Page 1

AN2771

Application note

2x58 W/T8 or 2x36 W/T8 ballast

demonstration board driven by L6585D

Introduction

This application note describes a demonstration board able to drive 2x58 W linear T8

fluorescent tubes. In addition, the modifications needed to adapt the same board for 2x36 W

linear T8 fluorescent tubes are specified.

The ballast is controlled by STMicroelectronics’ L6585D which integrates PFC and halfbridge control circuits, the relevant drivers, and the circuitry able to manage all lamp

operating phases (preheating, ignition and run mode). Protections against primary failures

(lamp disconnection, anti-capacitive mode, PFC overvoltage) are guaranteed and obtained

with a minimum number of external components. After presenting the circuit description and

design criteria, a short overview of the ballast performances is given.

Fluorescent lamps are driven more and more by electronic, rather than electromagnetic

ballast, primarily because fluorescent lamps can produce around 20 % more light for the

same input power when driven above 20 kHz instead of 50/60 Hz. Operation at this

frequency also eliminates both light flickering (the response time of the discharge is too slow

for the lamp to have a chance to extinguish during each cycle) and audible noise. An

electronic ballast consumes less power and therefore dissipates less heat than an

electromagnetic ballast. The energy saved can be estimated in the range of 20-25% for a

given lamp power. Finally the electronic solution allows better control of the filament current

and lamp voltage during preheating with the unquestionable benefit of increasing the mean

lamp life.

Figure 1. 2x58W T8 ballast demonstration board

August 2008 Rev 1 1/27

www.st.com

Page 2

Contents AN2771

Contents

1 Basis of half-bridge inverter topology . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Main characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Ballast design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 L6585D biasing circuitry (pin by pin) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 PFC power section design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3 Half-bridge inverter design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.4 Symmetrical and asymmetrical EOL protection: improvements . . . . . . . . 13

4 Experimental results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 Protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6 Conduction emissions test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1 Adapting the design for a 2x36 W T8 electronic ballast . . . . . . . . . . . . . . 21

7 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2/27

Page 3

AN2771 List of figures

List of figures

Figure 1. 2x58W T8 ballast demonstration board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. Electronic lamp ballast - capacitor-to-ground configuration . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 3. Electronic lamp ballast - lamp-to-ground configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 4. Dual lamp ballast series configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 5. Dual lamp ballast parallel configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 6. Electrical schematic 2x58 W T8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 7. TSM101 window comparator configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 8. External symmetrical EOL protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 9. L6585 startup sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 10. One lamp ignition phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 11. Low-side current in run mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 12. Voltage and current lamp in run mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 13. Asymmetrical EOL protection with broken cathode during run mode. . . . . . . . . . . . . . . . . 19

Figure 14. Symmetrical EOL protection behavior during ignition phase . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 15. Conducted emissions at 230 Vac 50 Hz - line 1 peak detector . . . . . . . . . . . . . . . . . . . . . 21

Figure 16. Conducted emissions at 230 Vac 50 Hz - line 2 peak detector . . . . . . . . . . . . . . . . . . . . . 21

3/27

Page 4

Basis of half-bridge inverter topology AN2771

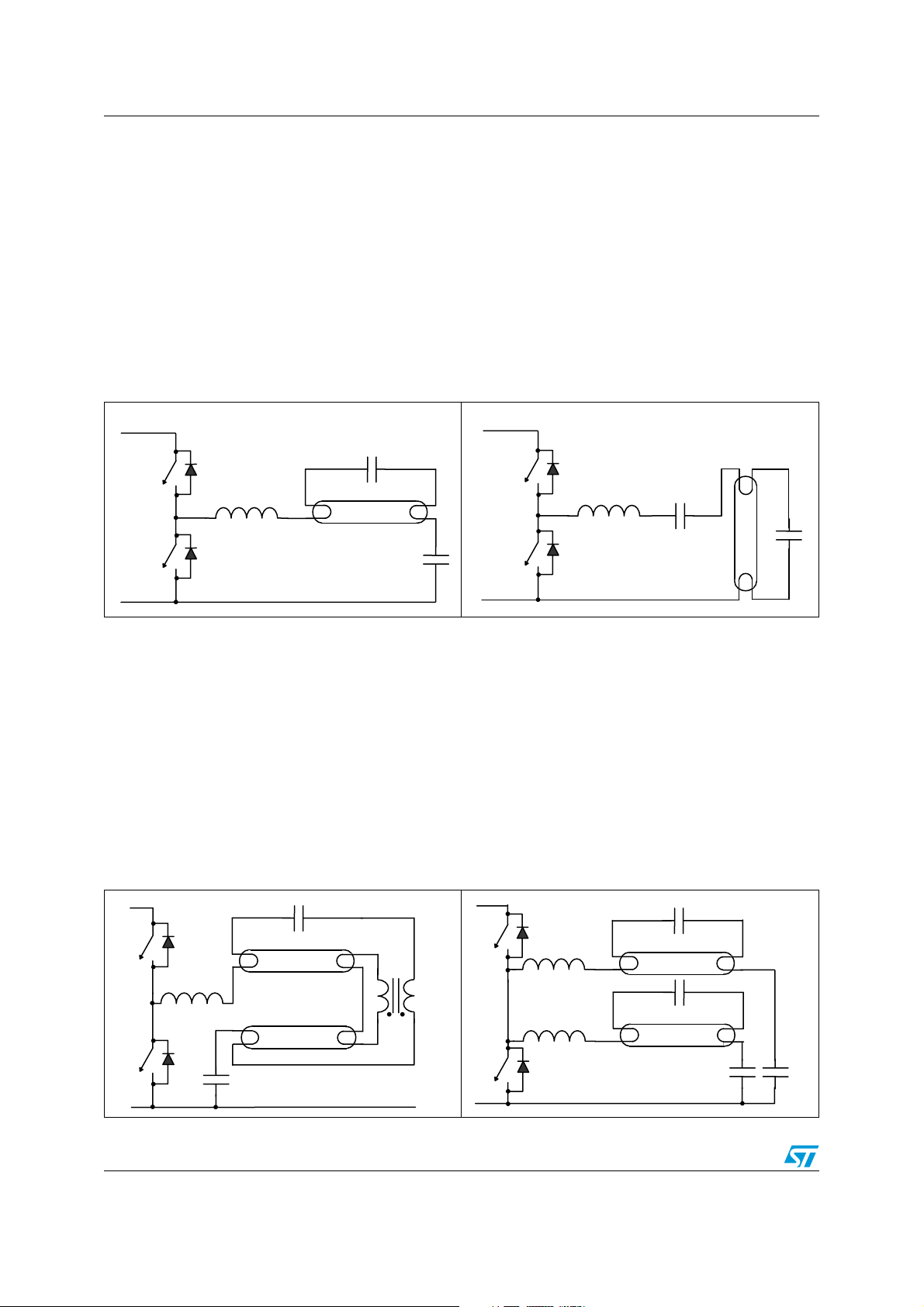

1 Basis of half-bridge inverter topology

The half-bridge inverter operates in zero voltage switching (ZVS) resonant mode, to reduce

the switching losses and the electromagnetic interference generated by the output wiring

and the lamp. Voltage-fed series resonant half-bridge inverters are currently used for

compact fluorescent lamp ballasts (CFL) and for many European tube lamp (TL) ballasts.

Generally, for lighting applications, considering the current preheating, it's possible to

choose between two different topologies of the resonant circuit: capacitor-to-ground

(Figure 2) or lamp-to-ground (Figure 3).

Figure 2. Electronic lamp ballast - capacitor-

to-ground configuration

Figure 3. Electronic lamp ballast - lamp-to-

ground configuration

+

L

RES

V

dc

C

RES

C

Block

_

In the design presented in this application note, a capacitor-to-ground configuration was

used. For dual lamp ballast the lamps can be connected in series (Figure 4) or in parallel

(Figure 5). In the system presented here, a parallel configuration was chosen for the

following reasons:

● lower voltage stress on the ballast output stage components, on the wiring, and on the

fixture sockets

● the resonant L and C associated with the lamps are less sensitive to component

tolerances due to the lower operating lamp voltages compared to the series

configuration

● better lamp control as it is possible to independently monitor both lamp operations

Figure 4. Dual lamp ballast series

+

configuration

C

RES

+

L

rRES

V

dc

C

Block

_

Figure 5. Dual lamp ballast parallel

configuration

C

+

RES

C

RES

L

rRES

C

-

Block

L

rPRE

4/27

L

rRES

C

-

Block

Page 5

AN2771 Main characteristics

2 Main characteristics

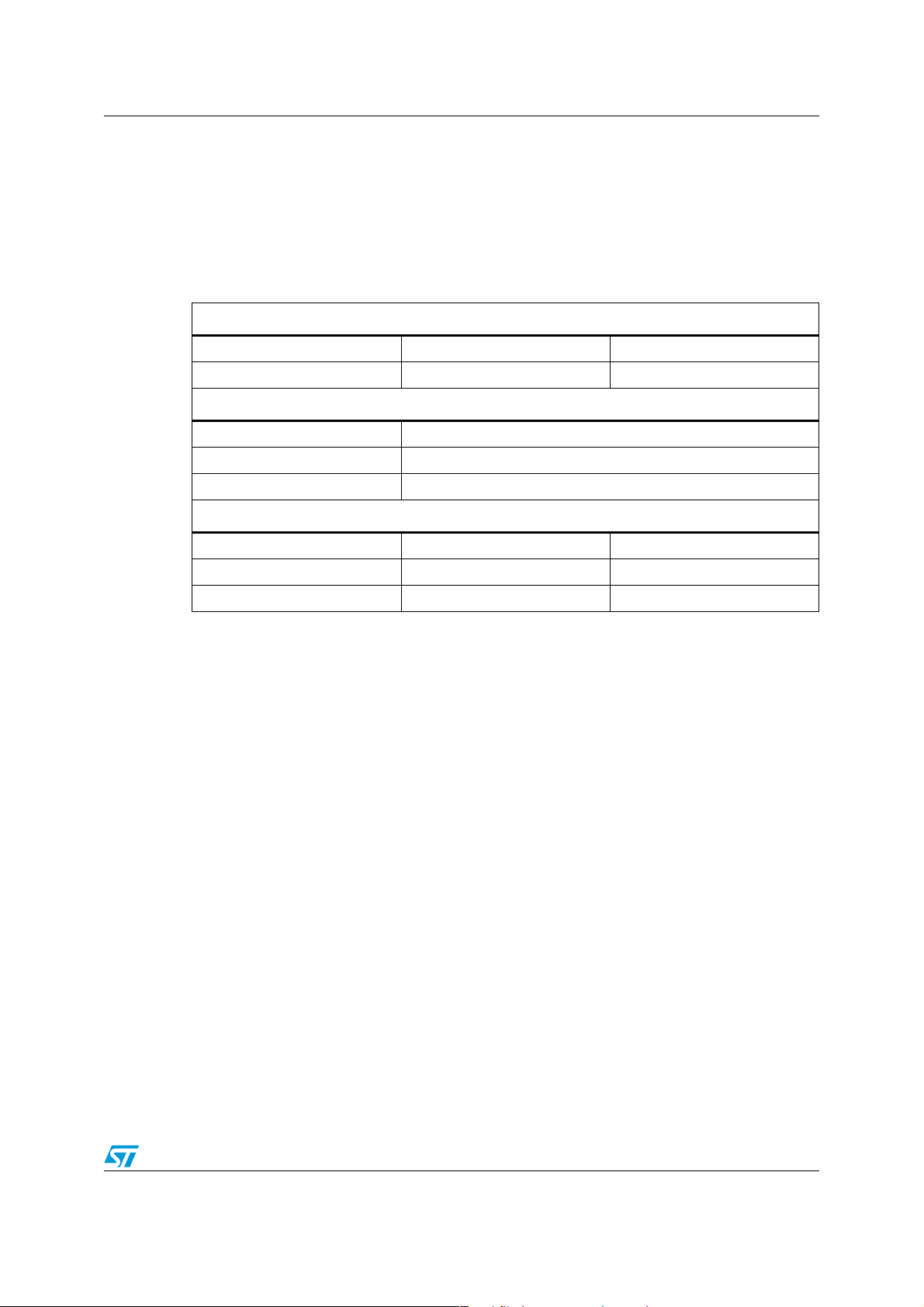

The electrical specifications for the electronic lamp ballast are given in Tab le 1 and the

schematic for the 2x58 W T8 is presented in Figure 6. The ballast design procedure is

detailed in the following section.

Table 1. Input and output parameters

Input parameters

V

IN

f

line

Number 2

Type T8 in parallel configuration

Power 58 W or 36 W

PF Power factor

THD% Total harmonic distortion ≤ 10

η % Efficiency

Input voltage range 185 to 265 V

Line frequency 50/60 Hz

Tube l a mp

Target output parameters

≈ 0.9

≈ 90 %

RMS

5/27

Page 6

Main characteristics AN2771

Figure 6. Electrical schematic 2x58 W T8

R540RR54

0R

10 kOhm

10 kOhm

R26

R26

C15

C15

R25

R25

1.6 kOhm

1.6 kOhm

100 nF, 400V

LAMP2

LAMP2

R53 0R53 0

1

4

L2

R22

R22

23

T8 Lamp1-58W

T8 Lamp1-58W

R40

R40

1.8 mHL21.8 mH

1 5

Q4

R23

R23

C25

CAP NP

C25

CAP NP

0.33 ohm 1% 1W

0.33 ohm 1% 1W

100 nF, 400V

R24

R24

1.802 MOhm

1.802 MOhm

68k

68k

STD8NM60NQ4STD8NM60N

62 Ohm

62 Ohm

7

8

5

6

Vrin

Crin

+Vcc

Output

Vref1Csense2Crref3GND

U2

56k

56k

R41

R41

C16

C16

R29 10 OhmR29 10 Ohm

D8 1N4148D8 1N4148

R31

R31

D13

D13

1 nF 1kV

1 nF 1kV

D9

C17

C17

LL4148

LL4148

16VD916V

C18

C18

4

100 nF

100 nF

C19

C19

0.33 ohm 1% 1W

0.33 ohm 1% 1W

R56

R56

100nF

100nF

4.7uF 50V

4.7uF 50V

TSM101U2TSM101

D12 BAT46ZD12 BAT46Z

D11 BAT46ZD11 BAT46Z

18k

18k

R46

470k

R46

470k

1

Q5

R47

R47

330k

330k

R49

R49

330k

330k

R52 0R52 0

BC847Q5BC847

32

R48 10R48 10

1

Q6

BC847Q6BC847

32

R50

R50

56k

56k

R51 2kR51 2k

2

Q7

XO205MAQ7XO205MA

R55

470

R55

470

1 3

1

32

BC847Q8BC847

Q8

1N4007

1N4007

D10

D10

D2

R4

R3

STTH1L06D2STTH1L06

560 kOhmR4560 kOhm

560 kOhmR3560 kOhm

R27

R27

R7

R6

0.8 mH

0.8 mH

56K

56K

910 kOhmR7910 kOhm

1.5 MOhmR61.5 MOhm

R5

LPFC1

LPFC1

1 MOhmR51 MOhm

C1

C1

1 3

5 8

R13

R13

C2

C21

C21

+

+

R8

C3

30 KOhm

30 KOhm

470//100 nFC2470//100 nF

R30

R30

R12

R12

910 kOhm

910 kOhm

R11

R11

1.5 MOhm

1.5 MOhm

100nF 630V

100nF 630V

47uF 450V

47uF 450V

R320R32

R9

16 kOhmR816 kOhm

33 nFC333 nF

56K

56K

0

390 kOhmR9390 kOhm

C7

R14

R14

240 kOhm

240 kOhm

R15

R15

C6

20 kOhm

20 kOhm

C5

R16

R16

470//220 nFC7470//220 nF

1.2 MOhm

1.2 MOhm

470//150C6470//150

1.8 nFC51.8 nF

R33 0R33 0

1

2

3

4

5

6

7

8

9

10

C8

R10

R10

C9

10 nF 1600VC910 nF 1600V

R34

R34

180k

180k

Q2

U1

L6585DU1L6585D

Osc

RF

EOI

Mult

INV

10 nFC810 nF

R19

R19

R18

R18

18 kOhm

18 kOhm

15 kOhm

15 kOhm

R17

20//11 kOhm

R17

20//11 kOhm

C22

C22

R20

R20

TCH

EOLP

EOL-R

CTR

Comp

13 kOhm

13 kOhm

220 pF 1kV

220 pF 1kV

62 Ohm

62 Ohm

4

LAMP1

LAMP1

1

2 3

L1

1 5

STD8NM60NQ2STD8NM60N

Boot

HSD

Out

VCC

LSD

GND

HBCS

PFG

PFCS

ZCD

C12

C12

T8 Lamp1-58W

T8 Lamp1-58W

1.8 mHL11.8 mH

20

19

18

17

16

15

14

13

12

11

D7

BAT46ZD7BAT46Z

100 nF, 400V

100 nF, 400V

R36

68k

R36

68k

Q3

C14

10 nF 1600V

C14

10 nF 1600V

R35

R35

180k

180k

R37

56k

R37

56k

C13

C13

100nF 50V

100nF 50V

R21

R21

10 Ohm

10 Ohm

STD6NK50ZQ3STD6NK50Z

C4

470 nFC4470 nF

GF1MD6GF1M

D4

GF1MD4GF1M

D6

D5

GF1MD5GF1M

D3

GF1MD3GF1M

C11

100nF 275V X2

C11

100nF 275V X2

43

LPFC2

LPFC2

12

2x39 mH/0.7A

2x39 mH/0.7A

C10

C10

100nF 275V X2

100nF 275V X2

F1 3AF1 3A

213

J1

CON3J1CON3

6/27

C20

C20

1nF 275 VAC Y1

1nF 275 VAC Y1

Page 7

AN2771 Ballast design

3 Ballast design

The design of the major parts of the circuit is described in this section.

3.1 L6585D biasing circuitry (pin by pin)

Designed in high-voltage BCD offline technology, the L6585D embeds a PFC controller, a

half-bridge controller, the relevant drivers and the logic necessary to build an electronic

ballast.

● Pin 1 OSC is one of the two oscillator inputs. The value of the capacitor connected to

ground defines the half-bridge switching frequency in each operating state. A value of

1.8 nF was chosen.

● Pin 2 RF. The component choice with oscillator capacitance defines the half-bridge

switching frequency in each operating state. A resistor R

the run frequency while during preheating the switching frequency is set by the parallel

of R

with R13 connected between pins RF and EOI (short-circuit during preheating).

14

Choosing the following frequencies and ignition time:

connected to ground sets

14

=

run

we can immediately calculate R

kHz39f

with the following formula:

14

pre

=

kHz65f

ign

=

ms60t

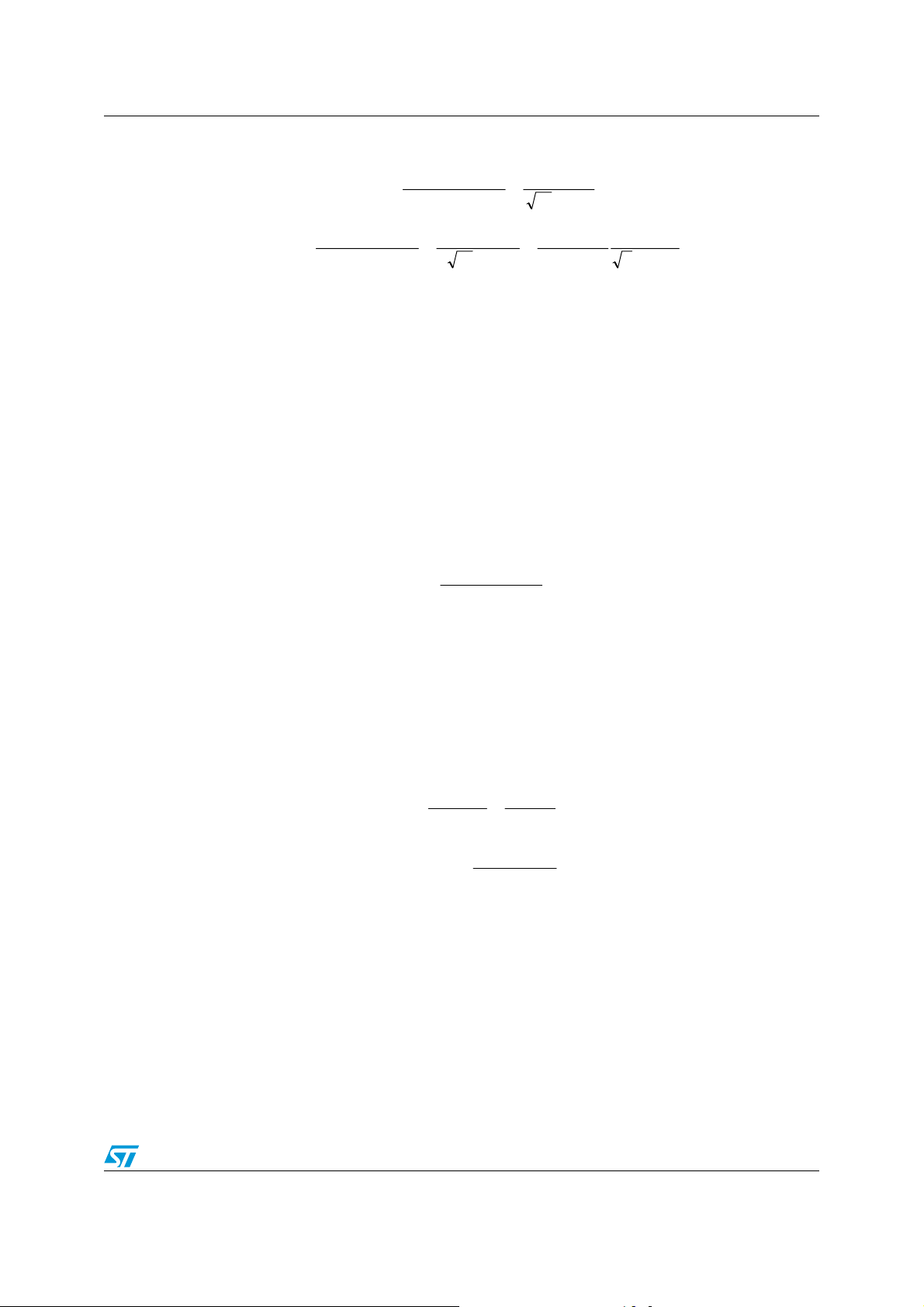

Equation 1

and for the value of R

13

14

⋅

Cf

5run

326.1

= k20

R

:

Ω=

Equation 2

R326.1

⋅

PRE

145pre

//R

14

41.1RCf

−⋅⋅

) connected between the RF pin and

RUN

Ω=

R

= k30

13

● Pin 3 EOI is a multifunction pin. During preheating the pin is internally shorted to

ground by the logic, so the resistor (R

ground sets the preheating switching frequency. During ignition pin EOI becomes high

impedance. The ignition time is the time necessary for the pin voltage to exponentially

rise from zero to 1.9 V. The growth is steered by the C

value of R

has already been calculated and t

13

ign

* R13 time constant. As the

6

at start is fixed, the value of C6 is

calculated by the following formula:

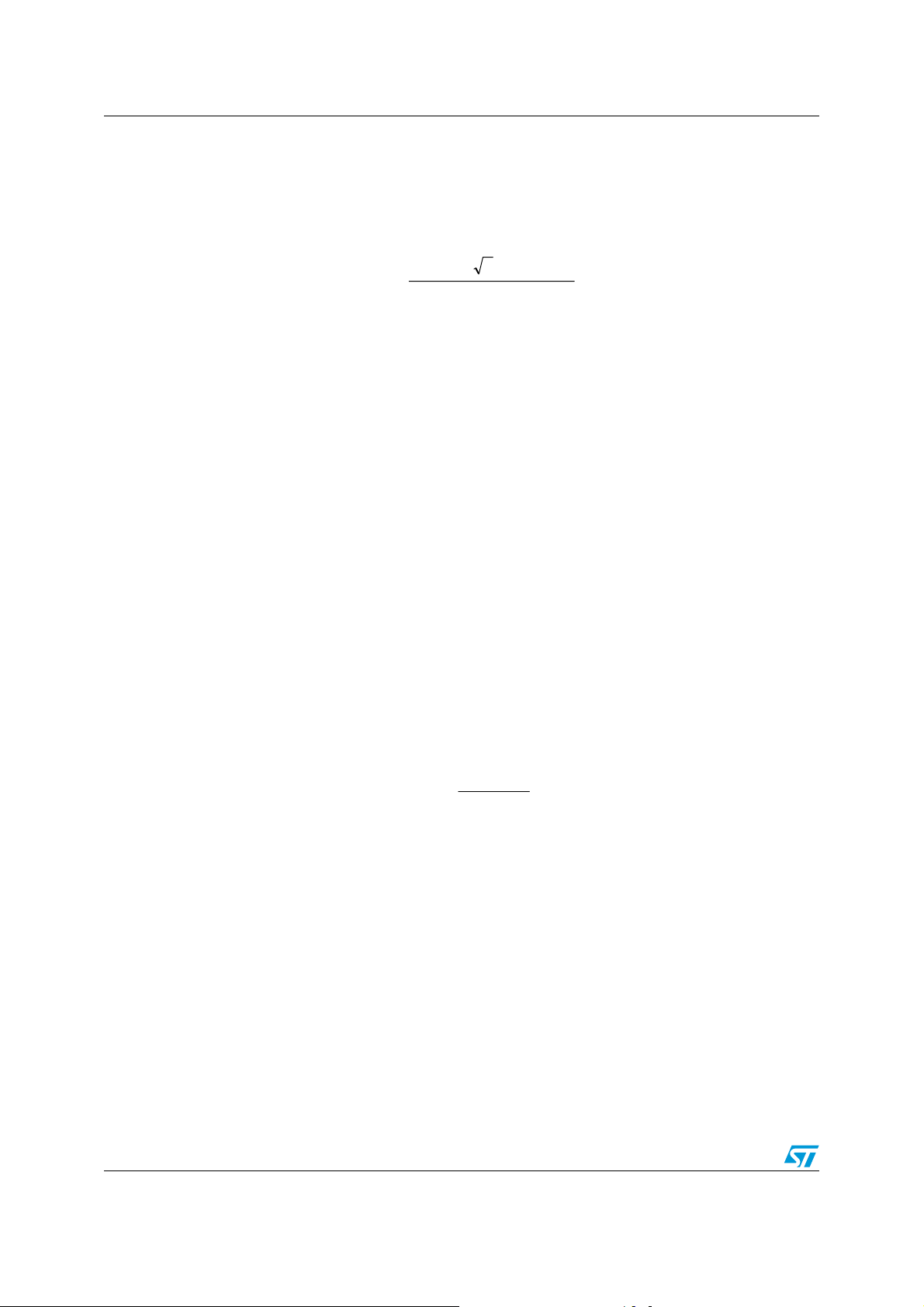

Equation 3

t

C

ign

=

6

R3

⋅

13

nF666

=

7/27

Page 8

Ballast design AN2771

The value C6=620 nF was chosen. In order to have this value, two capacitors in parallel

were mounted C

● Pin 4 TCH is the time counter and it is necessary to establish the preheating time and

=470//150 nF.

6

the protection intervention time (either overcurrent or EOL). To implement the time

counter, a R

=690 nF and t

C

7

we can calculate R

parallel network is connected between this pin and ground. Choosing

15C7

=1 sec and considering the internal current generator ICH=34 µA,

pre

as follows:

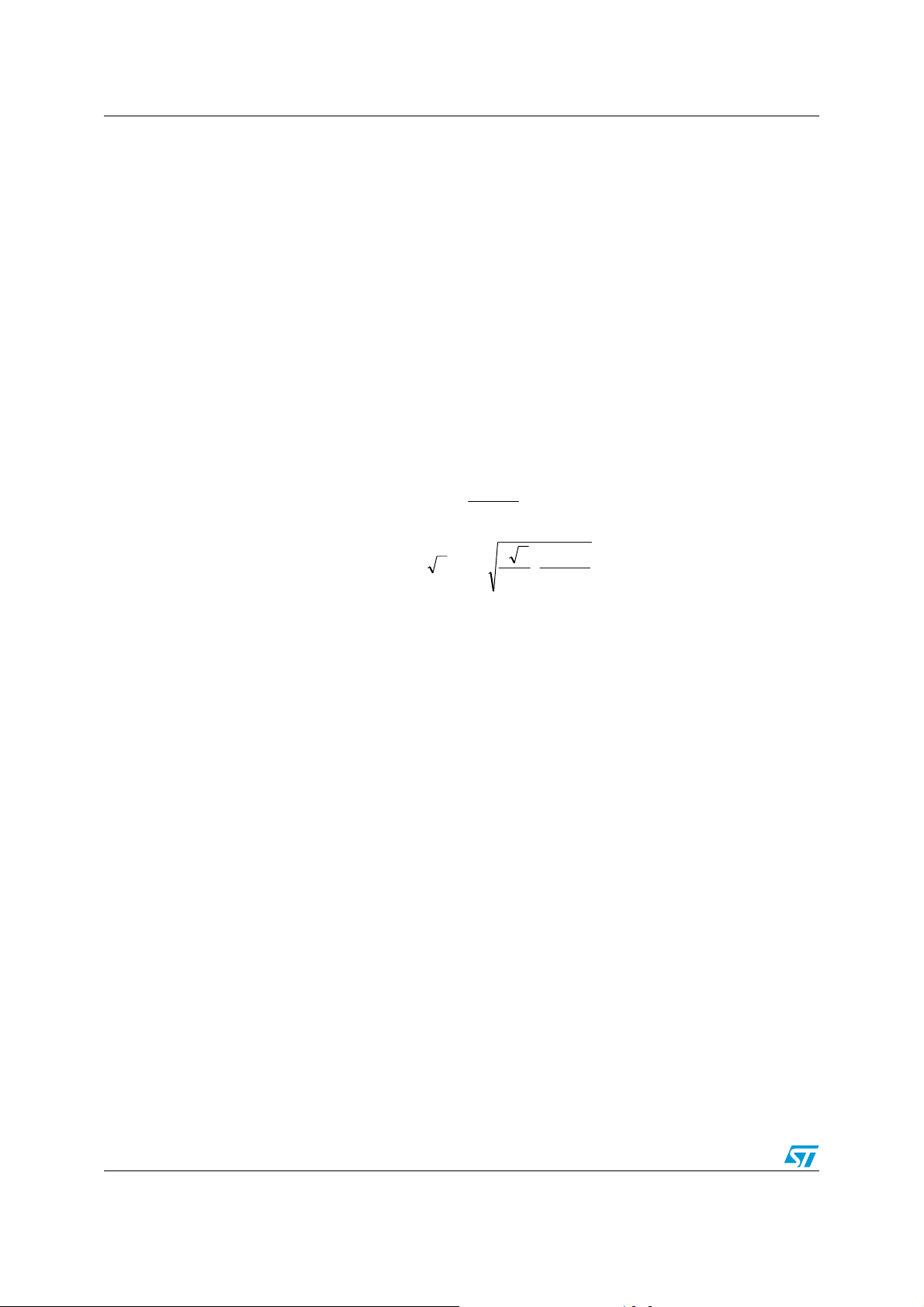

15

Equation 4

C

7

⋅−

t

pre

= M2.1

R

15

⋅

7

● Pin 5 EOLP is a 2 V reference and allows programming the window comparator of pin 6

63.4

I

CH

lnC

63.4

5.1

Ω=

(EOLR) according to table 5 of the L6585D datasheet. Choosing a reference tracking

with the CTR pin and a window voltage amplitude ± 220 mV, we chose R

● Pin 6 EOLR is the input of both the window comparator and a re-lamp comparator.

=240 kΩ.

16

Concerning the window comparator (choosing tracking with CTR pin), the center is the

same voltage as the CTR pin so the resistive divider connected across the block

capacitor (see C

in Figure 2) is set such that under normal conditions:

block

Equation 5

R

19

()

RRR

++

12719

R

8

()

++

RRR

438

()

RR

+

127

2

⋅=

43

1

+

R

8

V

EOLR

VV

CTREOLR

VV

⇒=

⋅=

BUSpfcCTR

V

BUSpfc

⋅=

2

()

RR

+

R

19

To determine the resistance values of (R7+R12), R19, (R3+R4), R8, decisions concerning

pin 7 CTR are needed.

● Pin 7 CTR is a multifunction pin (PFC overvoltage, feedback disconnection, reference

for EOL in case of tracking reading), connected to a resistive divider to the PFC output

bus. Establishing the maximum PFC overvoltage (PFC output overshoot e.g. at startup)

at V

OVPBUSpfc

pin must be V

= 13 kΩ. From Equation 5, fixing R3+R4 = 1120 kΩ, the following resistance value

R

19

is obtained R

● Pin 8 MULT. Assuming a peak value of V

= 480 V and considering that the correspondent threshold on the CTR

thrCTR

= 16 kΩ.

8

= 3.4 V, we can immediately calculate R7+R

multpkMax

= 1.8 V (at VAC = 265 V) on the

= 1.82 MΩ and

12

multiplier input (MULT, pin 8), the peak value at minimum line voltage is

V

MULTpkmin

= 1.8 × 185/265 = 1.25 V which, multiplied by the maximum slope of the

multiplier, 0.75, gives 0.94 V peak voltage on current sense (CS, pin 4). Since the

linearity limit (1 V) is not exceeded, this is acceptable. Considering about 250 µA

current for the divider, the lower resistor is 7.14 kΩ (20//11 kΩ ). To establish the upper

resistance value (referring to the PFC section of the L6585D datasheet), the ratio

between Vmult and Vin for different input voltage must be evaluated:

8/27

Page 9

AN2771 Ballast design

Equation 6

RRR

9517

inMin

V

=

V2

⋅

inMax

V

CSclamp

slopemax

maxmultPK

=

axmultSlopeM

3

−

108.4

⋅=

1

V2

⋅

inMin

3

−

101.5

⋅=

V

inMin

⇒

R

V

⇒

inMax

R

17

()

RRR

++

9517

17

()

++

V

=

⋅

V2

where:

● V

CSclamp

● max slope is the maximum slope of the multiplier characteristic family for L6585D

● V

multSlopeMax

is the clamp value of the voltage current sense for L6585D

is the maximum voltage in the mult pin with Vin=V

inMin

To work in the linear area of the multiplier characteristic family, the upper resistance choice

is made considering the lowest of ratios calculated in

R

● Pin 9 COMP is the output of the E/A and also one of the two inputs of the multiplier. The

= 1.390 MΩ was mounted.

5+R9

Equation 6 ⇒ R

=1.487 MΩ.

5+R9

feedback compensation network, placed between this pin and INV (10), is simply a

capacitor calculated as follows (considering R

is the upper resistance of the

6+R11

voltage divider between the PFC bus and COMP pin):

Equation 7

C

=

2

10

()

RR2

+⋅π⋅

116

nF530

=

A value of C2=560 nF was chosen.

● Pin 10 INV. To implement the voltage control loop, a resistive divider (Figure 6) is

connected between the regulated output voltage V

pin. The internal reference on the noninverting input of the E/A is 2.5 V, so R

Figure 6) are then selected, establishing a max overvoltage ∆V

(

= 420 V of the boost and the

BUSpfc

OVPBUSpfc

and R

6

= 60 V, as

11

follows:

Equation 8

V

RR

where I

+

R

18

RR

=+ M3

116

18

= 20 µA is the threshold current flowing through the compensation network in

OVPth

116

V

∆

OVPBUSpfc

I

BUSpfc

OVPth

1

−=

5.2

Ω=

Ω⇒Ω=⇒ k18k964.17R

case an abrupt load drop happens.

● Pin 11 ZCD is the input to the zero current detector circuit. The ZCD pin is connected to

the auxiliary winding of the boost inductor through a limiting resistor. The ZCD circuit is

negative-going edge-triggered: when the voltage on the pin falls below 0.7 V, the PWM

latch is set and the MOSFET is turned on. To do so, however, the circuit must first be

armed. Prior to falling below 0.7 V, the voltage on pin 11 must experience a positivegoing edge exceeding 1.4 V (due to the MOSFET's turnoff). The maximum main-to-

9/27

Page 10

Ballast design AN2771

auxiliary winding turn ratio, m, has to ensure that the voltage delivered to the pin during

the MOSFET's OFF-time is sufficient to arm the ZCD circuit.

Then:

Equation 9

m

≤

⋅−

4.1

(max)inRMSBUSpfc

10.33

=

V2V

We chose m=10.

Considering the upper and lower clamp voltage of the ZCD pin, its minimum current sink

current capability, according to the max and min voltage of the PFC bus, we can

immediately calculate and choose R

● Pin12 PFCS is the inverting input of the current sense comparator. As the voltage

= 15 kΩ.

10

across the sense resistor (proportional to the instantaneous inductor current) crosses

the threshold set by the multiplier output, the power MOSFET is turned off. Following

the indication given in AN966, page 13, considering the max peak current absorbed by

two lamps, it is possible to determine the following PFC sense resistor:

Equation 10

22

Ω≤ m340R

We chose R22=330 mΩ with a power rating of 0.5 W.

Considering the clamp value voltage on this pin, V

determine the maximum inductor current I

● Pin13 PFG. To correctly drive the external MOSFET, a resistor R

● Pin 14 HBCS. Establishing during ignition, for each lamp, a maximum current of

I

IGNmax

V

= 2.5 A and considering the HBCS threshold during ignition phase

HBCS-ign

= 1.6 V, we can calculate R

Lmax

senseHB=R31

CSclamp

= 3.5 A.

= 1.16 V, it was possible to

=10 Ω was used.

21

:

Equation 11

V

ignHBCS

R

31

−

I

TOTmaxIGN

Ω==

32.0

We chose R31 = 0.33 Ω.

● Pin 15 GND: ground

● Pin 16 LSD. To correctly drive the external half-bridge low-side MOSFET, a resistor

R

=62 Ω was used.

23

● Pin 17 Vcc. This pin is externally connected to the startup circuit (by means of R

R

, R40, R41) and to the self-supply circuit consisting of a charge pump composed of

37

the net C

● Pin 18 Out: high-side driver floating reference. This pin is connected close to the

, C17, C18, D8, D9, R29.

16

34

, R35,

source of the high-side power MOSFET.

● Pin 19 HSD. To correctly drive the external half-bridge low-side MOSFET a resistor

R

=62 Ω was used.

20

● Pin 20 Boot. For the high-side section a C

= 100 nF was selected.

boot

10/27

Page 11

AN2771 Ballast design

(

)

3.2 PFC power section design

Input capacitor

The input high-frequency filter capacitor C4 has to attenuate the switching noise due to the

high-frequency inductor current ripple. The worst conditions occur on the peak of the

minimum rated input voltage V

● the coefficient of maximum high frequency voltage ripple r = 0.05

● total system efficiency is possible, considering the minimum half-bridge switching

frequency f

= 39 kHz and the total output power P

swmin

determine the input capacitor C

Equation 12

C

C4=470 nF was chosen.

Output capacitor

The output bulk capacitor C1 selection depends on the DC output voltage, the admitted

overvoltage, the output power and the desired voltage ripple where:

● PFC output voltage V

● the coefficient of low-frequency (twice the mains frequency f

r

= 0.05

1

We can calculate the bulk capacitor in

busPFC

= 185 V where:

inmin

as follows:

4

=

4

= 420 V

P

outTOT

V

⋅η

minin

mininminsw

Equation 13:

= 2*58 = 116 W, to

outTOT

nF307

=

rVf2

⋅⋅⋅π⋅

= 50 Hz ) voltage ripple

min

Equation 13

P

outTOT

V

=

C

1

busPFC

rVf22

⋅⋅⋅π

1busPFCmain

F21

µ=

To have the smallest ripple and good reliability, we chose capacitor C1 =47 µF, 450 V.

Boost inductor

The inductance L

is greater than the maximum frequency of the internal starter in order to ensure a correct TM

operation. Considering the minimum suggested value for the PFC section f

and that it can occur at the either the maximum V

V

inrmsMin

= 185 V mains voltage, the inductor value is defined by:

Equation 14

To obtain a margin from f

the inductor is determined by V

stated in the PFCS pin description, a maximum current I

is usually determined so that the minimum switching frequency f

pfc

min pfc

L

min pfc

2

inrms

=

pfc

we chose f

= V

inrms

inrmsMax

P

f2

inrmsMax

out

⋅⋅

pfcmin

η

= 33 kHz. In this condition the lower value for

pfc

and L

= 265 V or the minimum

V2VV

⋅−⋅

inrmsbusPFC

V

⋅

busPFC

= 0.8 mH with, as previously

pfc

= 3.5 A.

Lmax

min pfc

= 20 kHz

11/27

Page 12

Ballast design AN2771

Power MOSFET

The choice of the MOSFET concerns mainly its R

, which depends on the output

DS(on)

power, and its breakdown voltage. This last voltage is fixed just by the output voltage

V

= 420 V, plus the overvoltage ∆V

buspfc

= 60 V allowed and a safety margin.

OVPpfc

The MOSFET's power dissipation depends on the conduction and switching losses.

Establishing maximum total power losses P

lossesAdm

= 1% and P

= 1.16 W, it is easy to

outTOT

verify that in choosing SuperMesh power MOSFET STD6NK50Z, the estimated total

MOSFET power losses, in the worst case, is about P

lossesEst

= 0.6 W, so this choice was the

definitive one.

Boost diode

The boost freewheeling diode is a fast recovery one. The breakdown voltage is fixed with the

same criterion as the MOSFET. The values of its DC and RMS current, which are needed to

choose the current rating of the diode, are given as follows:

Equation 15

P

I

outTOT

BUSpfc

⋅⋅=

==

24

9

π

dc2D

V

I22I

rmsrms2D

Since the PFC works in transition mode, the Turbo 2 Ultrafast high-voltage rectifier

STTH1L06 was selected.

V

inrms

V

BUSpfc

A276.0

A6.0

=⋅

3.3 Half-bridge inverter design

Concerning the resonant circuit design, according the criteria described in AN993 section 5,

we chose the following:

●

●

●

The P-Mos selection in the half-bridge section is performed mainly considering the max

power losses admitted on each switch P

current through it IrmsMOS ≅ 0.6 A. Concerning half-bridge devices, using the second

generation MDmesh Power MOSFET STD8NM60N, the estimated power losses in it result

in P

lossesEstHB

≅ 0.468 W.

===

21res

===

149res

===

1512block

lossesAdm1

mH8.1LLL

= 0.5% P

V1600/nF10CCC

V400/nF100CCC

≅ 0.6 W and the rms

outTOT

12/27

Page 13

AN2771 Ballast design

3.4 Symmetrical and asymmetrical EOL protection: improvements

As previously stated, the L6585D includes two functions concerning EOL protections which

are summarized as follows:

a) The first function has been designed to detect the ageing of the lamp with

particular attention to the effect appearing as asymmetric rectification. The idea is

to measure the variation of the DC component of the lamp voltage that can be

either positive or negative. A window comparator has been introduced (centered

around Vref with amplitude "V

than V

two standard ballast configurations (lamp-to-ground and block capacitor-toground).

b) Concerning the second function, as soon as a fault due to broken lamp in ignition

mode (1.6 V threshold crossing) or a symmetrical EOL in run mode (0.9 V

threshold crossing) triggers the TCH timer, the frequency control starts. When the

timer ends, the current is monitored on the HBCS pin at the first cycle. In both

conditions if the HBCS threshold is still crossed, the oscillator stops, the chip

enters low-consumption mode /shutdown mode and this condition is latched until

the mains supply is removed or re-lamp is detected.

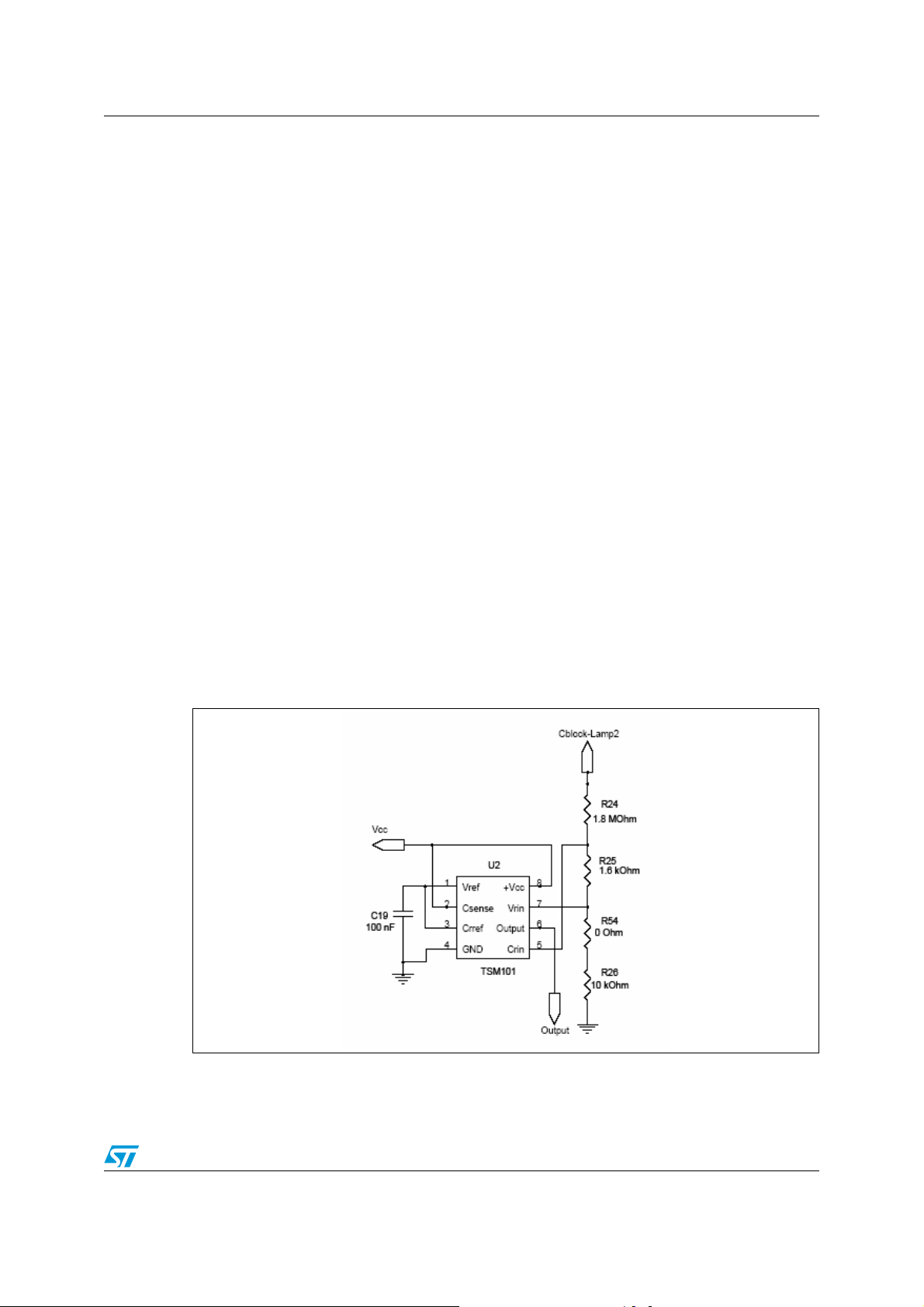

The following improvements in the protection functions have been implemented:

– The asymmetric rectification protection, described above, was implemented to

monitor the status of only one lamp. To protect the second lamp with the same

criteria (voltage window comparator) as the first one, a voltage and current control

TSM101 in the configuration shown in

possible to obtain the asymmetric rectification protection in a reliable and

independent manner for each lamp.

+ Vw/2 or lower than Vref- Vw/2. This kind of protection is compliant to the

set

") that triggers when the EOL-R voltage is higher

w

Figure 7 was used. With this circuit it was

Figure 7. TSM101 window comparator configuration

The design criteria for TSM101 in window comparator configuration is described in the

following paragraphs. By means of a voltage divider R

, R25, R54+R26, from the block

24

13/27

Page 14

Ballast design AN2771

capacitor of the second lamp, TSM101 checks that the average voltage value on the

capacitor is V

Considering that the voltage window used for the first lamp is ∆V

15%V

, for the second lamp a similar percent voltage window ∆V

CTR

AVE

= 210 V.

window1

window2

= 2*220 mV ≅

≅ 15%V

AVE

=

31 V was chosen. Establishing the second voltage window and considering that the voltage

reference in TSM101 is V

= 1.24 V, it is easy to calculate the resistance value of the

ref

voltage divider mentioned in the previous paragraph (presuming, in normal conditions, an

absorbed current in it of I

Vdivider

≅ 116 µA ) as follows:

Equation 16

V

RRRRR

26542524tot

R

AVE

−

tot

∆

V

+

⎛

V

⎜

AVE

⎝

⋅+−

∆

V

R

tot

2window

2

∆

V

−

2

R

tot

⎞

2window

⎟

2

⎠

⋅=+ k10RR9954

VRR

ref2654

V

()

RRV

2654ref

= k6.1R1540

R

25

⎛

V

⎜

AVE

⎝

AVE

I

Vdivider

⎞

2window

⎟

⎠

Ω==+++= M81.1

2654

25

Ω=+⇒Ω=

Ω=⇒Ω=

265425tot24

Ω⇒Ω=++−= M8.1M798.1)RRR(RR

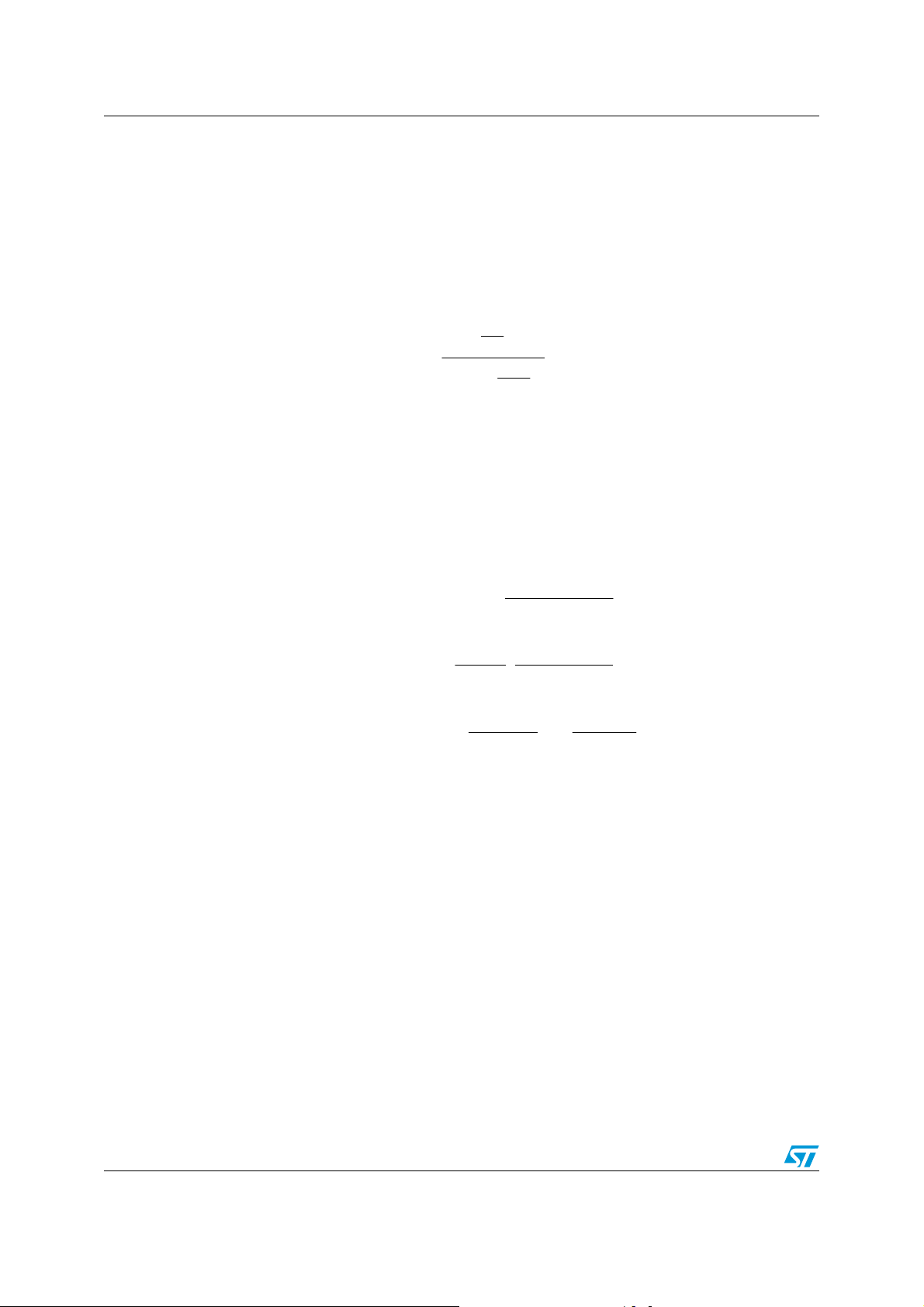

– The symmetrical EOL protection described in paragraph b of this section was

improved because for a two-lamp application an event such as the breaking of one

lamp and the ignition of the other one may not activate the embedded device

protection quickly enough.

To avoid this type of issue and in order to increase the reliability of the protection, an

external circuit as shown in

Figure 8 was implemented.

Figure 8. External symmetrical EOL protection

14/27

Page 15

AN2771 Ballast design

This circuit (considering that it is possible to latch the device maintaining the CTR pin to zero

voltage), by means of an inverting logic made by Q

the half-bridge current sense resistor V

. Overcoming a fixed voltage threshold on the HB

R31

current sense, the X0205MA SCR is activated which consequently activates Q

and Q6, is activated by the voltage on

5

and causes

8

the CTR pin to go down to zero voltage. The device is latched until the main supply is

removed.

15/27

Page 16

Experimental results AN2771

4 Experimental results

The schematic of the tested board is shown in Figure 6 . The board was first tested in terms

of efficiency, power factor, total harmonic distortion and thermal behavior for the input

voltage range.

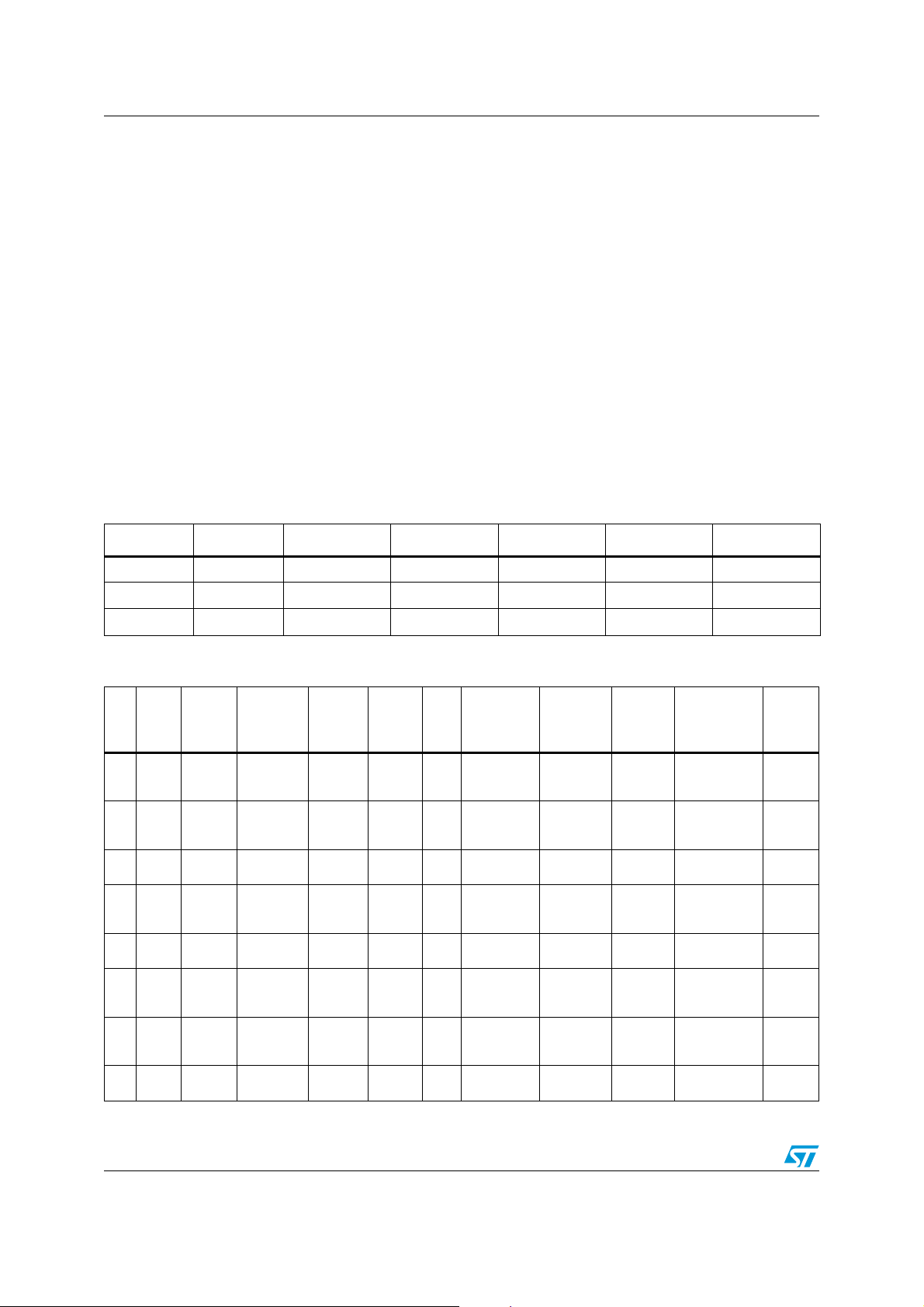

Table 2. 2x58 W T8 board performance

Ta bl e 2 and Tab le 3 show the results obtained for testing during 45 minutes.

V

IN

(V)

185 115.5 52 0.90 0.645 0.995 7.9

230 112.5 52 0.92 0.515 0.992 8

265 113.5 52 0.91 0.455 0.988 10

P

IN

(W)

P

OUTlamp1

(W)

I

η

(A)

IN

PF

THD

(%)

All results obtained are very good. Efficiency is about 90%, the power factor corrector is

constantly 0.99, and THD is about 8%.

Table 3. 2x58 W T8 thermal results of critical system components

V

(V) Ambient temp (°C)

IN

1852371795849

2302371794747

2652371784447

Temp MO S

LowSide

(°C)

Concerning thermal behavior, from the results given in

Tem p MOS

(°C)

HighSide

Temp MO S

(°C) Temp L6585D (°C)

PFC

Ta bl e 3 , it is easy to deduce,

considering the highest ambient temperature, that there is a good safety margin from the

max junction temperature of the MOS.

Startup sequence

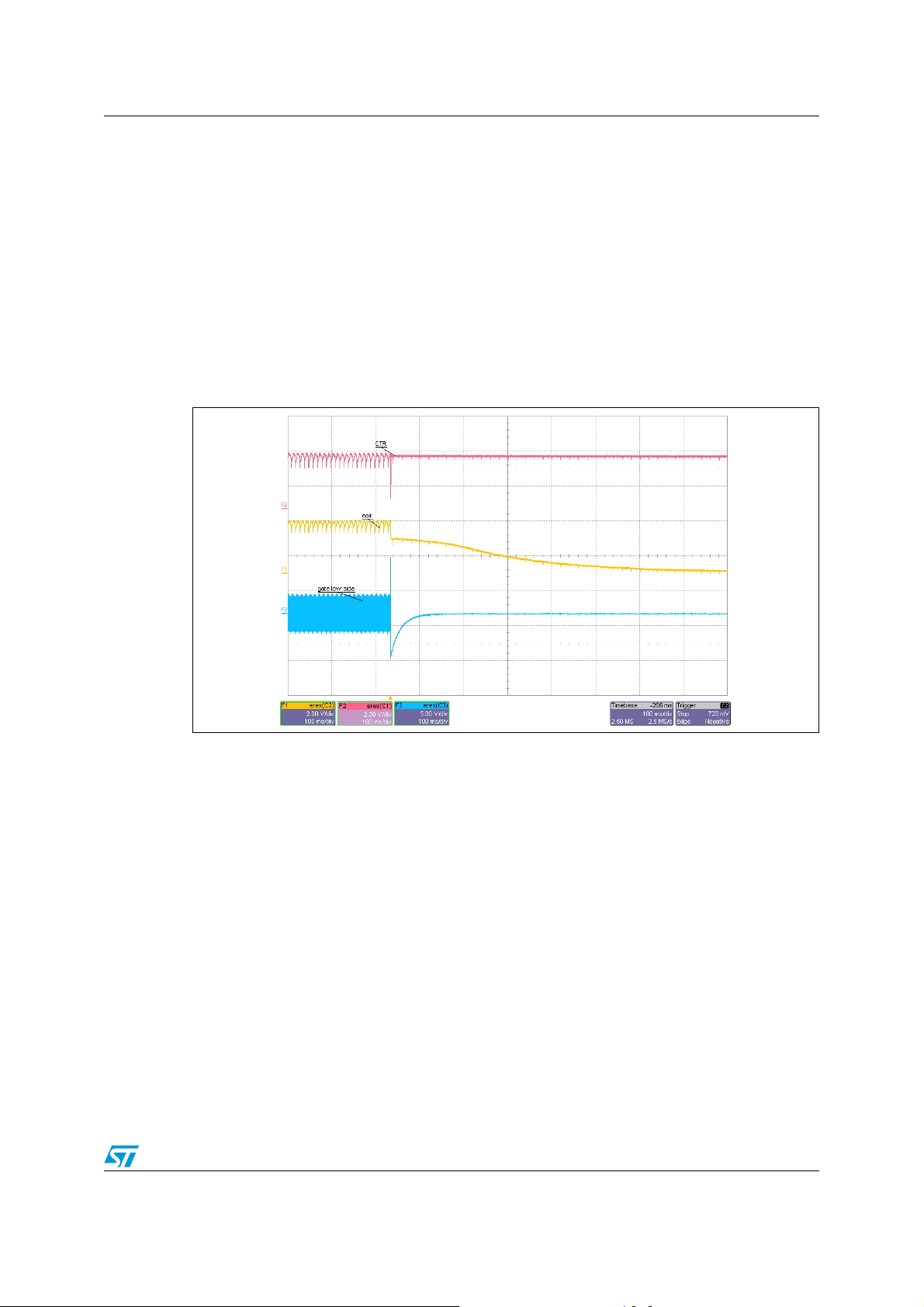

Figure 9 shows the startup sequence: the IC supply voltage V

bridge starts oscillating and starts the charge capacitor connected to TCH. When the

voltage at the TCH pin reaches VCHP (4.63 V), the same capacitor is discharged following

an exponential decrease steered by the time constant, which defines the preheating time.

During this time, the EOI pin is forced to ground and the switching frequency is set by the

oscillator at the preheating value. When the voltage at the TCH pin drops down to 1.53 V,

the EOI pin is exponentially charged according to a time constant that defines the ignition

time. At the same time the TCH pin goes down to ground. During this phase the oscillator

generates a reduction of the switching frequency. As the voltage at EOI exceeds 1.9 V, the

chip enters run mode.

16/27

reaches V

CC

CCon

, the half-

Page 17

AN2771 Experimental results

Figure 9. L6585 startup sequence

Figure 10

shows the lamp ignition phase. The voltage across it increases linearly as well as

the current flowing through it.

Figure 10. One lamp ignition phase

17/27

Page 18

Experimental results AN2771

Figure 11. Low-side current in run mode

Figure 12. Voltage and current lamp in run mode

18/27

Page 19

AN2771 Protections

5 Protections

As previously stated in Section 3.4, due to the presence of two lamps, TSM101 must be

added to implement the asymmetric EOL protection, and inverter logic with a SCR must be

added to implement the symmetrical EOL protection. The following failures were simulated

to test these:

● Cathode breaking in run mode

● Broken tube or failure to strike during ignition phase

As shown in Figure 13, as soon as a cathode of one lamp is broken, the voltage on the

EOLR pin goes out from the valid voltage window and the L6585D stops switching.

Figure 13. Asymmetrical EOL protection with broken cathode during run mode

When one of the two lamps is broken or the the gas inside is exhausted, during the ignition

phase, as illustrated in Figure 14, the right lamp is ignited normally, but the voltage across

the broken lamp rises up continually until an established threshold is exceeded that

activates the SCR, by means of an inverter logic, and moves the CTR pin down to ground. In

this condition the L6585D is latched.

19/27

Page 20

Protections AN2771

Figure 14. Symmetrical EOL protection behavior during ignition phase

20/27

Page 21

AN2771 Conduction emissions test

z

W

6 Conduction emissions test

Conducted emissions have been measured in neutral and line wires using peak detector

and considering the limits for lighting applications i.e. EN55015. The measurements have

been performed at 230 Vac line. The results are shown in

the emission level is below both the quasi-peak and average limits with an acceptable

margin, the power supply passes the precompliance test.

Figure 15. Conducted emissions at 230 Vac 50 Hz - line 1 peak detector

Figure 15 and Figure 16. Since

V

µ

AA

02:15:56 Feb 11, 2008

Atte n 0 dB

Mkr1 22.03 MH

30.66 dB

1

Sweep 881.3 ms (2115 pts)

Stop 3 0 M Hz

V

µ

Ref 75 dB

Peak

Log

10

dB/

W1 S2

S3 FC

Start 150 kHz

Res BW 9 kHz VBW 30 kHz

Figure 16. Conducted emissions at 230 Vac 50 Hz - line 2 peak detector

Ref 75 dB

Peak

Log

10

dB/

02:21:25 Feb 11, 2008

V

µ

Atte n 0 dB

Cntr1 22.034 MHz

31.67 dB

Marker Count: Widen Res B

1

V

µ

W1 S2

S3 FC

AA

Start 150 kHz

Res BW 9 kHz VBW 30 kHz

Sweep 881.3 ms (2115 pts)

Stop 3 0 M Hz

6.1 Adapting the design for a 2x36 W T8 electronic ballast

Using a developed design for 2x58 W T8 tubes, it was possible to do some simple

adjustments to adapt the same design for 2x36 W T8 tubes. Using the same resonant

21/27

Page 22

Conduction emissions test AN2771

circuit, the adjustments concern only the operating frequencies of the lamp, setting the

following ones at:

kHz65f

run

kHz49f

=

preh

=

we can immediately calculate, by means of Equation 1 and Equation 2, the following value

resistances:

14

Ω= k15R

13

Ω= k47R

In addition a new calibration for the symmetric end-of-life operation is needed, changing the

following resistance to:

56

Ω= 75R

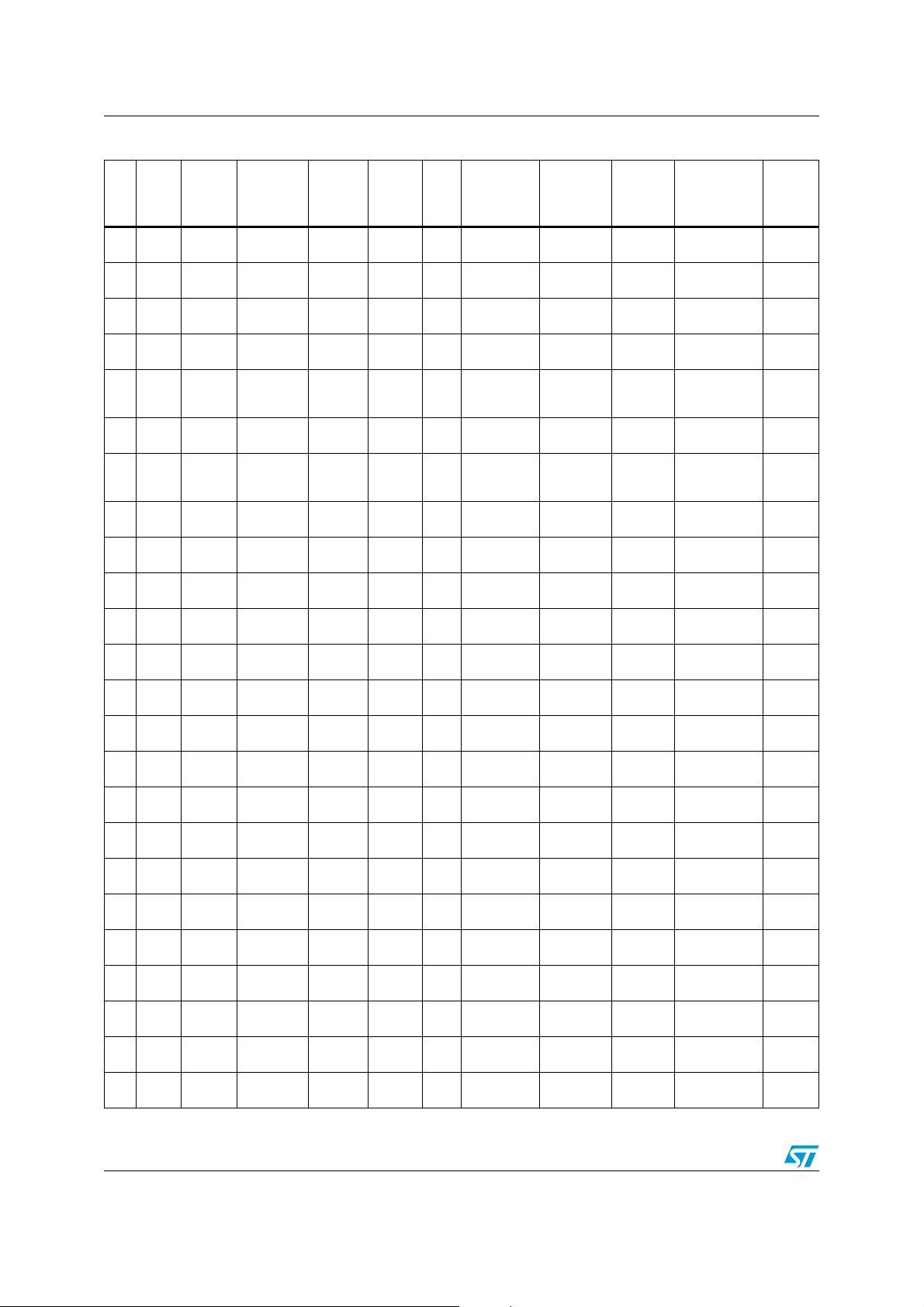

Testing the board with these modifications the experimental results are given below in

Ta bl e 4 :

Table 4. 2x36W T8 board performance

V

(V) P

IN

185 74 33 0.89 0.39 0.994 6.9

230 73.5 33 0.89 0.315 0.987 7.6

(W) P

IN

OUTlamp1

(W) η I

(A) PF THD (%)

IN

265 73.4 33 0.89 0.275 0.979 8.7

Table 5. Bill of material

Item Qty Ref. Part/value

1 1 C1 47 µF, 098 A 20% 450 V

21 C2

3 1 C3 33 nF 5% 50 V

4 1 C4 470 nF 10% 630 V

5 1 C5 1.8 nF 5% 50 V

61 C6

71 C7

81 C8

560 nF

(470//100

nF)

660 nF

(470//150)

nF- ceramic

680 nF

(470//220)

nF-ceramic

10 nF-

ceramic-

Tol er anc e

Volt a g e -

(%)

5% 50 V

5% 50 V

5% 50 V

5% 50 V

current

Watt

Techn ology

information

Electrolytic

capacitor

COG ceramic

capacitor

COG ceramic

capacitor

Polyester

capacitor

COG ceramic

capacitor

COG ceramic

capacitor

COG ceramic

capacitor

COG ceramic

capacitor

Package

footprint

SMD 0805

SMD 0806

Radial 22.5

mm lead

spacing

SMD 0805

SMD 0805

SMD 0805

SMD 0805

Manu-

facturer

EPCOS B43858C5476M

EPCOS

Manufacturer

B32523Q8474K

code

000

000

RS/

distrelec

/other

code

22/27

Page 23

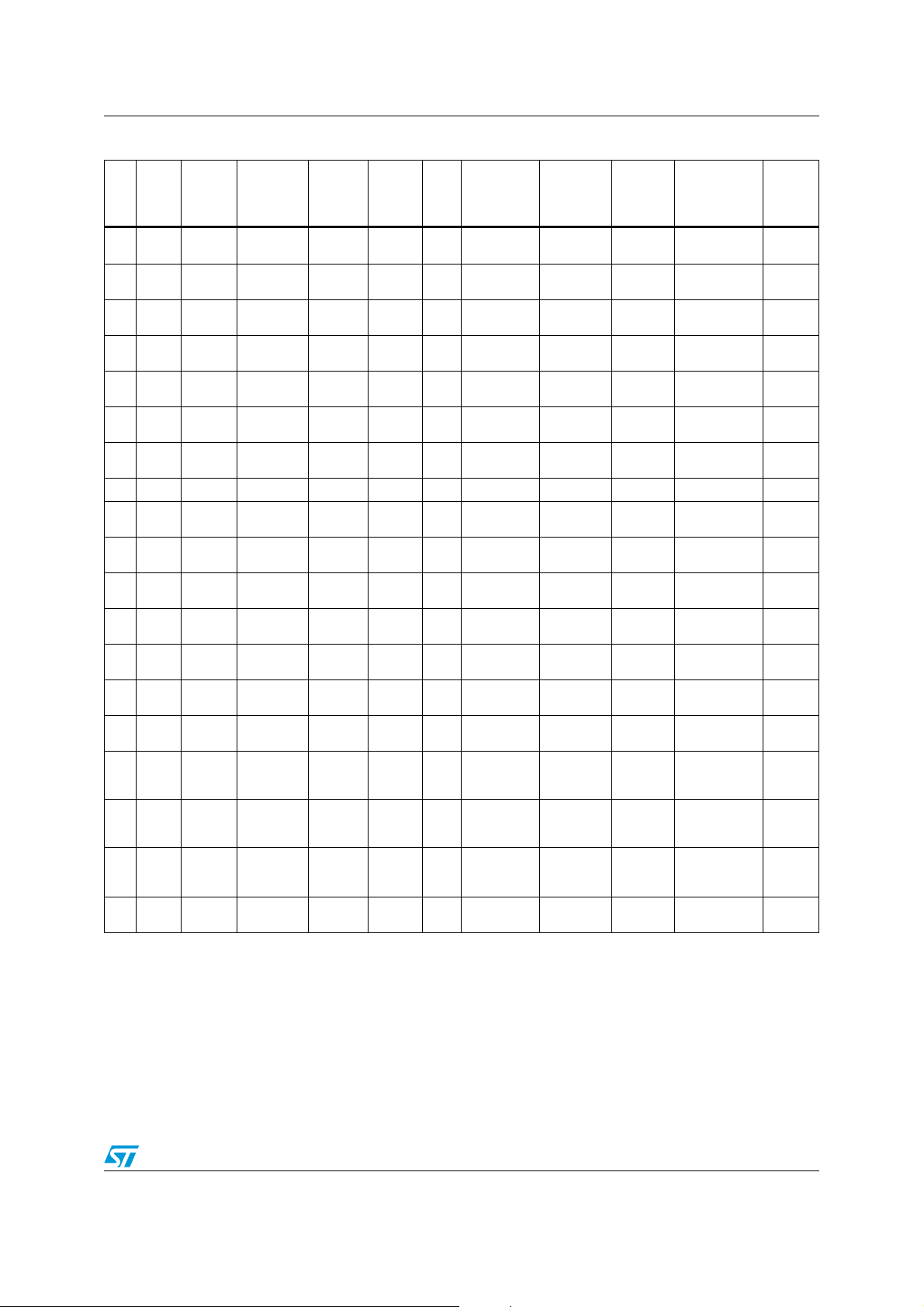

AN2771 Conduction emissions test

Table 5. Bill of material (continued)

RS/

distrelec

/other

code

Item Qty Ref. Part/value

Tol er anc e

(%)

Volt a g e -

current

Watt

Techn ology

information

Package

footprint

Manu-

facturer

Manufacturer

code

9 2 C9, C14 10 nF 5% 1600 V

10 2 C10,C11 100 nF 10% 300 Vac

100 nF,

11 2 C12, C15

12 1 C13

13 1 C16 1 nF 5% 630 V

14 1 C17 4.7 µF 20% 50 V

15 2 C18, C19

16 1 C20 1 nF Y1 20% 250 Vac

17 1 C21 100 nF 10% 630 V

18 1 C22

19 1 C25 Not mounted

20 3

21 1 D2 STTH1L06

22 4

23 2 D8, D13 LL4148

24 1 D9 16 V 5% 16 V

25 1 D10 1N4007

26 1 F1 3,15 A 250 V

27 1 J1 CON3

28

D7,D11,

D12

D3,D4,

D5,D6

Lamp,

Lamp2

400 V-

polyester-

lead spacing

10mm

100 nF-

50V- 10%

100 nFceramic

220 pF -

ceramic-

lead spacing

5 mm

BAT46 150 mA

GF1M-1A

T8 Lamp1-

58 W

10% 400 V

10% 50 V

5% 50 V

10% 1 kV

1000 V 1

75 V 150

A

mA

1000 V

1 A

250V

Metallized

polypropylene

film capacitors

X2

polypropylene

capacitor

Metallized

polyester film

capacitors

Ceramic

capacitor

Polypropylene

capacitor

Electrolytic

capacitor

COG Ceramic

capacitor

Y1 Ceramic

capacitor

polypropylene

capacitor

Ceramic disc

capacitor

Small signal

Schottky

diode

Ultrafast high

voltage

rectifier

Rectifier diode

Switching

diode

500

Zener diodes

mW

Rectifier diode DO-41

TR5 quick

acting submin

PCB F fuse

3 way screw

terminal block

7.5 mm pitch

4 pins PCB

terminal strip

Radial

22.5mm lead

spacing

Radial

10mm lead

spacing

SMD 1206

Radial 5mm

lead spacing

Cylindrical

2.5 mm lead

spacing

SMD 0805

Radial 9.5

mm lead

spacing

Radial 15

mm lead

spacing

Radial 5mm

lead spacing

SMD SOD-

323

DO-41

SMD

DO214BA

SMD SOD-

80

SMD SOD-

123

RADIAL

THT 7.5 mm

lead spacing

THT 5 mm

lead spacing

EPCOS

EPCOS

EVOX

RIFA

CERA

MITE

EPCOS B32652A6104K

Panasonic

STMicro-

electronics

STMicro-

electronics

WAGO

(www.

wago.it)

B32653A1103J

000

B32561J6104K

000

PFR5

102J630J11L4

440LD10-AD

10PCM

ECKA3A221KBPRS: 473-

BAT46JFILM

STTH1L06

739-104

RS: 441-

9616

RS: 240-

4836

RS: 214-

5896

RS: 190-

8371

0373

RS: 269-

451

RS: 447-

1838

RS: 226-

6549

RS: 548-

7317

23/27

Page 24

Conduction emissions test AN2771

Table 5. Bill of material (continued)

Item Qty Ref. Part/value

1

29

Note

30 1 LPFC2

31

Note

32 3

33 2 Q2, Q4

34 1 Q3 STD6NK50Z

35 1 Q7 X0205MA

36 2 R3, R4 560 kΩ 1% 1/4 W

37 1 R5, 1 MΩ 1% 1/4 W

38 2 R7, R12 910 kΩ 1% 1/4 W

39 2 R6, R11 1.5 MΩ 1% 1/4 W

40 1 R8 16 kΩ 1% 1/8 W

41 1 R9 390 kΩ 1% 1/4 W

42 1 R10 15 kΩ 5% 1/4 W

43 1 R13 30 KΩ 1% 1/8 W

44 1 R14 20 kΩ 1% 1/8 W

45 1 R15 1.2 MΩ 1% 1/8 W

46 1 R16 240 k

47 1 R17

48 1 R18 18 kΩ 1% 1/4 W

49 1 R19 13 kΩ 1% 1/4 W

50 2 R20, R23 62 Ω 1% 1/8 W

51 2

52 1 R29 10 Ω 1% 1/4 W

LPFC1 0.8 mH

(1)

2

L1, L2

(1)

Q5, Q6,

Q8

R21,

R48

2x39 mH/0.7

1.8 mH +/5%

BC847 100 mA

STD8NM60

20//11 kΩ -

parallelo-

10 Ω 1% 1/8 W

Tol er anc e

A

N

Ω 1% 1/8 W

Volt a g e -

(%)

5%

1% 1/4 W

current

6 0 0 V

500 V

600 V

0.050

Watt

7 A

6 A

mA

Techn ology

information

Common

mode choke

NPN

transistor

MDmesh™

Powe r

MOSFET

Supermesh

MOSFET

SCRs TO92

Metal film

resistor

Metal film

resistor

Metal film

resistor

Metal film

resistor

Metal film

resistor

Metal film

resistor

Carbon film

resistor

Metal film

resistor

Metal film

resistor

Metal film

resistor

Metal film

resistor

Metal film

resistor

Metal film

resistor

Metal film

resistor

Metal film

resistor

Metal film

resistor

Metal film

resistor

SMD SOT-23

Package

footprint

SMD DPAK

SMD DPAK

SMD 1206

SMD 1206

SMD 1206

SMD 1206

SMD 0805

SMD 1206

axial

SMD 0805

SMD 0805

SMD 0805

SMD 0805

SMD 1206

SMD 1206

SMD 1206

SMD 0805

SMD 0805

SMD 1206

Manu-

facturer

EPCOS

STMicro-

electronics

STMicro-

electronics

STMicro-

electronics

Manufacturer

code

B82732R2701B

030

STD8NM60N

STD6NK50Z

X0205MA

RS/

distrelec

/other

code

24/27

Page 25

AN2771 Conduction emissions test

Table 5. Bill of material (continued)

RS/

distrelec

/other

code

Item Qty Ref. Part/value

Tol er anc e

(%)

Volt a g e -

current

Watt

Techn ology

information

Package

footprint

Manu-

facturer

Manufacturer

code

53 2 R22, R31 0.33 Ω 1% 1W

54 1 R24 1.8 MΩ 1% 1/4 W

55 1 R25 1.6 kΩ 1% 1/4 W

56 1 R26 10 kΩ 1% 1/4 W

57 4

58 1 R50 56 kΩ 1% 1/8 W

59 3

60 2 R53, R54 0 Ω jumper SMD 0805

61 2 R34,R35 180 kΩ 1% 1/4 W

62 2 R36,R40 68 kΩ 5% 1/4 W

63 1 R46 470 kΩ 1% 1/8 W

64 2 R47,R49 330 kΩ 1% 1/8 W

65 1 R51 2 kΩ 1% 1/8 W

66 1 R55 470 Ω 1% 1/8 W

67 1 R56 18 kΩ 1% 1/4 W

68 1 U1 L6585D

69 1 U2 TSM101

70 15 JUMP

71 4 Spacer

R27,R3,

R37,R41

R32,R33,

R52

56 kΩ 5% 1/4 W

0 Ω jumper SMD 1206

Insulate

wire- jump

Note

Spacer/

distanziatori

Wire 0.6

(2)

mm

10 mm Nylon

Precision wire

resistors

Metal film

resistor

Metal film

resistor

Metal film

resistor

Carbon film

resistor

Metal film

resistor

Metal film

resistor

Carbon film

resistor

Metal film

resistor

Metal film

resistor

Metal film

resistor

Metal film

resistor

Metal film

resistor

Combo IC for

PFC and

ballast control

Voltage and

current

controller

Wire 0.6 mm

axial

SMD 1206

SMD 1206

SMD 1206

axial

SMD 0805

SMD 1206

axial

SMD 0805

SMD 0805

SMD 0805

SMD 0805

SMD 1206

SMD SO-20

SMD SO-8

1. Nostra Fornitura max 50 pcs

2. The wire-jump must be insulated

STMicro-

electronics

STMicro-

electronics

Distrele:

720643

L6585D

TSM101AIDT

25/27

Page 26

Revision history AN2771

7 Revision history

Table 6. Document revision history

Date Revision Changes

06-Aug-2008 1 Initial release

26/27

Page 27

AN2771

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2008 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

27/27

Loading...

Loading...