Page 1

AN2683

Application note

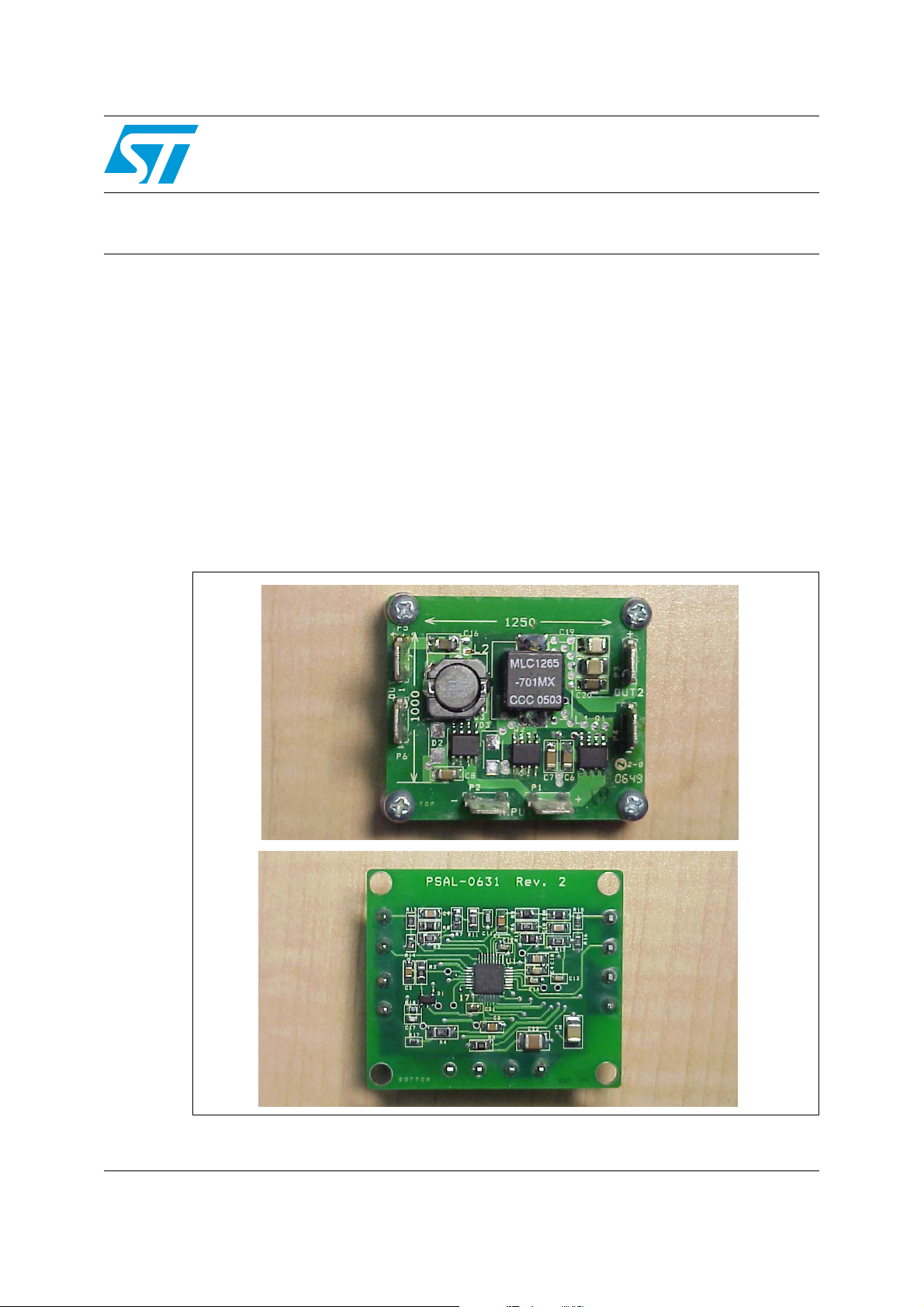

Compact dual output point of load converter

based on the PM6680 step-down controller

Introduction

This application note demonstrates the performance of the PM6680 dual step-down

controller by implementing a two output point of load converter in a small printed circuit

board footprint. Utilizing constant on-time architecture and featuring a no-audio skip mode of

operation, a common bus voltage that ranges between 10 to 16 V

at 10.5 amps and 1.8 V

no-audio skip feature significantly improves efficiency at light load. Using surface mount

components on both the top and bottom of the circuit board and featuring ceramic output

capacitors, the area needed for the converter measures only 1.0 by 1.25 inches (25.4 by

37.75 mm). The method for component value dimensioning is described along with the

schematic and construction details. Typical efficiencies and functional test data are also

presented.

Figure 1. PM6680 - top and bottom view

at 2.5 amps for a total output power level of 15 watts. The unique

DC

is converted to 1.0 VDC

DC

April 2008 Rev 1 1/38

www.st.com

Page 2

Contents AN2683

Contents

1 Main characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Input voltage range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Output ripple voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Switching frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Output overload/short circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Circuit description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4 Functional testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.1 Input/output voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2 Ripple/noise voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.3 Load transient overshoot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.4 Output current limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.5 Output short circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.6 Input under voltage lockout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5 Bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2/38

Page 3

AN2683 List of figures

List of figures

Figure 1. PM6680 - top and bottom view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

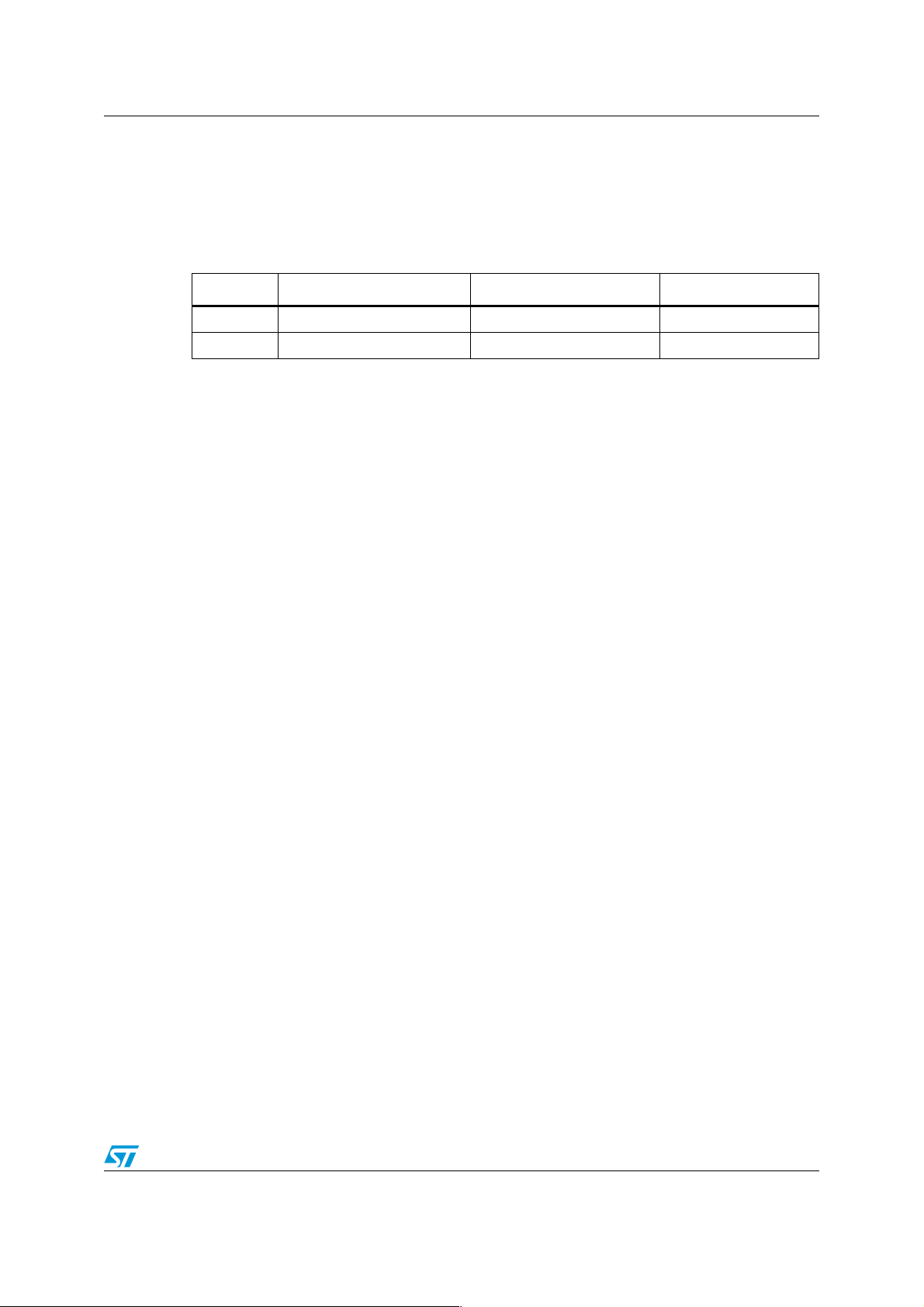

Figure 2. Circuit board schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

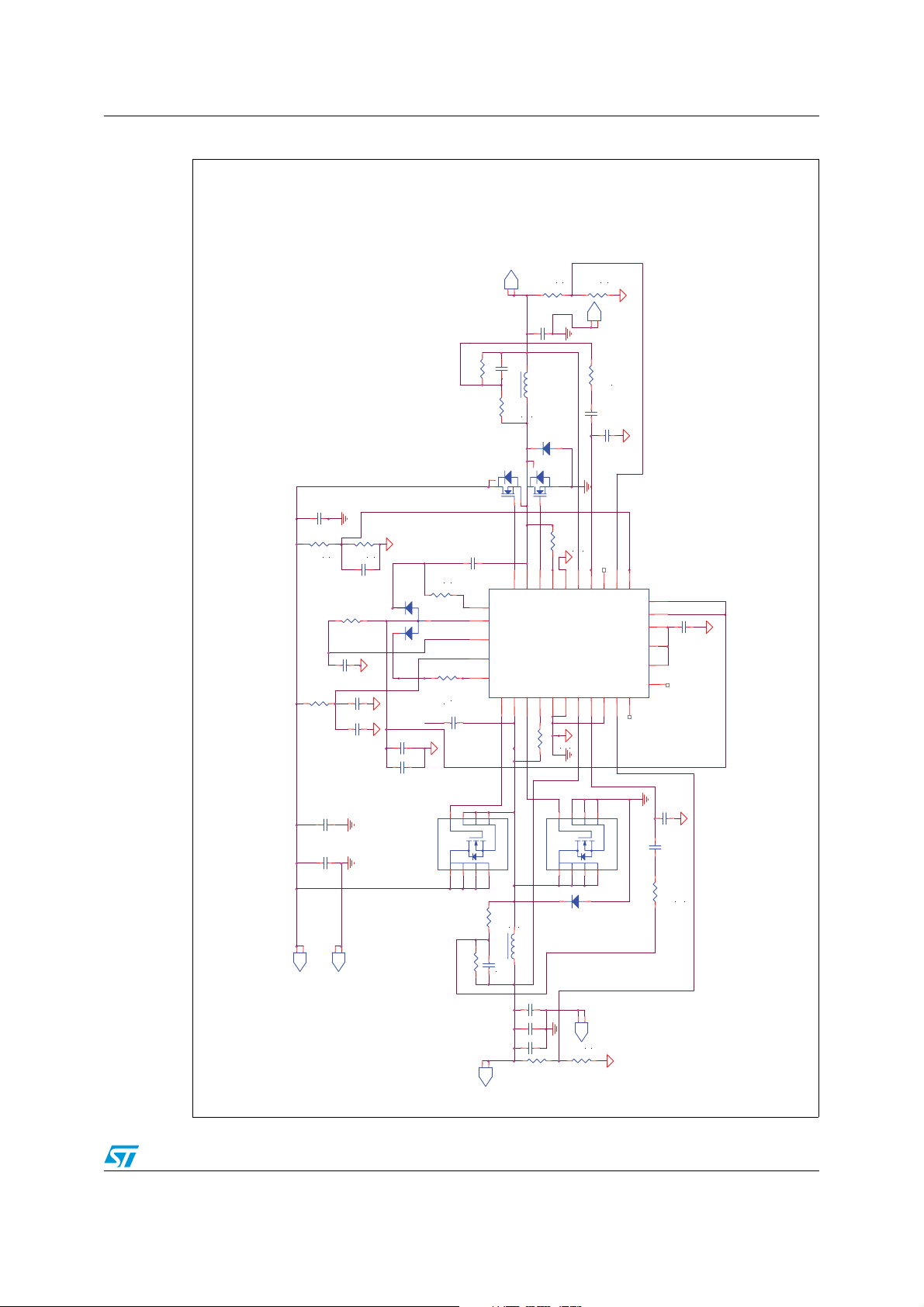

Figure 3. Components of virtual ESR network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 4. Top layer component placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 5. Top layer copper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 6. Inner layer 1 showing additional power traces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 7. Power ground layer (inner layer 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 8. Signal ground layer (inner layer 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 9. Bottom layer components placement (mirrored). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 10. Bottom layer copper (mirrored). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 11. Inner layer 4 (mirrored) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 12. Efficiency vs. load current in PWM mode (1.0 V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 13. Efficiency vs. load current in NA-skip mode (1.0 V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 14. Efficiency vs. load current in PWM mode (1.8 V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 15. Efficiency vs. load current in NA-skip mode (1.8 V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 16. V

Figure 17. V

Figure 18. V

Figure 19. V

Figure 20. V

Figure 21. V

output - 100% to 50% load change (20µs/div) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

DC

output - 50% to 100% load change (20µs/div) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

DC

output - 20% to 80% step load change (50µs/div). . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

DC

output - 100% to 50% load change (20µs/div) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

DC

output - 50% to 100% load change (20µs/div) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

DC

output - 20% to 80% step load change (50µs/div). . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

DC

3/38

Page 4

List of tables AN2683

List of tables

Table 1. Input voltage range 10 - 16 VDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 2. 1.0 V

Table 3. 1.8 V

Table 4. 1.0 V

Table 5. 1.8 V

Table 6. 1.0 V

Table 7. 1.8 V

Table 8. 1.0 V

Table 9. 1.8 V

Table 10. 1.0 V

Table 11. 1.8 V

Table 12. Part list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 13. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

DC

output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

DC

output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

DC

output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

DC

output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

DC

output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

DC

output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

DC

output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

DC

output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

DC

output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

DC

4/38

Page 5

AN2683 Main characteristics

1 Main characteristics

1.1 Input voltage range

Table 1. Input voltage range 10 - 16 V

Output Nominal voltage VDC Max. current amp Regulation %

11.8 2.5 0.44

2 1.0 10.5 2.6

1. Regulation over entire line and load range

1.2 Output ripple voltage

● Output 1: 45 mV p-p at maximum output current

● Output 2: 30 mV p-p at maximum output current

1.3 Switching frequency

● Output 1: 1 - 300 kHz

● Output 2: 2 - 400 kHz

1.4 Output overload/short circuit

● Output 1: nominal trip level 3.37 A (135%)

● Output 2: nominal trip level 13.65 A (130%)

DC

(1)

Protection is latched. Power must be cycled to reset.

5/38

Page 6

Circuit description AN2683

2 Circuit description

The PM6680 contains all the control circuitry needed to implement two independent stepdown synchronous buck regulators using the constant on-time method. The constant ontime method, an improved variant of hysteretic control, provides superior transient response

to changes of input voltage and load levels. One of the big advantages of this control

method is that it can provide this quick response without the use of an error amplifier which

in turn eliminates the need for frequency compensation.

As shown in the photographs (Figure 1) all the parts used are surface mount type including

the inductors. The circuit board is a multiple layer type consisting of six layers. The top two

layers are power routing, the middle two are ground layers split as power and signal, and the

bottom two are signal routing layers. In this design, in order to have a low inductor value for

the higher current 10.5 A output side, the PM6680 runs in its intermediate range with output

one running at 300 kHz and output two running at 400 kHz. So as a consequence the 2.5 A

output will run at 300 kHz. With the switching frequencies established the dimensions of the

other components can be defined.

6/38

Page 7

AN2683 Circuit description

Figure 2. Circuit board schematic

Vout 1 - 1.8 VDC @ 2.5 A

QC

P5

R15

10.0k

R16

D2

Open

A

Q3

3

750R

17

Csense1

U1

1

432

V5SW

PM6680

SGnd1

12

R12

1 2

29

30

Out1

Comp1

Out28PGnd14Csense2

2

10.0k

QC

P6

2.55k

C13

330pF

C14

22pF

28

26

5

En2

4

FB1

Shdn

En1

Pgood1

18

25

Vref

32

Skip

C18

24

0.1uF

Fsel

3

nc

6

Pgood2

FB27SGnd216Comp2

27

C12

22pF

C8

12

R17

110k

R4

3R92

1/4W

12

10 uF

12

C4

1%

C7

10 uF

12

R18

C17

R3

1%

47R5 1/8W

0.22uF

C3

0.1uF

C5

4.7uF

12

C16

47uF

C10

1.8nF

R10

3.74k

1 2

STS8DNF3LL

8

7

C1

R1

10R0

R2

432

0.1uF

23

18

31

19

9

10R0

C2

0.1uF

18

30.0k

100pF

D1BAT54A

12

K2

A

K1

12

C21

1uF

C22

4.7uF

2.5 uH

MSS1038

L2

R9

57.6k

1 2

K

5

6

2

4

1

R6

1 2

21

15

20

22

Boot1

Lgate1

Hgate1

Phase1

LD05

Vcc

Vin

Boot2

Phase2

Hgate2

Lgate2

12

11

10

13

R5

750R

1 2

C6

10 uF

P1

P2

QC

QC

-

+

Vin 10.2 - 16.0 VDC

Q1

STS12NH3LL

765

R7

26.1k

1 2

0.7uH

R8

5.11k

1 2

P3

MLC1550L1

C9 1.8n F

100uF

C19

100uF

C15

47uF

C20

12

R13

QC

765

Q2

A K

D3

Open

P4

QC

2

1

R14

1.10k

10.0k

C11

STS25NH3LL

330pF

R11

1.91k

1 2

Vout2 - 1.0 VDC @ 10.5 A

7/38

Page 8

Circuit description AN2683

As a starting point for the value of the inductors we look at the full load current (Ifl) for each

output and let the inductor ripple (I

value of 30 percent is used.

I

= I

* 0.3

r

fl

for

● Output 1: I

● Output 2: I

Then the values of the inductors are calculated using the formula:

Equation 1:

= 0.75 A

r

= 3.15 A

r

) current equal 20 to 30 percent of it. For this design a

r

VinV

L

–

------------------------ -

f

⋅

swIr

out

⋅=

V

out

---------- -

V

in

where V

frequency.

So for input 1:

Equation 2

and for output 2:

Equation 3

The output filter capacitors are roughly approximated so that the change in output voltage

(∆V

output voltage change of two to three percent of the total output voltage is considered

acceptable. The formula used is:

is the nominal input voltage, V

in

12 1.8–

----------------------------------------

L

300kHz 0.75⋅

----------------------------------------

L

400kHz 3.15⋅

) during a positive load transient (load is reduced) is minimized. For this design an

out

the output voltage and fsw the switching

out

1.8

------- -

6.8µH=⋅=

12

12 1–

12

------

1

0.7µH=⋅=

Equation 4

----------------------------------------------------------------

C

>

2VinV

⋅⋅

8/38

LI

⋅

–()ΛV

2

()

fl

out

out

Page 9

AN2683 Circuit description

For output 1 a ∆V

Equation 5

This is a nonstandard value so a 47 µF is used.

For output 2 a ∆V

Equation 6

As the formula indicates the capacitor value should be greater than that calculated. Even

though the board area is small, this section allows the use of ceramic capacitors that are

comprised of two 100 µF and one 47 µF all in parallel and which still fit in the required

footprint.

of 2.5% of 1.8 VDC or 45 mV is used, thus:

out

6.8µH2.5()

46.2µF

of 2% of 1.0 VDC or 20 mV is used:

out

175µF

----------------------------------------------------------

>

2121.8–()0.045⋅⋅

0.7µH 10.5()

----------------------------------------------------------

>

2121.0–()0.020⋅⋅

⋅

⋅

2

2

With these values of capacitors the ripple voltage can be checked. This is dominated by the

equivalent series resistance (ESR) of the capacitors. The ESR must be equal or less than

the value calculated by:

Equation 7:

V

r

ESR

where V

capacitors is given in their datasheets at the frequency they are used at as shown in the

graphs. The value is basically the same at both 300 and 400 kHz. For the 47 µF the ESR is

2 mΩ and for the 100 µF it is 1.5 mΩ. With these values we can calculate the ripple voltage

V

r

Equation 8:

by:

is the output ripple voltage and Ir is the inductor ripple current. The ESR for the

r

V

r

-----

≤

I

r

IrESR⋅=

9/38

Page 10

Circuit description AN2683

for output 1:

Equation 9

0.75A 2mΩ 1.5mV=⋅

for output 2:

Equation 10

3.15A 545µΩ 1.9mV=⋅

These values conform to the specification. They are higher in a practical circuit because of

parasitic inductance and loop resistance. Good circuit board layout techniques are

essential. Additionally, because of the constant on-time control, the system regulates the

output voltage by the valley value of the ripple voltage. A minimum amount of ripple voltage

of 30 mV should be on the comp pin to accomplish this. Since the calculated ripple voltage

is much lower than this, an additional circuit called the virtual ESR network is incorporated

to provide the additional voltage. Before addressing this design, the current limit resistor

values will be established. In this design the R

implement the current limit. For output 1 with its relatively low output current the MOSFET

chosen was the STS8DNF3LL with a nominal R

dual, that is two MOSFETs are contained in the same SO-8 package realizing further circuit

board space savings. The current limit is a valley type that operates during the conduction of

the low side MOSFET. A 100 µA internal current generator connected to the C

along with a resistor establishes a voltage to which the voltage generated by the R

compared. If the R

voltage is greater, then the voltage at the C

DS(on)

of a new conduction cycle is inhibited. The value of Rc

of the lower MOSFETS is used to

DS(on)

of 18 mΩ. This particular part is a

DS(on)

pin the generation

is determined by:

sense

sense

sense

pin

DS(on)

is

Equation 11:

Rc

sense

The 18 mΩ value for R

is a nominal 25 °C number. As current is switched through the

DS(on)

device and the ambient is raised, the R

140% is used. Targeting the maximum output current (I

0.750 A the valley current value is:

10/38

R

DS on()Ivalley

----------------------------------------- -=

⋅

100µA

increases. An increase of approximately

DS(on)

) at 3.375 A and having a Ir of

outmax

Page 11

AN2683 Circuit description

Equation 12

I

r

---–=

2

3.0A=–

then:

Equation 13

I

valley

3.375A

I

out max()

0.750

-------------- -

2

R

Equation 14

csense

is then:

25mΩ 3.0A⋅

----------------------------------- - 750Ω=

100µA

For output 2 the current levels are substantially higher than output 1 and two discrete

MOSFETS must be used. With a nominal input voltage of 12 volts and a one volt output the

low side MOSFET is conducting over 90 percent of the time. This means that the R

the low side MOSFET must be as low as possible. For this design the STS25NH3LL

MOSFET with a nominal 3.2 mΩ on resistance is used. Because of the high current and

duty cycle an R

the output 2 maximum current at 13.65 A the valley current is:

Equation 15

multiplier of 200% for the R

DS(on)

13.65A

3.15A

--------------- -

2

calculation is used. Again targeting

csense

12.075A=–

DS(on)

of

R

Equation 16

for output 2 then is:

csense

6.4mΩ 12.75A⋅

--------------------------------------------

100µA

11/38

773Ω=

Page 12

Circuit description AN2683

With the maximum output currents established attention can be redirected at designing the

virtual ESR network. As mentioned earlier, the ripple voltage should be greater than 30 mV

and range between 30 to 50 mV. To derive the necessary minimum value of the virtual ESR

(VESR) to produce the ripple voltage the following formula is used:

Equation 17

0.05V

⎛⎞

--------------- -

⎝⎠

I

r

–=

ESR

2mΩ 64.6mΩ=–

cout

for output 1:

Equation 18

VESR

min()

0.05V

⎛⎞

--------------- -

⎝⎠

0.75A

for output 2:

Equation 19

The total ESR (ESR

output capacitor.

for output 1:

Equation 20

for output 2:

Equation 21

0.05V

⎛⎞

--------------- -

⎝⎠

3.15A

) is the sum of the virtual ESR (VESR) and the ESR (ESR

tot

0.545mΩ 15.3mΩ=–

64.6mΩ 2mΩ 66.6mΩ=+

cout

) of the

15.3mΩ 0.545mΩ 15.8mΩ=+

12/38

Page 13

AN2683 Circuit description

The first component to be dimensioned in the virtual ESR network is C

Figure 3 below. Before this can be done the corner frequency (f

must be determined by:

Equation 22

out

1

ESR

tot

f

-------------------------------------=

Z

2πC

Figure 3. Components of virtual ESR network

) of the output capacitor

z

as shown in

int

for output 1:

Equation 23

--------------------------------------------------- 50.56kHz=

1

2π 47µF67mΩ⋅⋅

13/38

Page 14

Circuit description AN2683

for output 2:

Equation 24

--------------------------------------------------------------- 41.46kHz=

1

2π 247µF 15.54mΩ⋅⋅

With f

established the stability of the system needs to be verified. The system is stable if the

z

switching frequency (f

for output 1:

Equation 25

) is greater than 4 times the corner frequency (fz) of C

sw

50.56kHz 4 202.2kHz=⋅

Equation 26

202.2kHz 300kHz< OK

; fsw > fz x 4.

out

for output 2:

Equation 27

41.46kHz 4⋅ 165.8kHz=

Equation 28

165.8kHz 400kHz< OK

The value of C

from the computations is the value that should be used. In the formulas for calculating C

the following constants are used: gm = 50 µs (the transconductance of the integrator

amplifier); k = 4; V

is actually computed three different ways. The maximum value that results

int

= 0.9 V (internal reference voltage).

r

int

14/38

Page 15

AN2683 Circuit description

Equation 29

C

for output 1:

Equation 30

or

Equation 31

or

int

fsw

⎛⎞

2π

--------- fz–

⎝⎠

k

gm

--------------------------------

-------------------------------------------------------------------------

2π

⋅

V

r

---------- -

⋅> or

V

out

50µs

300kHz

⎛⎞

--------------------- 50.56kHz–

⎝⎠

4

50µs

----------------------------------------

2π 50.56kHz⋅

gm

----------------- -

2π fz⋅

0.9V

------------

⋅ 78.7pF=

1.8V

---------- -

⋅ or

V

0.9V

------------

⋅ 162.8pF=

1.8V

V

out

6µAC

r

⋅

-------------------------------- -

I

out max()

----------------------

out

4

I

r

-- -+

2

Equation 32

for output 2

Equation 33

or

6µA47µF⋅

------------------------------------------ 231.3pF=

3.375A

-------------------

4

-------------------------------------------------------------------------

⎛⎞

2π

⋅

⎝⎠

50µs

400kHz

--------------------- 41.46kHz–

4

0.75A

--------------- -+

2

0.9V

------------

⋅ 122.4pF=

1.0V

15/38

Page 16

Circuit description AN2683

Equation 34

50µs

----------------------------------------

2π 41.46kHz⋅

or

Equation 35

6µA 247µF⋅

------------------------------------------ 297.1pF=

13.65A

-------------------

4

Standard values must be used. In both cases a value rounded up to 330 pF will be used for

C

. The next part of the network to be calculated is the capacitor C

int

part is straightforward which is:

Equation 36

C

filt

0.9V

------------

⋅ 172.8pF=

1.0V

3.15A

--------------- -+

2

C

int

----------------------------------=

. The formula for this

filt

1q–()⋅

q

Where q is an attenuation factor equal to 0.95.

Since C

Equation 37

is the same for both outputs C

int

330pF 1 0.95–()⋅

-------------------------------------------------- 17.3pF=

is the same for both outputs:

filt

0.95

A standard value of 22 pF is used. Building on the previous calculations the value of R

the next part to be established. The formula for R

Equation 38

R

------------------------------------------------------------------------=

int

2π 10 fsw

⋅⋅ ⋅

is given below:

int

1

C

⋅

int

--------------------------

C

+

int

C

C

filt

filt

int

is

16/38

Page 17

AN2683 Circuit description

for output 1:

Equation 39

R

using standard value 2.55 kΩ

for output 2:

Equation 40

R

using standard value 1.91 kΩ

Then, the value of the C of the virtual ESR network is calculated. It is simply:

Equation 41

------------------------------------------------------------------------------------------------

int

2π 10 300kHz

⋅⋅ ⋅

------------------------------------------------------------------------------------------------

int

2π 10 400kHz

⋅⋅ ⋅

1

330pF 22pF⋅

---------------------------------------

330pF 22pF+

1

330pF 22pF⋅

---------------------------------------

330pF 22pF+

CC

int

2570Ω==

1929Ω==

5⋅=

Since C

Equation 42

is the same for both outputs:

int

C 330pF 5 1650pF=⋅=

Use standard value 1.8 nF.

Next, the R value of the network is established. This is determined by the formula:

Equation 43

------------------------------=

ESR

L

tot

C⋅

R

17/38

Page 18

Circuit description AN2683

for output 1:

Equation 44

6.8µH

--------------------------------------- 58.12KΩ=

65mΩ 1.8nF⋅

for output 2:

Equation 45

0.7µH

--------------------------------------- 25.92KΩ=

15mΩ 1.8nF⋅

The standard value of 57.6 KΩ can be used for output 1 and 26.1 KΩ for output 2. Finally the

last component of the virtual ESR network R1 is computed with the formula:

Equation 46

for output 1:

Equation 47

for output 2:

Equation 48

1

⎛⎞

----------- -

R

⋅

⎝⎠

Cπf

1

----------- -–

Cπf

z

z

57.6KΩ

R1

-----------------------------=

R

⎛⎞

----------------------------------------------

⋅

⎝⎠

1.8nFπ50.56kHz

1

-------------------------------------------------------------------------------

57.6KΩ

----------------------------------------------–

1

1.8nFπ50.56kHz

26.1KΩ

⎛⎞

----------------------------------------------

⋅

⎝⎠

1.8nFπ41.46kHz

1

-------------------------------------------------------------------------------

26.1KΩ

----------------------------------------------–

1

1.8nFπ41.46kHz

3723Ω=

5098Ω=

The standard value of 3.74 KΩ can be used for output 1 and 5.11 KΩ for output 2. With the

design of the virtual ESR complete the only other output components to be determined are

the resistor dividers that connect to the feedback pins FB1 and FB2. With an internal

reference voltage (V

18/38

) of 0.9 volts the determination of the values is straightforward by:

r

Page 19

AN2683 Circuit description

Equation 49

V

–

R2

outVr

----------------------=

V

------- -

r

R1

where R1 is the resistor connecting the feedback pin to ground (resistors R14 and R16 in

the schematic) and R2 is the resistor connecting the output to the feedback pin (resistors

R13 and R15 in the schematic). The value for R1 is chosen as 10.0 KΩ for both outputs. The

value for R2 is then:

for output 1:

Equation 50

1.8V 0.9V–

R2

-------------------------------

0.9V

-------------- -

10KΩ==

10KΩ

for output 2:

Equation 51

1.0V 0.9V–

R2

-------------------------------

0.9V

-------------- -

1.11KΩ==

10KΩ

Use standard values 10.0 KΩ ohm for R15 and 1.10 KΩ ohm for R13. With the output

component values determined it is important not to overlook the dimensioning of input

components critical to proper operation. These are the input capacitors that provide the high

frequency input currents needed by the converters. Locate these capacitors as close as

possible to the drain of the upper MOSFET and also make sure to minimize the inductance

to the other power components on the power ground plane. The ripple current (I

should meet or exceed the value as computed below:

Equation 52

I

where D is the duty cycle of the converter and is given by:

D

r

1Iout1

2

1D

–()⋅⋅ D

1

2Iout2

2

1D

–()⋅⋅+=

2

) ratings

r

19/38

Page 20

Circuit description AN2683

Equation 53

V

D

out

---------- -=

V

in

and I

For output 1 D1 is:

Equation 54

For output 2 D2 is:

Equation 55

So then we have:

Equation 56

is the maximum output current of the converter.

out

1.8V

------------ 0.15=

12V

1.0V

------------ 0.083=

12V

I

20/38

0.15 3.375

r

2

10.15–()⋅⋅ 0.083 13.65

2

1 0.083–()⋅⋅+ 3.95A==

Page 21

AN2683 Construction

3 Construction

With the components dimensioned the construction of the circuit board can be considered.

With this type of high frequency converter separate power and signal grounds are a must.

Additionally, the small board area necessitated component placement on both sides and the

use of additional layers for routing the signal interconnects and providing lower conductor

resistance in the heavy current paths. In Figure 4. below the top layer component placement

is shown. The top layer components are comprised of the power handling ones such as the

MOSFETS and inductors. Along with the power component placement is Figure 5 that

shows the top copper power traces. The first inner layer shown in Figure 6 is a layer that

has redundant power traces to lower resistance in the high current paths. The power ground

and signal ground layers are shown in Figure 7 and 8 respectively. Care must be taken that

they connect at only one point close to pin 14 of the PM6680. The component placement for

the bottom layer is shown in Figure 9, these are the parts that do the signal conditioning and

connect to the PM6680 controller. Of special note on the bottom layer copper shown in

Figure 10, is the square copper island under U1 (the PM6680). This island connects to the

thermal sink contact that is on the bottom of the package. A requirement for proper

operation is that this pad be connected to signal ground. As shown in Figure 11, which is the

fourth inner layer used for additional signal routing, a matrix of nine vias are used to make

the connection to the signal ground layer. The board uses 1-ounce copper on all layers.

While not necessary for the signal traces, keeping the copper weight even on all the layers

reduces the chances of the board warping during the manufacturing process.

Figure 4. Top layer component placement

21/38

Page 22

Construction AN2683

Figure 5. Top layer copper

Figure 6. Inner layer 1 showing additional power traces

22/38

Page 23

AN2683 Construction

Figure 7. Power ground layer (inner layer 2)

Figure 8. Signal ground layer (inner layer 3)

23/38

Page 24

Construction AN2683

Figure 9. Bottom layer components placement (mirrored)

Figure 10. Bottom layer copper (mirrored)

24/38

Page 25

AN2683 Construction

Figure 11. Inner layer 4 (mirrored)

25/38

Page 26

Functional testing AN2683

4 Functional testing

Using the component values calculated the demonstration board's efficiency was evaluated.

Each converter was tested individually with the idle converter disabled by grounding its

enable pin so that the power consumed by the idle converter's MOSFET driver section

would not be included in the input power calculation. The efficiency of each section was

measured in two different modes of operation, normal PWM and no-audible skip mode. In all

cases the input voltage was set to 12.0 V

Figure 12. Efficiency vs. load current in PWM mode (1.0 V)

1.0V Ef f vs Load Current in PWM mode

100

90

80

70

60

50

40

% Efficiency

30

20

10

0

01234567891011

Load Current

DC

.

Eff vs Load I

Figure 13. Efficiency vs. load current in NA-skip mode (1.0 V)

1.0V Eff vs Load Current i n NA - Ski p mode

100

90

80

70

60

50

40

% Effi ciency

30

20

10

0

01234567891011

Load Curr ent

26/38

Eff vs Load I

Page 27

AN2683 Functional testing

As can be seen at significant load current the efficiency for the 1.0 V output averages in the

lower eighty percent area. Additionally, the graph for no-audible skip mode shows the

advantage of running in this mode. By using the current zero-crossing detector the condition

of negative current that occurs at light load is sensed. The control circuit then keeps the

average current equal to the load current by skipping cycles. The result is higher efficiency

at light load. As the load is increased and the inductor current does not go to zero, normal

PWM operation is resumed.

Figure 14. Efficiency vs. load current in PWM mode (1.8 V)

1.8V Ef f vs Loa d Curr e nt i n PW M m ode

100

90

80

70

60

50

40

% Effi ci ency

30

20

10

0

0123

Load Current

Eff vs Load I

Figure 15. Efficiency vs. load current in NA-skip mode (1.8 V)

1.8V Ef f vs Load Cur r ent i n NA - Skip mode

100

90

80

70

60

50

40

% Effi ci ency

30

20

10

0

0123

Load Current

Eff vs Load I

27/38

Page 28

Functional testing AN2683

The graphs in Figure 14 and 15 show that the 1.8 V output has better efficiency than the 1.0

V output, in the high eighties at high current levels. Along with the efficiency measurements

further functional testing was conducted as outlined in the following sections.

4.1 Input/output voltage

The input voltage was swept from 10.2 to 16 VDC at the load levels indicated. The output

voltage was recorded at each level and did not vary more than 1 mV over the entire input

range. Input/output voltage at different load levels.

Table 2. 1.0 V

output

DC

Load current Output voltage

50 mA 0.998 V

7.5 A 1.019 V

10.5 A 1.027 V

Table 3. 1.8 VDC output

Load current Output voltage

50 mA 1.792 V

1.8 A 1.794 V

2.5 A 1.794 V

4.2 Ripple/noise voltage

The maximum peak to peak ripple voltage was measured at the load level indicated.

Table 4. 1.0 VDC output

Load current Ripple voltage p-p

DC

DC

DC

DC

DC

DC

10.5 A 25 mV

Table 5. 1.8 VDC output

Load current Ripple voltage p-p

2.5 A 20 mV

4.3 Load transient overshoot

The output load levels were varied in a stepwise fashion at the percentage and load levels

indicated. The maximum change in output voltage was recorded in the following

oscilloscope photographs.

28/38

Page 29

AN2683 Functional testing

Table 6. 1.0 V

Percent load change Current level change (A)

output

DC

100 to 50% 5.25 to 10.5

50 to 100% 5.25 to 10.5

20 to 80% 2.0 to 8.5

Figure 16. VDC output - 100% to 50% load change (20µs/div)

where:

● Top trace - L1 current 2 A/division

● Bottom trace - output voltage 50 mV/division

29/38

Page 30

Functional testing AN2683

Figure 17. VDC output - 50% to 100% load change (20µs/div)

where:

● Top trace - L1 current 2 A/division

● Bottom trace - output voltage 50 mV/division

Figure 18. V

output - 20% to 80% step load change (50µs/div)

DC

30/38

Page 31

AN2683 Functional testing

where:

● Top trace - L1 current 2 A/division

● Bottom trace - output voltage 50 mV/division

Table 7. 1.8 V

Percent load change Current level change (A)

Figure 19. V

DC

output

DC

100 to 50% 2.5 to 1.25

50 to 100% 1.25 to 2.5

20 to 80% 0.5 to 2

output - 100% to 50% load change (20µs/div)

where:

● Top trace - L1 current 0.5 A/division

● Bottom trace - output voltage 50 mV/division

31/38

Page 32

Functional testing AN2683

Figure 20. VDC output - 50% to 100% load change (20µs/div)

where:

● Top trace - L1 current 0.5 A/division

● Bottom trace - output voltage 50 mV/division

Figure 21. V

output - 20% to 80% step load change (50µs/div)

DC

32/38

Page 33

AN2683 Functional testing

where:

● Top trace - L1 current 0.5 A/division

● Bottom trace - output voltage 50 mV/division

4.4 Output current limit

Each output was loaded to its maximum rated load level. The load was increased in 10%

increments of the maximum rated load until the overcurrent limiting functioned. The level

was recorded.

Table 8. 1.0 V

output

DC

Table 9. 1.8 VDC output

After the overcurrent limit functioned, the load level was adjusted back the maximum rated

level and the input power was shut off and reapplied. The outputs resumed to normal

operation.

4.5 Output short circuit

Each output in turn was loaded to its maximum rated load level. A short was then applied to

the output at which time the overcurrent protection functioned. The opposite output

remained running. The short was then removed and the output remained latched off. The

input power was removed and then reapplied. The output resumed normal function. With

input power removed, each output in turn was shorted. Then input power was applied. The

shorted output's current limiting function operated while the non-shorted output ran

normally. The short was then removed and the input power was recycled. The output

resumed normal function.

Percent of maximum load (A)

130% (13.65)

Percent of maximum load (A)

130% (3.25)

4.6 Input under voltage lockout

With each output loaded to its nominal load level the input voltage was slowly increased

from 0 to 6 V

increased from 6 to 8 V

device turns on is adjusted by the voltage divider consisting of R17 and R18 connected to

the SHDN pin(5). The typical turn-on threshold is 1.35 V

down with 0.85 V

and the output voltages were recorded. The input voltage was then slowly

DC

DC

and the output voltages were recorded. The voltage at which the

DC

on the pin.

33/38

and the device typically shuts

DC

Page 34

Functional testing AN2683

Table 10. 1.0 VDC output

Voltage at Vin 6 V

0.0 1.017

Table 11. 1.8 VDC output

Voltage at Vin 6 V

0.0 1.795

DC

DC

Voltage a t Vin 8 V

Voltage a t Vin 8 V

DC

DC

34/38

Page 35

AN2683 Bill of material

5 Bill of material

Table 12. Part list

Part reference Value / type PCB footprint Manufacturer P/N

C1 0.1 µF 50 V X5R SM_0805 Any

C2 0.1 µF 50 V X5R SM_0805 Any

C3 0.1 µF 50 V X5R SM_0805 Any

C4 0.22 µF 25 V X5R SM_0805 Any

C5 4.7 µF 25 V X5R SM_1210 Any

C6 10 µF 25 V X5R SM_1206 Any

C7 10 µF 25 V X5R SM_1206 Any

C8 10 µF 25 V X5R SM_1206 Any

C9 1.8 nF 50 V X5R SM_0805 Any

C10 1.8 nF 50 V X5R SM_0805 Any

C11 330 pF 50 V NPO SM_0603 Any

C12 22 pF 50 V NPO SM_0603 Any

C13 330 pF 50 V NPO SM_0603 Any

C14 22 pF 50 V NPO SM_0603 Any

C15 100 µF 6.3 V X5R SM_1210 TDK or equivalent C3225X5ROJ107K

C16 47 µF 6.3 V X5R SM_1206 TDK or equivalent C3216X5ROJ476K

C17 100 pF 50 V NPO SM_0603 Any

C18 0.1 µF 50 V X5R SM_0805 Any

C19 100 µF 6.3 V X5R SM_1210 TDK or equivalent C3225X5ROJ107K

C20 47 µF 6.3 V X5R SM_1206 TDK or equivalent C3216X5ROJ476K

C21 4.7 µF 25 V X5R SM_1210 Any

C22 1 µF 16 V X5R SM_0603 Any

D1

D2 Open DO-214AC

D3 Open DO-214AC

L1 0.7 µH 17 A Custom Coilcraft MLC1265-701MLB

L2 7.0 µH 4.35 A Custom Coilcraft MSS1038-702NLB

Q1

Q2

BAT54A dual

Schottky

STS12NH3LL

MOSFET

STS25NH3LL

MOSFET

SOT-23 STMicroelectronics BAT54A

SO-8 STMicroelectronics STS12NH3LL

SO-8 STMicroelectronics STS25NH3LL

35/38

Page 36

Bill of material AN2683

Table 12. Part list (continued)

Part reference Value / type PCB footprint Manufacturer P/N

Q3

R1 10R0 1% SM_0805 Any

R2 10R0 1% SM_0805 Any

R3 47R5 1% SM_0805 Any

R4 3R92 1% SM_1206 Any

R5 750R 1% SM_0805 Any

R6 750R 1% SM_0805 Any

R7 21.6k 1% SM_0805 Any

R8 5.11k 1% SM_0805 Any

R9 57.6k 1% SM_0805 Any

R10 3.74k 1% SM_0805 Any

R11 1.91k 1% SM_0805 Any

R12 2.55k 1% SM_0805 Any

R13 1.10k 1% SM_0603 Any

R14 10.0k 1% SM_0603 Any

R15 10.0k 1% SM_0603 Any

R16 10.0k 1% SM_0603 Any

STS8DNF3LL dual

MOSFET

SO-8 STMicroelectronics STS8DNF3LL

R17 110k 1% SM_0603 Any

R18 30.0k 1% SM_0603 Any

U1

PM6680 Dual Dc-Dc

Controller

VFQFPN-32 5x5 STMicroelectronics PM6680

36/38

Page 37

AN2683 Revision history

6 Revision history

Table 13. Document revision history

Date Revision Changes

15-Apr-2008 1 Initial release.

37/38

Page 38

AN2683

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2008 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

38/38

Loading...

Loading...