Page 1

AN2708

Application note

2X36 W digital dimmable ballast with L6574 and ST7FDALI

Introduction

This document describes a high-efficiency, high power factor, low THD and digital dimming

electronic ballast designed to drive 2X36 W T8 tube lamps.

The system consists of three main blocks:

The high-frequency ballast includes an active power factor correction circuit based on the

L6562 for universal input voltage as well as a ballast control circuit based on the L6574. The

digital dimming is performed by interfacing the ST7FDALI microcontroller with the analog

half-bridge driver.

The DALI control unit is dedicated to address the slaves, to display the lamp status and to

send the dimming commands. This unit is provided with a keyboard which allows setting

different dimming scenes over a wide range (5-100%) as well as putting in standby and

restarting the ballast. The DALI communication protocol includes single and group mode, as

well as broadcast mode to address the slaves.

The AC-DC adapter is based on the VIPer12A-E. This is an offline double-output isolated

power supply in DCM flyback configuration. The outputs are set for 20 V to supply the

communication bus and for 5 V to supply the MASTER microcontroller.

The three blocks are described in detail and their performances are shown. In addition some

of DALI basics are explained.

March 2008 Rev 1 1/42

www.st.com

Page 2

Contents AN2708

Contents

1 Block diagram and system operating conditions . . . . . . . . . . . . . . . . . 5

2 High-frequency ballast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 PFC converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 Half-bridge inverter and ballast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2.1 Lamp dimming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2.2 Supply section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.2.3 Lamp turn-on and lamp turn-off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.2.4 Verification of lamp status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.2.5 Ballast performances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3 DALI master unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.1 Master unit schematic and bill of material . . . . . . . . . . . . . . . . . . . . . . . . 26

4 Basics of DALI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5 DALI master AC-DC adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.1 Adapter description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.2 Adapter bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.3 Adapter performances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.3.1 Steady state tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.3.2 Startup behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.3.3 Dynamic load tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.3.4 Line regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.3.5 Load regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.3.6 Efficiency variation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.3.7 Conducted emissions test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2/42

Page 3

AN2708 List of tables

List of tables

Table 1. System operating conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

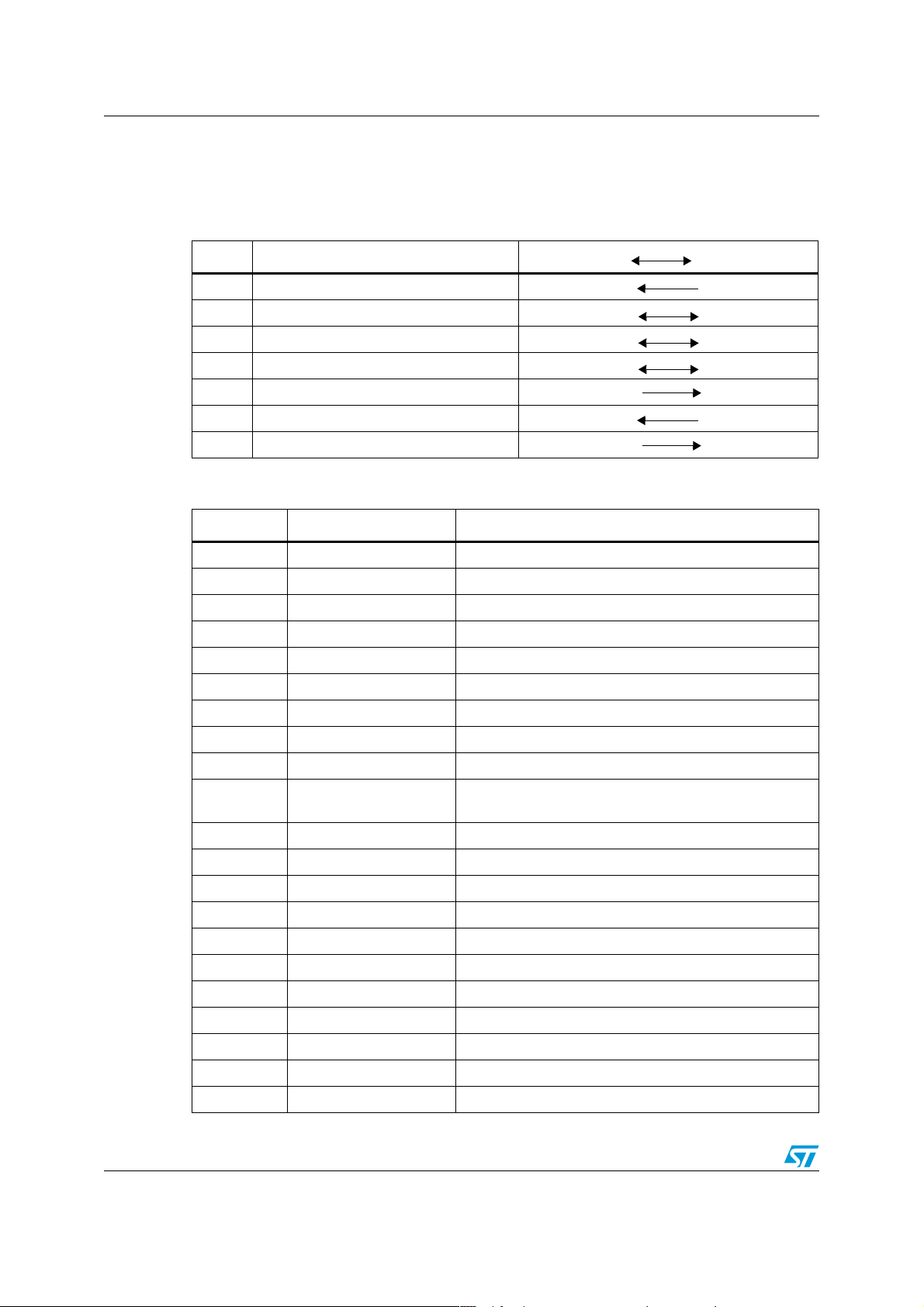

Table 2. Ballast-slave communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 3. Ballast bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 4. PFC operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 5. Power stage design equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 6. L6562 biasing circuitry design equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 7. Lamp parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 8. L6574 biasing circuitry design equations for operating conditions . . . . . . . . . . . . . . . . . . . 16

Table 9. Ballast performances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 10. Master unit bill of material. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 11. SMPS operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 12. Adapter bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 13. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3/42

Page 4

List of figures AN2708

List of figures

Figure 1. System block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2. 2X36 W digital dimmable ballast with L6574 and ST7FDALI . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. Ballast schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 4. PFC performances at 230 V

Figure 5. Lamp ballast model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 6. Ballast transfer functions (magnitude) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 7. DALI protocol brightness values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 8. Ballast controls timing chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 9. Idle state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 10. Turn-on procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 11. Turn-off procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 12. Forward frame timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 13. Backward frame timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 14. Ballast startup at 230 V

Figure 15. Lamps turn-on at 230 V

Figure 16. Lamps running at 230 V

Figure 17. Polling keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 18. Pressed button event . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 19. Master unit schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 20. Cable wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

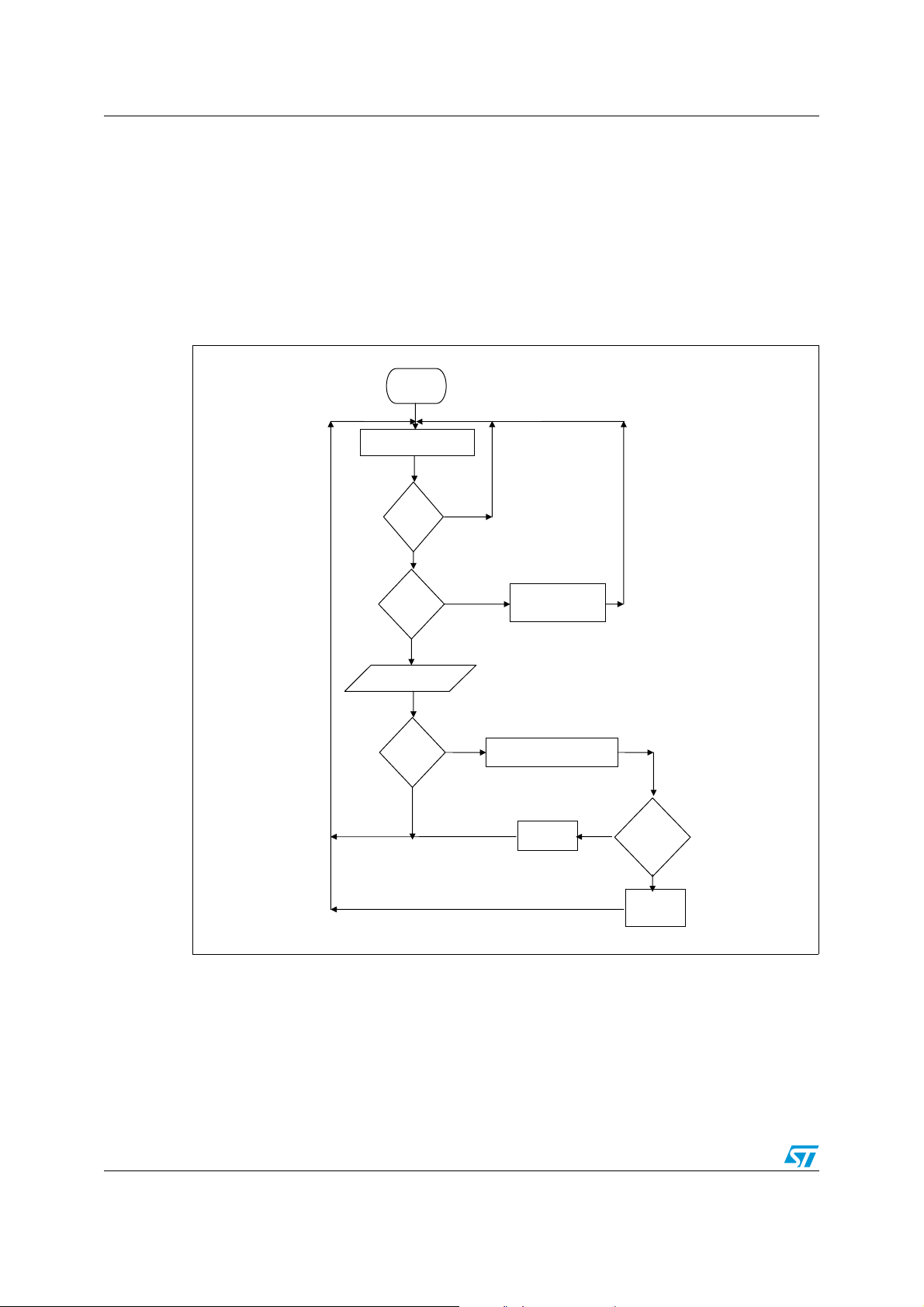

Figure 21. Master flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 22. Slave flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 23. Adapter schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 24. Adapter PCB layout - top side -silkscreen (to scale). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 25. Adapter PCB layout - bottom side - copper tracks (to scale) . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 26. Flyback transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 27. VIPer12A-E steady state behavior at full load at 110 V

Figure 28. VIPer12A-E steady state behavior at full load at 230 V

Figure 29. VIPer12A-E steady state behavior at minimum load at 110 V

Figure 30. VIPer12A-E steady state behavior at minimum load at 230 V

Figure 31. Startup waveforms at full load at 110 V

Figure 32. Startup waveforms at full load at 230 V

Figure 33. Startup waveforms at minimum load at 110 V

Figure 34. Startup waveforms at minimum load at 230 V

Figure 35. Dynamic load waveforms at 110 V

Figure 36. Dynamic load waveforms at 230 V

Figure 37. Line regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 38. Load regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 39. Efficiency variations vs. input voltage at full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 40. Conducted emissions at 110 V

Figure 41. Conducted emissions at 110 V

Figure 42. Conducted emissions at 230 V

Figure 43. Conducted emissions at 230 V

-50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

ac

-full power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

ac

-full power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

ac

- full power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

ac

- 60 Hz . . . . . . . . . . . . . . . . . . 36

ac

- 50 Hz . . . . . . . . . . . . . . . . . . . 36

ac

- 60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

ac

- 50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

ac

- 60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

ac

- 50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

ac

60 Hz - full load - line 1 peak detector . . . . . . . . . . . . . . 40

ac

60 Hz - full load - line 2 peak detector . . . . . . . . . . . . . 40

ac

50 Hz - full load - line 1 peak detector . . . . . . . . . . . . . . 41

ac

50 Hz - full load - line 2 peak detector . . . . . . . . . . . . . 41

ac

- 60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . 38

ac

- 50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . 38

ac

- 60 Hz . . . . . . . . . . . . . . 36

ac

- 50 Hz . . . . . . . . . . . . . . 36

ac

4/42

Page 5

AN2708 Block diagram and system operating conditions

1 Block diagram and system operating conditions

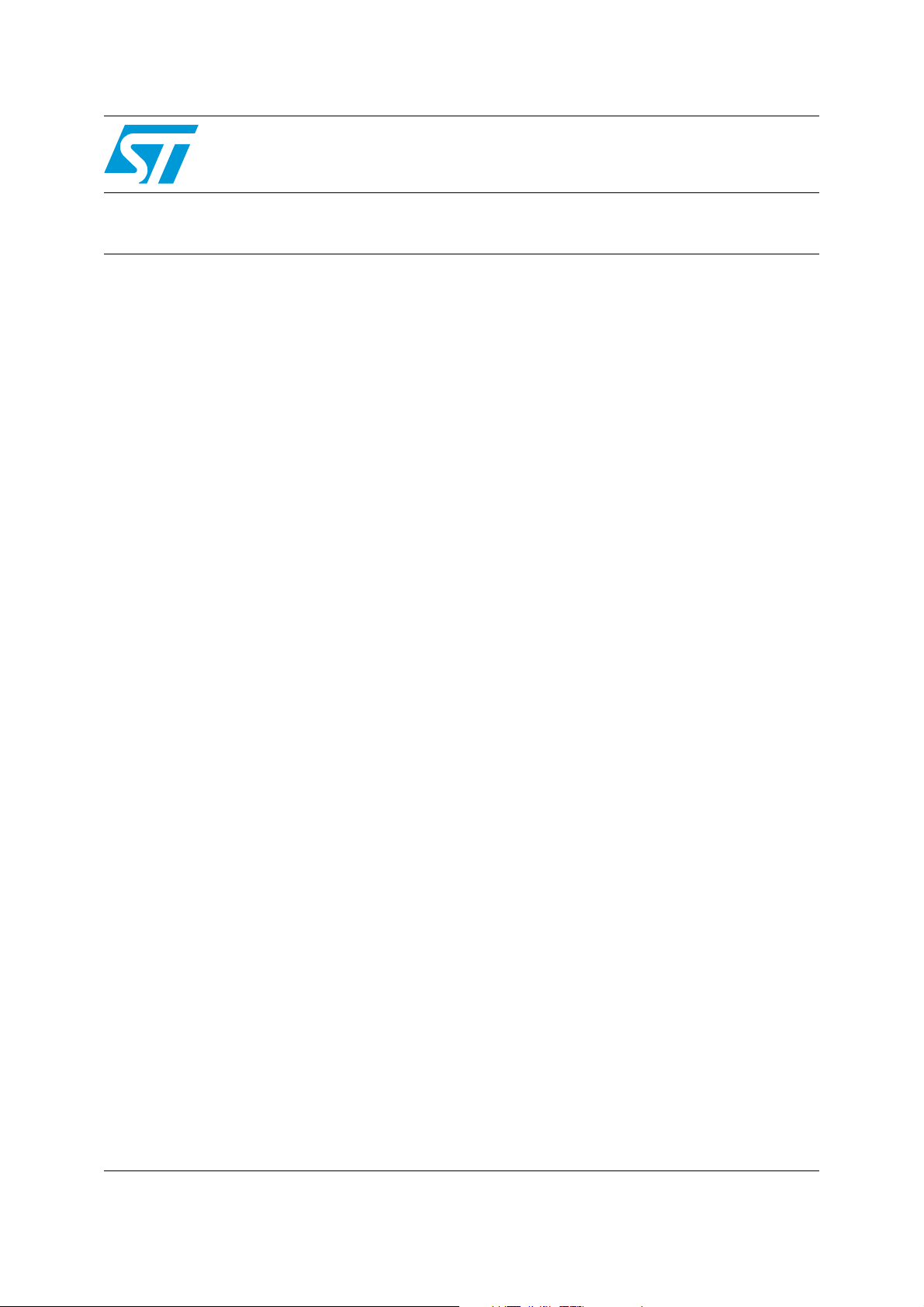

Figure 1 shows the block diagram of the system.

Figure 1. System block diagram

HIGH

FREQUENCY

BALLAST

ACíDC ADAPTER

SCI communication is considered as an option.

MASTER UNIT

SCI

Communication

Option

5/42

Page 6

Block diagram and system operating conditions AN2708

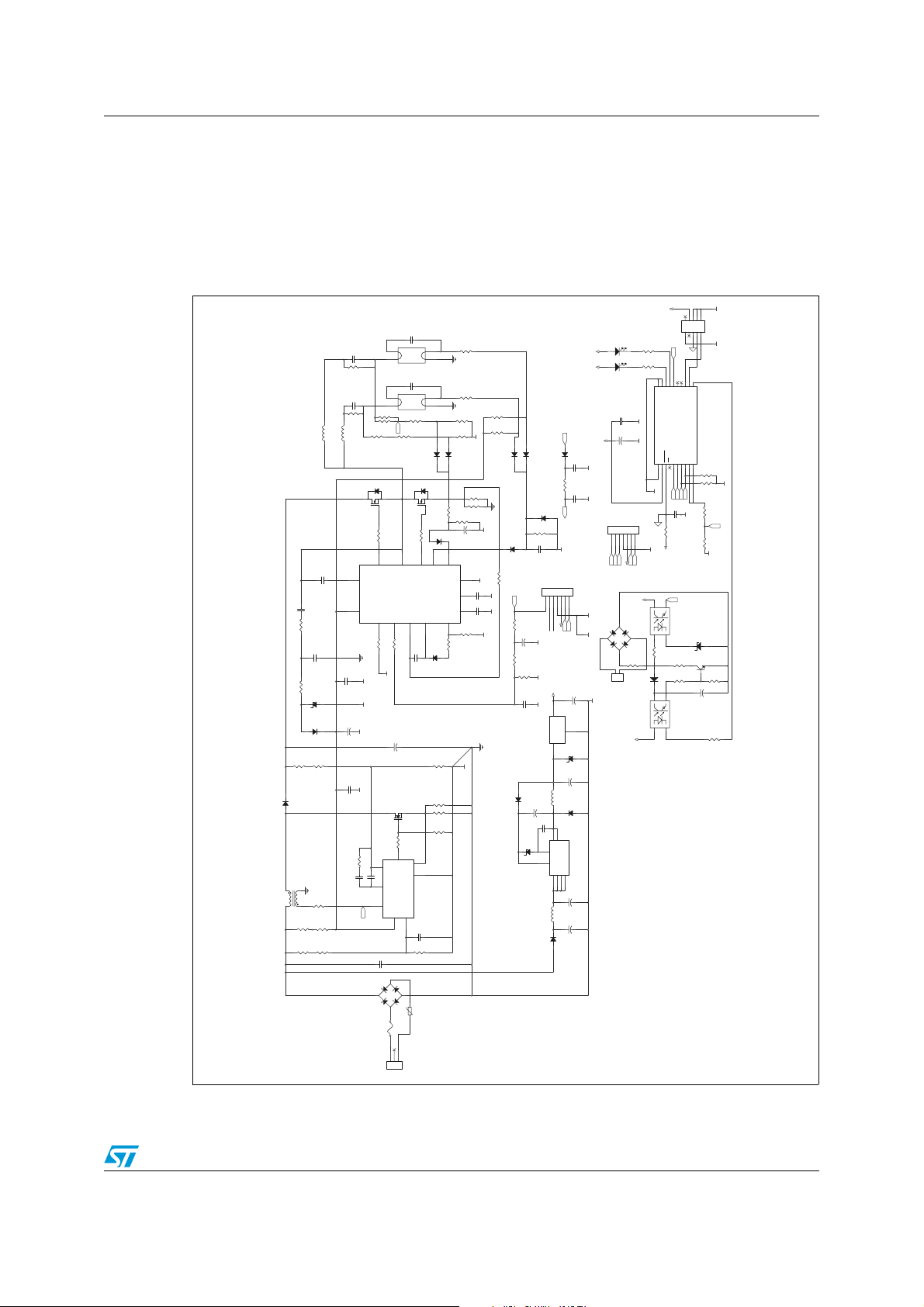

The present system has been designed according to the following specifications:

Table 1. System operating conditions

Parameter Value

Input voltage range 176-265 Vac/50 Hz; 90-140 Vac/60 Hz

Lamp type 2X36 W T8 tube lamps

Circuit power (max) 80 W

Lamp power (max) 72 W

Dimming range 5% to 100%

Power factor > 0.99

Current THD < 10%

Warm start < 1.5 sec

Standby mode power < 0. 6 W

In addition to the previous specs, the DALI communications are optically isolated, the digital

dimming is performed with high precision, and the lamp filament preheating time is

programmable as well as the ignition time.

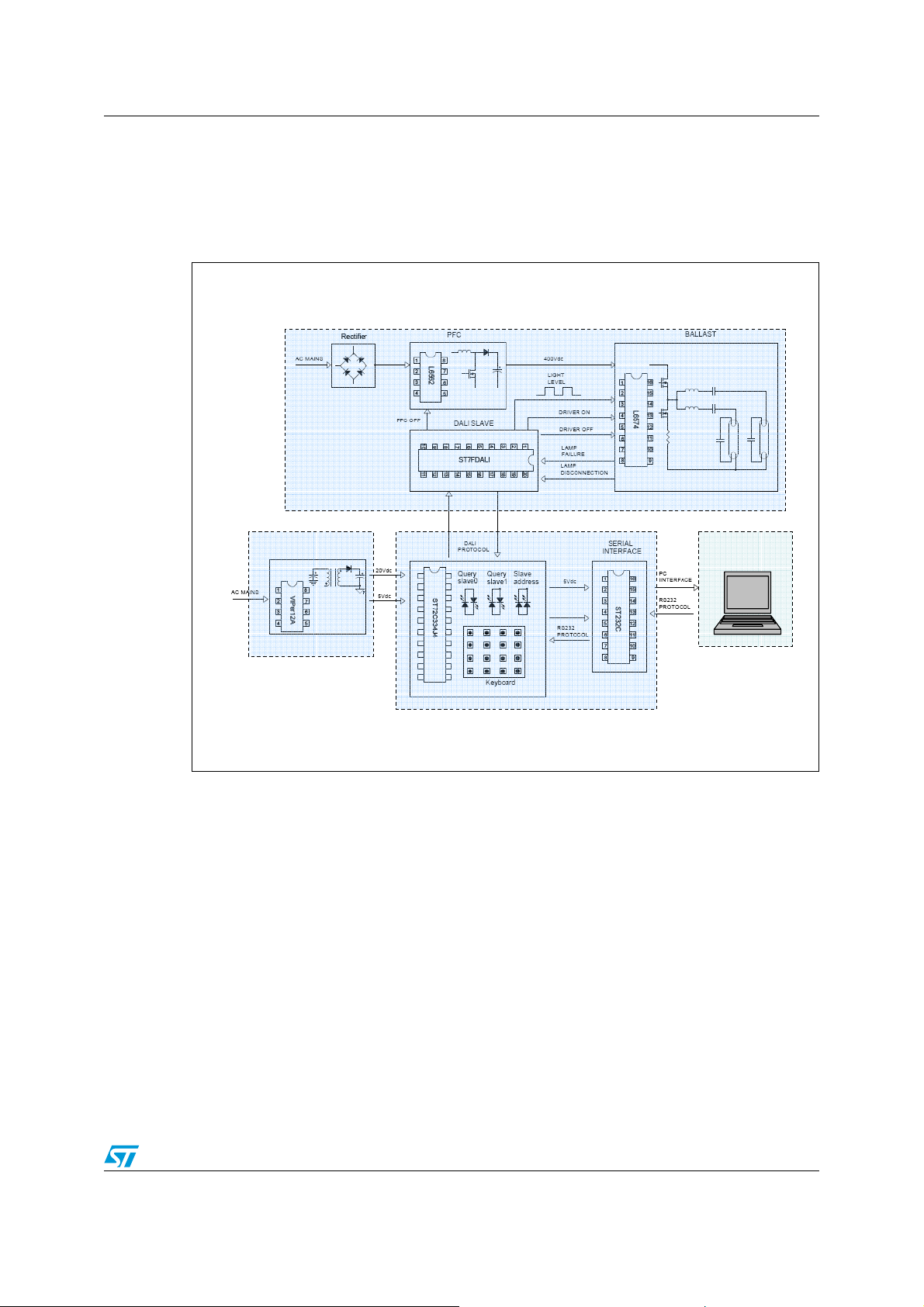

Figure 2. 2X36 W digital dimmable ballast with L6574 and ST7FDALI

HIGH FREQUENCY BALLAST

MASTER UNIT

MASTER UNIT

ACíDC

ACíDC

ADAPTE R

ADAPTE R

6/42

Page 7

AN2708 High-frequency ballast

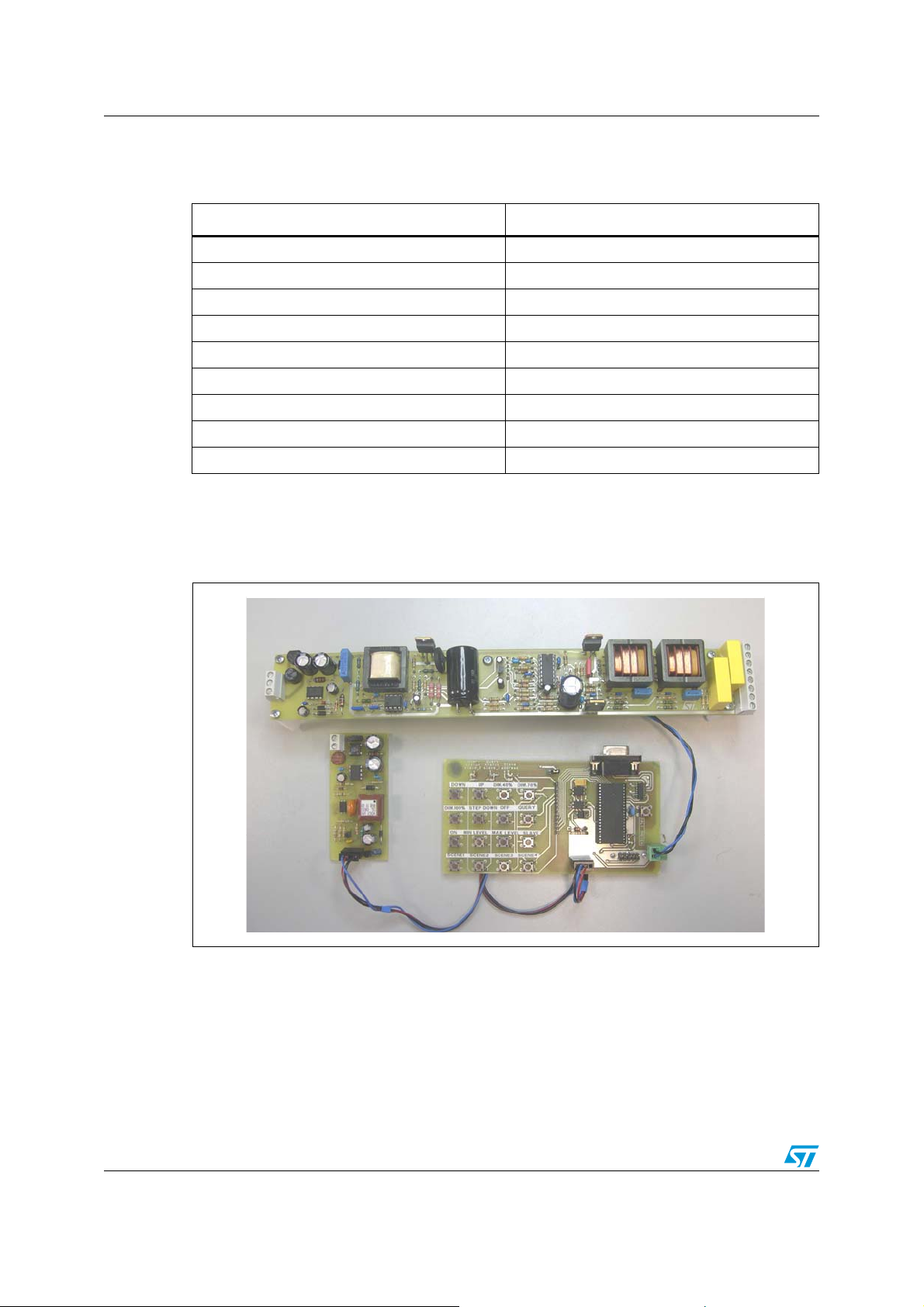

2 High-frequency ballast

This section describes the high-frequency ballast board which includes the power factor

correction stage, the half-bridge inverter driving circuitry, the output stage and the DALI

slave unit. The schematic of the board is shown in Figure 3.

Figure 3. Ballast schematic

5VDD

9

+1+3+5+7+

IC_GND

+2+4+6+8+

SIGN

IC_GND

IC_GND

0

R64

R63

CON7

IC_GND

5VDD

D17

2K49

1%

1%

2K49

19

20

OSC1/CLKIN

U11

VSS1VDD2RESET3SS/AIN0/PB04SCK/AIN1/ PB15MISO/AIN2/PB26MOSI/AIN3/PB37CLKIN/AIN4/PB48AIN5/PB59DALIIN/AIN6/PB6

IC_GND

Reset

R62

4

U10

112

R61

11K

BAS16

4

U9

112

J5

ICP Connector

10

Reset

PWM0

IC_GND

13

12

14

16

11

17

18

OSC2

PA0(HS)/LTIC

PA7/DALIOUT

PA1(HS)/ATIC

ST7FDALIF2M6

PA4(HS)/ATPWM2

PA3(HS)/ATPWM115PA2(HS)/ATPWM0

PA6/MC0/ICCCLK/BREAK

PA5(HS)/ATPWM3/ICCDATA

10

R70

1k 1%

R69

1k 1%

PB1

C45

100nF

4K7

1%

5VDD

334

SFH6156-2

2

1%

334

SFH6156-2

2

IC_GND

PB2

EN2

EN1

0

R68

50V

IC_GND

PIN3 SFH6156-2

R67

10K

1%

IC_GND

PIN3 SFH6156-2

D18

BZX284C 2V7

0.5W

Q4

BC817-25

312

R66

4R7

1%

R65

+

R72

3K16

1%

1%

332R

C46

22uF

20V

R71

1K21

1%

1600V

C20

8.2nF

C21

100nF

250V

1

23

Lamp2

T8 36W

1W

R30_2

100K

250V

C17

100nF

18

18

R30_1

100K

1W

L1

L2

1.8mH

1.8mH

213

Q2

16

C14

100nF

630V

C11

1nF

R17

22E 1W

Rs= max 5 ohm @100kHz

C10

4.7nF

R14

10E

DZ1

15V

On Air On Air

D3

1N4148

R9

750K

1%1%

D2

STTH1L 06

8 1

T1

5 4

TRANSFORMER

R6

R4

180K

R1

750KR2750K

VS

12

IC_GND

C19

100nF

0.5W

IC_GND

+

IC_GND

50V

C7

4.7uF

R10

750K

1%

IC_GND

C5

100n

R8

12K

C4

1000n

68K

PB2

R5

180K

1%

C1

R26_2A

R26_1

750K

STP8NM50

R21

10E

15

HVG

VBOOT

RPRE2OPIN+

R12

120K

1

C3

2

5

U1

100nF

BRIDGE

432

180K

R26_2

750K

R15

10K

IC_GND

23

R7

INV

330n

W08G

1

FUSE

4A/250V

Line

J1

1

23

SIGN

7

C6

+

33E

COMP

ZCD

VCC

8

C18

8.2nF

Lamp1

T8 36W

R27_2

750K

R27_1

750K

213

Q3

STP8NM50

R22

10E

14

OUT

U2

L6574

OPIN-6OPOUT5RING

C9

400V

47uF

Q1

STP8NM50

1

7

CS

GD

GND

U1

L6562

MULT

3

C2

R3

-+

NTC

15E@25° 3A

Neutral

123

CON3

4

1600V

4

LVG11EN18EN2

100nF

4

6

10nF

10K

1%

R29_2

15K

R29_1

15K

R24_2

680K

R28_2

4.7K

L1&L2: Choke Induc t or

- E25x13x7 core

- 2.62mm gap f or 1.8mH indu ct a nce

- 267 turns (AWG 40)

R24_1

680K

4.7K

R28_1

IC_GND

D5 BAT46

D7 BAT46

R23

330E

R20

D11

1N4148

EN1

EN2

9

GND

CPRE

CF

4

R1668K

D4

1N4148

R11

1%

9.53K

RS2

0.82E

1W

RS1

0.82E

1W

R13

47K

D6 BAT46

RS_2

1E

0.6W 0.6W

RS_1

1E

1K

+

IC_GND

C15

D8

1N4148

330uF 25V

IC_GND

10

R1910K

IC_GND

C13

PWM0

1000nF 25V

1

3

Rf

15K

C12

470pF

IC_GND

R18

68K

IC_GND

Rup

120K

C8

IC_GND

600V 1A

D14

STTH1L06

T1: Boost Inductor Spec (ITACOIL E2543/E)

- E25x13x7 core, 3C 85 f errite

- 1.5mm gap f or 0.7mH prim ar y inductanc e

- Primary: 105 turns (20 x 0.1mm)

- Secondary: 11 t ur ns (0 . 1m m )

SIGN

D61

BAT46

D9 BAT46

68K

1%

R100

D10

BAT46

PB1

R25

470E

IC_GND

C16

10nF 25V

J2

1234567

EN2

EN1

5VDD

PB2

+

Cf

Rlow

100nF

SIGN

50V

4.7uF

IC_GND

4.7K

5VDD

IC_GND

1

IC_GND

VOUT

GND

2

VIN

U7 LE50CZ

3

Cout

+

95mA

L3

1.8mH

CVdd

10uF 25V

+

2

Cfb

S1S

DZ2

15V 0.5W

22nF 25V

FB

3

Vdd

4

D5D6D7D

8

+

L4

680uH

240mA

+

D15

1N4007 1A 1000V

HSMG-C670

GREEN

LD2

5VDD5VDD

LD1

RED

HSMS-C670HE

C44

100nF

50V

C43

1uF

16V

+

5VDD

IC_GND

C72

33nF

50V

IC_GND

C73

50V

68pF

J4

1234567

PB2

EN1

EN2

5VDD

PWM0

CON7

3

-+

IC_GND

142

D16

MB2S

Vss_STDALI

C42

2.2uF16V

+

D12

18V 0.5W

10uF 25V

D13

STTH1L 06

600V

1A

U8 Viper12A

Cin2

3.3uF 450V

Cin1

3.3uF 450V

R60

1

2

J3

DALI Bus

CON2

Vss_ST7DALI

5VDD

7/42

Page 8

High-frequency ballast AN2708

This block is essentially a "double board" as the DALI slave board and its external circuitry

are mounted on a small separated board which is connected to the bottom side by means of

a 7-pin connector. Ta bl e 2 shows the ballast-slave communication.

Table 2. Ballast-slave communication

Pin ref. Description Analog stage Microcontroller

1 PWM0 (ref op-amp)

2 Disable L6574 EN1 & disconnected lamp

3 Enable L6574 EN2 & not ignited lamp

4GND

55 VDD

6 PB2 disable PFC

7 SIGN (lamp failure)

Table 3. Ballast bill of material

Reference Value Description

Bridge W08G 1.5 A 800 V Bridge rectifier

Cout, CVdd 10 µF 25 V Electrolytic cap

C7,Cf 4.7 µF 50 V Electrolytic cap

Cfb 22 nF 25 V Ceramic cap

Cin1,Cin2 3.3 µF 450 V Electrolytic cap

C1 100 nF 400 V Polyester cap

C2 10 nF 50 V Ceramic cap

C3 330 nF 50 V Ceramic cap

C4 1000 nF 50 V Ceramic cap

C5,C8,C9,C1

9

C6 47 µF 450 V Electrolytic cap

C14 100 nF 100 V Ceramic cap

C10 4.7 nF 100 V Ceramic cap

C11 1 nF 630 V Evox Rifa polypropylene cap Rs

C12 470 pF 50 V Ceramic cap

C13 1 µF 50 V Ceramic cap

C15 330 µF 25 V Electrolytic cap

100 nF 50 V Ceramic cap

= 5 Ω at 100 kHz

max

C16 10 nF 25 V Ceramic cap

C17, C21 100 nF 250 V Polyester cap

C18,C20 8.2 nF 1600 V Polyester cap

C42 2.2 µF16 V Electrolytic cap

8/42

Page 9

AN2708 High-frequency ballast

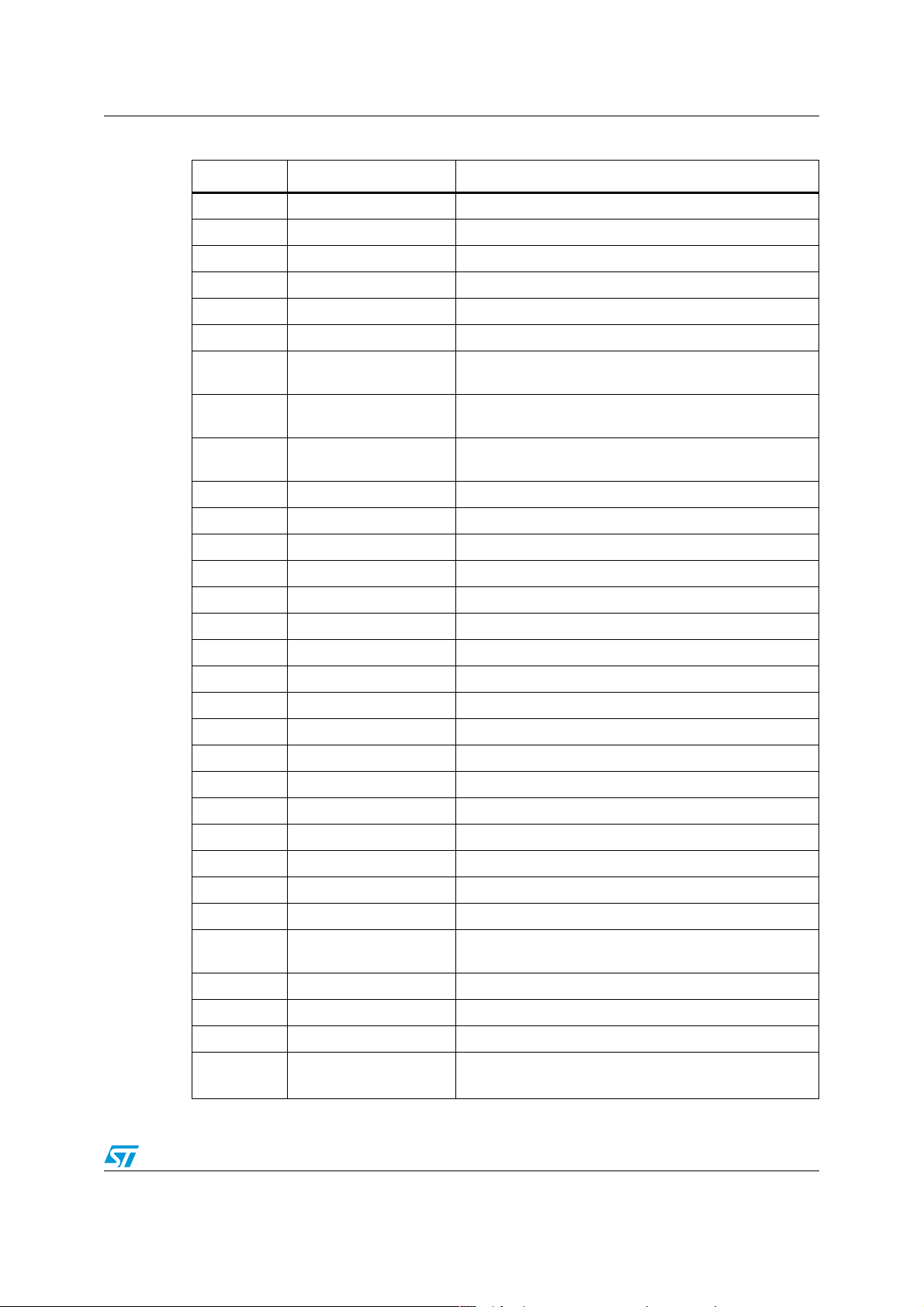

Table 3. Ballast bill of material (continued)

Reference Value Description

C43 1 µF 20 V SMD tantalum cap

C44,C45 100 nF 50 V 0805 SMD cap

C46 22 µF 20 V SMD tantalum cap

C72 33 nF 50 V 0805 SMD cap

C73 68 pF 50 V 0805 SMD cap

DZ1,DZ2 15 V 0.5 W Zener diode

D2,D13,D14 STTH1L06

D3,D4,D8,D1

1

1N4148 Small signal rectifier 200 mA 100 V

STMicroelectronics ultrafast high voltage rectifier 1 A 600

V

D5,D6,D7,D9

, D10,D61

D12 18 V 0.5 W Zener diode

D15 1N4007 1 A 1000 V General purpose rectifier

D16 MB2S 0.5 A 200 V SMD bridge rectifier

D17 BAS16 Small signal diode

D18 BZX284C 2V7 0.5 W Zener diode

FUSE 4 A 250 V Radial fuse

J1 Input 250 V connector 3-way PCB screw terminal, 5.08 mm

J2 Ballast-slave connector 7-way strip line socket

J3 Dali Bus 2-way vertical PCB header, 3.81 mm pitch

J4 Ballast-slave connector 7-way strip line connector

J5 ICP connector 10-way 2-row vertical through-hole boxed header

J13 4-way strip line socket

J14 4-way strip line connector

Lamp 1 Lamp connector 4-way PCB screw terminal, 5.08 mm

Lamp 2 Lamp connector 4-way PCB screw terminal, 5.08 mm

LD1 LS M67K-H2L1-1 2 mA red LED SMD 0805

LD2 LG M67K-G1J2-24 2 mA green LED SMD 0805

L1,L2 1.8 mH

L3 1.8 mH 95 mA Epcos BC series Axial inductor

L4 680 µH 240 mA Epcos LBC series Axial inductor

BAT46 DO 35 STMicroelectronics small signal Schottky diode

Choke inductor 2.62 mm gap, 267 turns (AWG40);

E25x13x7

NTC 15 Ω at 25 °C 3 A Inrush current suppressor

Q1,Q2,Q3 STP8NM50 TO220

STMicroelectronics N-CHANNEL 550 V 0.7 Ω - 8 A

MDmesh MOSFET

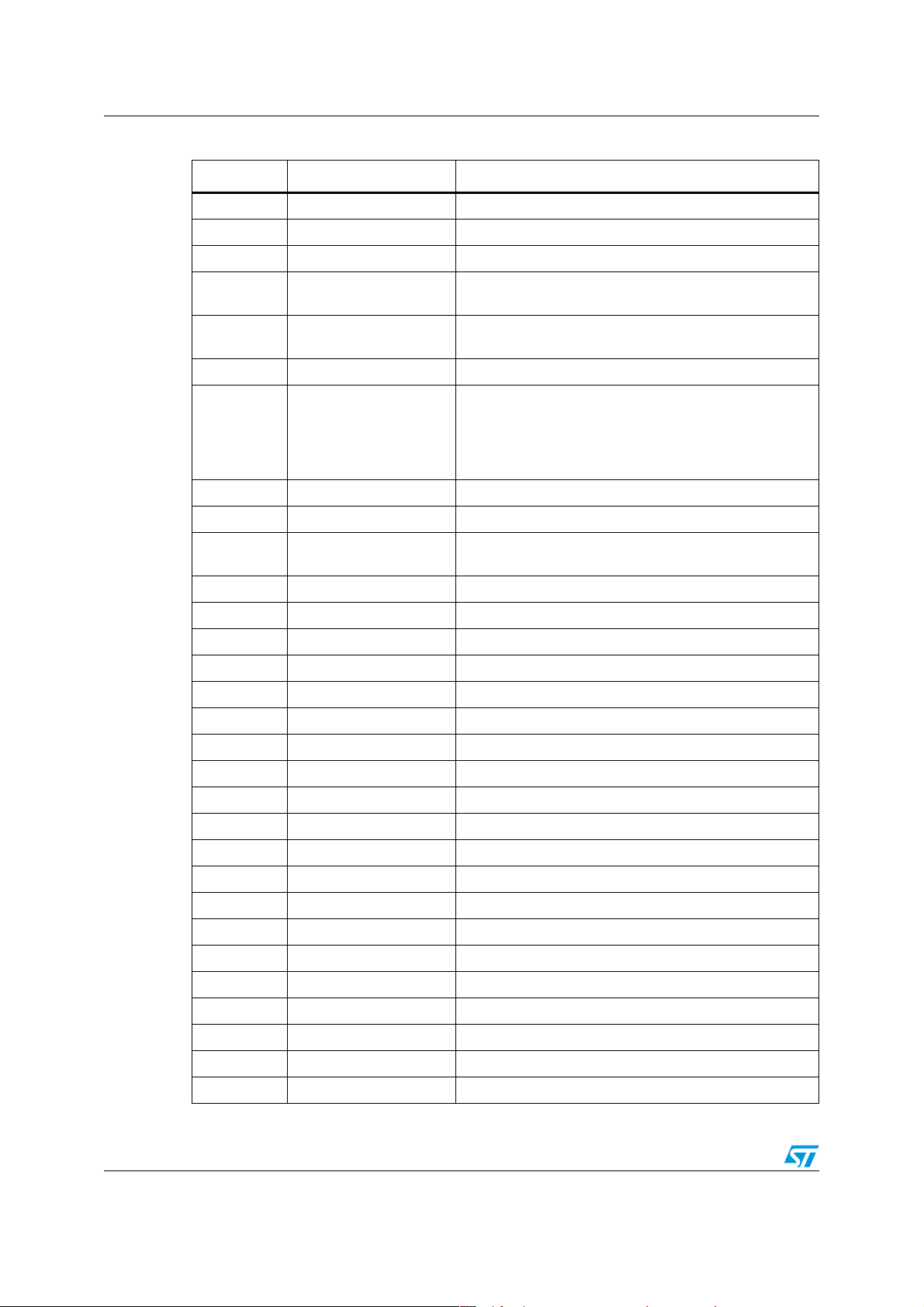

9/42

Page 10

High-frequency ballast AN2708

Table 3. Ballast bill of material (continued)

Reference Value Description

Q4 BC817-25 NPN small signal bipolar

RS_1,RS_2 1 Ω 0.6 W 1% metal film resistor

RS1,RS2 0.82 Ω 1 W resistor

R29_1,

R29_2,Rf

R28_1,

R28_2,Rlow

R12,Rup 120 kΩ Resistor

R1,R2,R9,

R10, R26_1,

R26_2,

R27_1,

R27_2

R15,R19 10 kΩ Resistor

R3 10 kΩ 0.6 W 1% resistor

15 kΩ Resistor

4.7 kΩ Resistor

750 kΩ 0.6 W 1% resistor

R4,R5,

R26_2A

R6,R16,R18 68 kΩ Resistor

R7 33 Ω Resistor

R8 12 kΩ Resistor

R11 9.53 kΩ 1% Resistor

R13 47 kΩ Resistor

R14,R21,R22 10 Ω Resistor

R17 22 Ω 1 W resistor

R20 1 kΩ Resistor

R23 330 Ω Resistor

R25 470 Ω Resistor

R60,R68 0 Ω SMD resistor 0805

R61 11 kΩ 1% SMD resistor 0805

R62 4.7 kΩ 1% SMD resistor 0805

R63,R64 1 kΩ 1% SMD resistor 0805

R65 330 Ω 1% SMD resistor 0805

R66 4.7 Ω 1% SMD resistor 0805

180 kΩ Resistor

R67 10 kΩ 1% SMD resistor 0805

R69,R70 1 kΩ 1% SMD resistor 0805

R71 1.2 kΩ 1% SMD resistor 0805

R72 3 kΩ 1% SMD resistor 0805

10/42

Page 11

AN2708 High-frequency ballast

Table 3. Ballast bill of material (continued)

Reference Value Description

R100 68 kΩ 1% SMD resistor 0805

R24_1,R24_

2

R30_1,R30_

2

T1 Transformer Choke boost inductor (ITACOIL E2543/E)

U1 L6562N STMicroelectronics transition-mode PFC controller

U2 L6574 STMicroelectronics ballast driver

U7 LE50CZ TO-92 STMicroelectronics very low drop voltage regulators

U8 VIPer12A-E DIP8

U9,U10 SFH6156-2 Optocoupler

U11 ST7FDALIF2M6 SO20

680 kΩ Resistor

100 kΩ 2 W resistor

STMicroelectronics offline SMPS primary IC 730 V 0.4 A

27R

STMicroelectronics

8-bit MCU with single voltage Flash memory, data

EEPROM, ADC, timers, SPI, DALI

Note: Resistors are 0.25 W unless specified. Q1, Q2 &Q3 are mounted with 8 °C/W heatsink.

2.1 PFC converter

This block allows drawing a quasi-sinusoidal current from the mains, in phase with the line

voltage in order to get a PF very close to 1 (more than 0.99).

To achieve such high PF the boost topology is implemented because of the advantages it

offers:

● Minimum number of external components, thus making it a low-cost solution

● Low input di/dt thus minimizing the noise generated at the input and, therefore, the

requirements on the input EMI filter

● The switch is source-grounded, therefore is easy to drive

However, boost topology requires the DC output voltage (400 Vdc) to be higher than the

maximum expected line peak voltage.

ST's L6562 has been used as the driver. It implements a transition mode control (fixed ON

time, variable frequency), that, for such output power, is preferred to the fixed frequency

average current mode being simpler and cheaper. The circuit operates on the boundary

between continuous and discontinuous current mode.

Besides providing good results in terms of power factor, this IC considerably reduces the

Total Harmonic Distortion (THD) as it reduces the conduction dead-angle that occurs to the

AC input current near the zero-crossings of the line voltage.

11/42

Page 12

High-frequency ballast AN2708

The basic design specifications are listed in Tab le 4 .

Table 4. PFC operating conditions

Parameter Value

Mains voltage range: Virms(min) - Virms(max) 90 – 265 Vac

Regulated DC output voltage: Vo 400 Vdc

Rated output power: Po 75 W

Minimum switching frequency: f

sw

Maximum output voltage ripple: ∆Vo < ± 10 V

35 kHz

Maximum overvoltage admitted: ∆V

Expected efficiency: η

PFC

OVP

60 V

> 90 V

For reference, it is useful to define also the following quantities:

● Input power: Pi (= Po / η ) ≈ 80 W

● Maximum mains RMS current: Iirms (= Pi/Virms(min)) ≈ 1 A

● Rated output current: Io (= Po/Vo) ≈ 0.2 A

The design guidelines are deeply explained in AN966 ("L6561, enhanced transition mode

power factor corrector"), AN1757 ("Switching from the L6561 to the L6562) and AN1089

("control loop model of L6561-based TM PFC"). The main design formulas are summarized

as follows inTab le 5.

Table 5. Power stage design equations

Input capacitor (C1) Boost inductor Power MOSFET (Q1) Boost diode (D1)

C1

Irms

------------------------------- ---------------------------------------- -=

2π fsw r Vinrmsmin⋅⋅⋅

where

r 0.01 0.1÷=

Output capacitor (C6)

Volume 4K L I2irms⋅⋅≥

V2irms Vo 2 Virms⋅–()⋅

L

-------------------------------- --------------------------------------------- -=

where

2fswPi Vo⋅⋅⋅

K1410

⋅⋅≅

V

Vo ∆V

DSS

2

Pon I

Qrms

where

3–

Ie

------------ -

Igap

I

Qrms

2 2 Iirms

OVP

⋅=

R

Vm inarg++=

DS on()

42

1

---------- -

---

9π

6

⋅–⋅⋅=

Virms

---------------- -

Vo

V

RRM

IF3Io⋅=

1.2 Vo⋅=

--------------------------------- ---------------- -

C6

≥

4π fVo∆Vo⋅⋅ ⋅

Po

Pcu

I2irms Rcu⋅⋅=

3

Pcross Vo Iirms t

⎛⎞

Pcap 3.3Coss V

⎝⎠

4

---

12/42

⋅⋅⋅=

fallfsw

1.5

drain

1

-- -

Cd V2drain⋅+⋅

2

P

lossesVTIDC

fsw⋅=

Rd I2rms⋅+⋅=

Page 13

AN2708 High-frequency ballast

Table 6. L6562 biasing circuitry design equations

Pin 1 (INV) Pin 2 (COMP) Pin 3 MULT Pin 4 (CS)

∆OVP R

V

out

high

R

-------------------------------- ---------- -

2.5

⋅=

6–

40 10

⋅⋅=

+()

highRlow

R

low

A RC-C network is

placed between this

pin and pin 1, leading

to a low crossover

frequency (some tens

of hertz) as well as to

an adequate phase

margin.

A small capacitor of 10 nF

filters the signal on MULT pin.

V

MULTpkx

------------------------------- -

Rlow

250 106–⋅

R

low

--------------------------------- -----

R

+

lowRhigh

-------------------------------- --------------- -=

2V

⋅

2.5

----------------------------- -==

250 106–⋅

2.5

inrmsmax

R

sense

Pin 5 (ZCD) Pin 6 (GND) Pin 7 (GD) Pin 8 Vcc

The supply voltage is

provided by a capacitive

power supply connected to

the half-bridge inverter.

R

start

Vout 2 V

m

--------------------------------- ---------------------------------------=

R6

≥

⋅–()

2.1 1.15⋅

Vout 2 V

---------------------------------- ------------------------------------ -

⋅–()

m310

⋅⋅

inrmsmax

inrmsmin

3–

IC ground. As a layout

hint, this pin has to be

kept separated from

power ground. All the

IC signals have to be

referred to this pin.

Gate driver.

A "bleeder" resistor between

the gate and the source is

used to avoid undesired

switch-on, without affecting

the power consumption.

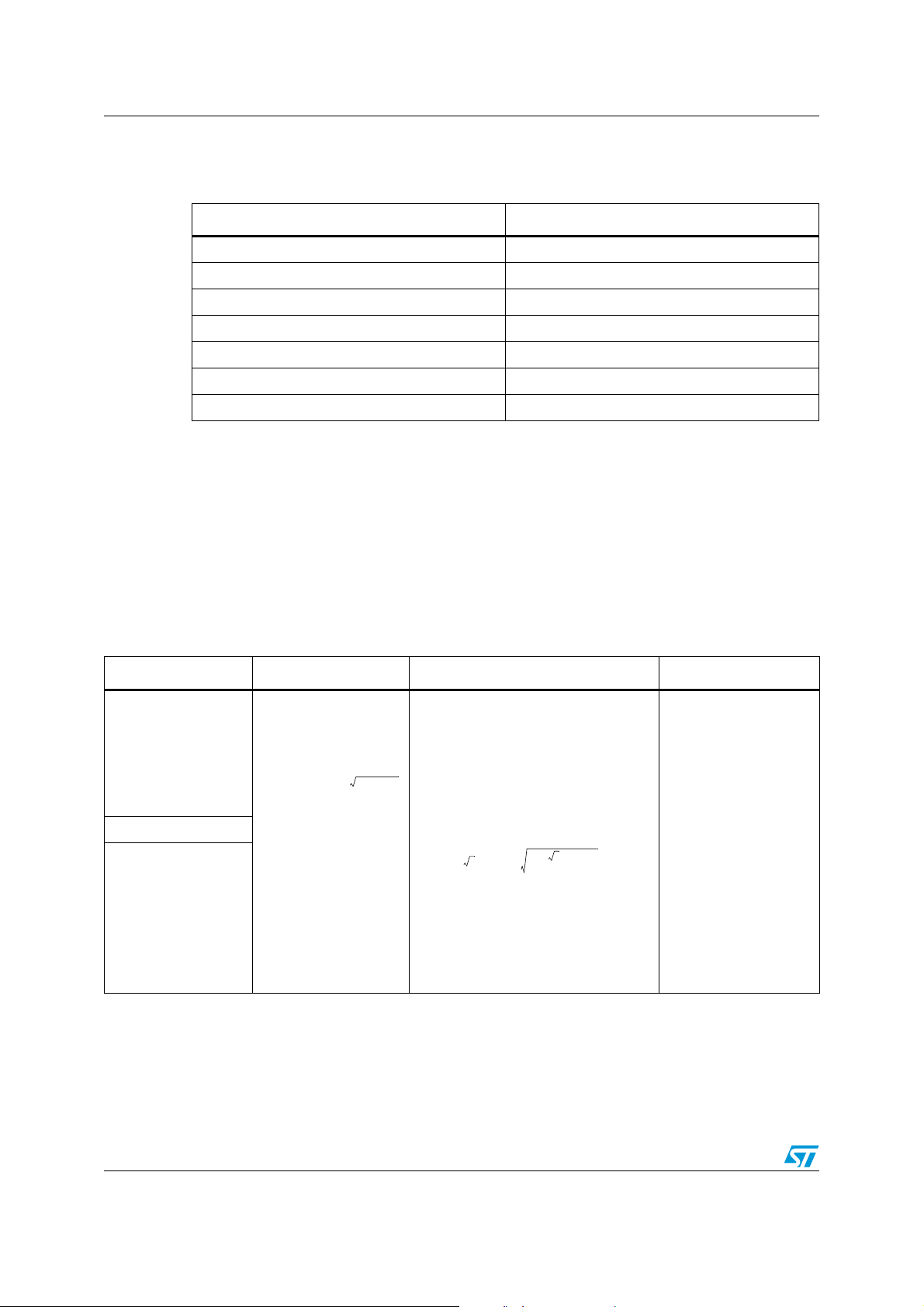

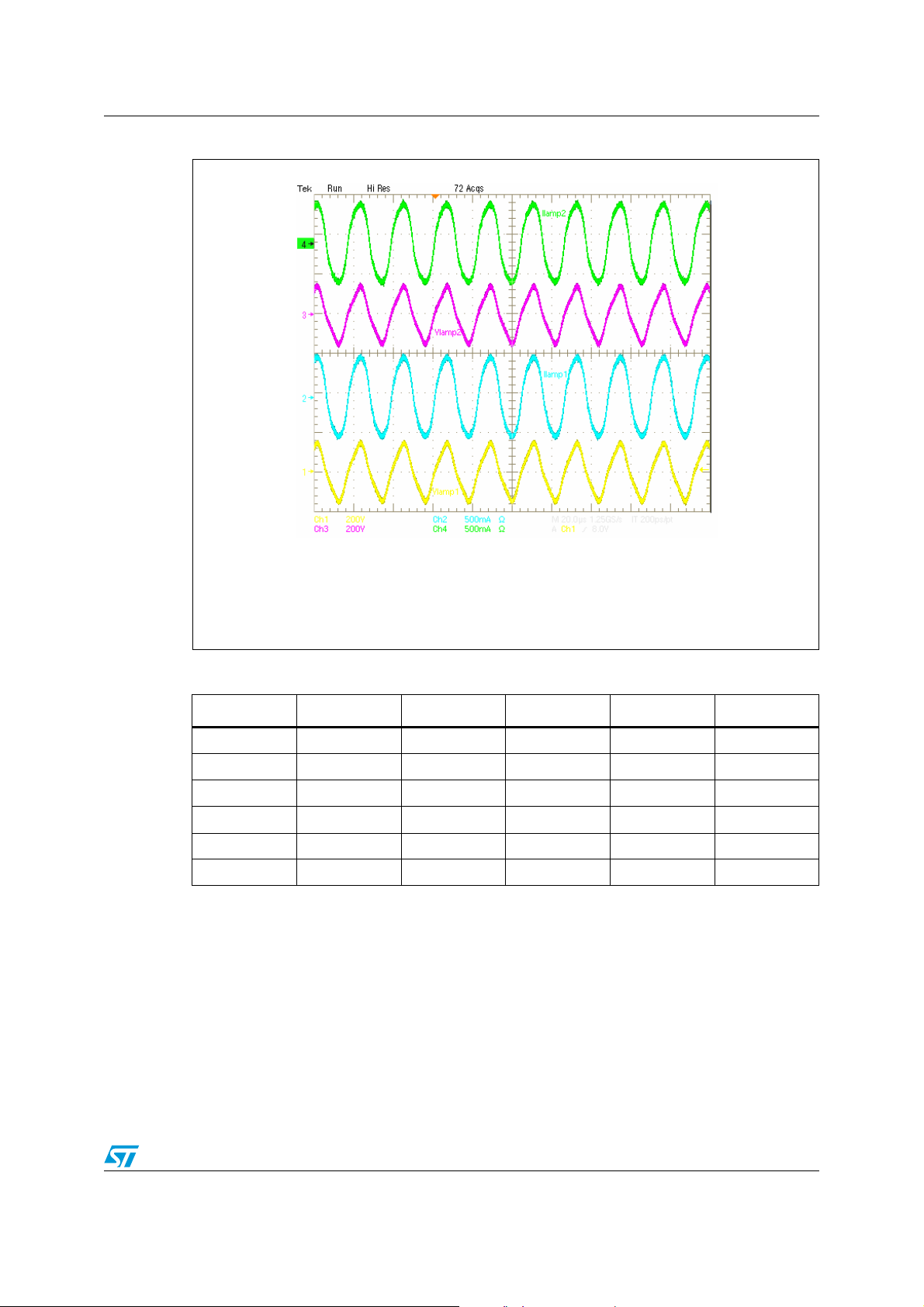

The PFC preregulator performances are shown in the following graphs:

Figure 4. PFC performances at 230 Vac-50 Hz

V

⎛⎞

inrmsmin

1.65 2.5

--------------------------------- --------------------------------------- -

≤

Pd Rs I

-------------------------------- -

⋅

⋅

⎜⎟

V

⎝⎠

inrmsmax

22I

⋅⋅

inrms

2

⋅=

Qrms

V

inrmsmin

-------------------------------- --------------=

I

2⋅

startup

CH1 (yellow): rectified input voltage

CH2 (blue): input current

13/42

Page 14

High-frequency ballast AN2708

2.2 Half-bridge inverter and ballast

A voltage fed series resonant half-bridge inverter has been implemented to drive the tubes.

This topology allows to easily operates in zero-voltage switching (ZVS) resonant mode,

heavily reducing the transistor switching losses and the electromagnetic interference. In

addition it guarantees design simplicity and low cost.

A parallel configuration has been chosen for the output stage. The half-bridge inverter

operating conditions and the ballast design have been obtained by assuming, for each lamp,

the following basic model:

Figure 5. Lamp ballast model

To increase the life time of the lamps a current mode preheat was preferred. The preheating

current brings the cathodes to the correct temperature, then a high voltage ignites the lamp

and finally the correct current guarantees the running power. These phases are ensured by

changing the frequency of the input voltage and properly selecting V

, L and C. During

IN

preheating and ignition, the lamp is not conducting and the circuit is reduced to a series L-C.

During running, the lamp is conducting and the circuit is an L in series with a parallel R-C. To

determine the optimum values for L and C and to calculate the ballast operating frequencies

the transfer functions for each mode of operation have to be inspected.

The table below shows the parameters and the values for a T8 36 W tube lamp which need

to be known in order to calculate the ballast operating conditions.

Table 7. Lamp parameters

Parameter Value

Input DC bus voltage: Vdc 400 V

Preheat current: Iph 0.6 A

Preheat time: Tph 1 sec

Max preheat voltage: Vphmax 300 Vpk

Ignition voltage: Vign 800 Vpk

Running lamp power: Prun 34 W

Running lamp voltage: Vrun 144 Vpk

Expected efficiency: η 95%

14/42

Page 15

AN2708 High-frequency ballast

Once the lamp and its parameters have been chosen, the ballast design will be optimized by

selecting the resonant components L and C as follows:

● Set Tpre

● Select frunmin (> 20 kHz)

● Choose ∆f = fmax-frunmin

● Select L & C such that fph > frun

● Select half-bridge switches

● Select L6574 biasing circuitry

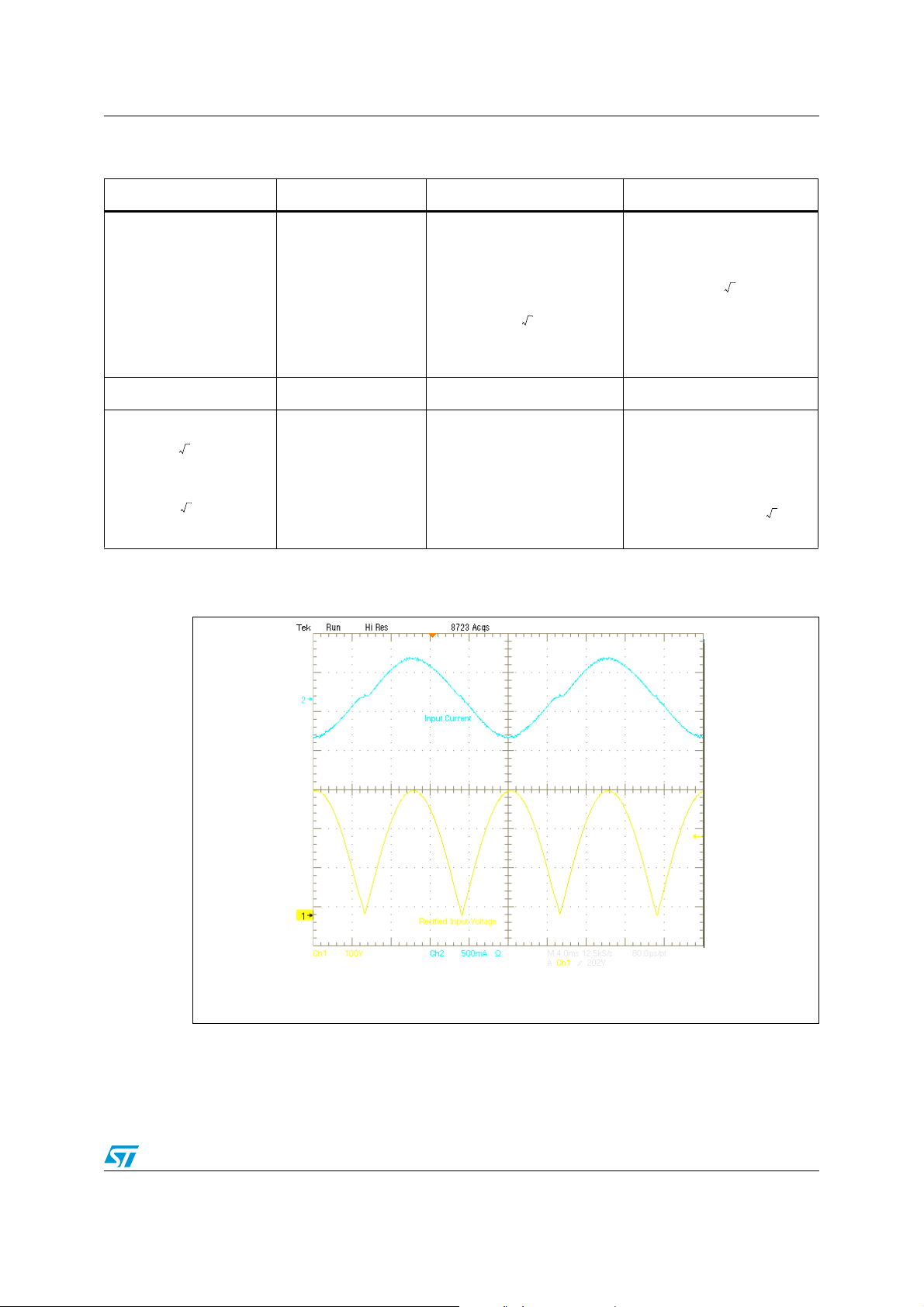

The magnitude of the transfer function (lamp voltage divided by input voltage) for the two

circuit configurations (preheating-ignition and running) illustrates the operating frequencies

and where they lie with respect to one another.

Figure 6. Ballast transfer functions (magnitude)

The currents and voltages corresponding to the resulting operating frequencies determine

the maximum current and voltage ratings for the inductor, capacitor, and the switches,

which, in turn, directly determine the size and cost of the ballast.

Moreover the zero-voltage switching is ensured as shown by the curves above in Figure 6.

STP8NM50 (8 A, 550 V) has been selected as power switch according to the current stress

and the input DC voltage.

The half-bridge inverter driving circuitry is based on the high performance L6574 which is an

OFF-LINE half-bridge driver designed in 600 V BCD technology, including all the features

needed to drive and properly control the tubes. A dedicated timing section in the L6574

allows setting the necessary parameters for proper preheat and ignition of the lamps. Also,

an op-amp is available to implement closed-loop control of the lamp current during normal

lamp burning. To avoid cross conduction of the power MOSFETs the internal logic ensures a

minimum deadtime. Moreover the L6574 is provided with two lamp status control functions

to protect the application against lamp failure as well as lamp disconnection. Finally it is

15/42

Page 16

High-frequency ballast AN2708

possible to modulate the output power in order to allow dimming by varying the switching

frequency.

The ballast operating frequencies determine the L6574 biasing circuitry as explained in

AN993 "Electronic Ballast With PFC Using L6574 and L6561" and as summarized below.

Table 8. L6574 biasing circuitry design equations for operating conditions

Pin 1 (CPRE) Pin 2 (RPRE) Pin 3 (CF) Pin 4 (RIGN) Pin 5 (OPOUT)

A capacitor is connected

Tph1.5 C

T

sh

K

PRE

---------------- -

10

⋅=

PRE

fph frun–

C

⋅=

PRE

----------------------- -=

R

1.41

PRE

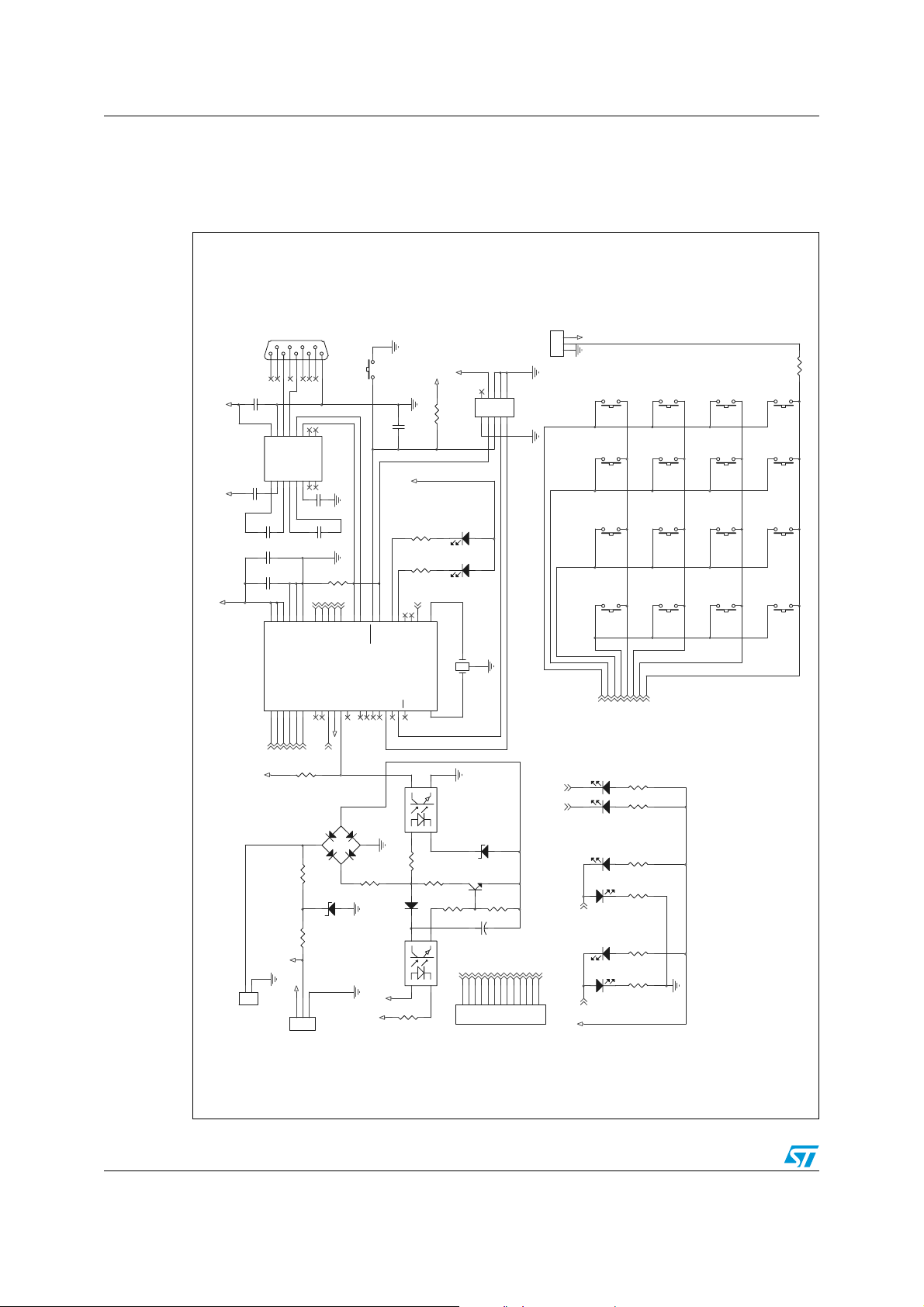

Cf

1.41

frun

------------------- -= frun

RignCf

1.41

------------------- -=

RignCf

between this pin and OPINfor the current feedback loop

compensation. It set also the

turn on delay in a dimming

application.

2.2.1 Lamp dimming

In this system the lamps are dimmed down to 5% by interfacing the ST7FDALI

microcontroller with the analog driver L6574.

A PWM output of the ST7FDALI microcontroller is used to generate a 0-5 V PWM at 4 kHz.

Its integrated value gives the op amp voltage reference. The dimming level is set by varying

the PWM duty cycle from 70% (100% dimming) to 14% (5% dimming). This modification

allows changing the L6574 op-amp positive reference voltage from 120 mV to 20 mV which

increases the switching frequency and reduces the current in the load.

On the slave unit the duty cycle values have been calculated according the DALI protocol

brightness values, listed in Figure 7.

16/42

Page 17

AN2708 High-frequency ballast

Figure 7. DALI protocol brightness values

To avoid the presence of stationary waves along the tubes at minimum dimming level, a

resistor of 100 kΩ / 2 W has been placed in parallel to the battery capacitor of each lamp.

The resistance value ensures an additional current of 2 mA on the cathodes without

affecting the ballast efficiency.

Finally, during the startup sequence the frequency always goes from fmax to fmin,

independently of the set dimming level. Only after lamp turn-on does the frequency move

towards higher values.

2.2.2 Supply section

To supply the DALI slave microcontroller an AC-DC buck converter based on the

VIPer12A-E and L78L05 has been implemented on the ballast board. It converts the

rectified and filtered mains to a 5 V regulated output voltage dedicated to the

microcontroller. The converter works in discontinuous current mode adjusting the duty cycle

17/42

Page 18

High-frequency ballast AN2708

of the VIPer12A-E power switch in order to deliver the energy from the input to the output by

means of an inductor. PWM driver, power switch, thermal and overcurrent protection are

integrated in the same silicon chip ensuring minimum size and good performances at very

low cost.

Thanks to this implementation strategy the microcontroller is always supplied, allowing the

lamps to turn on, even when L6562 and L6574 are in a latched shutdown state.

The startup procedure is very important in an application that contains two different

sections. The ballast section starts before the PFC, avoiding any extra voltage at the PFC

section output, and consequently the L6562 OVP activation. This behavior is guaranteed

under all conditions because the VS turn-on threshold of L6574 is lower than that of the

L6562. The turn-on threshold is reached by a resistor chosen in order to ensure the startup

current of both the L6562 and the L6574. When the ballast section is running, the charge

pump (C11, R14, D3 and DZ1) supplies both the devices and the filter R17-C10 allows to

reduce the noise at Vcc.

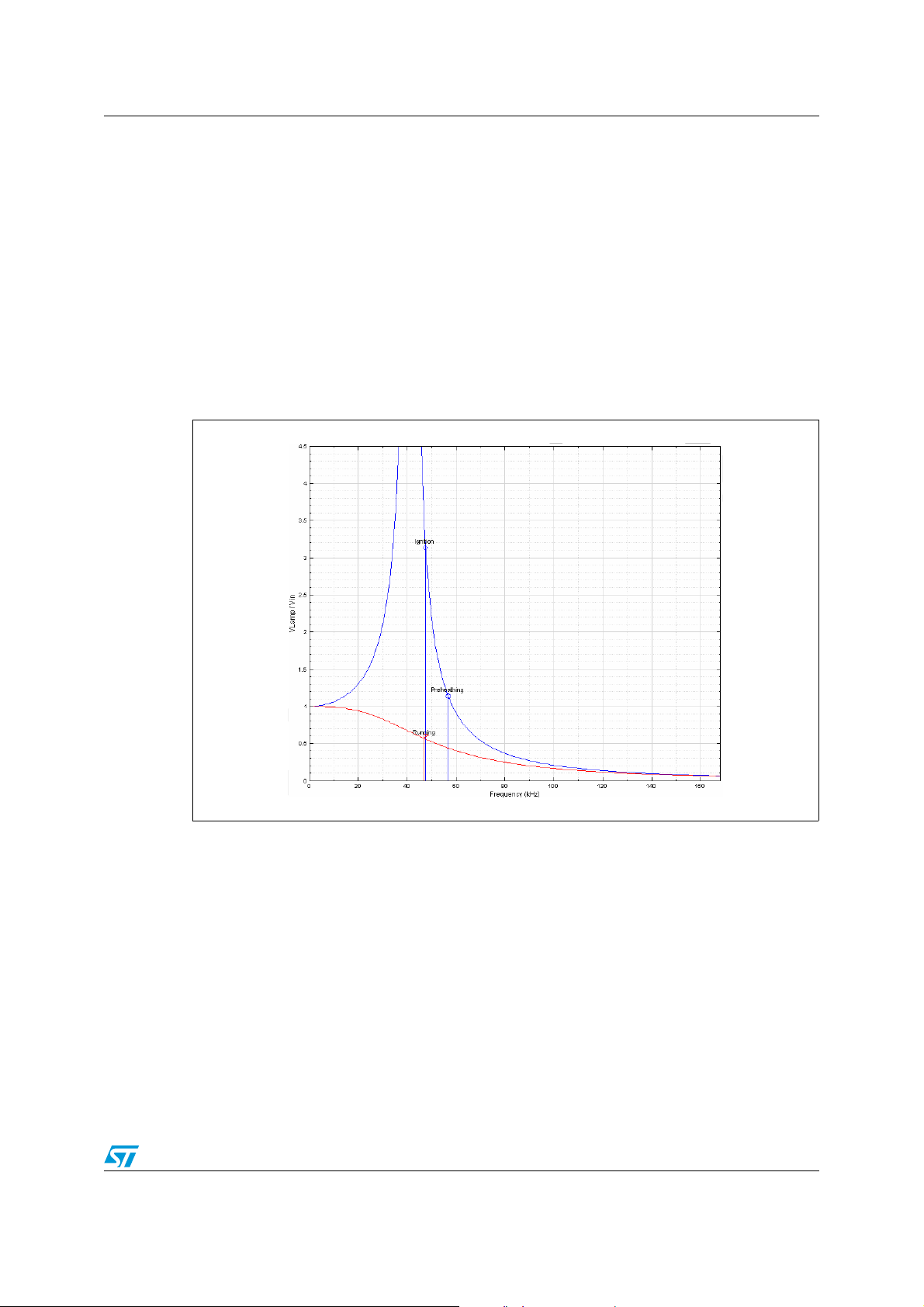

2.2.3 Lamp turn-on and lamp turn-off

To get low-power consumption (less than 0.6 W) during the lamps’ turnoff state, both the

half-bridge and the PFC have to be disabled, even in the presence of the mains at the

ballast input. To manage this standby condition the L6574 control section and the L6562

ZCD pin are interfaced with the DALI slave microcontroller.

Short pulses (> 200 nsec) at the EN1 and EN2 inputs are recognized by the L6574. In

particular, EN1 high (> 0.6 V) stops all the half-bridge functions and puts the L6574 in a

latched shutdown state. At the same time, by forcing externally the ZCD pin to a voltage

below 150 mV, the L6562 is stopped. To cancel this status, in order to turn on the lamps, a

pulse (>0.6 V) is sent by the microcontroller to the L6574 second control pin EN2 and the

ZCD pin external pull down is removed. The half-bridge driver restarts the preheating and

ignition procedure, and the L6562 performs again its operation. The controls timing diagram

is shown in Figure 8.

18/42

Page 19

AN2708 High-frequency ballast

Figure 8. Ballast controls timing chart

Vsupply

LVG

HVG

Latched

Disable

EN1

Forced

Restart

EN2

ZCD

GD

TIME

On the slave unit the turning ON/OFF process is implemented by setting the pins PB3 (EN1)

and PB4 (EN2) as output pull-up, while PB2 (ZCD) as output open drain. The three

corresponding bits in the port data register are clear by software. To "switch on" the ballast,

a pulse must be sent to PB4 (EN2 signal) and the third bit must be set in the port B (ZCD)

data register. To "switch off" the ballast, a pulse must be sent to PB3 (EN1 signal) and the

third bit must be cleared in the port B (ZCD signal) data register.

Figure 9, 10, and 11 show the idle state and the turn-on/off commands.

19/42

Page 20

High-frequency ballast AN2708

Figure 9. Idle state

CH3 (blue): EN1 low level

CH4 (green): EN2 low level

Figure 10. Turn-on procedure

CH3 (blue): EN1 low level

CH4 (green): EN2 pulse

Figure 11. Turn-off procedure

CH3 (blue): EN1 pulse

CH4 (green): EN2 low level

20/42

Page 21

AN2708 High-frequency ballast

2.2.4 Verification of lamp status

This function detects a lamp disconnection or a lamp failure on the slave board. The

microcontroller performs a double check: one on the PB1 pin for the lamp hardware status

and one on the flag "LAMP_ARC_POWER_ON" for the lamp software status. If the PB1

logical level is low and the flag is true, lamp disconnection happened. The condition is

recorded on ST7FDALI, so when the microcontroller receives a "query frame" from the

master, it changes the PB3 (EN1) and PB4 (EN2) configuration from input to output, and

sends a byte answer as 'STATUS INFORMATION' described below:

● bit 0 status of ballast; '1'= NOK

● bit 1 Lamp failure; '1'= NOK

● bit 2 Lamp arc power on; '0' = OFF

● bit 3 Query: Limit Error; '0' = Last requested arc power level is between MIN..MAX

LEVEL or OFF

● bit 4 Fade ready; '0' = fade is ready; '1' = fade is running

● bit 5 Query: 'RESET STATE'? '0' = 'No'

● bit 6 Query: Missing short address? '0' = 'No'

● bit 7 Query: 'POWER FAILURE'? '0' = 'No'; 'RESET' or an arc power control command

has been received after last power-on

When the master receives this frame, it displays the lamp status by means of two LEDs

(green stands for ok, red for status not ok). Once the failure condition has been detected

and solved, an "ON" command has to be sent to the slave, allowing the master's

microcontroller to toggle again the LED status from red to green. From the analog side, to

detect a disconnection or a failure event for each lamp, two signal Schottky diodes have

been used to bias the EN1 or EN2 pin of L6574. The failure condition is detected both at

startup and when running.

The forward and backward frame timing is shown in Figure 12 and 13:

Figure 12. Forward frame timing

21/42

Page 22

High-frequency ballast AN2708

Figure 13. Backward frame timing

The forward as well as the backward frame duration is the same for all kinds of commands.

2.2.5 Ballast performances

In this section the main ballast waveforms are shown.

Figure 14. Ballast startup at 230 Vac-full

power

CH2 (blue): lamp current

CH3 (magenta): V

CPRE

CH4 (green): supply voltage

Figure 15. Lamps turn-on at 230 Vac-full

power

CH1 (yellow): lamp1 voltage

CH2 (blue): lamp1 current

CH3 (magenta): lamp2 voltage

CH4 (green): lamp2 current

22/42

Page 23

AN2708 High-frequency ballast

Figure 16. Lamps running at 230 Vac - full power

CH1 (yellow): lamp1 voltage

CH2 (blue): lamp1 current

Ch3 (magenta): lamp2 voltage

CH4 (green): lamp2 current

Table 9. Ballast performances

Vin (Vac) Pin (W) PF THD (%) Po (W) η (%)

90 76.5 0.999 3.9 66 86.2

110 75.5 0.999 3.6 66 87.4

140 74.2 0.998 5.5 66 89

176 73.7 0.997 7.2 66 90

230 73 0.997 7.3 66 90

265 72.8 0.996 8.3 66 91

The efficiency of the system is a little bit lower than a standard HF ballast due to the supply

section of the slave and the resistors in series to the lamp’s cathode used to ensure a

minimum current at low dimming level.

23/42

Page 24

DALI master unit AN2708

3 DALI master unit

The ST2C334J4 microcontroller is used as master, implementing the DALI Peripheral via

software.

The communication master-slave uses a 20 V bus. To adapt the TTL level of the

microcontroller to the communication bus level, two opto-couplers and a NPN transistor BC817 have been used.

The RS232 interface with ST232C is available on the board to implement the SCI

communication as an option. This option expects the use of a PC to address the ballast

either with broadcast or group or single mode thanks to a GUI called (DALI Power Control).

The DALI master unit has been thought of as a standalone solution. In fact it is provided

with a keyboard to manage the DALI commands, to address the slaves and to display the

lamps’ status.

The keyboard is made up of 16 push buttons controlled by means of a matrix

representation. In particular the first four pins of PORTD are associated to the rows and the

first four pins of PORTB to the columns.

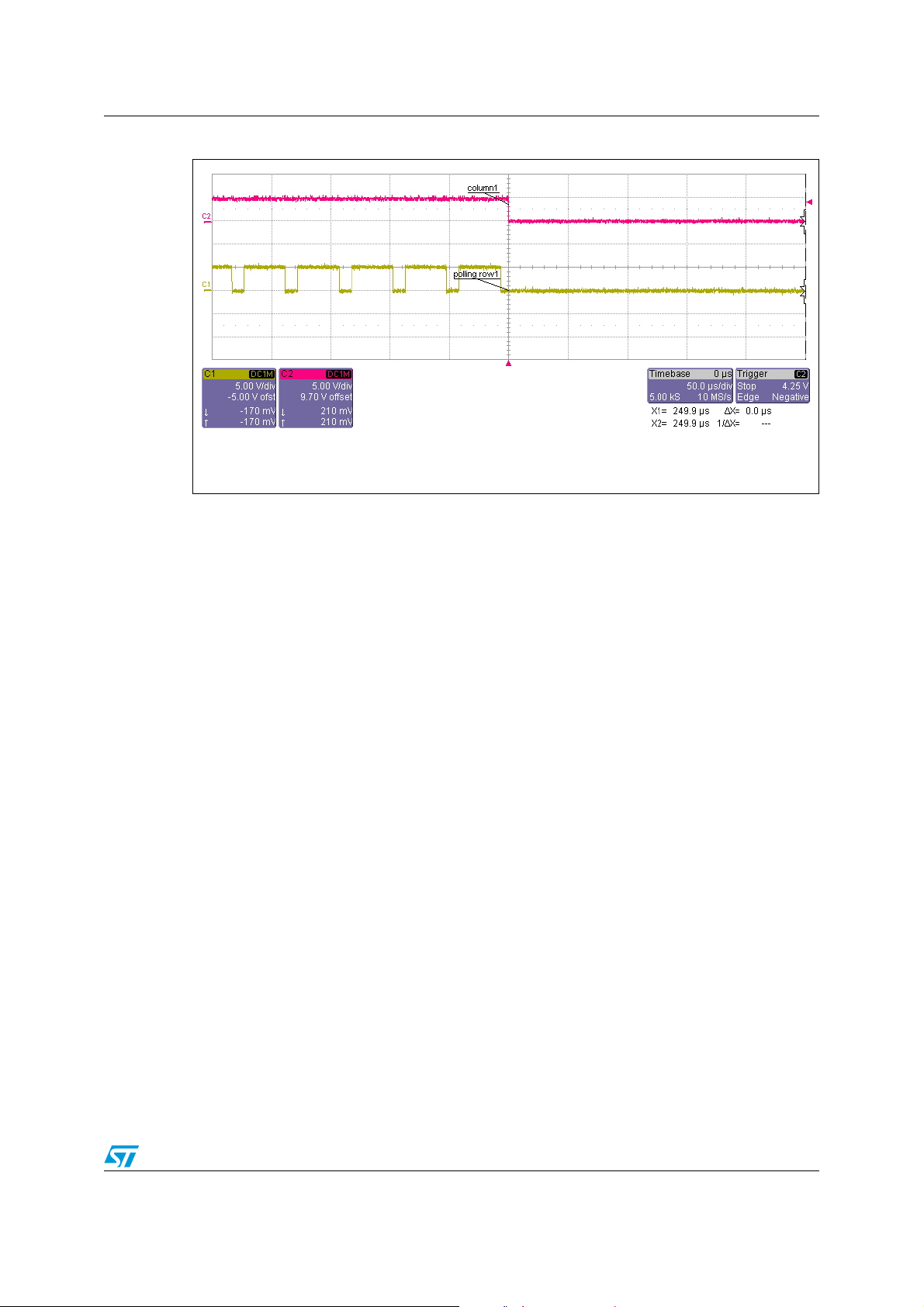

The check of the keyboard is implemented as a loop mode by clearing the PDDR register

port and setting the PBDR register port sequentially. When a button is pressed, the pin of

the port B corresponding to the interested column goes down and this condition is taken

over by an interrupt condition. Inside the interrupt routine, a read procedure of the port

registers PDDR and PBDR is expected and by this information the pressed button is

acknowledged. The “press button” procedure is described by Figure 17 and 18.

Figure 17. Polling keyboard

CH1 (yellow): row polling

CH2 (purple): column level

24/42

Page 25

AN2708 DALI master unit

Figure 18. Pressed button event

CH1 (yellow): row polling

CH2 (purple): column level

25/42

Page 26

DALI master unit AN2708

3.1 Master unit schematic and bill of material

The schematic of the master unit is shown in Figure 19.

Figure 19. Master unit schematic

5VDD

3

2

P1

C48

100nF

50V

5VDD

16

15

14

VDD

GND

T1OU T

C1+1V+2C1-3C2-5V-6T2OU T7R2IN8C2+

U13

5VDD

C47

50V

100nF

C51

100nF

50V

C50

50V

100nF

C49

220nF

50V

5VDD

8

36

VDDA

VDD_125VDD_2

U12

AIN0/PD02AIN1/PD13AIN2/PD24AIN3/PD35AIN4/PD46AIN5/PD57MCO/ PF 010BEEP/PF111PF212OCMP1_A/PF413ICAP1_A/(HS)/PF614EXTCLK_A/(HS)/PF715OCMP2_B/PC016OCMP1_B/PC117ICAP2_B/(HS)/PC218ICAP1_B/(HS)/PC319ISPDATA/MISO/PC420MOSI/PC521SCK/ISPCLK/ PC622SS'/PC723OSC1

RS232

594837261

SW1

Reset

13

11

9

12

T2IN10T1IN

R1IN

R2OUT

R1OUT

ST232C

4

C53

100nF

50V

C52

100nF

50V

R76

Col4

Col3

Col2

Col1

9

VSSA

PB4

1

PB039PB140PB241PB342PB4

33

VSS_126VSS_2

C54

10K

1%

30

37

38

31

32

RESET

ISPSEL

PE0/TD0

PE1/RD1

100nF

5VDD

PA4(HS)27PA5(HS)28PA6(HS)29PA7(HS)

5VDD

5VDD

9

+1+3+5+7+

+2+4+6+8+

J8

4.7K

R82

50V

R81

1K

R80

1K

PA3

34

24

PA3

OSC2

35

10

LD4

LG M67K-G1J2-24

Green

LD3

Red

LS M67K-H2L1-1

16MHz

Y1

ST72C334J4B6

1

J18

Pull-Up Jumper

R102

SW23SW24 SW25

ICP Connector

Porta

PD3

Row4

SW20 SW21

Porta

PD2

Row3

SW19

Porta

PD1

Row2

Porta

PB0

Colomn4

Porta

PB1

SW18

Porta

PD0

Row1

Rows

Row2

Row4

Row3

SW22

Columns

Row1

Col2

Col1

Col4

Col3

SW27SW28

SW30

Colomn3

Porta

PB2

SW26

SW31 SW32 SW33

Porta

PB3

Colomn2

Colomn1

SW29

10k

Row1

Row2

Row3

5VDD

R74

R7305%

VD

1

2

J6

DALI Bus

J7

TRANSM.

Row4

AIN5

PF2

R75

10K

1%

3

-+

1

D20

MB2S

4

5% 1W

220R

D19

BZX85C22

5VDD AIN4

123

Supply Volt age

4

334

SFH6156-2

U15

112

2

R77

0

TRAN SM.

2

R79

11K

1%

R84

4R7

1%

D21

BAS16

R83

4

334

SFH6156-2

U14

112

2

5VDD

J9

R78

1K2

1%

26/42

321

1%

330R

PA3

D28

LG M67K-G1J2-24

R91

1K

Query status

Query status

5VDD

Green

R90

1K

D27

Green

LG M67K-G1J2-24

R89

Green

D26

LG M67K-G1J2-24

1K

R88

1K

D25

PA3

Red

LS M67K-H2L1-1

R87

1K

Green

LG M67K-G1J2-24

D24

R86

1K

Red

D23

PB4

LS M67K-H2L1-1

AIN5

Slave address

AIN4

D22

BZ84C 2V7

Q5

BC817-25

3K

1%

R85

+

C55

22uF

25V

Row2

Row1

Row4

Row3

AIN4

PF2

AIN5

Col2

Col4

Col3

Col1

PB4

12345678910111213

Page 27

AN2708 DALI master unit

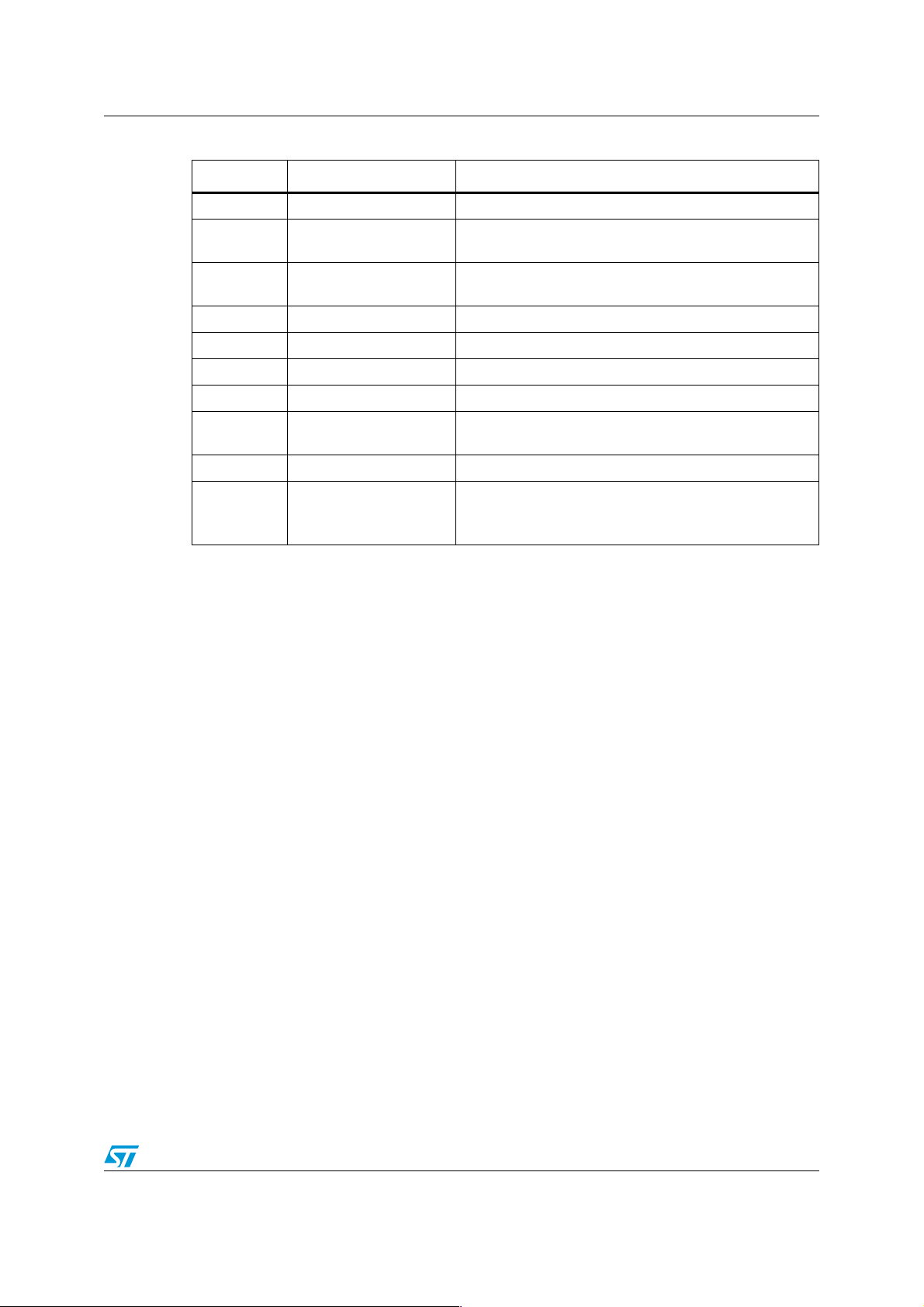

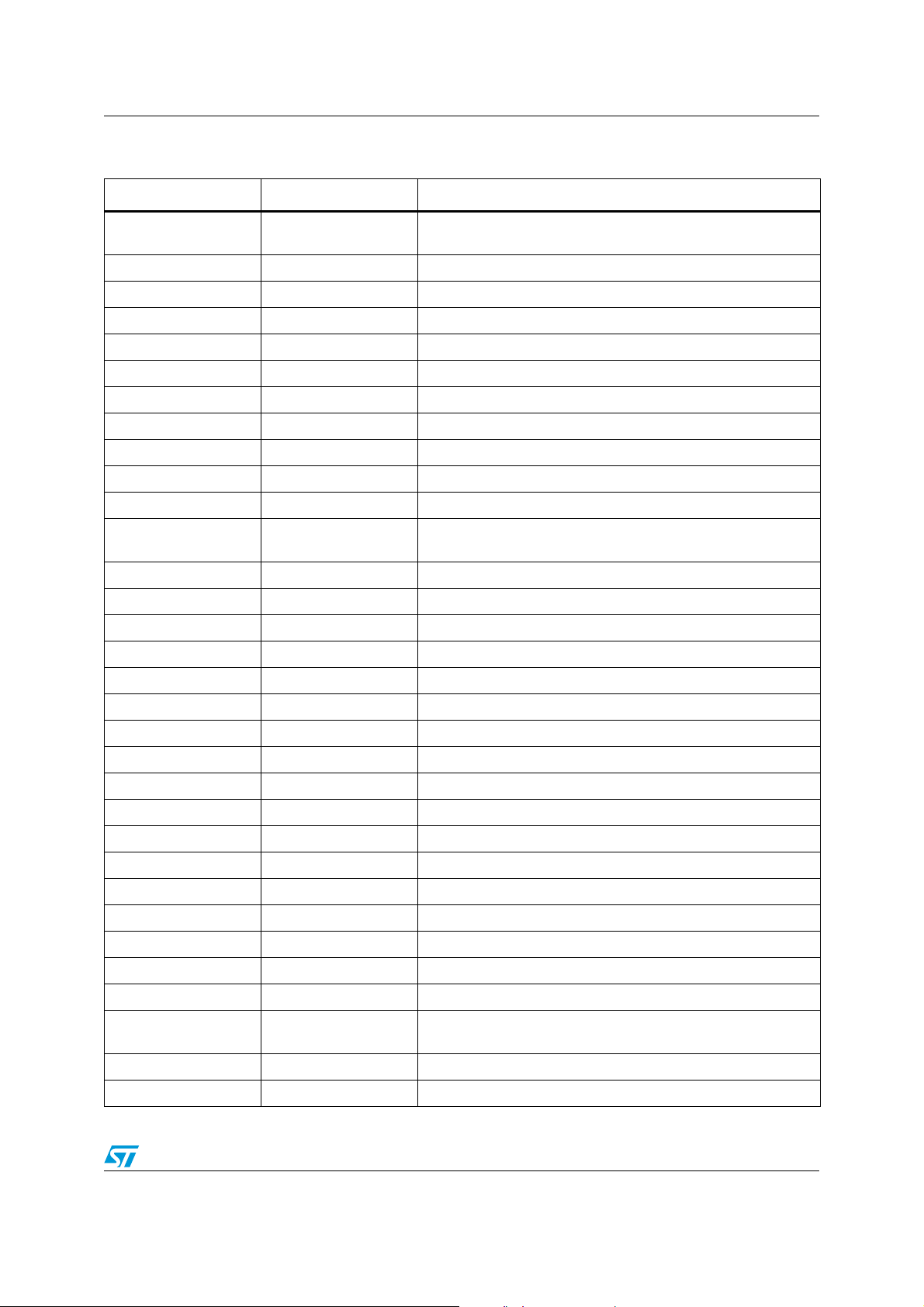

Table 10. Master unit bill of material

Reference Value Description

C47,C48,C50,C51,C52,

C53,C54

C49 220 nF 50 V Ceramic capacitor SMD 0805

C55 22 µF 25 V Tantalum capacitor SMD

D19 BZX85C22 22 V 0.5 W Zener diode

D20 MB2S SMD bridge rectifier

D21 BAS16 SMD diode

D22 BZ84C 2V7 2.7 V 0.5 W Zener SMD diode

D23,D25 LS M67K-H2L1-1 Red SMD LED 2 mA, 0805

D24,D26,D27,D28 LG M67K-G1J2-24 Green SMD LED 2 mA, 0805

J6 DALI BUS 2-way single row, header shrouded

J7 Supply voltage 3-way single row header shrouded

J8 ICP connector

J9 13-way strip line connector (not mounted)

J12 Pull-up jumper 3-way strip line connector

LD3 LS M67K-H2L1-1 Red SMD LED 2 mA, 0805

LD4 LG M67K-G1J2-24 Green SMD LED 2 mA, 0805

100 nF 50 V Ceramic capacitor SMD 0805

10-way 2-row vertical through-hole boxed header, 2.54 mm

pitch/grid

P1 Serial connector 9-way 90° PCB mount D plug

Q5 BC817-25 SMD NPN transistor

R73 0 Resistor SMD 1206

R77 0 Resistor SMD 0805

R74 220 Ω 1 W 5% resistor

R75,R76 10 kΩ 1% resistor SMD 0805

R78 1.2 kΩ 1% resistor SMD 0805

R79 11 kΩ 1% resistor SMD 0805

R80,R81 1 kΩ Resistor SMD 0805

R82 4.7 kΩ Resistor SMD 0805

R83 330 Ω 1% Resistor SMD 0805

R84 4.7 Ω 1% Resistor SMD 0805

R85 3 kΩ 1% Resistor SMD 0805

R86,R87,R88,R89,R90,

R91

R101 10 kΩ Resistor SMD 0805

SW1 Reset THT button

1 kΩ Resistor SMD 0805

27/42

Page 28

DALI master unit AN2708

Table 10. Master unit bill of material (continued)

Reference Value Description

SW2, SW3, SW4, SW5,

SW6, SW7, SW8, SW9,

SW10, SW11, SW12,

SW13, SW14, SW15,

SW16, SW17

U12

U13 ST232C SOP

U14,U15 SFH6156-2 SMD Opto-coupler

Y1 16 MHz Oscillator

Keyboard THT button

ST72C334J4B6

PSDIP42

8-bit MCU with single voltage flash memory, Adc, 16-bit timers,

STMicroelectronics 5 V powered multi-channel

STMicroelectronics

SPI, SCI interface

RS-232 drivers and receivers

Note: Resistors are 0.25 W unless specified

28/42

Page 29

AN2708 Basics of DALI

4 Basics of DALI

DALI stands for "Digital Addressable Lighting Interface". It is a standard interface for lighting

control solutions, defined by the main lighting manufacturers and standardized as IEC 929.

The DALI protocol is implemented on a master-slave architecture.

It uses the bi-phase Manchester asynchronous serial data format. All the bits of the frame

are bi-phase encoded except the two stop bits. Following are some of the standard features:

● Transmission rate at 1.2 kHz.

● Bi-phase bit period is 833.33 µS ±10%.

A forward frame consists of 19 bi-phase encoded bits:

– 1 start bit (0->1: logical '1')

– 1 address byte (8-bit address)

– 1 data byte (8-bit data)

– 2 high level stop bits (no change of phase)

A backward frame consists of 11 bi-phase encoded bits:

– 1 start bit (0->1: logical '1')

– 1 data byte (8-bit data)

– 2 high level stop bits (no change of phase)

Each frame has 2 stop bits which do not contain any change of phase.

The setting time between two subsequent forward frames is 9.17 ms (minimum), while the

delay between forward and backward frame goes from 2.92 ms to 9.17 ms. If a backward

frame has not been started after 9.17 ms, this is interpreted as "no answer".

In the event of code violation, the frame is ignored and the system is ready again for data

reception.

The main advantages of the DALI system can be summarized as follows:

● Simple wiring: all of the units in the system are interconnected using a simple five-core

cable.

Figure 20. Cable wiring

29/42

Page 30

Basics of DALI AN2708

N

N

N

N

● No mains switching required: lamps can be dimmed or switched on and off using

control system commands without any need for mains switching.

● Easy system re-configuration: the configuration of the system can be changed quickly

without any modification to the hardware.

● Easy system modification: if the lighting system needs to be enlarged, new

components can be added anywhere on the DALI cable.

● It is possible to define light scenes. A scene means a particular light level intensity. 16

scenes can be defined at maximum.

Figure 21. Master flowchart

START

POLLING KEYBOARD

PUSH

BUTTON

Y

BUTTON

NUMBER

11

SEND COMMAND

QUERY

FRAME

Y

Y

CHANGE SLAVE

ADDRESS

WAIT BACKWARD FRAME

NO

ANSWER

FRAME

RECEIVED

Y

TOGGLE

LED

30/42

Page 31

AN2708 Basics of DALI

g

,

d

Figure 22. Slave flowchart

Start

Main

New Frame Received

PWM

routine

Failure=1

Dali Peripheral

Pulse on EN1(OFF) or

EN2 (ON) change pin

confi

uration

Y

Pin

PB1=low

level

N

Process

Command

ON/

Y

OFF

N

Y

Other indirect

arc power control

comman

s

N

Query

N

command

Y

Send Lamp

OK

N

Failure=1

Y

Change

configuration

of PB3

PB4pin

Send Lamp

Failure

31/42

Page 32

DALI master AC-DC adapter AN2708

5 DALI master AC-DC adapter

This is an offline wide-range double-output SMPS based on the VIPer12A-E. The first

output, 20 V at 100 mA, is dedicated to the bus communication allowing to address up to 64

slaves, while the second one delivers 5 V at 10 mA to the MASTER DALI microcontroller

thanks to a linear post-regulator.

The VIPer12A-E combines on the same silicon chip a dedicated current mode PWM

controller, a high voltage power MOSFET and the protection features (thermal, overcurrent,

and overvoltage) which increases the converter reliability and saves size, parts count and

cost.

The converter topology is an isolated flyback designed to work in discontinuous current

mode according to the following specifications:

Table 11. SMPS operating conditions

Parameter Value

Input voltage range 90 – 265 Vac

Input frequency range 50/60 Hz

Output voltage 1 V1=20 V

Output voltage 2 V2=5 V

Output current 1 I1=100 mA

Output current 2 I2=10 mA

Output power (peak) 2.2 W

Line regulation +/- 1%

Load regulation +/- 1%

EMI EN55015

5.1 Adapter description

The schematic of the board is shown in Figure 23.

The AC input is rectified by the diodes bridge and then filtered by the bulk capacitor C1, and

C2 to generate the high voltage DC.

The input EMI filter is a simple CLC PI filter for both differential and common mode noise

suppression.

An NTC limits the inrush current and ensures a reliable operation of the bridge at startup.

The switching frequency is fixed at 60 kHz by the IC internal oscillator allowing optimization

of the transformer size and cost. An RCD snubber circuit (R92, C59, D30) reduces the

leakage inductance voltage spike and the voltage ringing on the drain pin of VIPer12A-E.

As soon as the voltage is applied on the input of the converter the high voltage startup

current source connected to the drain pin is activated and starts to charge the Vdd capacitor

C8 by a constant current of 1mA. When the voltage across this capacitor reaches the Vddon

threshold (about 14 V) the VIPer12AS-E starts to switch. During normal operation the smart

32/42

Page 33

AN2708 DALI master AC-DC adapter

power IC is powered by the auxiliary winding of the transformer via the diode D31. No spike

killer for the auxiliary voltage fluctuations is needed thanks to the wide range of the Vdd pin

(9-38 V). The primary current is measured using the integrated current sensing for current

mode operation.

The output rectifier D29 has been chosen in accordance with the maximum reverse voltage

and power dissipation. In particular a 1 A - 150 V power Schottky, type STPS1150, has

been selected.

The output voltage regulation is performed by secondary feedback on the 20 V output while

the 5 V output, is linearly post-regulated from the 20 V output. This operation is performed

by a low drop voltage regulator, L78L05CZ, in the TO92 package. The feedback network

consists of a programmable voltage reference, TL431, driving an optocoupler which ensures

the required insulation between the primary and secondary sections. The optotransistor

drives directly the VIPer12A-E feedback pin which controls the operation of the IC.

A small LC filter has been added on the 20 V output in order to reduce the high frequency

ripple with reasonable output capacitor value.

The flyback transformer is a layer type based on the EF13 core and Fi 324 ferrite,

manufactured by Vogt, and ensures safety insulation in accordance with the EN60950.

Figure 26 shows the main features of the transformer. The power supply has been

implemented on a double-sided 35 µm PCB in FR-4, sizing 81 x 37 mm.

Figure 23. Adapter schematic

L9

3

C61

2.2nF Y 1

+

1mH 130m A

C56

+

2.2uF

4

Vdd

FB

3

U18

VIPer12A

BRIDGE2

4

DF06

NTC2

10R @ 25°

J17

2

Input 250V Con

1

FUSE2 0.5A

T1: S MT

- EF12.6/3. 7c ore, F i324 f errite

- 0.16mm gap f or 2m H prim ary induc t anc e

- Primary : 135 t urns (0. 14m m -AW G35)

- Secondary: 28 turns (0.36mm-AWG27)

- Auxiliary : 21 t urns (0. 05m m -AW G44)

1

-+

2

C63

10uF

50V

5

+

2

C57

2.2uF

400V400V

STTH1L06

U17

PC817

43

R93

560R

C6510nF

+

L8

100uH 600mA

C59

150uF

35V

12

U19

2 1

TL431

20V@100mA

C60

+

22uF

35V

U16

L78L05CZ

VIN3VOUT

R96

R95

33K

1K

R98

150K

C64

100nF

50V

3

R99

4.7K

1

GND

2

2.2uF

5V@10mA

C62

+

Supply Volt age

J10

1

2

3

R92

C58

56K

D30

R94

10R

D31

1N4148

8

D

D7D6D

S1S

470pF

1kV

1

2

4

5

SL 060 918 11 01

D29

STPS1150

T3

9

6

R97

10K

50V

33/42

Page 34

DALI master AC-DC adapter AN2708

Figure 24. Adapter PCB layout - top side -

silkscreen (to scale)

Figure 26. Flyback transformer

Figure 25. Adapter PCB layout - bottom side -

copper tracks (to scale)

● Operating switching frequency: 60 kHz

● Core geometry: EF 12.6/3.7

● Core material: FI 324 or equivalent

● Primary inductance value: 2 mH

● Leakage inductance: 75 µH

● Air gap length: 0.16 mm

● Safety: EN60950

34/42

Page 35

AN2708 DALI master AC-DC adapter

5.2 Adapter bill of material

Table 12. Adapter bill of material

Reference Value Description

BRIDGE2 DF06M 1 A 600 V Bridge rectifier

C56,C57 2.2 µF 400 V Electrolytic cap

C58 470 pF 1 kV Ceramic cap

C59 150 µF 35 V Low ESR electrolytic cap

C60 22 µF 35 V Low ESR electrolytic cap

C61 2.2 nF Y1 Y1 ceramic cap

C62 2.2 µF 25 V Electrolytic cap

C63 10 µF 50 V Electrolytic cap

C64 100 nF 50 V Ceramic cap

C65 10 nF 50 V Ceramic cap

D29 STPS1150 STMicroelectronics power Schottky rectifier 1 A 150 V

D30 STTH1L06 STMicroelectronics ultrafast high-voltage rectfifier 1 A 600 V

D31 1N4148 Small signal rectifier 200 mA 100 V

FUSE2 0.5 A Radial fuse

J10 Supply voltage 3-way single row shrouded header

J11 Input 250 V connector 2-way PCB screw terminal, 5.08 mm

L8 100 µH 600 mA Axial inductor

L9 1 mH 130 mA Axial inductor

NTC2 10 Ω @ 25° Inrush current suppressor

R92 56 kΩ Resistor, metal film 0.25 W

R93 560 Ω Resistor, metal film 0.25W

R94 10 Ω Resistor, metal film 0.25 W

R95 1 kΩ Resistor, metal film 0.25 W

R96 33 kΩ Resistor, metal film 0.25 W

R97 10 kΩ Resistor, metal film 0.25 W

R98 150 kΩ Resistor, metal film 0.25 W

R99 4.7 kΩ Resistor, metal film 0.25 W

T3 SL 060 918 11 01 VOGT SMT

U16 L78L05CZ TO92 STMicroelectronics positive voltage regulator

U17 PC817 Sharp Optocoupler 5 kV

U18 VIPer12A-E DIP8 STMicroelectronics offline SMPS primary IC 730 V 0.4 A 27 Ω

U19 TL431 TO92 STMicroelectronics programmable voltage reference

35/42

Page 36

DALI master AC-DC adapter AN2708

5.3 Adapter performances

Several tests have been performed on the board to evaluate the converter behavior in terms

of efficiency, stability, safe operating area of the devices, line & load regulation and EMI

performances.

5.3.1 Steady state tests

These tests have been performed at the input voltage of 110 Vac and 230 Vac at full and

minimum load condition.

Figure 27. VIPer12A-E steady state behavior at

f u l l l o a d a t 1 1 0 V a c - 6 0 H z

CH1 (blue): drain voltage

CH4 (purple): drain current

As shown by the waveforms the power supply operates in discontinuous current mode.

Figure 29. VIPer12A-E steady state behavior at

minimum load at 110 Vac - 60 Hz

Figure 28. VIPer12A-E steady state behavior at

full load at 230 Vac - 50 Hz

CH1 (blue): drain voltage

CH4 (purple): drain current

Figure 30. VIPer12A-E steady state behavior at

minimum load at 230 Vac - 50 Hz

CH1 (blue): drain voltage

CH4 (purple): drain current

36/42

CH1 (blue): drain voltage

CH4 (purple): drain current

Page 37

AN2708 DALI master AC-DC adapter

At minimum load the VIPer12A-E ensures the burst mode operation, saving the input power

consumption.

5.3.2 Startup behavior

Figure 31, 32, 33, and 34 show the typical waveforms during the startup of the power supply.

In particular, the full load condition is considered since it represents the heaviest case in

terms of voltage and current stress, as well as the minimum load condition for loop stability

and voltage stress.

Figure 31. Startup waveforms at full load

at 110 Vac - 60 Hz

CH1 (blue): drain voltage

CH2 (red): 5 Vout

CH3 (green): 20 Vout

CH4 (purple): drain current

Figure 32. Startup waveforms at full load

at 230 Vac - 50 Hz

CH1 (blue): drain voltage

CH2 (red): 5 Vout

CH3 (green): 20 Vout

CH4 (purple): drain current

37/42

Page 38

DALI master AC-DC adapter AN2708

Figure 33. Startup waveforms at minimum

load at 110 Vac - 60 Hz

CH1 (blue): drain voltage

CH2 (red): 5 Vout

CH3 (green): 20 Vout

CH4 (purple): drain current

There is no overshoot on the output voltages and the measured wakeup time is 180 mS.

5.3.3 Dynamic load tests

Figure 34. Startup waveforms at minimum

load at 230 Vac - 50 Hz

CH1 (blue): drain voltage

CH2 (red): 5 Vout

CH3 (green): 20 Vout

CH4 (purple): drain current

These tests show the transient load response at 110 Vac and 230 Vac mains when the 20 V

output current is increased from 10% to 90% of the maximum value.

Figure 35. Dynamic load waveforms

at 110 Vac - 60 Hz

CH3 (green): 20 Vout voltage ripple

CH4 (purple): 20 Vout current

In the worst case the result is 224 mV or 1.12% of dynamic load regulation which indicates a

very good dynamic behavior.

Figure 36. Dynam i c load w aveforms

at 230 Vac - 50 Hz

CH3 (green): 20 Vout voltage ripple

CH4 (purple): 20 Vout current

38/42

Page 39

AN2708 DALI master AC-DC adapter

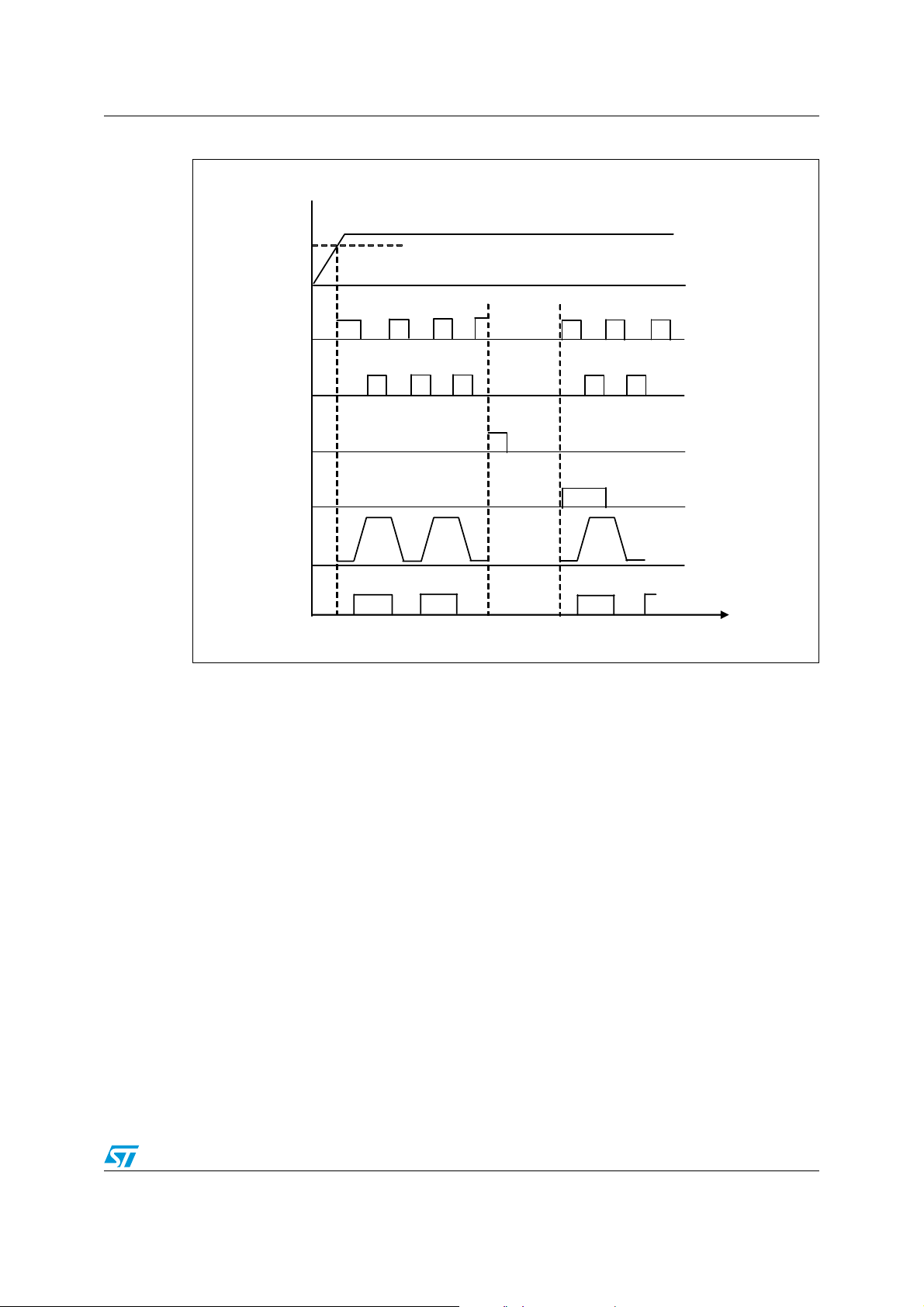

5.3.4 Line regulation

For this test the output power is kept at the peak value (2.2 W) while the line voltage is

slowly increased from 85 Vac to 265 Vac. The board has a line regulation of +0.9%.

Figure 37. Line regulation

23

21

19

17

15

13

11

9

Output Voltage (Vdc)

7

5

3

1

70 80 90 100 110 120 140 160 170 180 190 200 210 220 230 240 250 260 270 290 310

Input Voltage (Vac)

20Vout

5Vout

5.3.5 Load regulation

As the 5 V output is obtained by a linear regulator, the load regulation measurements have

been performed only on 20 V output by changing its load from 10 mA to full load 100 mA.

The input voltage is kept at the nominal value of 230 Vac.

The board has a load regulation of +0.9%.

Figure 38. Load regulation

24

23

22

21

20

19

20V Output (Vdc)

18

17

16

0 102030405060708090100110

20V Output

Output Current (mA)

39/42

Page 40

DALI master AC-DC adapter AN2708

5.3.6 Efficiency variation

For this test the efficiency is measured when the line input is varied from 85 Vac to

264 Vac at full load. The average efficiency is 66.5%. A moderate value is typical of low

power applications.

Figure 39. Efficiency variations vs. input voltage at full load

80

77.5

75

72.5

70

67.5

65

62.5

Effiiciency (%)

60

57.5

55

52.5

50

70 80 90 100 110 120 140 160 170 180 190 200 210 220 230 240 250 260 270 290 310

Input Voltage(Vac)

Efficiency

5.3.7 Conducted emissions test

Conducted emissions have been measured in neutral and line wires, using peak detector

and considering the limits for lighting applications i.e. EN55015. The measurements have

been performed at 110 Vac and 230 Vac line with fully loaded outputs. The results are

shown in Figure 40, 41, 42, and 43.

Since the emission level is below both the quasi-peak and average limits with acceptable

margin, the power supply passes the pre-compliance test.

Figure 40. Conducted emissions at 110 Vac

60 Hz - full load - line 1 peak

µ

Ref 75 dB

Peak

Log

10

dB/

W1 S2

S3 FC

AA

detector

01:55:30 Apr 10, 2007

V#

Atten 10 dB

Figure 41. Conducted emissions at 110 Vac

60 Hz - full load - line 2 peak

detector

Ref 75 dBµV#Atten 10 dB

Peak

Log

10

dB/

W1 S2

S3 FC

01:55:07 Apr 10, 2007

AA

Start 150 kHz

Res BW 9 kHz VBW 30 kHz

Sweep 881.3 ms (2115 pts)

Stop 30 MHz

40/42

Start 150 kHz

Res BW 9 kHz VBW 30 kHz

Sweep 881.3 ms (2115 pts)

Stop 30 MHz

Page 41

AN2708 References

Figure 42. Conducted emissions at 230 Vac

50 Hz - full load - line 1 peak

Ref 75 dBµV#Atten 10 dB

Peak

Log

10

dB/

W1 S2

S3 FC

AA

Start 150 kHz

Res BW 9 kHz VBW 30 kHz

detector

01:53:40 Apr 10, 2007

Sweep 881.3 ms (2115 pts)

Stop 30 MHz

6 References

1. "L6561, enhanced transition mode power factor corrector" (AN966)

2. "Switching from the L6561 to the L6562" (AN1757)

3. "Control loop modelling of L6561-based TM PFC" (AN1089)

4. "Electronic Ballast With Pfc Using L6574 And L6561" (AN993)

5. "Choosing A Dali Implementation Strategy With ST7DALI" (AN1756)

6. "Hardware Implementation for ST7DALI-EVAL" (AN1900)

Figure 43. Conducted emissions at 230 Vac

50 Hz - full load - line 2 peak

detector

Ref 75 dB

Peak

Log

10

dB/

W1 S2

S3 FC

Start 150 kHz

Res BW 9 kHz VBW 30 kHz

01:54:24 Apr 10, 2007

µ

V#

AA

Atten 10 dB

Sweep 881.3 ms (21 15 pts)

Stop 30 MHz

7 Revision history

Table 13. Document revision history

Date Revision Changes

07-Mar-2008 1 Initial release

41/42

Page 42

AN2708

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2008 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

42/42

Loading...

Loading...