

47 45 116 111 106 274

48 46 119 112 107 277

49 47 121 113 108 279

50 48 124 114 109 282

51 49 126 115 101 284

52 50 129 116 111 287

53 51 131 117 112 28

54 51 133 118 113 292

55 52 136 119 113 294

56 53 138 120 114 297

57 54 141 121 115 299

58 55 143 122 116 302

59 56 146 123 117 304

60 27 148 124 118 307

61 58 151 125 119 309

62 59 153 126 120 311

63 60 156 127 121 314

Value in seconds per

month (30 days) rounded

to the nearest second

24/28 Doc ID 14949 Rev 2

Page 25

AN2821 Additional notes on calibration and clock accuracy

dT

1

F0 dF+

-------------------- -

F0

-------------------- - 1 s–

1 s

-----------------------------------=

dT

1

32762.7648

-------------------------------

32766

------------------------------- 1 s–

1 s

--------------------------------------------- -=

Appendix B Additional notes on calibration and clock

accuracy

The purpose of this appendix is to provide an effective calibration and drift calculation

scheme by a mathematical approach.

It is easy to verify the actual (observed) result using the theoretical value obtained. The

procedure first consists in calculating how much the clock drifts ahead (due to crystal

frequency variation) in a month when not calibrated. This is the amount that the clock must

“lose” to keep time correctly.

Next, the procedure consists in calculating how much the clock actually loses as a result of

calibration.

Example of calculation

To implement this method, switch to calibration mode, and measure the frequency output on

the TAMPER-RTC pin using a suitable and very accurate frequency counter. Let F1 be the

result obtained with this counter. Let us assume that F1 = 512.0193 Hz.

Let F2 be the corresponding effective LSE frequency.

F2 = 64 × F1 = 64 × 512.0193 Hz = 32769.2352 Hz.

Let us put dF = F0 – F2, where F0 = 32766 in our case, because the RTC prescalor is set to

32766 and not 32768. This means that we get a tick every 32766 oscillator cycles.

Thus, dF = 32766 – 32769.2352 = –3.2352

Let us now calculate the time drift or deviation generated by crystal variations only. It is given

by:

that is:

= (1.00009875) – 1 = 0.00009875 s = 98.75 µs

So over 1 second, the positive time drift is of 98.75 µs.

Thus, over 1 month the drift becomes: 0.00009875 s × 60 × 60 × 24 × 30 = 255.95 s.

Let T1 be this positive time drift.

Therefore, if we want to compensate for this time drift, we must, as a result of the calibration

process, lose T1.

Doc ID 14949 Rev 2 25/28

Page 26

Additional notes on calibration and clock accuracy AN2821

Error in ppm

512.0193

32766

64

----------------–

32766

64

----------------

-----------------------------------------------

1000000 100.2 ppm==

number of seconds lost in 1 month

32766606024 30

2

20

--------------------------------------------------------------------

105

32766

------------------------------------------------------------------------------------ -

260 seconds =

Now let us look into the calibration process:

Referring to the calibration lookup table, the calibration value that corresponds to an error of

100.2 ppm is 105, which amounts to a compensation (subtraction) of 260 seconds. Let T2

be this compensation time.

(STM32 digital calibration subtracts [Calibration value] every 2

20

oscillator cycles. That is:

This means that the clock will run slower by (T2 – T1), that is 4 seconds at the end of a

month. Thus, ideally, an average drift of 4/30 (about 0.133) second a day is achievable.

You can refer to a precise and accurate web clock to synchronize your clock, for instance the

US Naval Observatory Master Clock (http://www.usno.navy.mil/).

Note: Temperature effects and measuring instrument accuracy are not taken into account in the

above calculations.

26/28 Doc ID 14949 Rev 2

Page 27

AN2821 Revision history

7 Revision history

Table 2. Document revision history

Date Revision Changes

23-Dec-2008 1 Initial release.

References to the STM32F10xxx firmware library updated to

30-Apr-2009 2

STM32F10xxx standard peripheral library.

Systick_Config updated to SystickConfig.

Doc ID 14949 Rev 2 27/28

Page 28

AN2821

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2009 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

28/28 Doc ID 14949 Rev 2

Loading...

Loading...