Page 1

AN2641

Application note

Using the color LCD controller (CLCD)

in the SPEAr embedded MPU family

Introduction

The SPEAr embedded MPU family is family of configurable MPUs, based on the ARM926

CPU core. Several members the SPEAr MPU family have an embedded ARM PL-110 ColorLCD controller (CLCD). This Application Note describes how to configure and operate any

type of color LCD with the CLCD controller and provides application developers with

troubleshooting information on common integration issues.

Color display devices play an important role in any embedded system, since usually

displays are the most visible output devices.

In SPEAr, the CLCD is connected internally to the AHB bus and acts as a bus master-slave

module. The CLCD performs translation of pixel-coded data into the required formats and

timings to drive a variety of single/dual mono and color STN as well as color TFT LCD

displays. The CLCD fetches the data for display from a frame buffer and uses its own

dedicated DMA controller to transfer the display data to the LCD panel.

October 2009 Doc ID 14027 Rev 1 1/37

www.st.com

Page 2

Contents AN2641

Contents

1 Overview of the CLCD controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 CLCD panel programmable parameters . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Panel dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.1 X and Y resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.2 Synchronization parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.3 Dimension related registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Panel clock source and frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.1 Clock related registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Panel display type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.1 Display related registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 CLCD controller dataflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Data related registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 Enabling and disabling the CLCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 CLCD interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1 Interrupt causes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2 Interrupt related registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 Linux frame buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1 Frame buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2 Kernel level modifications for CLCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.3 User level perspective of CLCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.3.1 Data structures for user level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.3.2 User level application sample . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.4 More details on the frame buffer in Linux . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.4.1 Data structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.4.2 A brief look at the source files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7 Touchscreen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.1 Theory of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.2 Linux input layer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2/37 Doc ID 14027 Rev 1

Page 3

AN2641 Contents

7.3 Calibration process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.1 Video flickering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.2 Video tearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.3 White screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9 Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Doc ID 14027 Rev 1 3/37

Page 4

List of tables AN2641

List of tables

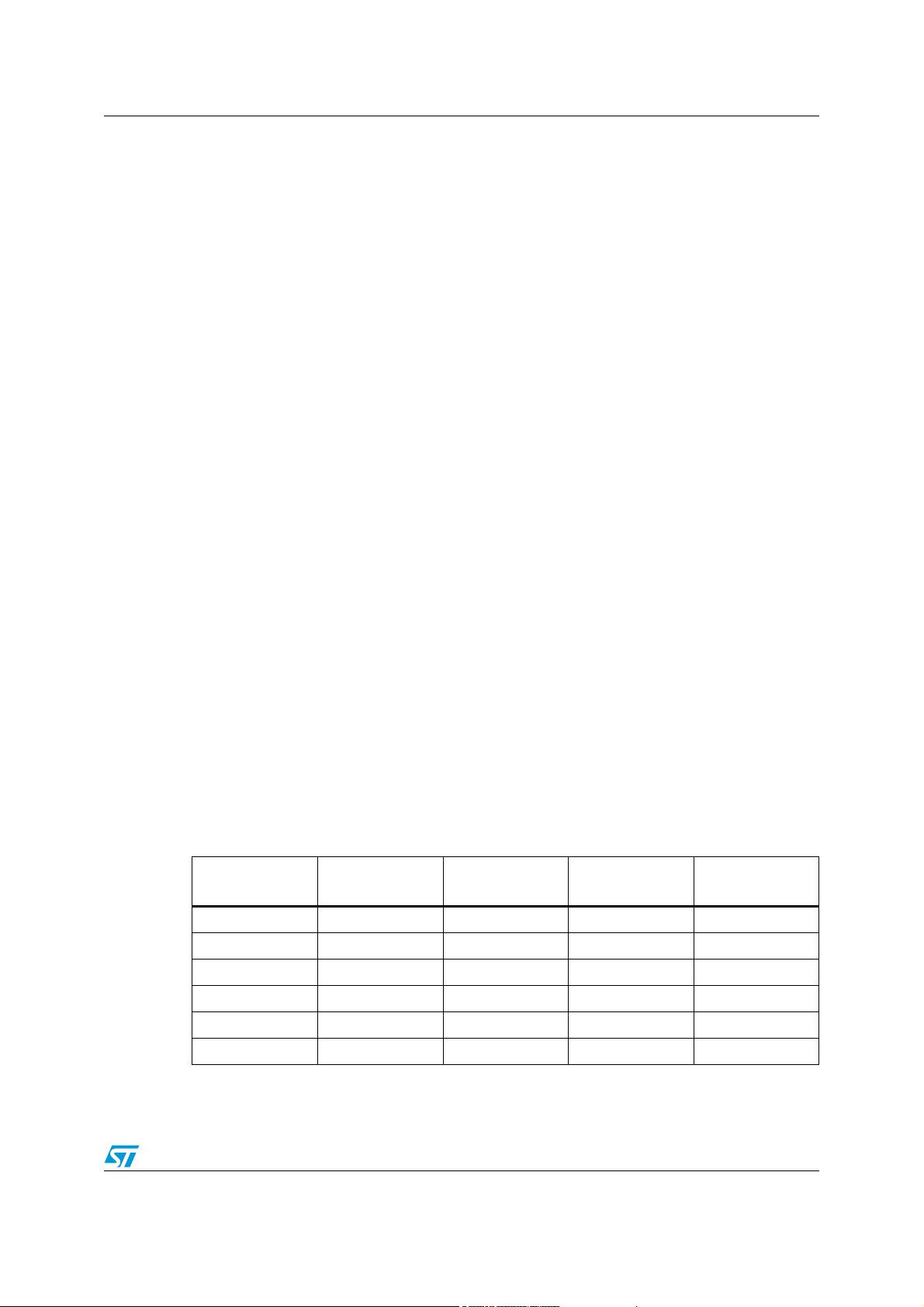

Table 1. Different display types and their properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 2. Palette data storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 3. Source code information on frame buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 4. Acronyms used in this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 5. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4/37 Doc ID 14027 Rev 1

Page 5

AN2641 List of figures

List of figures

Figure 1. A basic CLCD panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 2. CLCD panel layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 3. PLL2 connection for CLCD clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 4. Data flow in CLCD controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 5. CLCD OFF/ON sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 6. Advantage of using the frame buffer architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 7. CLCD panel structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 8. Return CLCD panel structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 9. Entry of CLCD info for menu config . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 10. CLCD selection from menu config - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 11. CLCD selection from menu config - 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 12. Structure fb_var_screeninfo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 13. Structure fb_fix_screeninfo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 14. Structure fb_cmap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 15. A sample user application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 16. Structure fb_info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 17. Structure fb_ops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 18. Touchscreen state machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 19. Sequence of events from touchscreen driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 20. Appearance of calibration tool for touchscreen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Doc ID 14027 Rev 1 5/37

Page 6

Overview of the CLCD controller AN2641

1 Overview of the CLCD controller

Main features:

● Dual 16-deep programmable 32-bit wide FIFOs for buffering incoming display data

● Supports single and dual panel mono Super Twisted Nematic (STN) displays with 4 or

8-bit interfaces

● Supports single and dual-panel color and monochrome STN displays

● Supports Thin Film Transistor (TFT) color displays

● Resolution programmable up to 1024 x 768

● 15 gray-level mono, 3375 color STN, and 32K color TFT support

● 1, 2, or 4 bits-per-pixel (bpp) palettized displays for mono STN

● 1, 2, 4 or 8 bpp palettized color displays for color STN and TFT

● 16 bits-per-pixel (bpp) true-color non-palettized, for color STN and TFT

● 24 bpp true-color non-palettized, for color TFT

● Programmable timing for different display panels

● 256 entry, 16-bit palette RAM, physically arranged as a 128 x 32-bit RAM

● Frame, line and pixel clock signals

● AC bias signal for STN and data enable signal for TFT panels

● Patented gray scale algorithm

● Supports little-endian, big-endian or WinCE data formats

● LCD can support standard panel resolutions such as:

– 320 x 200, 320 x 240

– 640 x 200, 640 x 240, 640 x 480

– 800 x 600

– 1024 x 768

Types of LCD panel supported are:

● Active matrix TFT panels with up to 24-bit bus interface

● Single-panel monochrome STN panels (4-bit and 8-bit bus interface)

● Dual-panel monochrome STN panels (4-bit and 8-bit bus interface per panel)

● Single-panel color STN panels, 8-bit bus interface

● Dual-panel color STN panels, 8-bit bus interface per panel

● Compliance to the AMBA Specification (Rev 2.0) onwards for easy integration into the

SPEAr MPU device

6/37 Doc ID 14027 Rev 1

Page 7

AN2641 CLCD panel programmable parameters

X-resolution

Y-res

olution

(0.0)

(0.X)

(X,Y)

(0,Y)

2 CLCD panel programmable parameters

To allow the CLCD controller to interface with the CLCD panel you intend to use in your

application, you have to program a set of parameters, which varies according to the type of

CLCD. For example, some parameters depend upon CLCD dimensions and

synchronization, other parameters depend on the CLCD clock source and frequency, or the

display panel type.

2.1 Panel dimensions

This section describes the parameters and the corresponding registers that depend on the

LCD dimensions: X and Y resolution, vertical and horizontal synchronization.

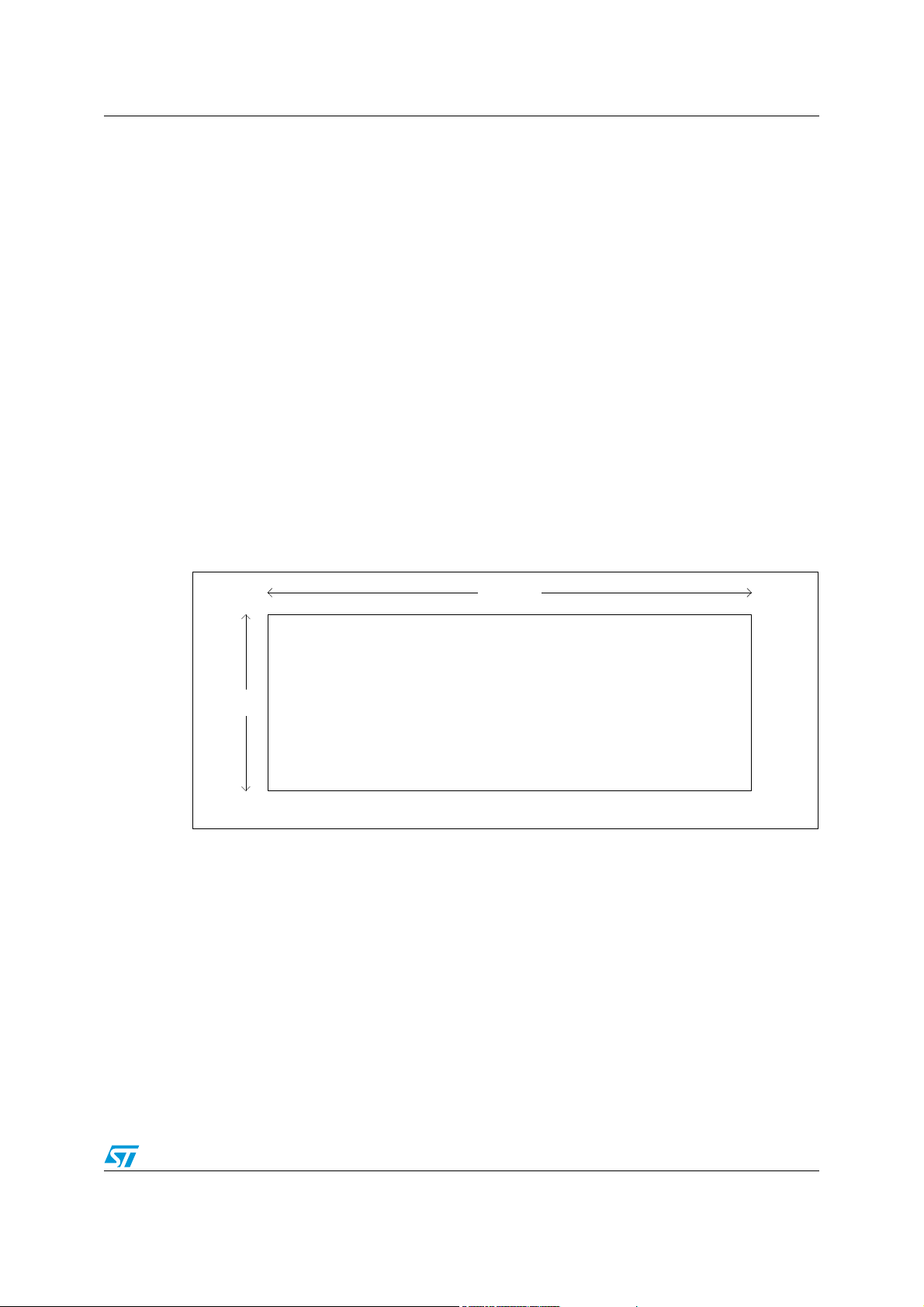

2.1.1 X and Y resolution

The entire screen of CLCD is composed of pixels, each pixel a single dot. The number of

pixels along the horizontal axis forms the X-resolution and the number of pixels along the

vertical axis make up the Y-resolution. X-resolution and Y-resolution are also known

respectively as the number of pixels per line and the number of lines per panel.

Figure 1. A basic CLCD panel

One common example is a 480 x 272 CLCD panel, which has 480 pixels horizontally and

272 pixels vertically.

2.1.2 Synchronization parameters

To draw any image on a CLCD panel, the screen is first scanned left to right is scanned and

then the screen is scanned top to bottom. After each scan-line, the electron beam has to

move back to the left side of the screen and to the next line, this is called the horizontal

retrace. After the whole screen (frame) is painted, the beam moves back to the upper left

corner, this is called the vertical retrace.

Since the CLCD panel does not know when a new scan-line starts, the CLCD controller

generates a synchronization pulse (Horizontal Sync Width) for each scan-line. Similarly, it

supplies a synchronization pulse (Vertical Sync Width) for each new frame. The position of

the image on the screen is controlled by the timing of the synchronization pulses.

Doc ID 14027 Rev 1 7/37

Page 8

CLCD panel programmable parameters AN2641

vertical back porch

vertical front porch

vertical sync pulse width

Y-res

horiz

back

porch

horiz

sync

pulse width

horiz

front

porch

X-res

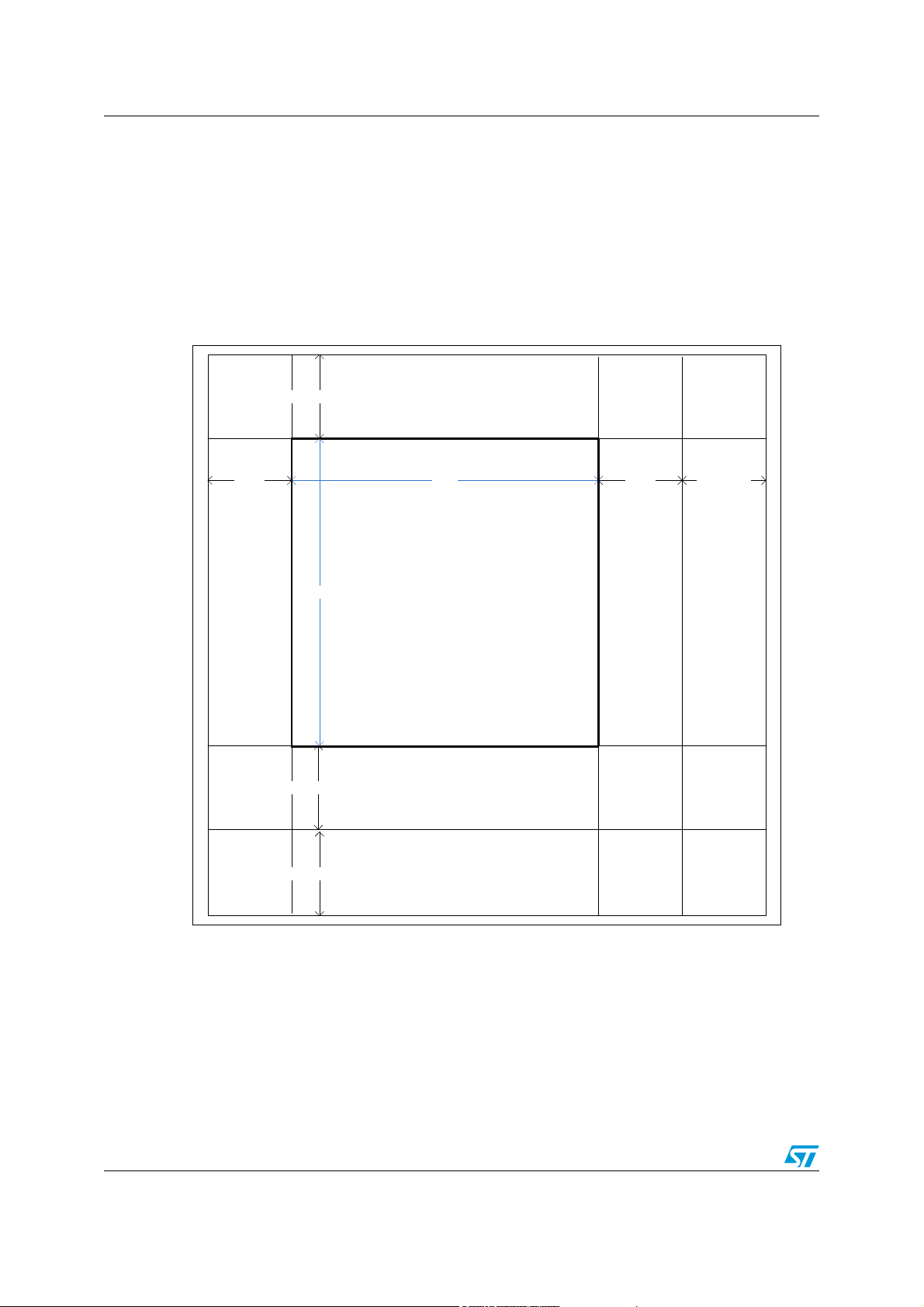

Figure 2 summarizes all the synchronization timings. The horizontal retrace time is the sum

of the horizontal back porch, the horizontal front porch and the horizontal sync width, while

the vertical retrace time is the sum of the vertical back porch, the vertical front porch and the

vertical sync width.

The horizontal front porch is the time from picture to sync and horizontal back porch is the

time from sync to picture.

The vertical front porch is the time from picture to sync and the vertical back porch is the

time from sync to picture.

Figure 2. CLCD panel layout

2.1.3 Dimension related registers

8/37 Doc ID 14027 Rev 1

1. HBP, 8-bit [31:24] field in the LCD-Timing1 register: specifies the number of pixel

clock periods inserted at the beginning of each line or row of pixels. After the line clock

for the previous line has been de-asserted, the value in HBP counts the number of pixel

clocks to wait before starting the next display line. HBP can generate a delay of 1-256

pixel clock cycles.

2. HFP, 8-bit [23:16] field in the LCD-Timing1 register: sets the number of pixel clock

intervals at the end of each line or row of pixels, before the LCD line clock is pulsed.

Page 9

AN2641 CLCD panel programmable parameters

When a complete line of pixels is transmitted to the LCD driver, the value in HFP counts

the number of pixel clocks to wait before asserting the line clock. HFP can generate a

period of 1-256 pixel clock cycles.

3. HSW, 8-bit [15:8] field in the LCD-Timing1 register: specifies the pulse width of the

line clock in passive mode, or the horizontal synchronization pulse in active mode.

4. PPL, 6-bit [7:2] field in the LCD-Timing1 register: is a value that represents between

16 and 1024 PPL. PPL controls how much data is read from the DMA input buffers

through to the gray-scaler as follows:

Actual pixels-per-line = 16 * (PPL + 1)

The Actual pixels-per-line specifies the number of pixels in each line (or row) of the

screen.

5. VBP, 8-bit [31:24] field, in the LCD-Timing1 register: specifies the number of line

clocks inserted at the beginning of each frame. The VBP count starts just after the

vertical synchronization signal for the previous frame has been negated for active

mode, or the extra line clocks have been inserted as specified by the VSW bit field in

passive mode. After this has occurred, the count value in VBP sets the number of line

clock periods inserted before the next frame. VBP generates from 0-255 extra line clock

cycles.

6. VFP, 8-bit [23:16] field, in the LCD-Timing1 register: specifies the number of line

clocks to insert at the end of each frame. When a complete frame of pixels is

transmitted to the LCD display, the value in VFP is used to count the number of line

clock periods to wait.

After the count has elapsed, the CLFP vertical synchronization signal, is asserted in

active mode, or extra line clocks are inserted as specified by the VSW bit-field in

passive mode. VFP generates from G0-255 line clock cycles.

7. VSW, 6-bit [15:10] field, in the LCD-Timing1 register: specifies the pulse width of the

vertical synchronization pulse. The register is programmed with the number of line

clocks in VSync minus one.

8. LPP, 10-bit [9:0] field, in the LCD-Timing1 register: specifies the total number of

lines or rows on the LCD panel being controlled. LPP has an allowed range 1-1024

lines. The register is programmed with the number of lines per LCD panel minus 1. For

dual panel displays this register is programmed with the number of lines on each of the

upper and lower panels.

2.2 Panel clock source and frequency

CLCD_CLK is a free running reference clock (currently 48 MHz), which drives the CLCD

controller.

CLCP, the output of the panel clock generator, is the CLCD panel clock frequency which

goes from the CLCD controller to the CLCD panel. CLCP can be programmed in the range

from CLCD_CLK/2 to CLCD_CLK/33 to match the BPP data rate of the LCD panel.

If the CLCD panel requires a frequency outside this range (CLCD_CLK/2 to

CLCD_CLK/33), then an alternative route is to use another clock source (for example PLL2

or AHB) instead of CLCD_CLK and use a prescaler to obtain the desired frequency.

● One choice is to select the AHB as input clock. This can be done just using software

modifications. You can select the AHB clock source using the CLKSEL bit and can

divide the AHB frequency using the PCD bits. All these registers are described in the

Doc ID 14027 Rev 1 9/37

Page 10

CLCD panel programmable parameters AN2641

RAS

ARM

Clock synthesizer

Pll1

Pll2

DDR

Control

ler

PL_CLK3

GPIO(1)

CLCD clock

next section. Using this technique it is possible to generate a frequency of AHB/2,

AHB/3, and AHB/4...etc. for CLCP.

● Another choice is to use PLL2. The connection is shown in Figure 3.

– In SPEAr600 the PLL2 output frequency can be taken directly from the clock

synthesizer.

– In SPEAr300, an additional connection at board level is required: GPIO (1) must

be shorted to PL_CLK3.

Figure 3. PLL2 connection for CLCD clock

2.2.1 Clock related registers

1. CLKSEL, bit [5] in the LCD-timing-2 register, drives CLCDCLKSEL which is the

select signal for the external LCD clock multiplexer.

2. Clocks per Line (CPL) field [25:16] in the LCD-Timing2 register, specifies the

number of actual CLCP clocks for each line of the LCD panel. This is the number of

PPL divided by 1 for TFT displays.

3. Panel Clock Divisor (PCD), bits [31:27] & [4:0] in the LCD-Timing2 register, is used

to derive the LCD panel clock frequency CLCP from the CLCDCLK frequency as

follows:

CLCP = CLCDCLK / (PCD+2)

For TFT, the PCD can be bypassed by setting the BCD bit.

4. Bypass pixel clock divider (BCD), bit [26] in the LCD-Timing2 register. Setting this

to 1 bypasses the PCD logic. This is mainly used for TFT displays.

5. Invert Output Enable (IOE) bit [14] in the LCD-Timing2 register, used to select the

10/37 Doc ID 14027 Rev 1

active polarity of the output enable signal in TFT mode. In this mode, the CLAC pin is

Page 11

AN2641 CLCD panel programmable parameters

used as an enable that indicates to the LCD panel when valid display data is available.

In active display mode, data is driven onto the LCD data lines at the programmed edge

of CLCP when CLAC is in its active state.

0 = CLAC output pin is active HIGH in TFT mode

1 = CLAC output pin is active LOW in TFT mode

6. Invert panel clock (IPC) bit [13] in the LCD-Timing2 register, used to select the

edge of the panel clock on which pixel data is driven out onto the LCD data lines.

0 = Data is driven on the LCD data lines on the rising edge of CLCP

1 = Data is driven on the LCD data lines on the falling edge of CLCP

7. Invert Horizontal Synchronization (IHS) bit [12] in the LCD-Timing2 register, used

to invert the polarity of the CLLP signal.

0 = CLLP pin is active HIGH and inactive LOW

1 = CLLP pin is active LOW and inactive HIGH

8. Invert Vertical Synchronization (IVS) bit [11] in the LCD-Timing2 register, is used

to invert the polarity of the CLFP signal.

0 = CLFP pin is active HIGH and inactive LOW

1 = CLFP pin is active LOW and inactive HIGH.

9. AC bias pin frequency (ACB) bits [10:6] in the LCD-Timing2 register, applies only

to STN displays, which require the pixel voltage polarity to be periodically reversed to

prevent damage due to DC charge accumulation. Program this field with the required

value minus 1 to apply the number of line clocks between each toggle of the AC bias

pin, CLAC. This field has no effect if the CLCD controller is operating in TFT mode

when the CLAC pin is used as a data enable signal.

2.3 Panel display type

The CLCD controller supports the following types of LCD panels:

● TFT (Thin Film Transistor) display: Active matrix display panels which require a

digital color value of each pixel to be applied to the display data inputs.

● STN (Super Twisted Nematic) display: Passive matrix display panels that require

algorithmic pixel pattern generation to provide pseudo gray scaling on mono or color

creation for display (for which a dedicated hardware element, grey scalar, is provided).

Table 1. Different display types and their properties

LCD type Single/dual panel

TFT Single Non-Palettized Color 24

TFT Single Non-Palettized Color 16

TFT Single Palettized Color 1, 2, 4 and 8

STN Single and Dual Non-Palettized Color 16

STN Single and Dual Palettized Color 1, 2, 4 and 8

STN Single and Dual Palettized Mono 1,2 and 4

Palettized/non-

palettized

Mono/color BPP

Doc ID 14027 Rev 1 11/37

Page 12

CLCD panel programmable parameters AN2641

2.3.1 Display related registers

1. LCD TFT, bit [5] in the LCD-Control register, selects the display type. For TFT, set to

1. For STN, set to 0.

2. LCD Dual, bit [7] in the LCD-Control register, selects dual or single STN panel. For

dual panel STN, set to 1, for single panel STN, set to 0. If TFT panel is used then set to

0.

3. LCD Mono bit [6] in the LCD-Control register, controls whether monochrome STN

LCD uses a 4 or 8-bit parallel interface. Set to 0 if mono LCD uses 4-bit interface and

set to 1 if mono LCD uses 8-bit interface. This bit has no meaning in other modes and

must be programmed to zero.

4. LCD BW bit [4] in the LCD-Control register, selects monochrome or color STN

panel. If STN LCD is monochrome (black and white), set to 1. If STN LCD is color, set

to 0. This bit has no meaning in TFT mode.

5. The color palette register is described in next section.

12/37 Doc ID 14027 Rev 1

Page 13

AN2641 CLCD controller dataflow

FIFO

CTR

UP

DMA

FIFO

LP

DMA

FIFO

PIXEL

SERIALIZER

PALETTE

GREY

SCALING

ALGO

UPPER

PANEL

OUTPUT

FIFO

LOWER

PANEL

OUTPUT

FIFO

STN/TFT

DATA

SELECT

FRAME

BUFFER

LCD

PANEL

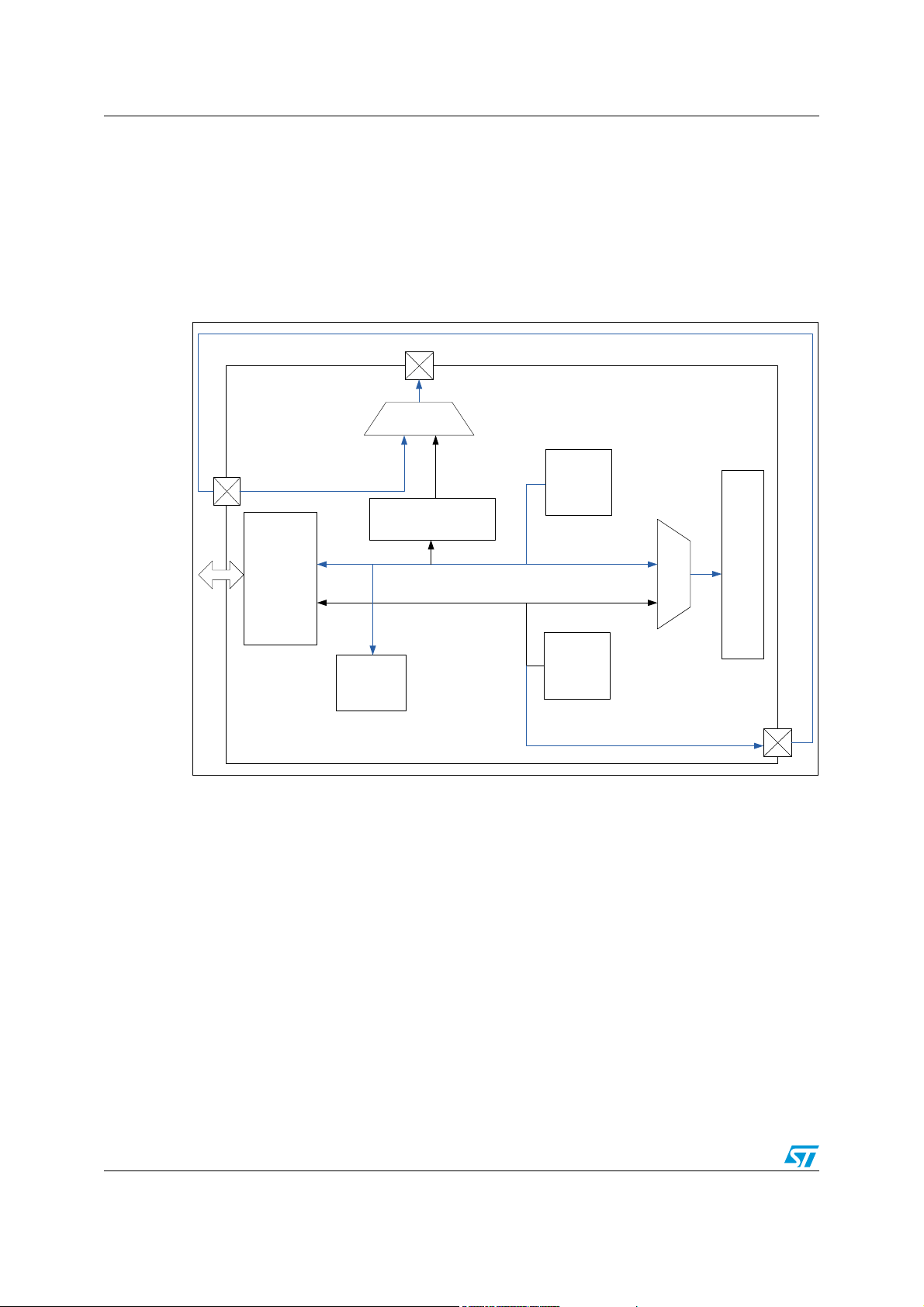

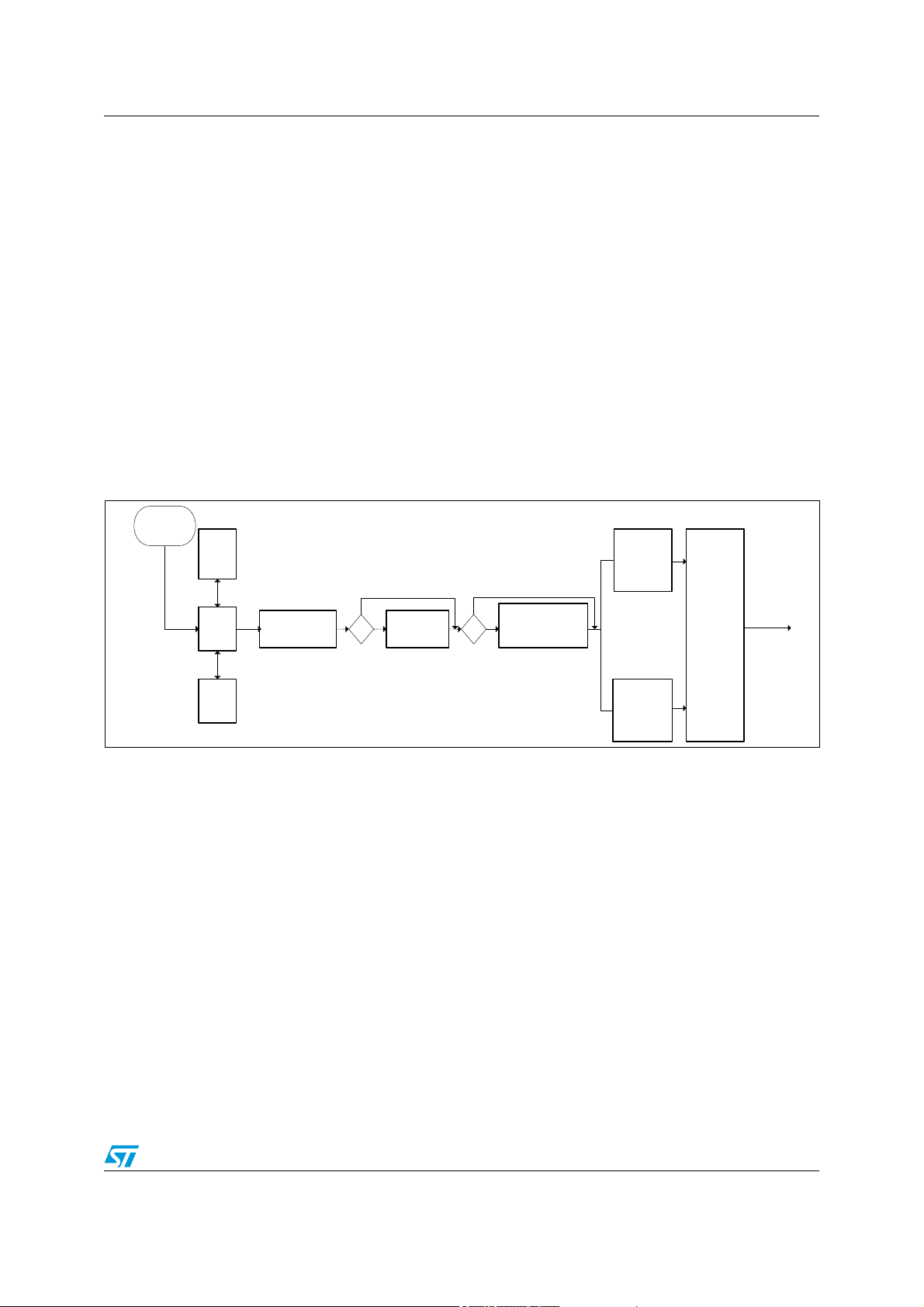

3 CLCD controller dataflow

Packets of pixel-coded data are first stored in memory (frame buffer). Then, they are fed, via

the AHB interface, to dual 16-deep 32 bit-wide DMA FIFO, both of which act as input data

flow buffers. The buffered pixel-coded data is then unpacked via a pixel serializer.

Depending on the LCD type and mode, the unpacked data may represent:

● an actual true display gray or color value or

● an address in a 256 x 16 bit wide palette RAM containing a gray or color value

In the case of STN displays, either a palette value or the true value is passed to the gray

scaling generators. The hardware coded gray scale algorithm logic sequences the

addressed pixels activity over a programmed number of frames to provide the effective

display appearance.

For TFT display, either an addressed palette value or true color value is passed directly to

the output display drivers.

Figure 4. Data flow in CLCD controller

Figure 4 shows the Data Flow in the respective hardware blocks. There are 2 decision

boxes.

First decision box - using the palette RAM:

● Dependent upon the LCD type and code, the unpacked data may represent:

– An actual true display gray or color value (16 BPP or higher) or

– An address to a 256 x 16 bit wide palette RAM gray or color value (1, 2, 4 or 8

BPP)

● Palette use is linked to display type and mode. A palette is used by:

– Mono STN displays with 1, 2 or 4 BPP

– Color STN or TFT displays with 1, 2, 4, 8 BPP

Otherwise, non-palettized true-color is used.

Second decision box - using the grey scaling algorithm:

● In the case of STN displays, either a palette value or the true value is passed to the

gray scaling generators. The hardware coded grey scale algorithm logic sequences the

Doc ID 14027 Rev 1 13/37

Page 14

CLCD controller dataflow AN2641

activity of the addressed pixels over a programmed number of frames to provide the

effective display appearance.

● For TFT displays, either an addressed palette value or true color value is passed

directly to the output display drivers, always bypassing the grey scale algorithm logic.

Three major components of the data flow are:

1. Pixel Serializer, this block reads the 32-bit wide LCD data from output port of the DMA

FIFO and extracts 24, 16, 8, 4, 2 or 1 BPP data, depending on the current mode of

operation. The CLCD controller supports big endian, little endian and WinCE data

formats.

Dependent upon the operation mode, the extracted data may be used to point to a

color/gray scale value in the palette RAM or may actually be a true color value that can

be directly applied to an LCD panel.

2. Palette RAM is a 256 x 16 bit dual port RAM (physically structured as 128 x 32 bits)

with independent controls and addresses for each port. Port1 is used as a read/write

port and is connected to the AMBA AHB slave interface. The palette entries can be

written and verified through this port. Port2 is used as a read-only port and is

connected to the gray scalar.

Ta bl e 2 shows the bit representation of each word in the palette.

Table 2. Palette data storage

Bit Name Description

[31] I Intensity/unused

[30:26] B [4:0] Blue palette data

[25:21] G [4:0] Green palette data

[20:16] R [4:0] Red palette data

[15] I Intensity/unused

[14:10] B [4:0] Blue palette data

[9:5] G [4:0] Green palette data

[4:0] R [4:0] Red palette data

3. A gray scale algorithm drives mono and color STN panels. This provides 15 gray

scales for mono displays. In the case of STN color displays, the three color components

(RGB) are gray scaled simultaneously which results in 3375 (15 x 15 x 15) available

colors. The gray scalar transforms each 4-bit gray value into a sequence of activity-perpixel over several frames to give the representation of gray scales and colors.

14/37 Doc ID 14027 Rev 1

Page 15

AN2641 CLCD controller dataflow

3.1 Data related registers

1. Panel frame base address register, is the CLCD DMA frame address read/write

register, which is used to program the base address of the frame buffer.

For example, if frame data is at a given location X then you just have to write X in this

register. This location X must be word-aligned.

Bits [1:0] are reserved but you do not need to explicitly shift the address before writing

to this register. You simply write the base address and the shift is handled automatically

by the controller hardware.

2. Panel current address value register is a read-only register that contains an

approximate value of the upper and lower panel data DMA addresses when read. The

registers can change at any time and therefore can be used for testing or for a coarse

delay mechanism.

3. BEBO (big-endian byte order), bit [9] in the LCD-control register, selects the byte

order. For little-endian byte order, set to 0. For big-endian byte order, set to 1.

4. BEPO (big-endian pixel ordering within a byte), bit [10] in the LCD-control

register. Setting 0 will do little-endian pixel ordering within a byte and setting 1 will do

big-endian pixel ordering within a byte. The BEPO bit selects between little and bigendian pixel packing for 1, 2 and 4 BPP display modes. It has no effect on 8 or 16 BPP

pixel formats.

5. BGR, bit [8] in the LCD-control register does RGB or BGR selection. Setting to 0 will

have RGB as normal output and 1 will be BGR (red and blue swapped)

6. BPP (bits-per-pixel) bits [3:1] in the LCD-control register, select the BPP. The

controller can support 1, 2, 4, 8, 16, and 24 BPP.

24 BPP (means each pixel can be represented by 24 bits) is for TFT only. However, we

actually use 32 bits, so 24 bits are for RGB (8 bits each) and the remaining 8 bits are

reserved or can be used for transparency.

Doc ID 14027 Rev 1 15/37

Page 16

Enabling and disabling the CLCD AN2641

Enable control signal

Enable data and power signal

Disable control signal

Disable data and power signal

Small delay to let the signal stabilize

Small delay to tet the signal stabilize

CLCD display and working

4 Enabling and disabling the CLCD

The procedure for enabling and disabling the CLCD is shown in Figure 5. The delay for

signal stabilization depends on the display type.

Caution: If the delay is too short or non existent, the panel may not work properly and sometimes

hangs with a white screen.

Figure 5. CLCD OFF/ON sequence

● Enable the control signals by setting the LCD controller enable bit [0] in the LCD-control

● Connect the power to the CLCD panel by setting LCD power enable bit [11] in the LCD-

16/37 Doc ID 14027 Rev 1

register to 1. To disable the control signals, set this bit to 0.

control register to 1. To disconnect the power from the panel, set this bit to 0.

Page 17

AN2641 CLCD interrupts

5 CLCD interrupts

The CLCD interrupt is connected the vectored interrupt controller (VIC) as follows:

● SPEAR600: IRQ45 (CLCD_INTR)

● SPEAr300: IRQ30 (generic Interrupt #3 from RAS)

5.1 Interrupt causes

There are 4 kinds of event that can cause an CLCD interrupt:

1. DMA FIFO underflow:

The FIFO underflow interrupt is asserted when data is requested from an empty DMA

FIFO. Note that the size of the DMA FIFO is 32 words.

Setting Watermark Level bit as 1 will cause this interrupt when DMA FIFO has eight or

more empty locations. Setting Watermark Level bit as 0 will cause this interrupt when

DMA FIFO has four or more empty locations.

The interrupt requests the display data from memory, to fill the FIFO to above the

programmed watermark.

2. Base address update:

The LCD base address update interrupt is asserted when the 'LCD panel frame buffer

base' values are transferred to the 'Current LCD panel frame buffer base'

incrementors. This signals to the system that it is safe to update the 'LCD panel frame

buffer base' registers with new frame base addresses if required.

This interrupt is mainly used to reprogram the base address when generating doublebuffered video.

3. Vertical compare:

The vertical compare interrupt is asserted when one of four vertical display regions, is

reached. By setting the following values in the LCD V-comp bit in the Control Register

the interrupt can be generated at the:

00 = Start of vertical synchronization

01 = Start of back porch

10 = Start of active video

11 = Start of front porch

4. Bus Error:

The master bus error interrupt is asserted when an ERROR response is received by

the master interface during a transaction with a slave. When this error is encountered,

the master interface enters an error state and remains in this state until clearance of the

error has been signaled to it (possibly by the interrupt service routine).

● A single combined interrupt is asserted if any of the above four interrupt lines is

asserted and each interrupt event is handled respectively by the interrupt service

routine.

5.2 Interrupt related registers

There are four registers which are used for handling Interrupts:

Doc ID 14027 Rev 1 17/37

Page 18

CLCD interrupts AN2641

1. Interrupt clear register is a write-only register. Writing logic 1 to the relevant bit clears

the corresponding interrupt. This register is mainly used by the interrupt service routine

to clear the interrupt, once it is handled.

2. Raw interrupt status register is a read-only register. On a read it returns five bits that

can generate interrupts when set. This register can be used to check whether an

interrupt occurred.

3. Interrupt mask set/clear register is used to enable the corresponding raw interrupt in

the 'Raw Interrupt Status register' (bit values) to be passed to the 'Masked Interrupt

Status register'. This read/write register can disable or enable an interrupt.

4. Masked interrupt status register is a read-only register. It is a bit-by-bit logical AND

of the 'Interrupt Mask Set/Clear register' and the 'Raw Interrupt Status register'.

Interrupt lines correspond to each interrupt. This register can be used to check whether

an interrupt is masked.

18/37 Doc ID 14027 Rev 1

Page 19

AN2641 Linux frame buffer

GUI, Console, Movie

Players etc

Common framebuffer API

Framebuffer driver 1 Framebuffer driver N

Video card 1 Video card N

… Video cards having

different graphics

controllers

6 Linux frame buffer

This section describes how to use the CLCD in a Linux environment from user space, what

modifications are needed in the kernel when adding a new CLCD in Linux, and explains the

concept of the frame buffer.

6.1 Frame buffer

The frame buffer is a part of the Linux Kernel and should not be confused with the Panel

Data Frame buffer register of the CLCD controller (as discussed inSection 3.1).

The frame buffer device provides a general abstraction for the graphics hardware and hence

allows application software to access the graphics hardware through a well-defined

programming interface, so the application software doesn't need to know anything about the

low-level (hardware register) stuff. Figure 6 show the advantage of frame buffer which allows

applications to be independent of the vagaries of the underlying graphics hardware.

Applications run unchanged over diverse types of video hardware if they and the display

drivers conform to the frame buffer interface.

Figure 6. Advantage of using the frame buffer architecture

If GUIs (Graphic User Interface) such as MiniGUI, MicroWindows are used, LCD device

drivers must be implemented as Linux frame buffer device drivers in addition to those low

level operations which only deal with commands provided by LCD controllers.

● The device is accessed through special device nodes, usually located in the /dev

directory, and have names such as /dev/fb0 (or /dev/fb/0), /dev/fb1 etc. The frame

buffer devices are also `normal' memory devices, this means one can read and write

their contents. You can, for example, even make a screen snapshot using:

cat /dev/fb0 > myfile

● Application software that uses the frame buffer device (for example the X server) can

use /dev/fb0 by default. One can specify an alternative frame buffer device by setting

Doc ID 14027 Rev 1 19/37

Page 20

Linux frame buffer AN2641

the environment variable $FRAMEBUFFER to the path name of a frame buffer device,

e.g. (for sh/bash users):

export FRAMEBUFFER=/dev/fb1

or (for csh users):

setenv FRAMEBUFFER /dev/fb1

After this the X server will use the second frame buffer.

6.2 Kernel level modifications for CLCD

The kernel can be changed to accommodate information about a new CLCD panel. The files

which need to changed are:

For SPEAr300:

'arch/arm/mach-spear300/spear300.c' (or 'arch/arm/mach-spearbasic/spearbasic.c')

and 'drivers/video/Kconfig'.

For SPEAr600:

'arch/arm/mach-spear600/spear600.c' (or 'arch/arm/mach-spearbasic/spearplus.c').

20/37 Doc ID 14027 Rev 1

Page 21

AN2641 Linux frame buffer

#ifdef CONFIG_FB_ARMCLCD_SHARP_LQ043T1DG01

static struct clcd_panel sharp_LQ043T1DG01_in = {

.mode = {

.name = "Sharp LQ043T1DG01",

.refresh = 0,

.xres = 480,

.yres = 272,

.pixclock = 48000,

.left_margin = 2,

.right_margin = 2,

.upper_margin = 2,

.lower_margin = 2,

.hsync_len = 41,

.vsync_len = 11,

.sync = 0, //FB_SYNC_HOR_HIGH_ACT |

.vmode = FB_VMODE_NONINTERLACED,

},

.width = -1,

.height = -1,

.tim2 = TIM2_IOE | TIM2_CLKSEL | 3, //TIM2_CLKSEL| 4,

.cntl = CNTL_LCDTFT | CNTL_BGR,

.bpp = 32,

};

#endif

{

Struct clcd_panel *panel;

#ifdef CONFIG_FB_ARMCLCD_SHARP_LQ043T1DG01

Panel = &sharp_LQ043T1DG01_in;

#endif

Return panel;

}

Step-by-step procedure:

1. The file 'arch/arm/mach-spear300/spear300.c' (or 'arch/arm/machspearbasic/spearbasic.c') fills the clcd_panel structure with all the information about

CLCD.

Figure 7. CLCD panel structure

The 'clcd_panel' structure has 4 important members: tim2 (corresponding to LCDTiming register 2), tim3 (corresponding to LCD-Timing register 3), cntl (corresponding

to LCD-Control register) and bpp (bits per pixel).

The 'mode' field (structure 'fb_videomode') of structure 'clcd_panel' has the kind of

information (panel resolution and margins) which needs to be filled in LCD-timing

register 0 and LCD-Timing register 1.

2. Return the appropriate CLCD panel structure by filling in the following function:

Figure 8. Return CLCD panel structure

3. Note the usage of macros like CONFIG_FB_ARMCLCD_SHARP_LQ043T1DG01.

They are defined in 'drivers/video/Kconfig', the file which defines the choices in the

menuconfig.

Doc ID 14027 Rev 1 21/37

Page 22

Linux frame buffer AN2641

choice

depends on FB_ARMCLCD

prompt "LCD Panel"

default FB_ARMCLCD_SHARP_LQ043T1DG01

config FB_ARMCLCD_SHARP_LQ043T1DG01

bool "SHARP LQ043T1DG01 CLCD 4.2\" TFT(480x272)"

help

This is an implementation of the Sharp LQ043T1DG01, a 4.2"

color High Performance TFT panel.

The native resolution is 480x272.

Figure 9. Entry of CLCD info for menu config

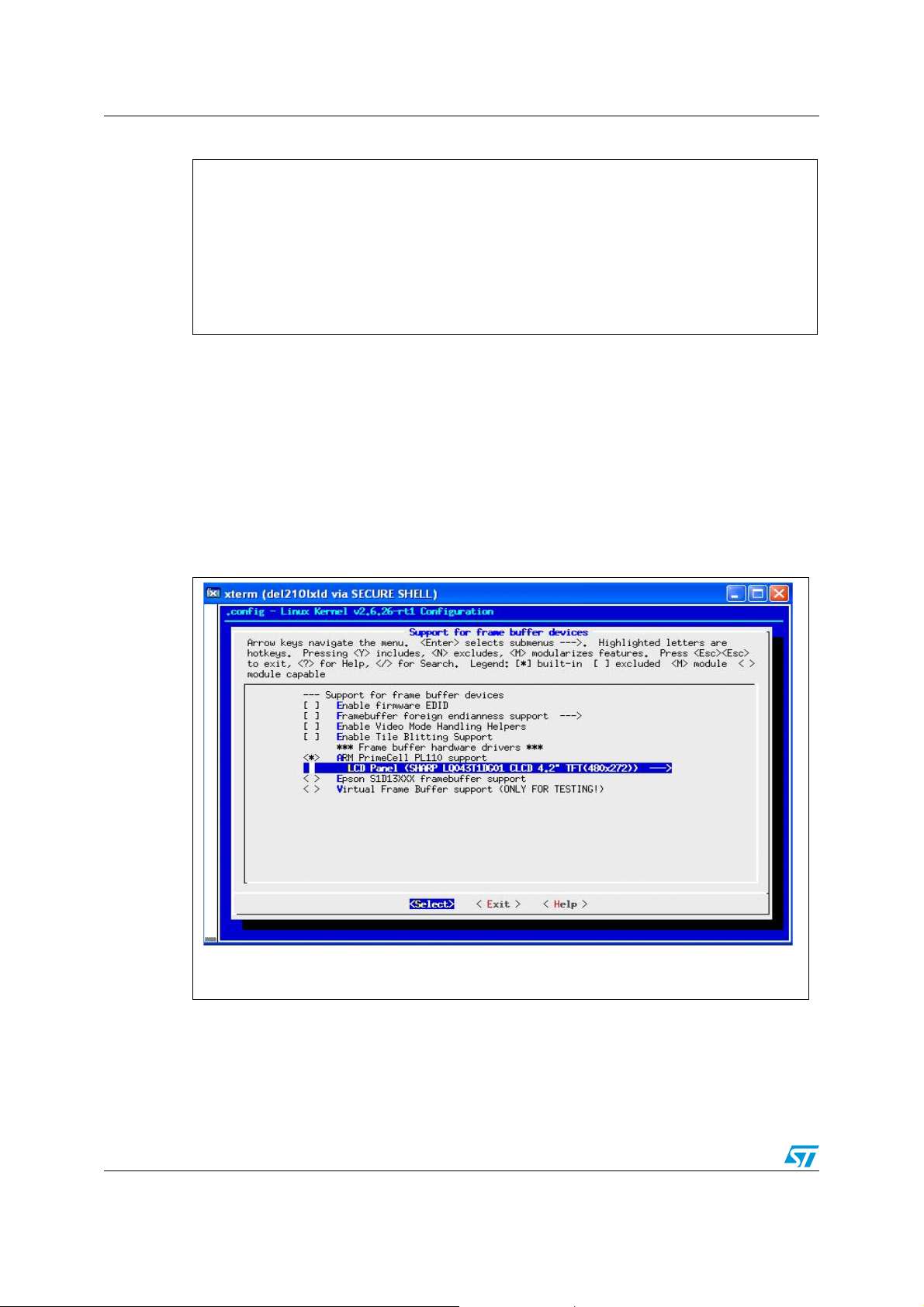

4. To select CLCD from menu config, just go to:

Device Drivers

→ Graphics support → Support for frame buffer devices →

Figure 10 and Figure 11 show how you can select CLCD panel from the menu. After

saving, the menu can be exited.

Just to verify whether CLCD is properly selected, verify that the .config file has:

– CONFIG_FB_ARMCLCD=y

– CONFIG_FB_ARMCLCD_SHARP_LQ043T1DG01=y

Now do, 'make uImage' and to generate a new kernel image containing the information on

the new CLCD panel.

Figure 10. CLCD selection from menu config - 1

22/37 Doc ID 14027 Rev 1

Page 23

AN2641 Linux frame buffer

Figure 11. CLCD selection from menu config - 2

6.3 User level perspective of CLCD

As we already know, a frame buffer device is a memory device like /dev/mem and it has the

same features. You can read it, write it, seek to some location in it and mmap() it (the main

usage). The difference is just that the memory that appears in the special file is not the

whole memory, but the frame buffer of the video hardware.

6.3.1 Data structures for user level

It is essential to understand the following three structures, they are used by all frame buffer

user applications.

1. Variable information pertaining to the video card is held in struct fb_var_screeninfo.

This structure contains fields such as the X-resolution, Y-resolution, bits required to

Doc ID 14027 Rev 1 23/37

Page 24

Linux frame buffer AN2641

struct fb_var_screeninfo {

__u32 xres; /* Visible resolution in the X axis */

__u32 yres; /* Visible resolution in the Y axis */

/* ... */

__u32 bits_per_pixel; /* Number of bits required to hold a pixel */

/* ... */

__u32 pixclock; /* Pixel clock in picoseconds */

__u32 left_margin; /* Time from sync to picture */

__u32 right_margin; /* Time from picture to sync */

/* ... */

__u32 hsync_len; /* Length of horizontal sync */

__u32 vsync_len; /* Length of vertical sync */

/* ... */

};

struct fb_fix_screeninfo {

char id[16]; /* Identification string */

unsigned long smem_start; /* Start of frame buffer memory */

__u32 smem_len; /* Length of frame buffer memory */

/* ... */

};

struct fb_cmap {

__u32 start; /* First entry */

__u32 len; /* Number of entries */

__u16 *red; /* Red values */

__u16 *green; /* Green values */

__u16 *blue; /* Blue values */

__u16 *transp; /* Transparency */

};

hold a pixel, pixclock, HSYNC duration, VSYNC duration, and margin lengths. These

values are programmable by the user:

Figure 12. Structure fb_var_screeninfo

2. Fixed information about the video hardware, such as the start address and size of

frame buffer memory, is held in struct fb_fix_screeninfo. These values cannot be

altered by the user:

Figure 13. Structure fb_fix_screeninfo

3. The fb_cmap structure specifies the color map, which is used to convey the user's

definition of colors to the underlying video hardware. You can use this structure to

define the RGB (Red, Green, and Blue) ratio that you desire for different colors: Device

independent color-map information. You can get and set the color-map using the

FBIOGETCMAP and FBIOPUTCMAP ioctls:

Figure 14. Structure fb_cmap

24/37 Doc ID 14027 Rev 1

Page 25

AN2641 Linux frame buffer

6.3.2 User level application sample

The Figure 15 shows a simple user application that works over the frame buffer API. The

program shows 3 color bands on the screen by operating on /dev/fb0, the frame buffer

device node corresponding to the display.

After opening the frame buffer device node the program gets the fixed screen and variable

screen information. It first deciphers the visible resolutions and the bits per pixel in a

hardware-independent manner using the frame buffer ioctl FBIOGET_VSCREENINFO. This

interface command gleans the display's variable parameters by operating on the

'fb_var_screeninfo' structure.

The command FB_ACTIVATE_FORCE (while put variable screen information) enables the

CLCD. This line is important to activate the CLCD.

The program then goes on to mmap() the frame buffer memory and writes color data on

each constituent pixel bit.

Doc ID 14027 Rev 1 25/37

Page 26

Linux frame buffer AN2641

#include <unistd.h>

#include <stdio.h>

#include <fcntl.h>

#include <linux/fb.h>

#include <sys/mman.h>

int main()

{

int fbfd = 0;

struct fb_var_screeninfo vinfo;

struct fb_fix_screeninfo finfo;

long int screensize = 0;

char *fbp = 0;

int x = 0, y = 0;

long int location = 0;

// Open the file for reading and writing

fbfd = open("/dev/fb0", O_RDWR);

if (!fbfd) {

printf("Error: cannot open framebuffer device.\n"); exit(1 );

}

// Get fixed screen information

if (ioctl(fbfd, FBIOGET_FSCREENINFO, &finfo)) {

printf("Error reading fixed information.\n"); exit(2);

}

// Get variable screen information

if (ioctl(fbfd, FBIOGET_VSCREENINFO, &vinfo)) {

printf("Error reading variable information.\n"); exit(3);

}

// Put variable screen information to Switch ON CLCD Panel

vinfo.activate |= FB_ACTIVATE_FORCE | FB_ACTIVATE_NOW;

if (ioctl(fbfd, FBIOPUT_VSCREENINFO, &vinfo)) {

printf("Error writing variable information.\n"); exit(3);

}

// Figure out the size of the screen in bytes

screensize = vinfo.xres * vinfo.yres * vinfo.bi ts_per_pixel / 8;

// Map the device to memory

fbp = (char *)mmap( 0, screensize, PROT_READ | PROT_WRITE, MAP_SHARED, fbfd, 0 );

if ((int)fbp == -1) {

printf("Error: failed to map framebuffer device to memory.\n"); exit(4);

}

//Loop will draw 3 color bands: blu e, green and red

for ( location = 0, y = 0; y < vinfo.yres; y++ )

for ( x = 0; x < vinfo.xres; x++ ) {

if ( y < (vinfo.yres/3) ) {

*(fbp + location) = 0xFF;//show Blue

*(fbp + location+1) = 0;//no Green

*(fbp + location+2) = 0;//no Red

*(fbp + location+3) = 0;//No Transparency

}

else if ( y < (2*vinfo.yres/3) ) {

*(fbp + location) = 0xFF;// no Blue

*(fbp + location + 1) = 0;// show Green

*(fbp + location + 2) = 0;// no Red

*(fbp + location + 3) = 0;// No transparency

}

else {

*(fbp + location) = 0;// no Blue

*(fbp + location + 1) = 0; // no Green

*(fbp + location + 2) = 0xFF;// show Red

*(fbp + location + 3) = 0;// No transparency

}

location +=4;

}

munmap(fbp, screensize);

close(fbfd);

return 0;

}

Figure 15. A sample user application

26/37 Doc ID 14027 Rev 1

Page 27

AN2641 Linux frame buffer

struct fb_info {

/* ... */

struct fb_var_screeninfo var; /* Variable screen information*/

struct fb_fix_screeninfo fix; /* Fixed screen information*/

/* ... */

struct fb_cmap cmap; /* Color map*/

/* ... */

struct fb_ops *fbops; /* Driver operations*/

/* ... */

char __iomem *screen_base; /* Frame buffer's virtual address */

unsigned long screen_size; /* Frame buffer's size */

/* ... */

/* From here on everything is device dependent */

void *par; /* Private area */

};

6.4 More details on the frame buffer in Linux

6.4.1 Data structures

1. The 'fb_info' structure defines the current state of the video card. 'fb_info' is only visible

from the kernel. Inside fb_info, there is a structure called 'fb_ops' which is a collection

of functions needed to make the driver work.

'struct fb_info' is the central data structure used by frame buffer drivers. This structure

is defined in include/linux/fb.h as follows:

Figure 16. Structure fb_info

The memory for fb_info is allocated by framebuffer_alloc(), a library routine provided by

the frame buffer core. This function also takes the size of a private area as an argument

and appends it to the end of the allocated fb_info. This private area can be referenced

using the par pointer in the fb_info structure.

2. The user application program can use the ioctl() system call to operate low level LCD

hardware. Methods defined in structure 'fb_ops' are used to support these operations.

The 'fb_ops' structure contains the addresses of all entry points provided by the lowlevel frame buffer driver. The first few methods in fb_ops are necessary for the

functioning of the driver, while those remaining are optional ones that provide for

graphics acceleration. The responsibility of each function is briefly explained in the

comments:

Doc ID 14027 Rev 1 27/37

Page 28

Linux frame buffer AN2641

struct fb_ops {

struct module *owner;

/* Driver open */

int (*fb_open)(struct fb_info *info, int user);

/* Driver close */

int (*fb_release)(struct fb_info *info, int user);

/* ... */

/* Sanity check on video parameters */

int (*fb_check_var)(struct fb_var_screeninfo *var, struct fb_info *info);

/* Configure the video controller registers */

int (*fb_set_par)(struct fb_info *info);

/* Create pseudo color palette map */

int (*fb_setcolreg)(unsigned regno, unsigned red, unsigned green, unsigned blue, unsigned transp, struct fb_info *info);

/* Blank/unblank display */

int (*fb_blank)(int blank, struct fb_info *info);

/* ... */

/* Accelerated method to fill a rectangle with pixel lines */

void (*fb_fillrect)(struct fb_info *info, const struct fb_fillrect *rect);

/* Accelerated method to copy a rectangular area from one screen region to another */

void (*fb_copyarea)(struct fb_info *info,const struct fb_copyarea *region);

/* Accelerated method to draw an image to the display */

void (*fb_imageblit)(struct fb_info *info, const struct fb_image *image);

/* Accelerated method to rotate the display */

void (*fb_rotate)(struct fb_info *info, int angle);

/* Ioctl interface to support device-specific commands */

int (*fb_ioctl)(struct fb_info *info, unsigned int cmd, unsigned long arg);

/* ... */

};

Figure 17. Structure fb_ops

28/37 Doc ID 14027 Rev 1

Page 29

AN2641 Linux frame buffer

6.4.2 A brief look at the source files

/dev/fb0 also allows several IOCTL commands to interface it, so that a whole range of

information about the hardware can be queried and set. The color map handling works via

IOCTLs, too. Look into <linux/fb.h> for more information on what IOCTLs exist and on which

data structures they work. Here's just a brief overview:

Table 3. Source code information on frame buffer

Directory or files Purpose

drivers/video/

include/linux/fb.h, Generic frame buffer structures are defined in this directory

include/video/. Chipset-specific headers are kept in this directory

drivers/video/fbmem.c

The frame buffer core layer and low-level frame buffer drivers reside

in this directory

Creates the /dev/fbX character devices and is the front end for

handling frame buffer ioctl commands issued by user applications

Doc ID 14027 Rev 1 29/37

Page 30

Touchscreen AN2641

- PRESS state comes when panel is

touched.

- It remains in the same state while touched

and send event again and again

IDLE

PRESS RELEASE

- This state comes when finger is

removed from panel

- Just send one event and change

state to IDLE

- Initial default state

- Comes back to IDLE state from

RELEASE after finger is removed

7 Touchscreen

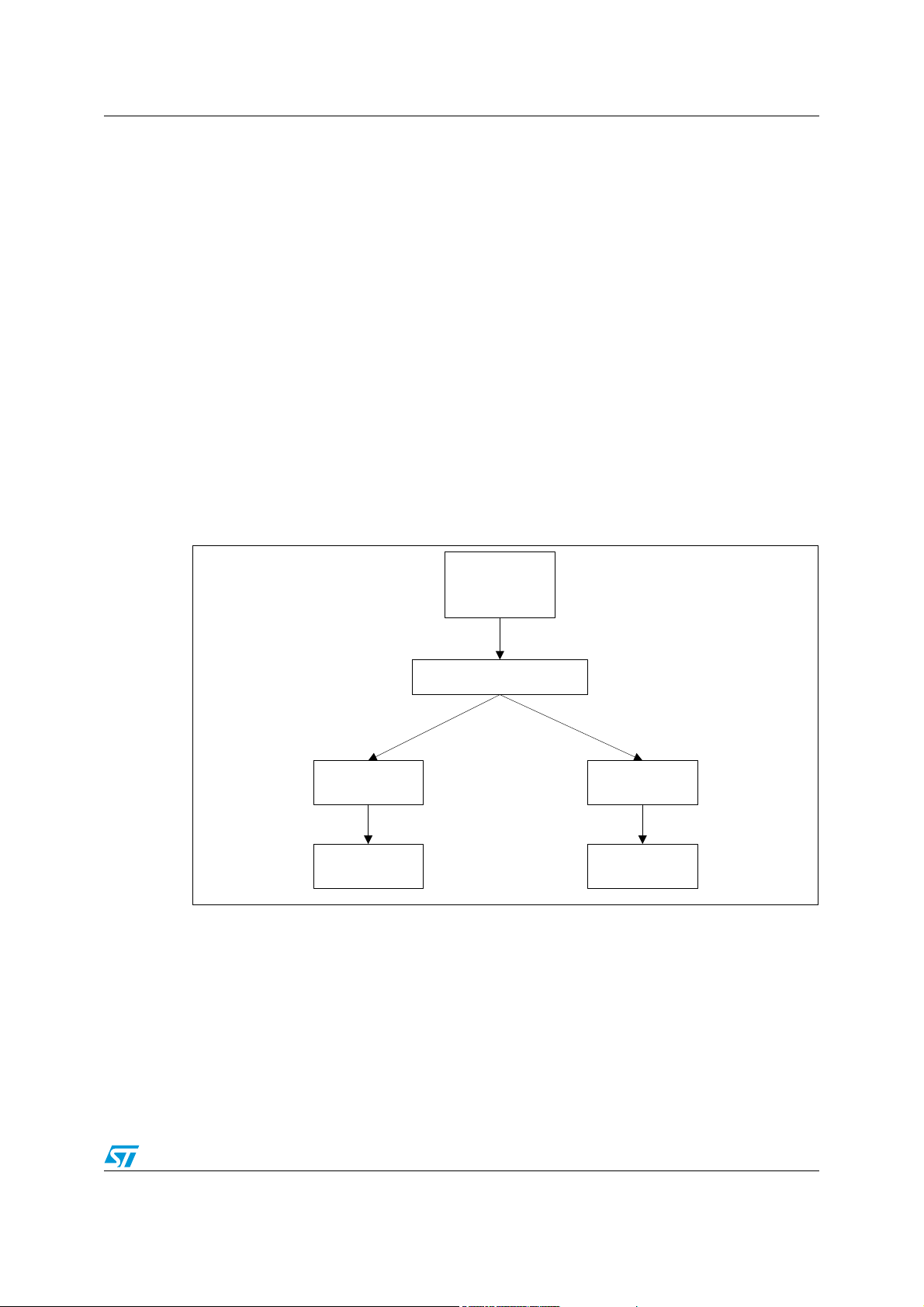

7.1 Theory of operation

SPEAr uses a combination of ADC and GPIO for touchscreen operation. By outputting

GPIO high the device-driver reads the X-coordinate from ADC channel number 5 and again

by outputting GPIO low it reads the Y-coordinate from ADC channel number 6. There is no

dedicated touchscreen controller in SPEAr.

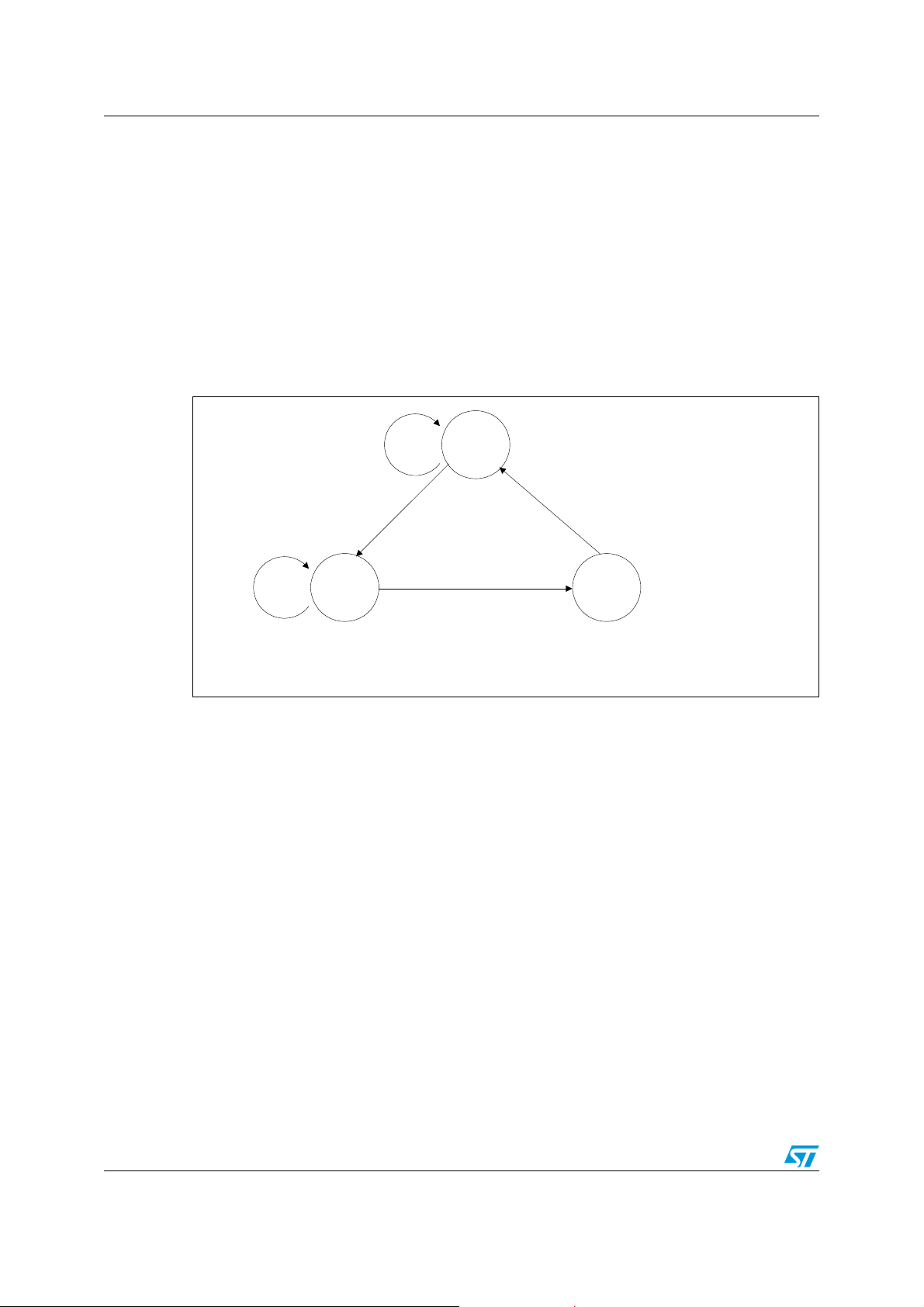

The touchscreen driver has a state machine which is called every 100 milliseconds and

reads each ADC channel. The state machine has 3 states and works as shown in Figure 18.

Figure 18. Touchscreen state machine

The touchscreen driver is probed as an input driver during Linux boot-up. At this time it only

opens the ADC. The State machine starts only after the CLCD is activated (at user level this

is typically done by an FB_ACTIVATE_FORCE call).

Just after Activation of the CLCD the ADC channels are read to get the idle values when

touchscreen is not touched. This gives an estimated threshold value.

Once the state machine is started, it reads the values from ADC channels (by polling in a

100 millisecond loop) and once it gets values above threshold, the touchscreen is assumed

to be touched (or pressed).

Once the touchscreen is pressed, the driver keeps sending coordinates unless the values

from the ADC channels go lower. This event means that the touchscreen is untouched (or

released).

The polling time (currently 100 milliseconds) of the driver is an important parameter

because it determines the touchscreen driver response time.

The touchscreen driver can be selected from menu config as follows:

Device Drivers → Input device support → Touchscreens →

[*] Touchscreen for SPEAr based platforms

● The name of the touchscreen device is '/dev/input/ts' with the major number 13 and

minor number 64.

30/37 Doc ID 14027 Rev 1

Page 31

AN2641 Touchscreen

PRESS EVENT (1)

X coordinate

Y coordinate

SYN

PRESS EVENT (1)

X coordinate

Y coordinate

SYN

(Press events may go multiple times )

.

.

.

RELEASE EVENT(0)

X coordinate

Y coordinate

SYN

(Release event will go only once)

7.2 Linux input layer

The kernel's input subsystem layer was created to unify scattered drivers that handle

diverse classes of data-input devices such as keyboards, mice, and touch screens.

The kernel's input subsystem layer permits the uniform handling of functionally similar input

devices even when they are physically different. For example, all mice, such as PS/2, USB

or Bluetooth, are treated alike.

It provides an easy event interface for dispatching input reports to user applications. The

driver does not have to create and manage /dev nodes and related access methods.

Instead, it can simply invoke input APIs to send mouse movements, key presses, or touch

events upstream to the user layer. Applications such as X Windows work seamlessly over

the event interfaces exported by the input subsystem layer.

The name of the touchscreen driver is "drivers/input/touchscreen/spear_ts.c" (or

"drivers/input/touchscreen/spr_ts_st.c"). To integrate with the input subsystem layer, the

driver fills the structure 'struct input_dev *input_dev' and register through the call

input_register_device( ).

The sequence of events sent to the application layer is as illustrated in Figure 19:

Figure 19. Sequence of events from touchscreen driver

7.3 Calibration process

Any CLCD panel touchscreen cannot return absolutely correct coordinates, rather it only

returns default values which need to be adjusted to the CLCD panel dimensions. This is the

purpose of a calibration tool.

The calibration tool works with a simple concept, it asks the user to touch four corner points

of the CLCD panel and stores these values. It then learns the offsets and scales used to

later calculate the correct coordinates. Calibration may vary for different CLCD panels so

before using the touchscreen, the CLCD panel has to be calibrated.

Once calibration is successfully performed, the calibration data is written in a file in a

particular format. It is up to the user application to use the information provided in the file to

calculate correct coordinates.

Figure 20 shows the calibration tool display after the calibration process is over.

Doc ID 14027 Rev 1 31/37

Page 32

Touchscreen AN2641

Figure 20. Appearance of calibration tool for touchscreen

32/37 Doc ID 14027 Rev 1

Page 33

AN2641 Troubleshooting

8 Troubleshooting

Here are some solutions to common issues that can occur during development of a CLCD

driver.

8.1 Video flickering

Flickering is caused by the CLCD master not having enough bandwidth over the AHB

memory system. In this case you need to configure the priority of the MPMC ports properly.

Solution: The Xloader takes care of this and puts CLCD port at the highest priority.

8.2 Video tearing

When displaying video frames if the rate is not fast enough, then while we can see a new

frame, the disappearing of the old frame can also be perceived by the human eye. Such an

overlapping is known as video tearing.

Solution: In this case you should change the driver implementation and add the dual frame

buffer capability. One buffer will be the current one, while the CPU prepares the second one.

Then the driver should switch the CLCD pointer.

8.3 White screen

If a CLCD application activates the panel at regular intervals then after a certains number of

iterations (this issue has been observed after 20 iternations) a white screen appears and

CLCD hangs unless power down occurs.

Solution: As described in Section 4: Enabling and disabling the CLCD on page 16 , there

two steps required for CLCD activation:

1. Control signal on

2. Data signal on.

A small delay (in milliseconds) is required between both to let the control signal stabilize.

Doc ID 14027 Rev 1 33/37

Page 34

Summary AN2641

9 Summary

In summary, before you start to integrate a new CLCD panel in the SPEAr system, you

mainly need three types of information:

● Type of CLCD panel

● Dimension-related parameters

● Clock-related parameters

The next step is to make the architectural modifications in Linux. You must know exactly

where the CLCD architectural information is in Linux. You should have a basic knowledge of

the frame buffer layer of Linux as well. All this information is given the different sections of

this application note.

The last step is to create a user level application so that the CLCD panel can be tested. This

is architecture independent and should be the same for all types of LCD panel.

If you are using a touchscreen, it must be calibrated before using it as an input device.

34/37 Doc ID 14027 Rev 1

Page 35

AN2641 Definitions

Definitions

Table 4. Acronyms used in this document

CLCD Color Liquid Crystal Display

CLCP CLCD panel clock requency

CLCD_CLK A free running reference clock

CLKSEL Clock select

TFT Thin film transistors

STN Super twisted nematic

HSW Horizontal synchronization width

HFP Horizontal front porch

HBP Horizontal back porch

PPL Pixels per line

LPP Lines per panel

VSW Vertical synchronization pulse width

VFP Vertical front porch

VBP Vertical back porch

BCD Bypass pixel divider

CPL Clocks per line

IOE Input output enable

IPC Invert panel clock

HIS Invert horizontal synchronization

IVS Invert vertical synchronization

PCD Panel clock divisor

ACB AC bias pin frequency

LEE LCD line end enable

Doc ID 14027 Rev 1 35/37

Page 36

Revision history AN2641

10 Revision history

Table 5. Document revision history

Date Revision Changes

29-Oct-2009 1 Initial release.

36/37 Doc ID 14027 Rev 1

Page 37

AN2641

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2009 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 14027 Rev 1 37/37

Loading...

Loading...