AN2668

Application note

Improving STM32F101xx and STM32F103xx

ADC resolution by oversampling

Introduction

The STMicroelectronics Medium- and High-density STM32F101xx and STM32F103xx

Cortex™-M3 based microcontrollers come with 12-bit enhanced ADC sampling with a rate

up to Msamples/s. In most applications, this resolution is sufficient, but in some cases where

higher accuracy is required, the concept of oversampling and decimating the input signal

can be implemented to save the use of an external ADC solution and to reduce the

application consumption.

This application note gives two methods to improve ADC resolution. These techniques are

based on the same principle: oversampling the input signal with the maximum 1 MHz ADC

capability and decimating the input signal to enhance its resolution.

The method and the firmware given within this application note apply to both Medium- and

High-density STM32F10xxx products. Some specific hints are given at the end of the

application note to take advantage of the Medium- and High-density STM32F103xx

performance line devices and of the High-density STM32F101xx access line devices.

This application note is split into two main parts: the first one describes how oversampling

increases the ADC-specified resolution while the second describes the guidelines to

implement the different methods available and gives the firmware flowchart of their

implementation on the STM32F101xx and STM32F103xx devices.

July 2008 Rev 1 1/21

www.st.com

Contents AN2668

Contents

1 Definition of ADC signal-to-noise ratio . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Nyquist theorem and oversampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Oversampling using white noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 SNR of oversampled signal with white input noise . . . . . . . . . . . . . . . . . . . 6

3.2 Decimation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3 When is this method efficient? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4 Method implementation on the STM32F10xxx devices . . . . . . . . . . . . . . . 8

3.4.1 Oversampling using a white noise firmware flowchart . . . . . . . . . . . . . . . 9

3.4.2 Oversampling using white noise result evaluation . . . . . . . . . . . . . . . . . 10

4 Oversampling using triangular dither . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 When does this method work? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 Method implementation on STM32F10xxx devices . . . . . . . . . . . . . . . . . 13

5 Comparing the first and second methods . . . . . . . . . . . . . . . . . . . . . . 15

6 Hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.1 What is the maximum number of bits that can be added to

the on-chip ADC resolution? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.2 Taking advantage of High-density STM32F10xxx devices . . . . . . . . . . . . 16

6.3 Taking advantage of the Medium- and High-density performance line

(STM32F103xx) devices 17

Appendix A Quantization error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2/21

AN2668 List of figures

List of figures

Figure 1. Oversampling effect on the quantization noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2. Histogram analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 3. Histogram analysis for DC = 1.65 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 4. Oversampling using a white noise flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 5. Ramp samples with 1 additional bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 6. Ramp samples with 2 additional bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 7. How to perform oversampling by adding a triangular signal . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 8. Hardware requirements of oversampling by adding a triangular signal . . . . . . . . . . . . . . . 13

Figure 9. Oversampling using triangular dither flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 10. Oversampling effect on the quantization error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3/21

Definition of ADC signal-to-noise ratio AN2668

SNR

dB

6.02N 1.76+=

1 Definition of ADC signal-to-noise ratio

The ADC gives a representation of an analog signal among a finite number of digital words.

Since the digital domain is represented by a finite number of words which have to present a

continuous signal, the conversion step introduces the quantization error function of the ADC

input range and resolution.

For an ideal ADC, the quantization error is between ±0.5 LSB. In the case where the input

signal is varying through many levels between samples, and the sampling rate is not

synchronized with the input frequency, the quantization error can be considered as a white

noise whose energy is uniformly spread from the DC domain to half of the sampling

frequency. Please refer to Appendix A for more details regarding the calculation of its

density.

The SNR (signal-to-noise ratio) is the ratio of the ADC noise to the input signal power. For

an ideal ADC, it is assumed that the SNR is equal to the quantization noise (no other noise

source is considered) to the input signal. It is demonstrated that for a full-scale sinusoidal

signal, the ADC SNR is maximum and given by the following formula:

, where N is the ADC resolution.

It is can be easily noticed that when the SNR increases, the ADC effective number of bits

increases.

For a real ADC, different error sources should be considered: offset, gain, INL (integral

nonlinear) and DNL (differential nonlinear). A brief description of these errors can be found

in the STM32F101xx and STM32F103xx datasheets. They degrade the ideal ADC

resolution. In this case, we speak of real effective number of bits.

Improving the SNR involves an enhancement of the ADC effective number of bits.

The following section demonstrates that sampling the input signal with higher rates than the

Nyquist frequency improves the SNR. The Nyquist frequency is introduced in the next

paragraph.

4/21

AN2668 Nyquist theorem and oversampling

2 Nyquist theorem and oversampling

The Nyquist theorem states that in order to be able to reconstruct the analog input signal,

the signal should be sampled at a rate f

maximum frequency component of the input signal.

Not respecting the Nyquist theorem causes aliasing effects and the analog signal cannot be

fully reconstructed from the input samples. Therefore, in most applications, a low-pass filter

is required at the ADC input to filter frequencies lower than half the sampling frequency. It is

difficult to handle the filter constraints with low sampling frequencies.

Oversampling consists in sampling the input analog signal at rates higher than the Nyquist

frequency limit, filtering the samples and reducing the sample rate by decimation. Using this

method relaxes the anti-aliasing low-pass filter constraints.

(sampling frequency) that is greater than twice the

S

5/21

Oversampling using white noise AN2668

SNR

OVS

6.02 N 1.76+⋅ 10 OS R()log+=

F

OVS

4pF

S

=

3 Oversampling using white noise

3.1 SNR of oversampled signal with white input noise

Let us assume that the quantization noise is assimilated to white noise. Then its power

density is uniformly distributed between DC and half the Nyquist frequency. This power

density is independent of the sampling frequency.

When sampling at higher rates, the quantization noise is spread over the bandwidth of the

sampling frequency.

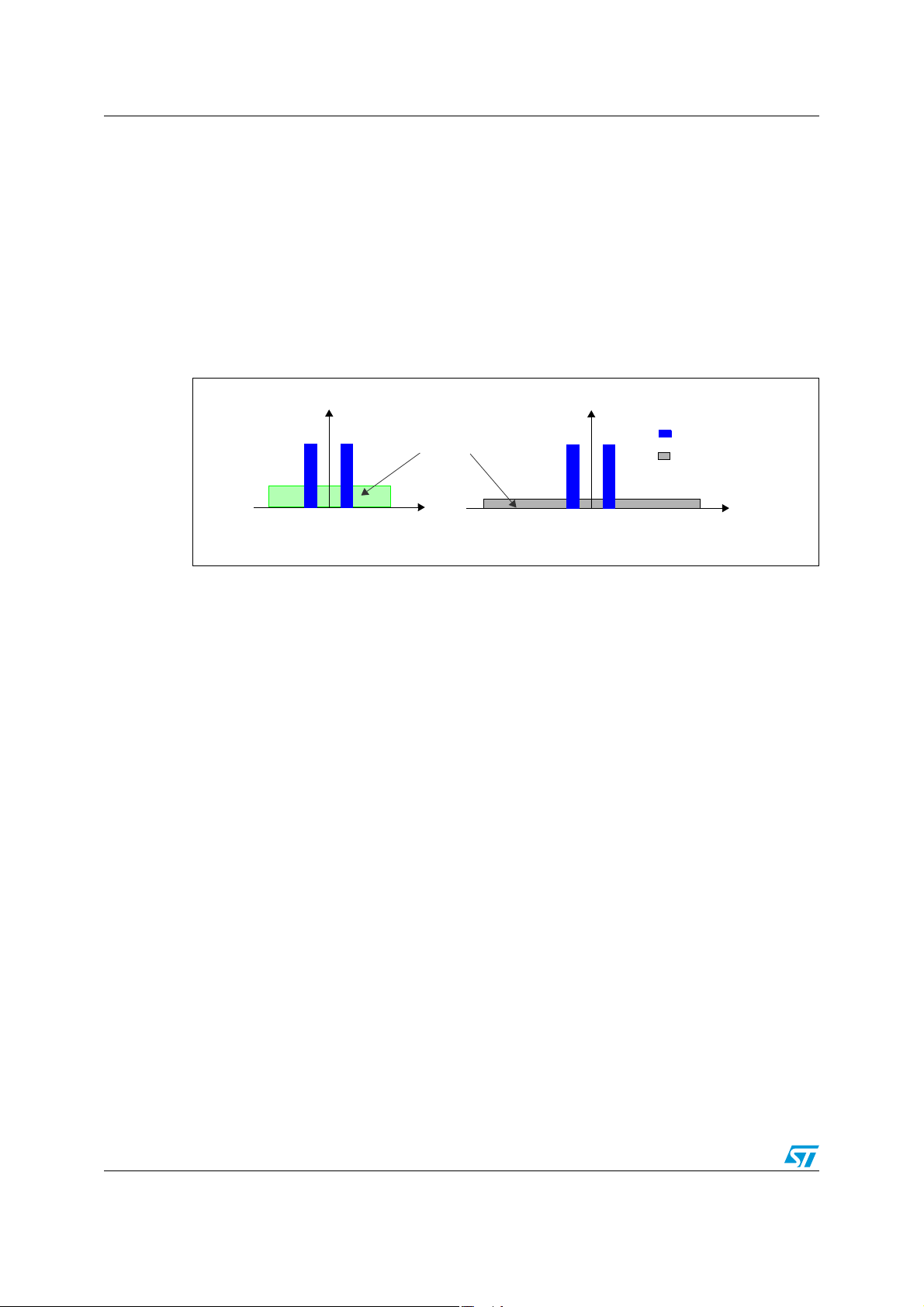

Figure 1. Oversampling effect on the quantization noise

-2.f

PSD

Same area

- f

m

m

fS = 2.f

f

m

F

m

-2.N.f

m

PSD

Input signal

Quantization error

PSD = Power signal density

F

- f

f

m

m

fS= 2.N.f

m

ai14937

According to Figure 1, when sampling the input signal at higher rates, the same noise

power, represented by the area of the green rectangle, is spread over a bandwidth equal to

the sampling frequency which is much greater than the signal bandwidth fm. Only a

relatively small fraction of the total noise power falls in the [–fm, fm] band, and the noise

power outside the signal band can be greatly attenuated with a digital low-pass filter.

Reducing the quantization noise enhances the signal-to-noise ratio and, consequently, the

ADC effective number of bits. Oversampling the input signal OSR times faster than the

Nyquist frequency gives the following SNR

It can be concluded that each doubling of the sampling frequency will lower the in-band

noise by 3 dB, and increase the measurement resolution by 1/2 bit. Therefore, 6dB SNR

gain is required to add 1 resolution bit to the ADC.

In general, if p additional bits are required by the application then, the ADC sampling

frequency should be at least:

, where F

is the current ADC sampling frequency used.

S

3.2 Decimation

The conventional meaning of averaging is adding m samples and dividing the result by m.

Averaging several data from an ADC measurement is equivalent to a low-pass filter which

attenuates the signal fluctuation and noise. The average method is often used to smooth

and remove speaks from the input signal.

Note that normal averaging does not increase the resolution of the conversion because the

sum of m N-bit samples divided per m is an N-bit representation of the sample.

6/21

AN2668 Oversampling using white noise

Decimation is an averaging method. When combined with oversampling, decimation

improves the ADC resolution.

In fact, adding 4

p

ADC N-bit samples, gives a representation of the signal on N+2p bits. In

order to have p additional effective bits, the sum is shifted to the right by p bits.

This FIR filter with equal filter coefficients enables the user to filter the oversampling

frequency by giving an output sample computed from the OSR input samples.

The oversampling method limits the maximum input frequency bandwidth. In fact, in the

case of the STM32F10xxx, signals having components up to 500 kHz can be processed by

the ADC. If for example, two additional resolution bits are required, then the maximum input

frequency that can be entered is 500 kHz/16 = 31.25 kHz when oversampling using white

noise.

3.3 When is this method efficient?

For the oversampling and decimating method to work properly, the following requirements

must be satisfied:

● There should be some noise in the input signal. This noise must approximate white

noise with a uniform power spectral density over the frequency band of interest.

● The noise amplitude must be sufficient to toggle the input signal randomly from sample

to sample by an amount of at least 1 LSB. Otherwise, the input samples would have the

same representation and the sum and average operations would not give any extra

resolution. In most applications, the internal ADC thermal noise and the input signal

noise are sufficient to use this method. In the case where the thermal noise does not

have a high-enough amplitude to toggle the input signal randomly, then artificial white

noise should be injected into the input signal. This operation is referred to as

“dithering”. Regarding this point, two questions can be raised. The first is “How to

evaluate the ADC noise and test its Gaussian criteria?” and “How to generate white

noise if needed?”

– A practical way of detecting the Gaussian criteria of the input signal noise is to see

the distribution of a clean DC signal over the ADC codes. The histogram method

can be used to verify if the input noise follows a Gaussian distribution. The

example in Figure 2 shows two possible situations.

7/21

Oversampling using white noise AN2668

ADC codes

N N+1 N+2N–1N–2

Histogram for a signal with white noise

ADC codes

N N+1 N+2N–1N–2

Histogram for a signal without white noise

ai14938

Figure 2. Histogram analysis

– In the case where external noise dither should be added to the input signal, then

the thermal noise generated by a diode or a resistor can be injected into the input

signal.

– The input noise should not correlate with the useful input signal and the input

signal should have equal probability to be between two adjacent ADC codes. This

means that for systems using feedback process, this method does not work.

3.4 Method implementation on the STM32F10xxx devices

This method describes the different steps undertaken to implement and test the

oversampling method on the STM32F10xxx devices.

According to the previous section, in order to make this solution work properly, there should

be some white noise to make the input signal toggle randomly by 1/2 LSB. For this, the

application environment noise should be considered.

The first step consists in computing the STM32F10xxx ADC thermal noise to conclude if

external white noise should be injected into the input signal. In a typical application board,

the computed noise does not include only the ADC internal noise but also the possible noise

generated by the different board components and the layout. Therefore, this evaluation

depends on the application board but the methodology remains the same.

The histogram method is used for different DC input voltages. This input voltage is sampled

a large number of times (example 5000). The related distribution can be easily interpreted

using a spreadsheet.

For example, for a 1.65 V DC input voltage applied on the STM3210B-EVAL evaluation

board, the histogram shown in Figure 3 is detected.

8/21

AN2668 Oversampling using white noise

ai14939

Figure 3. Histogram analysis for DC = 1.65 V

The ADC thermal noise can be computed from this histogram (though this can be shown, it

is not the objective of this application note and details are not offered here).

In order to carry on this ADC noise test, the user should do the following:

● uncomment the line #define Themal_Noise_Measure in the oversampling.h file

● configure the Total_Samples_Number which is the number of ADC conversion

operations. It should be smaller than 65535. The DMA channel is configured to store

the number of ADC samples in a RAM buffer. At the end of the transfer, an interrupt is

generated and the number of occurrences of each ADC code is computed

● In order to compute the occurrence of the ADC codes, a variable giving the relevant

ADC codes is defined

When the code is run, Relevant_ADC_Samples ADC samples and their corresponding

number of occurrences are displayed on the HyperTerminal. The HyperTerminal

configuration is 8-bit data, no parity, 115 200 baud rate. If the effective number of ADC

samples found is smaller than the defined Relevant_ADC_Samples variable, then 0 is

displayed for both ADC code and ADC code occurrence. The user can capture them and

build a histogram.

3.4.1 Oversampling using a white noise firmware flowchart

The STM32F10xxx on-chip ADC conversion frequency is fixed to 1 MHz. The ADC DMA

channel is configured to transfer the number of oversampled inputs from the ADC data

register to a buffer in RAM. This transfer is configured to occur one time. At the end of the

DMA transfer, an interrupt is triggered and the oversampled result is computed.

The STM32F10xxx general-purpose timer TIM2 is used to generate the input signal

sampling frequency. For this, the TIM2 reference clock is configured at 1 µs. Its period

determines the input signal sampling period. It is defined in the oversampling.h file as

#define Input_Signal_Sampling_Period. When the TIM2 update interrupt is

triggered, the DMA is re-enabled and the converted ADC values can be treated. Figure 4

summarizes the implemented functionality.

9/21

Oversampling using white noise AN2668

Sampling period = TIM2 period

ADC period = 1 µs

TIM2 update interrupt

Clear flag

Enable DMA

Time t

<=1µs

DMA transfer complete interrrupt

Clear DMA Interrupt pending bit

Compute the oversampled result

Update DMA counter and pointer

Disable DMA

ai14940

Figure 4. Oversampling using a white noise flowchart

The oversampled data are computed in the DMA transfer complete interrupt. For

synchronization reasons, it is recommended to read it in the second TIM2 interrupt.

Note that with this implementation, the TIM2 period should be greater than the time required

by the ADC to convert OSR samples, and greater than the ADC interrupt execution time.

If the sampling frequency required by the application is exactly OSR µs, then the user is not

required to use Timer TIM2 to generate the input sampling frequency. However, the DMA

should be configured to be functional in continuous mode and the DMA transfer complete

interrupt should be updated accordingly. The oversampled data are usually computed in the

DMA transfer complete interrupt.

3.4.2 Oversampling using white noise result evaluation

In order to evaluate the oversampling method, the user should uncomment the #define

Oversampling_Test line and configure the number of samples with the enhanced

resolution.

When this line is uncommented, a buffer is created in RAM to store the oversampled data.

The buffer contents are then displayed on the HyperTerminal. The HyperTerminal

configuration should be 8-bit data, no parity and 115 200 baud rate. The user can capture

them into a txt file and then compare the expected results to the real ones.

In order to evaluate the new enhanced ADC, a ramp with a 50 Hz frequency and a 1 V

amplitude is input into the ADC and sampled using the oversampling algorithm every 50 µs.

The firmware example related to this method is located in the WhiteNoiseMethod folder.

10/21

AN2668 Oversampling using white noise

50 H/1 V - 1 additional bit

3000

2500

2000

1500

1000

500

0

0

30

60

90

120

150

180

210

240

270

300

330

360

390

ai14942

50 H/1 V - 2 additional bits

6000

5000

4000

3000

2000

1000

0

0

41

82

123

164

205

246

287

328

369

410

451

492

533

574

615

656

697

738

779

ai14942

Figure 5. Ramp samples with 1 additional bit

Figure 6. Ramp samples with 2 additional bits

The oversampling algorithm using white noise is run with the same ramp (50 Hz frequency

and 1 V amplitude). Both Figure 5 and Figure 6 give the ADC oversampled data as a

function of time in µs. Figure 5 is the result of adding one bit while Figure 6 is the result of

adding two additional bits to the ADC on-chip resolution.

When the ramp is sampled without using any extra software resolution, with a 3.3 V

reference supply, 1 V corresponds to the digital value 1250.

When one additional bit is added, 1 V is sampled as 2500 and when two additional bits are

added, 1 V is sampled as 5000.

This means that the environment contains enough noise for this method to work.

11/21

Oversampling using triangular dither AN2668

q0

q1

Input signal @ q0+0.6LSB

Input signal + triangular

waveform samples q1

(q1+q0)/2

(q1+q0)/4

(q1+q0)/8

Average of q1 occurrences= 9/16 = 0.563

Result =(7x110 000+ 9x111 000 + 1) >>1=110 101

110 000

110 001

110 010

110 011

110 100

110 101

110 110

110 111

111 000

waveform samples q0

Input signal + triangular

-> The nearest value is 110 101

ai14943

SNR

Gain

20.

OSR

2

-------------

⎝⎠

⎛⎞

log=

F

OVS

2.2pF

S

=

4 Oversampling using triangular dither

Assuming that the input signal is between two successive quantization steps q0 and q1

during the oversampling period, then the converter may convert it either to q0 or q1. Adding

extra p bits of resolution means determining the relative position of the input signal between

q0 and q1.

With the addition of an appropriate triangular signal, the quantizer generates a series of q1s

and q0s. Averaging the q1 occurrences over a given interval determines the relative position

of the input signal between the lower and the higher quantization steps.

The theory states that the best results are achieved when dithering the input signal using a

triangular waveform with a period of OSR times the ADC sampling period and an amplitude

of n+0.5LSB where n = 0,1,2,3.

The theory behind this methods is quite complicated, so that Figure 7 serves as an example

to illustrate how this method works. In this example, the ADC on-chip resolution is 3 and

three extra bits are added by firmware. The input signal is assumed to have an amplitude of

q0+ 0.6LSB (q0 = 6 in this example). In order to add three additional bits, the input signal is

sampled 2.2

Figure 7. How to perform oversampling by adding a triangular signal

3

times (16 times).

If the input signal is not correlated with the triangular waveform, then it is demonstrated that

the gain in the SNR is equal to

Therefore, each doubling of the sampling frequency improves the SNR by 6dB and adds 1

ADC bit resolution.

In general, in order to add p-bit extra resolution, the oversampling frequency should be

equal to

4.1 When does this method work?

In order to make this method work, the input signal should not vary by more than ±0.5LSB

during the oversampling period and should not correlate with the triangular dither signal.

12/21

AN2668 Oversampling using triangular dither

Input signal

10 kΩ

VDD

-

+

PWM output

RC to filter the PWM

frequency

-

V

DD

/2

V

DD

/2

0

V

DD

4 MΩ

ADC Input

Vs

1 kΩ

1 kΩ

R2

10 kΩ

R1

R3

100 nF

0.46 kΩ

5.5 nF

ai14944

4.2 Method implementation on STM32F10xxx devices

In order to implement the second solution, the following is needed:

● An operational amplifier to perform the sum of the input signal and the triangular

waveform. For this, an op-amp inverter/summing stage is required. The ST component

LMV321 can be used.

● Triangular waveform with a period of OSR times the ADC conversion rate. The user can

either use a signal generator or one of the STM32F10xxx on-chip timers and an RC

network to generate this triangular signal. Indeed, the on-chip timer generates a PWM

signal with a duty cycle varying from 0 to 100%. This PWM output can be filtered with

an RC filter to generate a triangular signal varying from 0 to V

an amplitude of 0.5LSB, then the output is first passed through a capacitor (to cut the

DC component) and then divided by the prescaler R2/R3 (see Figure 8). This prescaler

is equal to the ADC number of words.

● The input signal should not be changed after the op-amp. For this reason, R1 should be

equal to R3.

● The sum of the input signal and the triangular dither is inverted. For this purpose, a

3.3 V offset is required on the positive entry of the op-amp. After the oversampled data

are computed, this offset is subtracted to give the input signal estimation with extra

resolution.

. In order to generate

DD

Figure 8. Hardware requirements of oversampling by adding a triangular signal

The STM32F10xxx on-chip ADC conversion frequency is fixed at 1 MHz. The ADC DMA

channel is configured to transfer the number of oversampled inputs from the ADC data

register to a buffer in RAM. This transfer is configured to occur one time. At the end of the

DMA transfer, an interrupt is triggered and the oversampled result is computed.

The STM32F10xxx general-purpose timer TIM2 is used to generate the input signal

sampling frequency. For this, the TIM2 reference clock base is configured at 1 µs. Its period

determines the input signal sampling period. It is defined in the oversampling.h file by

#define Input_Signal_Sampling_Period.

The triangular dither is generated using Timer TIM3 configured in PWM mode by updating

the Capture Compare Register CCR1. Timer TIM3 period should be equal to the ADC

conversion rate and CCR1 should be updated OSR times where OSR is the oversampling

factor. In order to do this, the possible CCR1 values are first computed and stored into a

RAM buffer, then DMA transfer is used to update the CCR1 register, removing the need for

interrupts.

Note that the ADC conversion rate limits the oversampling factor. For example, in the case

where the ADC is running at 1 MHz, the STM32F10xxx is operating at 56 MHz. In order to

13/21

Oversampling using triangular dither AN2668

Sampling period = TIM2 period

ADC period = 1 µs

TIM2 Update interrupt

Clear flag

Enable ADC DMA

Time t

<=1µ

ADC DMA transfer complete interrupt

Clear DMA Interrupt pending bit

Compute the oversampled result

Update ADC DMA counter and pointers

Disable DMA

Enable TIM3 DMA

Update TIM3 DMA counter and pointers

TIM 3 period = ADC period = 1 µs

TIM3 CCR1 register varies during OSR period (OSR = 4 in this example)

Input signal dithered with the

triangular signal

Input signal

ai14945

have a period of 1 µs, the auto-reload register of timer TIM3 should be equal to 55. The

maximum number of additional bits is then 4.

When a TIM2 update interrupt is triggered, the ADC and TIM3 DMA are re-enabled and the

converted ADC values can be treated to compute the new sample with the extra resolution

bits. Figure 9 summarizes the implemented functionality.

Figure 9. Oversampling using triangular dither flowchart

For this method to work, the input signal should not vary by more than ±0.5LSB during the

oversampling period. This means that for an STM32F10xxx operating from a 3.3 V VDD

power supply, the maximum allowed variations of the input signal during the oversampling

period is ~0.4 mV.

On the other side, a triangular waveform with an amplitude of 0.5LSB means a 0.4 mV

amplitude when operating the STM32F10xxx from a 3.3 V power supply. The application

environment must therefore not be very noisy. Any disturbance of the triangular waveform

will have an impact on the computed oversampled data.

According to the implementation, the triangular waveform is generated by means of the

STM32F10xxx timer and an RC filter that cuts the 1 MHz timer frequency. The timer PWM

output signal is integrated to provide a triangular signal with a 3.3 V amplitude. The division

is done with the ratio R4/R2.

The firmware related to this method is located in the TriangularDitherMethod

directory.

14/21

AN2668 Comparing the first and second methods

5 Comparing the first and second methods

The first method based on oversampling and averaging using white noise provides a half-bit

additional resolution for each doubling of the oversampling rate. The maximum input

frequency is drastically decreased with the additional number of additional bits.

For applications where this gain is sufficient, then it is a good choice. It requires the

presence of white noise in the input signal to make the signal toggle between two adjacent

ADC codes. In general, the ADC thermal noise is sufficient and there is no need to add

external hardware to act as an external white noise source. This makes the solution more

cost-effective.

The second method based on dithering the input signal using a triangular waveform and

computing its relative position between two quantized steps provides one more bit for each

doubling of the oversampling rate. This is twice the improvement given by the first method.

To make this method work, the input signal should not correlate with the triangular signal

and should not have a variation greater than 0.5LSB during the oversampling period.

However, external hardware is needed to add the input signal and the triangular waveform.

Ta bl e 1 summarizes the main differences between the two methods. It is not possible to say

that one method is better than the other. Each method has its advantages and limitations.

The user should select the one that better meets their application requirements (sampling

frequency, number of effective bits etc.).

Table 1. Oversampling using white noise vs. oversampling using triangular dither

Implementation conditions

Oversampling factor to add p bits

to he ADC on-chip resolution

Maximum Input signal frequency f

Dither signal

External hardware

Oversampling using

white noise

p

4

max/(2.4p)f

ADC

White noise with an

amplitude of at least 1 LSB

External white noise

source needed if the input

signal noise is not sufficient

Oversampling using triangular

ADC

Triangular signal with an amplitude

of n+0.5LSB

Triangular waveform generator: an

on-chip timer can be used.

– In this case, an RC network is

used to filter the PWM frequency

– An op-amp is needed to add the

triangular waveform and the input

signal

max/(2.2.2p)

dither

p

2.2

15/21

Hints AN2668

6 Hints

6.1 What is the maximum number of bits that can be added to the on-chip ADC resolution?

It can be easily shown that increasing the on-chip ADC resolution decreases the maximum

frequency component of the input signal.

For example, when using the STM32F10xxx ADC at 1 MHz and two additional bits are

required by the application, then the maximum input frequency is divided by:

● 16 when using the white noise method (62.5 kHz).

● 4 when using the triangular dither method (125 kHz)

What is the maximum number of bits that can be added to the on-chip ADC resolution?

For the two methods, the estimation of the input signal is done during an oversampling

period of OSR times the ADC conversion rate. In the case, the ADC is running at 1 MHz, the

input signal estimation is done over OSR µs. The signal should not vary by more than

1/2LSB for the white noise method and, by ±0.5LSB for the triangular waveform method.

● When using the white noise method, the maximum number of bits that can be added to

the ADC resolution depends only on the input signal.

● When using the triangular dither method, the maximum number of bits that can be

added to the ADC resolution does not depend only on the input signal. In fact, the steps

defining the triangular signal depend on the ADC and APB frequencies. The timer

period should be equal to the ADC rate:

2.2p ≤Timer period

P ≤ log2 (Timer period / 2)

In our example, running the ADC with a rate of 1 µs causes the STM32F103xx to operate at

56 MHz, which means that the timer period should be equal to 55. The maximum number of

bits that can be added in this case is 4.

6.2 Taking advantage of High-density STM32F10xxx devices

The new High-density STM32F101xx and STM32F103xx devices come with a DAC (digitalto-analog converter) that can be used in the oversampling method to avoid the use of

external components.

The DAC can be used in the two oversampling methods as follows:

● In the first method, the DAC can be used to generate a white-noise waveform with

programmable amplitude that can be injected into the input signal if noise is not

sufficient. The waveform is generated thanks to the implemented pseudo-random

algorithm. For more details, please refer to the STM32F10xxx reference manual.

● In the second method, the DAC can be used to generate the triangular waveform. This

removes the need for any additional external RC circuitry to filter the timer PWM

frequency.

Note: This hint is not implemented in the software given within the application note.

16/21

AN2668 Hints

6.3 Taking advantage of the Medium- and High-density performance line (STM32F103xx) devices

In the Medium- and High-density performance line devices, the Dual ADC mode is an

interesting feature that allows two ADCs to convert at the same time.

Using the Dual ADC Fast Interleave mode, the same channel is converted alternately by

ADC2 and ADC1. The time separating two successive samples is 7 ADC clock cycles. The

input signal is therefore oversampled faster. In the example described in this application

note, a sample is obtained every 1 µs. Using the Dual ADC Fast Interleave mode, it is

possible to have a sample every 7 ADC clock cycles, that is every 0.5 µs when running the

ADC at 14 MHz.

Note: This hint is not implemented in the software given within the application note.

17/21

Quantization error AN2668

q

V

AREF

2

N

-----------------=

e

q

q

2

-- -

≤

σ2Ee

q

2

() Peq()e

q

2

⋅()eqd

q

2

-- -–

q

2

-- -

∫

q

2

12

------== =

PSD

σ

2

f

s

-----=

η

0

2

σ

2

f

s

-----

fd

fm–

f

m

∫

σ

2

2f

m

f

s

---------

⋅ q

2

2f

m

12.f

s

------------

⋅===

F

f

m

- f

m

fS = 2.f

m

-2.f

m

F

f

m

- f

m

fS= 2.N.f

m

-2.N.f

m

PSD

PSD

Same area

Input signal

Quantization error

ai14946

Appendix A Quantization error

Let us assume that we have an N-bit analog-to-digital converter (ADC) and a voltage

reference V

Let quantum q be the minimum distance between two adjacent ADC codes. It is defined as

follows:

The quantization error equation is:

Let us assume that:

● the signal crosses many levels between samples

● the sampling rate is not synchronized to the signal frequency

● the input signal has equal probability of being anywhere in the quantization interval q,

leading to a random quantization error

Given the above assumptions, the quantization noise can be approximated to a random

variable equally distributed between ADC codes with zero mean. From this assumption, it

can be easily demonstrated that the quantization noise variance is given by the following

formula

AREF

.

According to the above formula, the quantization noise power depends on the ADC

resolution and decreases drastically when the ADC resolution increases.

Given an ADC sampling frequency f

(which is specified according to the MCU), in the case

S

where the Shannon criteria is respected, then the quantization noise power density is equal

to

Let f

be the maximum frequency component of the input signal. The quantization noise

m

power present in the band of interest is given by

Figure 10. Oversampling effect on the quantization error

18/21

AN2668 Quantization error

SNR

OVS

10

σ

x

2

σ

2

2f

m

f

s

---------

⋅

--------------------- -

⎝⎠

⎜⎟

⎜⎟

⎜⎟

⎛⎞

log SNR

2.f m

10 O SR()log+==

Note that increasing the sampling frequency reduces the in-band quantization noise power

and consequently improves the signal-to-noise ratio.

Given the same input signal and sampling it with 2.f

and fS = OSR.2.fm, the gain in SNR is

m

19/21

Revision history AN2668

Revision history

Table 2. Document revision history

Date Revision Changes

08-Jul-2008 1 Initial release.

20/21

AN2668

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2008 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

21/21

Loading...

Loading...