Page 1

AN2639

Application note

Soldering recommendations and package information

for Lead-free ECOPACK® microcontrollers

Introduction

STMicroelectronics microcontrollers support various types of Lead-free ECOPACK

package to meet customer requirements.

The mounting technologies are Surface mount technology (SMT), and Through hole

technology (THT). Beside the available mounting technology, the choice is often driven by

technical and economical concerns. This application note describes the various package

types used for microcontrollers, introduces the different mounting technologies, and gives

soldering recommendations.

®

May 2009 Doc ID 14016 Rev 2 1/15

www.st.com

Page 2

Contents AN2639

Contents

1 Lead-free packages at STMicroelectronics . . . . . . . . . . . . . . . . . . . . . . . 3

2 Microcontroller packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 SMD presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Handling SMDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Soldering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.1 Soldering methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Bending leads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Insertion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.2 Soldering recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3 Compatibility with leaded soldering process . . . . . . . . . . . . . . . . . . . . . . . 7

4.4 Reflow soldering conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5 SMD gluability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6 Dry packing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.1 Pop-corn effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.2 Dry pack opening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2/15 Doc ID 14016 Rev 2

Page 3

AN2639 Lead-free packages at STMicroelectronics

1 Lead-free packages at STMicroelectronics

STMicroelectronics is fully committed to environment protection and sustainable

development and started in 1997 a voluntary program for removing polluting and hazardous

substances from all devices. In 2000, a strategic program, named ECOPACK has been

officially launched to develop and implement solutions leading to environment friendly

packaging and ban progressively Pb and other heavy metals from our manufacturing lines.

ECOPACK is a registered trademark of STMicroelectronics.

STMicroelectronics ECOPACK products are RoHS compliant according to EU 2002/95/EC

directive.

For more detailed information please go to http://www.st.com.

Note: RoHS stands for ‘Restriction of the use of certain Hazardous Substances’. The directive

2002/95/EC of the European Parliament and of the Council of 27th January 2003 on the

RoHS in electrical and electronic equipment entered into force on 13th of February 2003.

The aim of this directive is to ban heavy metals (Lead, Mercury, Cadmium, Hexavalent

Chromium) and two brominated compounds (PBB and PBDE). The directive will be

applicable throughout EU by 1st July 2006.

Doc ID 14016 Rev 2 3/15

Page 4

Microcontroller packages AN2639

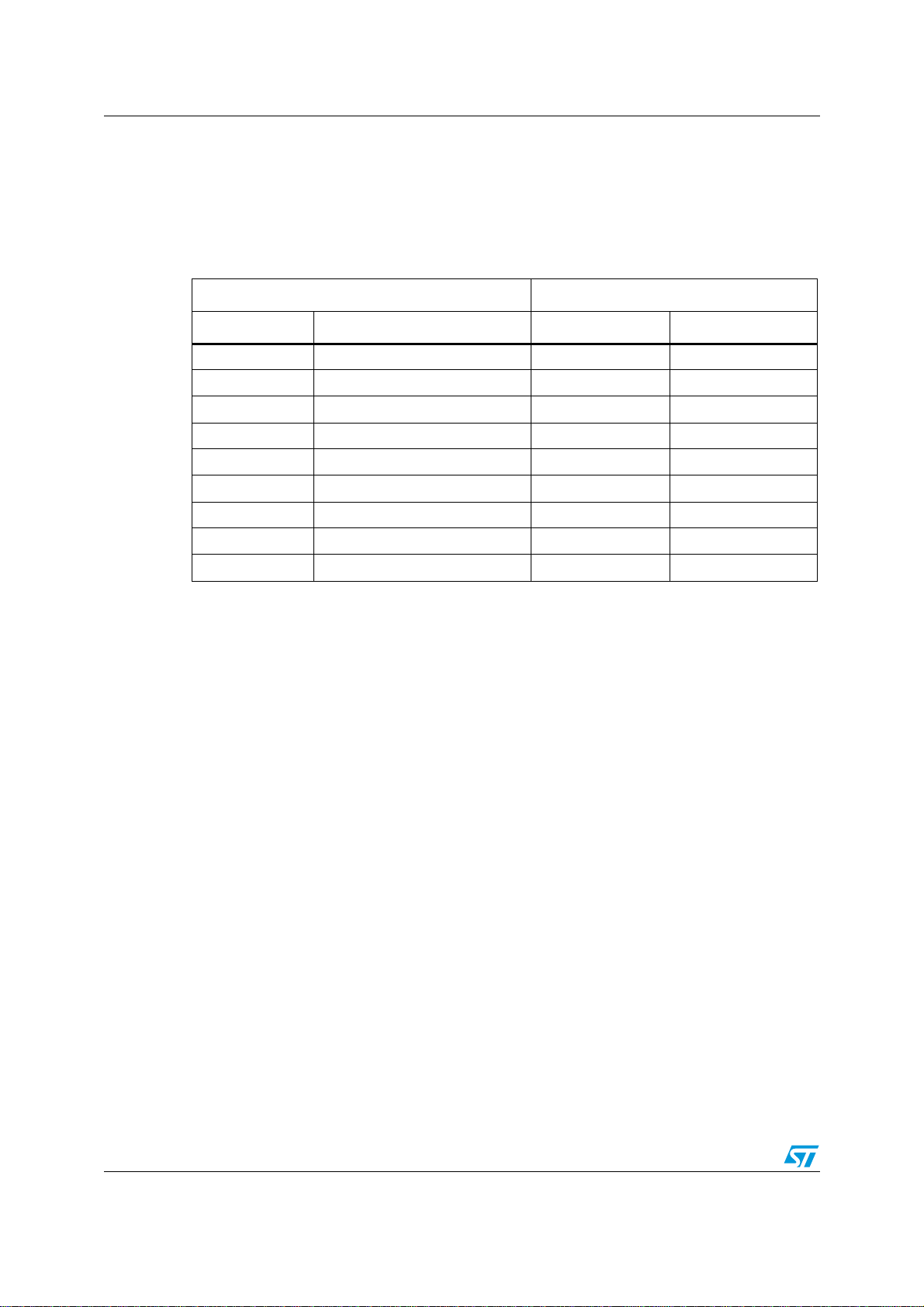

2 Microcontroller packages

The different packages available at STMicroelectronics for microcontrollers are described

Table 1.

Table 1. Microcontroller package types

Surface mount technology Through hole technology

Package Pin count Package Pin count

SON 8,16 PDIP .3 8, 16, 20

SOW 16, 20, 24, 28, 34 Shrink PDIP .4 32S

PLCC 44, 520 PDIP .6 28, 42S, 56S

PQFP 44, 52, 80, 100, 144, 208

LQFP 32, 44, 48, 52, 64, 80, 100, 128

LFBGA,TFBGA Up to 144

PBGA Up to 480

TSSOP 20

(1)

VFQFPN 8, 20, 24, 36, 40, 48, 64

1. Larger package portfolio can be proposed upon request.

Through hole technology (THT) and Surface mount technology (SMT) imply different

soldering technologies leading to different constraints.

In THT, the package body is exposed to relatively low temperatures (< 150 °C) because the

lead extremities are only dipped in the soldering alloy, whereas in SMT the whole package

body is exposed to a very high temperature (> 240 °C) during reflow soldering process.

In addition, molding compounds used for integrated circuit encapsulation absorb moisture

from the ambient medium. During rapid heating in solder reflow process (see Section 4:

Soldering for more details), this absorbed moisture can vaporize, generating pressure at

lead frame pad / silicon to plastic interfaces in the package, with a risk of package cracking

and potential degradation of device reliability.

4/15 Doc ID 14016 Rev 2

Page 5

AN2639 SMD presentation

3 SMD presentation

Unlike through hole technology where leads are inserted into the printed circuit board, SMD

(surface mount device) package is attached directly onto mounting pads of the substrate.

SMT is extensively used in electronic applications because it has the following advantages:

●

Packages are smaller and support higher pin counts

●

Packages are light and compact, thus reducing system sizes

●

Mounting can be done on either side of the PCB

●

No cost for drilling holes into the PCB

Surface mount technology also comes along with a few disadvantages:

●

Increased sensitivity to soldering heat because of their thinner dimension

●

Soldering conditions harder to determine (use of finer structures and higher pin count)

3.1 Handling SMDs

Though the intrinsic reliability of SMD packages is now excellent, the use of inappropriate

techniques or unsuitable tools during mechanical handling can affect the long term reliability

of the device, or even destroy it.

When handling a SMD package, it is strongly recommended to use adapted tools such as

vacuum pipes to avoid touching the pins as much as possible. Manual handling could affect

lead coplanarity and cause lead contamination or scratches that could generate solderability

problems. It is also not allowed to widen the interval between two consecutive pins.

Doc ID 14016 Rev 2 5/15

Page 6

Soldering AN2639

SOLDER PASTE

APPLICATION

GLUE

APPLICATION

DEVICE

MOUNTING

GLUE AGING

SOLDER PASTE

APPLICATION

SOLDERING

CLEANING

TESTING

SOLDER PASTE

APPLICATION

SOLDERING

CLEANING

TESTING

SOLDER PASTE

APPLICATION

GLUE

APPLICATION

DEVICE

MOUNTING

FLUX

APPLICATION

SOLDERING

CLEANING

TESTING

REFLOW

DOUBLE SIDED

REFLOW

SINGLE SIDED

WAVE

SOLDERING

SOLDERING

SOLDERING

VR02104B

MOUNTING

DEVICE

DEVICE

MOUNTING

4 Soldering

4.1 Soldering methods

There are 3 main soldering methods (which are detailed in Figure 1):

●

Single sided reflow soldering

●

Double sided reflow soldering

●

Wave soldering (for THT devices)

Bending leads

In all processes it is important to avoid straining the package and particularly the area where

the leads enter the encapsulating resin. If the package/lead interface is strained the

resistance to humidity and thermal stress will be compromised, affecting device reliability.

Insertion

When mounting devices on a printed circuit board the golden rule is, again, to avoid stress.

In particular, adhere to the specified pin spacing of the device: do not try to bend the leads

to fit non-standard hole spacing.

Figure 1. Soldering method descriptions

6/15 Doc ID 14016 Rev 2

Page 7

AN2639 Soldering

4.2 Soldering recommendations

The following recommendations must be followed for soldering each package type (see

Table 2).

Table 2. Package/soldering process compatibility

Reflow processing process Wave soldering process

Package

Process Reliability Process Reliability

PLCC OK OK impossible N/A

SOP OK OK feasible

QFP OK OK critical

BGA OK OK impossible N/A

VFQFPN OK OK impossible N/A

1. Reflow soldering with DIP and wave soldering with PLCC, BGA and VFQFPN are strictly impossible due to

the lead/ball configuration.

2. Wave soldering with SMT packages is not recommended because the thermal shock associated with

package body solder dipping may induced internal structural damage to the package (interface

delamination) that may affect long term reliability.

SMT Package characterizations performed as a standard by STMicroelectronics only include Solder

Reflow Resistance assessment.

JEDEC JESD22A111 recommends that wave soldering of SMT packages should be evaluated by the

USER, because the stress induced inside the package is very dependant of solder process parameters.

3. Wave soldering with PQFP is not recommended because it is difficult to avoid solder bridges when leads

pass through the double wave.

(1)

(3)

(2)

(2)

4.3 Compatibility with leaded soldering process

Lead-free packages can be assembled using leaded soldering process. For more details

about soldering process compatibilities and conditions, please refer to application note

AN2034.

Doc ID 14016 Rev 2 7/15

Page 8

Soldering AN2639

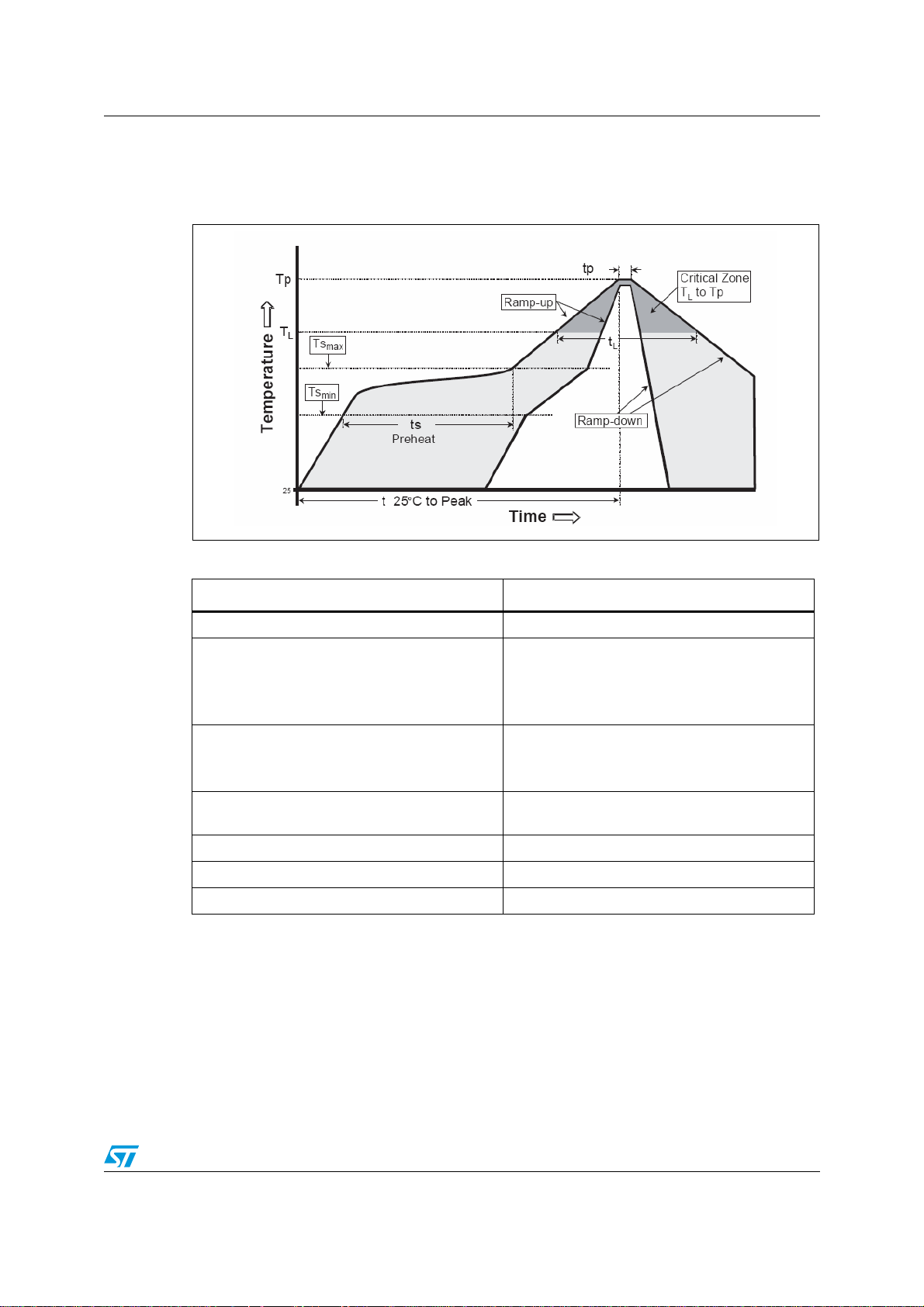

4.4 Reflow soldering conditions

The greater danger during reflow soldering is overheating. If an integrated circuit is exposed

to high temperature for an excessive period of time, it may be damaged and its reliability

reduced.

It is also important to use suitable fluxes for the soldering baths to avoid deterioration of the

leads or package resin. Residual flux between the leads or in contact with the resin must be

removed to guarantee long term reliability. The solvent used to remove excess flux should

be chosen with care. It is particular true for trichloroethylene (CHCl: CCl2). Base solvents

should be avoided because the residue could corrode the encapsulating resin.

High-quality low-defect soldering requires identifying the optimum temperature profile for

reflowing the solder paste, thus optimizing the process. The heating and cooling rise rates

must be compatible with the solder paste and components.

A typical profile consists of a preheat, dryout and reflow sections.

The most critical point in the preheat section is to minimize the temperature rise rate to less

than 2 °C/second, in order to minimize thermal shock on the semiconductor components.

The dryout section is used primarily to ensure that the solder paste is fully dried before

hitting reflow temperatures.

Solder reflow is accomplished in the reflow zone, where the solder paste is elevated to a

temperature greater than the melting solder point. Melting temperature must be exceeded

by approximately 20 °C to ensure quality reflow.

Figure 2. Typical reflow soldering profile

8/15 Doc ID 14016 Rev 2

Page 9

AN2639 Soldering

Refer to Figure 3 for the recommended reflow soldering profiles.

STMicroelectronics Lead-free packages are warranted for such reflow profile conditions.

Figure 3. Recommended reflow soldering profile

Table 3. JEDEC standard Lead-free reflow profile (according to J-STD-020D)

Profile feature Lead-free assembly

Average ramp-up rate (T

to TP) 3 °C/second max.

smax

Preheat

-Temperature Min (T

-Temparature Max (T

-Time (tL)

smin

smax

)

)

150 °C

200 °C

60-120 seconds

Time maintained above:

-Temperature (TL)

-Time (tL)

Peak/classification temperature (TP)

217°C

60-150 seconds

Package dependant, see temperature indicated

on box label.

Time within 5 °C of actual peak temperature (TP) 30 seconds

Ramp-down rate 6°C/second max.

Time 25 °C to peak temperature 8 minutes max.

1. All temperatures refer to topside of the package, measured on the body surface.

(1)

Doc ID 14016 Rev 2 9/15

Page 10

SMD gluability AN2639

VR02104F

0.25

0.5 0.75

1

OK

PROBLEM

GLUABILITY (kg / mm2)

5 SMD gluability

It is strongly recommended to follow glue application specifications from their glue supplier,

and to use 100% glue polymerization for optimal glue efficiency.

Figure 4. Recommended profiles for glue polymerization using regular oven and

linear flow oven

Figure 5. Gluability evaluation with a shear test

Various tests have shown that glue shear test specification limit conforms to the IPC SM817

standard (0.75 kg/mm2 minimum). Customer complaints usually happen when values are

below 0.5 kg/mm2. It has been verified that below 0.25 kg/mm2 components fall from PCB

during handling. General capability in plastic SMD is greater than 1 kg/mm2.

10/15 Doc ID 14016 Rev 2

Page 11

AN2639 Dry packing

6 Dry packing

Quality and reliability of SMDs after soldering depends heavily on moisture absorption

during storage. A specific packing, called dry pack, was implemented for defined conditions

at the delivery. Time and environment will modify the amount of absorbed humidity. Moisture

sensitive SMDs (SOP, PLCC, PQFP, BGA, VFQFPN) are dry packed to protect them from

moisture absorption during shipment / storage and then to reduce failure risks mainly due to

popcorn effect.

6.1 Pop-corn effect

Pop-corn effect is the cracking of the package during the soldering cycle. It has got a

growing importance due to the trends towards larger die size in integrated circuits. This

phenomenon is mainly caused by the moisture absorbed by the epoxy molding. When the

package is exposed to high temperatures, as in most SMT soldering processes, the water at

the interface between plastic and die pad vaporizes suddenly, generating high internal

pressure. Cracks may occur in the molding compound depending on the absorbed moisture

level, soldering temperature and time, die size, package structure and molding compound

characteristics.

SMD products are contained in tubes, on trays or on tape, and are then vacuum sealed in an

hermetic bag.

Opening the package will stop the ideal conditions and start the influence of the normal

environment. Figure 6 shows the recommended handling flow.

Doc ID 14016 Rev 2 11/15

Page 12

Dry packing AN2639

VR02104H

DRY PACK

DESSICANT

HUMIDITY

MARKING

DRY BAKE

TESTING

SEALING

CONTROL

INDICATOR

VACUUM

STORAGE

SOLDERING

Storage period

DELIVERED

GEL TURNED

PACK OPEN

> X Hours

(1)

?

PRODUCT

TO PINK ?

BAKE

125°C / 24 h

YES

NO

NO

YES

STMICROELECTRONICS

CUSTOMER

<25°C / <65% RH

Figure 6. Recommended flow to control package moisture absorption

6.2 Dry pack opening

12/15 Doc ID 14016 Rev 2

1. X depends on the MSL level (see JEDEC standard J-STD-020D).

Parts in dry pack are recommended to be stored in dry boxes (i.e. cabinets under nitrogen

atmosphere). See Table 4 for the recommended environmental conditions for storage when

no dry boxes are available.

Table 4. Environmental conditions

Condition Recommended value

Temperature 5 -> 30°C

Humidity 60°C max

Dust should also be minimized. There should be no vibration or shock which could distort

the packing container. To avoid excess weight packing, containers should not be stacked on

top of each other.

After opening a dry pack, soldering should be done within 24 hours. SMD products stored

over the specified storage period need to be baked at 125 °C for 24 hours (under nitrogen

atmosphere). Devices packed in tubes or in tapes must be transferred to metal tubes before

baking whereas trays are bake able.

Page 13

AN2639 Dry packing

Figure 7. Moisture absorption / drying curve

Doc ID 14016 Rev 2 13/15

Page 14

Revision history AN2639

7 Revision history

Table 5. Document revision history

Date Revision Changes

16-Oct-2007 1 Initial release

Modified tL and tP in Table 3: JEDEC standard Lead-free reflow

26-May-2009 2

profile (according to J-STD-020D).

Updated Figure 6: Recommended flow to control package

moisture absorption.

14/15 Doc ID 14016 Rev 2

Page 15

AN2639 Revision history

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2009 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 14016 Rev 2 15/15

Loading...

Loading...