Page 1

AN2755

Application note

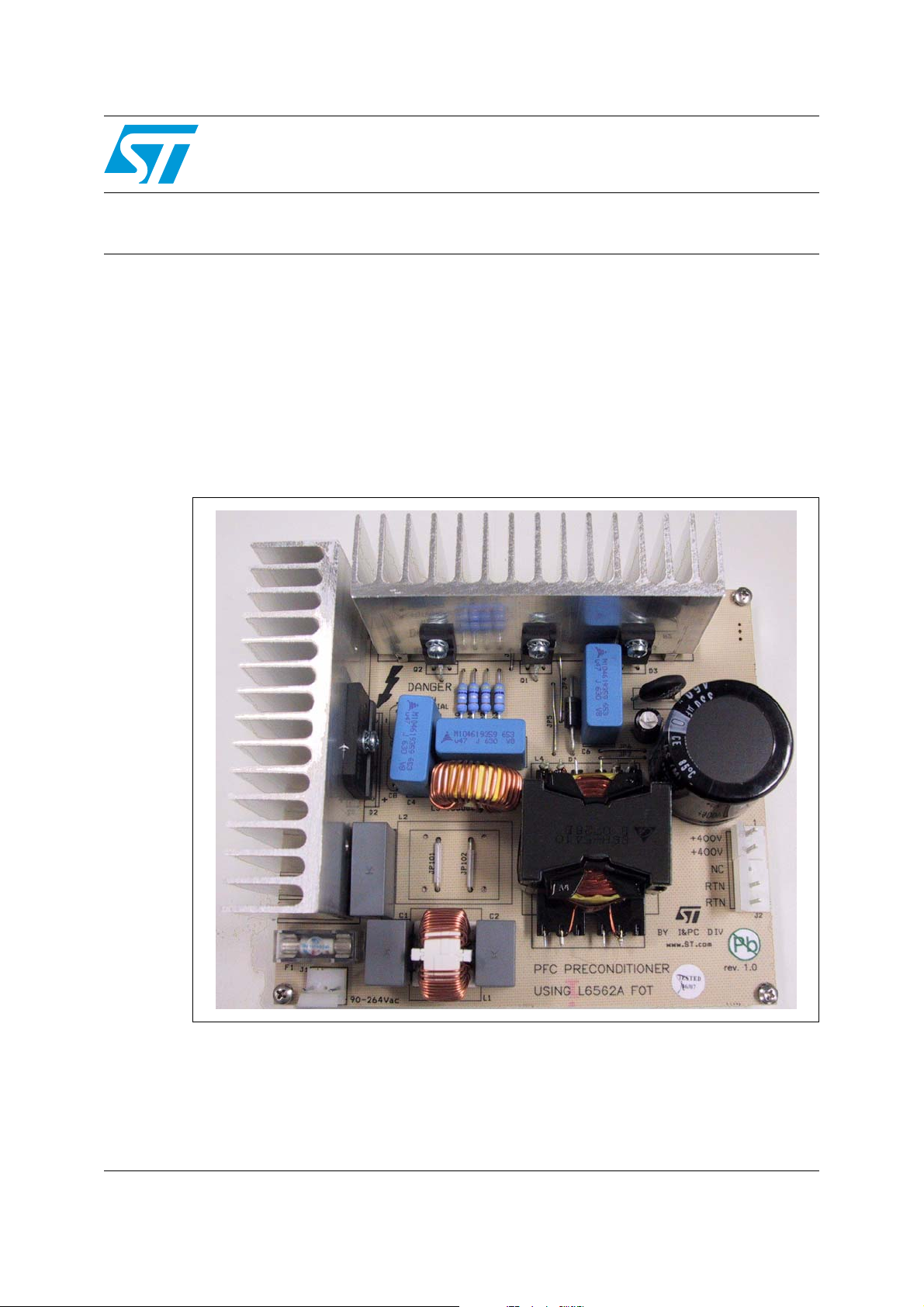

400 W FOT-controlled PFC pre-regulator with the L6562A

Introduction

This application note describes an demonstration board based on the transition-mode PFC

controller L6562A and presents the results of its bench demonstration. The board

implements a 400 W, wide-range mains input PFC pre-conditioner suitable for ATX PSU, flat

screen displays, etc. In order to allow the use of a low-cost device like the L6562A at this

power level, usually prohibitive for this device, the chip is operated with fixed-off-time control.

This allows continuous conduction mode operation, normally achievable with more

expensive control chips and more complex control architectures.

Figure 1. Demonstration board (EVL6562A-400W)

July 2008 Rev 1 1/24

www.st.com

Page 2

Contents AN2755

Contents

1 Main characteristics and circuit description . . . . . . . . . . . . . . . . . . . . . 5

2 Test results and significant waveforms . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Harmonic content measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Inductor current in FOT and L6562A THD optimizer . . . . . . . . . . . . . . . . 10

2.3 Overvoltage protection and disable function . . . . . . . . . . . . . . . . . . . . . . 11

3 Layout hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Audible noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Thermal measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6 Conducted emission pre-compliance test . . . . . . . . . . . . . . . . . . . . . . 16

7 Bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8 PFC coil specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8.1 General description and characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8.2 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8.3 Mechanical aspect and pin numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

9 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

10 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2/24

Page 3

AN2755 List of tables

List of tables

Table 1. Measured temperature table at 115 Vac and 230 Vac - full load . . . . . . . . . . . . . . . . . . . . 15

Table 2. Bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 3. Winding characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 4. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3/24

Page 4

List of figures AN2755

List of figures

Figure 1. Demonstration board (EVL6562A-400W) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. EVL6562A-400W demonstration board electrical schematic . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. EVL6562A-400W compliance to EN61000-3-2 standard at full load . . . . . . . . . . . . . . . . . 7

Figure 4. EVL6562A-400W compliance to JEIDA-MITI standard at full load . . . . . . . . . . . . . . . . . . . . 7

Figure 5. EVL6562A-400W compliance to EN61000-3-2 standard at 70 W load . . . . . . . . . . . . . . . 7

Figure 6. EVL6562A-400W compliance to JEIDA-MITI standard at 70 W load . . . . . . . . . . . . . . . . . . 7

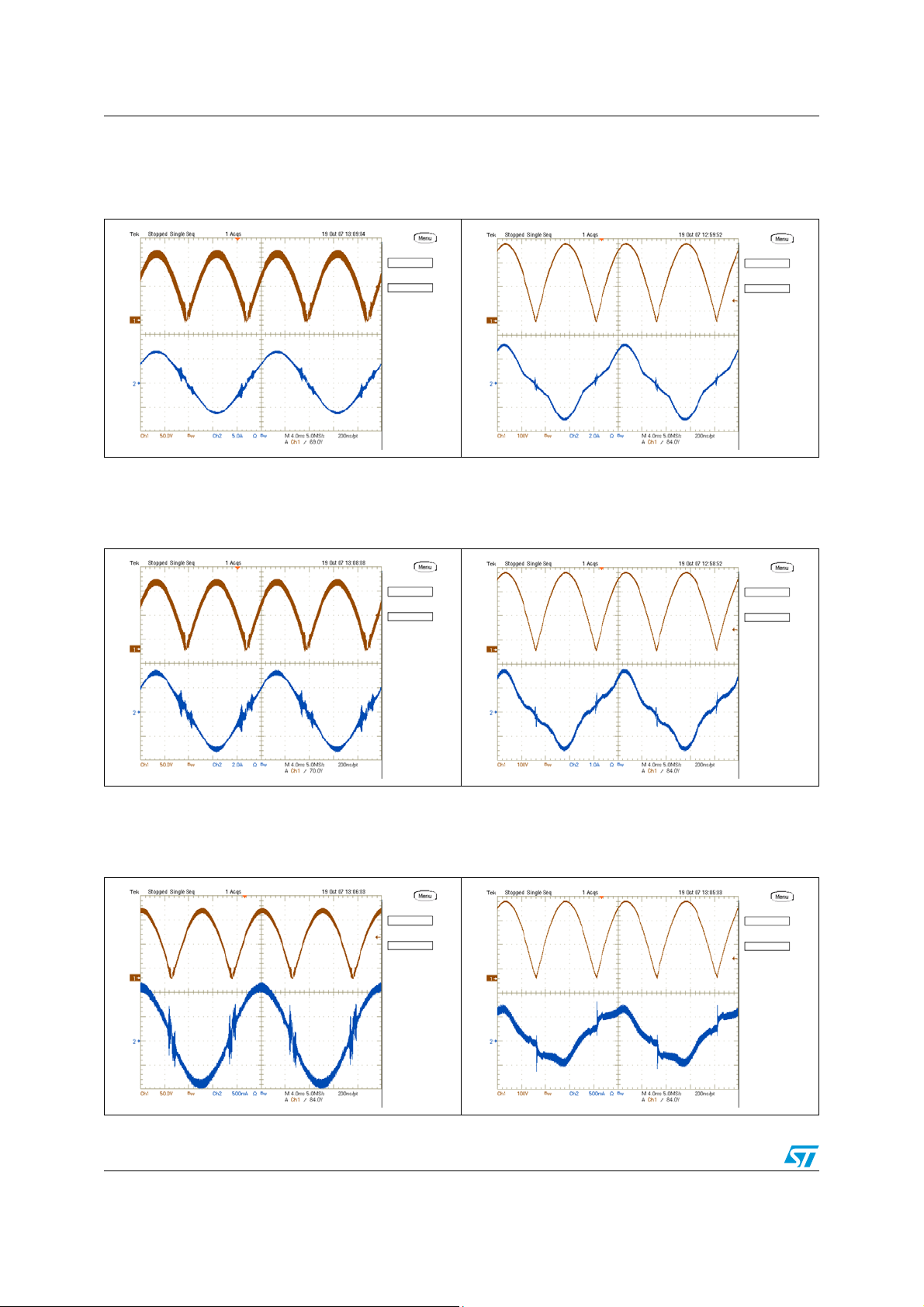

Figure 7. EVL6562A-400W input current waveform at 100 V - 50 Hz - 400 W load . . . . . . . . . . . . . . 8

Figure 8. EVL6562A-400W input current waveform at 230 V - 50 Hz - 400 W load . . . . . . . . . . . . . . 8

Figure 9. EVL6562A-400W input current waveform at 100 V - 50 Hz - 200 W load . . . . . . . . . . . . . . 8

Figure 10. EVL6562A-400W input current waveform at 230 V - 50 Hz - 200 W load . . . . . . . . . . . . . . 8

Figure 11. EVL6562A-400W input current waveform at 100 V - 50 Hz - 70 W load . . . . . . . . . . . . . . . 8

Figure 12. EVL6562A-400W input current waveform at 230 V - 50 Hz - 70 W load . . . . . . . . . . . . . . . 8

Figure 13. Power factor vs. Vin and load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 14. THD vs. Vin and load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 15. Efficiency vs. Vin and load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 16. Static Vout regulation vs. Vin and load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 17. EVL6562A-400W inductor current ripple envelope at 115 Vac - 60 Hz - full load . . . . . . . 10

Figure 18. EVL6562A-400W inductor current ripple (detail) at 115 Vac - 60 Hz - full load . . . . . . . . . 10

Figure 19. EVL6562A-400W inductor current ripple envelope at 230 Vac - 50 Hz - full load . . . . . . . 11

Figure 20. EVL6562A-400W Inductor current ripple (detail) at 230 Vac-50 Hz -full load. . . . . . . . . . . 11

Figure 21. EVL6562A-400W PCB layout (not scaled 1:1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 22. Thermal map at 115 Vac - 60 Hz - full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 23. Thermal map at 230 Vac - 50 Hz - full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 24. 115 Vac and full load - phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 25. 115 Vac and full load - neutral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 26. 230 Vac and full load - phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 27. 230 Vac and full load - neutral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 28. Electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 29. Pin side view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4/24

Page 5

AN2755 Main characteristics and circuit description

1 Main characteristics and circuit description

The main characteristics of the SMPS are listed here below:

● Line voltage range: 90 to 265 Vac

● Minimum line frequency (f

● Regulated output voltage: 400 V

● Rated output power: 400 W

● Maximum 2f

● Hold-up time: 22 ms (V

● Maximum switching frequency: 85 kHz (V

● Minimum estimated efficiency: 90 % (V

● Maximum ambient temperature: 50 °C

● EMI: In accordance with EN55022 class-B

● PCB type and size: Single side, 70 µm, CEM-1, 148.5 x 132 mm

● Low profile design: 35 mm component maximum height

output voltage ripple: 10 V pk-pk

L

The demonstration board implements a power factor correction (PFC) pre-regulator

delivering 400 W continuous power on a regulated 400 V rail from a wide-range mains

voltage and provides for the reduction of the mains harmonics, which allows meeting the

European norm EN61000-3-2 or the Japanese norm JEIDA-MITI. This rail is the input for the

cascaded isolated DC-DC converter that provides the output rails required by the load.

): 47 Hz

L

after hold-up time: 300 V)

DROP

= 90 Vac, P

in

= 90 Vac, P

in

= 400 W)

out

= 400 W)

out

The board is equipped with enough heat sinking to allow full-load operation in still air. With

an appropriate airflow and without any change in the circuit, the demonstration board can

easily deliver up to 450 W.

The controller is the L6562A (U1), integrating all the functions needed to control the PFC

stage.

The L6562A controller chip is designed for transition-mode (TM) operation, where the boost

inductor works next to the boundary between continuous (CCM) and discontinuous

conduction mode (DCM). However, with a slightly different usage, the chip can operate so

that the boost inductor works in CCM, hence surpassing the limitations of TM operation in

terms of power handling capability. The gate-drive capability of the L6562A is also adequate

to drive the MOSFETs used at higher power levels. This approach, which couples the

simplicity and cost-effectiveness of TM operation with the high-current capability of CCM

operation, is the Fixed-OFF-time (FOT) control. The control modulates the ON-time of the

power switch, while its OFF-time is kept constant. More precisely, it uses the line-modulated

FOT (LM-FOT) where the OFF-time of the power switch is not rigorously constant but is

modulated by the instantaneous mains voltage. Please refer to [2] for a detailed description

of this technique.

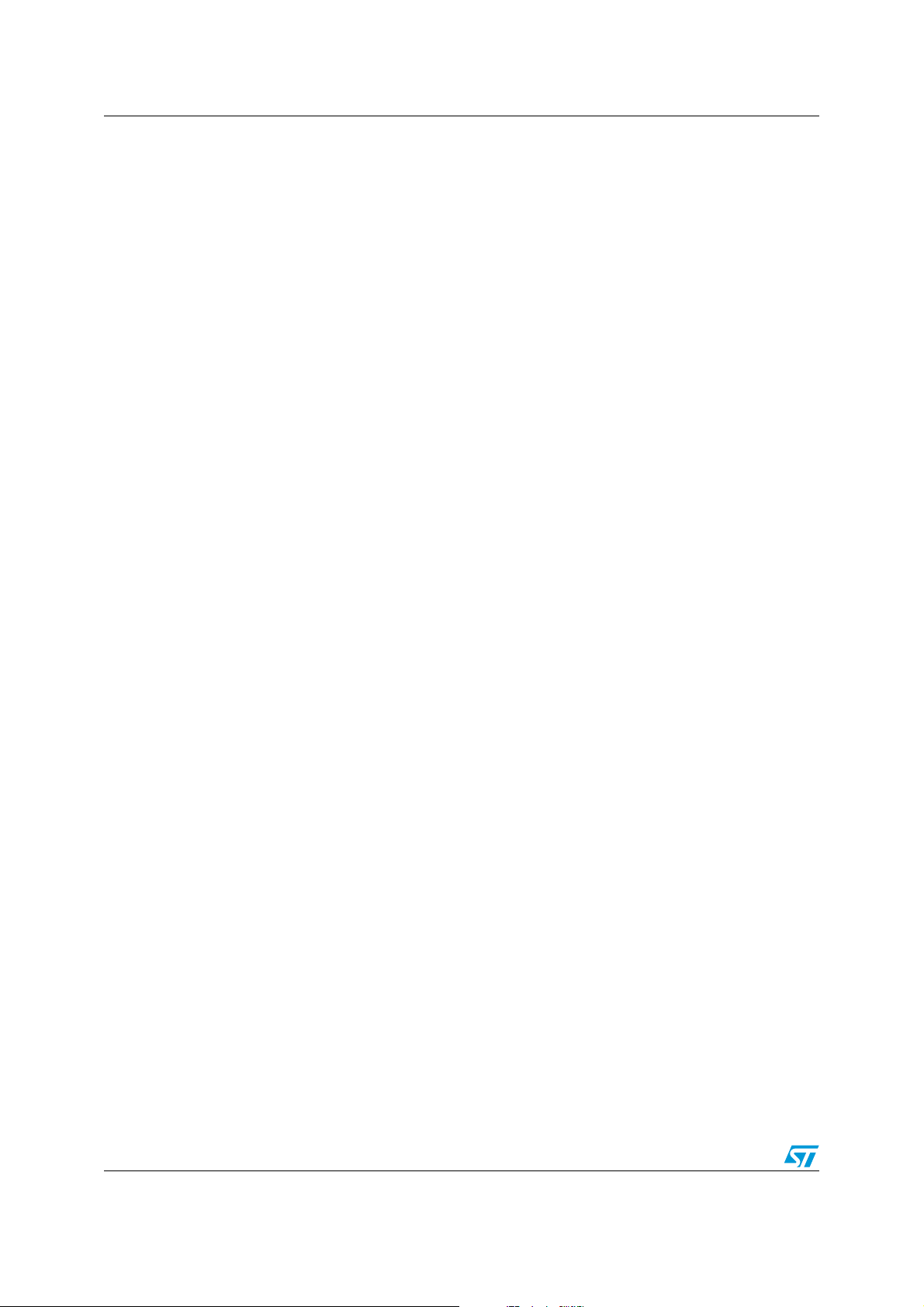

The power stage of the PFC is a conventional boost converter, connected to the output of

the rectifier bridge D2. It includes the coil L4, the diode D3 and the capacitors C6 and C7.

The boost switch is represented by the power mosfets Q1 and Q2. The NTC R2 limits the

inrush current at switch-on. It has been connected on the DC rail, in series to the output

electrolytic capacitor, in order to improve the efficiency during low-line operation.

Additionally, the splitting in two of output capacitors (C6 and C7) allows managing the AC

current mainly by the film capacitor C7 so that the electrolytic can be cheaper as it just has

to bear the DC part only.

5/24

Page 6

Main characteristics and circuit description AN2755

At startup the L6562A is powered by the Vcc capacitor (C12) that is charged via the

resistors R3 and R4. Then the L4 secondary winding (pins 8-11) and the charge pump

circuit (R5, C10, D5 and D4) generate the Vcc voltage powering the L6562A during normal

operation.

The divider R32, R33 and R34 provides the L6562A multiplier with the information of the

instantaneous voltage that is used to modulate the boost current. The divider R9, R10, R11,

R12 & 13 is dedicated to sense the output. The Line-Modulated FOT is obtained by the

timing generator components D6, C15, R15, C16, R16, R31, Q3.

The board is equipped with an input EMI filter designed for a 2-wire input mains plug. It is

composed of two stages, a common mode pi-filter connected at the input (C1, L1, C2, C3)

and a differential mode pi-filter after the input bridge (C4, L3, C5). It also offers the

possibility to easily connect a downstream converter.

Figure 2. EVL6562A-400W demonstration board electrical schematic

J1

1

2

90 - 265Vac

8A/250V

R32

620k

D2

C3

680nF-X2

INV

COMP

MULT

R10

510k

R12

47K

L6562A

Q3

BC857C

D15X B60

+

-~~

R102

0R0

R11

510k

R13

12k

8

VCC

7

GD

6

GND

5

ZCDCS

+400Vdc

CM-1.5mH-5A

L1

C1

R1

470nF-X2

1M5

C14

2.2uF

R33

620k

C2

470nF

R9

510k

C13

22 0nF

R14

47k

1

2

3

4

C21

R34

10nF

10k

F1

L3

DM-51uH-6A

C4

470n F-630 V

R3

100K

R4

100K

C11

470nF/50V

R31

3k

C16

120p F

R101

0R0

R16

30k

C12

100uF/50V

C15

68pF

C5

470nF-63 0V

R15

1k8

811

D4

LL4148

LL41 48

D6

5-6

T

PQ40- 500uH

R5

47R

C10

22N

D5

BZX8 5-C 18

C20

330pF

D1

1N54 06

1-2

D3

STTH8R06

C6

470nF-630V

R2

NTC 2R5-S237

330uF-450 V

+400Vdc

J2

1

+400Vdc

2

+400Vdc

3

NC

4

C7

RTN

5

RTN

+400Vout

D7

LL4148

D8

LL4148

R20

0R47-1 W

STP1 2NM50FP

R21

0R4 7-1W

Q1

Q2

STP1 2NM50FP

R22

R23

0R47-1W

0R4 7-1W

R36

3R9

R17

6R8

R35

3R9

R18

6R8

R19

1K0

6/24

Page 7

AN2755 Test results and significant waveforms

2 Test results and significant waveforms

2.1 Harmonic content measurement

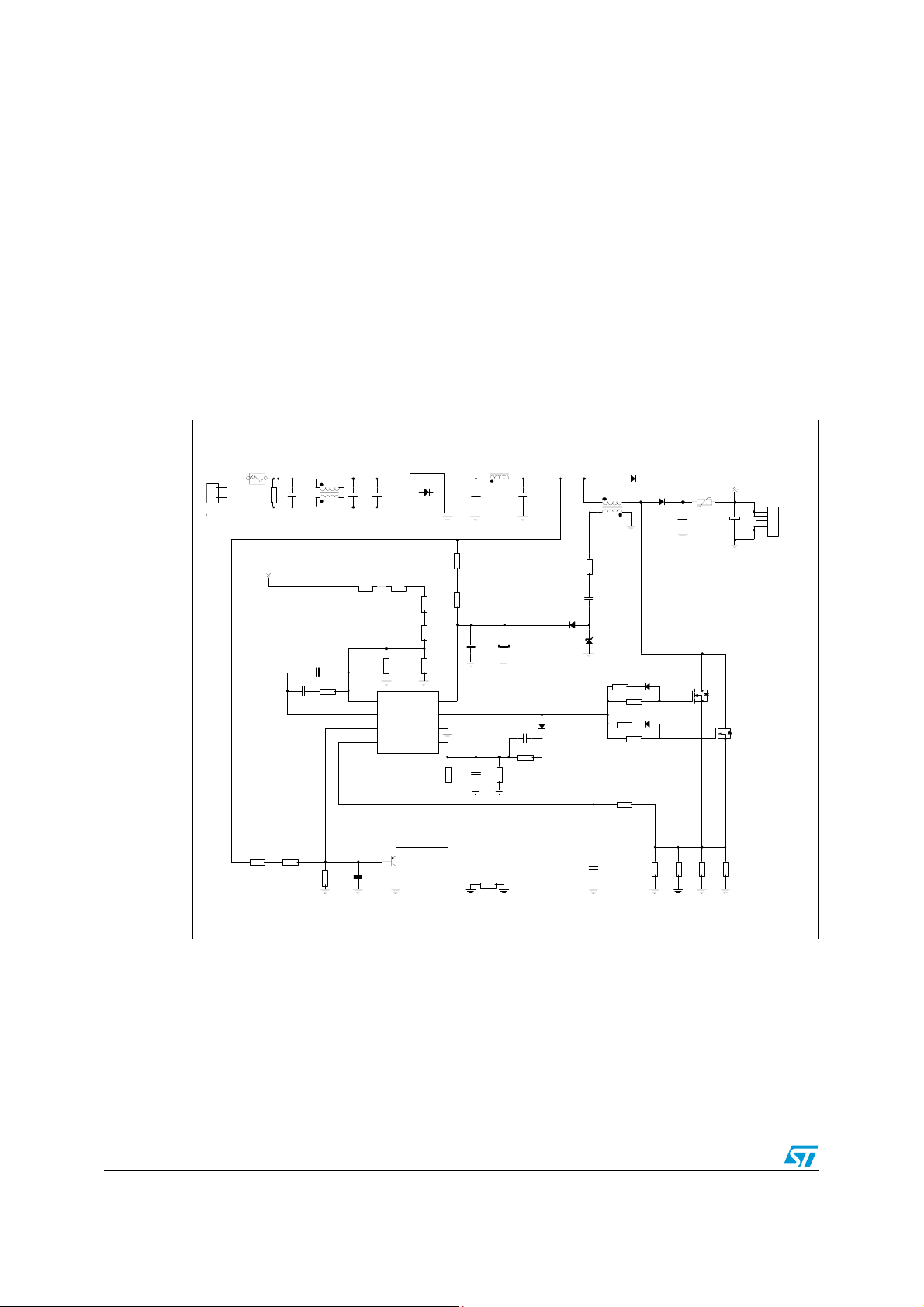

One of the main purposes of a PFC pre-conditioner is the correction of input current

distortion, decreasing the harmonic contents below the limits of the actual regulations.

Therefore, the board has been tested according to the European rule EN61000-3-2 class-D

and Japanese rule JEIDA-MITI class-D, at full load and 70 W output power, at both the

nominal input voltage mains.

As shown in the following figures of this page, the circuit is capable of reducing the

harmonics well below the limits of both regulations from full load down to light load. 70 W of

output power has been chosen because it approaches the lower power limit at which the

harmonics have to be limited according to the mentioned rules.

Figure 3. EVL6562A-400W compliance to

10

EN61000-3-2 standard at full load

Measurements @ 230Vac Full load EN61000-3-2 class D limits

Figure 4. EVL6562A-400W compliance to

JEIDA-MITI standard at full load

Measurements @ 100Vac Full load JEIDA-MITI class D limits

10

1

0.1

0.01

Ha rm on i c c u rr en t ( A)

0.001

0.0001

1 3 5 7 9 111315171921232527293133353739

Harmonic Order (n)

Figure 5. EVL6562A-400W compliance to

1

0.1

0.01

Harmonic current (A)

0. 00 1

0.0001

EN61000-3-2 standard at 70 W load

Measurements @ 230Vac 70W EN61000-3-2 class D limits

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39

Harmonic Order (n)

1

0.1

0.01

Harmonic current (A)

0.001

0.0001

1 3 5 7 9111315171921232527293133353739

Harmonic Order (n)

Figure 6. EVL6562A-400W compliance to

JEIDA-MITI standard at 70 W load

Harmonic current (A)

0.001

0.0001

Measurements @ 100Vac 70W JEIDA-MITI cla ss D lim its

1

0.1

0. 01

1 3 5 7 9 1113151719 212325272931 33 3537 39

Harmonic Order (n)

For user reference, waveforms of the input current and voltage at the nominal input voltage

mains and different load conditions are shown in the following figures.

7/24

Page 8

Test results and significant waveforms AN2755

Figure 7. EVL6562A-400W input current

waveform

at 100 V - 50 Hz - 400 W load

Figure 9. EVL6562A-400W input current

waveform

at 100 V - 50 Hz - 200 W load

Figure 8. EVL6562A-400W input current

waveform

at 230 V - 50 Hz - 400 W load

Figure 10. EVL6562A-400W input current

waveform

at 230 V - 50 Hz - 200 W load

Figure 11. EVL6562A-400W input current

waveform

8/24

at 100 V - 50 Hz - 70 W load

Figure 12. EVL6562A-400W input current

waveform

at 230 V - 50 Hz - 70 W load

Page 9

AN2755 Test results and significant waveforms

The power factor (PF) and the total harmonic distortion (THD) have been measured too and

the results are shown in Figure 13 and Figure 14. As visible, the PF at full load and half load

remains close to unity throughout the input voltage mains range while, when the circuit is

delivering 70 W, it decreases at high mains range. THD is low, remaining within 30 % at

maximum input voltage.

Figure 13. Power factor vs. Vin and load Figure 14. THD vs. Vin and load

1.05

1.00

0.95

0.90

PF

0.85

0.80

0.75

0.70

Pout = 400W

Pout = 200W

Pout = 70W

80 130 180 230 2 80

Vin (V ac)

35

30

25

20

15

TH D (%)

10

5

0

80 130 180 230 280

Vin (V ac)

Pout = 400W

Pout = 200W

Pout = 70W

The efficiency is very good at all load and line conditions. At full load it is always significantly

higher than 90%, making this design suitable for high efficiency power supply.

The measured output voltage variation at different line and load conditions is shown in

Figure 16. As visible, the voltage is perfectly stable over the input voltage range. Just at 265

Vac and light load, there are negligible deviations of 1 V due to the intervention of the burst

mode (for the "static OVP") function.

Figure 15. Efficiency vs. Vin and load Figure 16. Static Vout regulation vs. Vin and

404

403

402

401

400

Vout (V dc)

399

398

397

80 1 30 180 230 2 80

load

Pout = 400W

Pout = 200W

Pout = 70W

Pout = 15W

Vin (Va c)

9/24

Page 10

Test results and significant waveforms AN2755

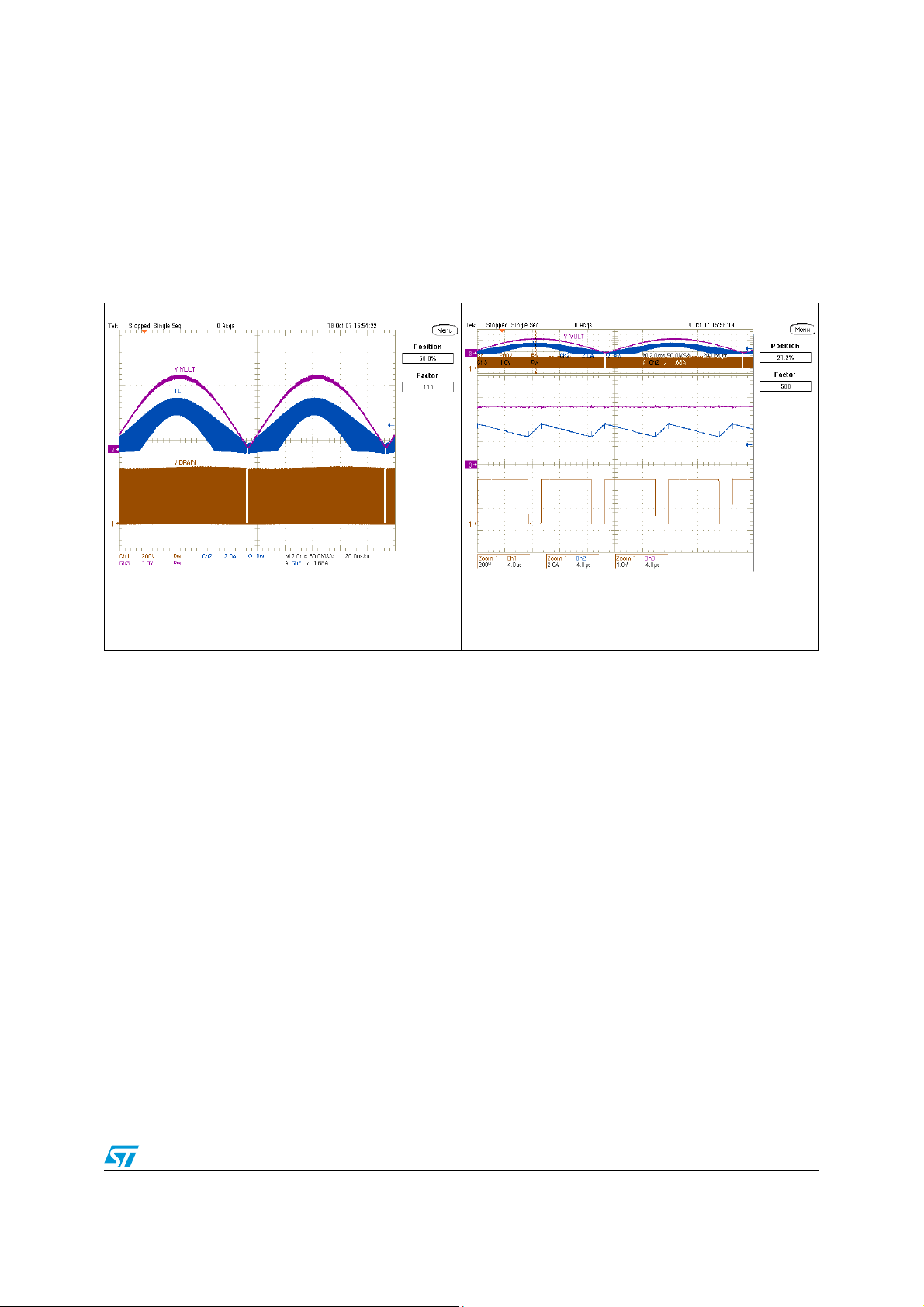

2.2 Inductor current in FOT and L6562A THD optimizer

The following figures show the waveforms relevant to the inductor current at different voltage

mains. As visible in Figure 17 and Figure 19, the inductor current waveform over a line halfperiod is very similar to that of a CCM PFC. In Figure 18 and Figure 20 the magnification of

the waveforms at the peak of the sine wave shows the different ripple current and off-times,

which is modulated by the input mains voltage. We can also note the transition angle from

DCM to CCM that occurs closer to the zero-crossing of the current sine wave at low mains

and moves toward the top if the circuit is working at high mains.

Figure 17. EVL6562A-400W inductor current

ripple envelope at 115 Vac - 60 Hz -

● CH1: Q1/Q2 drain voltage

● CH2: I L inductor current ripple envelope

● CH3: MULT voltage - pin #3

full load

On both the drain voltage traces shown in Figure 17 and Figure 19, close to the zerocrossing points of the sine wave, it is possible to note the action of the THD optimizer

embedded in the L6562A. It is a circuit that minimizes the conduction dead-angle occurring

to the AC input current near the zero-crossings of the line voltage (crossover distortion). In

this way, the THD (Total Harmonic Distortion) of the current is considerably reduced. A

major cause of this distortion is the inability of the system to transfer energy effectively when

the instantaneous line voltage is very low. This effect is magnified by the high-frequency

filter capacitor placed after the bridge rectifier, which retains some residual voltage that

causes the diodes of the bridge rectifier to be reverse-biased and the input current flow to

temporarily stop. To overcome this issue the device forces the PFC pre-regulator to process

more energy near the line voltage zero-crossings as compared to that commanded by the

control loop.

Figure 18. EVL6562A-400W inductor current

ripple (detail) at 115 Vac - 60 Hz -

● CH1: Q1/Q2 drain voltage

● CH2: I L inductor current ripple envelope

● CH3: MULT voltage - pin #3

full load

This results in both minimizing the time interval where energy transfer is lacking and fully

discharging the high-frequency filter capacitor after the bridge. Essentially, the circuit

artificially increases the ON-time of the power switch with a positive offset added to the

output of the multiplier in the proximity of the line voltage zero-crossings.

This offset is reduced as the instantaneous line voltage increases, so that it becomes

negligible as the line voltage moves toward the top of the sinusoid.

10/24

Page 11

AN2755 Test results and significant waveforms

To maximally benefit from the THD optimizer circuit, the high-frequency filter capacitors after

the bridge rectifier should be minimized, compatibly with EMI filtering needs. A large

capacitance, in fact, introduces a conduction dead-angle of the AC input current in itself thus

reducing the effectiveness of the optimizer circuit.

Figure 19. EVL6562A-400W inductor current

ripple envelope at 230 Vac - 50 Hz -

● CH1: Q1/Q2 drain voltage

● CH2: I L inductor current ripple envelope

● CH3: MULT voltage - pin #3

full load

Figure 20. EVL6562A-400W Inductor current

ripple (detail) at 230 Vac-50 Hz -

● CH1: Q1/Q2 drain voltage

● CH2: I L inductor current ripple envelope

● CH3: MULT voltage - pin #3

full load

2.3 Overvoltage protection and disable function

The L6562A is equipped by an OVP, monitoring the current flowing through the

compensation network and entering in the error amplifier (pin COMP, #2). When this current

reaches about 24 µA the output voltage of the multiplier is forced to decrease, thus reducing

the energy drawn from the mains. If the current exceeds 27 µA, the OVP is triggered

(dynamic OVP), and the external power transistor is switched off until the current falls

approximately below 7 µA. However, if the overvoltage persists (e.g. in case the load is

completely disconnected), the error amplifier eventually saturates low hence triggering an

internal comparator (static OVP) that keeps the external power switch turned off until the

output voltage comes back close to the regulated value.

The OVP function described above is able to handle abnormal overload conditions, i.e.

those resulting from an abrupt load/line change or occurring at startup.

The INV pin doubles its function as a non-latched IC disable. A voltage below 0.2 V shuts

down the IC and reduces its consumption to a lower value. To restart the IC, the voltage on

the pin must exceed 0.45 V. The main usage of this function is a remote ON/OFF control

input that can be driven by a PWM controller for power management purposes. However it

also offers a certain degree of additional safety since it causes the IC to shut down in case

the lower resistor of the output divider is shorted to ground or if the upper resistor is missing

or fails to open.

11/24

Page 12

Layout hints AN2755

3 Layout hints

The layout of any converter is a very important phase in the design process that sometimes

does not have enough attention from the engineers. Even if it the layout phase sometimes

looks time-consuming, a good layout does save time during the functional debugging and

the qualification phases. Additionally, a power supply circuit with a correct layout needs

smaller EMI filters or less filter stages which allows consistent cost savings.

The L6562A does not need any special attention to the layout, just the general layout rules

for any power converter have to be carefully applied. Basic rules are listed below, using the

EVL6562A-400W schematic as a reference. They can be used for other PFC circuits having

any power level, working either in FOT or TM control.

1. Keep power and signal RTNs separated. Connect the return pins of componentcarrying high currents such as C4, C5 (input filter), sense resistors, and C6, C7 (output

capacitors) as close as possible. This point is the RTN star point. A downstream

converter must be connected to this return point.

2. Minimize the length of the traces relevant to L3, boost inductor L4, boost rectifier D4

and output capacitor C6 and C7.

3. Keep signal components as close as possible to each L6562A relevant pin. Specifically,

keep the tracks relevant to pin #1 (INV) net as short as possible. Components and

traces relevant to the error amplifier have to be placed far from traces and connections

carrying signals with high dv/dt like the MOSFET drains (Q1 and Q2).

4. Connect heat sinks to power GND.

5. Add an external shield to the boost inductor and connect it to power GND.

6. Connect a ceramic capacitor (100 ÷ 470 uF) to pin #8 (Vcc) and to pin #6 (GND) and

close to the L6562A. Connect pin #6 (GND) to the RTN star point (see 1).

Figure 21. EVL6562A-400W PCB layout (not 1:1 scaled)

PFC PRECONDITIONER

PFC PRECONDITIONER

USING L6562A FOT

USING L6562A FOT

12/24

Page 13

AN2755 Audible noise

4 Audible noise

Differential mode currents in a circuit with high-frequency and low-frequency components

(like in a PFC) may produce audible noise due to intermodulation between operating

frequency and mains line frequency.

The phenomenon is produced because of mechanical vibration of reactive components like

capacitors and inductors. Current flowing in the winding can cause the vibration of wires or

ferrite which produces buzzing noise. Therefore to avoid this noise, boost and filter inductors

have to be wound with correct wire tension, and the component has to be varnished or

dipped. Frequently, X-capacitors and filter capacitors after the bridge generate acoustic

noise because of the AC current that causes the electrodes to vibrate which produces

buzzing noise. Thus, in order to minimize the AC current, inserting a differential mode (pifilter between the bridge and the boost inductor) helps to reduce the acoustic noise and

additionally the EMI filter benefits. This type of filter decreases significantly the ripple current

that otherwise has to be filtered by the EMI filter. The capacitors to select are polypropylene,

preferably dipped type, because boxed ones are generally more at risk to generate acoustic

noise.

The grounding of the boost inductor may help, because we decrease the emissions from the

most efficient "antenna" of our circuit. In fact, in case of improper layout, some picofarads of

layout parasitic capacitance, together with the very high dV/dt of the MOSFET drain voltage,

may inject noise somewhere in the circuit.

13/24

Page 14

Thermal measures AN2755

5 Thermal measures

In order to check the design reliability, a thermal mapping by means of an IR camera was

done. Figure 22 and 23 show thermal measures on the board component side at nominal

input voltages and full load. Some pointers visible on the pictures placed across key

components show the relevant temperature. Tab l e 1 provides the correlation between

measured points and components for both thermal maps. The ambient temperature during

both measurements was 27 °C. According to these measurement results, all components of

the board are working within their temperature limits.

Figure 22. Thermal map at 115 Vac - 60 Hz - full load

80.6

°C

73.9

67.2

60.5

53.8

Figure 23. Thermal map at 230 Vac - 50 Hz - full load

47.1

40.4

33.7

26.9

79.9

°C

73.2

66.6

60.0

53.3

46.7

40.0

33.4

26.8

14/24

Page 15

AN2755 Thermal measures

Table 1. Measured temperature table at 115 Vac and 230 Vac - full load

Point Component Temperature at 115 Vac Temperature at 230 Vac

A D2 64.7 °C 51.3 °C

B Q2 76.5 °C 62.0 °C

C Q1 74.1 °C 61.9 °C

D D3 72.8 °C 65.6 °C

E C7 41.0 °C 41.5 °C

F L1 58.5 °C 43.5 °C

G L3 59.2 °C 50.6 °C

H L4 – CORE 57.0 °C 56.5 °C

I L4 - WINDING 65.1 °C 60.9 °C

15/24

Page 16

Conducted emission pre-compliance test AN2755

6 Conducted emission pre-compliance test

The following figures show the peak measurement of the conducted noise at full load and

nominal mains voltages. The limits shown in the diagrams are EN55022 class-B which is the

most popular rule for domestic equipment using a two-wire mains connection. As visible in

the diagrams, in all test conditions there is a good margin of the measures with respect to

the limits.

Figure 24. 115 Vac and full load - phase Figure 25. 115 Vac and full load - neutral

Figure 26. 230 Vac and full load - phase Figure 27. 230 Vac and full load - neutral

16/24

Page 17

AN2755 Bill of material

7 Bill of material

Table 2. Bill of material

Ref.

Des.

C1 470 nF - X2 DWG X2 film capacitor R46-I 3470--M1- ARCOTRONICS

C10 22 nF 1206 100 V SMD cercap - general purpose AVX

C11 470 nF 1206 50 V SMD cercap - general purpose AVX

C12 100 uF

C13 220 nF 0805 50 V SMD cercap - general purpose AVX

C14 2.2 uF 1206 50 V SMD cercap - general purpose AVX

C15 100 pF 0805 50 V SMD cercap - general purpose AVX

C16 120 pF 0805 50 V SMD cercap - general purpose AVX

C2 470 n F - X2 DWG X2 film capacitor R46-I 3470--M1- Arcotronics

C20 330 pF 0805 50 V SMD cercap - general purpose AVX

C21 10 nF 1206 50 V SMD cercap - general purpose AVX

C3 680 nF - X2 DWG X2 film capacitor R46-I 3680--M1- Arcotronics

C4 470 nF / 630 V DWG Film capacitor MKP - B32653A6474J EPCOS

C5 470 nF / 630 V DWG Film capacitor MKP - B32653A6474J EPCOS

C6 470 nF / 630 V DWG Film capacitor MKP- B32653A6474J EPCOS

C7 330 uF / 450 V

Part type-

part value

Case/

Package

DIA8X11

(MM)

DIA 35x35

(MM)

Description Supplier

Aluminium elcap - YXF SERIES -

105 °C

Aluminium elcap - LLS series - 85 °C Nichicon

Rubycon

C8 RES DWG

C9 RES DWG

D1 1N5406 DO-201 Standard recovery rectifier Vishay

D2 D15XB60 DWG Rectifier bridge Shindengen

D3 STTH8R06 TO-220FP Ultrafast high voltage rectifier STMicroelectronics

D4 LL4148 MINIMELF Fast switching diode

D5 BZX85-C18 MINIMELF Zener diode

D6 LL4148 MINIMELF Fast switching diode

D7 LL4148 MINIMELF Fast switching diode

D8 LL4148 MINIMELF Fast switching diode

F1 8A/250V 5x20 MM 8 A mains input fuse Wickmann

J1 3-pins conn. (central rem.) P 3.96 KK series

J2 5-pins conn. (central rem.) P 3.96 KK series

JP101 JUMPER Wire jumper

Not used -

Vishay

Molex

17/24

Page 18

Bill of material AN2755

Table 2. Bill of material (continued)

Ref.

Des.

JP102 JUMPER Wire jumper

L1 CM-1.5 mH-5 A DWG CM choke - LFR2205B Delta electronics

L2 RES DWG Not used -

L3 DM-51 uH-6 A DWG Filter inductor - LSR2306-1

L4 PQ40-500 uH DWG PFC inductor - 86H-5410B

Q1 STP12NM50FP TO-220FP N-channel power MOSFET

Q2 STP12NM50FP TO-220FP N-channel power MOSFET

Q3 BC857C SOT-23 Small signal BJT - PNP Vishay

R1 1 M5 AXIAL HV resistor

R10 510 k 1206 SMD STD film res - 1% - 250 ppm / °C

R11 510 k 1206 SMD STD film res - 1% - 250 ppm / °C

R12 47 k 0805 SMD STD film res - 1% - 250 ppm / °C

R13 12 k 0805 SMD STD film res - 1% - 250 ppm / °C

R14 47 k 0805 SMD STD film res - 5% - 250 ppm / °C

R15 1 k8 0805 SMD STD film res - 1% - 100 ppm / °C

R16 30 k 0805 SMD STD film res - 1% - 100 ppm / °C

R17 6R8 0805 SMD STD film res - 5% - 250 ppm / °C

Part type-

part value

Case/

Package

Description Supplier

Delta electronics

STMicroelectronics

BC components

R18 6R8 0805 SMD STD film res - 5% - 250 ppm / °C

R19 1 K0 1206 SMD STD film res - 5% - 250 ppm / °C

R2 NTC 2R5 DWG NTC resistor 2R5 S237 EPCOS

R20 0R47-1 W AXIAL Axial res - 5% - 250 ppm / °C

R21 0R47-1 W AXIAL Axial res - 5% - 250 ppm / °C

R22 0R47-1 W AXIAL Axial res - 5% - 250 ppm / °C

R23 0R47-1 W AXIAL Axial res- 5% - 250 ppm / °C

R25 RES 1206 Not used -

BC components

18/24

Page 19

AN2755 Bill of material

Table 2. Bill of material (continued)

Ref.

Des.

R3 100 K 1206 SMD STD film res - 5% - 250 ppm / °C

R31 3 k 0805 SMD STD film res - 1% - 100 ppm / °C

R32 620 k 1206 SMD STD film res - 5% - 250 ppm / °C

R33 620 k 1206 SMD STD film res - 5% - 250 ppm / °C

R34 10 k 1206 SMD STD film res - 5% - 250 ppm / °C

R35 3R9 0805 SMD STD film res - 5% - 250 ppm / °C

R36 3R9 0805 SMD STD film res - 5% - 250 ppm / °C

R4 100 K 1206 SMD STD film res - 5% - 250 ppm / °C

R5 47 R 1206 SMD STD film res - 5% - 250 ppm / °C

R9 510 k 1206 SMD STD film res - 1% - 250 ppm / °C

R101 0R0 1206 SMD STD film res - 5% - 250 ppm / °C

R102 0R0 1206 SMD STD film res - 5% - 250 ppm / °C

U1 L6562AD SO-8 Transition-mode PFC controller STMicroelectronics

Part type-

part value

Case/

Package

Description Supplier

BC components

19/24

Page 20

PFC coil specification AN2755

8 PFC coil specification

8.1 General description and characteristics

● Application type: consumer, home appliance

● Inductor type: open

● Coil former: vertical type, 6+6 pins

● Max. temp. rise: 45 ºC

● Max. operating ambient temperature: 60 ºC

8.2 Electrical characteristics

● Converter topology: boost PFC pre-regulator, FOT control

● Core type: PQ40-30 material grade PC44 or equivalent

● Max. operating frequency: 100 kHz

● Primary inductance: 500 µH 10 % at 1 kHz - 0.25 V

●

Primary RMS current: 4.75 A

(a)

Figure 28. Electrical diagram

5 - 6 11

Primary Auxiliary

1 - 2

Table 3. Winding characteristics

Start pins End pins

11 8 5 (spaced) Single – G2 0.28Ø Bottom

5 - 6 1 - 2 65 Multistrand – G2 Litz 0.2Ø x 30 Top

Number

of turns

Wire type

8

Wire

diameter

Notes

a. Measured between pins 1-2 and 5-6

20/24

Page 21

AN2755 PFC coil specification

0

m

4

8.3 Mechanical aspect and pin numbering

● Maximum height from PCB: 31 mm

● Ferrite: Two symmetrical half cores, PQ40-30

● Material grade: PC44 or equivalent

● Central leg air gap: ~1 mm

● Coil former type: vertical, 6+6 pins

● Pin distance: 5 mm

● Row distance: 45.5 mm

● Cut pins: 9 - 12

● External copper shield: not insulated (for EMI reasons), connected to pin 11 (GND)

Figure 29. Pin side view

27.5 mm

10 mm

BARE COPPER

SHIELD (NOT

INSULATED):

10 mm x 0.05 mm

6

5

3

2

1

57 m

7

8

9

45 mm

1

11

12

Copper shield

soldering line

Tinned copper

wire

Soldering

points

10 1 1 7 8

Manufacturer:

P/N:

Delta electronics

86H-5410B

21/24

Page 22

References AN2755

9 References

1. "L6562A transition-mode PFC controller" datasheet

2. "Design of fixed-off-time-controlled PFC pre-regulators with the L6562", AN1792

3. "EVAL6562-375W demonstration board L6562-based 375W FOT-controlled PFC preregulator" AN1895

4. "L6561, enhanced transition-mode power factor corrector”, AN966

5. “400 W FOT-controlled PFC pre-regulator with the L6563”, AN2485

22/24

Page 23

AN2755 Revision history

10 Revision history

Table 4. Document revision history

Date Revision Changes

30-Jul-2008 1 Initial release

23/24

Page 24

AN2755

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2008 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

24/24

Loading...

Loading...