AN2682

Application note

Connecting I2S audio devices to

the STR7/STR9 MCU

Introduction

This application note describes how to interface the STR7xx SPI peripheral with an audio

device (Codec, ADC, DAC, filter...) using the I2S protocol via an external interface consisting

of a low cost small CPLD. The design is referenced to the I2S protocol specification, so any

I2S device is able to interface with the STR7xx and STR91x MCU through this bridge.

To avoid using extra hardware, an I2S solution could be implemented entirely by firmware

but this would put a huge load on the CPU. The SPI to I2S bridge solution proposed in this

application note is made with a very low cost hardware (about 1$) using a CPLD with less

than 32 macrocells and a minimum of firmware overhead. Only one Timer (one Output

Compare), 6 GPIOs and the DMA peripheral are used. The DMA available on STR75x and

STR91x allows the CPU to be totally free for other tasks, and on STR71x the CPU load is

3.9% at 32 MHz MCLK frequency. The footprint is less than 5 Kbytes in Thumb mode.

The example CPLD described in this application note was built for the STR71x and STR750

microcontrollers but can be easily tailored to the STR91x or STM32.

January 2008 Rev 1 1/15

www.st.com

Contents AN2682 - Application note

Contents

1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 I2S protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 SPI protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 CPLD design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 STR711 implementation example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Hardware implemention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 STR711 firmware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2.1 CPU usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 STR750 implementation example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 Hardware implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 STR750 firmware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2/15

AN2682 - Application note General description

1 General description

1.1 I2S protocol

I2S (IC to IC Sound) is an audio data transfer standard using a three-line bus for serial and

synchronous data transmission.

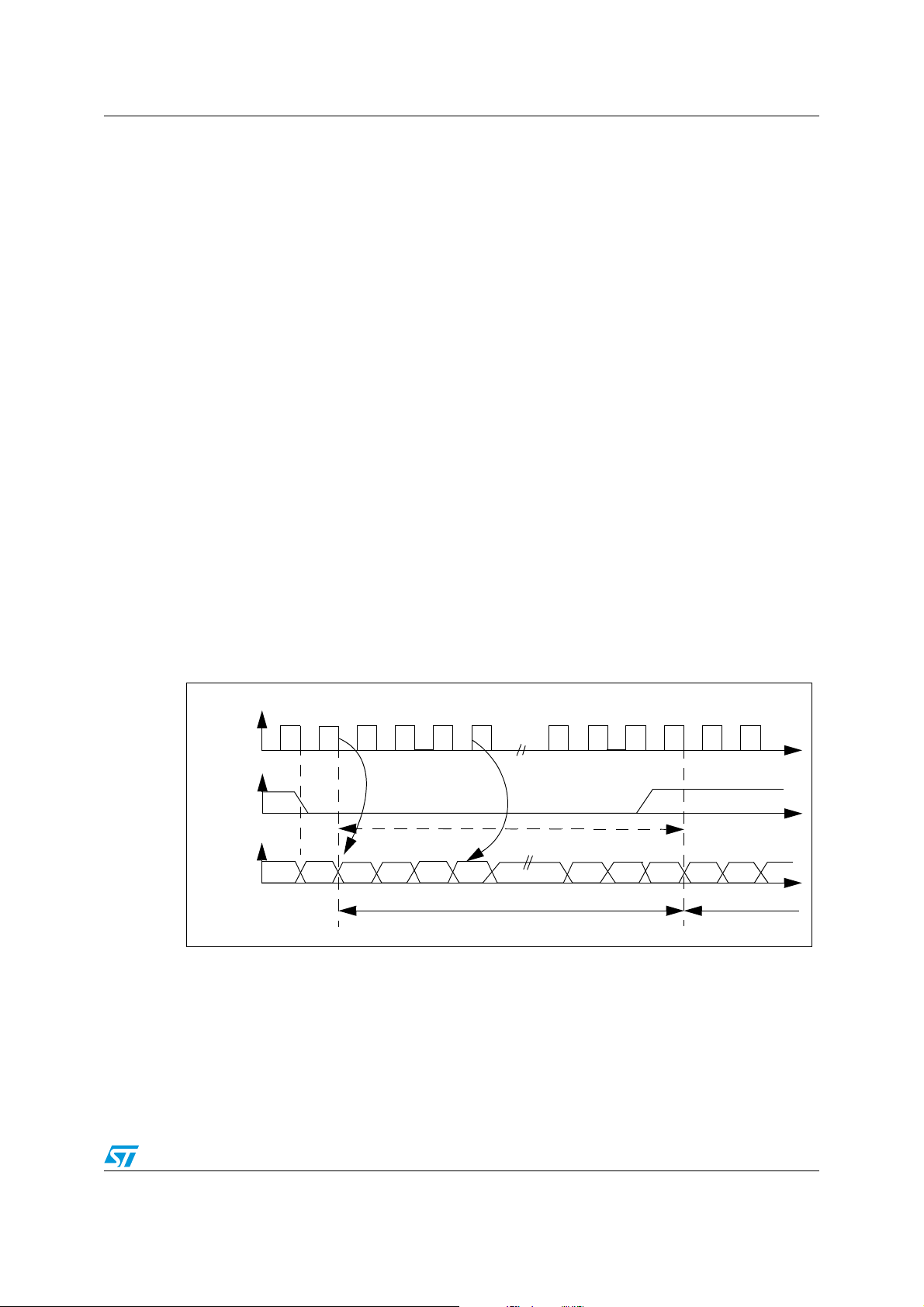

Data are transmitted on the SD line (Serial Data) in Little Endian format (MSB first). Data

length is not limited (usually 16/20/24/32/64 bits). Data are synchronized by the SCK (Serial

Clock) rising or falling edge for the transmitter, and falling edge only for the receiver. Refer to

Figure 1.

Data represent stereo digital sound, so each sample contains two words, the right channel

sample and the left channel sample. Instead of using two data channels, muxing is

performed by transmitting each word in half a sampling period and that allows, by doubling

the sampling rate, to transmit two words per period.

A control signal WS (Word Select) is then used to determine if the word being sent is the

right or the left one. This signal also determines the beginning and the end of the data: there

is no need to fix the data length. Receiver and transmitter data lengths can therefore be

different, as well as the right and left data lengths.

WS is synchronized either on the rising or the falling edge of SCK and precedes the MSB by

one SCK period in order to have enough time for storing and shifting operations.

As in the SPI protocol, there must be a master and a slave. The master controls and

provides the SCK clock and the WS signal, while the slave only sends or receives data. The

master can be the receiver or the transmitter or a third element (Controller). Refer to

Figure 2.

Figure 1. I2S Philips protocol waveforms 16/32-bit

CK

WS

SD

Transmission

MSB

Reception

16-bit or 32-bit

MSB

LSB

Left channel Right channel

3/15

General description AN2682 - Application note

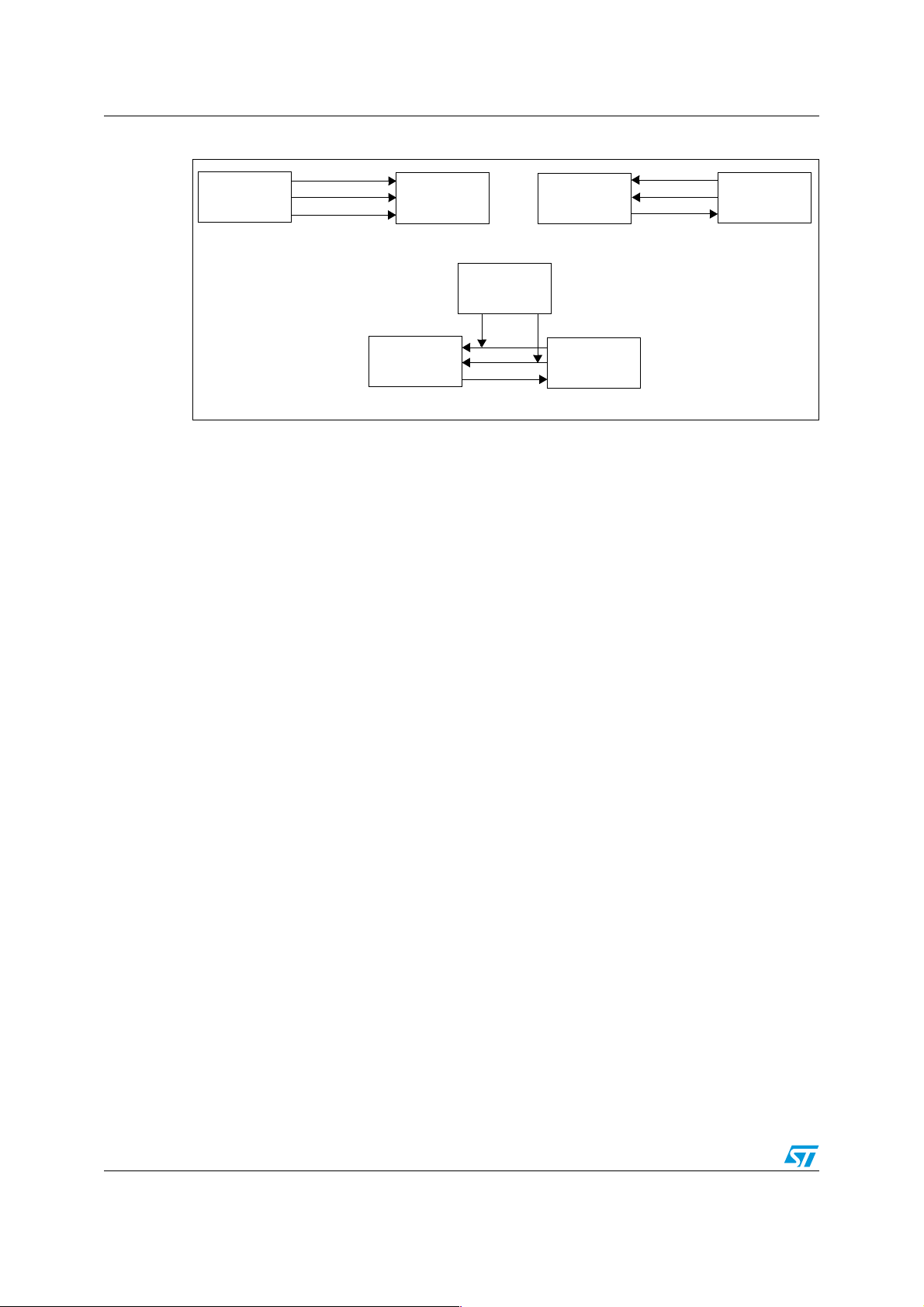

Figure 2. I2S protocol signal description and configuration

SCK

Transmitter Receiver

WS

SD

Transmitter = Master Receiver = Master

Receiver Transmitter

Controller

SCK

Transmitter

WS

SD

Controller = Master

Receiver

SCK

WS

SD

1.2 SPI protocol

The SPI is chosen to implement this solution because its protocol is the most similar to the

I2S protocol.

It uses four pins:

● Two pins (MOSI and MISO) to transmit and receive serial data

● One pin (SCLK) for data clocking (either rising or falling edge modes are available)

● One pin (nSS) to choose between master and slave modes.

When nSS is tied to Gnd, the SPI peripheral functions in Slave mode: it receives the data

clock (SCLK) from the master which controls how and when data are transmitted or

received.

When nSS is tied to Vcc, the SPI peripheral functions in master mode and SCLK is then an

output.

MISO is the Master Input in master mode and the Slave Output in slave mode.

MOSI is the Master Output in master mode and the Slave Input in slave mode.

There are two main differences between the I2S and SPI protocols:

● The I2S clock is continuous while the SPI clock is generated only during word

transmission and is stopped afterwards.

● The data format in SPI protocol is fixed to 16 or 8 bits only, while the data in I2S can

have any length.

Due to these two differences, the SPI peripheral cannot be configured in master mode in

this case. This is due to the fact that in SPI master mode, data are transmitted with a delay

between the words. Besides, many difficulties would arise when other tasks are performed

by the microcontroller. So the solution uses the SPI in slave mode.

4/15

AN2682 - Application note CPLD design

2 CPLD design

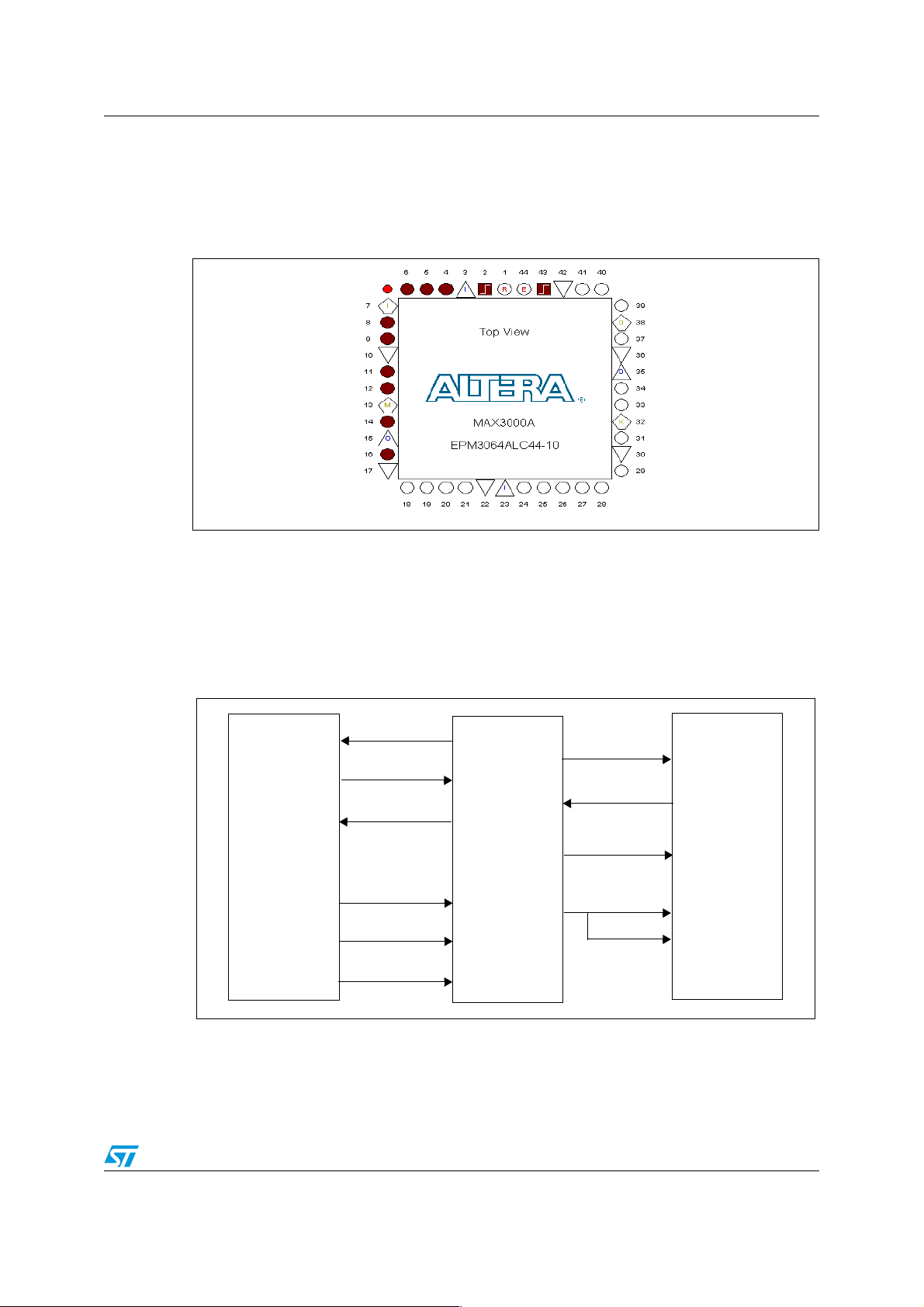

The CLPD design is based on the MAX3000A 32 macrocell device shown in Figure 3.

Figure 3. MAX3000A CPLD pin description

The CPLD bridge is intended to function as the master for both SPI and I2S devices. Since

the SPI peripheral is bidirectional, two I2S devices can be connected at once, as long as

they have the same SCK clock (some I2S devices are also bidirectional).

When a single device is interfaced to the microcontroller, the unused direction logic can

simply be ignored and has no effect on the interface. The CPLD bridge connections with the

STR7/9 MCU and the I2S audio device(s) are illustrated in Figure 4.

Figure 4. SPI to I2S CPLD bridge connections

AF

GPIO/AF

GPIO/AF

STR7/9

MCU

PWM OCMPA

GPIO

GPIO

MOSI

MISO

SCLK

CLK

Start

Conf

CPLD

interface

SDo

SDi

SCK

WSo

WSi

Audio

I2S

device(s)

The Conf pin is used only in configuration mode. In communication mode, it can be used for

any other application purpose.

5/15

CPLD design AN2682 - Application note

The I2S signal combination chosen for this solution is:

● Transmitter SD active on SCK falling edge

● Receiver SD active on SCK falling edge

● WS active on SCK falling edge

The CPLD brige functions in two modes:

1. Configuration mode: When the Start signal is low, the interface waits for configuration

parameters. These parameters are transmitted through a three-bit register named

Conf_Reg:

Figure 5. Conf_Reg content

bit 0 bit 1 bit 2

Transmit

Receive

DW

The Transmit and Receive bits activate or disactivate the corresponding directions in or

out of the CPLD interface.

DW (Double Word), when set, enables the support of any data format from 17 to 32 bits

by setting a WS length of 32 bits instead of 16.

The configuration register is set by the MISO line clocked by the falling edge of the Conf

signal while Start is low.

2. Communication mode: This mode is active when the Start signal is high. The

interface generates the SCLK and SCK signals with their associated delays. It also

controls the WS signal as well as the data lengths.

The CPLD implementation is illustrated in Figure 6.

Figure 6. SPI to I2S CPLD bridge internal diagram

CLK

Start

Conf

MISO

CLK

CLK

Start

WSt

Mode select

CLK

Delay control

WS generator

16 bits

32bits

Conf_reg

Tr an s m it

TR enable 1

TR enable 2

DW

Receive

WSt

MISO

Start

DW

Central

block

CLK

SCLK

MOSI

SDo

WSo

SCK

Start

I2S clock control

The solution is synthesized on ALTERA QUARTUSII software using a MAX3000A 32

macrocell device. The implementation is done with 17 macrocells.

The VHDL code implementation is provided with this AN for STR71x and STR750. The

STR750 VHDL code can also be used for the STR91x and STM32 microcontroller.

6/15

SCKi

SDi

WSi

AN2682 - Application note STR711 implementation example

3 STR711 implementation example

3.1 Hardware implemention

The CPLD and STR711 SPI connections are illustrated in Figure 7

Figure 7. MAX3000A and STR711 SPI connections

3.3 V

1

2

3

4

5

6

7

8

JTAG to USB Blaster connector

9

10

TCLK

Gnd

TDO

Vcc

TMS

NC

NC

NC

TDI

Gnd

TCLK

TDI

TDO

TMS

VCCIO

VCCIO

VCCINT

VCCINT

Gnd

Gnd

Gnd

Gnd

Gnd

Gnd

32

7

38

13

15

35

3

23

10

17

22

30

36

42

R

44

E

1

Start

43

CLK

2

MISO

4

MOSI

5

SCLK

6

Conf

8

WSo

9

EPM3064 ALC10-N

11

12

14

16

SDo

SCK

WSi

SDi

Left in HiZ input state

Left in HiZ input state

I2S Audio device

P0.12

OCMPA

MISO

MOSI

SCLK

P0.13

nSS

3

52

53

54

5

40

55

STR711

7/15

STR711 implementation example AN2682 - Application note

3.2 STR711 firmware description

This section describes how to use the SPI to I2S bridge in your application firmware, the

description is based on the source code for STR71x provided with this application note.

First, the STR71x peripherals are initialized:

● The TIM1 timer is configured in PWM mode with a period and duty cycle corresponding

to the user defined CLK frequency.

● The BSPI0 is configured in slave mode, with falling edge clock (CPOL=0, CPHA=1), 16

bit format, 10-word Transmit and Receive FIFO depth, clock divider calculated to

correspond to the user-defined BSPI clock frequency and Transmit FIFO empty

interrupt enabled (or Receive FIFO full interrupt if receive-only mode is active).

● The EIC interrupt controller is configured to enable BSPI interrupt IRQ with the highest

priority.

The STR71x microcontroller performs two main functions:

1. Configuration function: the microcontroller gets the user-defined Conf_Reg register

value from the DEFINE statements, then sets the Start pin low and transmits the three

bits clocked by the Conf falling edge.

2. Communication function: After setting the Start signal high, the microcontroller waits

for an internal interrupt indicating that the transmit FIFO is empty or that the receive

FIFO is full. Then in the interrupt handler, the transmit FIFO is loaded from the audio

file and the receive FIFO is read and loaded in the corresponding file. This whole

operation is done while the last word is being transmitted and received (bidirectional

BSPI shift register). This results in fluent data transfer with no delays or breaks.

8/15

AN2682 - Application note STR711 implementation example

3.2.1 CPU usage

In order to estimate the efficiency of this solution, for integration in different applications, we

can calculate the CPU load relative to the I2S communication. This value determines the

ratio of time dedicated to the I2S task. This value is calculated as follows:

Tc

C

------ -=

T

T is time between the transmission of two words, so:

1

----------------

T

SCLK

16 DW TF×××=

Where DW=1 or 2 depending on the word format (1 to 16 bits or 2 for 17 to 32 bits), and T

is the FIFO size.

Tc is the CPU usage time, obtained (considering a mean instruction length of 3 CPU

cycles), by adding:

● The time required to load the FIFOs (2 x T

● The time needed to save and reload the context (16 + 26 CPU cycles).

● The interrupt code execution time (47 x 3 CPU cycles).

● Other durations need to be added such as the latency between the APB and the AHB

x 3 CPU cycles).

F

buses, the time related to the library operations, the optimization type used...

Determining the exact duration of all these terms is outside the scope of this document

and requires specific and detailed explanations for each case. The intention here is to

give a simplified overview of the performance.

For a 32 MHz MCLK frequency, 16-bit format and 10-word FIFO length, the CPU usage is

therefore:

C = 3.9%

F

9/15

STR711 implementation example AN2682 - Application note

Figure 8. STR71x firmware flowchart

Begin

Initialize peripherals

(BSPI, XTI, TIM, EIC, GPIO...)

Generate CLK

Configuration mode

Set Conf_Reg

Communication mode

End of audio file?

YES

Configuration mode

END

File

File

NO

BSPI Interrupt

TrFIFO empty?

YES

Load TrFIFO (10 words)

Increment File pointer

NO

Tr & Rc mode?

YES

Read RcFIFO (10 words)

Increment File pointer

End of File?

YES

Disable BSPI interrupts

NO

NO

RcFIFO full?

YES

NO

10/15

Clear Flags

END

AN2682 - Application note STR750 implementation example

4 STR750 implementation example

4.1 Hardware implementation

The CPLD and STR750 SSP connections are illustrated in Figure 9.

Figure 9. MAX3000A and STR750 SSP connections

TCLK

TDI

TDO

TMS

VCCIO

3.3 V

1

2

3

4

5

6

7

8

JTAG to USB Blaster connector

9

10

TCLK

Gnd

TDO

Vcc

TMS

NC

NC

NC

TDI

Gnd

VCCIO

VCCINT

VCCINT

Gnd

Gnd

Gnd

Gnd

Gnd

Gnd

32

7

38

13

15

35

3

23

10

EPM3064 ALC10-N

17

22

30

36

42

44

1

43

2

5

8

9

11

12

14

16

R

Left in HiZ input state

Left in HiZ input state

E

Start

CLK

MISO

4

MOSI

SCLK

6

Conf

WSo

SDo

SCK

WSi

SDi

I2S Audio device

P2.18

PWM1

S0.MISO

S0.MOSI

S0.SCLK

P2.19

32

77

76

78

31

81

STR750

4.2 STR750 firmware description

For the STR750, the DMA is used instead of the interrupt method. That makes the software

more simple and, since the DMA automatically transfers the data from peripheral to memory

and from memory to peripheral there is no CPU load.

The STR750 SSP peripheral is configured in SPI Motorola mode.

11/15

STR750 implementation example AN2682 - Application note

First, the STR750 peripherals are initialized:

● The TIM0/PWM timer is configured in PWM mode with a period and duty cycle

corresponding to the user defined CLK frequency.

● The SSP0 is configured in slave mode, rising edge clock (CPOL=1, CPHA=1), 16 bit

format, 8 words Transmit and Receive FIFO depth.

● The DMA is configured to enable SSP Transmit (from memory to peripheral) on

channel 0 and SSP Receive (from peripheral to memory) on channel 1.

The STR75x microcontroller performs two main functions:

1. Configuration function: the microcontroller gets the user-defined Conf_Reg register

value from the DEFINE statements, then sets Start pin low and transmit the three bits

clocked by Conf falling edge.

2. Communication function: After setting the Start signal high, only the DMA is active

and it loads the Transmit FIFO from memory whenever it is half empty and loads the

memory from the Receive FIFO whenever it is half full. The CPU is totally free for any

other application tasks.

Figure 10. STR75x firmware flowchart

Begin

Initialize peripherals

End Of Count

(SSP, TIM0, DMA, GPIO...)

Stop PWM counter

Generate CLK

Clear Flags

Configuration mode

END

Set Conf_Reg

End Of Count

Communication mode

END

In this flowchart, the DMA function is not shown because it works in the background and has

no effect on the CPU. The same flowchart can be used for STR91x.

The STR75x firmware can be easily tailored to any STR91x or STM32 microcontroller.

12/15

AN2682 - Application note Conclusion

5 Conclusion

This application note gives a straightforward and low cost solution for using the STR7xx SPI

peripheral with an audio device (Codec, ADC, DAC, filter...) using I2S protocol via an

external interface consisting of a low cost small CPLD. This solution can be easily tailored to

the STR91x and STM32 microcontrollers.

13/15

Revision history AN2682 - Application note

6 Revision history

Table 1. Document revision history

Date Revision Changes

08-Jan-2008 1 Initial release.

14/15

AN2682 - Application note

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2008 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

15/15

Loading...

Loading...