Page 1

AN2799

Application note

Measuring mains power consumption

with the STM32x and STPM01

Introduction

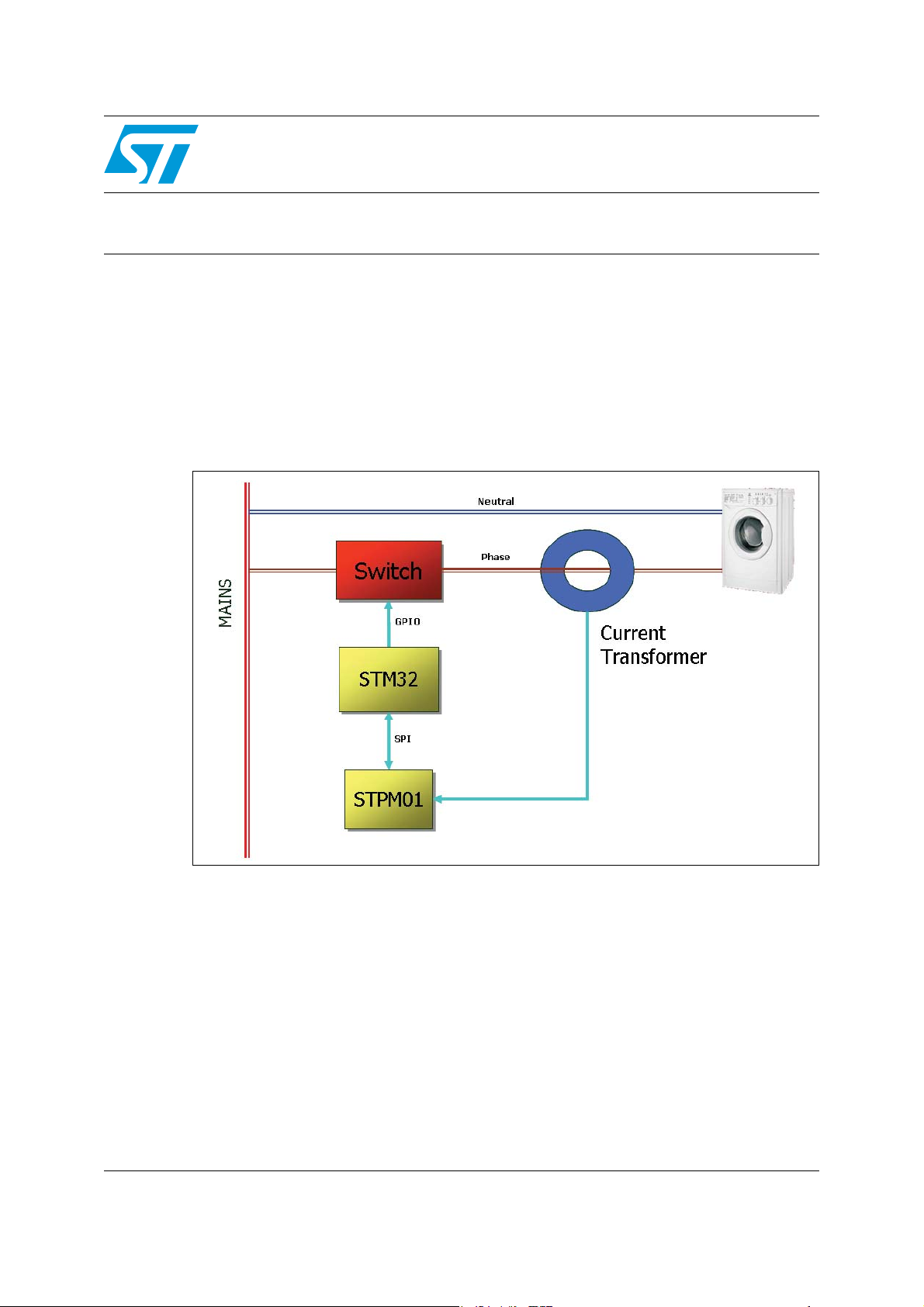

This document describes a software and hardware solution concerning the STM32x

microcontroller and the STPM01 power meter for measuring mains power consumption and

also provides hardware and firmware guidelines to interface the STPM01 with the STM32x

microcontroller. Figure 1 shows the block diagram of the solution. The system described in

this document is the first “brick” to build a complex system for distributed load management.

Figure 1. Block diagram

AM00076v1

November 2008 Rev 1 1/14

www.st.com

Page 2

Contents AN2799

Contents

1 File organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 STM32F103xx microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1.1 STPM01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Hardware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Firmware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.1 Power meter object description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.1.1 Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1.2 Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1.3 Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1.4 Deletion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Hardware abstraction layer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2.1 HAL functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.3 Application interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.3.1 Application interface functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2/14

Page 3

AN2799 File organization

1 File organization

The following table presents the firmware modules.

Table 1. Firmware modules

File Description

PowerMeterHal.h

PowerMeterHalTypes.h

PowerMeterObj.h

PowerMeterTypes.h

PowerMeterHal.c

PowerMeterObj.c

Meterlayer.h Definitions of application interface types and function prototypes

Meter.c

MeterHal.c

ExampleApp.c Library usage example

2 Hardware

The solution is based on the STM32F103xx in the LQFP64 package with 128 kB of Flash

and 20 kB of SRAM for demonstration purposes, but it can be easily ported on the smaller

STM32F101xx microcontroller family based on the same ARM Cortex™-M3 CPU as well.

The device used to measure the phase AC current is the STPM01 with a current

transformer.

Definitions of power meter hardware abstraction layer types and function

prototypes.

Definitions of power meter abstract objects and types.

Power meter hardware abstraction layer and abstract object

implementation

Application interface and hardware abstraction layer implementation

3/14

Page 4

Hardware AN2799

2.1 STM32F103xx microcontroller

The following list is a brief description of the features of the STM32F103xx microcontroller.

Please refer to the STM32F103xx datasheet for a more detailed description of the device.

● Core: ARM 32-bit Cortex™-M3 CPU

– 72 MHz, 90 DMIPS with 1.25 DMIPS/MHz

– Single-cycle multiplication and hardware division

● Memory

– 32-to-128 Kbytes of Flash memory

– 6-to-20 Kbytes of SRAM

● Clock, reset and supply management

– 2.0 to 3.6 V application supply and I/Os

– POR, PDR, and programmable voltage detector (PVD)

– 4-to-16 MHz quartz oscillator

– Internal 8 MHz factory-trimmed RC

– Internal 40 kHz RC

– PLL for CPU clock

– 32 kHz oscillator for RTC with calibration

● Low power

– Sleep, stop and standby modes

– VBAT supply for RTC and backup registers

● 2 x 12-bit, 1 µs A/D converters (16-channel)

– Conversion range: 0 to 3.6 V

– Dual-sample and hold capability

– Temperature sensor

● DMA

– 7-channel DMA controller

– Peripherals supported: timers, ADC, SPIs, I

● Debug mode

– Serial wire debug (SWD) & JTAG interfaces

● Up to 80 fast I/O ports

– 26/36/51/80 I/Os, all mappable on 16 external interrupt vectors, all 5 V-tolerant

except for analog inputs

● Up to 7 timers

– Up to three 16-bit timers, each with up to 4 IC/OC/PWM or pulse counter

– 16-bit, 6-channel advanced control timer: up to 6 channels for PWM output dead

time generation and emergency stop

– 2 watchdog timers (independent and window)

– SysTick timer: a 24-bit down counter

● Up to 9 communication interfaces

– Up to 2 I

2

C interfaces (SMBus/PMBus)

2

Cs and USARTs

4/14

Page 5

AN2799 Hardware

– Up to 3 USARTs (ISO 7816 interface, LIN, IrDA capability, modem control)

– Up to 2 SPIs (18 Mbit/s)

– CAN interface (2.0B Active)

– USB 2.0 full speed interface

● Packages are ECOPACK

®

(RoHS compliant)

2.1.1 STPM01

The STPM01 is a programmable single-phase energy metering IC which is designed for

effective measurement of active, reactive and apparent energy in a power line system using

a Rogowski coil, a current transformer and shunt sensors. The solution presented in this

document is based on a current transformer sensor. The following list is a brief description of

the main features of the STPM01. For more details, please refer to the device datasheet.

● Active, reactive, apparent energies and RMS values

● Ripple-free active energy pulsed output

● Live and neutral monitoring for tamper detection

● Easy and fast digital calibration in only one point over the whole current range

● OTP for calibration and configuration

● Integrated linear V

● Selectable RC or crystal oscillator

● Supports 50-60 Hz - IEC62052-11, IEC62053-2X specification

● Less than 0.1% error

● Precision voltage reference: 1.23 V and 30 ppm/°C max

for digital and analog supply

REGS

2.2 Hardware description

The hardware used in managing the STPM01 by the STM32x microcontroller is described in

this section. Figure 2 shows a reference schematic to interface the STM32x microcontroller

with the STPM01. The STPM01 bidirectional data line is connected to the SPI-MISO of the

STM32. This is because the speeds for the data read and data write operations of the

STPM01 SPI interface are much too different: 32 MHz for the read operation and 100 kHz

for the write operation. In fact during the write operation, the serial communication is

emulated by software to have very slow communication on the STPM01 data line and during

the read operation, the STM32 SPI peripheral is used to reach the maximum speed

possible. Since the maximum speed of the STM32 SPI is 18 MHz, it doesn't matter which

SPI peripheral is used to have the maximum read bit rate. In this application the SPI2 is

used. The STPM01 clock is provided by the PA8 pin configured as the MCO alternate

function. The AC current is provided to the STPM01 by a current transformer connected to

the current channel 1. For more details about analog parts related to the STPM01, please

refer to the STPM01 datasheet.

Note: The solution has been validated using the “SmartPlug” board. For further details please

refer to the “SmartPlug hardware user manual” .

5/14

Page 6

Hardware AN2799

TA

RO

EB

G

NE

OS

CC

OS

CC

V3

11

00

SP

20

OS

OS

76

PA

SA

DC

CH

PA

SA

DC

CH

PA

SA

PA

SA

PA

SS

DC

PA

PA

SO

DC

CH

PA

I/

DC

CH

PA

SA

CH

PA

SA

PA

CH

PA

CH

PA

PA

AT

PA

PA

PB

PB

BOO

PB

B1

SS

/I

BA

BK

PB

SP

1N

14

CH

15

SP

PB

PB

PB

PB

PB

DC

DC

DC

DC

DC

DC

NR

ST

BOO

AT

VS

DD

SE

ND

CR

S0

DD

SO

DD

DD

t

an

Mor2

ou

15

47

0n

DD

10

0n

1n

10

0n

10

Figure 2. Schematic diagram

JTAG-CK

JTAG-DO

JTAG-RS

JTAG-RST

JTAG-TMS

JTAG-DI

CTOR

CONNE

UG

G/DEB

G PRO

JT-TCK

JT-TRS

JT-TDO

JT-TDI

RESET#

JT-TMS

JTA

_3V3

VCC

_LINE

VDD33_LINE

GND

DN

NG

G D

VDD_IO#99VDD_IO#99

VCC_3V3

100n

C57

100n

C56

C55

C54

VCC_3V3

C-32-IN

OS

100n

n

Y1

100

12

_33

12

VDD

12

9

8

-IN10

PC0/ADC

1-ETR

VDDDD4

19

VDDDD3

64

VDDDD2

48

VDDDD1

32

_IN0/TIM2-CH

VBAT

1

RT2-CTS/ADC

0-WKUP/USA

PA

U12

15

14

C-32-OUT

C59

10pF

OS

8 Khz

32.76

10pF

C58

2.4k

R13

D5

2.4k

D4

R12

2.4k

R11

D3

_33

VDD

VOTP

0

ZCR

C-32-IN

C-32-OUT

JT-TDO

JT-TRS

OS

OS

26

40

11

37

10

24

25

38

51

PC6

PC839PC9

PC7

-IN11

-IN13

-IN12

-IN15

-IN14

PC1/ADC

PC3/ADC

PC2/ADC

PC5/ADC

PC4/ADC

2

2

1

-IN4

1/MCO

-IN1/TIM2-CH

-IN7/TIM3-CH

-IN6/TIM3-CH

ADC

/ADC

/USART2-CK/ADC

RT2-RTS/ADC

RT2-TX/ADC-IN2/TIM2-CH3

RT1-CK/TIM1-CH

RT1-TX/TIM1-CH2

RT2-RX/ADC-IN3/TIM2-CH4

7/SPI1-MOSI/

1/USA

2/USA

3/USA

4/SPI1-NSS

6/SPI1-MISO

8/USA

9/USA

5/SPI1-SCK/ADC -IN5

PA

PA

PA

PA

PA

PA

PA

PA

PA

17

20

22

23

42

16

21

41

43

28

57

27

55

53

PC1152PC12

PC10

4

3

10/USART1-RX/TIM1-CH

11/USART1-CTS/CAN-R X/USBDM(2)/TIM1-CH

PA

PA

44

45

56

2

4

3

T1

4/JTRST

PB3/JTDO

PB

PB2/BOO

PC14/OSC32-IN

PC13/ANTI-TAMP

PC15/OSC32-OUT

1/ADC-IN 9/TIM3-CH4

0/ADC-IN 8/TIM3-CH3

PB

PB

12/USART1-RTS/CAN-TX/USBDP(2)/ TIM1-ETR

14/JTCK-SWCLK

15/JTDI

13/JTMS-SWDAT

PA

PA

PA

PA

PD2/TIM3-ETR54PD0/OSC-IN

PD1/OSC-OUT

5

6

49

50

46

MCO

SYN0

JT-TMS

JT-TDI

JT-TCK

SCS0

SCLK

SPI0_MISO

D2

R10

2.4k

12

SYN0

I0_MISO

SP

SCS0

SCLK

61

59

29

30

33

35

58

5/I2C1-SMBA1

PB

36

62

34

2N

IN

8/TIM4-CH3

9/TIM4-CH4

PB

PB

6/I2C1-SCL/TIM4-CH 1

PB

7

T#

RESE

I2-MOSI/TIM1-CH3N

/SP

PB7/I2C1-SDA/TIM4-CH 2

11/I2C2-SDA/U SART3-RX

PB10/I2C2-SCL/U SART3-TX

1/USART3-CK/TIM1-BK

VSVSS4

PB

PB15

18

VSVSS3

63

VSVSS2

I2-SCK/USAR T3-CTS/TIM1-CH1N

47

VSVSS1

31

2C2-SMBA

/SPI2-MISO/USART3-RTS/TIM1-CH

/I

13/SP

PB

PB14

2/SPI2-NSS

PB1

T0

A

ST

SA

NR

VS

BOO

VDD

60

R109

_3V3

VCC

R108

1M

Y2

_33

VDD

STM32F103RBT6

12

13

0

R11

100K

C63

10n

10K

100n

C62

Rst

SW11

C61

20p

8MHz

p

20

C60

_IO#99

VDD

F

10n

C11

5

R18 47

R66

0K R232,21K

0R

R22 15

MCO

16

12

15

17

14

18

3

19

11

t

Vip13Vin

Scl

Ilp2

Iln2

Scs

Sda

Syn

CLKin

CLKou

U4

MON1MOP

led

2

20

ZCR0

f

C8

100n

C7

0nF

10

0nF

C6

10

F

C5

100n

0nF

C4

10

F

C3

1n

STPM01

Vss

Vdda8Votp

Iln1

Vddd

Vcc

Ilp1

4

6

9

7

5

10

R14 1k

D6

1N4148

R17

2M

C9

10nF

R21

261K

R20

261K

R19

261K

R16 1k

L

L_LINE

6.8

R68

R15

6.8

sf ormer

T1

Tran

Current

N_LINE

L

N

N

Mor2

1

2

W3 W2

mains

6/14

AM00077v1

Page 7

AN2799 Functional description

3 Functional description

The STPM01 host interface is a single bidirectional data line SPI with a 32 MHz maximum

read speed and 100 kHz maximum write speed. Due to these requirements the STM32

microcontroller is used in the following way:

● In the reading phase, the MISO and SCLK pins are configured in alternate functions

and used by the SPI2 peripheral. The maximum reading speed is 18 MHz by an APB

speed equal to 36 MHz, configuring the SPI baud rate with APB/2.

● In the writing phase the MISO and SCLK pins are configured as GPIOs and the SPI

operation is emulated by firmware controlling the speed operations to not exceed the

100 kHz writing speed limit. The MCO pin is configured to provide the HSE clock.

4 Firmware description

The firmware for the management of the STPM01 energy meter has been developed using

an object oriented programming (OOP) approach even if standard ANSI C programming

language has been used.

4.1 Power meter object description

The power meter object is defined and implemented in the PowerMeterObj.c,

PowerMeterObj.h and PowerMeterTypes.h files. The power meter is represented by a

structure containing the properties and the method of the Power Meter Object as illustrated

in Figure 3.

Figure 3. Power meter object

AM00078v1

7/14

Page 8

Firmware description AN2799

POWER_METER_OBJ

#define POWER_METER_OBJ

PM_u32 m_Voltage;

PM_u32 m_Current;

PM_u32 m_Energy ;

PM_RegistersType Registers;

PM_SignalsType Signals;

PM_ErrStatus (* Create)(PowerMeterType*);

PM_ErrStatus (* Destroy)(PowerMeterType*);

PM_ErrStatus (* Init)(PowerMeterType*);

PM_ErrStatus (* Reset)(PowerMeterType*);

PM_ErrStatus (*SetSignals)(PowerMeterType*,PM_SignalsType* pSignals);

PM_SignalsType* (*GetSignals)(PowerMeterType*);

PM_ErrStatus(*SetCfgRegsMode)(PowerMeterType*,PM_CfgRegsModeType CfgRegsMode);

PM_ErrStatus(*WriteConfigBit)(PowerMeterType*, PM_u8 uBitAddress, PM_u8

uBitValue);

PM_ErrStatus(*WriteConfigRegs)(PowerMeterType*,PM_u32 uCFL_Value, PM_u32

uCFH_Value);

PM_ErrStatus (*ReadRegisters)(PowerMeterType*, PM_u8 RegsToReadNum);

PM_ErrStatus (*ReadMeasure) (PowerMeterType*, PM_u8 MeasureType);

PM_u32 (*GetVoltage)(PowerMeterType*);

PM_u32 (*GetCurrent)(PowerMeterType*);

PM_u32 (*GetEnergy)(PowerMeterType*);

PM_ErrStatus (*OnSpiRxIrq)(PowerMeterType*);

typedef struct PowerMeter PowerMeterType; /* Forward declaration for circular

typedefs */

struct PowerMeter {

POWER_METER_OBJ

};

8/14

Page 9

AN2799 Firmware description

4.1.1 Attributes

The object attributes are described as follows:

● m_Voltage: “private” variable containing the last read voltage in mV

● m_Current: “private” variable containing the last read current in mA

● m_Energy: “private” variable containing the last read energy in mW

● Registers: “public” structured variables containing the STPM01 registers:

– DAP: type0 active energy

– DRP: reactive energy

– DSP: apparent energy

– DFP: type1 energy

– DEV: RMS values of measured voltage and current

– DMV: instantaneous values of measured voltage and current

– CFL: lower part of the configuration register

– CFH: higher part of the configuration register

● Signals: “public” structured variables containing the signals descriptor used to interface

STM32 with STPM01:

– PM_SCS: this signal enables the SPI operation when low

– PM_SYN: When SCS is low, this signal selects the read or write operation. When

both SCS and SYN signals are high, the results of the input or output data are

transferred to the transmission latches.

– PM_SDA: SPI MISO signal. This signal is used as the STPM01 data signal. The

direction of this signal depends on the SYN signal.

– PM_SCLK: SPI clock signal

Each signal descriptor contains the STM32 port and pin number. For further details about

SPM01 registers and the microcontroller interface, please refer to the STPM01 datasheet.

4.1.2 Methods

The object methods are implemented by means of pointers to functions which are described

as follows:

● Create: this function initializes all power meter object elements (properties and

methods).

● Destroy: not used. Implemented to have a general object implementation.

● Init: this function initializes the power meter object properties and the power meter

signals putting them in the idle state.

● Reset: this function executes the reset sequence to perform the “remote reset”

operation of the STPM01 (Figure 4).

● SetSignals: this function initializes the “signals” attribute of the power meter object and

configures the GPIOs related to the signals.

● GetSignals: this function retrieves the “signals” attribute of the power meter object.

● SetCfgRegMode: this function sets the STPM01 configuration register as shadow

latches or OTP. In current AN firmware the STPM01 is configured to use the shadow

latches for the configuration for testing reasons.

9/14

Page 10

Firmware description AN2799

● WriteConfigBit: this function writes a configuration bit of the STPM01 configuration

register formatting an 8-bit command word as the following:

1 bit data 6 bits configuration bits 1 bit don’t care

The configuration word is sent to the STPM01 by the SPI interface.

● WriteConfigRegs: this function writes the entire CFL and CFH configuration registers of

the STPM01.

● ReadRegisters: this function reads the registers from the STPM01 and assigns the

read values to the power meter object registers attribute. The number of read registers

depends on the RegToReadNum passed parameter.

● ReadMeasure: this function reads the RMS voltage and current registers from the

STPM01, calculates the real RMS values by multiplying the values of each register by

the calibration factors and assigns these values to the m_Voltage and m_Current

attributes of the power meter object.

● GetVoltage: this function retrieves the last read voltage value in mV.

● GetCurrent: this function retrieves the last read current value in mA.

● GetEnergy: this function retrieves the last read energy value in mW.

● OnSpiRxIrq: SPI interrupt event. Not used in this implementation. The SPI interrupt is

managed externally by the power meter object implementation.

Figure 4. Reset sequence

4.1.3 Construction

The power meter object is constructed by the NewPowerMeterObj function implemented

externally by the object itself. This function allocates the memory for the object, assigns the

create method and calls it to assign the rest of the object properties.

AM00079v1

10/14

Page 11

AN2799 Firmware description

4.1.4 Deletion

The power meter object is deleted by the DeletePowerMeterObj function implemented

externally by the object itself. This function first calls the deletion method to free dynamically

allocated variables during object creation (in this case does nothing) then frees the allocated

memory for the power meter object.

4.2 Hardware abstraction layer

The HAL is implemented using the following files:

● PowerMeterHal.c

● PowerMeterHal.h

● PowerMeterHalTypes.h

This module is useful to abstract the power meter object implementation from the STM32

standard library.

4.2.1 HAL functions

The hardware abstraction layer functions are described as follows:

● PM_ConfigSignal: this function configures a pin according to the passed signal

descriptor and configuration type.

● PM_ReceiveRegOnSpi: this function receives the STPM01 internal register from the

SPI interface.

● PM_OnSpiRxIrq: This function implements the interrupt service routine of the SPI

interface. It is called when the FIFO of the SPI peripherals contains 1 byte or more and

assigns the received value to a shared register variable.

● SendClkToGetData: this function is used to provide the SPI clock to the STPM01 to

receive data.

● ConfigPin: pin configuration function.

4.3 Application interface

The application interface is implemented using the following files:

● Meter.c

● MeterHal.c

● MeterLayer.h

This layer is useful to abstract the application from the specific board used. In fact, the

functions implemented in the described modules allow the hardware configuration of the

specific board used. The firmware described in this document has been validated using the

“SmartPlug” board that includes two STPM01 meters enumerated as

PM_METER_TYPE_CONSUMPTION and PM_METER_TYPE_DISPERSION.

11/14

Page 12

Conclusion AN2799

4.3.1 Application interface functions

The application interface functions are described as follows:

● PM_HwMetersCommonInit: this function configures the SPI peripheral (including the

interrupt controller), the STM32 MCO pin to provide the clock to both STPM01 and a

GPIO as input, useful to select two different operational modes:

– Normal Mode: typical operational mode.

– Calibration Mode: used to calibrate the STPM01 devices by an external tool. In

this mode the STM32 provides only the clock to the STPM01 devices.

These configurations are common to both STPM01 devices.

● M_HwMeterSignalsInit: this function initializes the signals specific for an STPM01. In

detail, the STM32 GPIO is used as the SCS for the specific device. The specific

STPM01 device is selected by an enumerator as already stated.

● ActivateMeter: this function includes all the operations to be done using the power

meter object for the STPM01 initialization.

All the initialization operations have been included in a single initialization procedure: Init,

establishing a power meter object and the STPM01 device identifier as parameters.

5 Conclusion

Summarizing, this document explains how to interface the STPM01 energy meter device to

the STM32x microcontroller including an easy-to-use firmware library. The firmware library

also includes the file ExampleApp.c which shows how to use the library itself. The user

application has to perform the standard STM32 configuration and simply call the

NewPowerObj for each STPM01 device to allocate the object, call the Init to perform the

power meters related initializations and configurations, call the ReadMeasure method to get

the data from STPM01 device and call GetVoltage and/or GetCurrent to get the last

measurement data.

12/14

Page 13

AN2799 Revision history

6 Revision history

Table 2. Document revision history

Date Revision Changes

27-Nov-2008 1 Initial release

13/14

Page 14

AN2799

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2008 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

14/14

Loading...

Loading...