Page 1

AN2650

Application note

L9942 stepper motor driver for bipolar stepper motors

Introduction

The L9942 is an integrated stepper motor driver for bipolar stepper motors. The device is

designed for automotive applications, such as headlamp leveling, steerable lights and

adaptive front lighting. Other applications, such as ventilation and air conditioning flap and

throttle positioning are also possible uses for the L9942.

The device drives bipolar stepper motors with high-efficiency and smooth operation. Microstepping is the preferred mode to provide low-noise operation since this technique

eliminates the effects of mechanical resonances, which can lower the motor torque.

A motor stall detection capability allows position alignment without an external sensor, while

its step counter is addressable via an SPI as well as by a separate input, to prevent the SPI

overloading when running multiple motors simultaneously.

November 2007 Rev 1 1/24

www.st.com

Page 2

Contents AN2560

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Typical application schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Calculation of the buffer capacitor Cbuffer . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Low drop reverse polarity protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Shorted coil detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 SPI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Fault bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 SPI communication monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 Decay modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 Slow decay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 Fast Decay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3 Advanced decay modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3.1 Mixed decay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3.2 Auto decay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Stall detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.1 Internal functionality (simplified) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2 How to determine the stall threshold at bench test . . . . . . . . . . . . . . . . . 17

6 Duty cycle for current regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1 Minimum duty cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2 Maximum duty cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7 Power dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.1 Static ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.2 Static freewheeling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.3 Dynamic slew rate power dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.4 Power dissipation for one PWM phase . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2/24

Page 3

AN2560 Contents

8 PCB footprint proposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

9 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3/24

Page 4

List of tables AN2560

List of tables

Table 1. Phase counter values for fast decay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 2. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4/24

Page 5

AN2560 List of figures

List of figures

Figure 1. Application schematic diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2. Low drop reverse polarity protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 3. Stepping modes (Auto decay mode, fast decay without delay time) . . . . . . . . . . . . . . . . . . 9

Figure 4. Auto decay, fast decay without delay time at phase 0 and 8 . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 5. SPI transfer timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 6. Slow decay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 7. Fast decay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 8. Mixed decay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 9. Auto decay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 10. Stall detection function overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 11. Cross current protection time and slew rate for maximum DC . . . . . . . . . . . . . . . . . . . . . . 18

Figure 12. Current flow and voltage drop during fast decay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 13. Power SSO24 solder mask layout (all values in mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 14. Power SSO24 solder mask opening (all values in mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5/24

Page 6

Typical application schematic AN2560

1 Typical application schematic

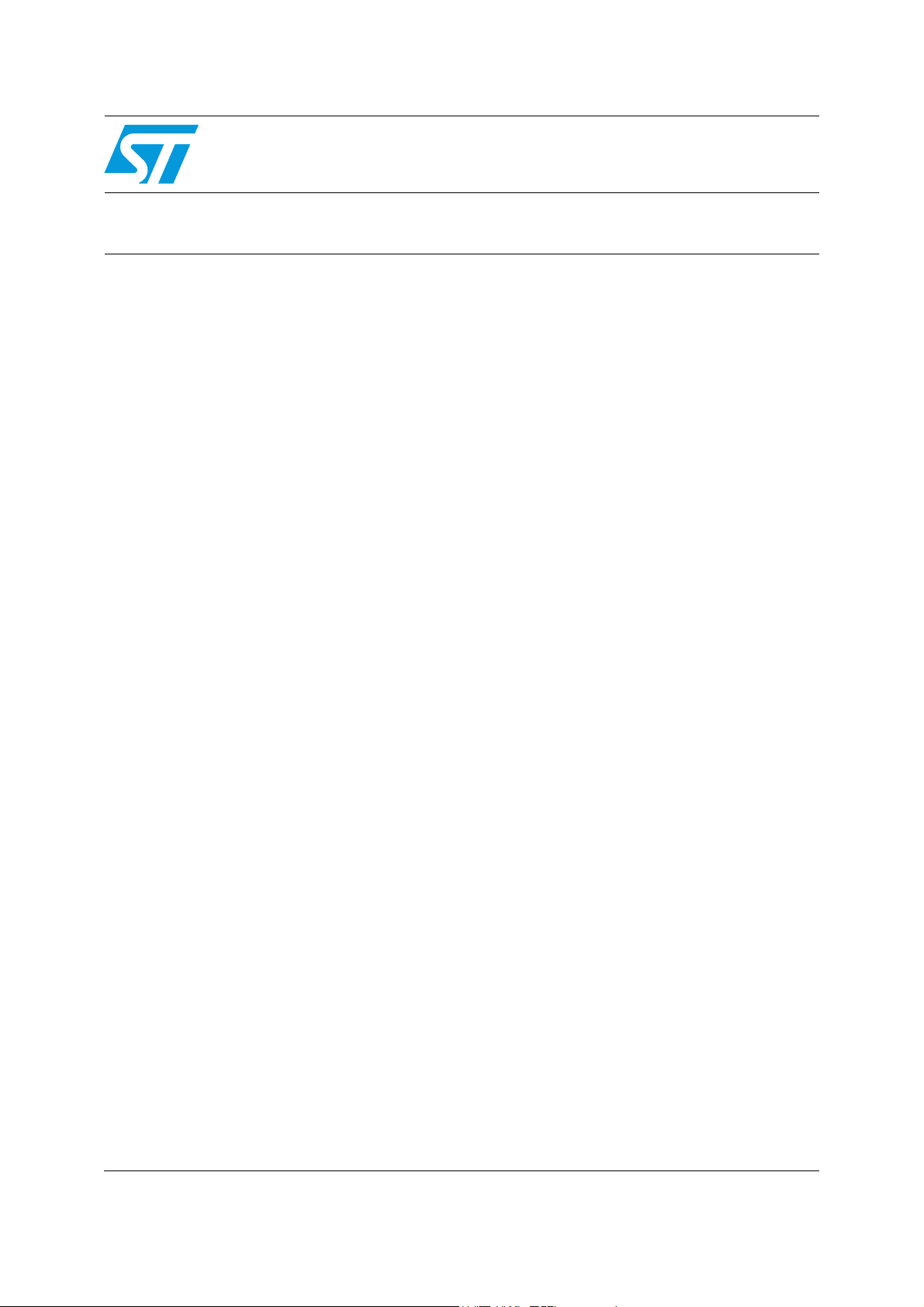

Figure 1. Application schematic diagram

V

bat

Vs

10

121

Vs

22

Vs

QA 1 2

QA 2

QB 1 11

QB 2

13 24

PGNDGND

C

buffer

23

2n2

2n2

14

2n2

2n2

SM

5V

V

reg

100n

out

out

in

µC

in

out

out

out

6k8

100n

19

16 15

Vcc

CP

STEP9

EN

21

PWM8

DO7

DI5

CLK4

CSN6

RREF

20

TEST

GND

1817

3

L9942

PGND PGND

The L9942 is driven by a microcontroller via the SPI (DO, DI, CLK, and CSN), STEP and EN

pins. Additional information is provided from the PWM pin.

The stepper motor driver is supplied from a 5 V voltage regulator and the reverse polarity

protected Vs. It is necessary to use a stabilization capacitor (with a minimum value of

minimum 100 nF) as close as possible at the Vcc pin. For the stabilization of the Vs supply

pin and to absorb motor energy, an electrolytic capacitor C

, with a minimum value as

buffer

calculated in Section 1.1, must be used.

Because the motor currents are supplied via the Vs-pins, all Vs-pins must have a low ohmic

connection to the supply voltage Vs. For the same reason, all GND and PGND pins must

have a low ohmic connection to the system ground. A star ground concept with separate

lines for GND and PGND is recommended.

At the charge pump pin, a capacitor with 100 nF to Vs is recommended.

To improve the EMI behavior, it is recommended to have 2.2 nF capacitors as close as

possible to the motor output pins, Qxy. Short motor connection wires also improve the EMI

behavior.

The internally-used reference voltage depends upon the value of the reference resistor,

positioned between the pin RREF and GND. Consequently, the precision of the L9942

depends upon the value of the reference resistor. One possible value for this resistor is

6.8 kΩ.

6/24

Page 7

AN2560 Typical application schematic

Due to the structure of the BCD process, the slug of the device is connected internally to

PGND and must also be connected externally to PGND.

1.1 Calculation of the buffer capacitor C

The stepper motor driver L9942 is usually designed in an environment similar to that shown

in Figure 1.

During motor operation, electrical energy is stored in the motor coils. If the motor shuts

down, this energy is fed back to the supply voltage Vs. Thus, there is a voltage increase at

Vs, which may cause an electrical overstress of the L9942. To avoid damage to the L9942,

the value of the buffer capacitor C

The energy balance can be calculated from:

motor

buffer

2

V

s1

2

⋅+ V

L

------------------ -

C

1

---

C

⋅⋅

bufferVs1

2

L

2

------------------ -

V

s1

C

V

s2

1

-- -

2

2

I

motor

motor

buffer

L

motorImotor

=

⋅+=

I

2

2

s2

2

motor

From this equation, it is possible to conclude:

● the voltage Vs2 must not exceed the maximum rating of the L9942

● if an over voltage shut down must be avoided, the voltage Vs2 must not exceed the

minimum over voltage threshold.

must be chosen carefully.

buffer

1

-- -

⋅⋅≈⋅⋅+

C

bufferVs2

2

2

buffer

Note: As a general recommendation, STMicroelectronics recommend a minimum buffer capacitor

of 47 µF. The ripple at Vs during normal motor operation should be between 5% and 10%.

7/24

Page 8

Typical application schematic AN2560

1.2 Low drop reverse polarity protection

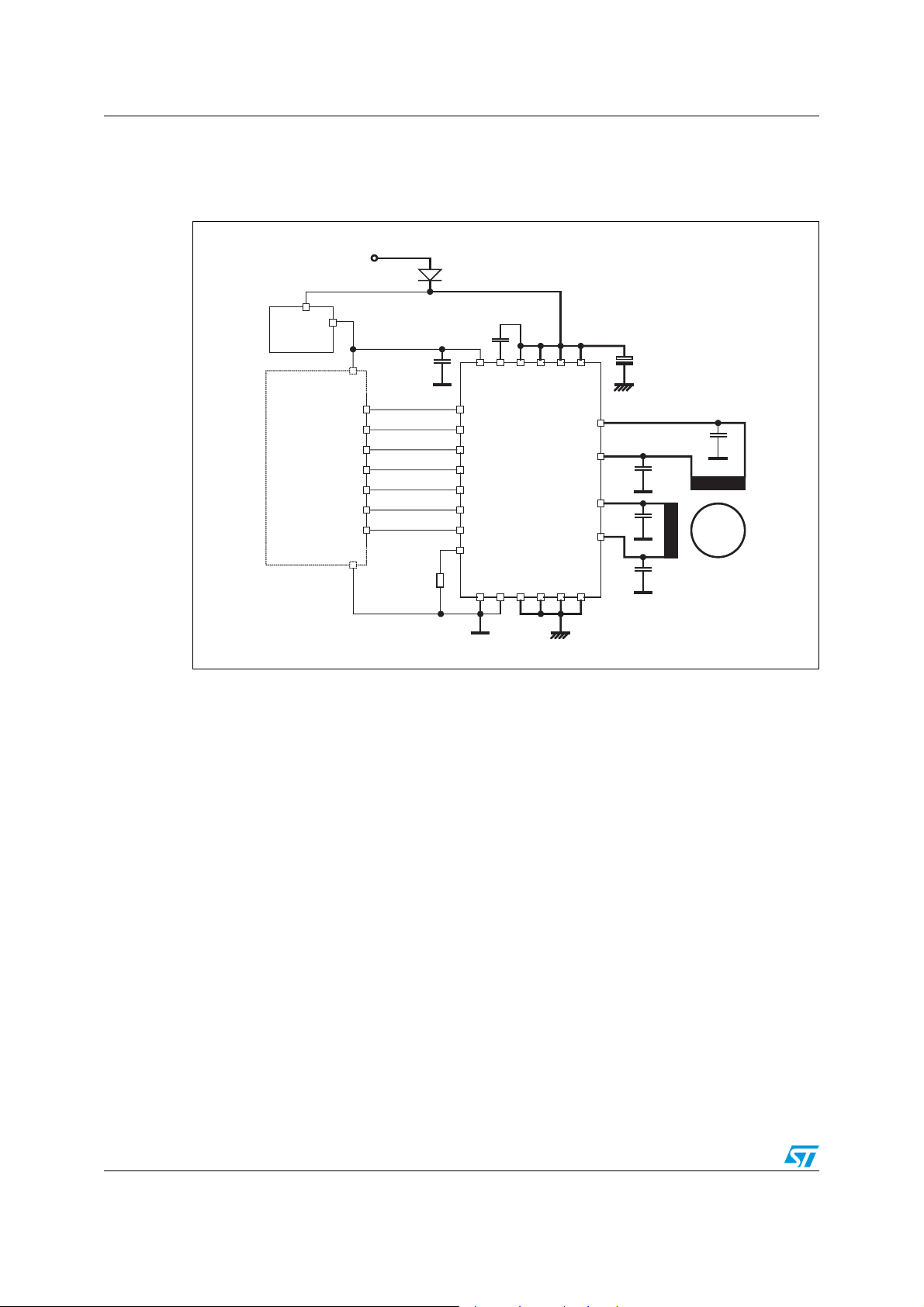

Figure 2. Low drop reverse polarity protection

V

bat

100k

STD17NF03LT4

100k

Vs

100n

310 2216 15

VsCP Vs

C

buffer

L9942 Vreg

L9942

As shown in Figure 2 the charge pump pin can be used for a low drop reverse polarity

protection. The charge pump pin can also be used for other devices in the same application.

Because of the additional gate capacity, the charge pump ramps up more slowly than

without the additional MOSFET gate.

8/24

Page 9

AN2560 Shorted coil detection

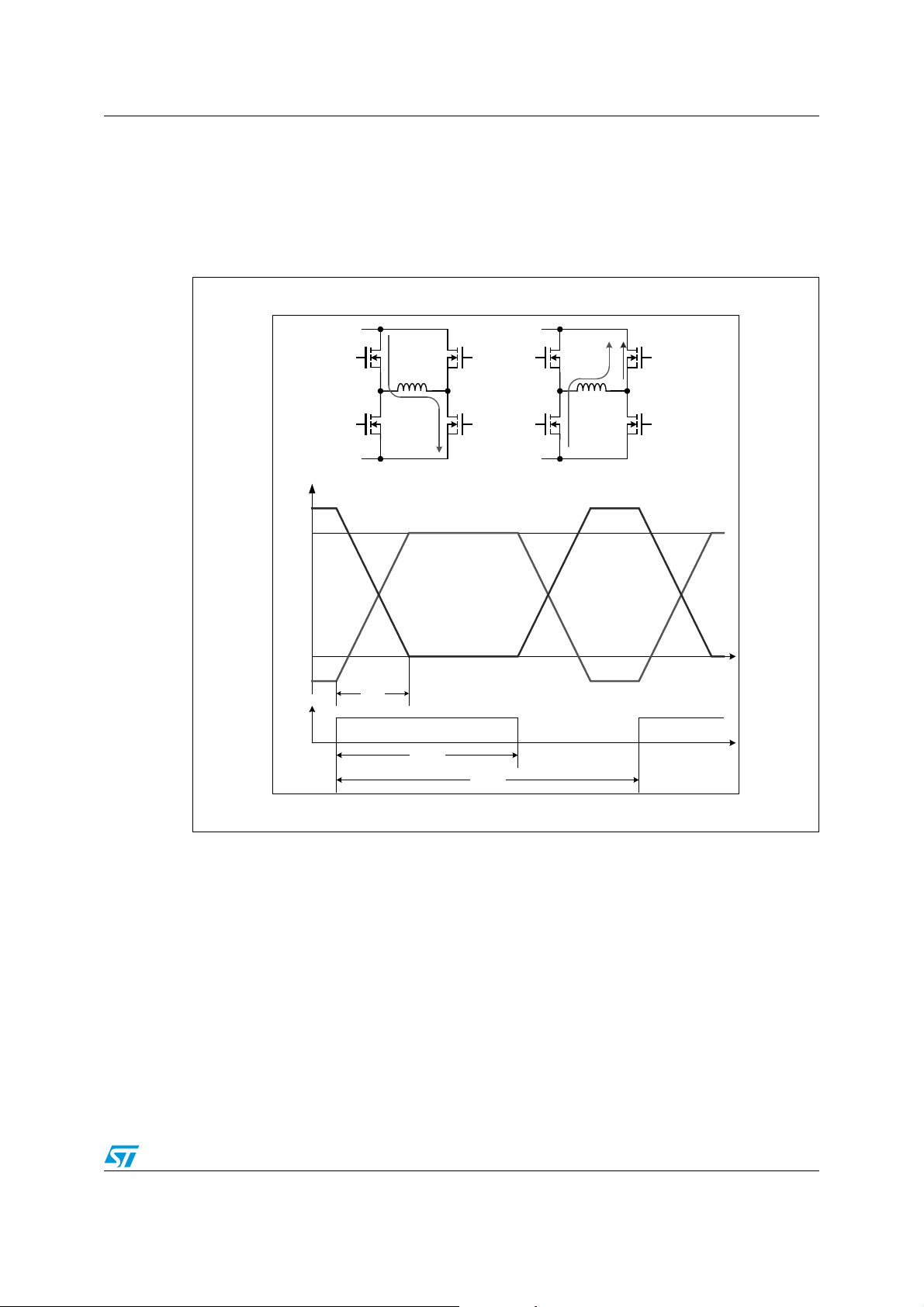

2 Shorted coil detection

During free-wheeling time, the L9942 can use several decay modes that are programmable

by the SPI.

However, only on Auto decay, fast decay without delay time it is possible to detect

shorted coil because, during free-wheeling time, both opposite transistors (HS and LS) are

switched on and high current can rise. During free wheeling the current in the output stage is

monitored, but not regulated, with PWM. Because of this, the short overcomes the over

current filter time and can be detected.

In other decay modes, the decay can periodically change during wheeling of the motor (for

example, every 200 ms) to Auto decay, fast decay without delay time for few microseconds

and than change it back to previous value. This can be done in one clock step.

The decay mode cannot be changed at all values of the phase counter because fast decay

is not active during the whole period but only during decreasing current phase in the coil

(during the rising current phase, the coil is active slow decay mode).

A detailed explanation of Auto decay, fast decay without delay time for all step modes is

given in Figure 3.

Figure 3. Stepping modes (Auto decay mode, fast decay without delay time)

Phase Counter

Current

Dr iv e r A

Current

Dr iv e r B

Step CLK

Phase Counter

Current

Dr iv e r A

Current

Dr iv e r B

Step CLK

Phase Counter

Current

Dr iv e r A

Current

Dr iv e r B

Step CLK

Phase Counter

Current

Dr iv e r A

Current

Dr iv e r B

Step CLK

Full -Step Mode, DIR=0 Full -Step Mode, DIR=1

0 8 16 24

Fast Decay

Slo w Dec ay

0088

Fast Decay

0 4 8 1216202428

04 48

Slo w Dec ay

Fast Decay

024681012141618202224262830

0246 024624624688

Slo w Dec ay

Fast Decay

012345678910111213141516171819202122232425262728293031

01234567 012345671234567123456788

Slo w Dec ay

Fast Decay

HSB1

Slo w Dec ay

Fast Decay

Slo w Dec ay

0880

Half-S tep Mode, DI R=0

Slo w Dec ay

04 48

Fast Decay

0484

Slo w Dec ay

Fast Decay

Mini -Step Mode, DIR=0 Mini -Step Mode, DIR=1

Slo w Dec ay

Fast Decay

02468 246 02468 246

Fast Decay

Slo w Dec ay

Micro-St ep Mode, DIR=0

HSA2

Slo w Dec ay

Fast Decay

HSB2

012345678 12345678 01234567 1234567

Slo w Dec ay

Fast Decay

Fast Decay

Slo w Dec ay

Fast Decay

Slo w Dec ay

0484

Fast Decay

Slo w Dec ay

Fast Decay

HSA1

Slo w Dec ay

Phase Counter

Current

Dr iv e r A

Current

Dr iv e r B

Step CLK

Phase Counter

Current

Dr iv e r A

Current

Dr iv e r B

Step CLK

Phase Counter

Current

Dr iv e r A

Current

Dr iv e r B

Step CLK

Phase Counter

Current

Dr iv e r A

Current

Dr iv e r B

Step CLK

Slo w Dec ay

Fast Decay

Half-S tep Mode, DI R=1

Slo w Dec ay

Fast Decay

Slo w Dec ay

Fast Decay

Slo w Dec ay

Micro-St ep Mode, DIR=1

Slo w Dec ay

Fast Decay

HSB1

Fast Decay

Slo w Dec ay

Fast Decay

Slo w Dec ay

Fast Decay

Fast Decay

HSA1

Slo w Dec ay

Slo w Dec ay

Fast Decay

0880

Slo w Dec ay

Fast Decay

Slo w Dec ay

Fast Decay

Slo w Dec ay

HSB2

Fast Decay

04840484

0246824602468246

01234567812345678012345671234567

081624

Fast Decay

0088

Slo w Dec ay

Fast Decay

Slo w Dec ay

Fast Decay

Slo w Dec ay

HSA2

Fast Decay

Slo w Dec ay

0481216202428

04480448

024681012141618202224262830

02460246246 24688

012345678910111213141516171819202122232425262728293031

01234567012345671234567 123456788

Tabl e 1 shows Phase Counter values where fast decay is active.

9/24

Page 10

Shorted coil detection AN2560

Table 1. Phase counter values for fast decay

Step Mode Bridge DIR=0 DIR=1

(1)

Full step

A (8) (24) (16

B (0) (16) (24

A (8, 12) (24, 28 (20, 16

Half step

B (0, 4) (16, 20) (28, 24

A (8, 10,12,14) (24,26,28,30) (22,20,18,16

Mini step

B (0, 2, 4, 6) (16,18,20,22) (30,28,26,24

A

(8,9,10,11,12,13,14,15)

(24,25,26,27,28,29,30,31)

Micro step

B

1. Current profile_0 must be greater than 0

(16,17,18,19,20,21,22,23)

(0, 1, 2, 3, 4, 5, 6, 7)

(23,22,21,20,19,18,17,16

(7, 6, 5, 4, 3, 2, 1, 0

(31,30,29,28,27,26,25,24

(15,14,13,12,11,10, 9, 8

(1)

) (0

)

(1)

(1)

) (8

)

(1)

(1)

(1)

(1)

(1)

) (4, 0

) (12, 8

) (6, 4, 2, 0

) (14,12,10, 8

(1)

)

(1)

)

(1)

)

(1)

)

(1)

)

)

(1)

)

(1)

)

2.1 Conclusion

To detect shorted coil in both bridges (A and B) and for all step modes (Full, Half, Mini and

Micro), it is necessary to change decay mode to Auto decay, fast decay without delay time at

phase counter values of 0 and 8 (or 16 and 24). For the opposite direction, DIR=1 can also

use 0 and 8 (or 16 and 24) but the amplitude of current profile_0 must be greater than 0.

This configuration is illustrated in Figure 4.

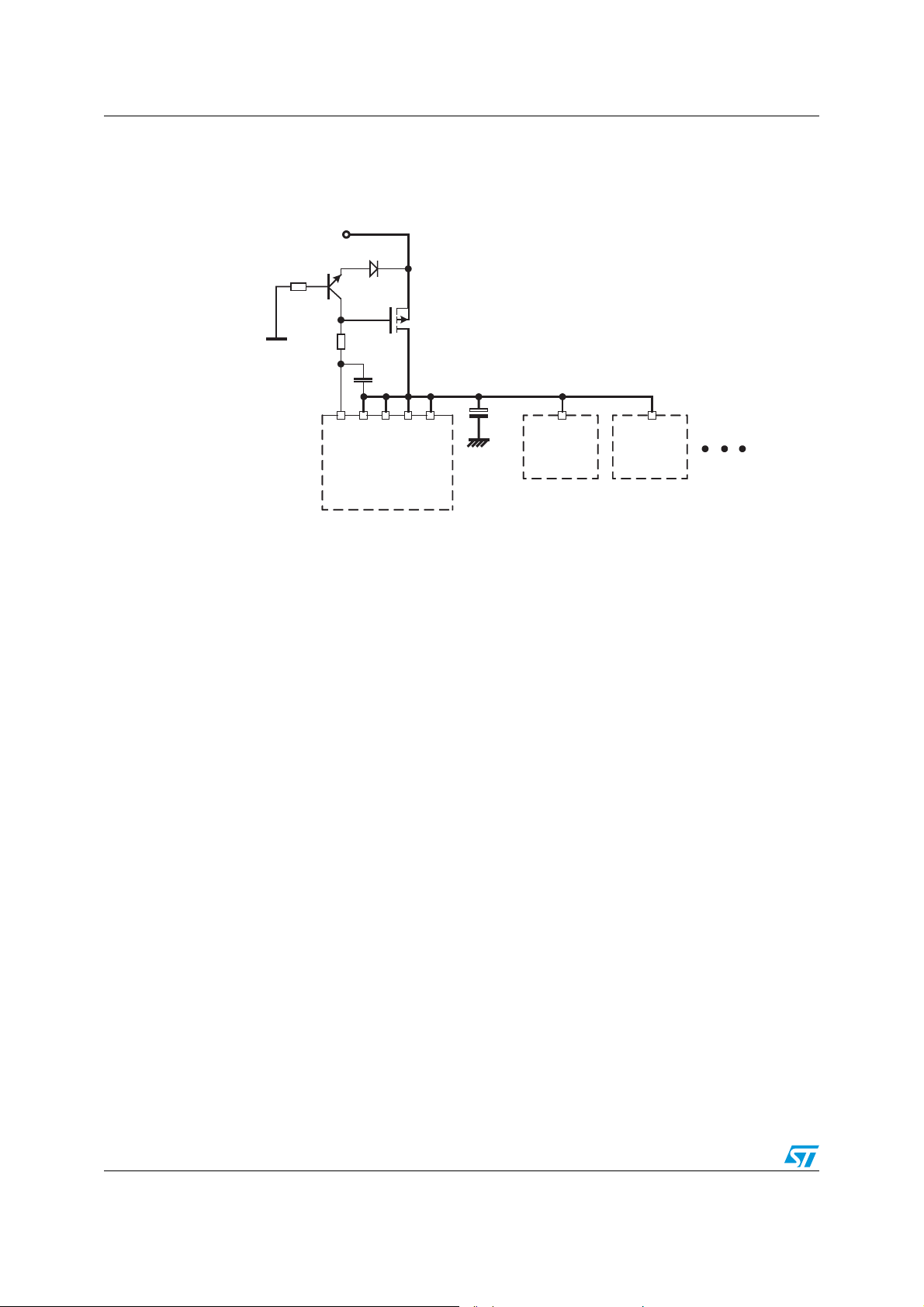

Figure 4. Auto decay, fast decay without delay time at phase 0 and 8

200ms

123456789 1 01 1121 31 4151 61 7181 92 0212 22 3242 52 6272 82 9303 1

phase

0

01234567 012345671234567123456788

012345678 12345678 01234567 1234567

Auto decay, fas t dec ay without delay time at phase 0 and 8 (DIR=0)

01234 1516171819202122232425262728293031

01234 01123456712345678

456787801234567 1234567

123456789 1 01 1121 31 4151 61 7

0

01234567 012345678

012345678 12345678

Note: Another possibility is to change the decay mode for Micro, Mini and Half Step mode at

phase counter values of 4 and 12 and for Full Step mode at phase counter values of 0 and

8.

10/24

Page 11

AN2560 SPI

3 SPI

3.1 Fault bit

Figure 5. SPI transfer timing diagram

CSN high to low: DO enabled

CSN

t

CSN_HI,min

time

CLK

DI

DO

Control and Status Register

1234 56789101101213141510

DI: data will be accepted on the rising edge of CLK signal

A1 A0 D12D11 D10 D9D8D7 D6 D5 D4A2 D3 D2 D1 D0

DO: data will change on the falling edge of CLK signal

D12D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

fault bit

actual data

status information

CSN low to high: actual data is

transfered to registers

old data

The first three bits of an SPI write frame are the register address. Thus, during this time, it is

not clear which register has to be written and read. This time is used at the DO-pin to

monitor the or-function of all diagnostic functions.

The register read out is started with the third falling edge of the SPI CLK. The read out is

finished 13 falling edges later and during the remaining time, until CSN is set to high, the orfunction of all diagnostic functions is monitored again.

Using this method, the failure status of the device can be checked without an SPI

communication. CSN is only pulled to low for a short while.

3.2 SPI communication monitoring

time

new data

A2 A1

time

D0

fault bit

actual data

time

time

SPI communication monitoring is described in the specification.

However, for register 0 the following two points should be considered.

1. During SPI communication, monitoring the STEP-pin must not be used. This could

cause the Phase Counter to be modified.

2. When not using the microstepping step mode, not all Current Profile Registers are

used. When sending a command to the Control Register 0 for SPI communication

monitoring with a Phase Counter value that not used in the selected step mode, the

device will correct the Phase Counter value itself. In this case, SPI communication

monitoring will fail.

11/24

Page 12

Decay modes AN2560

4 Decay modes

During the ON phase the current in the motor coil increases. After an ON phase, an OFF

phase follows that always starts with the cross current protection time (tcc).

The cross current protection time is automatically chosen with the slew rate and is typically

in the range from 0.5 to 4 µs.

After the cross current protection time, a programmed decay mode follows.

The basic decay modes of the stepper motor driver L9942 are:

● slow decay

● fast decay

● advanced decay modes, which are combinations of the slow and fast decay modes.

4.1 Slow decay

The slow decay mode realizes a minimum loss of energy in the motor coil. This means the

current decrease in the motor coil is “slow”.

Slow decay is illustrated in Figure 6.

Figure 6. Slow decay

I

L

„ON“

increase

I

L

Vs

ON

I

L

OFF

OFF

ON

cross current

protection

OFF

OFF

t

CC

t

slow

decay

Vs

BE

U

I

L

OFF

OFF

ON

OFF

Vs

Ron

ON

U

I

L

OFF

gnd

12/24

gnd

gnd

Page 13

AN2560 Decay modes

4.2 Fast Decay

The fast decay mode realizes a maximum loss of energy in the motor coil. This means the

current decrease in the motor coil is “fast”.

Fast decay is illustrated in Figure 7.

Figure 7. Fast decay

I

L

„ON“

increase

I

L

Vs

ON

OFF

I

L

gnd

OFF

ON

4.3 Advanced decay modes

With the stepper motor driver L9942, it is possible to combine the basic decay modes, slow

and fast decay.

4.3.1 Mixed decay

t

CC

cross current

protection

Vs

BE

OFF OFF

OFF

I

L

gnd

OFF

U

OFF

ON

fast

decay

t

Vs

Ron

ON

U

I

L

OFF

gnd

From the current point of view, for stepping down it is necessary to reduce the current in the

motor coil quickly. Therefore, a mostly slow decay is not useful because there is the danger

that the current in the motor coil does not reach the new (lower) current target. With fast

decay, the current undershoot may be stronger than necessary; this generates more EMI

than necessary.

A better result is obtained by mixing fast decay with slow decay. Mixed decay starts with fast

decay and switches to slow decay; the point for switching between the decay modes is

programmable. Mixed decay is shown in Figure 8.

13/24

Page 14

Decay modes AN2560

Figure 8. Mixed decay

I

● Mixed decay, fast decay until current undershoot

L

I

Target

t

t

CC

MD

I

II

t

In Figure 8, this behavior is shown with graph “I”. Fast decay is driven until the motor

coil current has undershot the target current and switches to slow decay until the end of

the phase.

● Mixed decay, fast decay until t

In Figure 8, this behavior is shown with graph “II”. The time t

cross current protection time tcc is over. After t

switches to slow decay. t

is programmable to 4µs or 8µs.

MD

> 4(8) µs

MD

is started after the

is finished the stepper motor driver

MD

MD

4.3.2 Auto decay

If the current in the motor coil is required to increase from step to step, it is sensible to save

the current in the motor coil. Therefore, the best decay mode is slow decay (see

Section 4.1).

If, on the other hand, the current in the motor coil should decrease from step to step, it is

sensible to reduce the current in the motor coil in a controlled way, as described in

Section 4.3.1. Therefore, the best decay mode is mixed decay.

The combination of slow decay for increasing current from step to step and mixed decay for

decreasing current from step to step is auto decay. A combination of slow decay and pure

fast decay is also possible but this option usually increases the EMI emission.

In Figure 9, auto decay is shown for one of the motor coils with micro stepping. For each

step, the appropriate current profile register is also shown.

Internally, a pointer moves from a current profile register to the next current profile register

with each StepCLK pulse. This start from the register 0 and goes step by step to register 8

and then back to register 0...

When the pointer is going in the direction from register 0 to 8, the L9942 uses slow decay.

When the pointer is going from register 8 to 0, mixed or fast decay is selected.

14/24

Page 15

AN2560 Decay modes

Figure 9. Auto decay

I

L

auto decay

fast or mixed

decay

t

t

012345678 1234567

slow decay

auto decay

StepCLK

V

current profile register

fast or mixed

slow decay

012345678 1234567

decay

● Auto decay, fast decay without delay time

Slow decay for current profile register going up (0 J 8) plus pure fast decay (see also

fast decay in Figure 7) for current profile register decreasing (8 I 0).

● Auto decay, fast decay until t

> 4(8) µs:

MD

Slow decay for current profile register going up (0 J8) plus mixed decay (see also

mixed decay in Figure 8, graph “II”) for current profile register decreasing (8 I0).

● Auto decay, fast decay until current undershoot

Slow decay for current profile register going up (0 I 8) plus mixed decay (see also

mixed decay in Figure 8, graph “I”) for current profile register increasing (0 J8).

15/24

Page 16

Stall detection AN2560

5 Stall detection

The stall detection function of the L9942 uses the reference drive of a stepper motor system,

such as that usually used in the start up phase of a front light levelling system.

5.1 Internal functionality (simplified)

The back EMF of the permanent magnetic rotor of the stepper motor is the effect that is

used for the stall detection function.

If the motor is turning “fast”, the back EMF is “high”. Thus, the voltage drop at the motor coils

is “low”. Combined with the inductance of the motor coils, it takes a “long” time to reach the

target current. Consequently, this means a “long” duty cycle of the pulse width modulation

(PWM).

If the motor is stopped mechanically, the back EMF is zero. Thus, the voltage drop at the

motor coils is “high”. Combined with the inductance of the motor coils, it takes a “short” time

to reach the target current. This means a “short” duty cycle of the PWM.

As is shown in Figure 10, an internal counter counts the duty cycle of the current regulation

PWM. This value is compared with a value given from the microcontroller via the SPI. If this

value is less than the one supplied by the microcontroller, the stall detection bit is set.

Figure 10. Stall detection function overview

I

L

PWM

PWM current

regulation

t

001000

From SPI

010011

for cur. reg.

counting

duty cycle

comp.

t

stall detection bit

16/24

Page 17

AN2560 Stall detection

5.2 How to determine the stall threshold at bench test

There are four steps to determine the stall threshold.

1. Drive motor in an environment with parameters as in a possible stall situation.

2. Run the motor so that it is turning continually and increase the stall threshold step by

step until the stall bit is set. This stall threshold value is called the “high value”.

3. With the same electrical conditions as before, stop the motor mechanically. Decrease

the stall threshold from the “high value”. After some steps the stall bit is reset. This stall

threshold value is called the “low value”.

4. The stall threshold is the middle value between the “high value” and the “low value”.

17/24

Page 18

Duty cycle for current regulation AN2560

6 Duty cycle for current regulation

The duty cycle for current regulation is always switched on for a minimum time and has a

maximum time of less than 100%.

6.1 Minimum duty cycle

The minimum duty cycle is the sum of the “Glitch filter delay time”, the “Slew rate” and the

“Cross current protection time”. The “Slew rate” and the “Cross current protection time” are

programmed with the same bits.

6.2 Maximum duty cycle

The maximum duty cycle is less then 100%. The negligible off time is related to the “Cross

current protection time”. “Cross current protection time” is illustrated in Figure 11.

Figure 11. Cross current protection time and slew rate for maximum DC

OUT

ON

Slew Rate B

OFF

Slew Rate A

t

T

CC

t

18/24

Page 19

AN2560 Power dissipation

7 Power dissipation

The calculation of the power dissipation depends upon the selected slew rate and decay

mode of the device. In Figure 12 the set up was selected with a fast decay.

Figure 12. Current flow and voltage drop during fast decay

V

OUT-A

V

OUT-B

PWM

Vs

ON

OUT-B

OFF

Vs

I

L

OFF

OUT-A OUT-A

ON

gnd

OFF

OUT-B

ON

Vs

Ron

ON

U

I

L

OFF

gnd

ON FW fast decay

t

t

r/f

t

Pulse

t

D

t

For a rough calculation of the power dissipation, three different phases are selected:

1. static ON

2. static free wheeling (FW), fast decay

3. dynamic on and off with slew rate.

7.1 Static ON

Only the RDS,on of the high and low side switches are used for generating power

dissipation.

19/24

Page 20

Power dissipation AN2560

7.2 Static freewheeling

Only the RDS,on of the high and low side switches are used for free wheeling and

generating power dissipation.

7.3 Dynamic slew rate power dissipation

During the H-bridge switching, the voltage and the current chang in a triangular form with

the defined slew rate.

7.4 Power dissipation for one PWM phase

The temporary power dissipations, explained above, are summed for the complete PWM

phase.

PP

ON

PP

ON

P2R

DS ON,

t

Pulstr

--------------------------- - P

f⁄–

t

D

FW

tD2trf⁄⋅–

---------------------------- 2P

t

D

2

I

⋅⋅+⋅=

tD2trf⁄⋅–

----------------------------

⋅ UI

t

D

tDt

Pulstr

--------------------------------------- P

t

D

trf⁄

-------- -

SR

t

D

t

f⁄

r

-------- -

⋅⋅+⋅⋅=

t

D

f⁄––

SR

2trf⁄⋅

---------------- -

⋅+⋅+⋅=

t

D

20/24

Page 21

AN2560 PCB footprint proposal

8 PCB footprint proposal

Figure 13. Power SSO24 solder mask layout (all values in mm)

21/24

Page 22

PCB footprint proposal AN2560

Figure 14. Power SSO24 solder mask opening (all values in mm)

22/24

Page 23

AN2560 Revision history

9 Revision history

Table 2. Document revision history

Date Revision Changes

2-Nov-2007 1 Initial release.

23/24

Page 24

AN2560

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

24/24

Loading...

Loading...