Page 1

AN2734

Application note

S-Touch™ design procedure

Introduction

The purpose of this application note is to provide the system/hardware engineers enough

ground knowledge to start the design of capacitive touch inferface solutions with the

S-Touch

The document highlights the recommended step-by-step procedures to be followed for a

successful S-Touch

production and production tests.

Each topic covered in this document is explained in detail in other application notes.

™ capacitive controller devices.

™ design-in: design flow, PCB layout, fabrication, assembly pre-

January 2010 Doc ID 14573 Rev 2 1/14

www.st.com

Page 2

Contents AN2734

Contents

1 Touch module design flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Touch module specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 PCB layout, fabrication and assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Pre-production tuning/test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.1 Hardware tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.2 Software tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Production test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2/14 Doc ID 14573 Rev 2

Page 3

AN2734 Touch module design flow

1 Touch module design flow

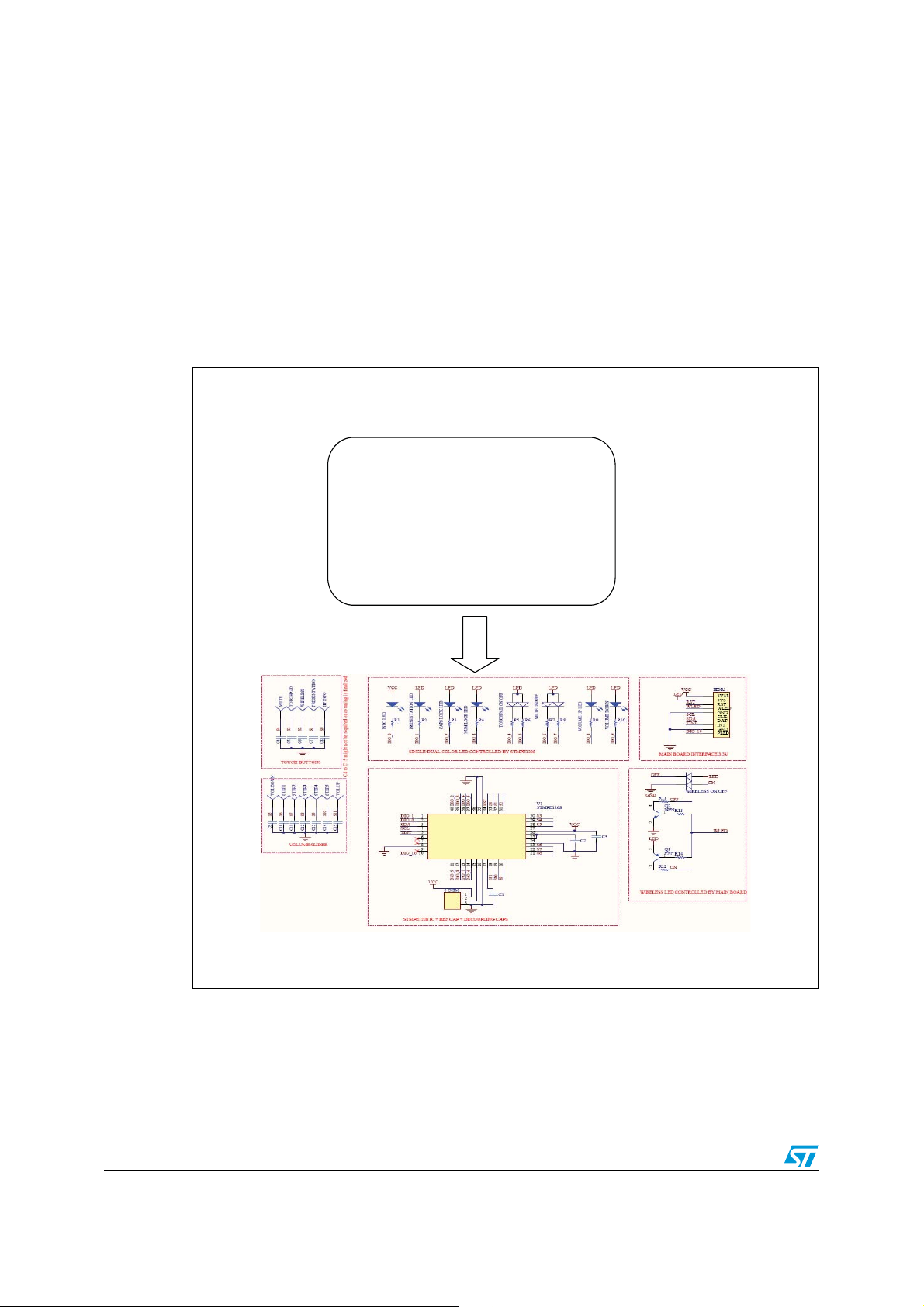

Figure 1 shows a simplified flowchart which describes the complete touch module design

flow starting from the specification to the mass production test of the PCB and the overall

system.

Figure 1. Touch module design flow

Spec ification

Dev ice

selection

Schematic

Specification review

layout, fab & ass embly

System integration test

PCB

Hardware

tuning

(s oftware tuning)

Mass production

(produc tion test)

PCB revision

GC25419

Doc ID 14573 Rev 2 3/14

Page 4

Touch module design flow AN2734

1.1 Touch module specifications

Before starting the design of a capacitive touch module, a clear specification should be

defined to establish:

● Touchkeys number and functions

● Slider/rotator implementation

● LED backlighting - white LEDs or red LEDs, 5 V system or 3.6 V system etc

● Signal connections to the host system

● Module form factor

Figure 2. Specification definitions to schematic implementation

Keys

Slider/rotator

Specifications:

Backlighting led

Connection to host

Form factor

PCB

The next step to be performed after finalizing the module specification is to choose the most

appropriate device from the S-Touch product family, based on the requirements of the target

application.

4/14 Doc ID 14573 Rev 2

Page 5

AN2734 Touch module design flow

The S-Touch devices have several sensor channels and various features. The STMPE821,

for example, consists of 8 I/Os that can be used as either normal input/outputs or as touch

sensor inputs. On a particular application, out of the eight I/Os, four I/Os can be used as

capacitive touch key input and the other four can be used for the backlighting LED control. If

the I/O is used for LED control, it can be configured as PWM output to create elaborate LED

effects.

Figure 3. STMPE821 block diagram

INT

RST

SCLK

SDAT

GPIO

controller

interface

GND VCC VIO

PWM

controller

I2 C

Impedance

Touchkey

controller

sensor

GPIO 0 - 7

/Touch 0 - 7

ARef

CS00046

For further details on S-Touch working principles and functional features, please refer to the

application note AN2693: "S-Touch

TM

devices: system considerations".

Doc ID 14573 Rev 2 5/14

Page 6

PCB layout, fabrication and assembly AN2734

2 PCB layout, fabrication and assembly

Measuring the capacitance of a sensor is quite simple. However, in order to obtain a reliable

measurement of finger capacitance, in-depth technical knowledge is required.

Two conductive materials such as wire, traces or metal that are at different potentials and in

close proximity to one another act as a conductive plate, forming a capacitor. Therefore,

when designing the layout for the touch module PCB, some standard guidelines should be

followed to route the sensor traces. Otherwise, crosstalk and disturbances between sensors

and wires, traces and the metal plate reduce touch module performance.

Periodic sampling signals are used to measure the sensors’ electrode capacitance. The

presence of noise might disturb the sensing of the signal and cause false detection in touch

keys and incorrect location reading in sliders or rotators.The controller IC can filter a low to

moderate amount of noise. It is therefore recommended to design the PCB layout in such a

way that the interaction between the external noise and the sensor/electrode circuitry is

minimized.

There are a few different types of sensor electrodes: button, slider, rotator, matrix key and

touch pad. Each one serves a specific function. Their shapes and sizes differ based on the

application and form factor requirements.

Figure 4. Sensor electrodes

For further details on the PCB and layout considerations, please refer to application note

AN2733 “S-Touch

TM

PCB and layout guidelines”.

6/14 Doc ID 14573 Rev 2

Page 7

AN2734 PCB layout, fabrication and assembly

2.1 Pre-production tuning/test

Once the PCB fabrication is complete, the S-Touch controller IC and the passive

components are assembled on the PCB.

2.1.1 Hardware tuning

The reference and input tuning capacitors are populated on the PCB as part of a process

called “hardware tuning”. This process is required due to the imbalance in the inherent

capacitance between the capacitive lines (reference and sensor inputs, see Figure 5). The

objective of the hardware tuning is to bring the no-touch impedance of all the unused sensor

inputs within the dynamic range for touch detection.

Figure 5. Imbalanced inherent capacitance

2EF

The hardware tuning process is described more in detail in the application note AN2801Hardware tuning procedures.

Figure 6. Dynamic range tuning software

As shown in Figure 6, the hardware tuning process can be achieved more easily by using

the provided software.

Doc ID 14573 Rev 2 7/14

Page 8

PCB layout, fabrication and assembly AN2734

2.1.2 Software tuning

The next step is software tuning. The S-Touch devices are register-based which means that

the host must configure the device for it to work properly. It is suggested to perform the

software tuning with the panel overlay attached to the PCB and with the touch module

assembled on the system.

When the touch module is assembled on the system, interactions with other components

and noise on the system affect the operation. This is why the software tuning is performed

on the system and not on the standalone touch module.

During the software tuning, the registers which control the sensitivity, noise filtering,

calibration and some other related registers are tuned to get optimum values. Once the

correct register values are tuned/validated properly, they are embedded as part of the host

system code. Each time the system is powered up, the host initializes the S-Touch device

with these register values.

The final register values validated during the software tuning process provide the optimal

configuration for the S-Touch registers, allowing the device to work properly in any condition.

Figure 7. Signal-to-noise ratio measurement

The system integration tests cover the signal-to-noise ratio measurement (Figure 7), water

drop tests for systems operating in wet environments and touch failure ratio. It includes

susceptibility to external disturbances such as external RF noise, effect of fluorescent lamp

emissions, mobile phone emisissions, etc.

8/14 Doc ID 14573 Rev 2

Page 9

AN2734 PCB layout, fabrication and assembly

Figure 8. Signal-to-noise ratio tool

For complete software tuning guidelines, please refer to the application notes AN2802 “STouch registers descriptions” and AN2805 "System integration test".

Doc ID 14573 Rev 2 9/14

Page 10

PCB layout, fabrication and assembly AN2734

2.2 Production test

The production test consists of a module production test and a system integration

production test.

The module production test is performed on the touch module PCB (without overlay panel)

in order to screen any assembly and/or components failures.

The system production test is performed with the touch module (attached to the overlay

panel) assembled on the system.

Figure 9. Mass production test tool

The system integration production tests can be performed automatically or manually. An

automated test can be carried out using a metallic plate to simulate a finger touch and a

manual test can be performed with a production operator manually touching the button to

test its functionalities.

10/14 Doc ID 14573 Rev 2

Page 11

AN2734 Conclusion

3 Conclusion

Below is a short summary table on the S-Touch design procedure.

Table 1. S-Touch design procedure

Step Description Notes STMicroelectronics tools

Define number of

System level functional

1

definition

Schematic design and PCB

2

layout

buttons/slider/wheel,

approximate placement, board

size, cover thickness/material

Device selection, number of

PCBs layers

PCB layout guidelines

Assembly of 5-10 boards for

3

capacitance tuning

Software

4

development/optimization

based on 5-10 boards

Assembly of 100-200

5

boards according to tuning

results (step 3)

Analysis of test (MP test,

SNR test, noise test) results

6

from 100-200 sets.

Fine tuning of capacitance

values if necessary

Tuning done with actual cover

material

Noise immunity

setting,optimized sensitivity

setting, SNR test

To check consistency/stability

of the capacitive module in

actual production condition

Results should be consistent

with system level requirements

Dynamic range tuning tool

Reference code, software

tuning tool, SNR tool

Mass production test software

toolkit

Doc ID 14573 Rev 2 11/14

Page 12

Reference AN2734

4 Reference

1. STMPE821 datasheet

2. STMPE1208S datasheet

3. AN2693, S-Touch

4. AN2733, S-Touch

5. AN2801, Hardware tuning procedures

6. AN2802, A programming guide for the touch module in capacitive S-Touch™ devices

7. AN2805, System integration test

™ devices: system considerations

™ PCB and layout guidelines

12/14 Doc ID 14573 Rev 2

Page 13

AN2734 Revision history

5 Revision history

Table 2. Document revision history

Date Revision Changes

30-Apr-2009 1 Initial release.

15-Jan-2010 2 Removed reference to AN2806.

Doc ID 14573 Rev 2 13/14

Page 14

AN2734

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2010 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

14/14 Doc ID 14573 Rev 2

Loading...

Loading...