Page 1

AN2783

Application note

PM8800 demonstration kit for standard and high power PoE

PD interface and power supply, with auxiliary sources

Introduction

This document details the characteristics and performances of the PM8800 demonstration

kit which has been designed to cover a broad range of power over Ethernet (PoE)

applications. PM8800 is a highly integrated device embedding an IEEE802.3af compliant

powered device (PD) interface together with a PWM controller and support for auxiliary

sources.

Even though PM8800 can be configured to work in both isolated and non-isolated

topologies, this application note focuses on an isolated topology only, in two different output

power configurations (10 W and 20 W) and 2 different output voltages (5 V and 3.3 V).

The PM8800 demonstration kit supports diode as well as synchronous rectification.

Auxiliary sources can be connected to the board on 2 input points. One input allows

prevalence of the auxiliary sources with respect to the PoE, while the other input allows the

usage of a wall adaptor with voltage lower than the internal PoE UVLO threshold and still

benefits from the inherent inrush and DC current limit.

The above mentioned configurations are all supported by the PM8800 demonstration kit as

options on the same PCB. The bill of material (BOM) (see Section 5 on page 12) provides

the list of components to be mounted for each of the targeted configurations.

Figure 1. PM8800 demonstration kit

The high-power board appears on the left of the photo and standard board is on the right.

September 2008 Rev 2 1/47

www.st.com

Page 2

Contents AN2783

Contents

1 Main features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Demonstration kit schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Board layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Input/output connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 Bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6 Power-up sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7 Input section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7.1 Diode bridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7.2 Input capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7.3 Transient voltage suppression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8 PoE section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.1 Signature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.2 Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.3 UVLO and power-on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.4 Inrush current limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.5 DC current limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8.6 AUXI input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

8.7 AUXII input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

9 Power transformer and operating input voltage . . . . . . . . . . . . . . . . . . 22

10 Power converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

10.1 Flyback continuous conduction mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

10.2 Main switch current and current sensing . . . . . . . . . . . . . . . . . . . . . . . . . 24

10.3 Main switch power dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2/47

Page 3

AN2783 Contents

10.4 Rectifier diode dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

10.5 PM8800 internal power dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

11 Layout guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

12 Test results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

12.1 Efficiency measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

12.2 5 V high-power board measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

12.3 3.3 V standard-power board measurements . . . . . . . . . . . . . . . . . . . . . . 36

12.4 IEEE 802.3af compatibility test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Appendix A Schematic of high-power board . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Appendix B Schematic of standard-power board . . . . . . . . . . . . . . . . . . . . . . . . 45

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3/47

Page 4

List of figures AN2783

List of figures

Figure 1. PM8800 demonstration kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. Demonstration kit schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 3. Assembly view: top and bottom layer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 4. Top layer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 5. Inner layer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 6. Inner layer 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 7. Bottom layer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 8. Inrush current limit vs. RIRL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 9. DC current limit vs. RDC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 10. Output power vs. VAUXII . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 11. 5 V out - standard board with diode rectification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 12. 5 V out - high-power board with synchronous rectification . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 13. 3.3 V out - standard board with diode rectification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 14. 3.3 V out - high-power board with synchronous rectification . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 15. Startup of the PM8800 demonstration kit with 5 V 1 A . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 16. Startup of the PM8800 demonstration kit with 5 V 4 A . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 17. Details of the inrush phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 18. Details of the soft-start phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 19. VDS and VGS of the primary MOSFET for 5 V 1 A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 20. VDS and VGS of the primary MOSFET for 5 V 4 A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 21. Details of the synchronous rectifier MOSFET voltage with 48 V and 4 A out . . . . . . . . . . 32

Figure 22. Output voltage ripple at 4 A output current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 23. Output voltage ripple at 4 A output current (1 sec persistence) . . . . . . . . . . . . . . . . . . . . . 33

Figure 24. Dynamic load 1 A to 4 A: output voltage (up) and output current (down) . . . . . . . . . . . . . 33

Figure 25. PM8800A response to a 6 A overload condition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 26. PM8800A recovering from a 6 A overload condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 27. PM8800A response to a short on the load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 28. PM8800A recovering from a short on the load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 29. Internal short on the secondary winding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 30. Switch between 48 V PoE and 24 V AUXII with 5 V at 2 A . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 31. back to 48 V removing the 24 V AUXII voltage with 5 V at 2 A . . . . . . . . . . . . . . . . . . . . . 35

Figure 32. Switch between 48 V PoE and 12 V AUXII with 5 V at 2 A . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 33. Back to 48 V removing the 12 V AUXII voltage with 5 V at 2 A . . . . . . . . . . . . . . . . . . . . . 36

Figure 34. Startup of the PM8800 demonstration kit with 3.3 V, 1 A . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 35. Startup of the PM8800 demonstration kit with 3.3 V, 3 A . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 36. Details of the inrush phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 37. Details of the soft-start phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 38. VDS and VGS of the primary MOSFET for 3.3 V 1 A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 39. VDS and VGS of the primary MOSFET for 3.3 V 3 A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 40. Details of the synchronous rectifier MOSFET voltage with 48 V and 3 A output current . . 38

Figure 41. Output voltage ripple at 3 A output current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 42. Output voltage ripple at 3 A output current (1 sec persistence) . . . . . . . . . . . . . . . . . . . . . 38

Figure 43. Dynamic load 1 to 3 A: output voltage (up) and output current (down) . . . . . . . . . . . . . . . 39

Figure 44. PM8800A response to a 5 A overload condition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 45. PM8800A recovering from a 5 A overload condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 46. PM8800A response to a short on the load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 47. PM8800A recovering from a short on the load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 48. Internal short on the secondary winding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4/47

Page 5

AN2783 List of figures

Figure 49. Switch between 48 V PoE and 24 V AUXII with 3.3 V at 2 A . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 50. Back to 48 V removing the 24 V AUXII voltage with 3.3 V at 2 A . . . . . . . . . . . . . . . . . . . . 41

Figure 51. Switch between 48 V PoE and 12 V AUXII with 3.3 V at 2 A . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 52. Back to 48 V removing the 12 V AUXII voltage with 3.3 V at 2 A . . . . . . . . . . . . . . . . . . . . 41

Figure 53. Schematic of the 3.3/5 Vout high power with synchronous rectification . . . . . . . . . . . . . . . 44

Figure 54. Schematic of the 3.3/5 Vout standard power with diode rectification . . . . . . . . . . . . . . . . . 45

5/47

Page 6

Main features AN2783

1 Main features

The PM8800 demonstration kit has been designed to cover several PoE configurations with

easy customization.

● Basic configuration: (high-power applications)

– 5 V output

– Up to 4 A output

– 250 kHz operating switching frequency

– Flyback topology DCM/CCM

● Board size 70 x 90 mm

● Power Good indication

● Overall efficiency of 85% at full-load condition (Figure 12)

● Prevalence of the auxiliary source with respect to the PoE line (Section 8.7)

● 1500 Vrms isolation ensured by the power transformer

● Support for (see BOM options in Section 5):

– 5 V and 3.3V output

– diode or synchronous rectification

– standard IEEE802.3af or high-power applications

– non-isolated flyback topology

● Support for class 0-3 (IEEE802.3af) and class 4 (pre-standard modes)

The following 2 basic board configurations are addressed with the same PCB and referred

in the rest of the text as:

– Standard power: this configuration covers IEEE802.3af applications and it is

based on flyback topology with diode rectification.

– High power: this configuration targets applications with output power in excess of

the IEEE802.3af standard up to 20 W as output. This configuration is based on

flyback topology with synchronous rectification. The same configuration can be

used in PoE designs targeting high efficiency and/or with wide range auxiliary

input (down to 12 V with prevalence of the auxiliary with respect to PoE).

6/47

Page 7

AN2783 Electrical specifications

2 Electrical specifications

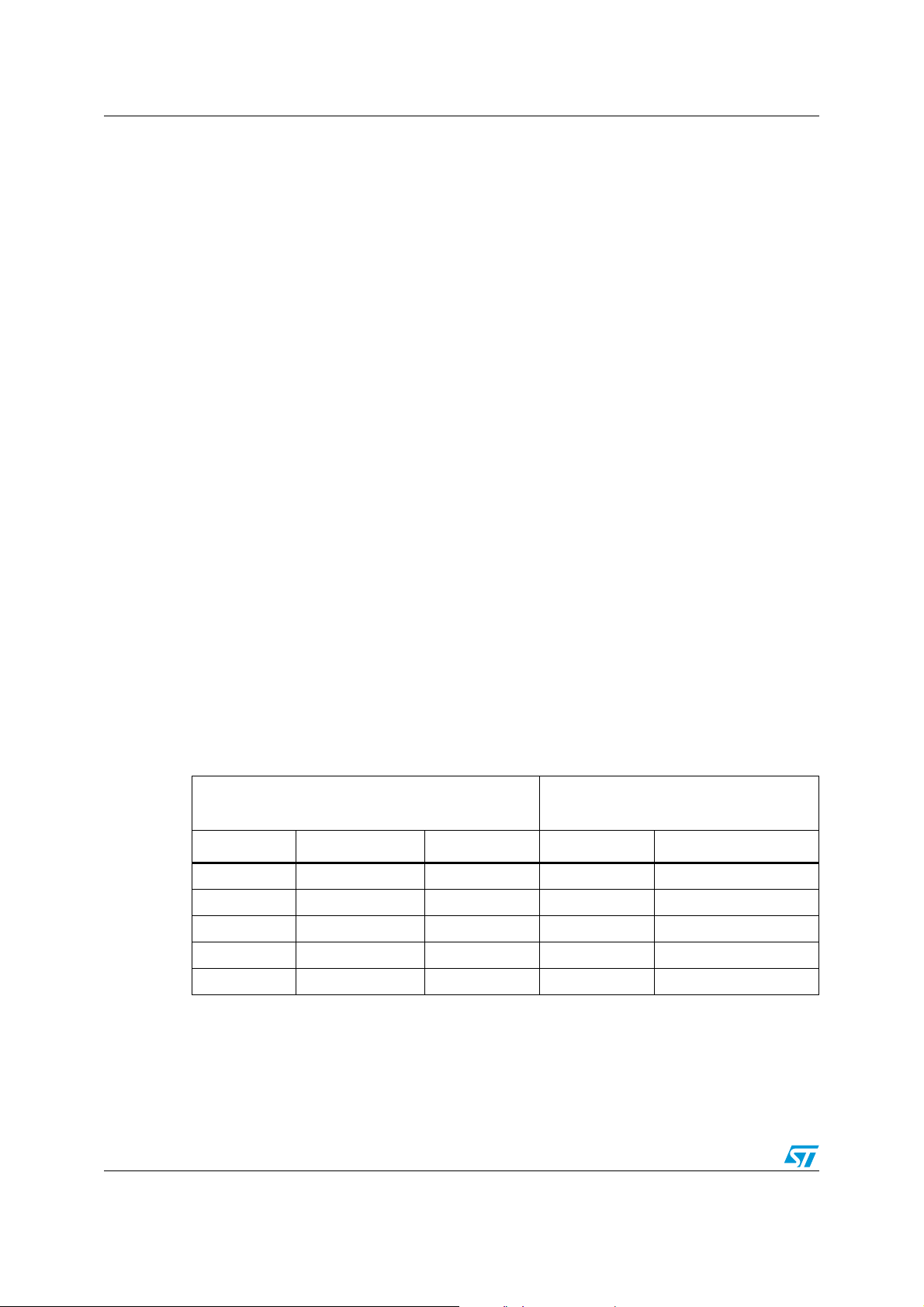

Table 1. Specifications

Parameter 10 W 20 W

VIN 30 V to 60 V at 10 W output 30 V to 60 V at 20 W output

Auxiliary VIN AUXI 18 V to 60 V 18 V to 60 V

Auxiliary VIN AUXII 12 V to 60 V 12 V to 60 V

VOUT

Peak-to-peak output

ripple

3.35 V +/- 100 mV at 3 A 3.35 V +/- 100 mV at 6 A

5.05 V +/- 100 mV at 2 A 5.05 V +/- 100 mV at 4 A

10 mVpp 20 mVpp

Efficiency DC-DC only

Overall efficiency

Switching frequency 250 kHz typ +/- 10% 250 kHz typ +/- 10%

Dynamic current step

Maximum overshoot 200 mV 400 mV

Maximum overshoot

time duration

Maximum undershoot 200 mV 400 mV

Maximum undershoot

time duration

Maximum DC test

current

Minimum DC test

current

83% typ at 3.3 V 3 A 86% typ at 3.3 V 6 A

87% typ at 5 V 2 A 88% typ at 5 V 4 A

78% typ at 3.3 V 3 A 81% typ at 3.3 V 6 A

81% typ at 5 V 2 A 84% typ at 5 V 4 A

1- 3 A max at 3.3 V 1- 6 A max at 3.3 V

1- 2 A max at 5 V 1- 4 A max at 5 V

200 ms 300 ms

200 ms 300 ms

3.5 A at 3.3 V 6.5 A at 3.3 V

2.5 A at 5 V 4.5 A at 5 V

00

7/47

Page 8

Demonstration kit schematic AN2783

g

g

g

k

k

k

k

k

n

y

y

g

k

k

M

3 Demonstration kit schematic

Figure 2. Demonstration kit schematic

J5

1

2

DC OUTPU T

0.1u

C39

TP14

OUTOUTOUT

1k

R17

RJ45 D ata Jac

10

Chassis

1

234

1

2

4

5

12

13

T3

16

1

234

Chassis

10

RJ45 D at a and Po wer Jac

T

J2

9

Chassis

OUTPU

5

6

7

8

0

R1

0805

R7NM

6

M

R

N

6

3

7

89

H2019 / TLA-6T127LF

10

111415

567

8

Chassis

T

9

J1

INPU

Chassis

0

1206

R30

0805

C7NM0805

200V

Chassis

5

C6

200V

080

NM

0805

To be placed on sol der si de

Termination

123

4

5

6

T4

7

8

9

11

10

C5

R5

NM

NM

0805

0805

M

R4

N

C4

200V

NM

0805

0805

R3

NM

C3

NM

0805

0805

R2

C2

NM

NM

0805

0805

D3

SMAJ58 A

TP1

C1

0805

100V

0.1u

D24

SMA

4

STPS1H10 0

-

+

1

D2

3

A

SM

D22

STPS1H10 0

0

D20

SMA

4

STPS1H10

+

-

1

D1

3

A

STPS1H100SM

D18

ETH1-230LD

16

15

12

14

13

s

The H2019 footpri nt will be placed

NOTE f or dat aTr a nsf or me r

200V

e

Chassis

C8

1808

2KV

NM

200V

Termi na t i onTo be placed on solder sid

200V

TP 2

0

D25

SMA

2512

2512

STPS1H10

R9 N M

R8 N M

2

DF01S N M

SMA

D23

STPS1H10 0

SEE BO M

D21

SMA

STPS1H10 0

The resistors must be placed on

NOTE for 2512 Power Resis tors

2

DF01S N M

D19

STPS1H100SMA

solder side, belhind the SO8 body .

NOTE for Output Inductor

The 1206 footpri nt wil l be placed

The DPack footprint for the diode will be on top side.

NOTE for Output Recti er

T2

321

inside the FA2706 footprint

NOTE for Power Transf or mer

The 13P footprint will be placed

inside the E TH1-230LD one

D6

D4

SMC

STTH302 S

C41

0805

0.1u

100V

SO8

5

678

R12

Q1

4

STS10PF30L

3

1

2

330K

R10

0805

C27

0.1u

0

R5 0

BZX84C15

SOT23

3

1

D5

TP3

R11

15K

0805

1

2

3

J4

DC Power Jac k

AUX II

M

SEE BO

L

2

2

4

M

L2

L3 NM

N

R1

1206

0.33uH

between the inductor pad s

The Power SO8 footpr int of the mosfe t and the

4

SOD323

BAT46J NM

330K

0805

0.33uH

LPS401 2- 331

DO1813H-331ML

1

1

SEE BO M

5

8

6

7

470p

C11

0805

DPac

1

2

3

STPS15L30CB

7

2

D8

TP

15

R13

1206

Snubber on solder si de.

8910

7

COILCRAFT POE13P

SMC

STTH302 S

GND

TP5

TP4

1

DC Power Jac k

Q

143

SEE BO M

10

9

NM

T1

4

3

D10

5

C16NM080

TP6

R16NM1206

A

D9

SMAJ58

C17

1812

100V

2.2u

SEE BO M

2.2u

100V

C15

1812

2.2u

C14

100V

1812

2

L1

3.3uH

ME32 2 0 - 332 ML

1

C13

22u100V

8x10.2

D7

BAS21

K

R15

15

0805

2

3

J3

AUXI_IRL

TP8

N

NTR

TR

D11

Green LED

C24

330u

8x10.5

6.3V

1206

6.3V

10u

C23

C21

10u

1206

6.3V

C20

1206

6.3V

10u

9

C1

6.3V

10u

1206

C18

6.3V

10u

1206

4

3

D13

1

1

PowerSO 8

D12

STSJ60NH3LL

3

7118

12

5

1

2

6

R1 8

10

SMA

STPS1H100

D14

C25

BAT46J

SOD323

3.3k

R19

D15

GND

M

R49

N

SEE BO M

D26

SOT2 3

R23

10k

0

R25

0

R24

NM

R22

R26

BZX84C18

SOT23

SOT23

BZX84C18

NOTE

PowerSO8 footpr int wi ll be pl aced

on the solder side behi nd the DPac k one

COILCRAFT FA2706 - BL

TP10

0603

1u

16V

GND

C26

0.1u

Green LED

C34

0.1u

AGND

NM

C42

C28

0.1u

AGND

15

16

R21

AGND

88.7K

1%

RT

U1

1

RT

SS

%

21k

R32

1

10

1u

16V

C30

0603

NM

R34

R29

1

23

R41

Sharp PC3 H7

U2

D

4 1

AGN

R28

1k

C32

0.1u

M

C31

N

Q3A N M

PowerSO 8

8

7

6

2 3

5

1

6

4

R4

R40

SEE BO M

DPac k

STD22NM20L

Q3

3

2

TP11

BAT46J

SOD323

R39

1

D17 N

10

R38

R31

10 0805

100

R33

C33

1%

R44

12.4

M

M

1%

R47

N

1%

10

R43

SEE BO

M

22

C35

SEE BO

C37

4.7n

4

3

5

U3

TS431

SOT23-5

NM

1206

Those components will be plac ed

NOTE

GND

A

0

R42

TP1 2

1206

NM

1206

0.47 ohm

GND

1206

0.47 ohm

on the solder sid e

1812

2.2n

R2 0

NM

1206

C29

0

round that will be connected to th e

nal

470p

round plane close to pin 9 of PM880

D

D

D

G

GPnDGPn

G

G

P

P

P

P

GD

CS

VCC

GND

n

nD

n

nDG

13

14

9

10

12

11

CS

GD

VFB

VCC

GND

nPGD

PM8800

COMP

UXII

SS2A

3

4

I

I

X

XUAII

VIN

UA

HTSSO1 6

C36

0.1u NM

0805

Ex Pad

17

S

S

VIN

RCLAS

AUXI_IRL

DCCL

VS

6

5

7

8

VSS

DCC L

RCLASS

AUXI_IRL

100V

D27 NM

15k

1%

R37

1%

NM

0805

R35

GND po wer

NOTE

The AGND is a dedicated pla ne of si

A

SM

STPS1H100

V

C40

100p N M

R48

NM

D16

10k

R27

R36

SOD323

BAT46 J

TP9

TP13

NM

e is 50

is 0603 and tolera nce 5 %

is 0603 and the volta

NOTE for Ca paci tors

Where not indicated the bod

NOTE for Re sist ors

Where not indicated the bod

Sync Input

2KV

GND

AM01333v1

8/47

Page 9

AN2783 Board layout

4 Board layout

Figure 3. Assembly view: top and bottom layer

9/47

Page 10

Board layout AN2783

Figure 4. Top layer

Figure 5. Inner layer 1

Figure 6. Inner layer 2

10/47

Page 11

AN2783 Board layout

Figure 7. Bottom layer

4.1 Input/output connectors

In Figure 3 the main input / output connections of the reference board are presented:

● J1 is the RJ45 connector for the PoE input, with data and power applied through the

CAT5 cable (as an alternative, a positive voltage between 30 V and 60 V can be applied

to test points TP1 + and TP2 -)

● J2 is the RJ45 data output

● J3 is the power jack for AUXI input (as an alternative, the test points TP 3 + and TP4 -

can be used)

● J4 is the power jack for AUXII input (as an alternative, the test points TP5 + and TP9 -

can be used)

● J5 is the DC output connector

4.2 Notes

● Please note that the use of TP1 and TP2 limits the voltage polarity applied and that

these points are after the data transformer and diode bridges.

● AUXII is not protected against reverse polarity applied to it.

● For synchronization tests the capacitor C40 =100 pF must be mounted. Please take

care when using test point TP13 because this is a high impedance point that can easily

pick up noise from the board.

● Resistive or electronic loads can be used as loads. Limit the output capacitance

externally applied in order to not impact the loop compensation.

● As an input source a DC power supply with 60 V and 2 A capability is required.

● For auxiliary inputs a DC source of 60 V and 3 A capability is recommended.

11/47

Page 12

Bill of material AN2783

5 Bill of material

Table 2. Components for the 4 isolated configurations possible with the PM8800

Reference Description Pkg Manufacturer

5 V std power

3.3 V std power

3.3 V high power

Qty Qty Qty Qty

Printed circuit board

1 1 1 1 PM8800 eval kit

Capacitors

1 1 1 1 C1 Ceramic cap 0.1 µF 100 V 805 TDK

NM NM NM NM C36 Ceramic cap 0.1 µF 100 V 805 NM

NM NM NM NM C2, C7 Ceramic cap 200 V 805 NM

5 V high power

(1)

NM NM NM NM C8 Ceramic cap 2 kV 1812 NM

NM NM NM NM C9 Ceramic cap 805 NM

NM NM NM NM C10, C12 Ceramic cap 805 NM

1 1 1 1 C11 Ceramic cap 470 pF 50 V 805 Std

1 1 1 1 C13 Electrolytic cap 22 µF 100 V KX 8 x 10.2 SANYO

2 2 2 2 C14, C15 Ceramic cap 2.2 µF 100 V 1812 TDK

NM 1 NM 1 C17 Ceramic cap 2.2 µF 100 V 1812 TDK

NM NM NM NM C16 Ceramic cap 805 NM

2 2 NM NM C18, C19 Ceramic cap 10 µF 6.3 V 1206 TDK

3 3 NM NM

NM NM 2 2 C18, C19 Ceramic cap 10 µF 16 V 1206 TDK

NM NM 3 3

NM NM NM NM C22, C38 Ceramic cap 1206 NM

1 1 1 1 C24 Electrolytic cap 330 µF 6.3 V EX 8 x 10.5 SANYO

2 2 2 2 C25, C30 Ceramic cap 1 µF 16 V 603 TDK

5555

1 1 1 1 C29 Ceramic cap 2.2 nF 2 kV 1812 TDK

C20, C21,

C23

C20, C21,

C23

C26, C27,

C28, C34,

C39

Ceramic cap 10 µF 6.3 V 1206 TDK

Ceramic cap 10 µF 16 V 1206 TDK

Ceramic cap 0.1 µF 50 V 603 Std

NM NM NM NM C31 Ceramic cap 603 Std

1 1 1 1 C32 Ceramic cap 0.1 µF 50 V 603 Std

12/47

Page 13

AN2783 Bill of material

Table 2. Components for the 4 isolated configurations possible with the PM8800 (continued)

Reference Description Pkg Manufacturer

5 V std power

3.3 V std power

3.3 V high power

Qty Qty Qty Qty

1 1 1 1 C33 Ceramic cap 470 pF 50 V 603 Std

1 NM 1 NM C35 Ceramic cap 1 nF 50 V 603 Std

NM 1 NM 1 C35 Ceramic cap 22 nF 50 V 603 Std

1 1 1 1 C37 Ceramic cap 4.7 nF 50 V 603 Std

NM NM NM NM C40 Ceramic cap 100 pF 50 V 603 Std

1 1 1 1 C41 Ceramic cap 0.1 µF 100 V 805 TDK

Diodes

NM NM NM NM D1, D2 Diode bridge DF01S Dip Diodes

2 NM 2 NM D1A, D2A Diode bridge HD01 MiniDip Diodes

1 1 1 1 D3 Diode SMAJ58A SMA STMicroelectronics

5 V high power

2 2 2 2 D4, D7 Diode STTH302S SMC STMicroelectronics

1 1 1 1 D5 Diode Zener BZX84C15 SOT23 Std

NM NM NM NM D6 Diode BAT46J SOT323 STMicroelectronics

1 NM 1 NM D8 Diode STPS15L30CB DPACK - TO252 STMicroelectronics

1 1 1 1 D9 Diode SMAJ40A SMA STMicroelectronics

1 1 1 1 D10 Diode STPR120A SMA STMicroelectronics

2222 D11, D15

2 2 2 2 D12, D13 Diode Zener BZX84C18 SOT23 Std

1 1 1 1 D14 Diode BAT46J SOT323 STMicroelectronics

1 1 1 1 D16 Diode BAS316 SOT323 Std

NM NM NM NM D17 Diode BAT46J SOT323 STMicroelectronics

NM 8 NM 8 D18 : D25 Diode STPS1H100A SMA STMicroelectronics

NM 1 NM 1 D26 Diode BAS316 SOT323 Std

NM NM NM NM D27 STPS1H100A SMA STMicroelectronics

Connectors

2 2 2 2 J1, J2 Shielded RJ45 8-pole THT

2 2 2 2 J3, J4 DC power jack THT RAPC722 THT

1 1 1 1 J5 DC power connector 2-pole pitch 5.08

Diode green LED Toshiba

TLGE1100B

SMD Toshiba

Inductors

13/47

Page 14

Bill of material AN2783

Table 2. Components for the 4 isolated configurations possible with the PM8800 (continued)

Reference Description Pkg Manufacturer

5 V std power

3.3 V std power

3.3 V high power

Qty Qty Qty Qty

1 1 1 1 L1 Inductor 3.3 µH ME3220-332ML Coilcraft

5 V high power

1NM1NM L2

NM 1 NM 1 L3

MOSFETs

1 1 1 1 Q1 Mosfet STS10PF30L SO-8 STMicroelectronics

NM 1 NM 1 Q2 Mosfet STSJ60NH3LL PowerSO-8 STMicroelectronics

1 NM 1 NM Q3 Mosfet STD5N20L DPACK - TO252 STMicroelectronics

NM 1 NM 1 Q3 Mosfet STD22NM20M DPACK - TO252 STMicroelectronics

Resistors

1 1 1 1 R1 Resistor chip 0 Ω 805 Std

NM NM NM NM R2:R7, R35 Resistor chip 805 Std

NM NM NM NM R8, R9 Resistor chip 2.2 Ω 2512 Std

2 2 2 2 R11, R15 Resistor chip 15 kΩ 805 Std

1111 R10 Resistor chip 330 kΩ 805 Std

1 1 1 1 R12 Resistor chip 33 kΩ 805 Std

1111 R13 Resistor chip 15 Ω 1206 Std

NM NM NM NM

R14, R16,

R20, R41

Inductor 0.33 µH LPS4012-

331L

Inductor 0.33 µH DO1813H-

331ML

Resistor chip 1206 Std

Coilcraft

Coilcraft

1111 R17 Resistor chip 1 kΩ 603 Std

1111 R18 Resistor chip 10 Ω 603 Std

1 1 1 1 R19 Resistor chip 3K3 603 Std

1 1 1 1 R21 Resistor chip 88K7 1% 603 Std

NM NM NM NM

3333

2 2 2 2 R24, R25 Resistor chip 0 Ω 603 Std

1111 R26 Resistor chip 10 Ω 603 Std

1111 R28 Resistor chip 1 kΩ 603 Std

1111 R29 Resistor chip 1 kΩ 603 Std

14/47

R22, R34,

R36

R23, R27,

R38

Resistor chip 603 Std

Resistor chip 10 kΩ 603 Std

Page 15

AN2783 Bill of material

Table 2. Components for the 4 isolated configurations possible with the PM8800 (continued)

Reference Description Pkg Manufacturer

5 V std power

3.3 V std power

3.3 V high power

Qty Qty Qty Qty

1 1 1 1 R30 Resistor chip 0 Ω 1206 Std

1111 R31 Resistor chip 10 Ω 805 Std

1 1 1 1 R32 Resistor chip 21 kΩ 1% 603 Std

1 1 1 1 R33 Resistor chip 100 Ω 603 Std

NM 1 NM 1 R37 Resistor chip 15 kΩ 1% 603 Std

2 2 2 2 R39, R40 Resistor chip 0R47 1206 Std

NM NM NM NM R20, R41 Resistor chip 0 Ω 1206 Std

1 1 1 1 R42 Resistor chip 0 Ω 603 Std

1 1 1 1 R43 Resistor chip 10 kΩ 1% 603 Std

5 V high power

1 1 1 1 R44 Resistor chip 12K4 1% 603 Std

NM NM NM NM R46 Resistor chip 0R47 1206 Std

NM NM 1 1 R47 Resistor chip 15 kΩ 1% 603 Std

NM NM NM NM R48 Resistor chip 10 kΩ 1% 603 Std

1 NM 1 NM R49 Resistor chip 0 Ω 603 Std

1 1 1 1 R50 Resistor chip 0 Ω 603 Std

Transformers

NM 1 NM NM T1 Transformer EFD17 FA2706-BL Coilcraft

NM NM NM 1 T1 Transformer EFD17 FA2707-BL Coilcraft

1 NM NM NM T2 Transformer EP13 PoE13P-33L Coilcraft

NM NM 1 NM T2 Transformer EP13 PoE13P-50L Coilcraft

1NM1NM T3

Transformer H2019 / TLA-

6T127LF

Pulse/TDK

NM 1 NM 1 T4 Transformer ETH1-230LD Coilcraft

13 13 13 13 TP1:TP13 Test point 5013 Keystone

ICs

1 1 1 1 U1 PM8800 HTSSOP16 STMicroelectronics

1 1 1 1 U2 Optocoupler PC3H7 Sharp

1 1 1 1 U3 TSA431AILT SOT23-5 STMicroelectronics

1. PM8800 demonstration kit printed circuit board has been manufactured with the following Cu layer thicknesses:

Layer 1, 4: 35 µm (1 oz.) (top / bottom side)

Layer 2, 3: 35 µm (1 oz.) (power plane)

15/47

Page 16

Power-up sequence AN2783

6 Power-up sequence

It is recommended to apply power at the PoE input first, slowly increasing the voltage to

verify the absence of abnormal input current levels.

From 1.5 V to 11.5 V input, the signature phase, the PM8800 presents a 24.5 k

resistor as load.

After that in the range 11.5 V to 23 V, the classification phase, the PM8800 draws about 1.5

mA plus the current fixed with the classification resistance, if mounted.

After those two steps are verified, the voltage can be increased to 48 V typical.

Two green LEDs indicate proper operation of the PoE and DC/DC section of the PM8800

demonstration kit. D15 is the nPGD LED and is on when the internal hot-swap MOSFET is

closed, while D11 indicates the presence of the output voltage.

Ω nominal

16/47

Page 17

AN2783 Input section

7 Input section

7.1 Diode bridges

Two diode bridges are required at the input because PD must be able to accept voltage from

an Ethernet cable with undefined polarity and coming from either Tx and Rx or spare pairs.

Diode bridges must be at least 0.5 A to 1 A, 100 V . They contribute to increasing the

resistance presented by the PD to the PSE during the signature phase. For this reason the

internal signature resistance is set to 24.5 kΩ. Care must be taken to not exceed the

standard accepted values between 23.75 kΩ and 26.25 kΩ.

On the high-power board the diode bridges are replaced with discrete Schottky diodes, that

due to the lower voltage drop, allow lower losses at high output power.

7.2 Input capacitors

The IEEE802.3af standard requires a capacitor whose values are between 50 nF to 120 nF

during the signature phase and a minimum of 5 µF during the operating phase. A 100 nF,

100 V ceramic capacitor is used, placed near the VIN pin of PM8800.

In order to reduce the conducted emission, a C-L-C input filter has been designed with a

100 V aluminum capacitor at the input side, a 3.3 µH inductor and three 100 V ceramic

capacitors on the output side.

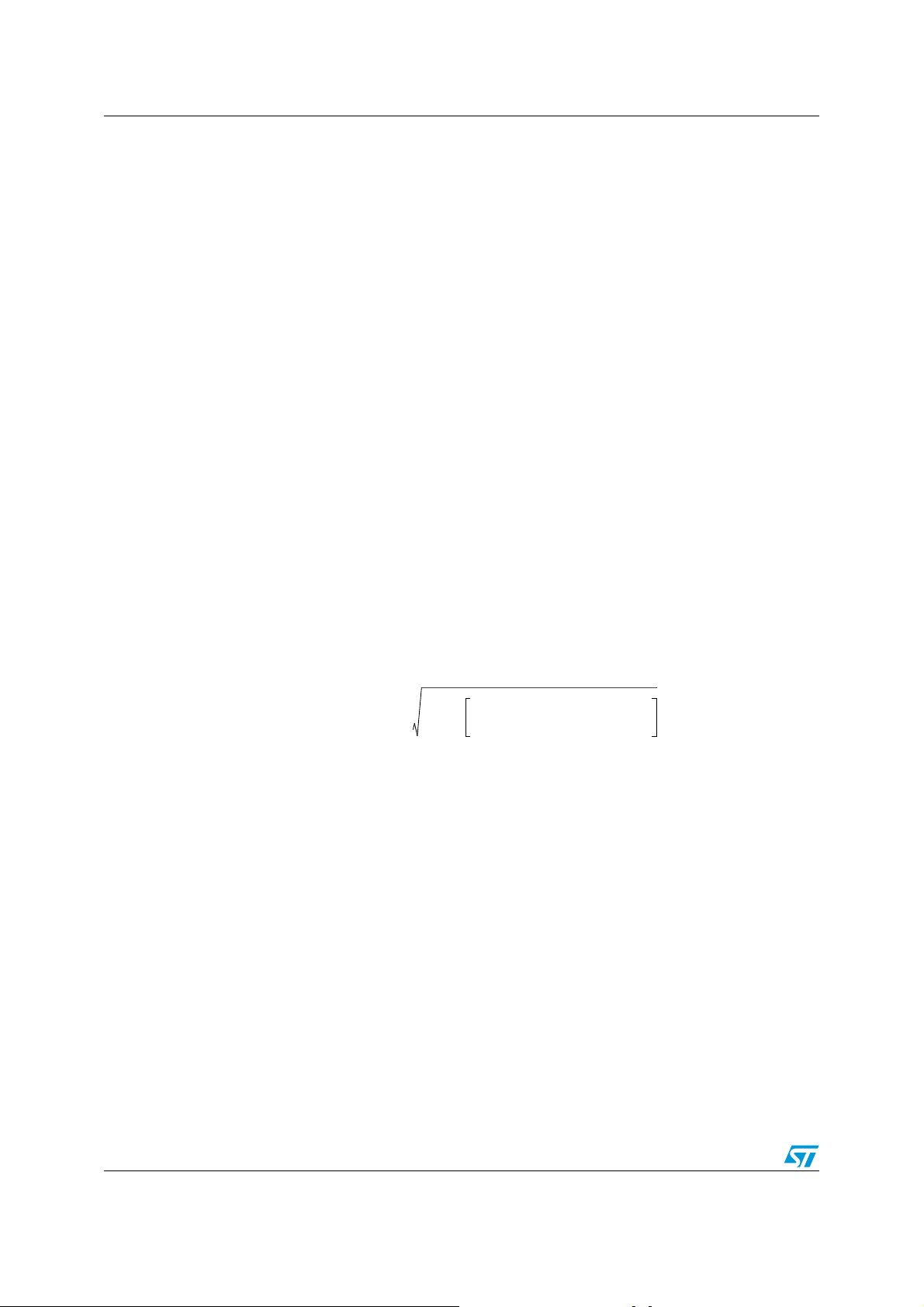

The resonant frequency of the filter is:

Equation 1

Freq

--------------------------------------- -=

2π LC

It has been selected to be about 5-10 times above the control loop bandwidth, to not impact

the stability of the control loop.

Equation 2

------------------------------------------------

C

≥

cer

8Fsw∆V

⋅⋅()

7.3 Transient voltage suppression

The PD in some circumstances (ringing, overshoot transients, static electricity, ground

differences, etc.) can see hundreds or thousands of volts at its RJ45 input connector. The

energy associated with these voltages can be quite large.

A transient voltage suppressor (TVS) is typically applied at the input of the PD, after the

diode bridge, in parallel to the 100 nF input capacitor.

1

⋅⋅()

cer

I

prms

ripple

The TVS must absorb this energy, but the PD interface must be designed to withstand an

additional 20 V or 30 V above the operating range until the TVS limits the voltage.

The TVS must be selected with a standoff voltage higher than the maximum voltage of 57 V

defined in the PoE standard which means a clamping voltage that can easily reach 100 V.

17/47

Page 18

PoE section AN2783

With the SMAJ58A the standoff is 58 V and the clamping voltage for a standard 10/1000 µs

transient is 93 V. PM8800 is able to withstand transient voltage up to 100 V without any

damage.

8 PoE section

8.1 Signature

Signature is the first phase in the PoE standard and allows a PSE (power source equipment)

to recognize the presence of a PD (powered device) that can accept power on the Ethernet

cable.

The PM8800 integrates a 24.5 kΩ resistance to simplify a standard PoE PD interface

design. Its value has been chosen to take into account the voltage drop across the diode

bridge and its effect on the effective resistor value presented at the RJ45 connector input.

This resistor is disconnected for input voltages higher than 11.5 V.

The required signature capacitance is obtained with C1= 100 nF, 100 V.

8.2 Classification

Classification is the second phase in the PoE standard and allows the PSE to allocate the

right amount of power for the PD connected on a single port.

The IEEE802.3af standard defines 4 power classes.

PM8800 has a dedicated pin for the classification resistor. The reference board has R35 left

open, corresponding to CLASS 0.

To select a different class please refer to the table below:

Table 3. RCLASS resistor value

CLASS PD power(W) R

0 0.44 -12.95 Open 0 4

1 0.44 - 3.84 158 9 12

2 3.84 - 6.49 82.5 17 20

3 6.49 - 12.95 52.3 26 30

4 Reserved 36.5 36 44

To provide a constant current during the classification phase, PM8800 has an internal

voltage regulator that maintains 1.4 V typ. across the classification resistor.

802.3af

classification current (mA)

(Ω)min. max

CLASS

The value of R35 is calculated taking into account the power consumption of PM8800 during

the classification phase, which is about 1.5 mA.

18/47

Page 19

AN2783 PoE section

R35 is disconnected at the end of the classification phase, when the input voltage rises

above 23 V.

8.3 UVLO and power-on

Power-on is the final state after successful detection and classification. The input voltage is

increased and an internal switch is closed to connect the PD load. The inrush current is

actively limited by the PM8800 itself.

The PM8800 is fully compliant with UVLO thresholds and inrush current limits defined in the

IEEE802.3af standard.

8.4 Inrush current limit

The inrush current in PM8800 has a three-step limit depending on the voltage across the

hot-swap MOSFET. The first two steps are fixed at 140 mA and 250 mA respectively, the

last step has a default value of 440 mA and it is programmable.

The external resistor to select the desired inrush current is found with the following formula:

Equation 3

R

kΩ[]

IRL

11200

----------------------- -=

I

IRL

mA[]

Figure 8. Inrush current limit vs. R

IRL

90

70

50

[kOhm]

IRL

R

30

10

100 150 200 250 300 350 400 450 500

I

[mA]

IRL

The PM8800 useful programming range for the inrush current limitation is between140 and

440 mA. The practical resistor value ranges between 25 kΩ and 82 kΩ.

Depending on the application, attention must be given to the choice of the inrush current

limit to avoid that the voltage drop on the external Ethernet cable causes UVLO conditions

during the charging phase of the bulk capacitor.

It is recommended to select this voltage drop (can be estimated as max: 20 Ω x I inrush) to

be lower than the UVLO hysteresis (7 Vmin) in order to avoid hiccup turn-on.

The inrush current is set to the default three-step values when the AUXI pin is pulled up over

the 2 V internal threshold by an auxiliary voltage.

19/47

Page 20

PoE section AN2783

Programming inrush current limit resistor R38 on the PM8800 reference board is left open,

thus the limits are set to the default values.

8.5 DC current limit

The continuous current limitation is internally set at 440 mA, but it is possible to modify it by

connecting a resistor between DCCL and VSS. This limitation is active after setting nPGD,

but in case the selected value is lower than the default inrush current, it also applies during

the inrush current phase.

The formula to select the desired DC current is the following:

Equation 4

11200

RDCkΩ[]

Figure 9. DC current limit vs. R

-----------------------=

mA[]

I

DC

DC

900

800

700

600

500

[mA]

DC

400

I

300

200

100

0

10 20 30 40 50 60 70 80

RDC [koh m]

The PM8800 useful programming range for the DC current limitation is between 150 mA and

800 mA. The practical resistor value ranges between 15 kΩ and 75 kΩ.

Please note that the DC current limit is not linked to the inrush current limit, both limits can

be set independently of each other.

Different current limits occur at different voltage drops between VSS and GND regardless of

the PM8800 operative phase:

● For a drop < 3 V, the DC limit occurs with a default value of 440 mA

● For a drop > 3 V but < 15 V, the 3rd step of inrush current occurs with a default value of

440 mA

● For a drop >15 V and < 30 V, the 2nd step of inrush current occurs with a default value

of 250 mA

● For a drop > 30 V, the 1st step of inrush current occurs with a default value of 140 mA

We suggest putting the DC limit over the inrush current which allows avoiding an increase of

current limiting during protection phases.

Programming DC current limit resistor R37 on the PM8800 standard reference board is left

open, leaving the default value as the limit, while a 15 kΩ is mounted on the high-power

version, putting the limit at 740 mA typ.

20/47

Page 21

AN2783 PoE section

8.6 AUXI input

The PM8800 reference board accepts auxiliary power sources applied before the hot-swap

MOSFET as low as 18 V (16 V seen at the pin VIN of device).

To do so and change the UVLO levels, the AUXI pin must be pulled up above 2 V with a

current greater than 70 µA.

The AUXI pin can be connected to the auxiliary voltage through a diode. In this case the

current flowing into the pin is internally limited to about 300 µA.

Depending on the output current drawn, the real operative AUXI voltage can be higher than

the above mentioned value, basically due to the DC current limitation which is maximum

input power at minimum applied on AUXI = 16V x 800 mA =12.8 W.

Another limitation on the operative AUXI voltage can be the power transformer, not designed

to work with a wide input voltage range for the maximum output power.

8.7 AUXII input

PM8800 can also accept auxiliary power sources applied after the hot-swap MOSFET as

slow as 12 V (9 V seen at the pins of device). In this case there is no current limitation and

an external circuit is recommended in order to limit the inrush current.

On the PM8800 reference board an active switch is implemented with a P-channel power

MOSFET, capable of limiting the inrush current at startup and with very low ohmic drop

during operation.

AUXII prevalence over PoE can be programmed forcing a current higher than 100µA in pin

AUXII of PM8800. In this case the PD is always powered from AUXII power source because

the interface circuits and the hot-swap MOSFET are forced in an off state. The pin can be

connected to the auxiliary voltage through a diode. In this configuration the current flowing

into the pin is internally limited to about 250 µA. AUXII can be conveniently used in case of

high-power PDs requiring input power higher than the 12.95 W specified in the IEEE802.3af

standard.

Please note that having the hot-swap MOSFET in an off state means having the IC

substrate in high impedance with GND. It is strongly recommended to move the signature

capacitor of 100 nF from the C1 position to C36. This capacitor is placed between VSS and

GND, implementing a low-impedance circuit at high frequency across the hot-swap

MOSFET, assuring a good HF connection of the IC substrate. The PM8800 reference board

is preset for AUXII prevalence over PoE, having R23 set to 10 kΩ.

Warning: In case of AUXII low input voltage sources, the condition

VIN < VCC must be avoided because of possible damage to

the device.

21/47

Page 22

Power transformer and operating input voltage AN2783

9 Power transformer and operating input voltage

The PM8800 demonstration kit can contain two different types of power transformers:

Table 4. Characteristics of the power transformer for the PM8800 evaluation kit

Type Lprimary N Ipeak sat Rsec

PoE13P-33L / 50L

FA2706-BL / 07-BL

127 µH

70 µH 6.8 / 4.85 3.5 A

6 / 4 1 A 24 mΩ/ 39 mΩ

8 mΩ/ 18.5 mΩ

The standard EP13 transformer is designed to operate at full IEEE802.3af power when the

input voltage is in the range 36-72 V. When working from auxiliary voltages lower than 36 V

the output power must be reduced in order to not saturate the transformer.

The custom transformer has been designed to work optimally over the full input range

between 12 V to 60 V in order to exploit the AUXII connection option made available by the

PM8800.

FA2706/7-BL can be also used to draw more power than 10 W when restricting the input

operational voltage range. For example about 20 W can be drawn with a minimum input

voltage of about 30 V, the minimum operating voltage of the PoE standard range.

Figure 10. Output power vs. VAUXII

Pout vs VAUXII wit h FA270x-BL

25

20

15

10

Pout ( W )

5

0

10 15 20 25 30 40 50 60

An auxiliary winding has been added in the FA2706/7-BL to directly drive a synchronous

power MOSFET as a secondary rectifier, in order to reduce the power losses associated

with a standard diode rectifier at high output currents.

When working at very low input voltage, as in the case of AUXII, the diode D6 can be added,

(actually not mounted on the reference board) to directly supply the VCC pin of PM8800.

Warning: In this condition please do not increase the AUXII voltage

above 15 V as permanent damage can occur to the device.

22/47

VAUXII ( V )

Page 23

AN2783 Power converter

10 Power converter

The PM8800 reference board implements a flyback converter operating in DCM

(discontinuous mode) at low output power and in CCM (continuous mode) for medium to

high output power.

The output secondary rectifier can be a classic diode for low to medium output power or a

synchronous rectifier for high output current.

Flyback configuration is the standard choice for a low-power isolated converter. It is the

simplest isolated converter, using the lowest number of power components.

CCM has been selected in order to reduce the stress on the power components, especially

on the secondary side.

CCM is assured only at medium to full output power, while in low output power the converter

works in DCM which allows reducing the size of the power transformer.

It is out of the scope of this document to show the whole flyback converter theory, which can

be found in every basic power supply handbook. In this application note we focus only on

the aspects directly related to the use of the PM8800 in a flyback converter.

10.1 Flyback continuous conduction mode

The flyback converter is in DCM when the energy stored during the ON phase has been

completely transferred to the secondary side during the OFF phase. This means that a

small period of time still remains during which no current is flowing on either side of the

power transformer.

When this period of time does not exist, i.e. when the energy stored has not been

completely transferred during the ON phase, the flyback is said to work in CCM.

Compared to CCM, DCM presents higher peak and rms current values on the primary

switch and on the output rectifier. This implies higher output ripple and require bigger input

and output filters.

CCM presents an RHP zero, which slightly complicates the control loop compensation. A

flyback converter designed to work in CCM is also stable in DCM.

The transfer function of a flyback in CCM is:

Equation 5

Vin Vds–()Ton⋅ Vout Vd+()NTswTon–()⋅⋅=

The above equation can be written as:

Equation 6

Vout Vd+()

------------------------------- -

Vin Vds–()

23/47

-------------------------- -=

N1D–()⋅

D

Page 24

Power converter AN2783

The maximum duty cycle can be obtained as:

Equation 7

Ton

max

--------------------

Tsw

------------------------------------------------------------------------------------=

Vin

min

N Vout Vd+()⋅

Vds–()N Vout Vd+()⋅+

10.2 Main switch current and current sensing

The current shape in the primary power switch is different when the flyback converter is

working in DCM or CCM. In DCM the shape is triangular with the current starting from zero,

while in CCM the shape is trapezoidal.

For CCM operations the peak current can be computed as:

Equation 8

Ipeak Ipave

∆I

L

--------+

-------------------------------------------- -

2

η N1D

Iout

–()⋅⋅

max

Vin

maxDmax

-----------------------------------------------------+==

Tsw⋅⋅

2Lp

which can be expressed as:

Equation 9

Ipeak

max

Pout

Vin Vds–()⋅⋅

--------------------------------------------------------- -

η D

Vin

maxDmax

-----------------------------------------------------+=

2Lp

Tsw⋅⋅

The RMS current can be:

Equation 10

2

∆I

L

L

---------- -+⋅

3

Iprms D

Ipeak2Ipeak

max

⎛⎞

–⋅=

⎜⎟

⎝⎠

∆I

--------

2

The above formula can be used to calculate the right current sense resistor, taking into

account that the first level of OCP is for PM8800 at 500 mV:

Equation 11

Rcs

500m V

----------------------------=

1.3 Ipeak⋅

The associated power dissipation on the sense resistor is:

Equation 12

Pcs Rcs Iprms

10.3 Main switch power dissipation

The power dissipation on the main power MOSFET is the sum of two terms:

24/47

2

⋅=

Page 25

AN2783 Power converter

Equation 13

Pswitching

Pcond Ron Iprms2D

Coss Vds2Fsw⋅⋅

------------------------------------------------ - Vds

⋅⋅=

2

max

max

Ipeak Tm Fsw⋅⋅⋅+=

where

Equation 14

Vds

max

1.2 Vin

Vspike is due to the leakage inductance of the power transformer and can be assumed to be

40 V max, as the snubber network on the primary side is built with a TVS with breakdown

voltage of 40 V.

Tm is the time to charge the Miller capacitor of the power MOSFET and can be estimated

as:

Equation 15

Tm

Note that if the major contribution to the MOSFET losses comes from the second term of the

switching power losses, the right choice is for a low gate charge power MOSFET.

10.4 Rectifier diode dissipation

The secondary output current is:

Equation 16

∆I

SL

Ispeak Isave

-----------+

2

Vspike+()NVoutVd+()⋅+[]⋅=

max

Qgd Rg⋅

-------------------------------- -=

Vcc Vgsth–

Iout

max

---------------------- -

1D

–

max

Vout Vd+()Tsw Ton–()⋅[]

-------------------------------------------------------------------------- -+==

Lp()N

⁄

2

2

∆I

SL

Isrms 1 D

–()Ispeak2Ispeak ∆I

max

SL

-----------+⋅–⋅=

3

The reverse voltage across the rectification diode is:

Equation 17

Vin

Vr

diode

max

------------------ - Vout+=

N

The power dissipated in the secondary diode, neglecting the reverse leakage losses, can be

estimated as:

Equation 18

P

diode

Isrms Vd 1 D

–()⋅⋅=

max

25/47

Page 26

Power converter AN2783

10.5 PM8800 internal power dissipation

A calculation must be done to verify that the PM8800 maximum junction temperature has

not been exceeded.

Major contributions to internal power dissipation are:

– startup circuit

– power MOSFET gate driver

– hot-swap MOSFET

– internal circuitry

It is strongly recommended to use an additional winding to generate an auxiliary VCC voltage of 9 V minimum, which switches off the internal startup circuit after the power-up of the

converter.

As mentioned before, the converter power MOSFET must be chosen as a good compromise

between low Ron and low total charge. The internal power dissipation associated to the gate

drive is:

Equation 19

P

drive

Vcc Qg Freq⋅⋅=

The hot-swap MOSFET dissipates internally:

Equation 20

P

hotswap

Ron Iin2⋅=

Internal power dissipation is due to circuits that draw current directly from VIN, like the hotswap controller or other logic circuits powered from VCC:

Equation 21

Typical operative values are I

P

device

= 5 mA and I

in

Vin Iin Vcc I iclog⋅+⋅=

= 3 mA.

logic

The total power dissipated by PM8800 is:

Equation 22

P

totPdrivePhotswapPdevice

++=

The following relationship must be satisfied:

Equation 23

T

ambPtot

where a typical value of Rth for PM8800 mounted on the ref board is 85 °C/W and Tjmax is

150 °C.

26/47

Rthja⋅ T<

+

jmax

Page 27

AN2783 Layout guidelines

11 Layout guidelines

We suggest the following guidelines for the layout of the PM8800:

● Place the component group including input ceramic capacitors, input side of

transformer, power MOSFET and sense resistors close to each other in order to keep

the interconnections as short as possible.

● Place the component group including secondary rectifier diode, output side of

transformer, output ceramic capacitors close to each other in order to keep the

interconnections as short as possible.

● Place the PM8800 in such a way as to have a short path to the gate of the power

MOSFET. Use a 20-30 mils wide path for this signal.

● Ground: there are basically 4 different grounds on the board (VSS, GND, RTN and

chassis ground).

– The exposed pad of PM8800 must be connected to VSS. Design a fill area with at

least 6 vias to the VSS plane. Try where possible to increase the number of VSS

power planes connected, at least below the PM8800 position, to improve the heat

dissipation of PM8800.

– GND must be divided into power gnd (to connect input caps, Rsense, PM8800 pin

9, AUXII circuitry, isolation cap) and signal gnd (to connect the other components

around the PM8800, the circuitry powered by VCC voltage, and the IC pin 16). The

signal gnd must be connected to power gnd in one point only, close to the PM8800

pin 9. Keep the power path on RTN (output side of transformer, secondary diode,

output connector) separated from the feedback network gnd, which is connected

only at the connector side.

● Design the power MOSFET area with at least 9-12 vias of connection to the internal

copper area. Try where possible to increase the number of power planes connected, at

least below the MOSFET position, to improve the heat dissipation.

● Design the secondary rectifier diode with at least 9-12 vias of connection to the internal

copper area.

● Try where possible to increase the number of power planes connected, at least below

the diode position, to improve the heat dissipation.

● Chassis: design copper areas on both side of the PCB. Do not place other grounds or

signals under the RJ45 and the data transformer area. Place any termination network

on the bottom side.

27/47

Page 28

Layout guidelines AN2783

More in detail:

Place the TVS close to the input diode bridges, if possible on the same side

1. Place the PM8800 and all the related components close to each other, use both sides

2. Place all the feedback components close to each other, use both sides

3. Place the sense resistors close to the power MOSFET, if possible on the same side

4. Place the input ceramic capacitors close to the input side of power transformer, if

possible on the same side

5. Place the primary snubber network close to the power transformer, on the bottom side

6. Place the rectifier diode close to the output side of the transformer, if possible on the

same side

7. Place the secondary snubber network close to the rectifier diode, bottom side

8. Place the output ceramic capacitors close to the rectifier diode and the power

transformer, on the copper areas, top side

9. Place the last ceramic capacitors close to the output terminal of the power connector,

bottom side

10. Place the 100 nF input capacitor close to the VSS and GND pins

11. Place the decoupling capacitors for VCC close to the relevant PM8800 pin

12. Place the components for RT and SS pins in a quiet area, separated as much as

possible from other signals

13. Use paths of at least 20 mils for signals connected to the IC pins 5,10,11

14. Connect the PM8800 pins 8,9,16 directly to the copper areas

15. Use a wide path or copper area for VIN, AUXI and AUXII networks

28/47

Page 29

AN2783 Test results

12 Test results

12.1 Efficiency measurements

Figure 11. 5 V out - standard board with diode rectification

90%

85%

80%

75%

Efficiency

70%

65%

60%

0.00 0.50 1.00 1.50 2.00 2.50

Iout [A]

5Vout DC-DC

5Vout Overall

Figure 12. 5 V out - high-power board with synchronous rectification

90%

85%

80%

75%

Efficiency

70%

5Vout HP DC-DC

65%

60%

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5

Iout [A]

5Vout HP overall

29/47

Page 30

Test results AN2783

Figure 13. 3.3 V out - standard board with diode rectification

90%

85%

80%

75%

Efficiency

70%

65%

60%

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3 .5

Iout [A]

3.3Vout DC-DC

3.3Vout overall

Figure 14. 3.3 V out - high-power board with synchronous rectification

90%

85%

80%

75%

Efficiency

70%

65%

60%

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5

Iout [A]

3.3Vout HP DC-DC

3.3Vout HP overall

In the following pages are shown tests done on the 5 V high-power version and 3.3 V

standard version of the reference board.

Similar results and behaviors could be obtained with the 3.3 V high-power version and 5 V

standard versions.

30/47

Page 31

AN2783 Test results

12.2 5 V high-power board measurements

Figure 15. Startup of the PM8800

demonstration kit with 5 V 1 A

Figure 16. Startup of the PM8800

demonstration kit with 5 V 4 A

Ch1= output voltage, Ch2 = VSS voltage with respect to GND, Ch3 = VCC voltage, Ch4 =

input current

Figure 17. Details of the inrush phase Figure 18. Details of the soft-start phase

Ch1= output voltage, Ch2 = VSS voltage with respect to GND, Ch3 = VCC voltage (left) and

soft-start (right), Ch4 = input current.

31/47

Page 32

Test results AN2783

Figure 19. V

DS

and V

of the primary

GS

MOSFET for 5 V 1 A

Ch2 = primary side power MOSFET gate voltage, Ch3 = primary side power MOSFET drain

voltage.

Figure 21. Details of the synchronous rectifier MOSFET voltage with 48 V and 4 A

out

Figure 20. VDS and V

MOSFET for 5 V 4 A

of the primary

GS

Ch1 = secondary side power MOSFET drain-source voltage, Ch3 = primary side power

MOSFET drain voltage

32/47

Page 33

AN2783 Test results

Figure 22. Output voltage ripple at 4 A output

current

Figure 24. Dynamic load 1 A to 4 A: output voltage (up) and output current (down)

Figure 23. Output voltage ripple at 4 A output

current (1 sec persistence)

33/47

Page 34

Test results AN2783

Figure 25. PM8800A response to a 6 A

overload condition

Ch1 = output voltage, Ch2 = soft-start voltage, Ch3 = voltage across the hot-swap MOSFET,

Ch4 = input current.

Figure 27. PM8800A response to a short on

the load

Figure 26. PM8800A recovering from a 6 A

overload condition

Figure 28. PM8800A recovering from a short

on the load

Ch1 = output voltage, Ch2 = soft-start voltage, Ch3 = voltage across the hot-swap MOSFET,

Ch4 = input current.

34/47

Page 35

AN2783 Test results

Figure 29. Internal short on the secondary winding

Ch1 = output voltage, Ch2 = soft-start voltage, Ch3 = voltage across the hot-swap MOSFET,

Ch4 = input current

Figure 30. Switch between 48 V PoE and 24 V

AUXII with 5 V at 2 A

Ch1 = output voltage, Ch2 = internal primary voltage, Ch3 = voltage across the hot-swap

MOSFET, Ch4 = AUXII input current

Figure 31. back to 48 V removing the 24 V

AUXII voltage with 5 V at 2 A

35/47

Page 36

Test results AN2783

Figure 32. Switch between 48 V PoE and 12 V

AUXII with 5 V at 2 A

Figure 33. Back to 48 V removing the 12 V

AUXII voltage with 5 V at 2 A

Ch1 = output voltage, Ch2 = internal primary voltage, Ch3 = voltage across the hot-swap

MOSFET, Ch4 = AUXII input current

12.3 3.3 V standard-power board measurements

Figure 34. Startup of the PM8800

demonstration kit with 3.3 V, 1 A

Ch1= output voltage, Ch2 = VSS voltage with respect to GND, Ch3 = VCC voltage,

Ch4 = input current

Figure 35. Startup of the PM8800

demonstration kit with 3.3 V, 3 A

36/47

Page 37

AN2783 Test results

Figure 36. Details of the inrush phase Figure 37. Details of the soft-start phase

Ch1= output voltage, Ch2 = VSS voltage with respect to GND, Ch3 = VCC voltage (left) and

soft-start (right), Ch4 = input current

Figure 38. VDS and V

MOSFET for 3.3 V 1 A

of the primary

GS

Ch2 = primary side power MOSFET gate voltage, Ch3 = primary side power MOSFET drain

voltage

Figure 39. VDS and V

MOSFET for 3.3 V 3 A

of the primary

GS

37/47

Page 38

Test results AN2783

Figure 40. Details of the synchronous rectifier MOSFET voltage with 48 V and 3 A

output current

Ch1 = secondary side power MOSFET drain-source voltage, Ch3 = primary side power

MOSFET drain voltage

Figure 41. Output voltage ripple at 3 A output

current

Figure 42. Output voltage ripple at 3 A output

current (1 sec persistence)

38/47

Page 39

AN2783 Test results

Figure 43. Dynamic load 1 to 3 A: output voltage (up) and output current (down)

Figure 44. PM8800A response to a 5 A

overload condition

Ch1 = output voltage, Ch2 = soft-start voltage, Ch3 = voltage across the hot-swap MOSFET,

Ch4 = input current

Figure 45. PM8800A recovering from a 5 A

overload condition

39/47

Page 40

Test results AN2783

Figure 46. PM8800A response to a short on

the load

Ch1 = output voltage, Ch2 = soft-start voltage, Ch3 = voltage across the hot-swap MOSFET,

Ch4 = input current

Figure 48. Internal short on the secondary winding

Figure 47. PM8800A recovering from a short

on the load

Ch1 = output voltage, Ch2 = soft-start voltage, Ch3 = voltage across the hot-swap MOSFET,

Ch4 = input current

40/47

Page 41

AN2783 Test results

Figure 49. Switch between 48 V PoE and 24 V

AUXII with 3.3 V at 2 A

Ch1 = output voltage, Ch2 = internal primary voltage, Ch3 = voltage across the hot-swap

MOSFET, Ch4 = AUXII input current

Figure 51. Switch between 48 V PoE and 12 V

AUXII with 3.3 V at 2 A

Figure 50. Back to 48 V removing the 24 V

AUXII voltage with 3.3 V at 2 A

Figure 52. Back to 48 V removing the 12 V

AUXII voltage with 3.3 V at 2 A

Ch1 = output voltage, Ch2 = internal primary voltage, Ch3 = voltage across the hot-swap

MOSFET, Ch4 = AUXII input current

41/47

Page 42

Test results AN2783

12.4 IEEE 802.3af compatibility test

Additional tests of compatibility to the IEEE802.3af standard have been done with the

PDA100 PD tester from Sifos Technologies. Results obtained with the 5 V, 2 A standard

board are summarized inTab le 5, 6, and 7. All tests have been successfully completed.

Table 5. Compatibility test at -45 degC

Alt-A MDI Alt-A MDI-X Alt-B MDI Alt-B MDI-X

Det. resistance 25.18 kΩ 25.16 kΩ 25.25 kΩ 25.25 kΩ

Det. capacitance 0.109 µF 0.092 µF 0.109 µF 0.103 µF

Class. current 1.4 mA 1.4 mA 1.4 mA 1.4 mA

Class result 0 0 0 0

Average power 12.52 W 12.52 W 12.38 W 12.38 W

Max current 266.2 mA 261.6 mA 258.8 mA 258.6 mA

Min current 260.3 mA 260.3 mA 257.4 mA 257.3 mA

Av. current 261.0 mA 260.9 mA 258.0 mA 258.0 mA

Turn-on voltage 40.0 V 40.0 V 40.0 V 40.0 V

Turn-off voltage 33.9 V 33.9 V 33.1 V 33.1 V

Table 6. Compatibility test at room temperature

Alt-A MDI Alt-A MDI-X Alt-B MDI Alt-B MDI-X

Det. resistance 24.90 kΩ 24.99 kΩ 24.95 kΩ 25.09 kΩ

Det. capacitance 0.103 µF 0.104 µF 0.104 µF 0.109 µF

Class. current 1.4 mA 1.3 mA 1.3 mA 1.3 mA

Class result 0 0 0 0

Average power 12.53 W 12.53 W 12.34 W 12.34 W

Max current 266.2 mA 262.0 mA 257.7 mA 257.6 mA

Min current 260.7 mA 260.5 mA 256.8 mA 256.8 mA

Average current 261.1 mA 261.2 mA 257.2 mA 257.1 mA

Turn-on voltage 40.0 V 40.0 V 40.0 V 40.0 V

Turn-off voltage 34.2 V 34.1 V 33.1 V 33.0 V

Table 7. Compatibility test at +85 degC

Alt-A MDI Alt-A MDI-X Alt-B MDI Alt-B MDI-X

Det. resistance 25.47 kΩ 25.49 kΩ 25.54 kΩ 25.57 kΩ

Det. capacitance 0.114 µF 0.112 µF 0.109 µF 0.103 µF

Class. current 1.3 mA 1.3 mA 1.3 mA 1.3 mA

Class result 0000

Average power 12.59 W 12.59 W 12.36 W 12.37 W

42/47

Page 43

AN2783 Test results

Table 7. Compatibility test at +85 degC (continued)

Alt-A MDI Alt-A MDI-X Alt-B MDI Alt-B MDI-X

Max current 267.2 mA 263.0 mA 258.6 mA 258.6 mA

Min current 261.8 mA 261.8 mA 257.4 mA 257.2 mA

Average current 262.3 mA 262.4 mA 257.7 mA 257.8 mA

Turn-on voltage 39.8 V 39.7 V 39.7 V 39.7 V

Turn-off voltage 34.1 V 34.1 V 32.9 V 32.9 V

43/47

Page 44

Schematic of high-power board AN2783

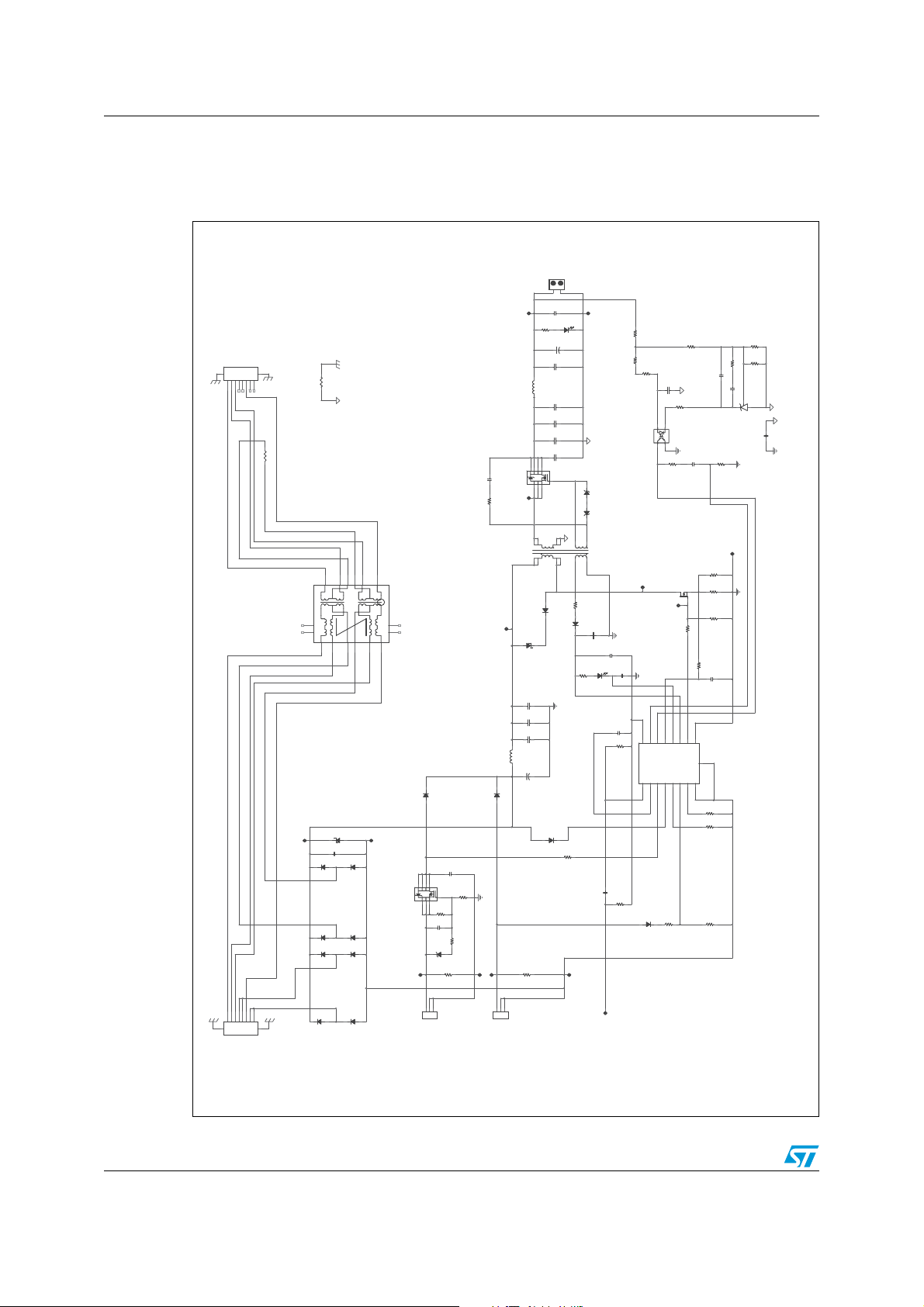

Appendix A Schematic of high-power board

Figure 53. Schematic of the 3.3/5 Vout high power with synchronous rectification

J5

J5

1

1

2

2

DC OUTPU T

DC OUTPU T

C39

0.1u

C39

0.1u

TP14

TP14

OUTOUTOUT

OUTOUTOUT

1k

1k

R17

R17

RJ45 Data Jack

RJ45 Data Jack

J2

J2

10

10

9

9

23456

23456

Chass is

Chass is

OUTPUT

OUTPUT

7

8

7

8

0

0

R1

R1

0805

0805

Chass is

Chass is

1

1

T4

T4

7

7

8

8

TP1

TP1

Chass is

Chass is

0

0

1206

1206

R30

R30

6

6

9

9

1011121314

1011121314

D3

D3

SMAJ58A

SMAJ58A

C1

0.1u

0805

C1

0.1u

0805

D24

D24

SMA

SMA

STPS1H 10 0

STPS1H 10 0

D22

STPS1H100

SMA

D22

STPS1H100

SMA

D20

D20

SMA

SMA

STPS1H 10 0

STPS1H 10 0

2

2

L3

L3

0.33uH

0.33uH

DO1813H-331ML

DO1813H-331ML

1

1

678

678

51

51

470p

470p

C11

C11

0805

0805

2

2

3

3

Q2

Q2

TP7

TP7

15

15

R13

R13

1206

1206

T1

T1

3

3

4

4

12345

12345

D10

ETH1-230LD

ETH1-230LD

16

16

15

15

D4

D4

SMC

SMC

STTH302S

STTH302S

TP2

TP2

100V

100V

D25

D25

SMA

SMA

STPS1H 10 0

STPS1H 10 0

D23

D23

STPS1H100

SMA

STPS1H100

SMA

D21

D21

SMA

SMA

STPS1H 10 0

STPS1H 10 0

SO8

SO8

678

678

51

51

STS10PF30L

STS10PF30L

2

3

2

3

C27

C27

BZX84C15

BZX84C15

TP3

TP3

SMC

SMC

STTH302S

STTH302S

0.1u

0.1u

C41

C41

100V

100V

0805

0805

R12

330K

R12

330K

Q1

Q1

0805

0805

4

4

GND

GND

330K

330K

R10

R10

0805

0805

0.1u

0.1u

R50

0

R50

0

SOT23

SOT23

1 3

1 3

D5

D5

TP5

TP4

TP5

TP4

R11

15K

R11

15K

0805

0805

D10

TP6

TP6

D9

D9

SMAJ58A

SMAJ58A

1812

1812

C17

2.2u

100V

C17

2.2u

100V

C15

2.2u

1812

100V

C15

2.2u

1812

100V

C14

2.2u

1812

C14

2.2u

1812

100V

100V

2

2

L1

3.3uH

L1

3.3uH

ME3220-332ML

ME3220-332ML

1

1

C13

22u

C13

22u

100V

100V

8x10.2

8x10.2

D7

D7

BAS21

BAS21

R15

15K

R15

15K

0805

0805

TP8

TP8

D11

RTNRTN

D11

RTNRTN

Green LED

Green LED

C24

330u

8x10.5

C24

330u

8x10.5

6.3V

6.3V

1206

6.3V

1206

6.3V

10u

10u

C23

C23

C21

C21

10u

10u

1206

6.3V

1206

6.3V

C20

C20

10u

6.3V

10u

6.3V

1206

1206

C19

C19

6.3V

6.3V

10u

1206

10u

1206

C18

C18

10u

1206

10u

1206

6.3V

6.3V

4

4

3

3

D13

D13

BZX84C18

BZX84C18

1

1

1

1

PowerSO8

PowerSO8

D12

D12

STSJ60NH3LL

STSJ60NH3LL

BZX84C18

BZX84C18

3

3

11812109

11812109

7

7

1

2

6

1

2

6

5

5

R18

10

R18

10

SMA

SMA

STPS1H100A

STPS1H100A

D14

D14

C25

C25

SOD323

SOD323

BAT46J

BAT46J

R19

R19

3.3k

3.3k

D15

D15

GND

GND

D26

D26

SOT23

SOT23

R23

10k

R23

10k

TP9

TP9

0

0

R25

R25

0

0

R24

R24

R26

R26

SOT23

SOT23

SOT23

SOT23

SEE BOM

SEE BOM

COILC RAFT F A27 06 -BL

TP10

TP10

1u

16V

0603

1u

16V

0603

GND

GND

C26

0.1u

C26

0.1u

Green LED

Green LED

C34

0.1u

C34

0.1u

AGND

AGND

C28

0.1u

C28

0.1u

AGND

AGND

16

16

R21

R21

AGND

AGND

88.7K

1%

88.7K

1%

RT1SS2AUXII3VIN

RT1SS2AUXII3VIN

U1

U1

RT

RT

C40

C40

100p NM

100p NM

R48

R48

NM

NM

21k

21k

1%

1%

R32

R32

10

10

1u

1u

16V

16V

C30

C30

0603

0603

1k

1k

R29

R29

23

23

Sharp PC3H7

Sharp PC3H7

U2

U2

4 1

4 1

AGND

AGND

R281kC32

0.1u

R281kC32

0.1u

R40

R40

DPack

DPack

Q3

Q3

STD22NM20N

STD22NM20N

32

32

R39

R39

TP11

TP11

1

1

10k

10k

R38

R38

R31

R31

10 0805

10 0805

100

100

R33

R33

C33

C33

GDGD

CS

VCC

GND

nPGDnPGDnPGDnPGDnPGDnPGD

GDGD

CS

VCC

GND

nPGDnPGDnPGDnPGDnPGDnPGD

12

12

15

15

9

9

11

11

14

14

10

10

13

13

CS

CS

GD

GD

VFB

VFB

VCC

VCC

GND

GND

nPGD

PM88 0 0

HTSSO1 6

nPGD

PM88 0 0

R27

R27

RCLASS5AUXI_IRL6DCCL

RCLASS5AUXI_IRL6DCCL

RCLASS

RCLASS

10k

10k

HTSSO1 6

Ex Pad

Ex Pad

17

17

VSS

VSS

7

7

8

8

VSS

VSS

DCCL

DCCL

AUXI_IRL

AUXI_IRL

R37

15k

R37

15k

0805

0805

R35

R35

R36

NM

R36

NM

COMP

COMP

4

4

VIN

SS

VIN

SS

AUXIIAUXII

AUXIIAUXII

D16

D16

SOD323

SOD323

BAT46J

BAT46J

1%

1%

R44

R44

12.4k

12.4k

1%

1%

R47

R47

NM

NM

1%

1%

10k

10k

R43

R43

22n

22n

C35

C35

SEE BOM

SEE BOM

C37

C37

4.7n

4.7n

4

4

3

5

3

5

U3

U3

TS431

TS431

SOT23-5

SOT23-5

2.2n

1812

2KV

2.2n

1812

2KV

C29

C29

GND

GND

AGND

AGND

0

0

R42

R42

TP12

TP12

1206

1206

0.47 ohm

0.47 ohm

GND

GND

1206

1206

0.47 ohm

0.47 ohm

470p

470p

GND power ground plane close to pin 9 of PM880 0

GND power ground plane close to pin 9 of PM880 0

The AGND is a dedicated plane of signal groun d that will be connect ed to the

The AGND is a dedicated plane of signal groun d that will be connect ed to the

NOTE

NOTE

1%

1%

1%

1%

NM

NM

123

D18

D19

SMA

D18

D19

SMA

STPS1H 10 0

SMA

STPS1H 10 0

STPS1H 10 0

SMA

23456

23456

1

8

1

8

7

7

Cha ss is

Cha ss is

10

10

Cha ss is

Cha ss is

9

9

J1

J1

RJ45 Data and Power Jack

RJ45 Data and Power Jack

INPUT

INPUT

STPS1H 10 0

123

J4

J4

DC Power Jack

DC Power Jack

AUX II

AUX II

44/47

123

123

J3

J3

DC Power Jack

DC Power Jack

AUXI_IRL

AUXI_IRL

TP13

TP13

Sync Input

Sync Input

Where not indicat ed the bo dy is 0603 and tol erance 5%

Where not indicat ed the bo dy is 0603 and tol erance 5%

NOTE for Resistors

NOTE for Capacitors

Where not indicat ed the bo dy is 0603 and the vol tage is 50V

NOTE for Resistors

NOTE for Capacitors

Where not indicat ed the bo dy is 0603 and the vol tage is 50V

AM01334v1

Page 45

AN2783 Schematic of standard-power board

g

g

0

k

k

k

k

d

y

g

k

k