Page 1

AN2791

Application note

L9352B coil driver for ABS/ESP applications:

current regulated channel analysis

Introduction

This document describes a detailed analysis on the current regulated channels of the ST

coil driver L9352B. This intelligent quad-low side switch is typically used to drive inductive

loads such as on-off valves of the hydraulic modulator of ABS

(a)

/ESP

(b)

control unit.

a. Antilock Brake System (ABS).

b. Electronic Stability Program (ESP).

June 2008 Rev 1 1/18

www.st.com

Page 2

Contents AN2791

Contents

1 L9352B overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Test bench layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Linearity relationship test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Opening/closing time of the INLET valves versus duty-cycle of the

hold-phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 Virtual current control loop on the Q1, Q2 channels of L9352B . . . . . 13

6 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2/18

Page 3

AN2791 List of tables

List of tables

Table 1. INLET valve opening/closing time versus duty-cycle strategy . . . . . . . . . . . . . . . . . . . . . . 12

Table 2. Results of the first operative condition under test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 3. Results of the second operative condition under test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 4. Comparison between the current on loadsdrien by reg. channels and unreg.

channels before and after the VCCL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 5. Results of the last operative condition under test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 6. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3/18

Page 4

List of figures AN2791

List of figures

Figure 1. L9352B application diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2. Comparison between the "ideal" linear relationship and the experimental data. . . . . . . . . . 6

Figure 3. Test bench layout used to characterize current control channels of L9352B. . . . . . . . . . . . 7

Figure 4. Current waveform produced on the load by the test coil energizing strategy . . . . . . . . . . . . 8

Figure 5. Comparison between the "ideal" linear relationship and the experimental data

for two different load conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 6. Coil current driven by means of L9352B in a typical ABS mission profile: coils on valves . . 9

Figure 7. Coil current driven by means of L9352B in a typical ABS mission profile: stand-alone coils. 10

Figure 8. "Pull-in"- "hold" phase duty-cycle strategy traditionally adopted to drive on-off valves. . . . 11

Figure 9. Evaluation of the VCCL on the L9352B unregulated channels:

first test condition block scheme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 10. Evaluation of the VCCL on the L9352B unregulated channels:

last test condition block scheme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4/18

Page 5

AN2791 L9352B overview

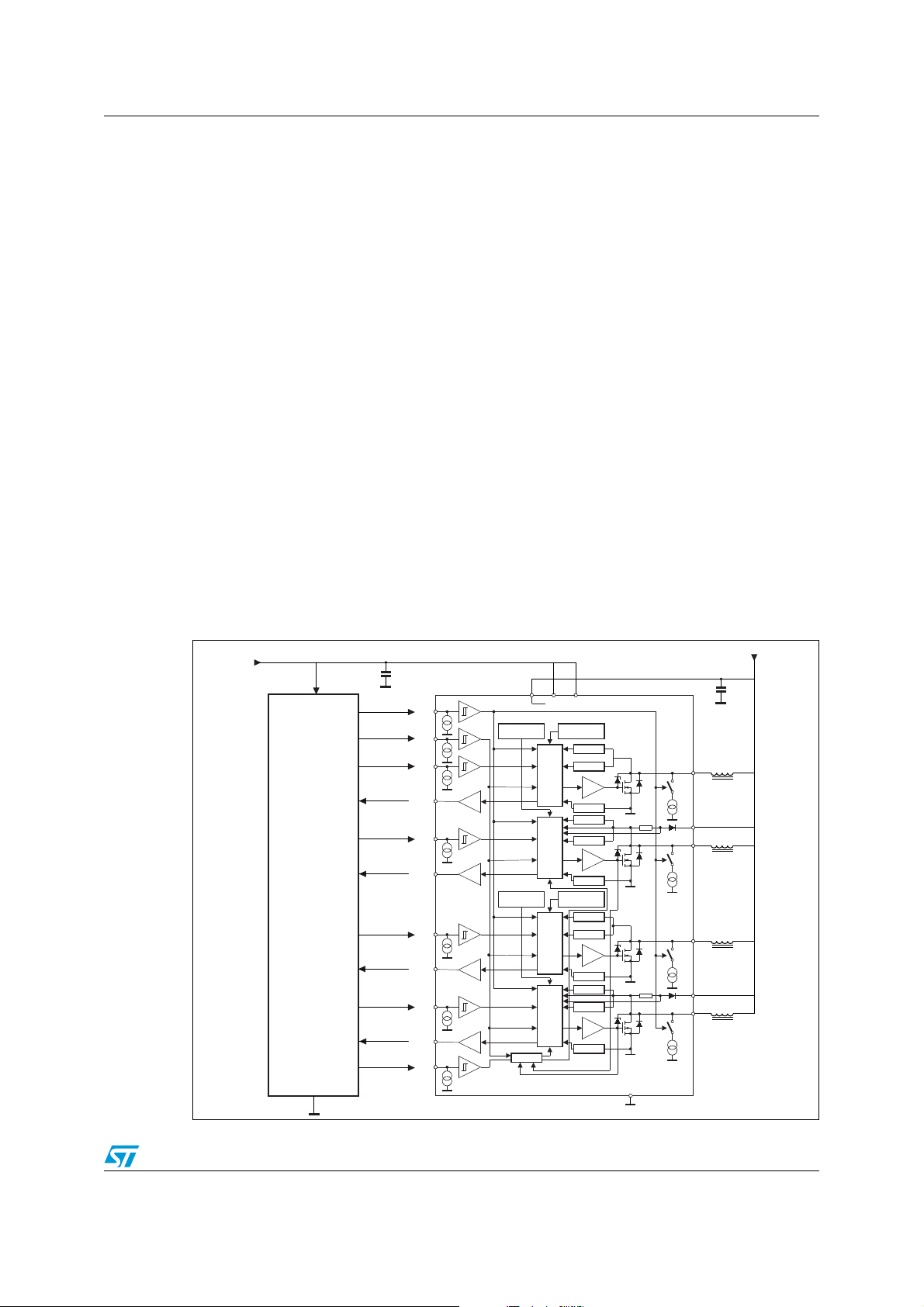

1 L9352B overview

The L9352B (see Figure 1) is designed to drive inductive loads (e.g. relays, electromagnetic

valves, etc.) in low side configuration. Integrated active Zener-clamp, for channels 1 and 2,

or free wheeling diodes, for channels 3 and 4, allow the recirculation of the current of the

inductive loads during the off-state of the DMOS.

All four channels are monitored with a status output. All wiring to the loads and supply pins

of the device are controlled.

The device is self-protected against short circuit at the outputs and over-temperature.

Channels 3 and 4 work as current regulator.

A PWM signal, with a 2 kHz frequency, on the input defines the target for the output current,

in particular, there is a linear relationship between the duty-cycle of the PWM input signal

and the target value of the current (see Figure 2).

The current is measured during recirculation phase of the load, that is, during the off-state of

the DMOS. A sensing resistor, integrated in the IC and placed on the drain of the DMOS and

of the free-wheeling diode, is devoted to measure the current.

The benefit of the current regulation is an optimization of the PWM duty-cycle strategy

against changes in the load conditions (e.g. temperature gradient and as a consequence

coil resistor increases). Moreover, a test mode compares the differences between the two

regulators. This "drift" test compares the output PWM of the regulators. Using this feature a

drift of the load during lifetime can be detected.

Figure 1. L9352B application diagram

5 V logic supply

EN

CLK

IN1

ST1

IN4

ST4

Microcontroller

IN2

ST2

IN3

ST3

TEST

VS VCC VDD

Overtemperature

Channel 4

LOGIC

LOGIC

Overtemperature

Channel 3

LOGIC

LOGIC

drift-det.

Internal Supply

Overtemperature

Channel 1

&

DA

Overtemperature

Channel 2

&

DA

Open Load

Overload

GND-det.

Open Load

Overload

GND-det.

Open Load

Overload

GND-det.

Open Load

Overload

GND-det.

Vbatt

Q1

Free wheeling valve

IPD

D4

Q4

Regulated valve

IPD

Q2

Free wheeling valve

IPD

D3

Q3

Regulated valve

IPD

GND

5/18

Page 6

L9352B overview AN2791

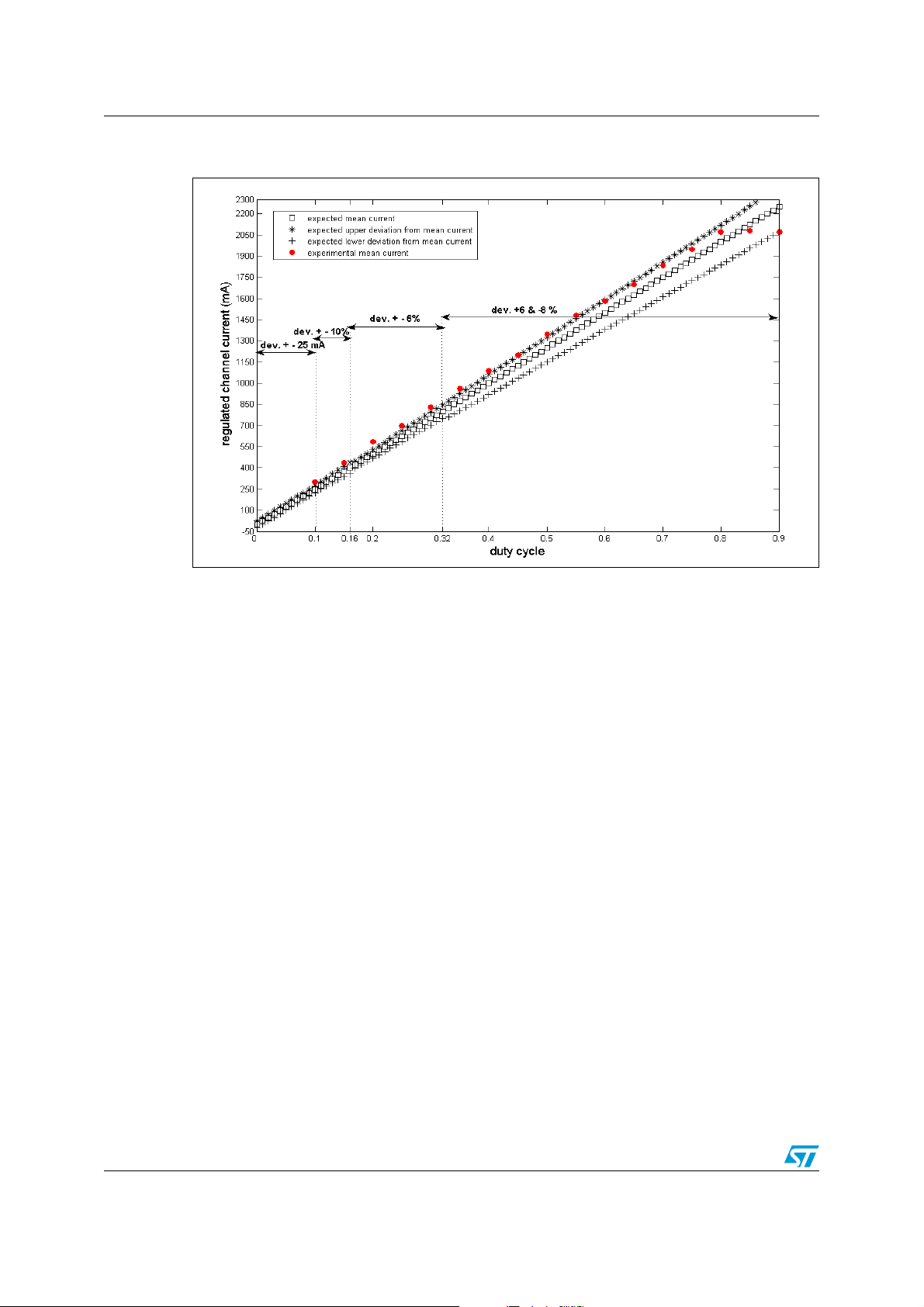

Figure 2. Comparison between the "ideal" linear relationship and the experimental

data

6/18

Page 7

AN2791 Test bench layout

2 Test bench layout

As shown in the Figure 2, the accuracy in the current control of the L9352B depends on the

range of values of the PWM input signal duty-cycle. Basically, for duty-cycle greater than

16% it is possible to consider a current control accuracy of 6 %. The experimental data

shown in the Figure 2 (i.e. red point) are related to the following test layout (see Figure 3):

● dSPACE Microautobox

● LEM Sensor LAH 25-NP

● INLET valves of the 8.0 ABS/ESP Bosch control unit

● coils with a resistor of 4.6 Ohm

● coil energizing frequency (i.e. valve opening/closing frequency) of 5 Hz

● coil energizing strategy:

– for the first 20 ms, duty-cycle = 0.1 %

– for the next 30 ms, duty-cycle = 90 %

– for the last 150 ms, duty-cycle = [5:5:90] %

The current waveform produced by this coil energizing strategy is shown in the Figure 4.

Figure 3. Test bench layout used to characterize current control channels of

L9352B.

7/18

Page 8

Linearity relationship test AN2791

3 Linearity relationship test

The measurements of the values of the mean current to compare with the "ideal" linear

relationship of the L9352B current control channels have been carried out on the "hold-

phase" of the current waveform. The Figure 5 describes a comparison between the results

obtained on two different loads:

● stand-alone coils (i.e. blue stars, crosses and balls);

● coils on the valves (i.e. red stars, crosses and balls);

The main difference between the two considered different load conditions is that for the coils

stand alone you have an equivalent R-L circuit with a fixed inductance.

On the other hand, when as load you consider a coil on a valve, from the point of view of the

equivalent R-L circuit there is an inductance changing with the opening/closing dynamics of

the valve.

As the results of our analysis show in the Figure 5, 6 and 7 the current control loop of the Q3

and Q4 channels has been conceived in order to drive variable inductance loads, in fact, the

spread between maximum and minimum values of the current for a fixed duty-cycle value of

the PWM input signal is minimum in the case of a variable inductance load.

Figure 4. Current waveform produced on the load by the test coil energizing

strategy

8/18

Page 9

AN2791 Linearity relationship test

Figure 5. Comparison between the "ideal" linear relationship and the experimental

data for two different load conditions

Blue stars, crosses and balls indicate minimum, maximum and mean value of the target current for

stand-alone coils. Red stars, crosses and balls indicate minimum, maximum and mean value of the

target current for coils on valves.

Figure 6. Coil current driven by means of L9352B in a typical ABS mission profile:

coils on valves

9/18

Page 10

Linearity relationship test AN2791

Figure 7. Coil current driven by means of L9352B in a typical ABS mission profile:

stand-alone coils

10/18

Page 11

AN2791 Opening/closing time of the INLET valves versus duty-cycle of the hold-phase

4 Opening/closing time of the INLET

duty-cycle of the hold-phase

The conventional strategy adopted to drive on-off valves used in the hydraulic modulator of

ABS/ESP control unit is described in the Figure 8. The "pull-in" phase corresponds to the

maximum values of duty-cycle applied for the first part of the valve opening/closing time.

This phase guarantees the opening/closing of the valve against stiction phenomena due, for

example, to the aging of the valve, to the dirt into the brake fluid, to the stiffness change of

the valve spring and so on.

The "hold" phase corresponds to the duty-cycle value that is necessary to maintain the valve

opened/closed. Clearly this value is less than that used for the "pull-in" phase, because the

force required to overcome the static friction is greater than the force required to overcome

the dynamic one. Obviously, this kind of duty-cycle strategy is power saving too.

Figure 8. "Pull-in"- "hold" phase duty-cycle strategy traditionally adopted to drive

on-off valves

(a)

valves versus

Several tests have been carried out fixing the coil energizing frequency at 5 Hz and the time

strategy at:

● for the first 20 ms, duty-cycle = 0.1 %

● for the next 30 ms, duty-cycle = 90 %

● for the last 150 ms, duty-cycle = [5:5:90] %

The different duty-cycle configurations considered are summarized on the first column of the

Tab l e 1 . In these tests, we measured the opening and closing time of the INLET valve, and,

in addition, the time in which armature-piston of the valve starts its motion. An interesting

result comes out. While the armature-piston motion and the closing time of the INLET valve

are not affected by the duty-cycle configurations, the opening time is affected. In particular,

this increases of 0.5 ms for each 5 % of duty-cycle increase of the "hold" phase.

a. Take into account that the INLET valves of an ABS/ESP hydraulic modulator are on-off valves normally opened and

normally controlled by a current control loop. On the hydraulic modulator there are also OUTLET valves. These valves

normally closed do not require a current control loop but conventional low-side switch.

11/18

Page 12

Opening/closing time of the INLET valves versus duty-cycle of the hold-phase AN2791

Table 1. INLET valve opening/closing time versus duty-cycle strategy

Duty-cycle strategy

[“pull-in”_”hold”]

Armature-piston

motion [ms]

Closing time [ms] Opening time [ms]

20_75 1.5 7 5

20_80 1.5 6.5 5

20_85 1.5 6 5

20_90 1.5 6 5

25_75 1.5 7 5.5

25_80 1.5 6.5 5.5

25_85 1.5 6 5.5

25_90 1.5 6 5.5

30_75 1.5 7 6

30_80 1.5 6.5 6

30_85 1.5 6 6

30_90 1.5 6 6

35_75 1.5 7 6.5

35_80 1.5 6.5 6.5

35_85 1.5 6 6.5

35_90 1.5 6 6.5

12/18

Page 13

AN2791 Virtual current control loop on the Q1, Q2 channels of L9352B

5 Virtual current control loop on the Q1, Q2 channels of

L9352B

In this section we describe an analysis, done on the unregulated channels Q1, Q2 of the

L9352B, aimed to understand the limits of a virtual current control loop on the same

channels. The idea is to tune the duty-cycle of the Q

the duty-cycle observed on the regulated channels Q

load conditions, that is, for both the regulated and unregulated channels of the L9352B, we

considered same coils, same INLET valves. Furthermore, to balance the difference of PWM

signal frequency on the L9352B channels, the unregulated ones (i.e. Q

driven with a frequency of 3.9 kHz

off-state of the Q

, Q2 channels, external free-wheeling diodes have been used to link the

1

(b)

. In order to allow the current recirculation during the

channel output and Vbat. As free-wheeling diode we have considered the ST power Shottky

diodes 1N5817.

Figure 9. Evaluation of the VCCL on the L9352B unregulated channels: first test

condition block scheme

, Q2 channels on a measurement of

1

, Q4. Clearly, we considered same

3

, Q2) have been

1

As first operative condition for our tests (see Figure 9) we can refer to the following data:

● INLET valve opening/closing frequency of 1Hz

● for the first 450 ms, duty-cycle = 0.1 %

● for the next 50 ms, duty-cycle = 90 %

● for the last 500 ms, duty-cycle =[ 15:10:75] %

The Tab l e 2 shows the results related to this first operative condition that we considered for

our tests. As we can see in the last four columns, the difference between the mean current

on the load driven by the unregulated channel and the mean current on the load driven by

the regulated channel reduces as the set-point, that is, the duty of the hold phase increases.

b. Take into account that the ideal frequency of the output PWM signal of the current regulated channels (i.e. Q3,

Q4) is the (clock frequency)/64, that is, 3.9 kHz for a clock frequency of 250 kHz.

13/18

Page 14

Virtual current control loop on the Q1, Q2 channels of L9352B AN2791

Similar results have been observed considering another operative condition, characterized

by a different duty-cycle strategy (see Tab l e 3). Clearly, the duty-cycle applied on the

unregulated channels in both the operative conditions under test is the same measured on

the regulated channel. See columns 2, 3 of the following tables to understand the difference

between the two duty-cycles applied on the unregulated and regulated channels of the

L9352B on the same load conditions.

As second operative condition for our tests (see Figure 9) we can refer to the following data:

● INLET valve opening/closing frequency of 1 Hz

● for the first 500 ms, duty-cycle = 0.1 %

● for the last 500 ms, duty-cycle = [15:10:75] %

The Tabl e 2 and 3 show the results of a comparison between the mean current on the loads

driven by the regulated channels of L9352B and the unregulated ones. These last have

been trained on the output duty-cycle of the regulated channels.

Table 2. Results of the first operative condition under test

Input duty

(hold phase)

Unreg. ch.

output duty

(before the

regulation)

manual

Reg. ch.

output duty

Unreg. ch.

mean current

[mA]

Unreg. ch.

pk-to-pk

current [mA]

Reg. ch.

mean current

[mA]

Reg. ch.

pk-to-pk

current [mA]

0.15 0.83 0.75 520 280 390 360

0.25 0.73 0.65 749 360 660 360

0.35 0.64 0.53 990 400 920 480

0.45 0.55 0.41 1200 480 1200 480

0.55 0.44 0.26 1480 480 1480 480

0.65 0.35 0.1 1700 480 1740 440

0.75 0.23 0.09 1780 520 1760 480

Table 3. Results of the second operative condition under test

Unreg. ch.

Input duty

(hold phase)

output duty

(before the

manual

Reg. ch.

output duty

Unreg. ch.

mean current

[mA]

Unreg. ch.

pk-to-pk

current [mA]

Reg. ch.

mean current

[mA]

regulation)

0.15 0.83 0.75 530 320 390 360

0.25 0.73 0.65 780 400 660 360

0.35 0.64 0.53 980 440 920 440

0.45 0.53 0.39 1240 480 1200 480

0.55 0.44 0.25 1460 560 1480 520

Reg. ch.

pk-to-pk

current [mA]

0.65 0.34 0.09 1630 440 1740 480

0.75 0.25 0.09 1630 440 1820 480

Just to highlight the results obtained by this analysis, it is important to summarize the

difference in the coil current of the unregulated channels of L9352B before and after the

14/18

Page 15

AN2791 Virtual current control loop on the Q1, Q2 channels of L9352B

regulation inspired to the duty-cycle value carried out by the regulated channels of the same

device.

In Ta b l e 4 we can see the results of a comparison between the mean current on the loads,

driven by the L9352B regulated channels and L9352B unregulated channels before and

after the VCCL regulation.

Table 4. Comparison between the current on loadsdrien by reg. channels and unreg. channels

before and after the VCCL

Mean current on the

Hold phase duty

0.35 530 450 560

0.45 660 550 670

cycle-time for the reg. ch.

[mA]

Mean current on the cycle-

time for the unreg. ch. –-

before the regulation -- [mA]

Mean current on the cycle-

after the regulation -- [mA]

As last operative condition considered in our tests we can refer to the following data and the

Figure 10:

● INLET valve opening/closing frequency of 1 Hz

● for the first 450 ms, duty-cycle = 0.1 %

● for the next 50 ms, duty-cycle = 90 %

● for the last 500 ms, duty-cycle = [15:10:75] %

The main idea is to increase the resistance of the loads of about the 15 %. The initial value

of 4.8 Ohm, that is, 4.6 Ohm of the coil resistor plus 0.2 Ohm of Rds-ON of the DMOS has

been increased of 0.6 Ohm. So doing, we simulated a gradient temperature of about 35°.

For this calculation we referred to the formula of the resistance of the chopper versus the

temperature:

R

last

= R

(1 + 0.004ΔT)

initial

From the results shown in the table 7-4, it comes out that the unregulated channels

maintains a satisfactory tracking capability of the current values driven on the loads also in

simulated conditions of temperature gradient.

time for the unreg. ch. –-

Figure 10. Evaluation of the VCCL on the L9352B unregulated channels: last test

condition block scheme

15/18

Page 16

Virtual current control loop on the Q1, Q2 channels of L9352B AN2791

In Ta b l e 5 comparison between the mean current on the loads driven by the regulated

channels of L9352B and the unregulated ones. These last have been trained on the output

duty-cycle of the regulated channels.

Table 5. Results of the last operative condition under test

Input duty

(hold phase)

0.15 0.83 0.73 500 220 400 260

0.25 0.73 0.6 730 280 670 300

0.35 0.64 0.46 1000 380 945 360

0.45 0.54 0.32 1180 440 1220 400

0.55 0.44 0.09 1400 480 1480 400

0.65 0.35 0.09 1400 480 1620 440

0.75 0.23 0.09 1400 480 1600 400

Unreg. ch.

output duty

(before the

regulation)

manual

Reg. ch.

output duty

Unreg. ch.

mean current

[mA]

Unreg. ch.

pk-to-pk

current [mA]

Reg. ch.

mean current

[mA]

Reg. ch.

pk-to-pk

current [mA]

16/18

Page 17

AN2791 Revision history

6 Revision history

Table 6. Document revision history

Date Revision Changes

25-Jun-2008 1 Initial release.

17/18

Page 18

AN2791

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2008 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

18/18

Loading...

Loading...