Page 1

AN2730

Application note

High power LED driver for single Flash with I²C interface

Introduction

This application note is dedicated to the design of a Flash LED driver using the STCF06

device, which is a buck-boost current mode converter with an I

functional description, recommendations for PCB layout and external components selection

are also discussed in this application note. This device is designed for driving a single LED

with a forward voltage range from 2.7 to 5 V.

Figure 1. STCF06 demonstration board

2

C interface. The schematic,

April 2008 Rev 1 1/28

www.st.com

Page 2

Contents AN2730

Contents

1 Schematic description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Application schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Selection of external components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Input and output capacitor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Inductor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 LED selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 D1 selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 RFL selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6 RTR selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.7 NTC AND RX resistor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 PCB design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 PCB design rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 PCB layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.1 A four-layer PCB with application area 55 mm2 for BGA package . . . . . 10

4 Internal registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Accessing the internal registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Operation modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1 Shutdown mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2 Shutdown mode with the NTC feature activated . . . . . . . . . . . . . . . . . . . 14

5.3 Ready mode and NTC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.4 Torch mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.5 Flash mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6 The status register and the ATN pin . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1 The status register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7 Reading and writing to the STCF06 registers through the I2C bus . . 19

7.1 Writing to a single register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.2 Writing to multiple registers with incremental addressing . . . . . . . . . . . . 19

2/28

Page 3

AN2730 Contents

7.3 Reading from a single register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.4 Reading from multiple registers with incremental addressing . . . . . . . . . 20

8 Examples of register setup for each mode . . . . . . . . . . . . . . . . . . . . . . 21

8.1 Example 1: 1066 mA Flash with 200 ms duration . . . . . . . . . . . . . . . . . . 21

8.2 Example 2: 48 mA torch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8.3 Example 3: an auxiliary LED running at 10 mA for 500 ms . . . . . . . . . . . 23

8.4 Example 4: red-eye reduction (multiple short flashes) . . . . . . . . . . . . . . . 24

8.5 Example 5: a Flash pulse longer than 1.5 s . . . . . . . . . . . . . . . . . . . . . . . 25

9 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3/28

Page 4

List of tables AN2730

List of tables

Table 1. Recommended components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 2. Accessibility of internal registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 3. COMMAND register data to enter shutdown mode (version A) . . . . . . . . . . . . . . . . . . . . . 14

Table 4. COMMAND register data to enter shutdown mode (version B) . . . . . . . . . . . . . . . . . . . . . 14

Table 5. COMMAND register data to enter shutdown mode with NTC activated . . . . . . . . . . . . . . . 14

Table 6. COMMAND register data to enter ready mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 7. COMMAND register data to enter ready mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 8. COMMAND register data to enter torch mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 9. COMMAND register data to enter Flash mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 10. STATUS register bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 11. Effect of the status register bits on the operation of the device . . . . . . . . . . . . . . . . . . . . . 18

Table 12. Torch mode and Flash mode DIMMING registers settings . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 13. COMMAND register data to enter Flash mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 14. DIMMING register data for the Flash mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 15. I

Table 16. COMMAND register data for the torch mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 17. DIMMING register data for the torch mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 18. I

Table 19. I

Table 20. COMMAND register data for the AUX_LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 21. AUX_LED register data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 22. I

Table 23. I

Table 24. COMMAND register data for Flash mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 25. DIMMING register data for Flash mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 26. I

Table 27. I

Table 28. 1

Table 29. 2

Table 30. 3

Table 31. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2

C data packet for activating the Flash mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2

C data packet for activate torch mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2

C data packet for terminating the torch mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2

C data packet for activating the ready mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2

C data packet for activating the AUX_LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2

C data packet for activating the Flash mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2

C data packet for activating the Flash mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

st I2

C data packet to restart the Flash mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

nd I2

C data packet to restart of the Flash mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

rd I2

C data packet to restart of the Flash mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4/28

Page 5

AN2730 List of figures

List of figures

Figure 1. STCF06 demonstration board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. A typical application schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. Top layer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 4. Middle layer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 5. Middle layer 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 6. Bottom layer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 7. Top overlay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 8. Splitting the Flash pulse into several shorter pulses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 9. Writing to a single register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 10. Writing to multiple registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 11. Reading from a single register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 12. Reading from multiple registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 13. Multiple flashes handled by the TRIG pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 14. I

2

C bus packets timing for a Flash lasting longer than FTIM max . . . . . . . . . . . . . . . . . . . 27

5/28

Page 6

Schematic description AN2730

1 Schematic description

The Flash LED driver STCF06 has a high operational frequency (1.8 MHz) which allows the

usage of small external components.

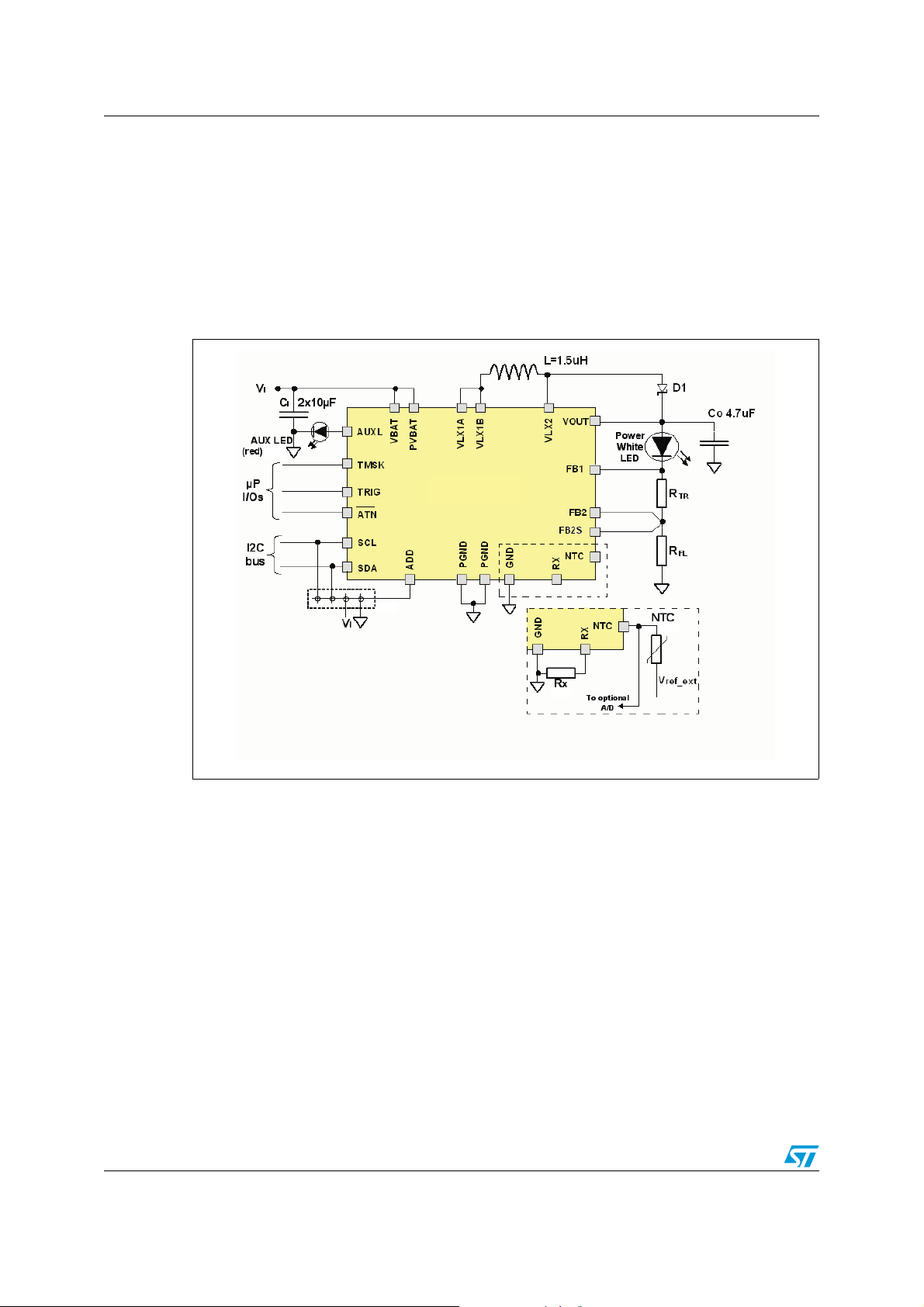

1.1 Application schematic

Figure 2. A typical application schematic

(Note 2)

STCF06

(Note 1)

(Note 2)

Note 1: connect to V1, or GND or SDA or SCL to choose one of the 4 different I²C slave addresses

Note 2: optional components to support auxiliary functions

(Note 2)

6/28

Page 7

AN2730 Selection of external components

2 Selection of external components

2.1 Input and output capacitor selection

It is recommended to use ceramic capacitors with low ESR as input and output capacitors. It

is recommended to use 2x10 µF/6.3 V as a minimum value for the input capacitor, and

4.7 µF/6.3 V as the optimal value for the output capacitor to achieve a good stability of the

device, for a supply range varying from low input voltage (2.7 V) to the maximum ratings of

output power.

Note: see recommended components in Tab le 1 .

2.2 Inductor selection

A thin shielded inductor with a low DC series resistance of winding is recommended for this

application. To achieve a good efficiency in step-up mode, it is recommended to use an

inductor with a DC series resistance R

DCL=RD

resistance of the LED.

For nominal operation, the peak inductor current can be calculated by the following formula:

/10 [ Ω; Ω ], where RD is the dynamic

Equation 1

I

PEAK

= ((I

/ η) + ((V

OUT

– VIN) x VIN ²) / (2 x L x f x V

OUT

Where:

● I

● I

● η: Efficiency of the STCF06

● V

● V

● L: Inductance value of the inductor

● f: Switching frequency

: Peak inductor current

PEAK

: Current sourced at the V

OUT

: Output voltage at the V

OUT

: Input voltage at the V

IN

BAT

- pin, this is the LED current

OUT

- pin

OUT

- pin

Note: see recommended components in Tab le 1 .

2.3 LED selection

All LEDs with a forward voltage range ranging from 2.7 V to 5 V are compatible with

STCF06. The forward voltage spread of any selected LED must however lay within this

range (2.7 V to 5 V). It is possible to set the maximum level of the LED current in Flash

mode and Torch mode by setting the values of the corresponding sensing resistors, lower

current values can be then set through the I

LED with forward voltage as low as possible to get the best performance in terms of current

consumption and efficiency

²)) x V

OUT

2

C port. It is strongly recommended to use the

OUT

/ V

IN

Note: see recommended components in Tab le 1 .

7/28

Page 8

Selection of external components AN2730

2.4 D1 selection

All the Schottky diodes are compatible with the STCF06. It is recommended to use the

Schottky diode with forward voltage as low as possible to get the best performance of the

application in terms of input current consumption and efficiency of the application.

Note: see recommended components in Tab le 1 .

2.5 RFL selection

The value of the RFL resistor can be calculated by the following equations:

Equation 2

Equation 3

R

FL=VFB2/IFLASH(max)

P

RFLASH=RFL*IFLASH

where V

= 227 mV

FB2

2

where P

is the power dissipated on the RFL resistor. It is recommended to use a thin

RFL

metal film resistor in the 0606 package size and 1% tolerance. The maximum LED current in

Flash mode for STCF06 is 1.5 A for a battery voltage ranging from 3.5 V to 5.5 V, 1.3 A from

3 V to 3.5 V and 1 A from 2.7 V to 3 V.

2.6 RTR selection

The value of the RTR resistor can be calculated by the following equations:

Equation 4

and

Equation 5

where P

RTORCH

equation R

It is recommended to use a thin metal film resistor with 1% or 5% tolerance. The maximum

LED current in torch mode for SCTF03 is 370 mA for a battery voltage ranging from 2.7 V to

5.5 V.

is the power dissipated on the RTR resistor. It is recommended to follow the

=6.66* RFL to avoid any jump in the current DIMMING values.

TR

R

= (V

P

=R

-I

*R

)/I

2

*I

2.7 NTC AND RX resistor selection

STCF06 supports the usage of a negative thermistor (NTC) for sensing the LED

temperature. In order to implement this functionality, the R

reference are needed too. Once the NTC feature is activated, the internal switch connects

the R

resistor to the NTC, and this creates a voltage divider supplied by the external

X

reference voltage connected to the NTC.

8/28

resistor and an external voltage

X

Page 9

AN2730 Selection of external components

If the temperature of the NTC-thermistor rises due to the heat dissipated by the LED, the

voltage on the NTC pin increases. When this voltage exceeds 0.56 V, the NTC_W bit in the

STATUS register is set to high, and the ATN pin is set to low to inform the microcontroller

that the LED is becoming hot. The NTC_W bit is cleared by reading the status register.

If the voltage on the NTC pin rises further and exceeds 1.2 V, the NTC_H bit in the status

register is set to high, and the ATN pin is set to low to inform the microcontroller that the LED

is too hot and the device goes automatically to the ready mode to avoid damaging the LED.

This status is latched, until the microcontroller reads the status register. Reading the

STATUS register clears the NTC_H bit.

The selection of the NTC and R

resistor values strongly depends on the power dissipated

X

by the LED and all components surrounding the NTC-thermistor and on the cooling

capabilities of each specific application. The R

and the NTC values in Tab le 1 below work

X

well in the demonstration board presented in this application note. A real application may

require a different type of NTC-thermistor to achieve optimal thermal protection.

The procedure to activate the NTC-feature is described in Section 5.2.

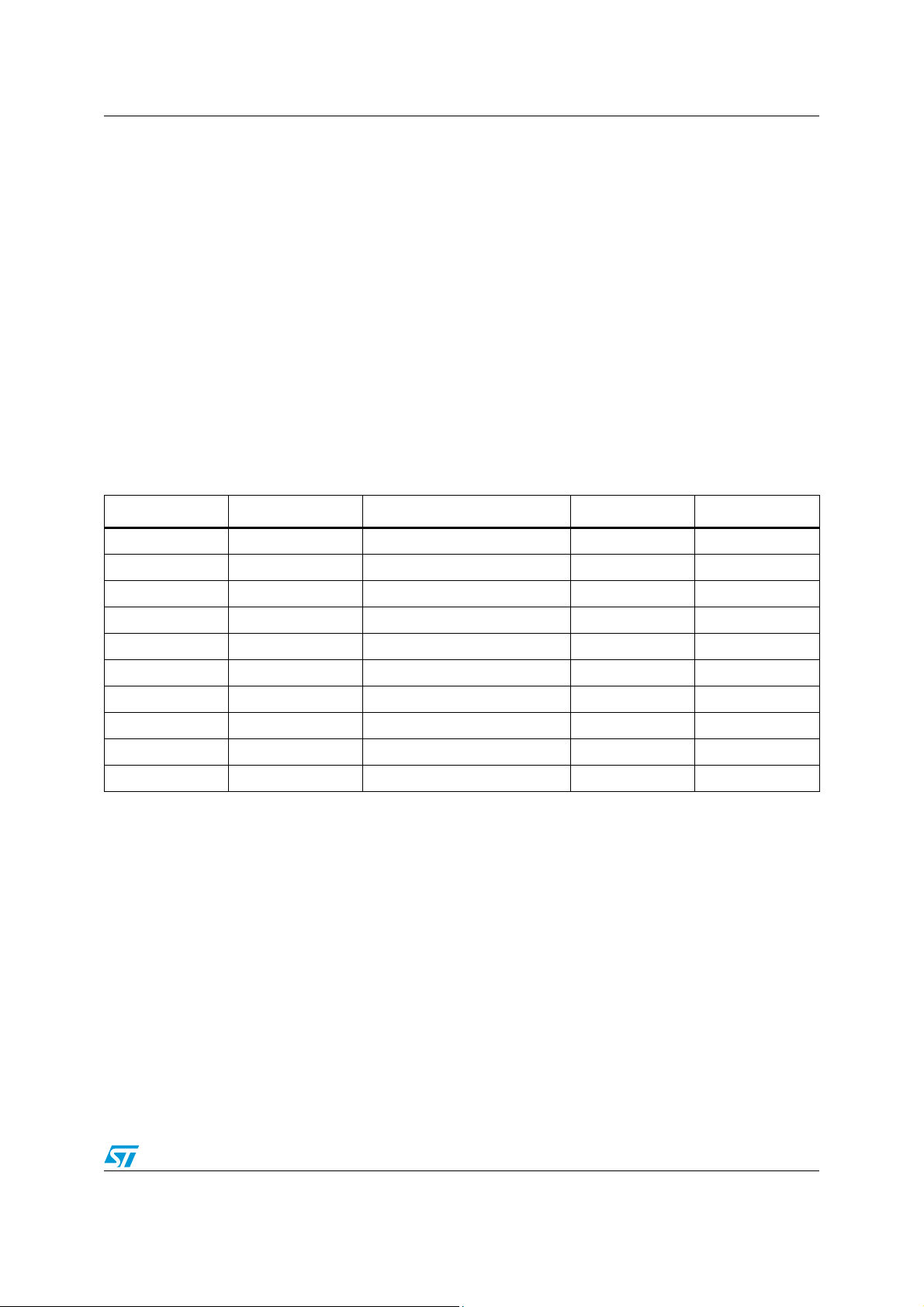

Table 1. Recommended components

Component Manufacturer Part number Value Size

C

I

C

O

L TDK VLF4014AT-1R5M1R8-1 1.5 µH 3.7 x 3.5 x 1.4 mm

NTC Murata NCP21WF104J03RA 100 kΩ 0805

R

FL

R

TR

R

X

LED Luxeon LED LXCL-PWF1 0805

D1 STMicroelectronics STPS1L20MF 3.8x1.9x0.85 mm

(1)

D1

1. When the minimum application area is targeted, the BAT20J should be used, then the output current performance is

decreased.

TDK C1608X5R0J106M 10 µF 0603

TDK C1608X5R0J475M 4.7 µF 0603

Tyco RL73K1JR15JTD 0.15 Ω 0603

Rohm CRG0805F1R0 1 Ω 0805

Rohm MCR01MZPJ15K 15 kΩ 0402

STMicroelectronics BAT20J-FILM 2.7x1.3x1.1 mm

9/28

Page 10

PCB design AN2730

3 PCB design

3.1 PCB design rules

The STCF06 is a powerful switching device where the PCB must be designed in line with

switched supplies design rules. The power tracks (or wires in the demonstration board) must

be as short as possible and wide enough, because of the large currents involved. It is

recommended to use a 4-layer PCB to get the best performance. All the external

components must be placed as close as possible to the STCF06. All high-energy switched

loops should be as small as possible to reduce EMI. Most of the LEDs need efficient

cooling, which could be done by using a dedicated copper area on the PCB. Please refer to

the selected LED's reference guide to design the heatsink. Place the RFL resistor as close

as possible to the PGND pins and the ground pin of the COUT capacitor. In case a

modification of any PCB layer is required, it is highly recommended to use enough vias.

Place the NTC resistor as close as possible to the LED for good temperature sensing. Direct

connection between GND and PGND is necessary in order to achieve correct output current

value. No LED current should flow through this track. Voltage sensing on the RFL resistor

must be done on a track from ball FB2 and directly connected to the R

current should flow through this track. Pin FB2S must be connected to the R

Vias connecting the STCF06 pins to the copper tracks (if used) must be 0.1 mm in diameter

for BGA version. It is recommended to use the filled vias.

resistor. Again, no

FL

resistor pin.

FL

3.2 PCB layout

3.2.1 A four-layer PCB with application area 55 mm2 for BGA package

Figure 3. Top layer

10/28

Page 11

AN2730 PCB design

Figure 4. Middle layer 1

Figure 5. Middle layer 2

Figure 6. Bottom layer

11/28

Page 12

PCB design AN2730

Figure 7. Top overlay

12/28

Page 13

AN2730 Internal registers

4 Internal registers

4.1 Accessing the internal registers

There are 4 internal registers in the STCF06: COMMAND, DIMMING, AUX_LED, STATUS.

The STATUS register is read-only.

The COMMAND register can be accessed in any operation mode. All the other registers can

be accessed in any mode, except in shutdown mode. When the device enters shutdown

mode, the DIMMING, AUX_LED and status registers are cleared. The COMMAND register

value remains untouched when entering shutdown mode. The table below shows the

accessibility of each register in all operation modes.

Table 2. Accessibility of internal registers

Mode

Register Address

Shutdown Ready Torch Flash

COMMAND 00 Read / write Read / write Read / write Read / write Untouched Cleared

DIMMING 01 Inaccessible Read / write Read / write Read / write Cleared Cleared

AUX_LED 02 Inaccessible Read / write Read / write Read / write Cleared Cleared

Status 03 Inaccessible Read only Read only Read only Cleared Cleared

Shutdown

value

PowerON

reset value

13/28

Page 14

Operation modes AN2730

5 Operation modes

5.1 Shutdown mode

Shutdown mode is entered after the Power-ON reset. This mode is mainly used to decrease

the power consumption of the device. During this mode, only the I

only thing which can be done in shutdown mode is to access the COMMAND register.

Entering shutdown mode by writing to the COMMAND register aborts any running operation

and clear the values of the DIMMING, AUX_LED and status registers. The COMMAND

register value is not affected by entering shutdown mode.

The following data must be written to the COMMAND register to enter shutdown mode.

Table 3. COMMAND register data to enter shutdown mode (version A)

PWR_ON TRIG_EN TCH_ON NTC_ON FTIM_3 FTIM_2 FTIM_1 FTIM_0

CMD_REG

Table 4. COMMAND register data to enter shutdown mode (version B)

CMD_REG

0xxXxxxx

MSB LSB

PWR_ON TRIG_EN TCH_ON NTC_ON FTIM_3 FTIM_2 FTIM_1 FTIM_0

0xx0xxxx

MSB LSB

2

C interface is alive. The

5.2 Shutdown mode with the NTC feature activated

When this operation mode is activated, the microcontroller can still monitor the NTC voltage

through its A/D converter, while STCF06 remains in shutdown mode and therefore saves

power.

The following data must be written to the COMMAND register to enter shutdown mode +

NTC.

Table 5. COMMAND register data to enter shutdown mode with NTC activated

PWR_ON TRIG_EN TCH_ON NTC_ON FTIM_3 FTIM_2 FTIM_1 FTIM_0

CMD_REG

0xx1xxxx

MSB LSB

5.3 Ready mode and NTC

The ready mode allows the user to access all the internal registers. The NTC feature can be

activated in this mode and the temperature of the LED can be sensed by the A/D converter

of the microcontroller.

The following data must be written to the COMMAND register to enter ready mode.

14/28

Page 15

AN2730 Operation modes

Table 6. COMMAND register data to enter ready mode

PWR_ON TRIG_EN TCH_ON NTC_ON FTIM_3 FTIM_2 FTIM_1 FTIM_0

CMD_REG

1000xxxx

MSB LSB

The following data must be written to the COMMAND register to activate the NTC feature.

Table 7. COMMAND register data to enter ready mode

PWR_ON TRIG_EN TCH_ON NTC_ON FTIM_3 FTIM_2 FTIM_1 FTIM_0

CMD_REG

1001xxxx

MSB LSB

As soon as the NTC feature is activated, the internal switch connects the NTC resistor to the

resistor, thereby creating a voltage divider. The voltage on this divider can be, if desired,

R

X

monitored by the A/D converter of the microcontroller. An external voltage reference must be

connected to the NTC to use this feature. The bits NTC_W and NTC_H of the STATUS

register will not be properly set if there is no external reference voltage connected to the

NTC.

If the NTC feature is not going to be used, neither the negative thermistor, nor the external

reference needs to be connected. In this case, it is recommended to ground the RX pin. As

the NTC feature is automatically activated during the Flash and torch mode, leaving the R

pin floating could lead to unwanted interruptions of the light due to non-defined voltages on

the R

pin.

X

X

5.4 Torch mode

This mode is intended to be used for low light intensities. The LED current in TORCH mode

can be adjusted in a range from 29 mA up to 370 mA.

The torch mode is activated by writing the following data to the COMMAND register.

Table 8. COMMAND register data to enter torch mode

PWR_ON TRIG_EN TCH_ON NTC_ON FTIM_3 FTIM_2 FTIM_1 FTIM_0

CMD_REG

101xxxxx

MSB LSB

The DIMMING register value (TDIM) must be set as well, unless it has already been set

during a previous operation. If TDIM register is not set, then the default output current value

is at the minimum.

There is no internal timer which controls the torch duration. Therefore, as soon as the torch

mode is activated, it remains active until a new mode is entered by writing a new data to the

COMMAND register.

If the torch mode has been terminated by entering ready or Flash mode, it can be restarted

again by writing the corresponding data to the COMMAND register only, because entering

any of the ready and Flash modes does not influence the TDIM value. If the torch mode was

15/28

Page 16

Operation modes AN2730

terminated by entering into shutdown mode, then the TDIM value must be set again during

the restart of the torch because entering the shutdown mode clears the TDIM value.

As soon as the torch mode is activated, the NTC feature is automatically activated too in

order to protect the LED against overheating. The NTC feature is activated even if the

NTC_ON bit in the COMMAND register is set to zero.

5.5 Flash mode

This mode is intended to be used for high light intensities. The LED current in Flash mode

can be adjusted up to 1.5 A with the input voltage ranging from 3.5 V up to 5.5 V. The Flash

mode is activated by writing the following data to the COMMAND register.

Table 9. COMMAND register data to enter Flash mode

PWR_ON TRIG_EN TCH_ON NTC_ON FTIM_3 FTIM_2 FTIM_1 FTIM_0

CMD_REG

11xxxxxx

MSB LSB

The DIMMING register value (FDIM) must be set as well, unless it has already been set

during a previous operation.

The activation of the Flash mode requires the TRIG pin to be high. The FLASH mode is

active only when both the TRIG_EN bit in the COMMAND register is set to 1 and the TRIG

pin is high. This gives the user the possibility to choose between soft and hard triggering of

the FLASH .

The soft triggering is done by writing data to the internal registers only, while the TRIG pin is

permanently kept high, for example by connecting it to V

. This saves one pin of the

BAT

microcontroller, which can be used for a different purpose, but this way of triggering is less

accurate than the hard one. The second disadvantage of this solution is that the Flash

duration can only be set in discrete increments of the internal timer ( increment = approx.

100 ms).

Hard-triggering of the Flash mode requires the microcontroller to manage the TRIG pin. The

COMMAND and the DIMMING registers are loaded with data before the TRIG pin is set to

high. This allows the user to avoid the I

2

C-bus latency. Flash mode then starts as soon as

the TRIG pin is set to high. It takes typically about 0.7 ms to ramp up the LED current to the

adjusted value. This time may vary according to the LED current value and the battery

voltage. When the TRIG pin is kept High long enough, the internal timer reaches zero and

the Flash mode is over. As soon as the Flash is timed out, the ATN pin is pulled down for

11 µs to inform the microcontroller that the status register has been updated and the flash is

over. If the TRIG pin is set to low before the internal timer reaches zero, the Flash mode will

be interrupted and can be restarted by setting the TRIG pin to high again. The internal timer

is paused while the TRIG pin is low. This means that the user can split the Flash into several

pulses of a total length equal to the FTIM value. Figure 8 shows how to split the Flash into

several shorter pulses. The cumulative length of all the pulses is determined by the FTIM

value. Figure 8 shows the case for FTIM = 9 (900 ms Flash time). The cumulative time when

the TRIG pin is high is 1000 ms (5 pulses 200 ms long). The last Flash pulse is only 100 ms

long. The reason is that the internal Flash timer reaches zero and the TRIG_EN bit is set to

0.

16/28

Page 17

AN2730 Operation modes

Figure 8. Splitting the Flash pulse into several shorter pulses

1300 ms

100

200

ms

ms

9 8 7 6 5 4 3 2 1 0

Time when the

internal flash

timer reaches 0

I2C bus packet

TRIG_EN bit

TRIG pin

LED current

Internal Flash timer values

Hard triggering allows therefore a smooth setting of the Flash duration. The resolution is

about 8.8 µs. The minimum Flash duration is limited by the ramp-up time of the LED current

and the maximum is limited by the FTIM value. If it is necessary to make a flash pulse longer

than the maximum allowed by FTIM, then it is necessary to reload the COMMAND register

before the internal timer reaches zero (start a new Flash before the previous one elapses).

See Section 8.5 for more details.

17/28

Page 18

The status register and the ATN pin AN2730

6 The status register and the ATN pin

6.1 The status register

Table 10. STATUS register bits

Bit name N/A F_RUN LED_F NTC_W NTC_H OT_F OC_F VOUTOK_N

MSB LSB

A detailed description of each bit is also given in the STCF06 datasheet.

Table 11. Effect of the status register bits on the operation of the device

Bit name

Default value0000000

Latched (

Ready mode

when set

Sets ATN low

when set

(1)

Forces

F_RUN

(STAT_REG)

) NO YES YES YES YES NO YES

NO YES NO YES YES NO YES

NO YES YES YES YES NO YES

LED_F

(STAT_REG)

NTC_W

(STAT_REG)

NTC_H

(STAT_REG)

OT_F

(STAT_REG)

OC_F

(STAT_REG)

VOUTOK_N

(STAT_REG)

1. YES means that the bit is set by internal signals and is reset to its default value by an I2C-read operation of STAT_REG;

NO means that the bit is set and reset by internal signals in real-time.

When the status register is latched, reading and writing to the registers is still possible, but

the bits TRIG_EN and TCH_ON in the COMMAND register and AUXL register cannot be

changed, until the device is unlatched. It is necessary to read the STATUS register to

unlatch the device.

The ATN pin is also pulled down when the internal timer reaches zero in Flash mode. In this

case the ATN pin is pulled down for 11 µs only. It is recommended to connect the ATN pin to

the interrupt input of the microcontroller. If it is not connected to the interrupt input, the ATN

pin should be pulled fast enough not to miss the 11µs pulse, for example by a programming

loop which is entered after the start of the Flash mode. This loop runs until the ATN pin

becomes low. It is recommended to make a timeout of such a loop.

18/28

Page 19

AN2730 Reading and writing to the STCF06 registers through the I2C bus

7 Reading and writing to the STCF06 registers through

2

the I

7.1 Writing to a single register

Writing to a single register starts with a START bit followed by the 7-bit device address of

STCF06. The 8

operation. Then the master awaits an acknowledgement from STCF06. The 8-bit address of

the desired register is sent afterwards to STCF06. It is also followed by an acknowledge

pulse. The last transmitted byte is the data that is going to be written into the register. It is

followed again by an acknowledge pulse from STCF06. Then the master generates a stopbit and the communication is over, see Figure 9 below.

Figure 9. Writing to a single register

C bus

th

SDA LINE

bit is the R/W bit, which is 0 in this case. R/W = 1 means a Reading

DEVICE

ADDRESS

7 bits

M

S

S

T

A

B

R

T

W

R

I

T

E

L

R

S

/

B

W

A

C

K

ADDRESS OF

M

S

B

REGISTER

DATA

S

A

L

A

M

C

S

C

S

B

K

K

B

A

L

T

C

S

O

B

K

P

7.2 Writing to multiple registers with incremental addressing

It would be unpractical to send several times the device address and the address of the

register when writing to multiple registers. STCF06 supports writing to multiple registers with

incremental addressing. When data is written to a register, the register address is

automatically incremented (by one), and therefore the next data can be sent without sending

again the device address and the register address, see Figure 10 below.

Figure 10. Writing to multiple registers

W

DEVICE

R

ADDRESS OF

I

REGISTER i

T

E

M

A

L

R

S

C

S

/

B

K

B

W

DATA i

A

M

L

A

M

C

S

S

C

S

K

B

B

K

B

DATA i+1

A

L

M

C

S

S

K

B

B

DATA i+2

A

L

M

C

S

S

K

B

B

DATA i+2

A

L

M

C

S

S

K

B

B

DATA i+n

L

M

A

S

S

C

B

B

K

SDA LINE

ADDRESS

7 bits

M

S

S

T

A

B

R

T

S

A

L

T

C

S

O

K

B

P

19/28

Page 20

Reading and writing to the STCF06 registers through the I2C bus AN2730

7.3 Reading from a single register

The reading operation starts with a START bit followed by the 7-bit device address of

STCF06. The 8

th

bit is the R/W bit, which is 0 in this case. STCF06 confirms the receiving of

the address + R/W bit by an acknowledge pulse. The address of the register which should

be read is sent after and confirmed by an acknowledge pulse from STCF06 again. Then the

master generates a START-bit again and sends the device address followed by the R/W-bit,

which is 1 now. STCF06 confirms the receiving of the address + R/W-bit by an acknowledge

pulse, and starts to send data to the master. No acknowledge pulse from the master is

required after receiving the data. Then the master generates a STOP bit to terminate the

communication, see the Figure 11 below.

Figure 11. Reading from a single register

W

DEVICE

R

ADDRESS

7 bits

ADDRESS OF

I

REGISTER i

T

E

DATA i

DATA i+1

DATA i+2

DATA i+2

DATA i+n

SDA LINE

M

M

S

S

T

A

B

R

T

A

L

R

S

C

S

/

B

K

B

W

A

M

L

A

M

C

S

S

C

S

K

B

B

K

B

A

L

M

C

S

S

K

B

B

A

L

M

C

S

S

K

B

B

A

L

M

C

S

S

K

B

B

L

M

A

S

S

C

B

B

K

S

A

L

T

C

S

O

K

B

P

7.4 Reading from multiple registers with incremental addressing

Reading from multiple registers starts in the same way like reading from a single register. As

soon as the first register is read, the register address is automatically incremented. If the

master generates an acknowledge pulse after receiving the data from the first register, then

reading from the next register can start immediately without having to send once more the

device and the register addresses. The last acknowledge pulse before the STOP bit is not

required. See the Figure 12 below.

Figure 12. Reading from multiple registers

W

DEVICE

R

ADDRESS

7 bits

ADDRESS OF

I

REGISTER i

T

E

SDA LINE

M

S

S

T

A

B

R

T

A

L

M

R

C

S

S

/

K

B

B

W

20/28

DEVICE

R

ADDRESS

E

A

7 bits

D

A

L

S

C

S

T

A

K

B

R

T

R

/

W

DATA i

A

C

K

DATA i+1

A

L

M

C

S

S

K

B

B

DATA i+2

A

L

M

C

S

S

K

B

B

DATA i+2

A

L

M

C

S

S

K

B

B

DATA i+n

L

M

A

S

S

C

B

B

K

S

L

N

T

S

O

O

B

P

A

C

K

Page 21

AN2730 Examples of register setup for each mode

8 Examples of register setup for each mode

Table 12. Torch mode and Flash mode DIMMING registers settings

T_DIM

F_DIM

curren

t [mA]

al step

V

Sense

Resist.

Note: LED current values refer to RFL= 0.15 Ω, RTR = 1 Ω

0 1 2 3 4 5 6 7 8 9 A B C D E F

(hex)

(hex)

LED

29 34 40 48 58 69 82 98 120 139 165 197 220 266 313 373 446 526 633 753 893 1066 1266 1513

Intern

1 2 3 4 5 6 7 8 9 101112131415 16 1718192021 22 23 24

33 40 47 56 67 80 95 113 134 160 190 227 33 40 47 56 67 79 95 113 134 160 190 227

REF1

[mV]

R

R

R

R

R

R

FL

FL

FL

+

+

R

R

TR

TR

FL

+

+

R

T

R

+

R

R

T

R

R

R

FL

FL

FL

+

+

R

R

T

T

TR

R

0 1 2 3 4 5 6 7 8 9 A B C D E F

R

R

R

R

R

FL

FL

+

R

TR

FL

+

+

R

TR

+

R

R

T

R

R

RFLRFLRFLRFLRFLRFLRFLRFLRFLRFLRFLR

FL

FL

+

R

T

T

R

FL

8.1 Example 1: 1066 mA Flash with 200 ms duration

Let's suppose that RFL = 0.15 Ω. The targeted value of the flash current is 1066 mA and the

flash duration should be 200 ms.

The reference voltage must be set to 160 mV to achieve a 1066 mA flash current with a

0.15 Ω sensing resistor. The value of FDIM (4 bits) must be set to 0xD to set up the

reference voltage to 160 mV (see Tab le 1 2).

The flash duration timer can be set to 100ms up to 1500 ms in 100ms increments. If the

desired flash duration is 200 ms the value FTIM (4 bits) must be set to 0x2.

● Bit PWR_ON of the COMMAND register must be set to 1

● Bit TRIG_EN of the COMMAND register must be set to 1

● Bit TCH_ON of the COMMAND register must be set to 0

● Bit NTC_ON of the COMMAND register can be set to any value, because NTC is

automatically ON when the Flash mode is active. Setting this bit to 0 does not switch off

the NTC.

Table 13. COMMAND register data to enter Flash mode

PWR_ON TRIG_EN TCH_ON NTC_ON FTIM_3 FTIM_2 FTIM_1 FTIM_0

CMD_REG

11xX0010

MSB LSB

21/28

Page 22

Examples of register setup for each mode AN2730

Table 14. DIMMING register data for the Flash mode

TDIM_3 TDIM_2 TDIM_1 TDIM_0 FDIM_3 FDIM_2 FDIM_1 FDIM_0

DIM_REG

00001101

MSB LSB

It is necessary to write 4 bytes to the STCF06 to make a Flash.

Table 15. I2C data packet for activating the Flash mode

Byte Hex Binary Comment

16201100010 Device address + R/W bit

20000000000 COMMAND register address

3D211010010 Data of the COMMAND register

40D00001101 Data of the DIMMING register

8.2 Example 2: 48 mA torch

Let's suppose that RFL = 0.15 Ω, RTR = 1 Ω and the targeted value of the torch current is 48

mA.

The reference voltage must be set to 56 mV to achieve 48 mA in torch mode with the

resistor values mentioned above. The value of TDIM (4 bits) must be set to 0x3 to set up the

reference voltage to 56 mV.

● Bit PWR_ON of the COMMAND register must be set to 1.

● Bit TRIG_EN of the COMMAND register must be set to 1.

● Bit TCH_ON of the COMMAND register must be set to 0.

● Bit NTC_ON of the COMMAND register can be set to any value, because NTC is

automatically ON, when torch mode is active. Setting this bit to 0 does not switch off the

NTC.

Table 16. COMMAND register data for the torch mode

PWR_ON TRIG_EN TCH_ON NTC_ON FTIM_3 FTIM_2 FTIM_1 FTIM_0

CMD_REG

10110000

MSB LSB

Table 17. DIMMING register data for the torch mode

TDIM_3 TDIM_2 TDIM_1 TDIM_0 FDIM_3 FDIM_2 FDIM_1 FDIM_0

DIM_REG

00110000

MSB LSB

It is necessary to write 4 bytes to the STCF06 to run the torch mode.

22/28

Page 23

AN2730 Examples of register setup for each mode

Table 18. I

Byte Hex Binary Comment

16201100010 Device address + R/W bit

20000000000 COMMAND register address

3B010110000 Data of the COMMAND register

43000110000 Data of the DIMMING register

2

C data packet for activate torch mode

The duration of the torch mode is "unlimited". Torch mode is terminated by setting the

TCH_ON bit in the COMMAND register to 0.

Termination of the torch mode can be done by writing the following data to STCF06.

Table 19. I2C data packet for terminating the torch mode

Byte Hex Binary Comment

16201100010 Device address + R/W bit

20000000000 COMMAND register address

38010000000 Data of the COMMAND register

This puts the STCF06 into ready mode.

8.3 Example 3: an auxiliary LED running at 10 mA for 500 ms

STCF06 must be into ready mode (both bits TRIG_EN and TCH_ON are 0) to activate the

auxiliary LED.

A 10 mA output current is reached when AUXI is set to 0x8. AUXT must be set to 0x5 to

have a 500 ms duration of the auxiliary LED lighting.

Table 20. COMMAND register data for the AUX_LED

PWR_ON TRIG_EN TCH_ON NTC_ON FTIM_3 FTIM_2 FTIM_1 FTIM_0

CMD_REG

Table 21. AUX_LED register data

AUX_L ED

10000000

MSB LSB

AUXI_ 3 AUXI_ 2 AUXI_1 AUXI_0 AUXT_3 AUXT_2 AUXT_ 1 AUXT _0

10000101

MSB LSB

Writing the 3 bytes in Ta b le 2 2 to STCF06 puts it into ready mode. This can be skipped if it

already is in ready mode.

23/28

Page 24

Examples of register setup for each mode AN2730

Table 22. I

Byte Hex Binary Comment

16201100010 Device address + R/W bit

20000000000 COMMAND register address

38010000000 Data of the COMMAND register

2

C data packet for activating the ready mode

Writing the following 3 bytes to STCF06 activates the auxiliary LED for the desired time.

Table 23. I2C data packet for activating the AUX_LED

Byte Hex Binary Comment

16201100010 Device address + R/W bit

20200000010 Auxiliary LED register address

38510000101 Data of the auxiliary LED register

8.4 Example 4: red-eye reduction (multiple short flashes)

There are two ways to manage this task. The first one is to use hardware triggering of the

flashes through the TRIG pin. This is the most suitable and recommended solution, as it

reduces the usage of the I

continuously. The second solution is to use the software triggering feature, which means a

periodical reloading of the COMMAND register. This however increases traffic on the I

bus and the flashes can only have length adjustable in 100 ms increments only.

2

C bus and the length of each flash pulse can be adjusted

2

C

Let's suppose that R

= 0.15 Ω and the targeted value of the flash current is 1066 mA. The

FL

task is to make 5 flashes of 100 ms duration with a 100 ms pause between each.

The setting of the reference voltage is identical to the one in Section 8.1.

The Flash timer (FTIM) is set to 0xF, which represents 1.5 s.

Table 24. COMMAND register data for Flash mode

PWR_ON TRIG_EN TCH_ON NTC_ON FTIM_3 FTIM_2 FTIM_1 FTIM_0

CMD_REG

11011111

MSB LSB

Table 25. DIMMING register data for Flash mode

TDIM_3 TDIM_2 TDIM_1 TDIM_0 FDIM_3 FDIM_2 FDIM_1 FDIM_0

DIM_REG

00001101

MSB LSB

The data packet which has to be sent is given in Ta bl e 2 6.

24/28

Page 25

AN2730 Examples of register setup for each mode

Table 26. I

2

C data packet for activating the Flash mode

Byte Hex Binary Comment

16201100010 Device address + R/W bit

20000000000 COMMAND register address

3DF11011111 Data of the COMMAND register

40D00001101 Data of the DIMMING register

Figure 13 shows the TRIG pin and the I2C bus timings.

Figure 13. Multiple flashes handled by the TRIG pin

I2C bus packet

TRIG_EN bit

TRIG pin

100

100

ms

100

ms

ms

100

ms

100

ms

900 ms

100

ms

100

ms

100

ms

100

ms

8.5 Example 5: a Flash pulse longer than 1.5 s

Let's suppose that RFL = 0.15 Ω and the targeted value of the flash current is 630 mA. The

task is to make a single flash pulse with a 4-second duration.

It is necessary to reload FTIM in the COMMAND register before the internal flash timer

reaches zero. This guarantees that the Flash continues and does not stop after 1.5 sec.

The first packet must contain also the DIMMING register data, if they are different from

those which were used in the previous operation.

● Packet 1

Sets Flash mode with 1.5 s duration and the proper DIMMING.

Table 27. I2C data packet for activating the Flash mode

Byte Hex Binary Comment

16201100010 Device address + R/W bit

20000000000 COMMAND register address

3AF10101111 Data of the COMMAND register

40D00001010 Data of the DIMMING register

25/28

Page 26

Examples of register setup for each mode AN2730

● Packet 2

Sets Flash mode with 1.5 s duration. DIMMING is not set again as it is same as before

Table 28. 1

Byte Hex Binary Comment

16201100010 Device address + R/W bit

20000000000 COMMAND register address

3AF10101111 Data of the COMMAND register

st I2

C data packet to restart the Flash mode

● Packet 3

Sets Flash mode with 1.5 s duration. DIMMING remains untouched again.

Table 29. 2nd I2C data packet to restart of the Flash mode

Byte Hex Binary Comment

16201100010 Device address + R/W bit

20000000000 Command register address

3AF10101111 Data of the COMMAND register

● Packet 4

Sets Flash mode with 1 s duration. DIMMING remains untouched again.

Table 30. 3rd I2C data packet to restart of the Flash mode

Byte Hex Binary Comment

16201100010 Device address + R/W bit

20000000000 COMMAND register address

3AA10101010 Data of the COMMAND register

Please refer to Figure 14 for more details about the I

2

C-bus packets timing.

The solution described above is using a software termination of the Flash pulse. (It is timed

out by the internal timer.) The Flash pulse could be also terminated by setting the TRIG pin

to low after 4 seconds. In this case, the fourth packet could be the same as packets 2 and 3

because the timing of the Flash is done by the TRIG pin and it is not necessary to change

the value of FTIM in the COMMAND register.

This way of periodical reloading of the COMMAND register can be used to achieve a

continuous Flash light. In this case, it is very strongly recommended to guarantee an

efficient cooling of both the LED and the chip, otherwise the light can be interrupted by

activation of the thermal protections.

26/28

Page 27

AN2730 Revision history

p

Figure 14. I2C bus packets timing for a Flash lasting longer than FTIM max

Timeout of the

first Flash

1.5s

1.0s 1.0s 1.0s 1.0s

Timeout of the

second Flash

1.5s

4.0s

9 Revision history

Table 31. Document revision history

Date Revision Changes

30-Apr-2008 1 Initial release

Timeout of the

third Flash

1.5s

1.0s

Timeout of the

fourth Flash –

ending of the

whole Flash

ulse

I2C bus packets

TRIG_EN bit

TRIG pin

27/28

Page 28

AN2730

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2008 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

28/28

Loading...

Loading...