Page 1

1 Introduction

This application note describes the easy programmer which is a low cost solution allowing

the content of the STM8A Flash program memory to be updated when the chip is already

soldered on the application board. The easy programmer works by calling the functions of

the bootloader, an IAP application embedded in the system memory of the device (the ROM

memory). Through the bootloader firmware, the device memory can be erased and

programmed using one of the standard communication interfaces present on the particular

device. The easy programmer interfaces the bootloader using a serial port (USART

protocol) with the application board for the upload.

Section 2 of this document gives a brief introduction to the STM8A bootloader. Section 3,

Section 4, and Section 5 describe the easy programmer procedure and its software and

hardware requirements.

For further information on the STM8A family features, pinout, electrical characteristics,

mechanical data and ordering information, please refer to the STM8A128 Kbyte and STM8A

32 Kbyte datasheets. For more details on the bootloader, please refer to the bootloader user

manual (UM0500). All documents are available on st.com.

AN2792

Application note

STM8A easy programmer

This document, its associated firmware, and other such application notes are written to

accompany the STM8S firmware library which is available on st.com.

November 2008 Rev 1 1/12

www.st.com

Page 2

Contents AN2792

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Bootloader description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Bootloader flowchart description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Peripheral settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Transferring the .s19 file to the easy programmer . . . . . . . . . . . . . . . . . 7

4 Transfering the .s19 file to the STM8A application board . . . . . . . . . . . 8

5 Software and hardware requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.1 Batch file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.2 Application software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.3 Easy programmer board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.4 Application hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2/12

Page 3

AN2792 Bootloader description

2 Bootloader description

The bootloader code is stored in the internal boot ROM memory. Its main task is to

download the application program into the internal memories through the USART, LINUART,

SPI, or CAN peripherals.

The main features of the bootloader are:

● Polling the serial interface (USART and LINUART are both configured as a normal

UART, SPI or CAN) to check which peripheral is used

● Programming code, data, option bytes and/or the vector table at the address(es)

received from the host.

The STM8A reset vector is located at the beginning of the boot ROM (6000h), while the

other vectors are in the Flash program memory starting at address 8004h.

The device jumps inside the boot ROM area and after checking certain address locations

(see Table 1: Initial checking on page 6), it jumps to the reset vector in the Flash program

memory (8000h).

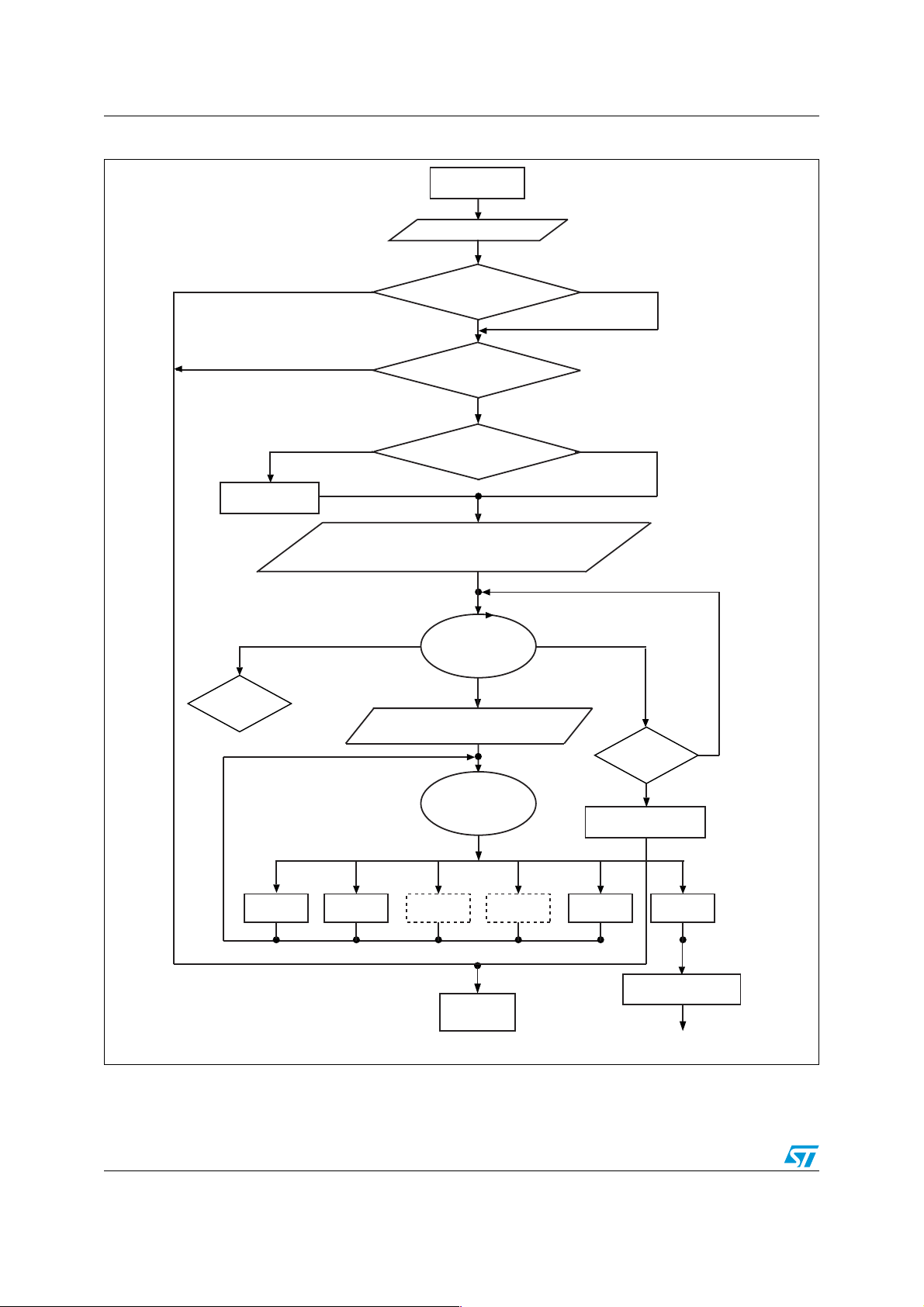

2.1 Bootloader flowchart description

The bootloader activation flowchart is shown in Figure 1 on page 4. The basic steps are

described below.

3/12

Page 4

Bootloader description AN2792

GET cmd

Figure 1. Bootloader activation flowchart

ROM reset

(6000h)

1

Disable all interrupt sources

2

3rd condition verified

Checks according to

Table 1

2nd condition verified

1st condition verified

Yes (memory read out protected)

Ye s No

4

Initializes CAN at

125 kbps

Configure HSI and initialize RX-LINUART pin (PD6) and

RX-USART pin (PDA) in GPIO mofe (pull-up state).

Received a byte/message! = SYNCHR

6

SYNCHR

failed

RM cmd EM cmd

GET cmd

routine

RM cmd

routine

Is ROP active?

No (memory not read out protected)

Is an external clock present?

Configure SPI in slave mode

6

Wait for SYNCHR

SYNCHR received

Send ACK byte and disable unused

peripherals. Execute RASS KEYs

Wait for a command

Command received

EM cmd

routine

Timeout (1 s)

8

WM cmd GO cmd

WM cmd

routine

3

4

7

Is Flash virgin?

Recover the registers

SD cmd

SD cmd

routine

5

No

reset status

6

Ye s

6

GO cmd

routine

Remove EM and WM

Flash reset

(8000h)

routines from the RAM

Jump to host address

ai15000b

1. See flowchart description below for explanation of points 1 to 8.

2. Dotted routines are loaded in RAM by the host. They are removed by the go command before jumping to the Flash program

memory to execute an application.

4/12

Page 5

AN2792 Bootloader description

1. Disable all interrupt sources (any peripheral managed by polling).

2. The host can reprogram the Flash program memory and the bootloader option byte

values as shown in Tab l e 1 according to the content of the first Flash program memory

location (8000h).

3. When read out protection (ROP) is equal to AAh (ROP active), the Flash program

memory is read out protected. In this case, the bootloader stops and the user

application starts. If ROP is not equal to AAh, the bootloader continues to be executed.

4. The CAN peripheral can only be used if an external clock (8 MHz, 16 MHz, or 24 MHz)

is present. It is initialized at 125 kbps. The USART, LINUART, and SPI peripherals do

not require an external clock.

5. Set the high speed internal RC oscillator (HSI) to 16 MHz and initialize the USART and

LINUART receiver pins in input pull-up mode in the GPIO registers. Initialize the SPI in

slave mode.

6. Interface polling: The bootloader polls the peripherals waiting for a synchronization

byte/message (SYNCHR) within a timeout of 1 s. If a timeout occurs, either the Flash

program memory is virgin in which case it waits for a synchronization byte/message in

an infinite loop, or the Flash program memory is not virgin and the bootloader restores

the registers’ reset status before going to the Flash program memory reset vector at

8000h.

Note: When synchronization fails and the bootloader receives a byte/message different

to ‘SYNCHR’, two different situations can be distinguished according to the peripheral:

With USART or LINUART, a device reset or power-down is necessary before

synchronization can be tried again.

With CAN or SPI, the user can continue to poll the interfaces until a synchronization or

a timeout occurs.

7. If the synchronization message is received by the USART or LINUART, the bootloader

detects the baud rate and initializes the USART or LINUART respectively and goes to

step 8 below. If the synchronization message is received by the CAN or SPI, the

bootloader goes directly to step 8 below.

Note: Once one of the available interfaces receives the synchronization message, all

others are disabled.

8. Waiting for commands: Commands are checked in an infinite loop and executed. To exit

from the bootloader, the host has to send a ‘go’ command. When this is done, the

bootloader removes the EM and WM routines from the RAM memory before jumping to

the address selected by the host.

5/12

Page 6

Bootloader description AN2792

Table 1. Initial checking

Checks

st

1

nd

2

rd

3

1. After interface initialization, a write protection test is performed to avoid non-authorised reading of the

Flash program memory/data EEPROM,

Program memory

location 8000h

XXh! = (82h or ACh) XXh XXh

XXh = (82h or ACh) 55h AAh

XXh = (82h or ACh) XXh! = 55h XXh! = AAh

2.2 Peripheral settings

This section describes the hardware setting of the STM8A USART communication

peripheral.

(1)

Bootloader

check

opt_byte 487Eh

Bootloader

check

opt_byteN

487Fh

Actual Flash program

memory status

-> Flash action

Flash program memory

virgin

-> jump to bootloader

Flash program memory

already written

-> jump to bootloader

Flash program memory

already written

-> jump to Flash program

memory reset

Note: LINUART, SPI and CAN peripherals may also be used during bootloading, however, only

one peripheral is enabled at a time; all others are disabled.

Table 2. Serial interfaces associated with STM8A devices

Device Serial interface

128 Kbyte, 96 Kbyte, 64 Kbyte, 48 Kbyte USART, LINUART, CAN

32 Kbyte, 16 Kbyte LINUART, SPI

The USART settings are:

● Data frame: 1 start bit, 8 data bit, 1 parity bit even, 1 stop bit

● Baud rate: The baud rate is autodetected by the bootloader. When the user sends

synchronization byte, 7Fh, the bootloader automatically detects the baud rate and sets

the USART to the same baud rate. Maximum baud rate = 1 Mbps; minimum baud rate

= 4800 bps.

Mandatory: To perform the automatic speed detection, the RX line (PA4) has to be stable in

the application board.

Note: The USART peripheral is accessible via pins PA4 (RX) and PA5 (TX).

6/12

Page 7

AN2792 Transferring the .s19 file to the easy programmer

3 Transferring the .s19 file to the easy programmer

The .s19 file is the application file which the user needs to download to the microcontroller of

the device application board. To do this, it is loaded into the micro SD memory card using

the ‘STxx boatloader tester’ tool.

Synchronizing the easy programmer with the bootloader:

1. Connect the easy programmer board (the STM8A evaluation board USART1 can be

used) to a PC using a cross-serial cable.

2. Switch on /apply power to the easy programmer, press the reset button, press the key

button, and release the reset button until the message ‘start synchronization’ appears

on the display screen.

3. Execute the STxx bootloader tester and set the following configuration in the menu

‘settings’ -> ‘base settings’:

– Port name: Depends on the port of the PC being used

– Baud rate: 115200

– Data bits: 8

– Parity: Even

– Stop bits: 1

4. Press ‘connect’ to send the synchronization character to the microcontroller which

starts the connection. The message ‘connection opened’ in the log window indicates

that the microcontroller is in boot mode and is ready to receive the service requests

from the USART. If this message is not received, steps 1 to 4 should be repeated. The

USART service requests are as follows:

– 00h ? Get

– 11h ? Read memory

– 21h ? Go

– 31h ? Write memory

– 43h ? Erase

Sending .s19 application firmware to the micro SD memory card:

5. Click on ‘open file’ and select the .s19 file (the application file to be transferred).

6. Set the following in the buffer selection window:

– Start address: 00008000h

– End address: The end address of the application (depending on its dimensions).

–Transfer size : 128

7. Select ‘write data/start address’ as 00008000h and press ‘OK’.

8. The message ‘79h’ in the log window indicates that the .s19 file is loaded in the micro

SD memory card of the easy programmer.

9. Click on ‘read data’, set the start address as 8000, and press ‘OK’. An error message is

received, which is normal.

10. If the LCD display message does not read ‘write block finished’, steps 1 to 9 should be

repeated.

11. Press the reset button of the easy programmer.

7/12

Page 8

Transfering the .s19 file to the STM8A application board AN2792

4 Transfering the .s19 file to the STM8A application

board

During this phase the .s19 file is downloaded to the application board of the STM8A. If the

device is virgin, it is already in boot mode, and, the easy programmer can start to read

blocks of 128 bytes from the micro SD memory card and write them in the STM8A memory

using the boot service routine.

If the device is not virgin, and, the easy programmer has not succeeded in synchronizing

with the STM8A after three attempts, the easy programmer sends a pulse on the PH4 pin.

This pulse is captured by the STM8A application board firmware using an external I/O

interrupt. The interrupt routine (see Section 5.2: Application software on page 9) writes two

option bytes (487Eh and 487Fh) and the device is forced into boot mode. Once in boot

mode, the device starts reading and writing blocks, as described above, using the boot

service routine.

The steps are as follows:

1. Connect the easy programmer to the STM8A application board using the connector

described in Section 5.4: Application hardware on page 10.

2. Reset the easy programmer and wait for the LCD to display the message ‘press key to

start transfer’.

3. Press the ‘key’ button of the easy programmer and wait until the LCD displays the

message ‘transfer OK press key’.

4. If no errors occur, the easy programmer is ready to program another device. Otherwise,

if the LCD displays the message ‘ERROR! Boot Mode’, check the connections and

ensure the application firmware contains the interrupt routine described in Section 5.2:

Application software on page 9.

8/12

Page 9

AN2792 Software and hardware requirements

5 Software and hardware requirements

5.1 Batch file

The STxx boot loader tester tool, used to load files into the application board, manages .s19

files in a standard format. There are 16 bytes for single string and increase addresses

options (option -m16 and -s respectively). To produce a .s19 file with both these options, the

following check option must be added:

Es.

"%COS_PATH%\chex" -m16 -s ".\%PRJ_PATH%\%PRJ_NAME%.st7" >

".\PRJ_PATH\%PRJ_NAME%.s19"

COS_PATH is the COSMIC compiler path

PRJ_NAME is the name of the project

5.2 Application software

To program the application board of the STM8A, the device must be in boot mode (see

Section 4: Transfering the .s19 file to the STM8A application board on page 8). If the device

is not in boot mode, the easy programmer must write two option bytes (487Eh and 487Fh).

This is done by the easy programmer sending a pulse on the PH4 pin which is connected to

the external interrupt pin of the application board (PORTx/pin). This external interrupt forces

the application code to execute the interrupt routine that writes the option bytes and resets

the device (the option bytes are updated with the new values only after reset). The interrupt

routine code is as follows:

@interrupt void EXTI_PORTx_IRQHandler (void)

{

volatile u8 opt @0x487E;

volatile u8 nopt @0x487F;

if ( GPIOx.IDR & 0xPin )

{

/* Enable write to EEProm Data */

FLASH.DUNPR = 0xAE;

FLASH.DUNPR = 0x56;

/* Enable write to option byte */

FLASH.CR2 |= 0x80;

FLASH.NCR2 &= 0x7F;

/* Write option byte */

opt = 0x55;

nopt = 0xAA;

/* Reset micro with LSWDG */

IWDG.KR = 0xCC;

IWDG.KR = 0x55;

}

return;

}

‘PORTx’ and ‘pin’ indicate any pin of PORTx with external interrupts. Pins can be chosen

from any available I/0 pin of the application board.

9/12

Page 10

Software and hardware requirements AN2792

5.3 Easy programmer board

The easy programmer is based on firmware, but, to run the code, a hardware platform must

be used where the STM8A microcontroller is interfaced with a USART port, a micro SD

memory card and the easy programmer connector (see Section 5.4: Application hardware

on page 10). In this application note, the STM8A evaluation board is used as an easy

programmer board because all hardware requirements are satisfied. The USART1 is used

to transfer the data, the firmware to be downloaded in the application board microcontroller

is loaded in the Micro SD memory card (64 Mbytes), and the LCD is used to display

messages to control the flow of operations.

5.4 Application hardware

The STM8A device must be uploaded with the easy programmer connection so that data

can be transferred and stimuli sent. Figure 2 shows the easy programmer connections and

Ta bl e 3 gives a description of each of the easy programmer signals.

Figure 2. Easy programmer connections

Easy programmer

U

RX RX

S

A

TX

R

PORTH

PH4 GND

Table 3. Description of the easy programmer signals

T

TX

STM8A application board

U

S

A

R

T

GND Pin

Easy programmer STM8A application board

Pin name Description Pin name Description

RX USART receive TX USART transmit

TX USART transmit RX USART receive

PH4 Stimulus to write option bytes PORTx/pin

External interrupt pin which forces

option bytes to be written

PORTx

GND Ground GND Ground

10/12

Page 11

AN2792 Revision history

6 Revision history

Table 4. Document revision history

Date Revision Changes

03-Nov-2008 1 Initial release

11/12

Page 12

AN2792

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2008 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

12/12

Loading...

Loading...