AN2684

Application note

STEVAL-IFP006V1: designing with VNI4140K quad high-side

smart power solid-state relay ICs

Introduction

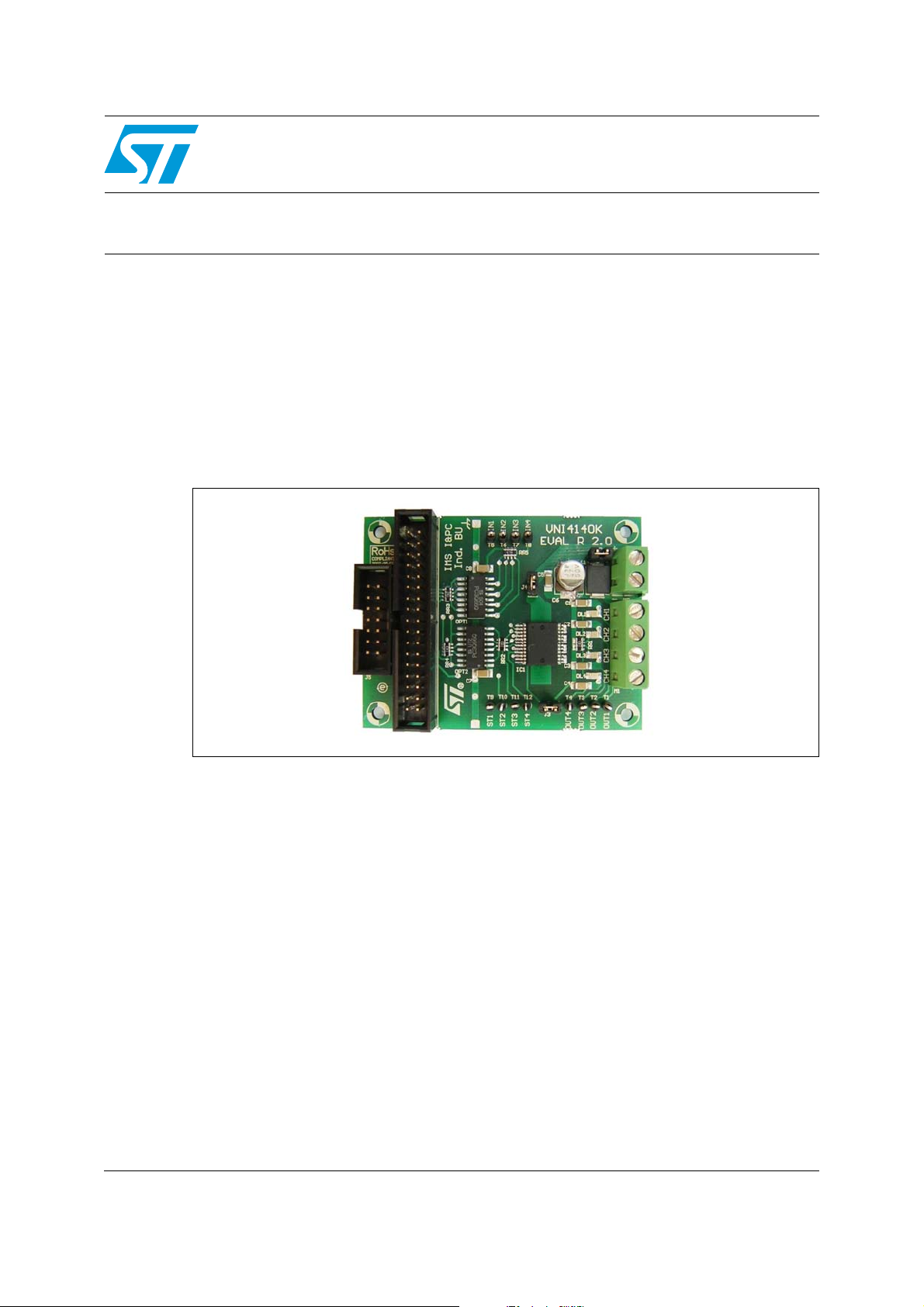

The STEVAL-IFP006V1 demonstration board has been developed to show the new

VNI4140K device functionalities within industrial applications such as PLCs (programmable

logic controllers) which drive lamps, valves, relays, and similar loads.

This tool allows evaluating VNI4140K features, in particular all kinds of embedded selfprotections, power-handling capabilities, operation and diagnostic feedback, thermal

behavior and conformity to inherent IEC standards.

Figure 1. STEVAL-IFP006V1

A double-sided PCB allows obtaining the best trade-off between a routing solution and

thermal management results.

The main features of the demonstration board are:

■ Four output channels (4 x 0.7 A)

■ Four input channels

■ Four feedback channels for diagnostic purposes

■ Bidirectional opto-isolated interface for MCU safe connection

■ TTL/CMOS compatible signals for MCU direct connection

■ LEDs to indicate output state

■ Compliance to IEC61000-4-4 and IEC61000-4-5

May 2009 Doc ID 14266 Rev 1 1/21

■ Compatibility with existing STMicroelectronics tools (IBU communication board,

CANIC10…)

■ 10.5 V to 36 V DC power supply voltage range

www.st.com

Contents AN2684

Contents

1 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 VNI4140K quad high-side smart power solid-state relay IC

description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 IFP006V1 demonstration board description . . . . . . . . . . . . . . . . . . . . . . 8

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.2 IFP006V1 schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.3 IFP006V1 connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.4 IFP006V1 thermal management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.5 EMC immunity test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.5.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.5.2 Test conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.5.3 Burst immunity test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.5.4 Surge test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Appendix A Bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Appendix B PCB layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Appendix C References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2/21 Doc ID 14266 Rev 1

AN2684 List of figures

List of figures

Figure 1. STEVAL-IFP006V1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. IFP006V1 top view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 4. IFP006V1 bottom view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 5. IFP006V1 schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 6. J1 connector pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 7. J5 connector pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 8. IFP006V1 PCB copper heatsink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 9. Thermal map in steady state condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 10. Thermal map in demagnetization condition (1 Hz repetitive cycling on 48 W 1.2 H load) . 11

Figure 11. Steady state thermal behavior 3D simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 12. Repetitive demagnetization thermal behavior 3D simulation (1 Hz repetitive cycling on

48 W 1.2 H load) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 13. Burst timing waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 14. Surge standard timing waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 15. IFP006V1 component layer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 16. IFP006V1 copper top layer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 17. IFP006V1 copper bottom layer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Doc ID 14266 Rev 1 3/21

Electrical characteristics AN2684

1 Electrical characteristics

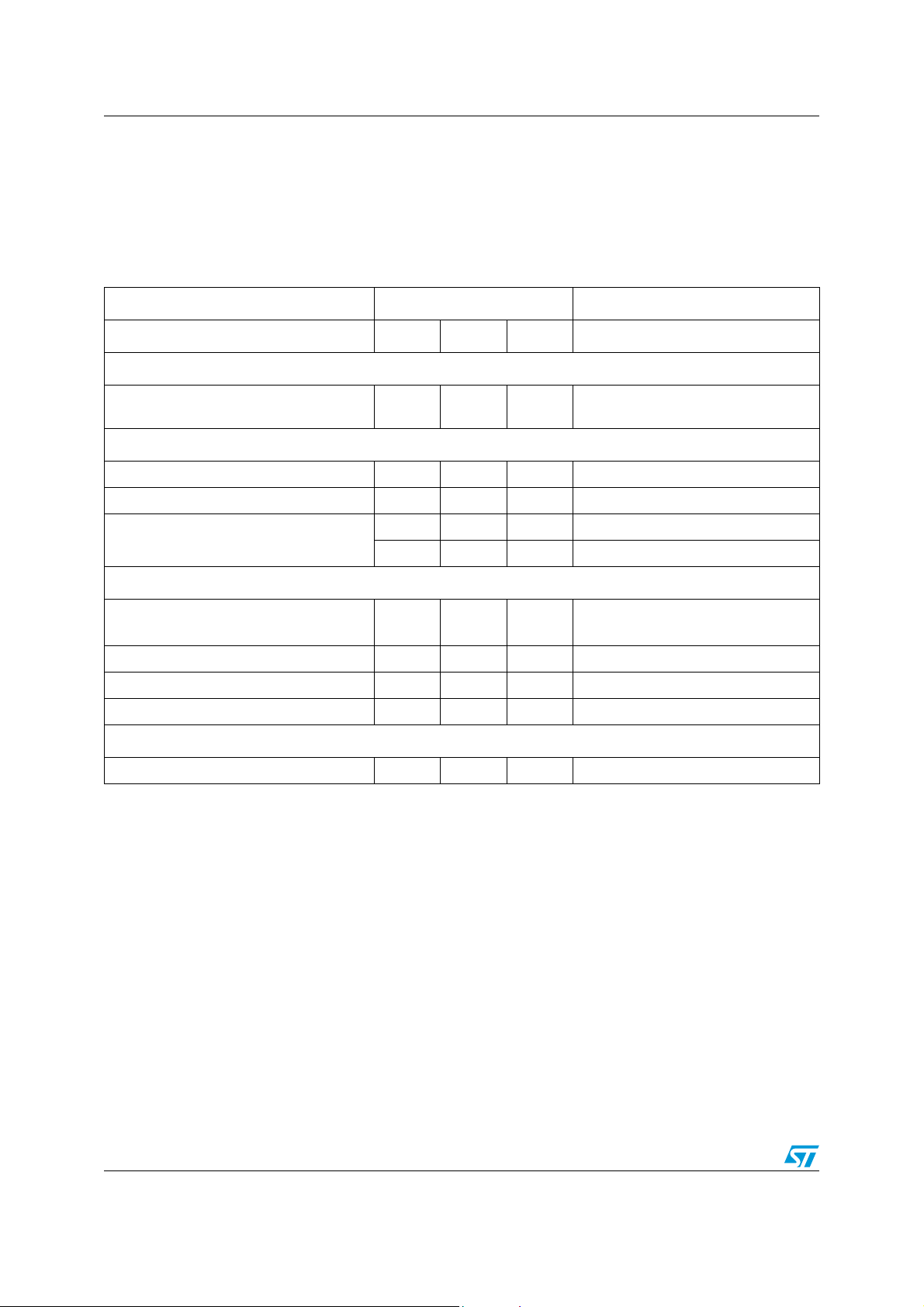

The electrical characteristics of the VNI4140k demonstration board (STEVAL-IFP006V1)

are given in Tab l e 1 .

Table 1. STEVAL-IFP006V1 electrical characteristics

Parameter Value Notes

Min Typ Max

Operating conditions

Ambient operating temperature 85 °C

If the VNI4140K junction temperature

exceeds 180 °C, device shuts down

Power supply

Vcc supply voltage 10.5 V 24 V 36 V

Vdd logic supply voltage 5 V From eval communication board

250 µA All channels in OFF state

Supply current on Vdd

2.4 mA 4.8 mA ON state with V

= 5 V

in

Output stage

Output channel ON current limitation 0.7 A 1.7 A

IC internally limited

V

CC = 24 V; RLOAD < 10 mΩ

Maximum DC output current 1.4 A Dynamic load

dV/dt(ON) turn-on voltage slope 0.7 V/µs IOUT = 0.5 A, resistive load

(off) turn-off voltage slope 1.5 V/µs IOUT = 0.5 A, resistive load

dV/dt

Demagnetization protection

Output voltage on inductive turn-off V

CC-41 VCC-45 VCC-50 IOUT = 0.5 A; LLOAD >= 1 mH

4/21 Doc ID 14266 Rev 1

AN2684 Safety precautions

2 Safety precautions

The board must be used only by expert technicians. The copper areas around the

VNI4140K device have a heat sink function, visible in the top layer layout view, refer to

Figure 8. In case of short-circuit, current limiting or hard demagnetization, the STEVAL-

IFP006V1 board, or part of it, might reach a very high temperature with consequent danger.

No specific protections are implemented for reverse DC accidental connection. Remember

that an electrolytic capacitor is connected to the supply bus, therefore a reverse continuous

DC voltage applied to it may produce a dangerous explosion.

Warning: ST assumes no responsibility for any consequences which

may result from the improper use of this tool.

Doc ID 14266 Rev 1 5/21

VNI4140K quad high-side smart power solid-state relay IC description AN2684

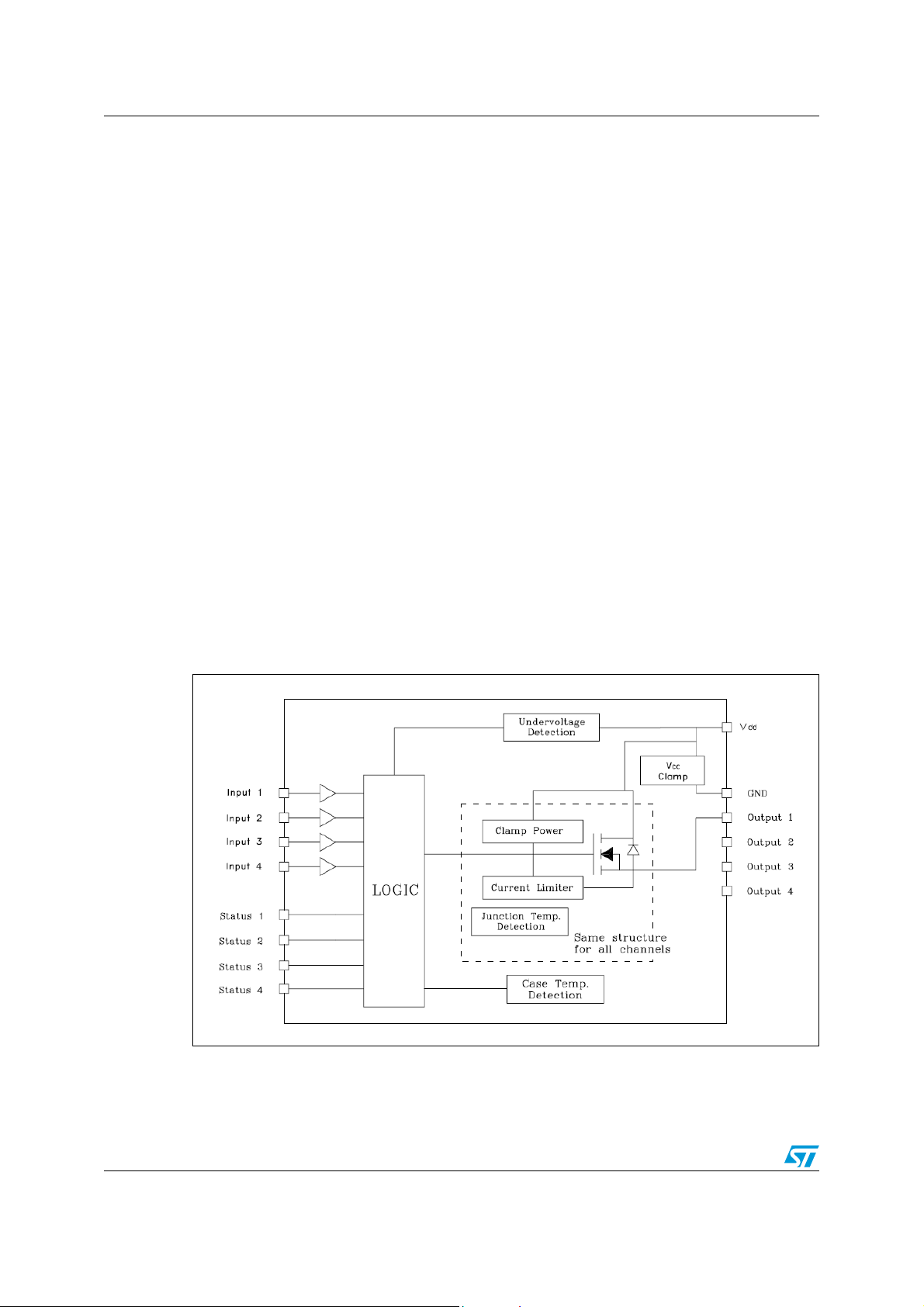

3 VNI4140K quad high-side smart power solid-state

relay IC description

The VNI4140k is a monolithic 4-channel driver featuring a very low supply current. The IC,

which uses STMicroelectronics VIPower technology, is intended for driving loads with one

side connected to ground.

Active channel current limitation, combined with thermal shutdown (independent for each

channel) and automatic restart, protect the device against overload.

The main features of the VNI4140K IC are:

● Output current: 0.7 A per channel

● Shorted load protections for each channel

● Junction overtemperature protection

● Case overtemperature protection for thermal independence of the channels

● Thermal case shutdown and restart not simultaneous for the various channels

● Protection against ground disconnection

● Current limitation

● Undervoltage shutdown

● Open drain diagnostic outputs

● 3.3 V CMOS/TTL compatible inputs

● Fast demagnetization of inductive loads

● Conforms to IEC 61131-2

Figure 2. Block diagram

Active current limitation avoids that the system power supply drops in case of shorted load.

In overload condition, the channel turns OFF and back ON automatically after the IC

temperatures decrease below a threshold fixed by a temperature hysteresis so that junction

6/21 Doc ID 14266 Rev 1

AN2684 VNI4140K quad high-side smart power solid-state relay IC description

temperature is controlled. If this condition makes the case temperature reach the case

temperature limit (T

has exceeded the junction protection threshold, T

protection reset threshold, T

only when the case temperature decreases below the case protection reset threshold (T

), overloaded channels (i.e. the ones for which junction temperature

CSD

) are turned OFF. These channels restart, non-simultaneously,

jR

, and has not fallen below the junction

jSD

CR

).

Non-overloaded channels continue to operate normally.

The open drain diagnostic outputs indicate related channel overtemperature conditions.

Doc ID 14266 Rev 1 7/21

IFP006V1 demonstration board description AN2684

4 IFP006V1 demonstration board description

4.1 Overview

The VNI4140K demonstration board is composed of two main sections:

● Opto-isolated interface for input and status signals

● A four-channel self-protect power stage section with STMicroelectronics Tr an si l™

diode protection

The demonstration board consists of a double-sided FR4 printed circuit board with 35 µm

copper plating. The PCB dimensions are 52 mm x 68 mm. The top and bottom views are

shown below.

Figure 3. IFP006V1 top view

Figure 4. IFP006V1 bottom view

8/21 Doc ID 14266 Rev 1

AN2684 IFP006V1 demonstration board description

4.2 IFP006V1 schematic

Figure 5. IFP006V1 schematic

C8

4.7nF

GND

+24Vdc

M2

C7

4.7nF

OPEN

STAT4STAT3

STAT2STAT1

M.2VITEB

1

2

J2

A B

FOR

OVL TEST

C6

47uF

+

C5

100nF

1206

T1

T2

D1

SM15T39AC

C1

10nF LV

1206

20

21

C2

T3

10nF LV

IC1

1206

OUT1

123

C3

OUT3

OUT2

4

T4

10nF LV

1206

OUT4

M1

M.4VITEB

13

1206

DL1

DL2

DL3

DL4

VNI4140K

LED

LED

LED

LED

10nF LV

RR1

C4

10K 1206

1 2

VDD

1 2

OUT2_b

3 4

5 6

7 8

9 10

11 12

13 14

J5

CAN7

IN1 IN2

IN3 IN4

RR5

47K 1206

OR

J4

Vcc DISC. TEST

CURRENT PROBE

TAB

A B

OUT1_a24OUT1_b23OUT1_c22OUT2_a

Vcc

IN1

Vcc

2

1

T5

IN2

4

T6

OUT2_c19OUT3_a18OUT3_b17OUT3_c16OUT4_a15OUT4_b14OUT4_c

VNI4140K

IN38IN4

10

J3

GND

STAT1

STAT37STAT4

STAT2

3

9

5

GND DISC. TEST

6

A B

T12

T11

T10

T9

T7

RR2

T8

10

11

12

13

14

15

16

STAT1

1234567

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

J1

EVALCOMMBOARD

8 9

RR3

1K 1206

OPT1

TLP281-4

89

10111213141516

10K 1206

1234567

OPT2

TLP281-4

IN1

IN2

IN3

IN4

VDD

STAT4

STAT3

STAT2

IN1

IN2

IN3

IN4

STAT1

STAT2

STAT3

STAT4

RR4

VDD

10K 1206

Doc ID 14266 Rev 1 9/21

IFP006V1 demonstration board description AN2684

4.3 IFP006V1 connectors

The demonstration board is equipped with input and output connectors. Specifically, there

are two input header connectors (J5 and J1), one 4-channel output connector (M1), and a

supply voltage connector (M2).

Both input connectors, J5 and J1, provide the same bidirectional signals guaranteeing the

maximum compatibility with existing STMicroelectronics tools such as the industrial

communication board (see AN2451) and similar products.

Figure 6. J1 connector pinout

Figure 7. J5 connector pinout

Table 2. J1 and J5 pin description

J1 pin number J5 pin number Signal Type

11 1 Vdd 5/3.3 V supply voltage

23 2 GND Signal ground

9 3 IN1 Input channel 1

13 4 IN2 Input channel 2

15 5 IN3 Input channel 3

17 6 IN4 Input channel 4

6 7 STAT1 Status channel 1

25 8 STAT2 Status channel 2

21 9 STAT3 Status channel 3

19 10 STAT4 Status channel 4

10/21 Doc ID 14266 Rev 1

AN2684 IFP006V1 demonstration board description

4.4 IFP006V1 thermal management

The IFP006V1 PCB has two heatsinks: approximately 1 sq. cm on the top layer and 3 sq.

cm on the bottom layer, thermally interconnected through 9 vias, as shown in Figure 8.

In a steady state condition low R

ensures a very low dissipation but in current

DS(on)

limitation and in fast demagnetization, the power dissipation is much higher, requiring a low

thermal resistance through the device exposed tab, soldering space, top layer, vias and

bottom layer path. A 35 µm copper (10 oz/sq. ft) thickness and 0.3 mm diameter for the vias

are used according to EIA/JESD51-5.

Figure 8. IFP006V1 PCB copper heatsink

Figure 9 and 11 show the IFP006V1 temperature map with all channels permanently

switched ON, 48 Ω loads, 24 V supply voltage and ambient temperature of 25 °C. The IC

temperature increase is only about a few degrees.

Figure 10 and 12 show a similar map when the IC is cycling at 1 Hz, 50% duty cycle, 48 Ω

1.2 H loads, 24 V supply voltage and ambient temperature of 25 °C.

Figure 9. Thermal map in steady state

condition

Figure 10. Thermal map in demagnetization

condition (1 Hz repetitive cycling on

48 Ω 1.2 H load)

AM01851v1

Doc ID 14266 Rev 1 11/21

AM01852v1

IFP006V1 demonstration board description AN2684

Figure 11. Steady state thermal behavior 3D

simulation

AM01853v1

In particular Figure 11 and 12 show 3D thermal modelization of the device.

4.5 EMC immunity test

4.5.1 Description

Figure 12. Repetitive demagnetization thermal

behavior 3D simulation (1 Hz

repetitive cycling on 48 Ω 1.2 H

load)

AM01854v1

IFP006V1 has been tested according to EMC immunity standards IEC61000-4-4 (fast

transient burst) and IEC61000-4-5 (high energy surge).

A fast transient burst test has been performed all channels.

Each channel under test is cycling ON and OFF at 1 Hz, duty cycle 50%, on four 48 Ω load

resistors at 24 Vdc supply voltage.

A burst signal was applied using an ultra-compact simulator with an internal capacitive

coupling clamp tool.

4.5.2 Test conditions

● Ambient temperature: 25.6 °C

● Ambient humidity: 46%

● Main voltage power supply: 24 Vdc

● DC insulated voltage: 5 Vdc

● Loads: 4 x 48 Ω power resistor

12/21 Doc ID 14266 Rev 1

AN2684 IFP006V1 demonstration board description

4.5.3 Burst immunity test

Tab le 3 gives the burst setup configuration adopted to perform this test.

Table 3. Burst setup configuration

Test level Condition

Pulse time rt 5 ns ± 30%

Pulse duration td 50 ns ± 30%

Source impedance Zq = 50 Ω ± 20%

Polarity Positive / negative

Burst duration (td) 15 ms ± 20%

Burst frequency (f) 5 kHz

Burst period (tr) 300 ms ± 20%

Duration time (T) 5 min

Figure 13 below shows the standard timing waveform applied during the burst test.

Figure 13. Burst timing waveform

Tab le 4 shows the results of an inherent burst test. Normal performance has been observed

when applying four different disturbance levels on the output ports and Vcc main voltage

power supply.

Doc ID 14266 Rev 1 13/21

IFP006V1 demonstration board description AN2684

Table 4. Burst test results

Burst standard test routines Level Voltage (kV) Acceptance criteria

(1)

IEC 61000-4-4 Level 1 0.5 A

IEC 61000-4-4 Level 2 1 A

IEC 61000-4-4 Level 3 2 A

IEC 61000-4-4 Level 4 4 A

1. Classification of the test

(Criteria A): normal performance

(Criteria B): temporary degradation or loss of function or performance with automatic return to normal operation

(Criteria C): temporary degradation or loss of function with external intervention to recover normal operation

(Criteria D): degradation or loss of function, need replacement of damaged components to recover normal

operation.

4.5.4 Surge test

A high energy surge test was performed in differential mode. A high surge signal was

injected on the DUT (device under test) through a 42 Ω decoupling resistor. The test

consisted of three positive and three negative discharges with a repetition rate of 1

discharge per minute.

Figure 14 shows the standard timing waveform applied on the DUT.

Figure 14. Surge standard timing waveform

Tab le 5 below shows normal performance of the device.

14/21 Doc ID 14266 Rev 1

AN2684 IFP006V1 demonstration board description

Table 5. Surge test results

Surge standard test

routines

Level Voltage (V) Acceptance criteria

IEC 61000-4-5 Level 1 500 A

IEC 61000-4-5 Level 2 1000 A

IEC 61000-4-5 Level 3 2000 A

1. Classification of the test

(Criteria A): normal performance

(Criteria B): temporary degradation or loss of function or performance with automatic return to normal operation

(Criteria C): temporary degradation or loss of function with external intervention to recover normal operation

(Criteria D): degradation or loss of function, need replacement of damaged components to recover normal

operation.

(1)

Doc ID 14266 Rev 1 15/21

Bill of material AN2684

Appendix A Bill of material

Table 6. IFP006V1 demonstration board bill of material

Designator Part type Description

RR1 10 kΩ x 4 SMD resistor pack 1206 format

RR2 10 kΩ x 4 SMD resistor pack 1206 format

RR3 1 kΩ x 4 SMD resistor pack 1206 format

RR4 10 kΩ x 4 SMD resistor pack 1206 format

RR5 47 kΩ x 4 SMD resistor pack 1206 format

C1 10 nF LV SMD capacitor 1206 format

C2 10 nF LV SMD capacitor 1206 format

C3 10 nF LV SMD capacitor 1206 format

C4 10 nF LV SMD capacitor 1206 format

C5 100 nF SMD capacitor 1206 format

C6 47 µF 50 V SMD electrolytic capacitor

C7 4.7 nF SMD capacitor 1206 format

C8 4.7 nF SMD capacitor 1206 format

D1 SM15T39AC Transil™ diode

DL1 LED diode SMD LED diode 0805 format

DL2 LED diode SMD LED diode 0805 format

DL3 LED diode SMD LED diode 0805 format

DL4 LED diode SMD LED diode 0805 format

OPT1 PC3Q66Q 4-channel OPTO isolator

OPT2 PC3Q66Q 4-channel OPTO isolator

IC1 VNI4140K ST IC Industrial 4 CH HSD

J1 HADER 34-pin Compatible EVALCOMMBOARD

J2 Jumper Overvoltage test

J3 Jumper Ground disconnection test

J4 Jumper V

disconnection test

cc

J5 Hader 14-pin Compatible ST7CANIC DB

M1 4 screw plugs HSD output connector

M2 2 screw plugs Power supply connector

T1 Test point HSD output channel 1 voltage

T2 Test point HSD output channel 2 voltage

T3 Test point HSD output channel 3 voltage

T4 Test point HSD output channel 4 voltage

16/21 Doc ID 14266 Rev 1

AN2684 Bill of material

Table 6. IFP006V1 demonstration board bill of material (continued)

Designator Part type Description

T5 Test point HSD input channel 1 signal

T6 Test point HSD input channel 2 signal

T7 Test point HSD input channel 3 signal

T8 Test point HSD input channel 4 signal

T9 Test point HSD channel 1 status

T10 Test point HSD channel 2 status

T11 Test point HSD channel 3 status

T12 Test point HSD channel 4 status

Doc ID 14266 Rev 1 17/21

PCB layout AN2684

Appendix B PCB layout

Figure 15. IFP006V1 component layer

Figure 16. IFP006V1 copper top layer Figure 17. IFP006V1 copper bottom layer

18/21 Doc ID 14266 Rev 1

AN2684 References

Appendix C References

1. AN1351 - VIPower and BCDmultipower: making life easier with ST's high side drivers

Doc ID 14266 Rev 1 19/21

Revision history AN2684

Revision history

Table 7. Document revision history

Date Revision Changes

20-May-2009 1 Initial release

20/21 Doc ID 14266 Rev 1

AN2684

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2009 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 14266 Rev 1 21/21

Loading...

Loading...