Page 1

AN2687

Application note

STM8S20xxx

LCD software driver

Introduction

This application note describes two different methods for driving liquid crystal displays

(LCD) with any standard STM8S20xxx microcontroller (MCU), without any specific on-chip

LCD driver hardware:

● the first method uses the timer 2 channel resource and also allows LCD contrast

control through software

● the second method uses the Auto-wakeup mode only

This application note starts with an introduction on LCDs in Section 1: LCD principle and

Section 2: LCD drive signals.

Section 3 then presents a solution based on a standard STM8S20xxx MCU directly driving a

quadruplex LCD. This solution can be implemented with any MCU as it only requires the

standard I/O ports and some timings.

Section 4 gives consumption considerations. Section 5 describes how to control contrast

through software: for this purpose, two push-buttons connected to two standard I/Os are

used. Finally, Section 6 gives an overview of the LCD demo board based on an

STM8S20xxx microcontroller, and provides the board schematics.

For more information on the LCD drive theory, please refer also to AN1048.

The number of external components is kept to a minimum of two external resistors per COM

line. The number of I/Os depends on the number of LCD segments used. Software contrast

control is a very flexible solution that can be easily adapted to a wide range of applications.

April 2009 Doc ID 14296 Rev 1 1/22

Page 2

Contents AN2687

Contents

1 LCD principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 LCD drive signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Quadruplex LCD drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.1 LCD mean voltage calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.2 Contrast calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Example of a quadruplex LCD driver with STM8 . . . . . . . . . . . . . . . . . 10

3.1 First method: Timer 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 Second method: Auto-wakeup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Consumption considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Software contrast control with the first method . . . . . . . . . . . . . . . . . 17

5.1 Contrast calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 LCD demo board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1 Board information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2/22 Doc ID 14296 Rev 1

Page 3

AN2687 List of tables

List of tables

Table 1. LCD RAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 2. First method - consumption (Timer 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 3. Second method - consumption (AWU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 4. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Doc ID 14296 Rev 1 3/22

Page 4

List of figures AN2687

List of figures

Figure 1. LCD principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2. Equivalent electrical schematic of an LCD segment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. Basic LCD segment connection in quadruplexed mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 4. LCD timing diagram for quadruplex mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 5. Hardware connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 6. LCD timing diagram with dead & active time (to decrease Vrms). . . . . . . . . . . . . . . . . . . . 15

Figure 7. LCD timing diagram with active and dead time (to increase Vrms) . . . . . . . . . . . . . . . . . . 16

Figure 8. Schematic diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4/22 Doc ID 14296 Rev 1

Page 5

AN2687 LCD principle

Mean Signal

2

1 LCD principle

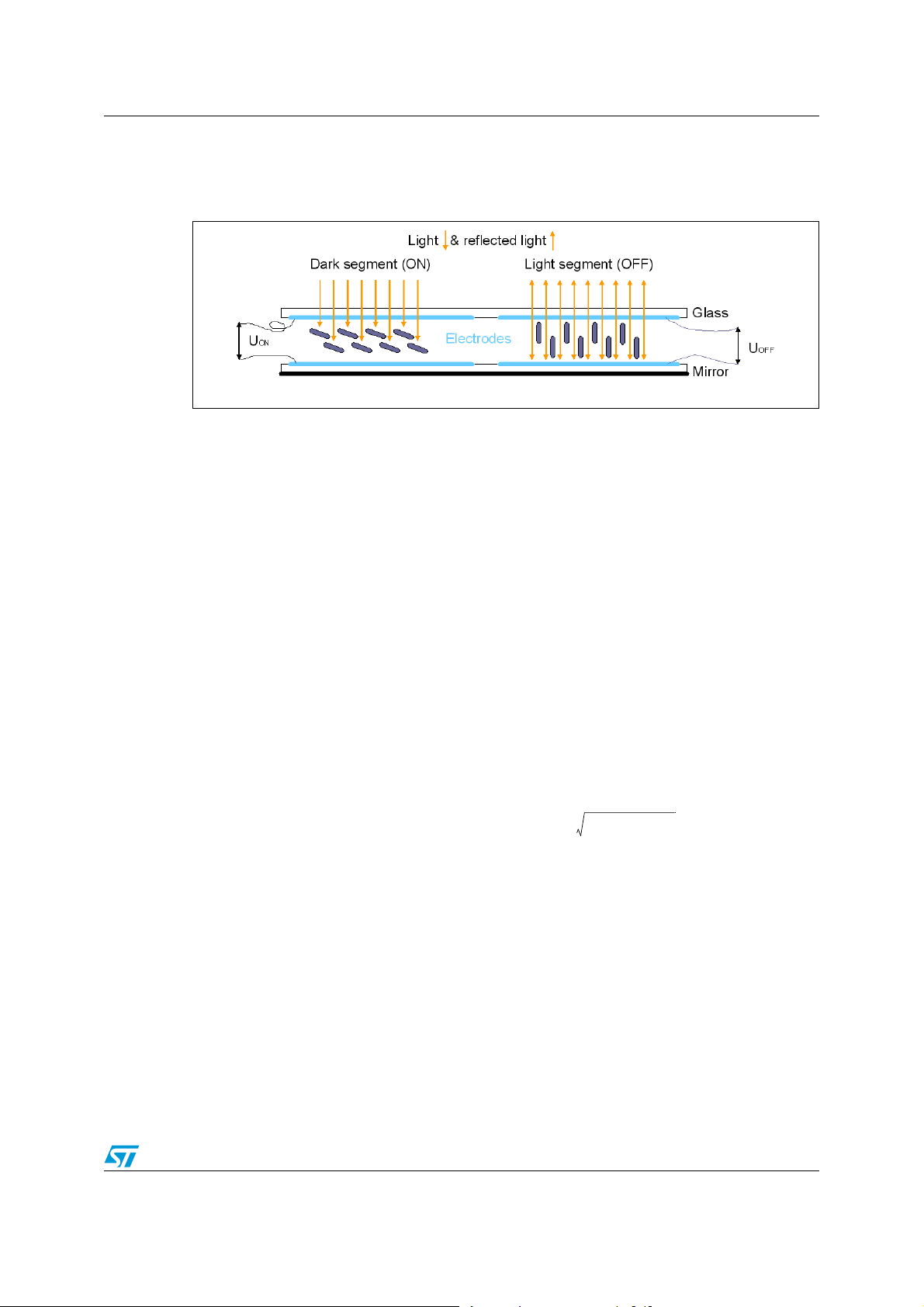

Figure 1. LCD principle

An LCD panel is composed of many layers. A liquid crystal is filled between two of them

(glass plates), which are separated by thin spacers coated with transparent electrodes that

contain orientation layers. The orientation layer usually consists of a polymer (e.g.

polyimide) which has been unidirectionally rubbed using, for instance, a soft tissue. As a

result, the liquid crystal molecules are fixed with their alignment more or less parallel to the

plates, in the direction of rubbing. The crystal alignment directions at the surface of the two

plates are perpendicular so that the molecules between the two plates undergo a

homogeneous twist deformation in alignment to form a helix.

If no electric field is applied, the birefringent liquid crystal molecules keep their helical

structure and rotate linearly polarized light waves passing through the plates. The

transmitted light wave is then allowed through a crossed exit polarizer. As a result, the

modulator has a bright appearance.

On the other hand, if an AC voltage of a few volts is applied, the resulting electric field forces

the liquid crystal molecules to align themselves along the field direction and the twist

deformation (the helix) is unwound. In this case, the polarization of the incident light is not

rotated by the crystal molecules and the crossed exit polarizer blocks the light wave. As a

result, the modulator appears dark.

The inverse switching behavior can be obtained with parallel polarizers. It must also be

noted that gray scale modulation is easily achieved by varying the voltage between the

crystal molecule reorientation threshold (reorientation is resisted by the elastic properties of

liquid crystals) and the saturation field.

LCDs are sensitive to root mean square voltage (Vrms= ) levels. With a low

root mean square voltage applied to it, an LCD is practically transparent (the LCD segment

is then inactive or off). To turn an LCD segment on, causing the segment to turn dark (from

light gray to opaque black), an LCD RMS voltage greater than the LCD threshold voltage is

applied to the LCD. The LCD RMS voltage is the RMS voltage across the capacitor C in

Figure 2, which is equal to the potential difference between the SEG and COM values.

The LCD threshold voltage depends on the quality of the liquid used in the LCD and the

temperature. The optical contrast is defined by the difference in transparency of an LCD

segment that is on (dark) and an LCD segment that is off (transparent). The optical contrast

depends on the difference between the RMS voltage on an on segment (V

voltage on an off segment (V

V

(rms), the higher the optical contrast. The optical contrast also depends on the level of

OFF

V

versus the LCD threshold voltage. If VON is below or close to the threshold voltage, the

ON

LCD is completely or almost transparent. If V

). The higher the difference between VON(rms) and

OFF

is close or above the threshold voltage, the

OFF

) and the RMS

ON

LCD is completely black.

Doc ID 14296 Rev 1 5/22

Page 6

LCD principle AN2687

C

R

S

S

COM

ai14758

In this document, contrast is defined as D = VON(rms) / V

OFF

(rms).

The applied LCD voltage must also alternate to give a zero DC value to prevent the

electrolytic process and so, ensure a long LCD lifetime.

The higher the multiplexing rates, the lower the contrast. The signal period also has to be

short enough to avoid visible flickering on the display.

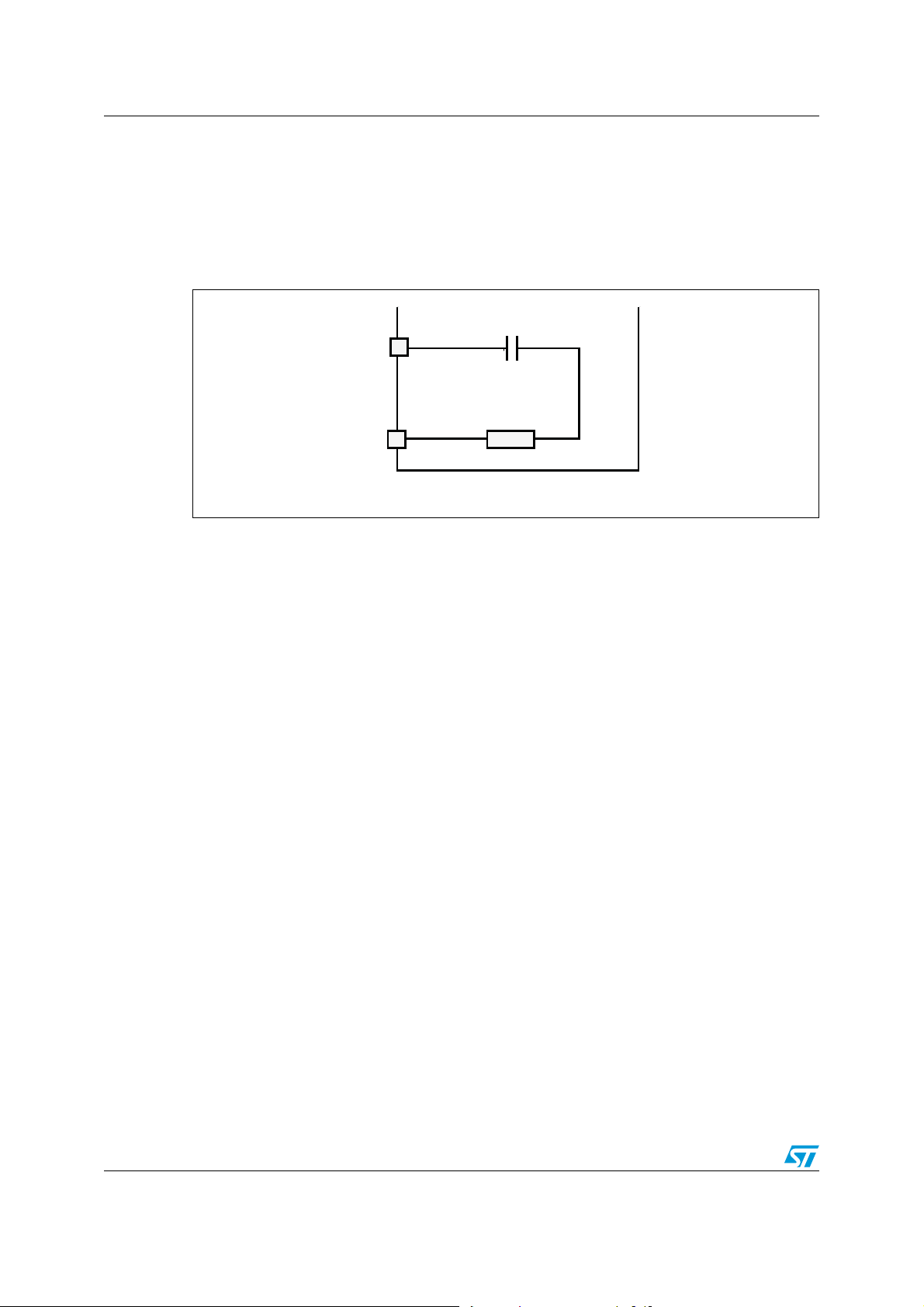

Figure 2. Equivalent electrical schematic of an LCD segment

Note: The DC value should never be more than 100 mV (refer to the LCD manufacturer’s

datasheet), otherwise the LCD lifetime may be shortened. The frequency range is 30 Hz to

200 Hz typically. If a lower frequency is used, the LCD flickers, if a larger frequency is used,

power consumption increases.

6/22 Doc ID 14296 Rev 1

Page 7

AN2687 LCD drive signals

S11

S1

COM1

ai14762

S2 S3

COM2

S14

COM3

COM4

S12

S13

2 LCD drive signals

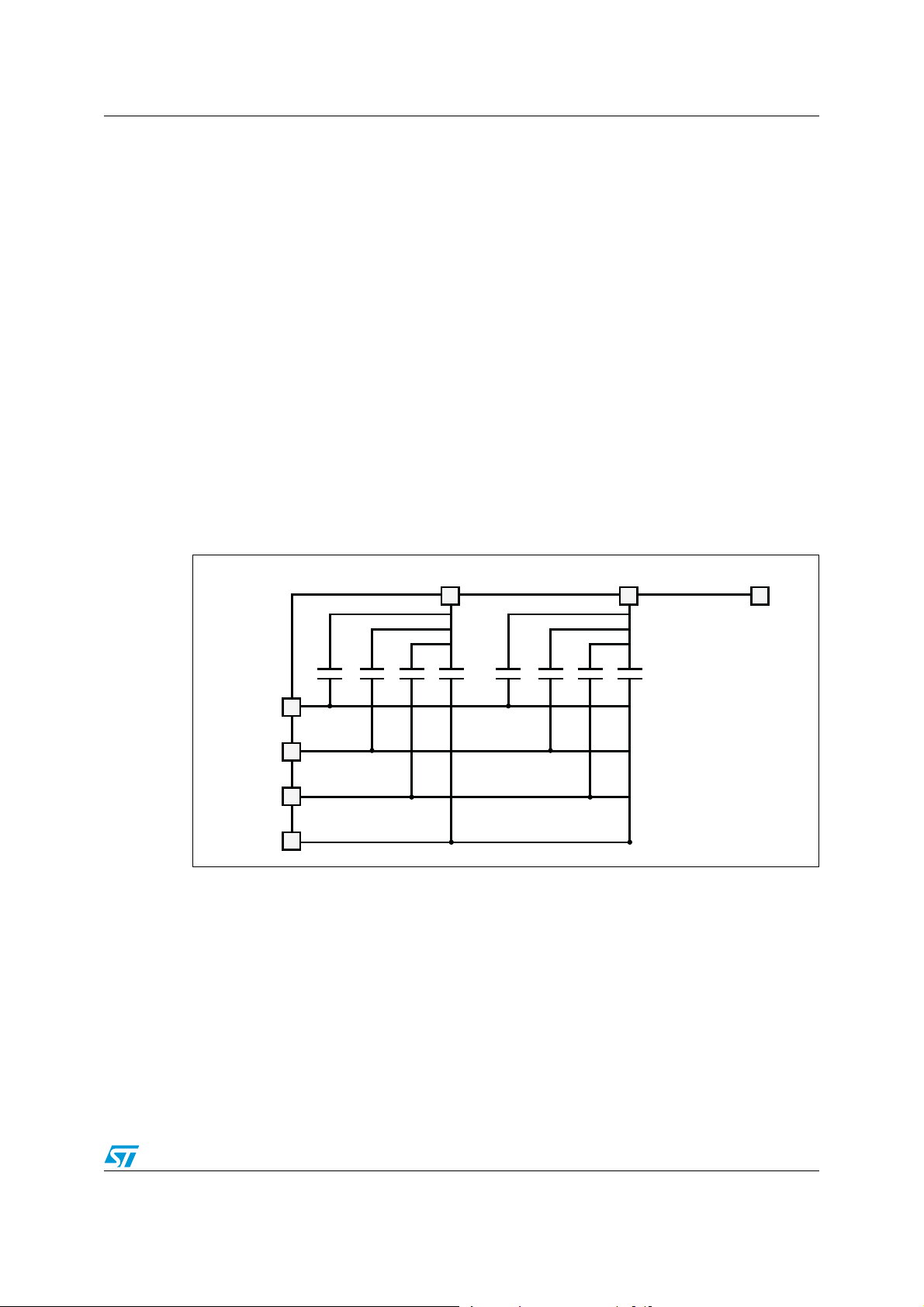

2.1 Quadruplex LCD drive

In a quadruplex LCD drive, four backplanes (common lines) are used. Each LCD pin is

connected to four LCD segments, whose other side is connected to one of the four

backplanes (refer to Figure 3). Thus, only (S/4)+4 MCU pins are necessary to drive an LCD

with S segments. For example, to drive an LCD with 128 segments (32 × 4), only 36 I/O

ports are required (32 I/O ports to drive the segments, 4 I/O ports to drive the backplanes).

Three different voltage levels have to be generated on the common lines: 0, V

The Segment line voltage levels are 0 and V

only. The LCD segment is inactive if the

DD

/2, VDD.

DD

RMS voltage is below the LCD threshold voltage and is active if the LCD RMS voltage is

above the threshold.

The intermediate voltage V

selected as backplanes are set by software to output mode for 0 or V

high-impedance input mode for V

/2 is only required for backplane voltages. The MCU I/O pins

DD

/2. The VDD/2 voltage is determined by two resistors of

DD

levels and to the

DD

equal value, externally connected to the I/O pins as shown in Figure 5. When one backplane

or COM is active, the other ones are neutralized by applying V

/2 to them.

DD

Figure 3. Basic LCD segment connection in quadruplexed mode

Doc ID 14296 Rev 1 7/22

Page 8

LCD drive signals AN2687

Figure 4. LCD timing diagram for quadruplex mode

COM1

COM2

COM3

COM4

Vsegx

V

COM

+VDD/2

Single-frame period

Control

period

T/8 T/4 T/2 3T/4 T

Segx_1 On Segx_2 Off Segx_3 On Segx_4 Off

LCD

COM1

COM2

COM3

COM4

SEG1

Vseg – V

COM

Vseg – V

COM1

2.1.1 LCD mean voltage calculation

The LCD mean voltage must be very close to zero to guarantee long life to the LCD. The

LCD mean voltage for On and Off periods can be calculated as shown below:

Vmean(On) = 1/8 Vseg + 1/8 (–V

Vmean(Off) = 3(Vseg/2) + 3(–Vr/2) (2)

Vmean(On) and Vmean(Off) assume identical periods for each phase.

Equating equations (1) & (2) to zero, that is putting Vmean(On) = 0 and Vmean(Off) = 0,

gives:

Vseg = V

● V

● Vr/2 is the voltage in the middle of the resistor bridge, applied on the COM line

● Vseg is the maximum voltage on the Segx line

● V

is the maximum voltage on the COM line

COM

is the microcontroller power supply

DD

= Vr = VDD, where:

COM

Vseg – V

) + 3(Vseg – Vr/2) + 3(–Vr/2) (1)

COM

COM4

ai15954

8/22 Doc ID 14296 Rev 1

Page 9

AN2687 LCD drive signals

1

T

---

ft2dt

0

T

1

T

---

VDD2dt VDD2dt

V

DD

2

----------

2

dt

2T

8

------ -

T

+

T

8

---

2T

8

------ -

+

0

T

8

---

1

T

---

VDD

2

T

8

--- VDD

2

T

8

---

VDD

2

4

------------------

6T

8

----------- -

++

0.661V

DD

=

1

T

---

0dt 0dt

V

DD

2

----------

2

dt

2T

8

------ -

T

+

T

8

---

2T

8

------ -

+

0

T

8

---

0.433V

DD

=

2.1.2 Contrast calculation

The performance of an LCD driving system is defined by the contrast.

Contrast (D) = Vrms(On) / Vrms(Off)

For the quadruplex signal as described on the previous page:

Vrms(On) = =

Vrms(On) =

Vrms(Off) =

Contrast (D) = Vrms(On) / Vrms(Off) = 0.661V

For comparison, a hardware LCD drive uses 1/3 bias voltage. With 1/3 bias control, the

contrast value (D) is 1.73. Therefore, 1/3 bias gives only a small contrast advantage. This

advantage is reduced to zero when using software contrast control.

/ 0.433VDD = 1.53

DD

Doc ID 14296 Rev 1 9/22

Page 10

Example of a quadruplex LCD driver with STM8 AN2687

3 Example of a quadruplex LCD driver with STM8

The following example describes a drive for a quadruplex mode (4 COM) LCD using the

STM8S20xxx (QFP64 package 10 × 10 mm). The only external components needed for

driving the LCD are eight resistors (refer to Figure 5). The resistor value of 470 k is used to

reach a low current consumption.

One I/O port per segment and one I/O port for each COM line are needed to drive the LCD.

In our example, to drive a quadruplex LCD that has 128 segments (with 32 segment lines

and 4 COM lines) 36 I/O ports are required.

In the example program, the PG0-PG7, PE0-PE7, PD0-PD7 and PB0-PB7 port pins are

connected to the 32 segment lines and are used to generate the segment signals. As PE1

and PE2 are true open drain I/Os (I

been added.

Port G segments control the display of LCD digits 1 and 2, port E segments control digits 3

and 4, port D segments controls digits 5 and 6 and port B segments control the display of

LCD digits 7 and 8.

Ports PC4 through PC7 are connected to the 4 COM lines (COM 4, 3, 2 and 1, respectively)

and are used to generate the COM signals.

2

C alternate function), two 10 k pull-up resistors have

The LCD driver consists of:

● one initialization function (LCD_ON) that correctly configures the required I/Os and the

Timer 2 resource (to get the 2 real-time clock interrupts) for the first method, or the

AWU mode one for the second method.

● one display function (LCD_Display) that enables the user to easily enter the string of

characters (8 characters maximum) to be displayed on the 8-digit LCD screen.

● one LCD RAM part that contains the coding of the numbers or letters to be displayed

on the LCD (refer to Ta b le 1 ). This LCD RAM table is filled automatically each time

LCD_Display function is called, depending on the characters composing the string to

display.

● a generic.h file containing:

– the different possible configurations in terms of numbers of COM and SEG (one

configuration has to be selected, knowing that the default configuration is 4 COM

and 32 SEG)

– the clock (HSI with one possible prescaler or LSI)

– the values put in the Timer 2 compare and autoreload registers depending on the

chosen LCD frame rate for the first method

● the letter and number constant coding tables which are contained in the lcd.c file.

The file can be easily modified by the user depending on the LCD type used.

When the LSI clock is used, in order to speed up the I/O toggling execution, the program

switches to the HSI clock, and returns to the LSI clock once this is done.

For more information regarding the software architecture, please refer to the lcd_awu.pdf

and lcd_timer2.pdf files attached with the source codes in the zip file associated with

this application note.

10/22 Doc ID 14296 Rev 1

Page 11

AN2687 Example of a quadruplex LCD driver with STM8

Table 1. LCD RAM

COM76543210Port

S7 S6 S5 S4 S3 S2 S1 S0 Port B

COM1

(PC7)

COM2

(PC6)

COM3

(PC5)

COM4

(PC4)

S15 S14 S13 S12 S11 S10 S9 S8 Port D

S23 S22 S21 S20 S19 S18 S17 S16 Port E

S31 S30 S29 S28 S27 S26 S25 S24 Port G

S7 S6 S5 S4 S3 S2 S1 S0 Port B

S15 S14 S13 S12 S11 S10 S9 S8 Port D

S23 S22 S21 S20 S19 S18 S17 S16 Port E

S31 S30 S29 S28 S27 S26 S25 S24 Port G

S7 S6 S5 S4 S3 S2 S1 S0 Port B

S15 S14 S13 S12 S11 S10 S9 S8 Port D

S23 S22 S21 S20 S19 S18 S17 S16 Port E

S31 S30 S29 S28 S27 S26 S25 S24 Port G

S7 S6 S5 S4 S3 S2 S1 S0 Port B

S15 S14 S13 S12 S11 S10 S9 S8 Port D

S23 S22 S21 S20 S19 S18 S17 S16 Port E

S31 S30 S29 S28 S27 S26 S25 S24 Port G

Doc ID 14296 Rev 1 11/22

Page 12

Example of a quadruplex LCD driver with STM8 AN2687

V

DD

470 kΩ

470 kΩ

Network resistors

Common lines

LCD Glass

Segment lines

PC4-PC7

ai14904

8

8

8

8

PB0-PB1

PD0-PD1

PE0-PE1

PG0-PG1

STM8

V

DD

PE1

PE2

10 kΩ

Figure 5. Hardware connection diagram

3.1 First method: Timer 2

In this method, the LCD timing is generated by the Timer 2 edge alignment mode using 2

interrupts: a compare one (value loaded into the TIM2_CCR1 register) and an overflow one

(value loaded into the TIM2_ARR register).

Each LCD display cycle consists of 4 phases, one for each backplane. Each COM line

generates its waveform during the corresponding phase e.g. COM1 line during phase1,

COM2 line during phase 2, etc.

When they are not generating their waveforms the COM lines remains at level V

phase consists of two parts:

1. active time

2. dead time

During the active time, the segment lines and COM lines are used to drive the LCD. During

the dead time, the segment and COM lines are used to tune the contrast.

The active time starts after the Compare interrupt and, the dead time starts after the

Overflow interrupt. A total of 16 interrupts is generated in each frame period with 4 interrupts

per control period. There are 2 Compare events (CCR1_1 and CCR1_2 managed in the

12/22 Doc ID 14296 Rev 1

/2. Each

DD

Page 13

AN2687 Example of a quadruplex LCD driver with STM8

same interrupt function) and 2 Overflow events (OVF) in each phase. The latter are

described below:

● During CCR1_1, V

is applied to the segments that have to be turned on and 0, to the

DD

segments that have to be turned off. The COM line that corresponds to this phase is set

to low level. Other COM lines are set to the V

● During OVF1, all COM lines are inactive (set to low level), then if Vrms has to be

/2 level.

DD

decreased (see Figure 6) all segments are set low or, if it has to be increased (see

Figure 7), all segments are set high.

● During CCR1_2, the segment lines are supplied with voltage levels that are inverted

compared to those applied during CCR1_1. The COM line that corresponds to this

phase is set to high level. Other COM lines are set to the V

● During OVF2, if Vrms has to be decreased then all COM lines and segments are

/2 level.

DD

inactive (set to low level) and if Vrms has to be increased (see Figure 7), the COM lines

are set high and the segments are set low.

In order to reduce consumption, the MCU is placed in WFI (wait for interrupt) mode in the

main routine. The MCU is then woken up by the Timer 2 interrupts and the external

interrupts (PA4/PA5 connected to push-buttons, refer to Section 6 for more information).

3.2 Second method: Auto-wakeup

In this method, the LCD timing is generated by the Auto-wakeup time base. The MCU is

placed in Auto-wakeup mode, meaning that it is in Halt mode but woken up periodically as

the LSI source clock (embedded low-power RC around 128 kHz) remains active. When

woken up, the MCU toggles the COM and SEG lines in the AWU interrupt routine, exactly as

it was doing in the previous method in the Timer 2 interrupt routine.

The software contrast control is not as easy to implement with this method as AWU timeouts

are fixed. It could be less fine-tuned.

Using this method, consumption can be very low (a total consumption of 1.08 mA at 3.3 V

with HSI as the master clock).

Doc ID 14296 Rev 1 13/22

Page 14

Consumption considerations AN2687

4 Consumption considerations

The number of code lines the MCU has to execute to drive the LCD is the same whatever

the CPU frequency. It is then easy to understand that the faster the CPU clock, the faster

these code lines are executed, the less they represent in terms of CPU load, and the less

the MCU consumes.

In order to reduce consumption with both methods, the PCKEN (peripheral clock gating)

register of the Clock Controller is used in order to clock only the used peripherals. V

also be decreased, especially in the first method (as the contrast can be compensated for by

software) to further reduce the consumption.

The consumption values obtained with the first method (at 3.3 V) are given in Tab le 2 .

Table 2. First method - consumption (Timer 2)

DD

can

Clock master

Consumption of the MCU

executing LCD driver (mA)

Consumption of the

LCD driver (mA)

Consumption of the MCU

executing an empty loop

HSI 2.38 0.3 2.08

HSI/2 1.73 0.38 1.35

HSI/4 1.45 0.49 0.96

HSI/8 1.3 0.7 0.6

LSI 1.17 0.94 0.23

Note: These typical values are given for guidance only. The LCD driver consumption is obtained

by subtracting the consumption of the MCU executing the LCD driver function and the

consumption of the MCU executing an empty loop (with all I/Os configured as output low

level).

The consumption values obtained with the second method (at 3.3 V) are given in Tab le 3 .

Table 3. Second method - consumption (AWU)

Clock master

Consumption of the MCU

executing LCD driver (mA)

HSI 1.08 0.36 0.72

HSI/2 1.12 0.4 0.72

HSI/4 1.26 0.51 0.75

HSI/8 1.34 0.58 0.76

Consumption of the

LCD driver (mA)

Consumption of the MCU

executing an empty loop

LSI 1.02 0.33 0.69

Note: These typical values are given for guidance only. The LCD driver consumption is obtained

by subtracting the consumption of the MCU executing the LCD driver function and the

consumption of the MCU executing an empty loop (with the MCU in AWU mode with all its

I/Os configured as output low level).

14/22 Doc ID 14296 Rev 1

Page 15

AN2687 Consumption considerations

COM1

ai15957

V

COM

+VDD/2

COM2

Segx_1 Off

T/4 T/2 3T/4 T

COM3

COM4

Vseg

Control periodDead time Active time

V

COM

+VDD/2

V

COM

+VDD/2

V

COM

+VDD/2

+VDD/2

Segx_1 On

V

COM

+VDD/2

CCR1_1 CCR1_2 CCR1_1

OVF1 OVF2

Vseg

Segx_1 (On)

Figure 6. LCD timing diagram with dead & active time (to decrease Vrms)

Doc ID 14296 Rev 1 15/22

Page 16

Consumption considerations AN2687

COM1

ai15953

V

COM

+VDD/2

COM2

Segx_2 Off

T/4 T/2 3T/4 T

COM3

COM4

Vseg

Control period

Dead time Active time

V

COM

+VDD/2

V

COM

+VDD/2

V

COM

+VDD/2

+VDD/2

Segx_1 On

Vseg

+V

DD

/2

CCR1_1 CCR1_2

OVF1 OVF2

Vseg

Segx

Dead time Dead time Dead time Dead time Dead time

Segx_1 On Segx_2 Off Segx_3 On Segx_4 On

Figure 7. LCD timing diagram with active and dead time (to increase Vrms)

16/22 Doc ID 14296 Rev 1

Page 17

AN2687 Software contrast control with the first method

1

TxT+

---------------- -

ft2dt

0

TxT+

1

TxT+

---------------- -

V

DD

2dt VDD–2dt

V

DD

2

---------- -

2

dt Vx2dt 8

0

xT

8

------ -

+

2T

8

------ -

T

+

T

8

---

2T

8

------ -

+

0

T

8

---

1

TxT+

-----------------V

DD

2

T

8

---

V

DD

2

T

8

---

V

DD

4

-----------

2

6T

8

-------

Vx

2

xT

8

-------

8+++

1

1x+

------------

14V

DD

32

----------------- -

2

Vx2x+

5 Software contrast control with the first method

Software contrast control is under patent from STMicroelectronics. The use of this technique

with a non-STMicroelectronics microcontroller has to be agreed by STMicroelectronics.

LCD contrast is entirely controlled by software with no need for any external component.

LCD contrast can be adjusted to the optimal value depending on the operating voltage of the

used LCD. LCD contrast is controlled by varying the dead phase timing as shown in the LCD

timing diagrams. This corresponds to the variation of the compare event value.

Dead time can be used to either decrease or increase the LCD Vrms. Dead time is the

voltage compensation time to regulate the rms voltage up and down. Dead time can be

implemented either after each control period or at the end of the frame. To avoid flickering,

the dead time duration must be adjusted depending on the quality of LCD and the frequency

of the frame.

In the example shown in Figure 6, the Vrms value of the LCD decreases when the dead

time duration increases and the Vrms value increases when the dead time duration

decreases. The opposite process is shown in Figure 7.

Two push-buttons connected to PA4 and PA5 are used on the demo board to decrease and

increase contrast, respectively, using this software method.

Relatively high software contrast control steps were chosen with the object of reaching

maximum or minimum contrast by pressing the push-buttons around 10 times. This can be

further fine-tuned if needed.

5.1 Contrast calculations

Let the frame period be T + xT, where:

● T is the Active time

● xT is the Dead time

In the formulas below, x corresponds to the proportion of dead time and Vx corresponds to

the voltage during the Dead time.

Vrms(on) =

Vrms(on) =

Vrms(on) =

Vrms(on) =

Doc ID 14296 Rev 1 17/22

Page 18

Software contrast control with the first method AN2687

1

1x+

------------

14V

DD

32

----------------- -

2

1

1x+

------------ 0.661V

DD

1

TxT+

---------------- -

0dt 0dt

V

DD

2

---------- -

2

dt Vx2dt 8

0

xT

8

------ -

+

2T

8

------ -

T

+

T

8

---

2T

8

------ -

+

0

T

8

---

1

TxT+

---------------- -

6V

DD

32

-------------- -

2

dt Vx2x+

1

1x+

------------ 0.433V

DD

1

1x+

------------ 0.661V

DD

1

1x+

------------ 0.433V

DD

-----------------------------------------------------

Since Vx = 0 (in case of a decrease in Vrms)

Vrms(on) = =

Vrms(off) =

Vrms(off) =

Since Vx = 0 (in case of a decrease in Vrms)

Vrms(off) =

Contrast (Dx) = , where Dx is the contrast calculated with the contrast

control method

Contrast D, between V

ON

and V

been changed only by tuning V

is constant (quality of contrast). The optical contrast has

OFF

close to the threshold value of the LCD.

ON

18/22 Doc ID 14296 Rev 1

Page 19

AN2687 LCD demo board

6 LCD demo board

Figure 8. Schematic diagram

PC5

PC4

PB1

PB3

PB5

PB7

PE1

PD7

PD5

PD3

PD1

1919202021212222232324242525262627272828292930303131323233333434353536

0

1

2

18

PE0

PD6

PD4

PD2

PD0

PB6

PB4

PB2

PB0

PC7

PC6

VCC

GND

C5

100nF

C9

4.7μF

SWIM

VDD

VCC

3

PD1

PA0

VSS

PA0

PD1

GND

VSS

External clock

PG7

PG5

PG3

PG1

PE7

PE5

PE3

36

VIM878-DP-RC-LV

1122334455667788991010111112121313141415151616171718

LCD

PG6

PG4

PG2

PG0

PE6

PE4

PE2

Con1

GND

PA1

Con1

1

S3

SW-PB

PG4

PG3

PG2

PG1

PG0

PC6

STM8

STM8-test

48

PG5

49

PG5

PG6

10K

PG7

R4

VCCVCC

Alim

PE4

PE3

PE2

PE1

PE0

10K

PD0

R3

PD1

PD2

PD3

PD4

PD5

PD6

PD7

VCC

W1

Jumper

2

112

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

GND

PE4

PG6

PG7

PE2/I2C_SDA

PE1/I2C_SCL

PE0/MCO

PD1/SWIM

PD5/LIN_TX

PD6/LIN_RX

PD7/TLI

PA0

PC7

43

42

41

40

44

C10

PG1/CAN_Rx

PG0/CAN_Tx

PC7/SPI_MISO

470nF

4.7μF

C7

C1

100nF

GND

VCC

39

VSSIO_2

VDDIO_2

PC6/SPI_MOSI

STM8

47

PI0

PG245PG346PG4

PE3/TIM3_BKIN

PD0/TIM2_CH2

PD2/TIM2_CH1

PD3/TIM1_CH2

PD4/TIM1_CH1

RESET1PA1/OSCIN2PA2/OSCOUT3VSSIO_14VSS5VCAP6VDD7VDDIO_18PA3/TIM1_CC39PA4/USART_RX10PA5/USART_TX11PA6/USART_CK12PF7/AIN15

PA1

PC5

38

PC5/SPI_SCK

QFP64

PE5

PC4

37

36

33

PE6/AIN9

PE5/SPI_NSS

PE7/AIN8

PC1/TIM3_CH134PC2/TIM3_CH235PC3/TIM3_CH3

PCA/TIM3_CH4

PF6/AIN14

13

14

C3

C2

100nF

PB0/AIN0

PB1/AIN1

PB2/AIN2

PB3/AIN3

PB4/AIN4

PB5/AIN5

PB6/AIN6

PB7/AIN7

PF0/AIN10

PF1/VREFVSSA

VDDA

PF2/VREF+

PF3/AIN11

PF5/AIN1315PF4/AIN12

16

100nF

S2

SW-PB

S1

SW-PB

R1

10K

VCC

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

R2

10K

10K

R5

PE6

PE7

PB0

PB1

PB2

PB3

PB4

PB5

PB6

PB7

VCC

GND

VCC

C6

100nF

PA0

C8

C4

4.7μF

VCC

470K

R12

GND

470K

R10

470K

R8

470K

R6

VCC

100nF

PC7

GND

PC6

PC5

GND

PC4

470K

R13

470K

R11

470K

R9

470K

R7

GND

ai14970

Doc ID 14296 Rev 1 19/22

Page 20

LCD demo board AN2687

6.1 Board information

The LCD demo board should be supplied by a DC voltage of 3.3 V through connector W1.

There is no regulator present on the demo board to enable the user to modify V

the impact on the LCD contrast. The maximum absolute ratings for the power supply must

be respected (please refer to the product datasheet). It is also strongly recommended not to

apply a V

voltage higher than 3.3 V for too long.

DD

The LCD chosen for use on the demo board is driven at 3 V, which gives a better contrast for

low-voltage range MCUs like the STM8S20xxx.

The two pieces of software attached to this application note display “STM8 LCD” and the

contrast can be tuned with the ST software patented method through two push-buttons (S1

to increase the contrast and S2 to decrease it) with the first method (LCD driver directory in

the attached zip file).

and see

DD

Vrms is increased by applying first V

while first V

, then VSS is applied to the COM lines.

DD

Vrms is decreased by applying V

, then VDD (during the dead times) to the segment,

SS

to the segment during the same dead times. The

SS

voltage average is then kept. Refer to the software attached to this application note for more

details.

The demo board uses the STM8S20xxx microcontroller and can be reprogrammed and

debugged using the SWIM communication protocol through the SWIM interface. The board

is provided with the SWIM connector.

The device can be reset by pressing switch S3 on the demo board.

20/22 Doc ID 14296 Rev 1

Page 21

AN2687 Revision history

7 Revision history

Table 4. Document revision history

Date Revision Changes

17-Apr-2009 1 Initial release.

Doc ID 14296 Rev 1 21/22

Page 22

AN2687

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2009 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

22/22 Doc ID 14296 Rev 1

Loading...

Loading...