Page 1

AN2753

Application note

6 W single-output VIPer17 demonstration board

Introduction

The new VIPer17 device integrates in the same package two components: an advanced

PWM controller with built-in BCD6 technology and an 800 V avalanche rugged vertical

power MOSFET. The device is suitable for offline power conversion operating either with

wide range input voltage (85 V

(85 V

265 V

advantage of using few external components compared to a discrete solution, providing

several switch mode power supply protections and very low standby consumption in no-load

condition. The device operates at fixed frequency that can be 115 kHz or 60 kHz.

Frequency jittering is implemented which helps to meet the standards regarding

electromagnetic disturbance. The protections present on the device such as overload and

output overvoltage protections, secondary winding short-circuit protection, hard transformer

saturation and brownout protections improve the reliability and safety of the design.

Moreover internal thermal shutdown and an 800 V avalanche rugged power MOSFET

improve the robustness of the system.

- 132 VAC or 175 VAC - 265 VAC). With European range input voltage (175 VAC -

AC

) the device can handle up to 10 W of output power. The proposed solution has the

AC

- 270 VAC) up to 6 W or with single range input voltage

AC

The VIPer17 demonstration board is a standard single-output isolated flyback converter that

uses all the protections mentioned above. If brownout and overvoltage protection are not

necessary, the number of external components is further reduced.

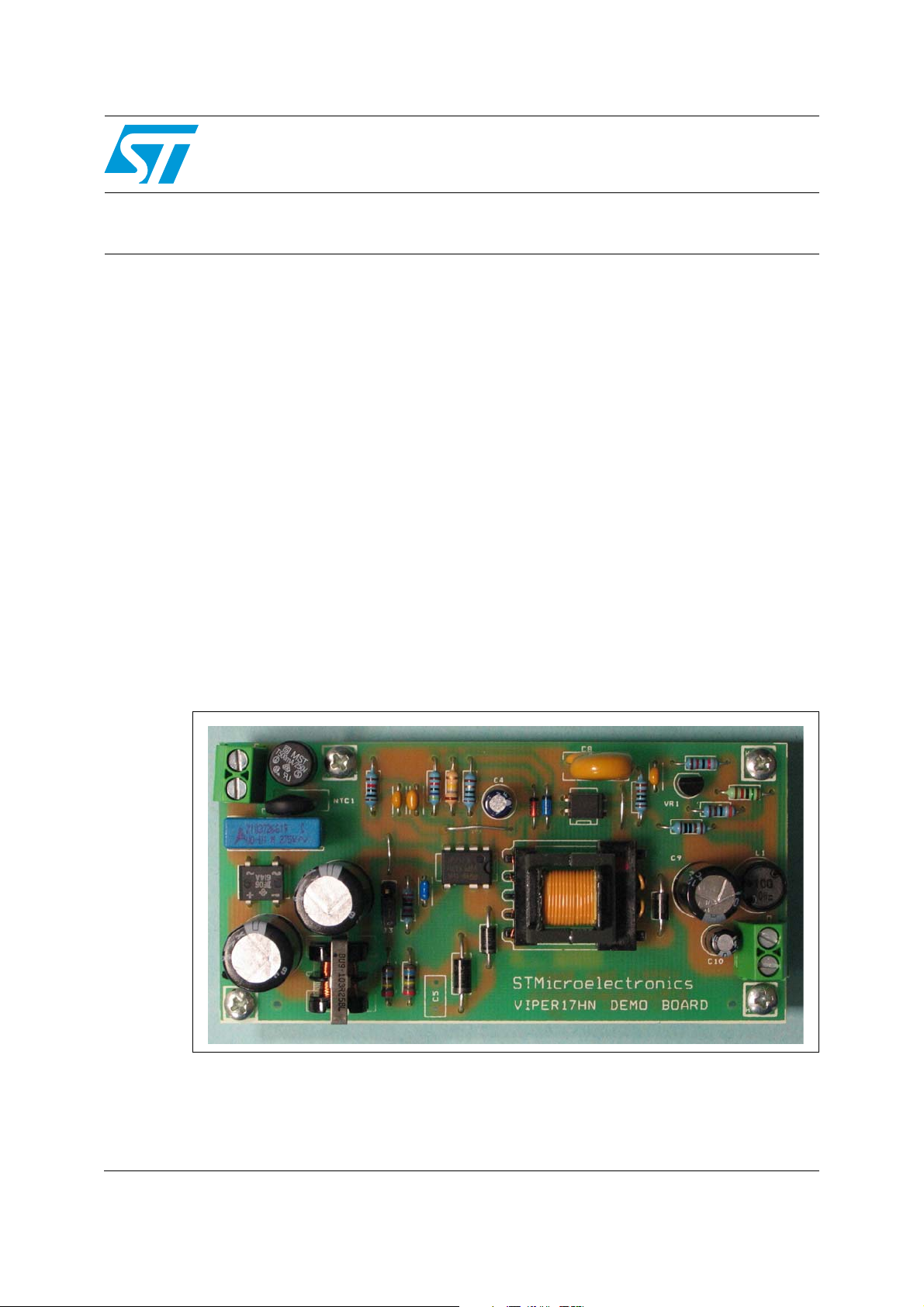

Figure 1. VIPer17HN demonstration board

Note: VIPer17HN is the full order code.

October 2009 Doc ID 14654 Rev 2 1/31

www.st.com

Page 2

Contents AN2753

Contents

1 Board description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Testing the board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Typical board waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Precision of the regulation and output voltage ripple . . . . . . . . . . . . . 11

3.1 Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2 Light-load performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3 Soft-start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4 Overload protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.5 Secondary winding short-circuit protection . . . . . . . . . . . . . . . . . . . . . . . 20

3.6 Output overvoltage protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.7 Brownout protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.8 EMI measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2/31 Doc ID 14654 Rev 2

Page 3

AN2753 List of tables

List of tables

Table 1. Electrical specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 2. Bill of materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 3. Transformer characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 4. Output voltage and V

Table 5. High frequency output voltage ripple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 6. Burst mode related output voltage ripple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 7. Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 8. Active mode efficiencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 9. Line voltage averaged efficiency vs. load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 10. ENERGY STAR

Table 11. No-load input power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 12. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

®

line-load regulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

DD

recommended active mode efficiency vs. Pno [1]. . . . . . . . . . . . . . . . . 17

Doc ID 14654 Rev 2 3/31

Page 4

List of figures AN2753

List of figures

Figure 1. VIPer17HN demonstration board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

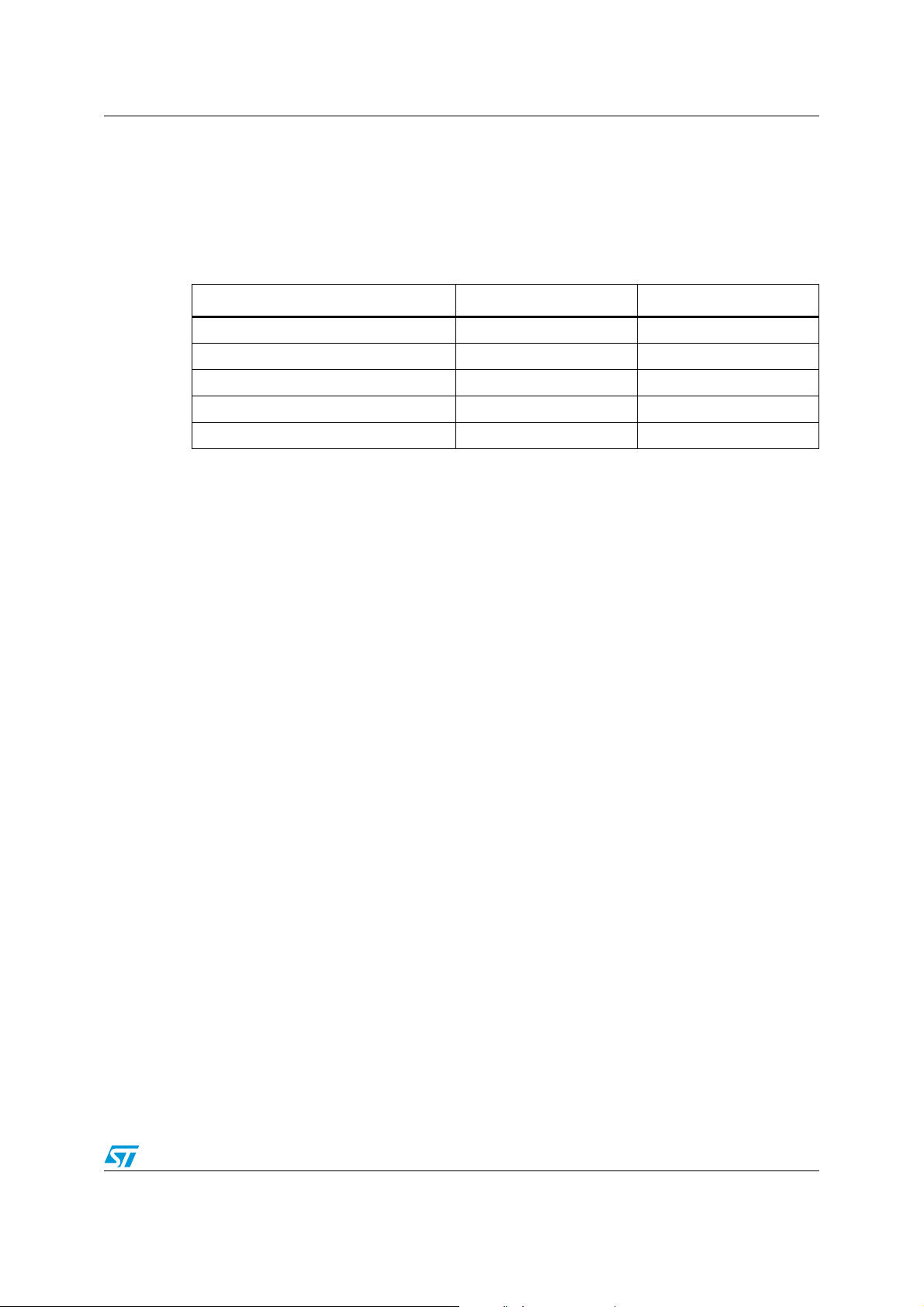

Figure 2. Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. Bottom view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 4. Side view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 5. Pins distances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 6. Electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 7. Drain current and voltage at full load and nominal input voltages (115 V

Figure 8. Drain current and voltage at full load and nominal input voltages (230 V

Figure 9. Drain current and voltage at full load and minimum input voltage (90 V

Figure 10. Drain current and voltage at full load and maximum input voltages (265 V

Figure 11. Frequency jittering (115 VIN_AC, full load) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 12. Output voltage ripple 115 VIN_AC full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 13. Output voltage ripple 115 VIN_AC full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 14. Output voltage ripple 115 VIN_AC no load (burst mode) . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 15. Output voltage ripple 230 VIN_AC no load (burst mode) . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 16. Efficiency vs. V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

IN

Figure 17. Efficiency vs. load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 18. Active mode efficiency vs. V

Figure 19. V

Average efficiency vs. load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

IN

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

IN

Figure 20. Soft-start feature waveforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 21. Output short-circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 22. Operation with output shorted. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 23. 2

nd

OCP protection tripping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 24. Operating with secondary winding shorted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 25. OVP circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 26. OVP protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 27. OVP protection (detail) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 28. Jumper J3 setting for brownout protection - brownout disabled . . . . . . . . . . . . . . . . . . . . . 24

Figure 29. Jumper J3 setting for brownout protection - brownout enabled . . . . . . . . . . . . . . . . . . . . . 24

Figure 30. Brownout protection block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 31. Brownout protection tripping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 32. Operating with brownout protection activated. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 33. Restart after brownout protection activated (detail) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 34. Restart after brownout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 35. 115 V

Figure 36. 230 V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

AC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

AC

) . . . . . . . . . . . . 9

AC

) . . . . . . . . . . . . 9

AC

) . . . . . . . . . . . . 9

AC

). . . . . . . . . . . 9

AC

4/31 Doc ID 14654 Rev 2

Page 5

AN2753 Board description

1 Board description

The electrical specifications of the VIPer17 demonstration board are listed in the table

below.

Table 1. Electrical specification

Parameter Symbol Value

Input voltage range V

Output voltage V

Max output current I

Precision of output regulation Δ

High frequency output voltage ripple Δ

IN

OUT

OUT

VOUT_LF

VOUT_ HF

90 V

; 265 V

RMS

12 V

500 mA

±5%

50 mV

RMS

The schematics and bill of material of the board are shown in Figure 2 and Tab le 2

respectively and the transformer description is given in Tab le 3 .

In order to minimize magnetic component size, the higher operating frequency device

(VIPer17) in the DIP7 package was selected. The average switching frequency (f

SW_avg

) is

115 kHz (typ.). The switching frequency is modulated by a triangular waveform at 250 Hz

between and where Δf

(frequency jittering) spreads the spectrum of the electromagnetic interference generated by

f

SWavg

-

fmΔ=

is 8 kHz (typ.). This frequency modulation

m

the switching of the MOSFET, reducing its maximum value and facilitating compliance with

EMI standards.

In order to obtain good precision in the output regulation, a secondary regulation scheme

was used, monitoring directly the output voltage.

Thanks to the adjustable primary current limitation it is possible to fix the maximum power

that the converter can deliver to the output. The overload protection offers a good degree of

safety under output short-circuit or overload condition. As the protection is tripped the

system operates in hiccup mode reducing the power throughput to a few hundreds of

milliwatts. A second level of current limitation that latches the device if exceeded ensures

safety also in case of output diode failure (short) or secondary winding short-circuit. Output

overvoltage protection and brownout protection are also implemented. By simply changing

the position of a jumper in the board it is possible to disable the brownout protection if it is

not necessary in the specific application.

Doc ID 14654 Rev 2 5/31

Page 6

Board description AN2753

Figure 2. Schematic

1

2

J2

12V 500mA

CON2

R8

15k 1%

R9

3.9k 1%

C10

R6

L1 10uH

ZLG 47uF 25V

R13

1k

C9

1k

12

R10

C11

82k

33nF

3

VR1

TL431

2 1

43

OPTO1

PC817

81

7

DRAIN

VIPER17HN

VDD

BROWN OUT

5

U1

2

13

J3

JUMPER

F1

500mA F U SE

C7

SOURCE

FB

4 2

CONTROL

33nF

R12

10k

C6

3.3nF

CONT

3

R3

R5

47k

22k

2

1

J1 CON2

C4

C12

10nF

22uF 25V

7

4 691

ZL 470uF 25V

8

C8 Y1 1.8nF

TRANSFORMER

2

D4

STPS2H100

T1

5

D3

STTH1L06

D5

P6KE250

D1

BAT46

R1

10

C5

N.M

R14

D2

1N4148

C3

10uF 450V

4

T2

C2

2

1 3

10uF 450V

2

-+

3

BR1

1

R4

1600k

4

C1 X2

180k

R2

1600k

NTC1

10 Ohm NTC

12

t

6/31 Doc ID 14654 Rev 2

Page 7

AN2753 Board description

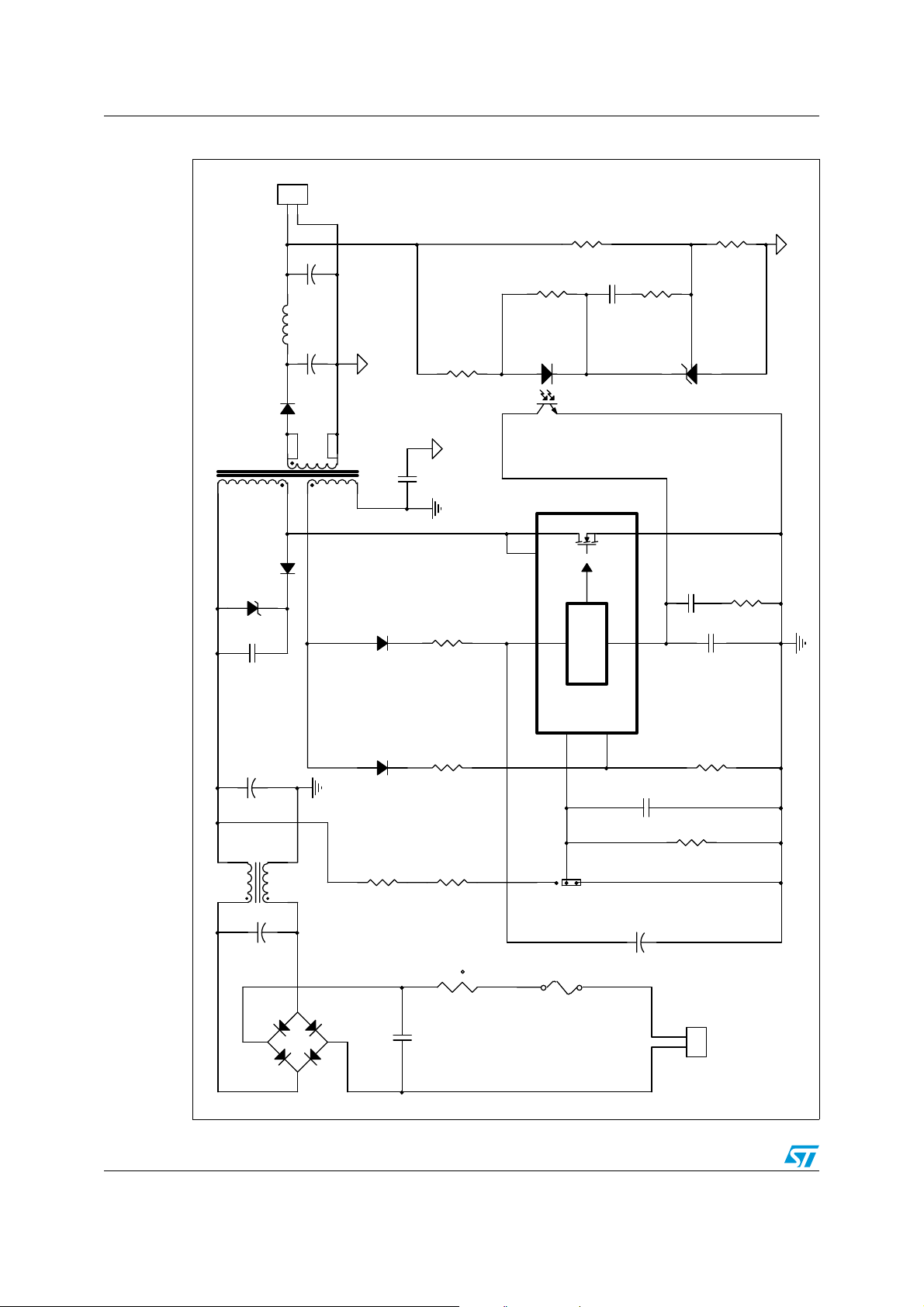

Table 2. Bill of materials

Item Quantity Reference Part

11BR1 Bridge

2 1 C1 EPCOS X2 100 nF MKP B32922

3 2 C2,C3 Rubycon YXA 10 µF 450 V

4 1 C4 22 µF 25 V

5 1 C5 47 pF 630 V (not mounted)

6 1 C6 3.3 nF

7 2 C7,C11 33 nF

8 1 C8 Y1 1.8 nF

9 1 C9 Rubycon ZL 470 µF 25 V

10 1 C10 Rubycon ZLG 47 µF 25V

11 1 C12 10 nF

12 1 D1 BAT46

13 1 D2 1N4148

14 1 D3 STTH1L06

15 1 D4 STPS2H100

16 1 D5 P6KE250

17 1 F1 500 mA fuse

20 1 L1 10 µH

21 1 NTC1 EPCOS B57153S0100M 10 Ω NTC

22 1 OPTO1 PC817

23 1 R1 10

24 2 R2,R4 1500 kΩ

25 1 R3 47 kΩ

26 1 R5 18 kΩ

27 2 R6,R13 1 kΩ

28 1 R8 15 kΩ 1%

29 1 R9 3.9 kΩ 1%

30 1 R10 82 kΩ

31 1 R12 10 kΩ

32 1 R14 180 kΩ

33 1 T1 Transformer

34 1 T2 Coilcraft BU9-10325BL

35 1 U1 VIPer17

36 1 VR1 TL431

Doc ID 14654 Rev 2 7/31

Page 8

Board description AN2753

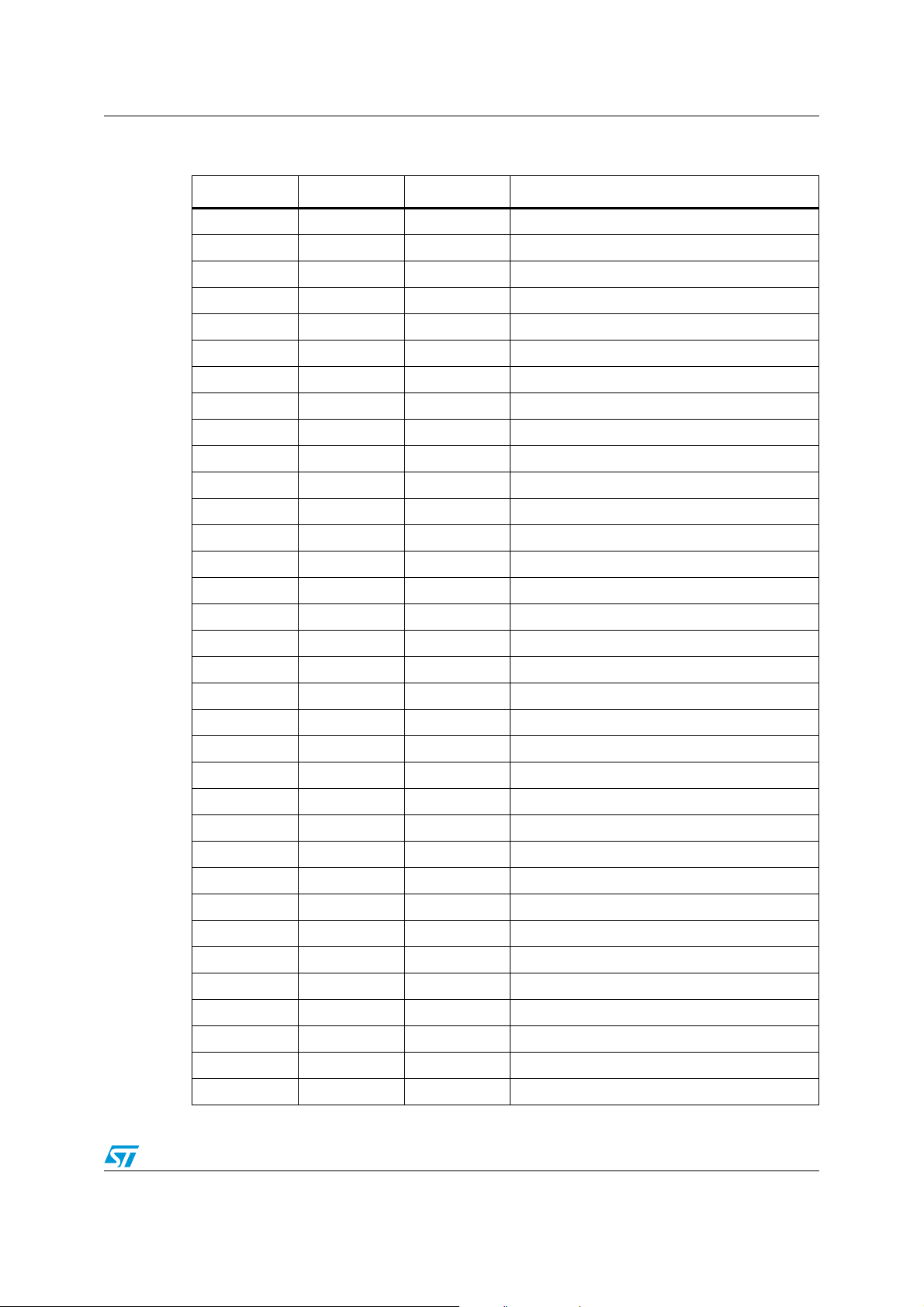

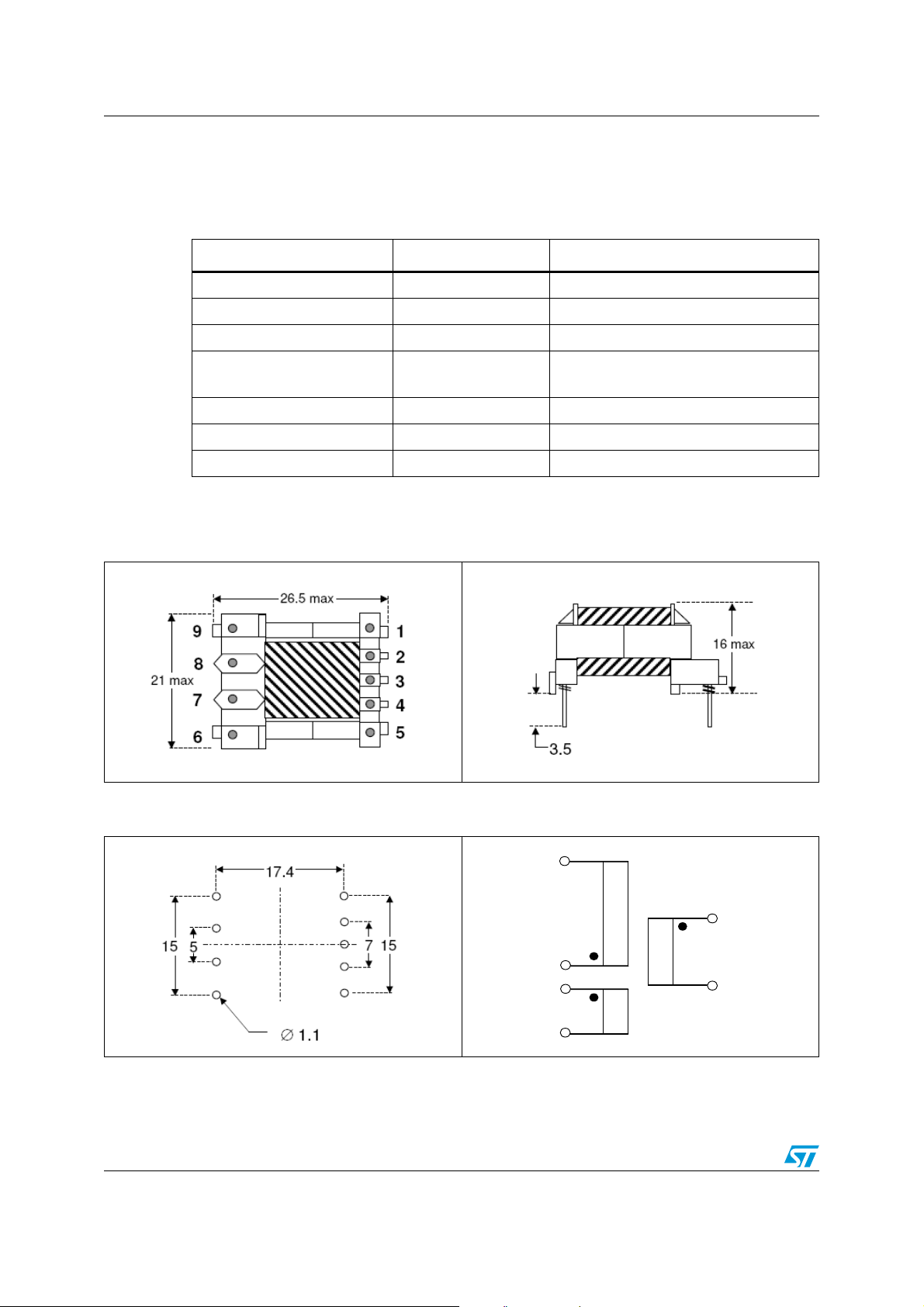

1.1 Transformer

Transformer characteristics are listed in the table below.

Table 3. Transformer characteristics

Item name Value Measure condition

Manufacturer Magnetica

Part number 1335.0034 Rev01

Primary inductance 1.2 mH +/- 15% Fr = 1 kHz, Ta = 20 °C

Leakage primary inductance 3.2% of primary

Primary to secondary turn ratio 7.85 ± 5% Fr = 10 kHz Ta = 20 °C

Primary to auxiliary turn ratio 7.85 ± 5% Fr = 10 kHz Ta = 20 °C

Insulation 4 kV Primary to secondary

Figure 3, 4, 5, 6 show size (mm), pin connection and pins distances (mm) of the transformer.

Pins 1 & 2 shorted, pins 7 & 8 shorted

Fr=10 kHz, Ta = 20 °C

Figure 3. Bottom view Figure 4. Side view

Figure 5. Pins distances Figure 6. Electrical diagram

5

A

C

4

1

2

B

7

8

8/31 Doc ID 14654 Rev 2

Page 9

AN2753 Testing the board

2 Testing the board

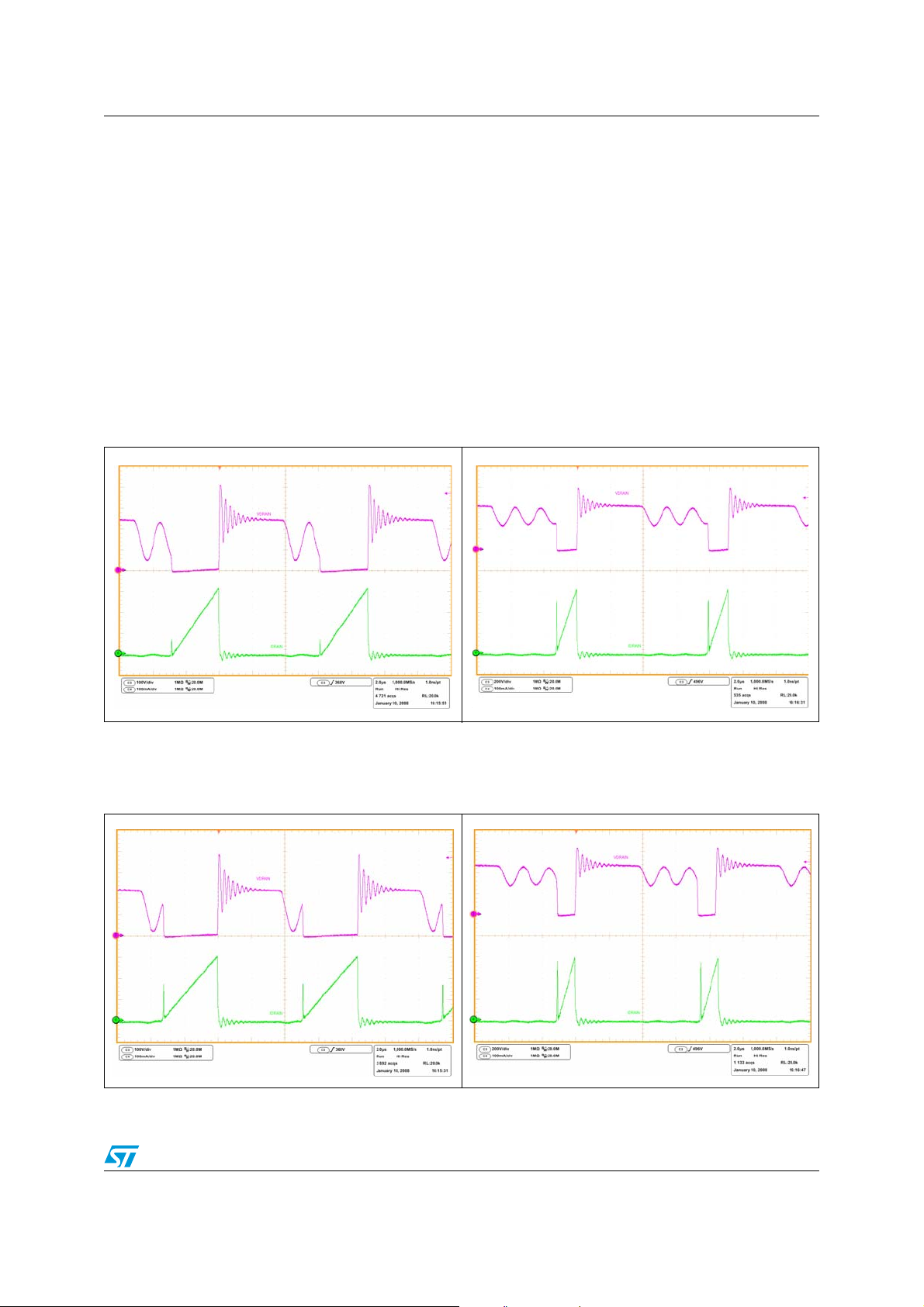

2.1 Typical board waveforms

The board operates with wide range input voltages and the relevant waveforms are shown

with the minimum, maximum and nominal input voltages.

Figure 7 and Figure 8 show the drain current and the drain voltage waveforms at the

nominal input voltages, that are 115 V

(500 mA). Figure 9 and Figure 10 show the same waveforms for the same load condition,

but the input voltages are the minimum (90 V

and 230 VAC when the load is the maximum

AC

) and the maximum (265 VAC).

AC

Figure 7. Drain current and voltage at full

load and nominal input voltages

(115 V

AC

)

Figure 9. Drain current and voltage at full

load and minimum input voltage

(90 V

AC

)

Figure 8. Drain current and voltage at full

load and nominal input voltages

(230 VAC)

Figure 10. Drain current and voltage at full

load and maximum input voltages

(265 VAC)

Doc ID 14654 Rev 2 9/31

Page 10

Testing the board AN2753

Figure 11 shows the drain current and the voltage on the feedback pin in a time interval of

about 10 ms. The system is working with a constant load but the voltage on the feedback

pin is a triangular wave shape as well as the peak drain current. These changes are the

result of the frequency jittering.

In a fixed frequency flyback converter, operating in discontinuous conduction mode, the

output power is proportional to the switching frequency according to the following formula:

Equation 1

P

OUT

1

-- -

2

2

L

I

fSWη⋅⋅ ⋅ ⋅=

PK

P

where L

is the transformer primary inductance, IPK is the drain peak current and η is the

P

converter's efficiency. The VIPer17 internal oscillator gives a switching frequency modulated

by a triangular waveform of 250 Hz (typ.). The power demand of the load is constant, but,

due to the variable switching frequency, the power delivered is not constant if I

is constant.

PK

The control loop reacts to the unsteady switching frequency, modulating the feedback pin

voltage and then, the drain peak current.

Figure 11. Frequency jittering (115 V

IN_AC

, full load)

CH2: VFB 200 mV/Div (Light blue)

CH4: I

50 mA/Div (Green)

DRAIN

Time: 1 ms/Div

10/31 Doc ID 14654 Rev 2

Page 11

AN2753 Precision of the regulation and output voltage ripple

3 Precision of the regulation and output voltage ripple

The output voltage of the board was measured in different line and load conditions. The

results are given in Ta bl e 3 . The output voltage variation range is a few mV for all tested

conditions. The V

of the device.

voltage was also measured to verify that it is inside the operating range

DD

Table 4. Output voltage and V

line-load regulation

DD

No load Half load Full load

V

(V)

INAC

V

(V) VDD (v) V

OUT

(V) VDD (V) V

OUT

(V) VDD (V)

OUT

90 12.068 10.67 12.066 19.35 12.064 21.16

115 12.068 10.60 12.066 19.33 12.064 21.23

230 12.068 10.29 12.066 19.36 12.064 21.24

265 12.068 10.21 12.066 19.28 12.064 21.22

The ripple at the switching frequency superimposed at the output voltage was also

measured. The board is provided with an LC filter to better filter the voltage ripple. The high

frequency voltage ripple across capacitor C9 (V

OUT_FLY

), that is the output capacitor of the

flyback converter before the LC filter, was also measured to verify the effectiveness of the

LC filter and for completeness of results.

Table 5. High frequency output voltage ripple

No load Half load Full load

V

(V)

INAC

90 20 150 24 508 30 520

115 22 164 24 504 40 520

230 22 200 24 512 30 524

265 26 212 24 508 32 536

V

OUT

(V) V

OUT_FLY

(V) V

OUT

(V) V

OUT_FLY

(V) V

OUT

(V) V

OUT_FLY

(V)

Waveforms of the two voltages (V

Doc ID 14654 Rev 2 11/31

OUT

and V

OUT_FLY

) are reported in Figure 12 and 13.

Page 12

Precision of the regulation and output voltage ripple AN2753

Figure 12. Output voltage ripple 115 V

CH1: V

CH2: V

(Yellow)

OUT

OUT_FLY

(Light blue)

Figure 13. Output voltage ripple 115 V

IN_AC

IN_AC

full load

full load

In the V

OUT_FLY

CH1: V

CH2: V

(CH1) waveform shown in the previous figures we see a high frequency

(Yellow)

OUT

OUT_FLY

(Light blue)

oscillation. This oscillation is due to a parasitic inductance (ESL) present in series with the

flyback output capacitor. This parasitic inductance is partially the parasitic inductance of the

capacitor itself and partially is due to the printed circuit wires.

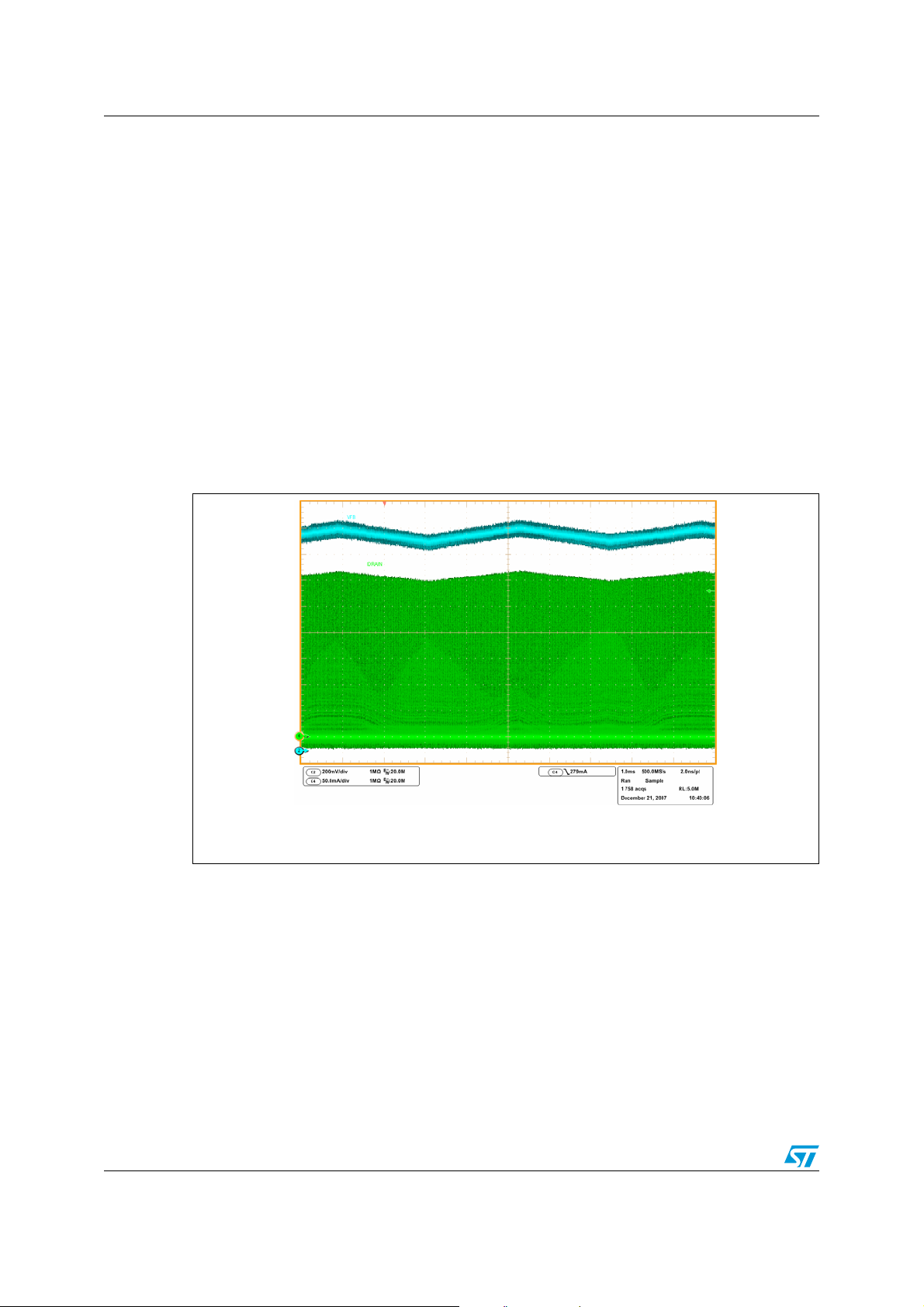

A lower frequency ripple is present when the device is working in burst mode. In this mode

of operation the converter does not supply continuous power to its output. It alternates a

period when the power MOSFET is kept off and no power is processed by the converter and

a period when the power MOSFET is switching and power flows towards the converter

output. Even if no load is present at the output of the converter, during non-switching periods

the output capacitors are discharged by their leakage currents and by the currents needed

to supply the part of the feedback loop present at the secondary side. During the switching

period the output capacitance is recharged. Figure 14 and 15 indicate the output voltage

12/31 Doc ID 14654 Rev 2

Page 13

AN2753 Precision of the regulation and output voltage ripple

and the feedback voltage when the converter is not loaded. In Figure 14 the converter is

supplied with 115 V

and with 230 VAC in Figure 15.

AC

Figure 14. Output voltage ripple 115 V

CH1: V

CH2: V

(Yellow)

OUT

(Light blue)

FB

Figure 15. Output voltage ripple 230 V

no load (burst mode)

IN_AC

no load (burst mode)

IN_AC

CH1: V

CH2: V

(Yellow)

OUT

OUT_FLY

(Light blue)

Ta bl e 6 shows the measured value of the burst mode frequency ripple measured at different

operating conditions. The measured ripple in burst mode operation is very low and always

below 25 mV.

Doc ID 14654 Rev 2 13/31

Page 14

Precision of the regulation and output voltage ripple AN2753

Table 6. Burst mode related output voltage ripple

V

IN

90 6.02 8.96 10.6

115 6.63 9.68 10.4

230 7.58 11.0 13.3

265 7.35 11.8 13.6

3.1 Efficiency

The converter's efficiency is measured under different loads and input voltage operating

conditions. This efficiency was measured at full load and with 75%, 50%, and 25% with

respect to the full load condition for different input voltages applied. The results are given in

Ta bl e 7 .

Table 7. Efficiency

V

(VRMS)

INAC

90 76.92 79.62 80.76 80.32

110 79.33 80.89 81.19 79.48

115 79.75 81.03 81.19 79.48

120 80.17 81.03 81.19 79.48

No load (mV) 10 mA load (mV) 25 mA load (mV)

Efficiency (%)

Full load (0.5 A) 75% load (0.375 A) 50% load (250 mA) 25% load (125 mA)

132 80.70 81.18 80.98 78.66

175 80.91 80.60 79.71 75.17

220 79.64 79.48 77.28 71.98

230 79.33 78.93 76.50 71.31

240 79.02 78.39 74.99 70.65

265 78.11 77.33 72.93 69.05

These results were plotted in the following diagrams. In Figure 16 the efficiency versus V

IN

for four different load values was plotted. In Figure 17 the value of the efficiency versus load

for four different input voltages was plotted.

14/31 Doc ID 14654 Rev 2

Page 15

AN2753 Precision of the regulation and output voltage ripple

Figure 16. Efficiency vs. V

IN

Figure 17. Efficiency vs. load

The converter's active mode efficiency is defined as the average of the efficiencies

measured in different load conditions. These different load conditions are the 25%, 50% and

75% of maximum load and the maximum load itself. Ta b le 8 gives the active mode efficiency

calculated from the measured value in Tab le 7 . For clarity the values in Tab le 8 are plotted in

Figure 18. In Figure 19 the averaged (average was done considering the efficiency at

different input voltages) values of the efficiency versus load are shown.

Table 8. Active mode efficiencies

Active mode efficiency

V

INAC

90 79.41

110 80.22

115 80.36

120 80.47

132 80.38

Doc ID 14654 Rev 2 15/31

Efficiency

Page 16

Precision of the regulation and output voltage ripple AN2753

Table 8. Active mode efficiencies (continued)

Active mode efficiency

V

INAC

175 79.10

220 77.10

230 76.52

240 75.76

265 74.35

Figure 18. Active mode efficiency vs. V

Efficiency

IN

Table 9. Line voltage averaged efficiency vs. load

Load (% of full load) Efficiency

100 79.39

75 79.85

50 78.67

25 75.56

16/31 Doc ID 14654 Rev 2

Page 17

AN2753 Precision of the regulation and output voltage ripple

Figure 19. VIN Average efficiency vs. load

®

In order to be compliant with ENERGY STAR

recommendations regarding the efficiency in

active mode (recommendation is given in table below) the active mode efficiency has to be

higher than 65.13% (use Equation 1 considering 6 W as nameplate output power) at the

nominal input voltages (115 V

and 230 VAC in our case).

AC

Table 10. ENERGY STAR

Nameplate output power (Pno)

0 to ≤ 1 W ≥

> 1 to ≤ 49 W ≥ [0.09 * In (Pno)] + 0.49

> 49 W ≥ 0.84

®

recommended active mode efficiency vs. Pno [1]

For all the considered input voltages the efficiencyresults (see Tab l e 8 ) are higher than the

recommended value.

3.2 Light-load performance

The majority of consumer electronic manufacturers want to be compliant with the standby

mode recommendations and the device helps to achieve compliance. If the feedback pin

voltage falls below 450 mV (typ.), the MOSFET is kept off and it restarts switching when the

feedback pin voltage value exceeds 500 mV (typ.). The resulting behavior is an intermittent

working (burst mode) of the device. When the MOSFET is switching, the power delivered is

higher than necessary but it compensates the missing power during the periods where the

MOSFET is not switching. Thanks to this burst mode operation, the average switching

frequency is strongly reduced and consequently the switching losses, which are the majority

of the losses when the system is not loaded or very lightly loaded, are minimized and the

very low power consumption of the VIPer17 itself further reduces the average power that the

system has to process. The input power of the converter was measured in no-load condition

for different inputs.

Minimum average efficiency in active mode

(expressed as a decimal)

0.49 * Pno

Doc ID 14654 Rev 2 17/31

Page 18

Precision of the regulation and output voltage ripple AN2753

Table 11. No-load input power

Vin AC (VRMS) Pin (mW)

90 53

115 57

230 88

265 100

3.3 Soft-start

When the converter starts to operate, the output capacitor is totally discharged and it needs

some time to reach the nominal output power as well as the steady state condition. During

this time the power demand from the control loop is the maximum while the reflected voltage

is low. These two conditions could lead to a deep continuous operating mode of the

converter. When the MOSFET is switched on, it cannot be switched off immediately as the

minimum on time (t

because of the deep continuous working mode of the converter, during this minimum t

excess of drain current is possible which can overstress the component of the converter as

well as the device itself, the output diode, and the transformer. Transformer saturation is

also possible under these conditions.

) has to be elapsed. Even if VIPer17 has a very low minimum ton,

on

on

, an

To avoid all the described negative effects possible during the startup phase VIPer17 has on

board a soft-start feature. As the device starts to work, even if the control loop asks for the

maximum power (maximum drain current), the drain current is allowed to increase from zero

to the maximum value gradually.

The drain current limit is incremented in steps, and the values range from 0 to the fixed drain

current limitation value (value that can be adjusted through an external resistor) which is

divided in 16 steps. Each step length is 64 switching cycles. The total length of the soft-start

phase is about 8.5 ms. Figure 20 shows the soft-start phase of the presented converter

when it is operating at minimum line voltage and maximum load.

Figure 20. Soft-start feature waveforms

CH1: V

CH2: V

CH4: I

OUT

FB

DRAIN

Working conditions:

= 90V

V

IN

I

LOAD

AC

: 500 mA

18/31 Doc ID 14654 Rev 2

Page 19

AN2753 Precision of the regulation and output voltage ripple

3.4 Overload protection

If the load power demand increases, the output voltage decreases and consequently the

feedback loop reacts, increasing the voltage on the feedback pin.

The feedback pin voltage increase leads to the PWM current set point increase, with the rise

of the power delivered to the output. This process ends when the delivered power equals the

load power request.

If the load power demand exceeds the converter power capability (that can be adjusted

using R

limited to the fixed current limitation value.

), the voltage on the feedback pin continuously rises, but the drain current is

LIM

When the feedback pin voltage exceeds V

(3.3 V typ), VIPer17 assumes it to be a

FB_lin

warning status of an output overload condition. Before stopping the system, the device waits

for a time fixed by the capacitor present on the feedback pin. When the voltage on the

feedback pin exceeds V

, an internal pull-up circuit is disconnected and the pin starts

FB_lin

sourcing a 3 µA current that charges the capacitor connected to the feedback pin itself. As

the feedback pin's voltage reaches the V

stops switching and is not allowed to switch again until the V

V

DD_RESTART

(4.5 V typ.).

threshold (4.8 V typ.), the power MOSFET

FB_olp

voltage falls below

DD

The following waveform shows the behavior of the converter when the output is shorted.

Figure 21. Output short-circuit

Output shorted here

Normal operation

Over Load Delay

Stop switching

If the short-circuit is not removed, the system starts to work in auto-restart mode. The

behavior when a short-circuit is permanently applied on the output is a short period of time

where the MOSFET is switching and the converter tries to deliver to the output as much

power as it can, and a longer period where the device is not switching and no power is

processed.

If the duty cycle of power delivery is very low (around 2%), then the average power

throughput is also very low.

Doc ID 14654 Rev 2 19/31

Page 20

Precision of the regulation and output voltage ripple AN2753

Figure 22. Operation with output shorted

~ 30ms

~ 1.5s

3.5 Secondary winding short-circuit protection

The VIPer17 is provided with a first adjustable level of primary overcurrent limitation that

switches off the power MOSFET if this level is exceeded. This limitation acts cycle by cycle

and its main purpose is to limit the maximum deliverable output power. A second level of

primary overcurrent protection is also present and in this case it is fixed to 600 mA (typical

value). If the drain current exceeds this 2

nd

OCP (second overcurrent protection) threshold,

the device enters a warning state. If in the following cycle the drain current goes higher than

the second level of overcurrent protection, a secondary winding short-circuit or a hard

saturation of the transformer is assumed and the power MOSFET is no longer allowed to be

switched on. In order to enable the power MOSFET to be switched on again, the V

voltage has to be recycled which means that V

rise up to V

. When the VIPer17 is switched on again (VDD equals V

DD_ON

has to go down up to V

DD

DD_RESTART

DD_ON

DD

), the

, then

MOSFET can restart to switch. If the cause of the primary overcurrent is permanently

present, the device goes in auto-restart mode.

This protection was tested on the VIPer17 board. The secondary winding of the transformer

was shorted in different operating conditions. The following Figure 23 and 24 show the

behavior of the system during these tests.

20/31 Doc ID 14654 Rev 2

Page 21

AN2753 Precision of the regulation and output voltage ripple

Figure 23. 2nd OCP protection tripping

CH2: V

CH3: V

CH4: I

(Light blue)

FB

DRAIN

DRAIN

(Purple)

(Green)

Test condition:

V

= 11 V

IN

AC

Full load before short

In Figure 23 when the board is working in full load condition with an input voltage of 115 V

the secondary winding has been shorted. The short condition on the secondary winding

leads to high drain current. After two switching cycles, the system stops and continuous

running with high currents in the primary as well as in the secondary windings are avoided

Figure 24. Operating with secondary winding shorted

CH1: V

CH2: V

CH4: I

(Yellow)

DD

(Light blue)

FB

DRAIN

(Green)

AC

3.6 Output overvoltage protection

Monitoring the voltage across the auxiliary winding during the MOSFET off time, through the

D2 diode and the resistor divider R3 and R14 (see Figure 2) connected to the CONT pin of

the VIPer17, allows the implementation of the output overvoltage protection. If the voltage

on CONT pin exceeds the V

thresholds (3 V typ.) an overvoltage event is assumed and

OVP

Doc ID 14654 Rev 2 21/31

Test condition

=115

V

IN

Secondary winding

shorted

Page 22

Precision of the regulation and output voltage ripple AN2753

the device is no longer allowed to switch. To re-enable operation the VDD voltage has to be

recycled. In order to provide high noise immunity and to avoid that the spikes erroneously

trip the protection, a digital filter was implemented. The CONT pin has to sense a voltage

higher of V

for four consecutive cycles in a row before it stops operation.

OVP

Figure 25. OVP circuit

OCP

Daux

Auxiliary

winding

Rovp

CONT

Rlim

SOFT

START

OVP DETECTION

LOGIC

To OVP Protec t i on

Curr. Lim.

BLOCK

From Sens eF ET

Curr ent Lim i t C om p arator

+

To P WM Log ic

The value of the output voltage when the protection has to be tripped can be fixed by

properly selecting the resistor divider R2 and R14. With R2 selected and considering the

maximum power that the converter has to manage, output R14 has to be selected according

to the following formula.

Equation 2

R

OVP R14()

-

R

LIM R2()

-

-----------------------

3V

N

AUX

⎛⎞

--------------

⋅=

⎝⎠

V

N

OUTOVPVdropDovp D2()

S

– 3V–⋅

-

-

-

The protection has to be tested by disconnecting the opto-coupler from the feedback pin and

supplying the converter with a minimum load at its output. In this way the converter operates

in open loop condition and delivers the maximum power it can to output . The excess of

power with respect to the load charges the output capacitance, increasing the output voltage

until the OVP is tripped and the converter stops working.

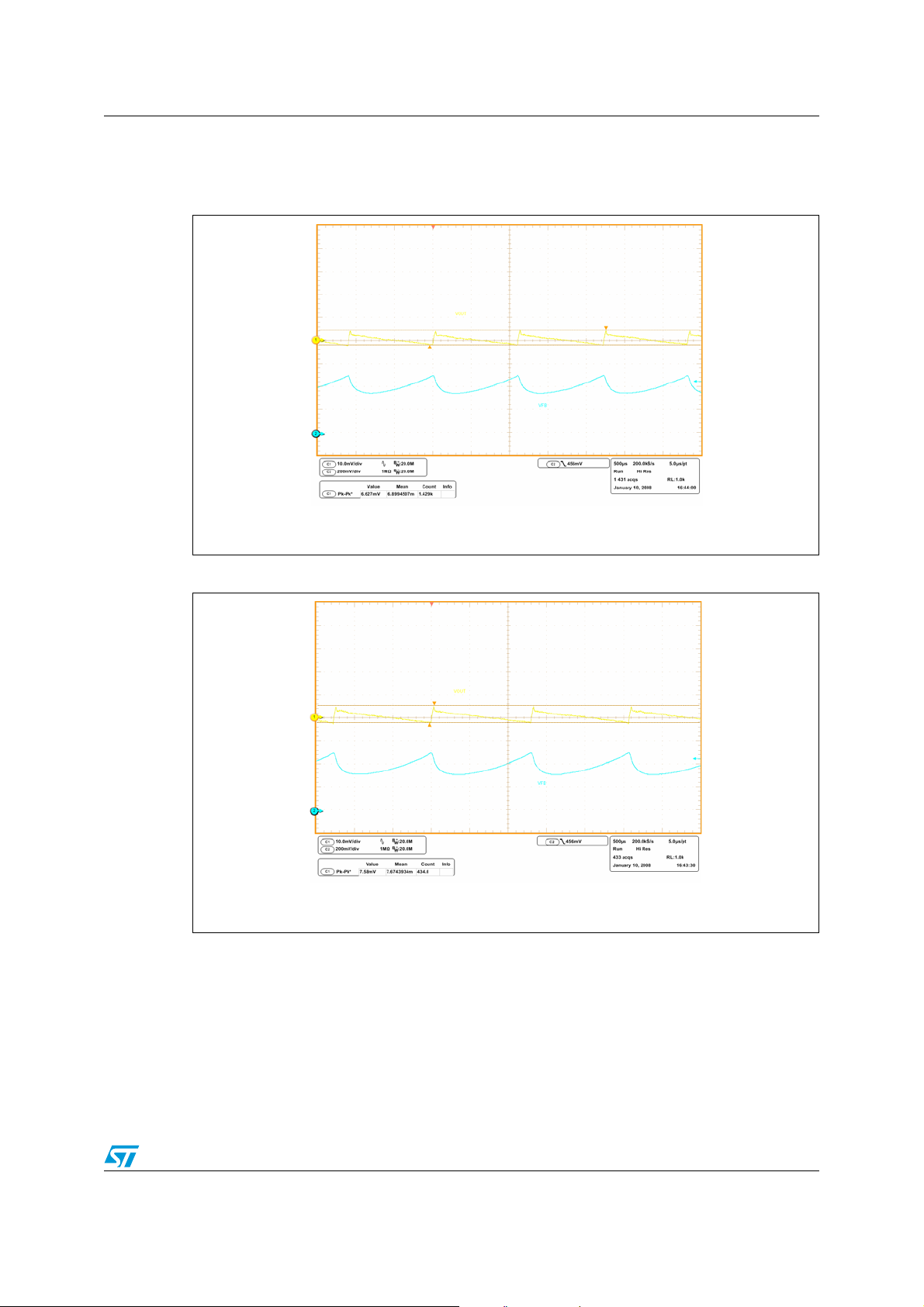

In Figure 26 the output voltage increases as a consequence of the excess of power and the

output voltage reaches the value of 16 V when the power MOSFET stops switching. In

Figure 27 the CONT pin voltage, the drain current, and the output voltage are shown in

detail from when the converter is supplied up to when the overvoltage protection is tripped.

The crest value of the CONT pin voltage tracks the output voltage. Figure 27 shows the

detail of the last switching cycles before the protection is tripped.

If this protection is not desired, it is possible to not implement it. Not mounting diode D2 and

resistor R14 (see Figure 2) reduces the number of components.

22/31 Doc ID 14654 Rev 2

Page 23

AN2753 Precision of the regulation and output voltage ripple

Figure 26. OVP protection Figure 27. OVP protection (detail)

3.7 Brownout protection

The brownout protection is basically an unlatched device shutdown functionality whose

typical use is to sense a mains undervoltage. The VIPer17 has a pin (BR, pin 5) dedicated to

this function that must be connected to the DC HV bus. If the protection is not required, it

can be disabled by connecting the pin to ground. In the presented converter the brownout

protection is implemented but can be disabled by changing the jumper J3 (see Figure 2)

settings. The settings of the jumper J3 are shown in Figure 28 and 29. The converter's

shutdown is accomplished by means of an internal comparator internally referenced to 450

mV (typ, VBRth) that disables the PWM if the voltage applied at BR pin is below the internal

reference, as shown in Figure 30. PWM operation is re-enabled as the BR pin voltage is

more than 450 mV plus 50 mV of voltage hysteresis that ensures noise immunity. The

brownout comparator is also provided with current hysteresis. An internal 10 µA current

generator is ON as long as the voltage applied at the brownout pin is below 450 mV and is

OFF if the voltage exceeds 450 mv plus the voltage hysteresis.

Doc ID 14654 Rev 2 23/31

Page 24

Precision of the regulation and output voltage ripple AN2753

Figure 28. Jumper J3 setting for brownout

protection - brownout disabled

When the brownout protection is enabled, through a partition divider R4, R2 (RH in the block

diagram of Figure 30) and R5 (R

in Figure 30) in the schematic of Figure 2, the flyback

L

input voltage is sensed and feeds to the brownout pin.

The converter shutdown can be accomplished by means of an internal comparator internally

referenced to 450 mV (typ, V

) that disables the PWM if the voltage applied at its

BRth

externally available (non-inverting) input is below the internal reference, as shown in

Figure 30. PWM operation is re-enabled as the voltage at the non-inverting input is more

than 450 mV plus 50 mv of voltage hysteresis that ensure noise immunity. The brownout

comparator is also provided with current hysteresis. An internal 10 µA current generator is

ON as long as the voltage applied at the non-inverting input is below 450 mV and is OFF if

the voltage exceeds 450 mv plus the voltage hysteresis.

Figure 29. Jumper J3 setting for brownout

protection - brownout enabled

Figure 30. Brownout protection block diagram

HV Input bus

Rh

BR

Rl

0.1V

0.45V

15u

The current hysteresis provides an additional degree of freedom. It is possible to set the ON

threshold and the OFF threshold for the flyback input voltage separately by properly

24/31 Doc ID 14654 Rev 2

V

Vcc

+

-

+

DD

AC_OK D isable

VinOK

Page 25

AN2753 Precision of the regulation and output voltage ripple

choosing the resistors of the external divider. The following relationships can be established

for the ON (V

IN_ON

) and OFF (V

) thresholds of the input voltage:

IN_OFF

Equation 3

RHRL+

⎛⎞

-------------------- -

V

INOFFVBR

-

⋅=

⎝⎠

R

L

Equation 4

+

R

HRL

⎛⎞

where: I

and V

BR

V

INON

-

=10 µA (typ.) is the current hysteresis, Vh=50 mV (typ.) is the voltage hysteresis

h

V

+()

BRVh

-------------------- -

⎝⎠

R

=450 mV (typ.) is the brownout comparator internal reference.

R

⋅+⋅=

L

HIH

The following figures show how the brownout protection works in the VIPer17 board when

used. Figure 31 shows the behavior of the board when the input voltage is changed from 90

V

to 75 VAC with full load applied. The system stops switching and the output load, no

AC

longer supplied, decays monotonically to zero.

Figure 31. Brownout protection tripping

Figure 32 shows in the same situation the behavior of the voltage on the V

VIPer17. After the device stops switching, the V

decays to the V

DD

DD_RESTART

pin of the

DD

value

(4.5 V typ.), then the internal high voltage startup current source starts to charge the

capacitor connected at that pin (C4 in the schematic) with a constant current. When the V

voltage reaches the V

threshold, the VIPer17 is on, but it is not allowed to switch as

DD_ON

the input voltage is below the correct value.

Doc ID 14654 Rev 2 25/31

DD

Page 26

Precision of the regulation and output voltage ripple AN2753

Figure 32. Operating with brownout protection activated

Figure 33. Restart after brownout protection activated (detail)

Figure 34. Restart after brownout

26/31 Doc ID 14654 Rev 2

Page 27

AN2753 Precision of the regulation and output voltage ripple

3.8 EMI measurements

A pre-compliant test to EN55022 (Class B) European normative was also performed and the

results are shown in the two figures below.

Figure 35. 115 V

Figure 36. 230 V

AC

AC

Doc ID 14654 Rev 2 27/31

Page 28

Conclusion AN2753

4 Conclusion

A general-purpose single-output flyback converter demonstration board using the new

VIPer17 device was presented and the results show that very good efficiency can be

obtained using this new device. The various protections that this new device has on board

and the 800 V power section allow improving safety of the converter. Power consumption of

the converter in no-load condition is very low and good efficiency is obtained even in lightload condition.

28/31 Doc ID 14654 Rev 2

Page 29

AN2753 References

5 References

1. ENERGY STAR® program requirements for single voltage external AC-DC adapter

(Version 1.1)

2. VIPer17 datasheets.

Doc ID 14654 Rev 2 29/31

Page 30

Revision history AN2753

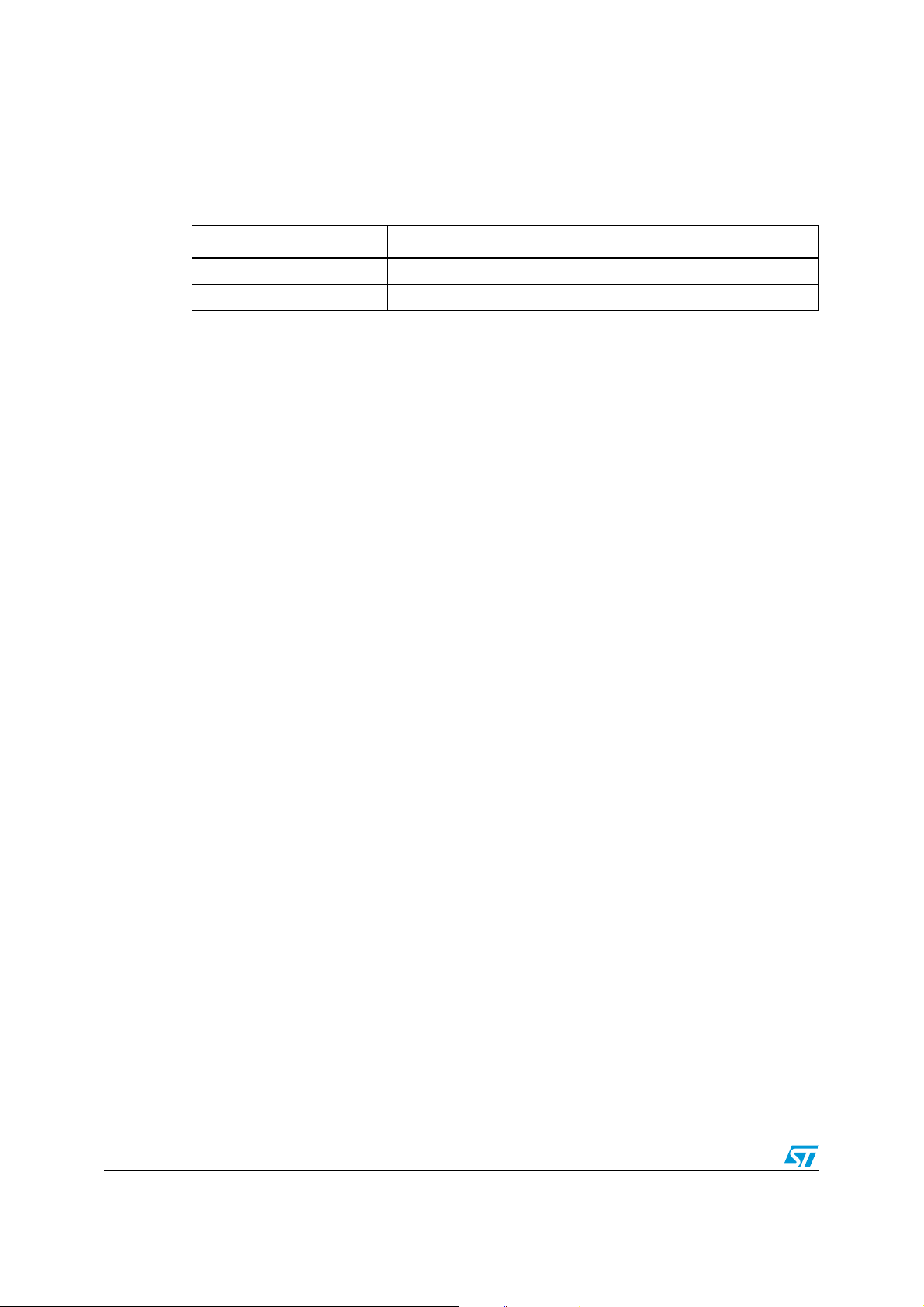

6 Revision history

Table 12. Document revision history

Date Revision Changes

12-Jun-2008 1 Initial release

19-Oct-2009 2 Modified Table 2: Bill of materials (items 2 and 21)

30/31 Doc ID 14654 Rev 2

Page 31

AN2753

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2009 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 14654 Rev 2 31/31

Loading...

Loading...