Page 1

AN2680

Application note

Fan speed controller based on STDS75 or STLM75 digital

temperature sensor and ST72651AR6 MCU

Introduction

This application note describes the method of defining the system for regulating the speed

of the 5 Vdc fan using an ST72651AR6 microcontroller and digital temperature sensor

STDS75 or STLM75.

The sensor measures the temperature data and communicates this data to the

microcontroller. Based on this temperature data, the microcontroller issues a PWM signal

with varying duty cycle to the fan for regulating its speed.

The key features of the system are:

● Microcontroller with I

and for regulating the fan speed

● Digital temperature sensor to measure the ambient temperature

● 5 Vdc fan to show the speed regulation

Section 1 highlights the features of the STDS75 or STLM75 sensor and explains its

interfacing with the microcontroller. Section 2 explains BLDC fan management and PWM

signal control to regulate the fan speed. Section 3 focuses on the hardware setup and in

Section 4 the application flow of the system is defined.

2

C interface and PWM peripheral to communicate with the sensor

February 2008 Rev 1 1/15

www.st.com

Page 2

Contents AN2680

Contents

1 Digital temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Theory of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Interfacing of sensor with the microcontroller . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Configuring the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Alarm signal behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 BLDC fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Principle used for fan speed control using PWM . . . . . . . . . . . . . . . . . . . . 5

2.2 Method of fan speed control using a power MOSFET . . . . . . . . . . . . . . . . 5

2.2.1 PWM control using transistor at low side drive . . . . . . . . . . . . . . . . . . . . 5

3 Hardware setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Description of the hardware setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1.1 Sensor - microcontroller connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1.2 Microcontroller - fan connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Software flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Description of fan control logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Description of alarm control logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2/15

Page 3

AN2680 Digital temperature sensor

1 Digital temperature sensor

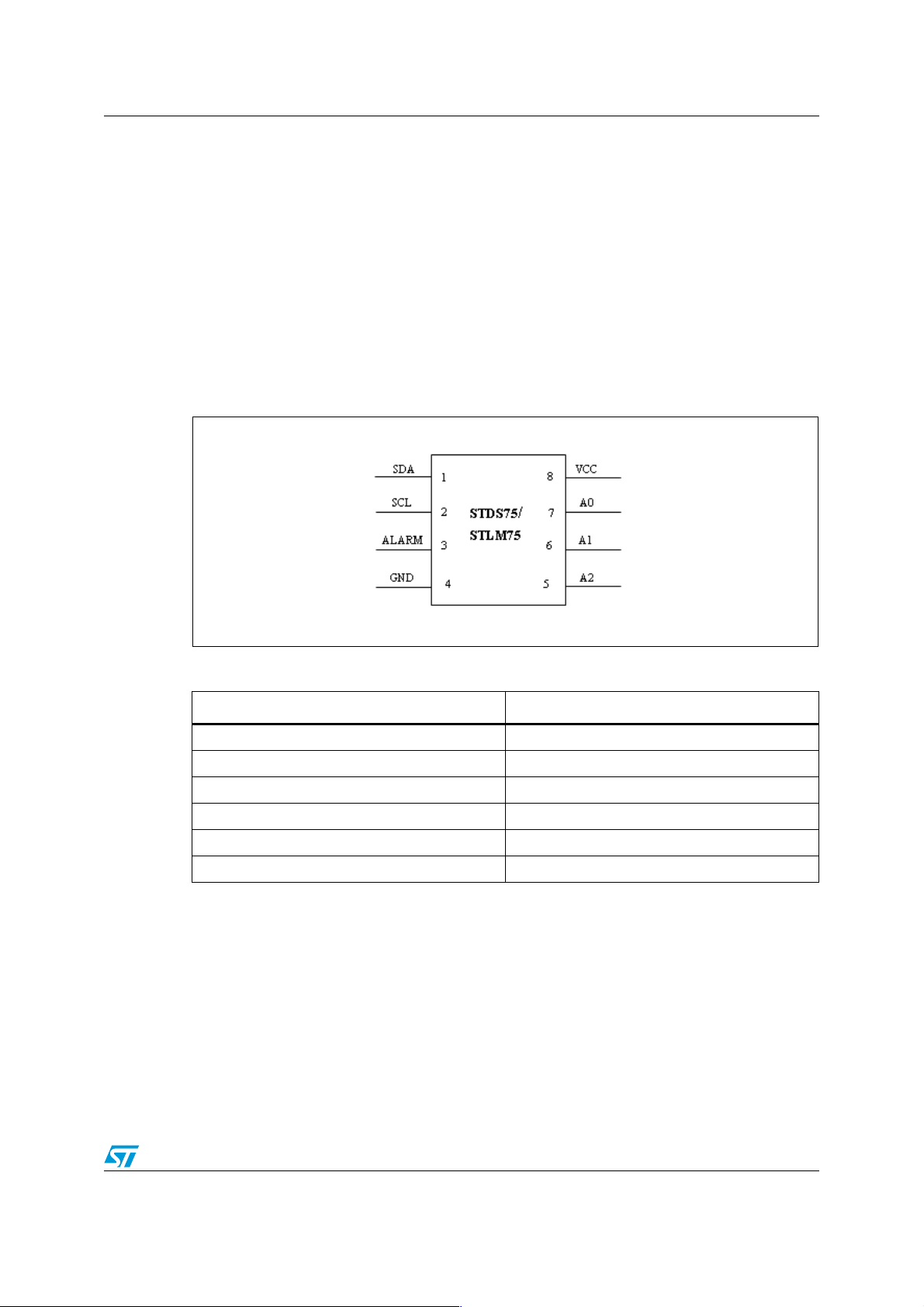

The STDS75 and STLM75 are digital temperature sensors that measure the ambient

temperature and give the digital output. Both the STDS75 and STLM75 are 8-pin ICs

available in two packages , SO-8 and TSSOP-8. The measurable temperature range of the

sensors is -55 °C to 125 °C.

The STLM75 and STDS75 differ o nly in terms of the resolution of the temper ature da ta. The

STLM75 has a fixed 9-bit resolution whereas the STDS75 has configurable resolution

starting from 9 to 12 bits. In the present application, we move with the default resolution

settings of the sensor that is 9 bits a nd thus both t he STDS75 a nd STLM 75 ar e dealt with in

the same manner.

Figure 1. Temperature sensor pin description

Table 1. Pin description

Name Description

SDA Serial data input output pin

SCL Serial clock input pin

Alarm Alarm output pin

GND DC ground

A0,A1,A2 Address lines

VCC Supply voltage (2.7 V- 5.5 V)

1.1 Theory of operation

This temperature sensor is a high-precision CMOS IC with a delta-sigma analog-to-digital

converter (ADC) and I

converts the measured temperature to a digital value that is calibrated in degree Celsius.

Negative temperature is shown in two's compliment form. The sensor also has an alarm

output signal.

2

C compatible serial digital interface. The on board delta-sigma ADC

3/15

Page 4

Digital temperature sensor AN2680

1.2 Interfacing of sensor with the microcontroller

The sensor supports the I2C communication protocol. It has 3 configurable address lines,

thus can support up to 8 different addresses. All 3 address lines are g rounded in the present

application and hence the address of sensor is made 0x90.

The sensor is connected to the microcontroller through 2 communication lines of I

interface (SDA and SCL).

2

C

1.3 Configuring the sensor

The sensor has 3 internal registers which are used to configure its behavior:

1. Configuration register: Tconfig (8-bit)

2. Oversaturation register: T

3. Hysteresis register: Thys (16-bit)

Based on the value configured in the configuration register the behavior of sensor is

achiev ed. In our application these settings are made as 0x40. This setting configures the

mode of operation of the sensor and the nature of the output alarm signal. For details,

please refer to the STDS75 datasheet.

The value set in the ov ersatur ation register defin es the threshold valu e at which fan starts. In

our application the fan starts as the temperature rises above 29 degrees Celsius. Thus the

setting for this register is made as 0x1D00. Also as the temperature rises above this

oversaturation value the alarm signal turns ON. This alarm is shown as an LED in the

system.

(16-bit)

os

A setting in the hysteresis register is used to control the output of the alarm output signal of

sensor. It is set at 27 degrees Celsius in our application which means that as the

temperature fa lls below 27 degrees Celsius the alarm goes OFF. Thus the settings for this

register are made 0x1B00.

1.4 Alarm signal behavior

The alarm signal of the sensor is configured to go ON when the measured temperature

exceeds 29 degrees Celsiu s and goes OFF when the temperature falls below 27 degrees

Celsius.

4/15

Page 5

AN2680 BLDC fan

2 BLDC fan

The basic DC brushless fan is a 2-wire de vice ov er which a DC voltage is app lied. Brushless

DC fans are called "brushless" because the electric motor is commutated electronically.

The basic brushless DC motor consists of two main parts:

a) the rotor

b) the stator

a) Rotor: As the name implies, the roto r is the pa rt that rotates. The rot or house s the

permanent magnets, and in the case of the fan, the f an bl ades are also attached to

the rotor. The number of poles in the permanent magnet varies according to the

characteristics of the motor.

b) Stator: The stator is the stationary part of the motor. It consist s of the motor coil

number which varies according to the characteristics of the motor. The stator for

the 2-phase motor consists of four coils.

2.1 Principle used for fan speed control using PWM

The speed of the DC fan can be modi fied by varying the DC voltage across the two

terminals of the fan motor. However if we t ak e a DC fan and switch on the DC supply across

it, the fan motor takes some time to speed up.This is because the fan motor has an inductive

coil so it does not respond immediately to the applied voltage. If we switch the power off

before the motor reaches full speed, the motor starts to slow down. If we switch the power

on and off quickly enough the fan motor and hence the fan run at some speed between the

zero and full speed. This is what is achie v ed th rough the PWM signal. The fan speed can be

modified with the variation in the duty cycle of the PWM signal.

2.2 Method of fan speed control using a power MOSFET

To control the speed of the DC fan using the PWM signal, we need to use a switch which

can be switched on and off at PWM frequency and hence control the supply voltage across

the motor of the DC fan. This switch can be made by using a high switching speed power

MOSFET. The action of switch is to connect and disconnect the power across the fan at

PWM frequency.

2.2.1 PWM control using transistor at low side drive

In low side drive connection, the fan positive terminal is kept at constant DC voltage (5 V for

5 V fan) while the negative terminal of the fan is connected to th e drain of power MOSFET.

The source of the power MOSFET is conne cted to ground . The PWM signal is applied to the

gate terminal of the power MOSFET, thus the power MOSFET switches be t w ee n o n a nd off

condition at the rate of the PWM signal. When the power MOSFET is ON, the current builds

up in the coil of the fan motor and the fan starts to attain speed, whereas when the power

MOSFET is off, the fan starts losing speed. Figure 2 illustrates the low side drive transistor.

5/15

Page 6

BLDC fan AN2680

Figure 2. Low side drive circuit

LOW SIDE DRIVE

5 Volt DC

DC

Fan

PWM

Drive

Signal

N-MOSFET

The speed of the DC fan can be regula ted b y the PWM driv e signal that chang es the supply

across the DC fan. So, varying the duty cycle of this PWM signal modifies the fan speed. At

100% duty cycle the fan runs at full speed.

6/15

Page 7

AN2680 Hardware setup

3 Hardware setup

This system consists of an ST72651AR6 microcontroller, STDS75 or STLM75 temperature

sensor, 5 V BLDC fan, N-channel power MOSFET and an alarm LED. The power to the

system is provided through USB power. Figure3 shows the setup for the system.

Figure 3. Connection diagram of the system

VCC

5 Volts

10 k

GND

NMOS

FAN

VCC

1k

MCU

PWM

I2C

Note: 1 Temperature sensor STDS75/STLM75

3.1 Description of the hardware setup

The complete system is shown in Figure 3 with the temperature sensor and f an con trol logic.

SDA

SCL

LED

10 k

I2C

ALARM

GND

VCC

TS

(1)

A0

A1

A2

Major components used in the system are:

● Microcontroller: ST72651AR6

● BLDC fan: 5 V

● Temperature sensor: STDS75

● N-Channel power MOSFET: STB100NF03L

For this application we can a lso choose any other microcontroller having a PWM peripheral

2

and I

C interface.

7/15

Page 8

Hardware setup AN2680

3.1.1 Sensor - microcontroller connection

The sensor is connected to the microcontroller using two communication lines of I2C

interface (SDA and SCL). The address lines of the sensor are grounded so that the address

of the sensor is hardwired to 0x90 (refer to the STDS75 datasheet for details). An LED is

connected to the alarm output of the sensor to show the ala rm signal. P ow er to the senso r is

provided through the 5 V USB power. A pull resistor of 10 kΩ is connected to the SDA and

SCL line of the I

2

C interface.

3.1.2 Microcontroller - fan connection

Fan control is ach ie v ed thro ugh the MOSFET switching action due to PWM signal coming to

its gate terminal. An N-channel MOSFET is used in the low side driving of the fan. The

positive terminal of the fan is connected to t he 5 V pow er supply and the negativ e terminal of

the fan is connected to th e drain of the MOSFET. The source of the MOSFET is grounded

while the gate is driven by the PWM output of the microcontroller. Current limiting resistors

are connected to the gate ter m ina ls of th e MO SF ET.

8/15

Page 9

AN2680 Software flow

4 Software flow

The software architecture of the system demonstra tes the flow of co ntrol of the f an speed on

the basis of digital temperature sensed. Figure 4 shows the flow chart of the MCU firmware

for the system.

Figure 4. Software flow diagram for fan control

Power up the system

Initialize the I2C

communication

Configure the Temperature

Sensor Device

Measure the temperature

Switch ON the Fan and

ramp up the speed with

No

(T)

T > = Tos

Yes

temperature

T > = Tmax

Yes

Run Fan at maximum

Speed

4.1 Description of fan control logic

For fan control logic, the microcontroller monitors the temperature continuously and

changes accordingly the duty cycle of the PWM output signal controlling the fan.

Switch of the Fan

No

Firstly the system is initialized and temperature is measured. This measured temperature is

compared with the threshold value (T

) set in the oversaturation register (29 degrees

os

Celsius). If the measured temperature is greate r than this v alue, then the f an is s witched ON

and the temperature is monitored again. The dut y cycle of t he PWM signa l is chang ed from

9/15

Page 10

Software flow AN2680

0 to 100% as the measured temperat ure increases from Tos to T

max

. T

is the value of the

max

temperature set through the firmware at which the fan runs at maximum speed.

Thus to control the duty cycle of the PWM signal a linear relationship is establish ed between

the measured temperature and t he duty cycle of PWM. As the measur ed temperature ramps

up, the duty cycle is also moved towards 100%.

The linear relationship with temperature is controlled by the following conditions:

● Temperature < threshold value; duty cycle is made 0% and thus fan is OFF.

● Threshold value <Temperature < T

value; duty cycle is ramped linearly towards

max

100%, thus fan runs at variable speed.

● Temperature> T

value; duty cycle is made 100%, thus fan runs at maximum speed.

max

The duty cycle is handled by writing in the registers of the PWM peripheral of the

microcontroller.

Figure 5. Software flow diagram for alarm control

Power up the system

Initialize the I2C

communication

Configure the Temperature

Sensor Device

Measure the temperature

Measure the temperature

NO

(T)

Is

T >= Tos?

YES

Alarm LED

ON

(T)

Is

T <= Thys?

YES

Alarm LED

OFF

NO

NO

Is Alarm

LED ON?

YES

10/15

Page 11

AN2680 Software flow

4.2 Description of alarm control logic

Tos is the temperature setting put in the oversatura tion register and Thys is the temperature

setting put in the hysteresis reg ister. In our app lication these values are:

● T

● Thys = 0x1B00 (27 degrees Celsius)

● T

The temperature measurement is put in continuous loop. As the measured temperature

rises above T

below the Thys value for first time.

Thus alarm behavior for measured temperature (T):

● T >= T

● Thys < T < T

● T<= Thys; alarm OFF

= 0x1D00 (29 degrees Celsius)

os

= 40 degrees Celsius

max

for the first ti me the alarm goes ON. It rem ains ON until the temperatur e f alls

os

; alarm ON

os

; alarm ON

os

11/15

Page 12

Firmware AN2680

5 Firmware

All the source files are in 'C' language and the application uses ST7 firmware library

functions.

The source files are only for guidance. STMicroelectronics shall not be liable for any direct,

indirect or consequential damages with respec t to any claim arising from use of this

software.

12/15

Page 13

AN2680 References

6 References

1. ST72651AR6 microcontroller datasheet

2. STDS75 temperature sensor datasheet

3. STLM75 temperature sensor datasheet

4. STB100NF03L power MOSFET datasheet

5. ST7 software manual user library

13/15

Page 14

Revision history AN2680

7 Revision history

Table 2. Document revision history

Date Revision Changes

06-Feb-2008 1 Initial release

14/15

Page 15

AN2680

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sal e.

Purchasers are solely res ponsibl e fo r the c hoic e, se lecti on an d use o f the S T prod ucts and s ervi ces d escr ibed he rein , and ST as sumes no

liability whatsoever relati ng to the choice, selection or use of the ST products and services de scribed herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third pa rty p ro duc ts or se rv ices it sh all n ot be deem ed a lice ns e gr ant by ST fo r t he use of su ch thi r d party products

or services, or any intellectua l property c ontained the rein or consi dered as a warr anty coverin g the use in any manner whats oever of suc h

third party products or servi ces or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICUL AR PURPOS E (AND THEIR EQUIVALE NTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJ URY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST fo r the ST pro duct or serv ice describe d herein and shall not cr eate or exten d in any manne r whatsoever , any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document su persedes and replaces all info rmation previously supplied .

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2008 STMicroelectronics - All rights reserved

STMicroelectronics group of compan ie s

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

15/15

Loading...

Loading...