Page 1

AN2679

Application note

Smart inductive proximity switch

Introduction

The STEVAL-IFS006V1 inductive proximity switch demonstration board is designed based

on the principle of metal body detection using the eddy current effect on the HF losses of a

coil. It consists of a single transistor HF oscillator, an ST7LITEUS5 microcontroller and the

TDE1708DFT intelligent power switch. The board is a compact and cost-effective solution

for an inductive proximity sensor designed for simplicity and for a wide temperature range

and supply voltage variations. Other board features include:

■ Great flexibility: the MCU firmware can be modified depending on application

requirements

■ Sensitivity and hysteresis adjustment

■ In-circuit programming and debugging capabilities

■ Analog and digital temperature compensation

■ PNP and NPN sensor functionality configurations

■ Indicator status LED

■ Overload and short-circuit protection

■ GND and Vs open wire protection

■ Compact design

■ Supply voltage: 6 V to 48 VDC

■ Temperature range: -25 °C to +85 °C

Figure 1. Smart inductive proximity switch demonstration board

July 2008 Rev 1 1/16

www.st.com

Page 2

Contents AN2679

Contents

1 Sensor overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Sensor circuit description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Initial configuration and jumper settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Output driver configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Application schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Bill of materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5 ICC connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Software implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2/16

Page 3

AN2679 List of tables

List of tables

Table 1. Initial configuration and jumper settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 2. Low side (NPN) output driver configuration jumper settings. . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 3. High side (PNP) output driver configuration jumper settings . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 4. Bill of materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 5. Diagnostic LED blinking modes (power up self-test) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 6. Diagnostic LED blinking modes (normal operation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 7. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3/16

Page 4

List of figures AN2679

List of figures

Figure 1. Smart inductive proximity switch demonstration board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

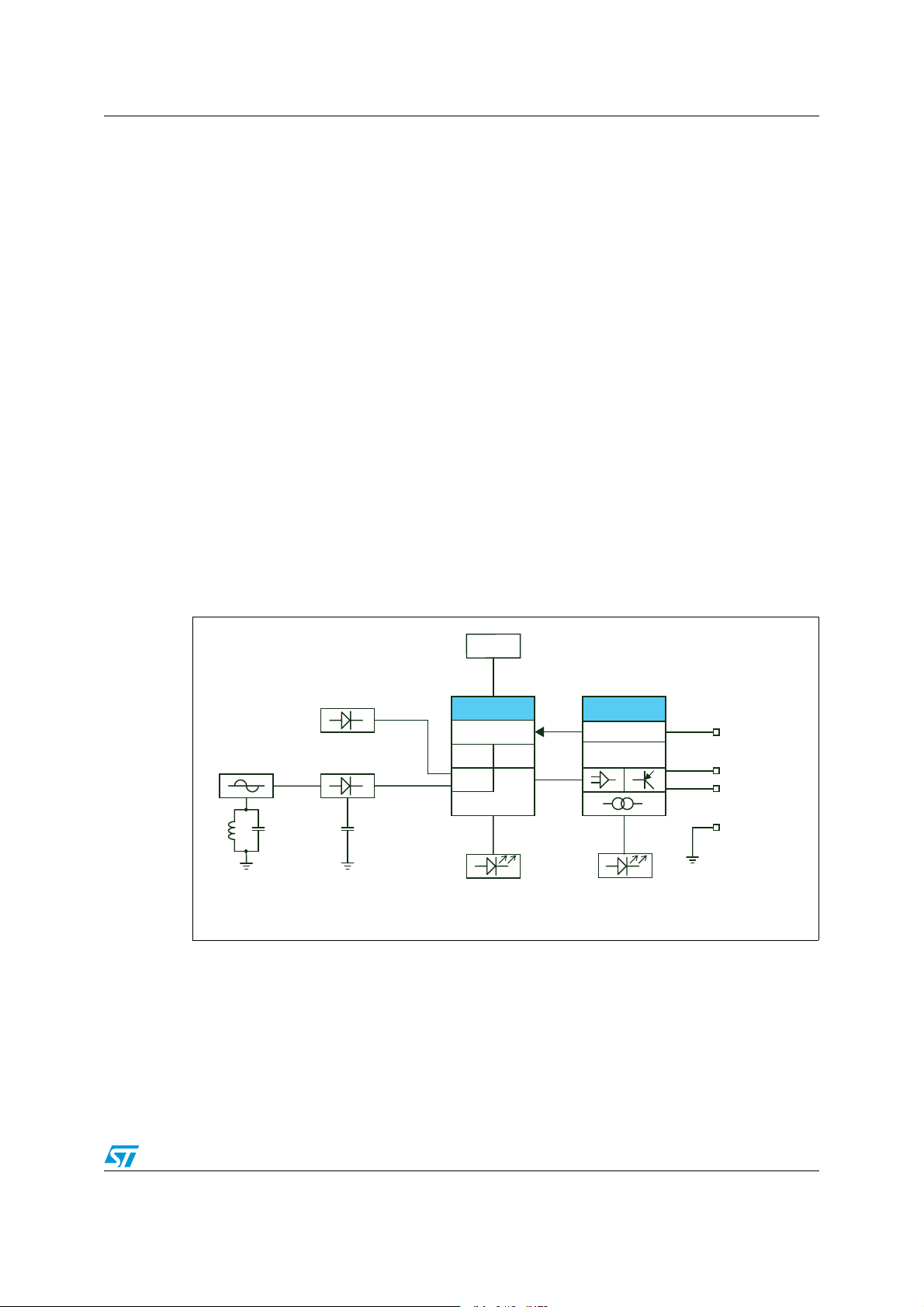

Figure 2. Smart inductive proximity switch block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

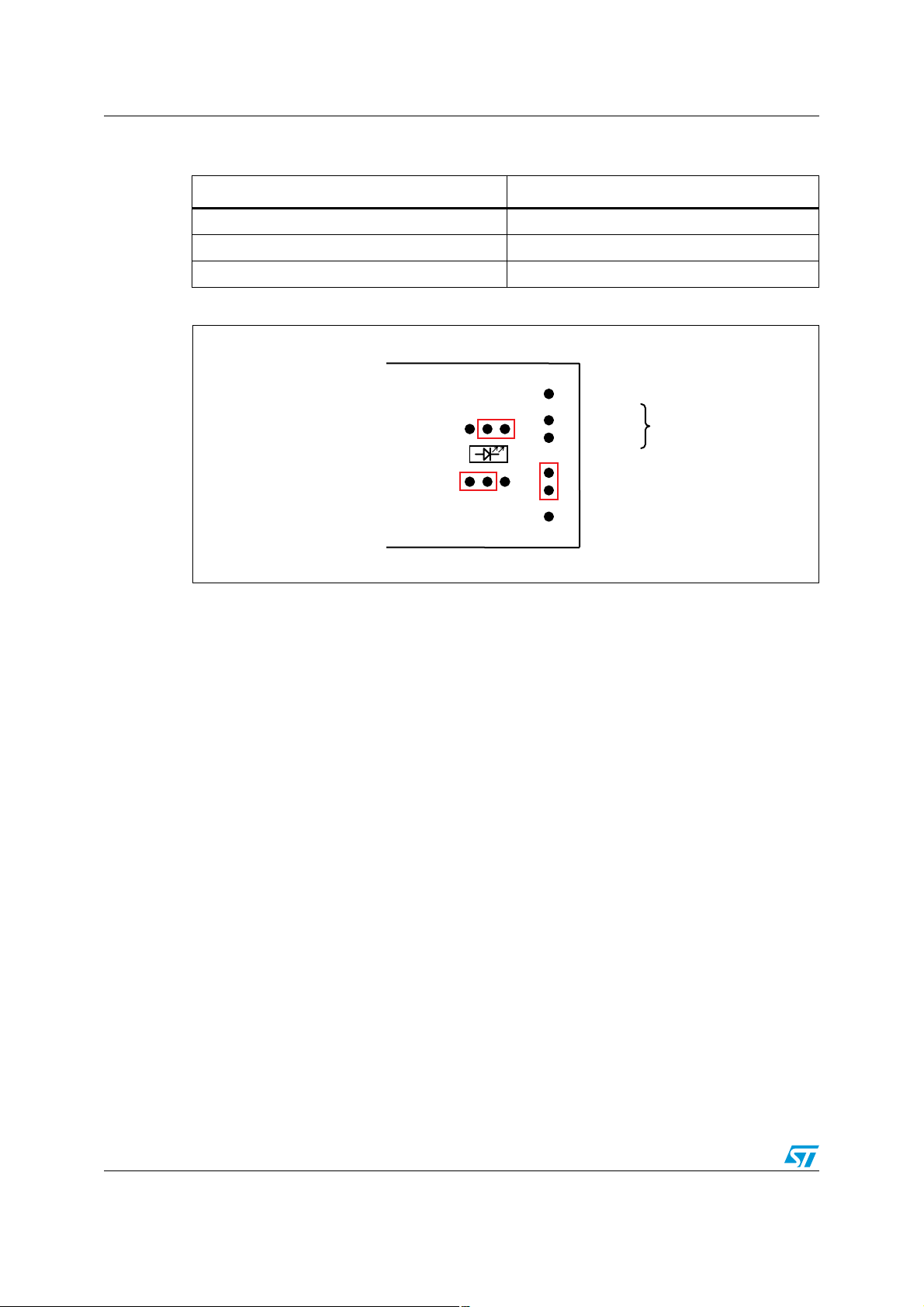

Figure 3. Initial configuration and jumper settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 4. Low side (NPN) output driver configuration jumper settings. . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 5. High side (PNP) output driver configuration jumper settings . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 6. Smart inductive proximity switch schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 7. Inducing the demonstration board self-test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 8. Oscillator amplitude vs. temperature (MCU pin 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 9. D2 voltage vs. temperature (MCU pin 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4/16

Page 5

AN2679 Sensor overview

1 Sensor overview

Proximity switches are generally used to sense the position of a moving object in

manufacturing processes. Typically, they utilize an oscillator driver circuit in combination with

an induction tank circuit. The tank circuit includes an induction coil as a means for sensing

the presence of an object such as metal. The magnetic field induces eddy currents in a

conductive object which enters within the generated magnetic field. The oscillation

amplitude is attenuated due to the energy drawn from the induction coil. The amount of the

attenuation is directly related to the distance between the metal object and the induction

coil.

A typical inductive proximity switch employs a ferrite cup core as the sensing element. It

allows the flux field to be focused in front of the cup and to further increase the sensing

distance. The oscillator typically operates between 100 kHz and 800 kHz, where the eddy

current losses are significant.

Some benefits of the MCU approach compared with a traditional solution are:

● more reliable operation thanks to the sensor self-diagnostics

● cheap and easy sensor trimming in the production line

● digital temperature compensation

● linearization of the sensor characteristic

● simple implementation of an analog or PWM output

Figure 2. Smart inductive proximity switch block diagram

)#0

/SCILLATOR

,

^K(Z

#

4EMPSENSOR

$ETECTOR

#

&

M6+

$#TO6

345LTRA,ITE

&,!3(

4)-%23

!$#

BIT

3ELFDIAGNOSTICS,%$

'0)/

+

4$%$&4

6

62%'6

)NDICATORSTATUS,%$

6TO6

3UPPLY6OLTAGE

,O

WSIDEOUTPUT

(IGHSIDEOUTPUT

'.$

!-6

5/16

Page 6

Sensor circuit description AN2679

2 Sensor circuit description

The sensor HF oscillator circuit is based on the Colpitts oscillator type which has a simple

circuit configuration, produces a very clean sinusoidal wave signal and is capable of

oscillating in a wide frequency range. The resonant circuit consisting from the inductor L1

and capacitors C12, C9 and C8 determine the frequency of the oscillations according to the

formula in Equation 1. Actually the circuit will oscillate at a slightly lower frequency due to

coupling capacitor C10, junction capacitances of transistor Q1 and other stray capacitances.

Equation 1

f

------------------------------------------------------------- -=

2π

The oscillator employs a transistor, Q1, operating in a common base configuration that

derives its feedback from the capacitor divider C9 andC8. Resistors R3 and R6 set its bias

point and the temperature of diode D2 stabilizes it.

The oscillator signal amplitude is further detected by diodes D4 and D5, and filtered by

capacitor C13. Together with C10 this circuit acts as a charge pump, thus the full range of

the ST7 ADC converter (0 V - 5 V) is used.

1

12

C8C

--------------------- -+

C8C9+

9

⎛⎞

L1C

⎜⎟

⎝⎠

The other function of diode D2 is temperature sensing. The voltage across a diode operated

at constant current is linear in a very large range of temperature and reduces with

increasing temperature by approximately -2 mV/ k (see Figure 9). With the ST7 10-bit ADC

converter, the temperature can be measured with an accuracy of approximately 2.5 °C

which is enough for overall correction of the sensor temperature variations (see Figure 8).

2.1 Initial configuration and jumper settings

Ta bl e 1 and Figure 3 represent the initial (high side) output driver configuration and jumper

settings. The diagnostic LED D3 shares the MCU pin 2 with the ICC connector. In case of

programming/debugging problems, it can be disconnected by removing the jumper from

pins P14 and P15.

Table 1. Initial configuration and jumper settings

Pins Setting

P10 - P11 A - HS

P4 - P5 LED - C

P3 - P7 +Vs - LS

P14 - P15 +5V - A

6/16

Page 7

AN2679 Sensor circuit description

Figure 3. Initial configuration and jumper settings

$

!(3

$

'.

'.

(3

$

,OAD

0OWER

3UPPLY

,%$#

6

6S

!

!-6

2.2 Output driver configurations

The demonstration board output can be configured using the jumpers for low side (see

Ta bl e 2 and Figure 4) and/or high side (Ta bl e 3 and Figure 5) functionality.

Table 2. Low side (NPN) output driver configuration jumper settings

Pins Setting

P9 - P10 LED - A

P5 - P6 C - LS

P8 - P12 HS - GND

Figure 4. Low side (NPN) output driver configuration jumper settings

,%$!

$

#,3

'.$

,3

6S

6S

,OAD

!-6

7/16

Page 8

Sensor circuit description AN2679

Table 3. High side (PNP) output driver configuration jumper settings

Pins Setting

P10 - P11 A - HS

P4 - P5 LED - C

P3 - P7 +Vs - LS

Figure 5. High side (PNP) output driver configuration jumper settings

!(3

$

,%$#

'.$

'.

(3

6S

$

,OAD

!-6

8/16

Page 9

AN2679 Sensor circuit description

2.3 Application schematic

Figure 6. Smart inductive proximity switch schematic

P1

+Vs1P3

+Vs1P7

LS

1

C2

10nF

C1

D1

1

P6

LS

1

P5

C

1

P4

LED

100nF

Status LED

P8

HS1P12

GND1P13

GND

1

PA0

PA1

R4

10nF

C7

1

P11

HS

1

P10

A

1

P9

LED

10K

8

Vss

7

PA0/AIN0/ATPWM/ICCDATA

6

5

PA2/LTIC/AIN2

PA1/AIN1/ICCCLK

9

7

+Vs

VREG +5V

U1

TDE1708DFT

6

+5V

PA3

0

R1

PA1

PA0

10

8

2

4

6

GND

RESET

ICCCLK

ICCDATA

GND

GND

GND

Vdd

P2

+5V

CLKIN

Con ICC

1

3

5

7

9

PA5

4

2

1

8

L. S. OUT

LED DRIVER

IN

5

PA0

H. S. OUT

GND

9

C8

R2

D2

1.5nF

4.7K

1N4148

+5V +5V

P15

A

P14

+5V

+5V

DELAY

3

10nF

C3

10uF/6.3V

C6

100nF

C5

+5V

C4

100nF

+5V

1

1

1.5K

R3

Vdd1PA5/AIN4/CLKIN2PA4/AIN33PA3/RESET

U2

ST7LITEUS5

1.5K

R5

D3

Diag. LED

D4

C10

100pF

C9

Q1

BC857B

PA5

1N4148

47pF

4

C14

10nF

PA3

R7

220K

1.5nF

C13

D5

1N4148

470pF

C12

L1

10K

R6

10nF

C11

9/16

Page 10

Sensor circuit description AN2679

2.4 Bill of materials

Table 4. Bill of materials

Reference Value Description Quantity Supplier Order code

U1 Intelligent power switch 1 STMicroelectronics TDE1708DFT

U2 8-bit MCU 1 STMicroelectronics ST7FLITEUS5U3

C1, C7 10 nF Capacitor 2 EPCOS B37941A1103K0xx

C2 100 nF Capacitor 1 EPCOS B37941A5104K0xx

C3, C11, C14 10 nF Capacitor 3 EPCOS B37931A5103K0xx

C4, C5 100 nF Capacitor 2 EPCOS B37931K0104K0xx

C6 10 µF/6.3 V Polarized capacitor 1

C8, C13 1.5 nF Capacitor 2 EPCOS B37931A5152K0xx

C9 100 pF Capacitor 1 EPCOS B37930A5101J0xx

C10 47 pF Capacitor 1 EPCOS B37930A5470J0xx

C12 470 pF Capacitor 1 EPCOS B37930A5471J0xx

D1 Status LED LED 1

D2, D4, D5 1N4148 Diode 3

D3 Diag. LED LED 1

L1 68 µH PS-core inductor 1 Bohemia Electric BES070815

Core EPCOS B65933A0000X022

Coil former EPCOS B65512C0000T001

P1, P3 +Vs Header, 1-pin 2

P2 Con ICC ICC connector 1

P4, P9 LED Header, 1-pin 2

P5 C Header, 1-pin 1

P6, P7 LS Header, 1-pin 2

P8, P11 HS Header, 1-pin 2

P10, P15 A Header, 1-pin 2

P12, P13 GND Header, 1-pin 2

P14 +5 V Header, 1-pin 1

Q1 BC857B PNP transistor 1

R1 0 Resistor 1

R2 4.7 kΩ Resistor 1

R3, R5 1.5 kΩ Resistor 2

R4, R6 10 kΩ Resistor 2

R7 220 kΩ Resistor 1

10/16

Page 11

AN2679 Sensor circuit description

2.5 ICC connector

The board ICC connector offers in-circuit programming and debugging capabilities and thus

simplifies the firmware development. More information about ST7 development tools is

available from www.st.com/mcu.

11/16

Page 12

Software implementation AN2679

#

O

3 Software implementation

After the first start-up following the firmware upload, the ST7 MCU performs a simple board

self-test. It reads the oscillator amplitude level and voltage across the temperature-sensing

diode D2 and checks whether these values are within a specific range (this state is indicated

by blinking diagnostic LED D3; see Ta bl e 5 ). The oscillator amplitude level detected during

this test is also considered as an initial oscillator level when no metal object approaches the

sensing inductor L1, and its value is recorded to the Flash memory (address 0xfc00) using

an in-application programming (IAP) method. This value is later used for amplitude

reduction comparisons caused by metal objects.

Note: The initial board self-test procedure can be performed at any time by placing a jumper

on pins 3 and 4 of the ICC connector (see Figure 7) and powering up the application.

Figure 7. Inducing the demonstration board self-test

#ON)##

During normal operation, the MCU then controls the sensor output based of the information

about the oscillator amplitude and the actual temperature. The main sensor part of the

firmware is implemented in an auto-reload timer interrupt service routine. In equidistant time

intervals the oscillator amplitude is sampled and its value is compared with two system

variables (ucUpperCompThreshold and ucLowerCompThreshold). One of these defines the

ON to OFF transition, and the other defines the OFF to ON transition of the sensor state.

The distance between them determines the hysteresis. These threshold variable values are

defined as a percentage of the initial oscillator level recorded in the Flash memory and are

further modified depending on the temperature by a coefficient from a lookup table.

Table 5. Diagnostic LED blinking modes (power up self-test)

LED status Meaning

Blinking Input values within limits

Constant Error

Table 6. Diagnostic LED blinking modes (normal operation)

Flashing style Meaning

❋ ❋ ❋ ❋ ❋ ❋ Under-temperature

❋❋ ❋❋ ❋❋ ❋❋ Over-temperature

❋❋❋ ❋❋❋ ❋❋❋ Ferrite approaching the coil

12/16

Page 13

AN2679 Software implementation

Figure 8. Oscillator amplitude vs.

temperature (MCU pin 3)

Figure 9. D2 voltage vs. temperature (MCU

pin 5)

13/16

Page 14

References AN2679

4 References

1. ST7LITEUS5 datasheet

2. TDE1708DFT datasheet

3. Application note AN495

4. EN60947-5-2: "Low-voltage switchgear and controlgear - Part 5-2: Control circuit

devices and switching elements - Proximity switches"

14/16

Page 15

AN2679 Revision history

5 Revision history

Table 7. Document revision history

Date Revision Changes

07-Jul-2008 1 Initial release.

15/16

Page 16

AN2679

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2008 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

16/16

Loading...

Loading...