Page 1

AN2629

Application note

STM32F101xx, STM32F102xx and STM32F103xx

low-power modes

Introduction

This application note is intended for system designers who require a software and hardware

implementation overview of the low-power modes of the STM32F101xx, STM32F102xx and

STM32F103xx products. It describes how to use the STM32F10xxx product family and

details the clock systems, register settings and low-power management in order to optimize

the use of STM32F10xxx in applications where low power is key.

This application note should be read in conjunction with the datasheet of the relevant

STM32F10xxx product and the STM32F10xxx reference manual. For information on

programming, erasing and protection of the internal Flash memory please refer to the

STM32F10xxx Flash programming manual.

The STM32F10xxx datasheets, the reference and Flash programming manuals are all

available from the STMicroelectronics website www.st.com.

For information on the Cortex™-M3 core please refer to the Cortex™-M3 Technical

Reference Manual, available from the www.arm.com website at the following address:

http://infocenter.arm.com/help/index.jsp?topic=/com.arm.doc.ddi0337e/.

The first four sections of this application note introduce the part of the STM32F10xxx

devices that is used for low-power configuration. The next sections demonstrate the lowpower feature in an applicative way. Each section refers to software delivered with this

document, which give a practical view of power optimization.

April 2009 Doc ID 13922 Rev 2 1/43

www.st.com

Page 2

Contents AN2629

Contents

1 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1.1 Independent A/D converter supply and reference voltage . . . . . . . . . . . . 7

1.1.2 Battery backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.1.3 Voltage regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2 Low-power modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2.1 Slowing down system clocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2.2 Peripheral clock gating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2.3 Sleep mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.2.4 Stop mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.2.5 Standby mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.2.6 Debug mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.2.7 Auto-wakeup (AWU) from low-power mode . . . . . . . . . . . . . . . . . . . . . . 13

2 Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3 Real-time clock (RTC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2 Main features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3.2 Resetting RTC registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.3.3 Reading RTC registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.3.4 Configuring RTC registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.3.5 RTC flag assertion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4 Backup registers (BKP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3 Tamper detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.4 RTC calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5 Power and wakeup time measurement . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2/43 Doc ID 13922 Rev 2

Page 3

AN2629 Contents

5.2 Power measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2.1 Context . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2.2 Detailed description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2.3 Measurement results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.3 Wakeup time measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.3.1 Context . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.3.2 Detailed description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.3.3 Measurement results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.3.4 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6 Optimizing power consumption in your application . . . . . . . . . . . . . . 30

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2 Using the advance clock configuration of the STM32F10xxx . . . . . . . . . . 30

6.2.1 Context . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2.2 Detailed description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.3 Typical measurement results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.4 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7 Using the Stop and Standby mode in battery-operated applications 35

7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.2 Using Wait For Event & Stop Wait For Event . . . . . . . . . . . . . . . . . . . . . . 35

7.2.1 Context . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.2.2 Detailed description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.3 Using the Standby mode in an applicative way . . . . . . . . . . . . . . . . . . . . 37

7.3.1 Context . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.3.2 Detailed description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.4 Typical measurement results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.5 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8 Using the Backup domain in very low-power applications . . . . . . . . . 40

8.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.2 Using the Backup domain in an applicative way . . . . . . . . . . . . . . . . . . . 40

8.2.1 Context . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.2.2 Detailed description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.3 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Doc ID 13922 Rev 2 3/43

Page 4

Contents AN2629

9 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4/43 Doc ID 13922 Rev 2

Page 5

AN2629 List of tables

List of tables

Table 1. Low-power modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 2. Sleep-now. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 3. Sleep-on-exit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 4. Stop mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 5. Standby mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 6. Power measurement results in Sleep mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 7. Power measurement for Stop and Standby modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 8. Wakeup time measurement results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 9. Example measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 10. Example measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 11. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Doc ID 13922 Rev 2 5/43

Page 6

List of figures AN2629

List of figures

Figure 1. Power supply overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

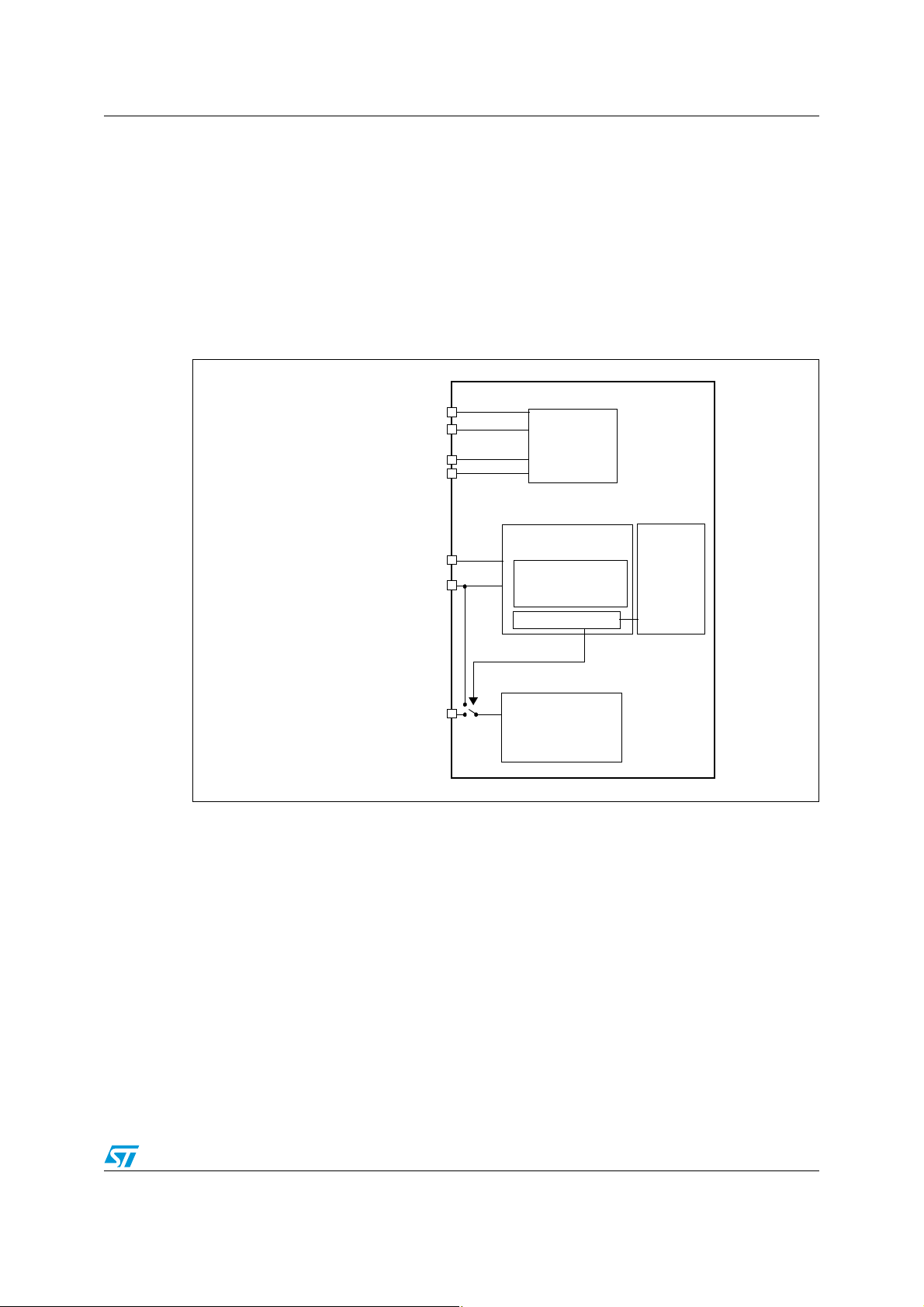

Figure 2. Clock tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 3. RTC simplified block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 4. RTC second and alarm waveform example with PR=0003, ALARM=00004 . . . . . . . . . . . 19

Figure 5. RTC Overflow waveform example with PR=0003. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 6. HyperTerminal time adjustment interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 7. WFE & STOP WFE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 8. Standby. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 9. HyperTerminal display of time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6/43 Doc ID 13922 Rev 2

Page 7

AN2629 Power supply

A/D converter

V

DDA

V

DD

V

SSA

(3.3 V)

V

REF+

V

BAT

V

SS

I/O Ring

(V

DD

)

(V

DD

)

(from 2 V up to V

DDA

)

BKP registers

Temp. sensor

Reset block

Standby circuitry

PLL

(Wakeup logic,

IWDG)

RTC

Voltage Regulator

Core

Memories

digital

peripherals

Low voltage detector

V

REF-

V

DDA

domain

V

DD

domain

1.8 V domain

Backup domain

LSE crystal 32K osc

RCC BDCR register

(V

SSA

)

ai14677

1 Power supply

1.1 Introduction

The device requires a 2.0 V to 3.6 V operating voltage supply (VDD). An embedded regulator

is used to supply the internal 1.8 V digital power.

The real-time clock (RTC) and backup registers can be powered from the V

the main V

supply is powered off.

DD

Figure 1. Power supply overview

voltage when

BAT

1.1.1 Independent A/D converter supply and reference voltage

To improve conversion accuracy, the ADC has an independent power supply that can be

filtered separately, and shielded from noise on the PCB.

● The ADC voltage supply input is available on a separate V

● An isolated supply ground connection is provided on the V

When available (depending on package), V

must be tied to V

REF–

DDA

SSA

SSA

pin

pin

.

On 100-pin packages

To ensure a better accuracy on low-voltage inputs, the user can connect a separate external

reference voltage ADC input on V

. The voltage on V

REF+

may range from 2.0 V to V

REF+

Doc ID 13922 Rev 2 7/43

DDA

.

Page 8

Power supply AN2629

On packages with 64 pins or less

REF+

and V

REF-

DDA

The V

voltage supply (V

1.1.2 Battery backup

To retain the content of the Backup registers when VDD is turned off, the V

connected to an optional standby voltage supplied by a battery or another source.

The V

digital supply (V

pin also powers the RTC unit, allowing the RTC to operate even when the main

BAT

) is turned off. Switching to the V

DD

down reset (PDR) circuitry embedded in the Reset block.

If no external battery is used in the application, V

1.1.3 Voltage regulator

The voltage regulator is always enabled after reset. It works in three different modes

depending on the application modes:

● in Run mode, the regulator supplies full power to the 1.8 V domain (core, memories and

digital peripherals)

● in Stop mode, the regulator supplies low power to the 1.8 V domain, preserving the

contents of the registers and SRAM

● in Standby mode, the regulator is powered off. The contents of the registers and SRAM

are lost except for those concerned with the Standby circuitry and the Backup domain.

pins are not available, they are internally connected to the ADC

) and ground (V

SSA

).

pin can be

BAT

supply is controlled by the power

BAT

must be connected externally to VDD.

BAT

1.2 Low-power modes

By default, the microcontroller is in Run mode after a system or a power Reset. Several lowpower modes are available to save power when the CPU does not need to be kept running,

for example when waiting for an external event. It is up to the user to select the mode that

gives the best compromise between low-power consumption, short startup time and

available wakeup sources.

The STM32F10xxx devices feature three low-power modes:

● Sleep mode (CPU clock off, all peripherals including Cortex-M3 core peripherals like

NVIC, SysTick, etc. are kept running)

● Stop mode (all clocks are stopped)

● Standby mode (1.8V domain powered-off)

In addition, the power consumption in Run mode can be reduce by one of the following

means:

● Slowing down the system clocks

● Gating the clocks to the APB and AHB peripherals when they are unused.

Ta bl e 1 below summarizes the low-power modes of the STM32F10xxx MCU.

8/43 Doc ID 13922 Rev 2

Page 9

AN2629 Power supply

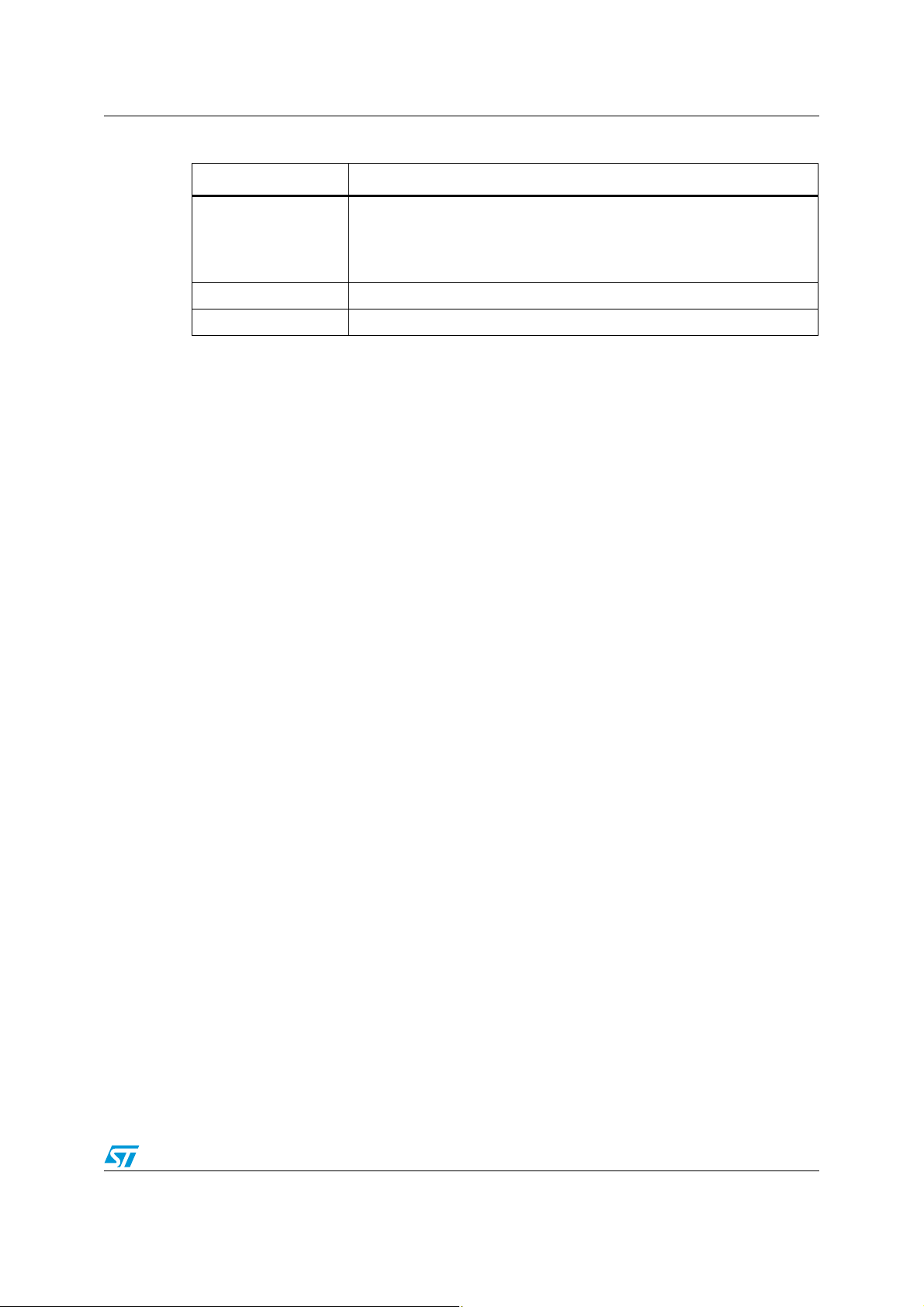

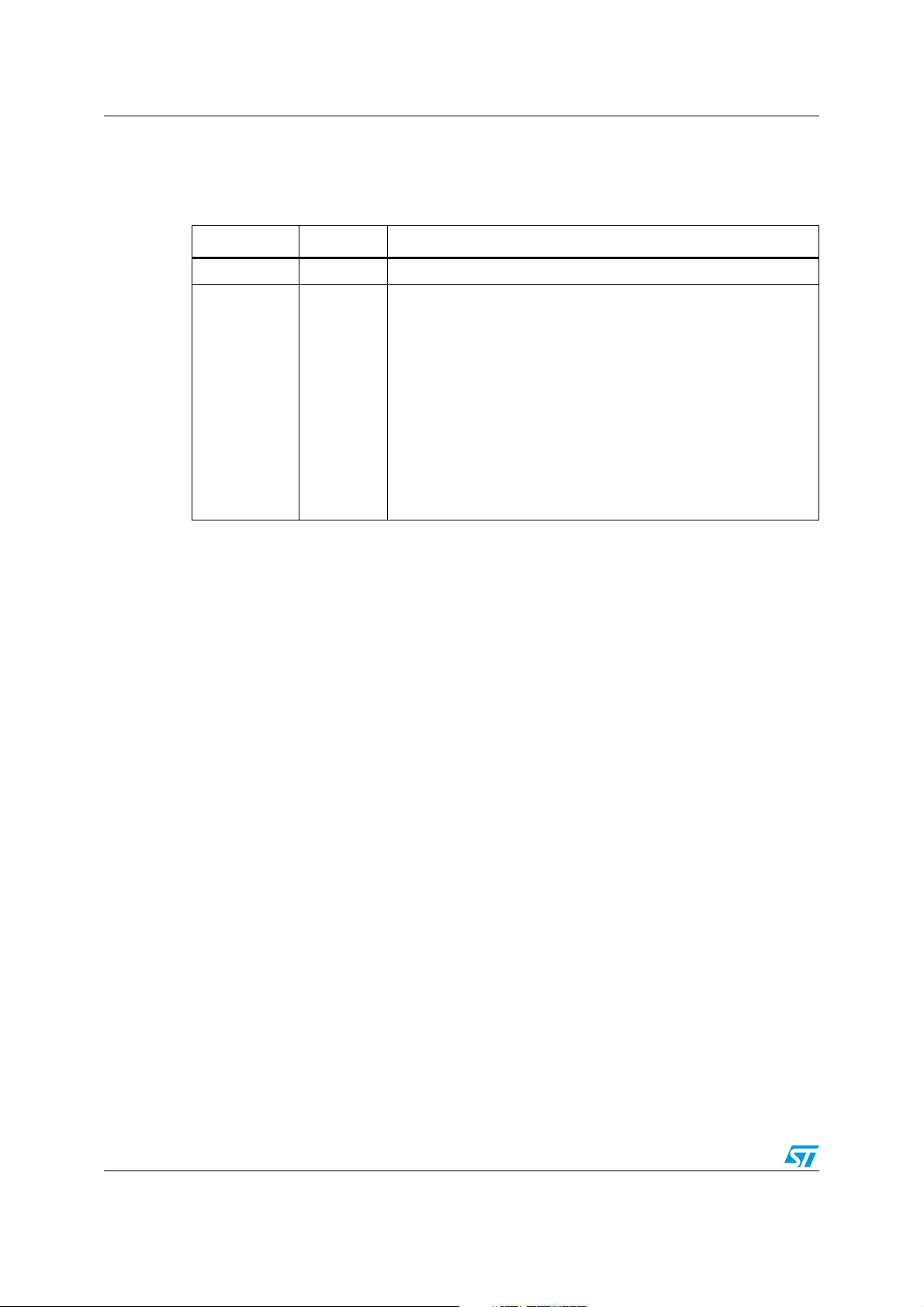

Table 1. Low-power modes

Mode name Entry Wakeup

Sleep

WFI Any interrupt CPU clock OFF

(Sleep-now

or Sleep-on-

WFE Wakeup event

exit)

PDDS and

Stop

LPDS bits +

SLEEPDEEP

bit + WFI or

Any EXTI line

(configured in the EXTI

registers)

WFE

Standby

PDDS bit +

SLEEPDEEP

bit + WFI or

WFE

WKUP pin rising edge,

RTC alarm, external

reset in NRST pin,

IWDG reset

1.2.1 Slowing down system clocks

Effect on 1.8 V

domain clocks

No effect on other

clocks or analog

clock sources

All 1.8 V domain

clocks OF

Effect on

VDD domain

clocks

Vol tag e

regulator

None ON

ON or in

low-power

mode

(depends

on the

Power

HSI and HSE

oscillators

OFF

control

register,

PWR_CR

)

OFF

In Run mode the speed of the system clocks (SYSCLK, HCLK, PCLK1, PCLK2) can be

reduced by programming the prescaler registers. These prescalers can also be used to slow

down peripherals before entering Sleep mode.

1.2.2 Peripheral clock gating

In Run mode, the HCLK and PCLKx for individual peripherals and memories can be stopped

at any time to reduce power consumption.

To further reduce power consumption in Sleep mode the peripheral clocks can be disabled

prior to executing the WFI or WFE instructions.

Peripheral clock gating is controlled by the AHB peripheral clock enable register

(RCC_AHBENR), the APB1 peripheral clock enable register (RCC_APB1ENR) and the

APB2 peripheral clock enable register (RCC_APB2ENR).

Doc ID 13922 Rev 2 9/43

Page 10

Power supply AN2629

1.2.3 Sleep mode

Entering Sleep mode

The Sleep mode is entered by executing the WFI (Wait For Interrupt) or WFE (Wait for

Event) instructions. Two options are available to select the Sleep mode entry mechanism,

depending on the SLEEPONEXIT bit in the Cortex-M3 System Control register:

● Sleep-now: if the SLEEPONEXIT bit is cleared, the MCU enters Sleep mode as soon

as WFI or WFE instruction is executed.

● Sleep-on-exit: if the SLEEPONEXIT bit is set, the MCU enters Sleep mode as soon as

it exits the lowest priority ISR.

In the Sleep mode, all I/O pins keep the same state as in the Run mode.

Refer to Table 2 and Table 3 for details on how to enter Sleep mode.

Exiting Sleep mode

If the WFI instruction is used to enter Sleep mode, any peripheral interrupt acknowledged by

the nested vectored interrupt controller (NVIC) can wake up the device from Sleep mode.

If the WFE instruction is used to enter Sleep mode, the MCU exits Sleep mode as soon as

an event occurs. The wakeup event can be generated either by:

● enabling an interrupt in the peripheral control register but not in the NVIC, and enabling

the SEVONPEND bit in the Cortex-M3 System Control register. When the MCU

resumes from WFE, the peripheral interrupt pending bit and the peripheral NVIC IRQ

channel pending bit (in the NVIC interrupt clear pending register) have to be cleared.

● or configuring an external or internal EXTI line in event mode. When the CPU resumes

from WFE, it is not necessary to clear the peripheral interrupt pending bit or the NVIC

IRQ channel pending bit as the pending bit corresponding to the event line is not set.

This mode offers the lowest wakeup time as no time is wasted in interrupt entry/exit.

Refer to Table 2 and Table 3 for more details on how to exit Sleep mode.

Table 2. Sleep-now

Sleep-now Description

WFI (Wait for Interrupt) or WFE (Wait for Event) while:

Mode entry

Mode exit

Wakeup latency None.

– SLEEPDEEP = 0 and

– SLEEPONEXIT = 0

Refer to the Cortex-M3 System Control register.

If WFI was used for entry ->Interrupt

If WFE was used for entry ->Wakeup event

10/43 Doc ID 13922 Rev 2

Page 11

AN2629 Power supply

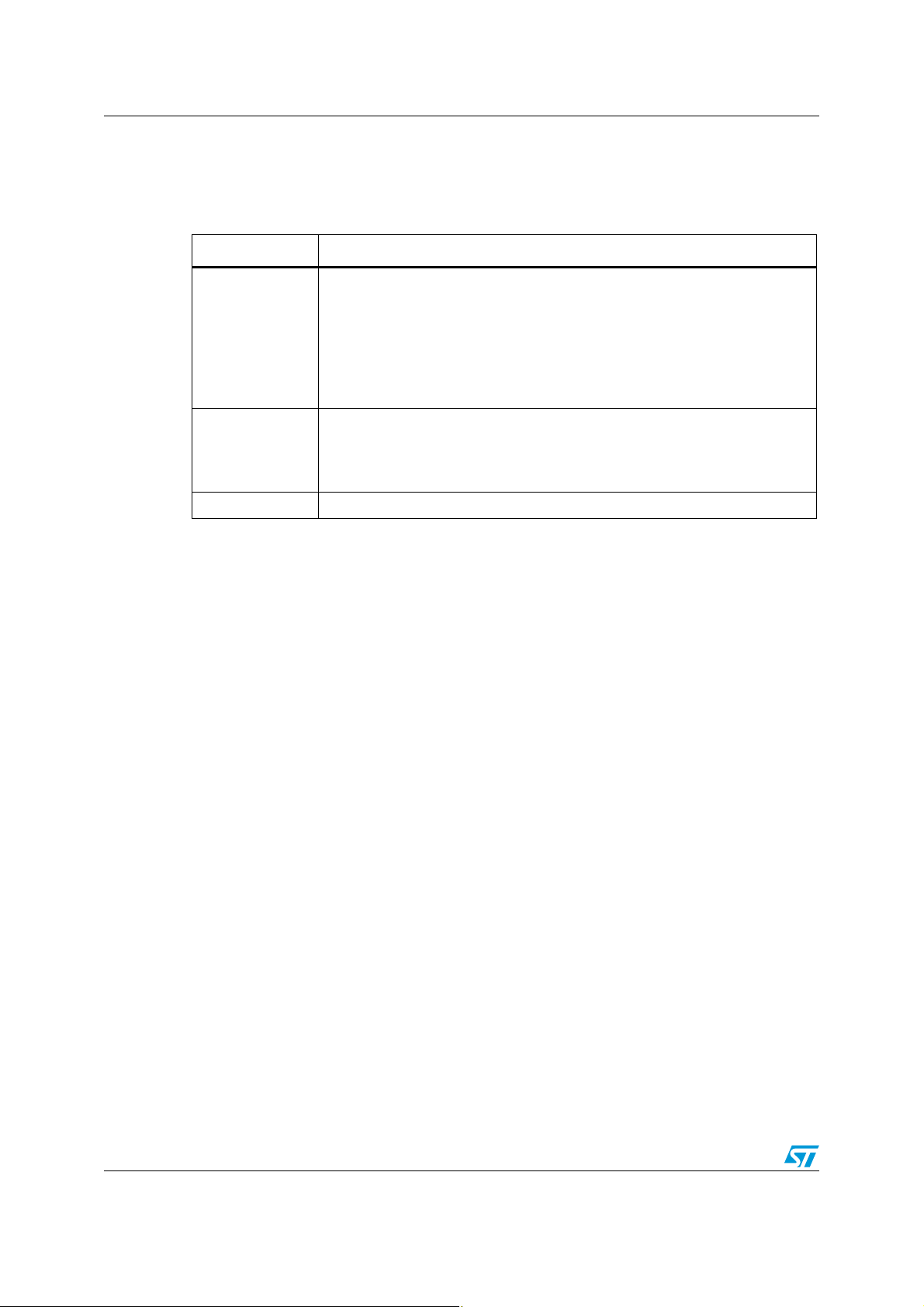

Table 3. Sleep-on-exit

Sleep-on-exit Description

WFI (wait for interrupt) while:

Mode entry

SLEEPDEEP = 0 and

SLEEPONEXIT = 1

Refer to the Cortex™-M3 System Control register.

Mode exit Interrupt.

Wakeup latency None.

1.2.4 Stop mode

The Stop mode is based on the Cortex-M3 deepsleep mode combined with peripheral clock

gating. The voltage regulator can be configured either in normal or low-power mode. In Stop

mode, all clocks in the 1.8 V domain are stopped, the PLL, the HSI and the HSE RC

oscillators are disabled. SRAM and register contents are preserved.

In the Stop mode, all I/O pins keep the same state as in the Run mode.

Entering the Stop mode

Refer to Table 4 for details on how to enter the Stop mode.

To further reduce power consumption in Stop mode, the internal voltage regulator can be

put in low-power mode. This is configured by the LPDS bit of the Power control register

(PWR_CR).

If Flash memory programming is ongoing, the Stop mode entry is delayed until the memory

access is finished.

If an access to the APB domain is ongoing, The Stop mode entry is delayed until the APB

access is finished.

In Stop mode, the following features can be selected by programming individual control bits:

● Independent watchdog (IWDG): the IWDG is started by writing to its Key register or by

hardware option. Once started it cannot be stopped except by a Reset.

● Real-time clock (RTC): this is configured by the RTCEN bit in the Backup domain

control register (RCC_BDCR)

● Internal RC oscillator (LSI RC): this is configured by the LSION bit in the Control/status

register (RCC_CSR).

● External 32.768 kHz oscillator (LSE OSC): this is configured by the LSEON bit in the

Backup domain control register (RCC_BDCR).

The ADC or DAC can also consume power during the Stop mode, unless they are disabled

before entering it. To disable them, the ADON bit in the ADC_CR2 register and the ENx bit

in the DAC_CR register must both be written to 0.

Exiting the Stop mode

Refer to Table 4 for more details on how to exit the Stop mode.

When exiting Stop mode by issuing an interrupt or a wakeup event, the HSI RC oscillator is

selected as system clock.

Doc ID 13922 Rev 2 11/43

Page 12

Power supply AN2629

When the voltage regulator operates in low-power mode, an additional startup delay is

incurred when waking up from Stop mode. By keeping the internal regulator ON during Stop

mode, the consumption is higher although the startup time is reduced.

Table 4. Stop mode

Stop mode Description

WFI (Wait for Interrupt) or WFE (Wait for Event) while:

– Set SLEEPDEEP bit in Cortex-M3 System Control register

– Clear PDDS bit in Power Control register (PWR_CR)

Mode entry

Mode exit

Wakeup latency HSI RC wakeup time + Regulator wakeup time from low-power mode

– Select the voltage regulator mode by configuring LPDS bit in PWR_CR

Note: To enter Stop mode, all EXTI Line pending bits (in Pending register

(EXTI_PR)) and RTC Alarm flag must be reset. Otherwise, the Stop mode entry

procedure is ignored and program execution continues.

If WFI was used for entry:

Any EXTI Line configured in Interrupt mode (the corresponding EXTI Interrupt

vector must be enabled in the NVIC).

If WFE was used for entry: Any EXTI Line configured in event mode.

1.2.5 Standby mode

The Standby mode allows to achieve the lowest power consumption. It is based on the

Cortex-M3 deepsleep mode, with the voltage regulator disabled. The 1.8 V domain is

consequently powered off. The PLL, the HSI oscillator and the HSE oscillator are also

switched off. SRAM and register contents are lost except for registers in the Backup domain

and Standby circuitry (see Figure 1).

Entering the Standby mode

Refer to Tab l e 5 for more details on how to enter the Standby mode.

In Standby mode, the following features can be selected by programming individual control

bits:

● Independent watchdog (IWDG): the IWDG is started by writing to its Key register or by

hardware option. Once started it cannot be stopped except by a reset.

● real-time clock (RTC): this is configured by the RTCEN bit in the Backup domain control

register (RCC_BDCR)

● Internal RC oscillator (LSI RC): this is configured by the LSION bit in the Control/status

register (RCC_CSR).

● External 32.768 kHz oscillator (LSE OSC): this is configured by the LSEON bit in the

Backup domain control register (RCC_BDCR)

Exiting the Standby mode

The microcontroller exits Standby mode when an external Reset (NRST pin), IWDG Reset,

a rising edge on WKUP pin or an RTC alarm occurs. All registers are reset after wakeup

from Standby except for the Power control/status register (PWR_CSR).

After waking up from Standby mode, program execution restarts in the same way as after a

Reset (boot pins sampling, vector reset is fetched, etc.). The SBF status flag in the Power

control/status register (PWR_CSR) indicates that the MCU was in Standby mode.

12/43 Doc ID 13922 Rev 2

Page 13

AN2629 Power supply

Table 5. Standby mode

Standby mode Description

WFI (Wait for Interrupt) or WFE (Wait for Event) while:

Mode entry

– Set SLEEPDEEP in Cortex-M3 System Control register

– Set PDDS bit in Power Control register (PWR_CR)

– Clear WUF bit in Power Control/Status register (PWR_CSR)

Mode exit

WKUP pin rising edge, RTC alarm, external Reset in

Reset.

NRST pin, IWDG

Wakeup latency Regulator start up + Reset phase

I/O states in Standby mode

In Standby mode, all I/O pins are high impedance except:

● Reset pad (still available)

● TAMPER pin if configured for tamper or calibration out

● WKUP pin, if enabled

1.2.6 Debug mode

By default, the debug connection is lost if the application puts the MCU in Stop or Standby

mode while the debug features are used. This is due to the fact that the Cortex™-M3 core is

no longer clocked.

However, by setting some configuration bits in the DBGMCU_CR register, the software can

be debugged even when using the low-power modes extensively.

1.2.7 Auto-wakeup (AWU) from low-power mode

The RTC can be used to wakeup the MCU from low-power mode without depending on an

external interrupt (Auto-wakeup mode). The RTC provides a programmable time base for

waking up from Stop or Standby mode at regular intervals. For this purpose, two of the three

alternative RTC clock sources can be selected by programming the RTCSEL[1:0] bits in the

Backup domain control register (RCC_BDCR):

● Low-power 32.768 kHz external crystal oscillator (LSE OSC).

This clock source provides a precise time base with very low-power consumption (less

than 1µA added consumption in typical conditions)

● Low-power internal RC Oscillator (LSI RC)

This clock source has the advantage of saving the cost of the 32.768 kHz crystal. This

internal RC Oscillator is designed to add minimum power consumption.

To wakeup from Stop mode with an RTC alarm event, it is necessary to:

● Configure the EXTI Line 17 to be sensitive to rising edge

● Configure the RTC to generate the RTC alarm

To wakeup from Standby mode, there is no need to configure the EXTI Line 17.

Doc ID 13922 Rev 2 13/43

Page 14

Clock AN2629

2 Clock

Three different clock sources can be used to drive the system clock (SYSCLK):

● HSI oscillator clock

● HSE oscillator clock

● PLL clock

The devices have the two secondary clock sources listed below:

● 40 kHz low-speed internal RC (LSI RC) that drives the independent watchdog and

optionally the RTC used for Auto-Wakeup from Stop/Standby mode.

● 32.768 kHz low speed external crystal (LSE crystal) that optionally drives the real-time

clock (RTCCLK)

Each clock source can be switched on or off independently when not used, to optimize

power consumption.

14/43 Doc ID 13922 Rev 2

Page 15

AN2629 Clock

HSE OSC

4-16 MHz

OSC_IN

OSC_OUT

OSC32_IN

OSC32_OUT

LSE OSC

32.768 kHz

HSI RC

8 MHz

LSI RC

40 kHz

to Independent Watchdog (IWDG)

PLL

x2, x3, x4

PLLMUL

HSE = High-speed external clock signal

LSE = Low -speed external clock signal

LSI = Low-speed internal clock signal

HSI = High-speed internal clock signal

Legend:

MCO

Clock Output

Main

PLLXTPRE

/2

..., x16

AHB

Prescaler

/1, 2..512

/2

PLLCLK

HSI

HSE

APB1

Prescaler

/1, 2, 4, 8, 16

ADC

Prescaler

/2, 4, 6, 8

ADCCLK

PCLK1

HCLK

PLLCLK

to AHB bus, core,

memory and DMA

USBCLK

to USB interface

USB

Prescaler

/1, 1.5

to ADC1, 2 or 3

LSE

LSI

HSI

/128

/2

HSI

HSE

peripherals

to APB1

Peripheral Clock

Enable

Enable

Peripheral Clock

APB2

Prescaler

/1, 2, 4, 8, 16

PCLK2

TIM1 & 8 timers

to TIM1 and TIM8

peripherals to APB2

Peripheral Clock

Enable

Enable

Peripheral Clock

48 MHz

72 MHz max

72 MHz

72 MHz max

36 MHz max

to RTC

PLLSRC

SW

MCO

CSS

to Cortex System timer

/8

Clock

Enable

SYSCLK

max

RTCCLK

RTCSEL[1:0]

TIMxCLK

TIMXCLK

IWDGCLK

SYSCLK

FCLK Cortex

free running clock

/2

TIM2,3,4,5,6,7

to TIM2,3,4,5,6 and 7

To SDIO AHB interface

Peripheral clock

enable

HCLK/2

to FSMC

FSMCCLK

to SDIO

Peripheral clock

enable

Peripheral clock

enable

to I2S3

to I2S2

Peripheral clock

enable

Peripheral clock

enable

I2S3CLK

I2S2CLK

SDIOCLK

ai14752c

If (APB1 prescaler =1) x1

else x2

If (APB2 prescaler =1) x1

else x2

Figure 2. Clock tree

1. When the HSI is used as a PLL clock input, the maximum system clock frequency that can be achieved is

Several prescalers allow the configuration of the AHB frequency, the high speed APB

(APB2) and the low speed APB (APB1) domains. The maximum frequency of the AHB and

APB2 domains is 72 MHz. The maximum allowed frequency of the APB1 domains is

64 MHz.

36 MHz. The RCC feeds the external clock of the Cortex system timer (SysTick) with the

AHB clock (HCLK) divided by 8. The SysTick can work either with this clock or with the

Cortex clock (HCLK), configurable in the SysTick Control and Status Register. The ADCs

are clocked by the high speed domain (APB2) clock divided by 2, 4, 6 or 8.

The timer clock frequencies are twice the frequency of the APB domain to which they are

connected. Nevertheless, if the APB prescaler is 1, the clock frequency of the timer is the

same as the frequency of the APB domain to which it is connected.

FCLK acts as the Cortex™-M3 free running clock. For more details refer to the ARM

Cortex™-M3 Technical Reference Manual.

Doc ID 13922 Rev 2 15/43

Page 16

Real-time clock (RTC) AN2629

3 Real-time clock (RTC)

3.1 Introduction

The real-time clock is an independent timer. The RTC provides a set of continuously-running

counters which can be used, with suitable software, to provide a clock-calendar function.

The counter values can be written to set the current time/date of the system.

3.2 Main features

● Programmable prescaler: division factor up to 2

●

32-bit programmable counter for long-term measurement

● Two separate clocks: PCLK1 for the APB1 interface and RTC clock (must be at least

four times slower than the PCLK1 clock)

● Two separate reset types:

– The APB1 interface is reset by system reset

– The RTC Core (Prescaler, Alarm, Counter and Divider) is reset only by a Backup

domain reset (see “Backup domain reset” section in the STM32F10xxx reference

manual).

● Three dedicated maskable interrupt lines:

– Alarm interrupt, for generating a software programmable alarm interrupt.

– Seconds interrupt, for generating a periodic interrupt signal with a programmable

period length (up to 1 second).

– Overflow interrupt, to detect when the internal programmable counter rolls over to

zero.

20

3.3 Functional description

3.3.1 Overview

The RTC consists of two main units (see Figure 3 on page 17). The first one (APB1

Interface) is used to interface with the APB1 bus. This unit also contains a set of 16-bit

registers accessible from the APB1 bus in read or write mode. The APB1 interface is

clocked by the APB1 bus clock in order to interface with the APB1 bus.

The other unit (RTC Core) consists of a chain of programmable counters made of two main

blocks. The first block is the RTC prescaler block, which generates the RTC time base

TR_CLK that can be programmed to have a period of up to 1 second. It includes a 20-bit

programmable divider (RTC Prescaler). Every TR_CLK period, the RTC generates an

interrupt (Second Interrupt) if it is enabled in the RTC_CR register. The second block is a

32-bit programmable counter that can be initialized to the current system time. The system

time is incremented at the TR_CLK rate and compared with a programmable date (stored in

16/43 Doc ID 13922 Rev 2

the RTC_ALR register) in order to generate an alarm interrupt, if enabled in the RTC_CR

control register.

Page 17

AN2629 Real-time clock (RTC)

RTC_Over flow

32-bit programmable

RTC_DIV

RTC_ALR

RTC_CNT

=

Reload

TR_CLK

RTC prescaler

APB1 interface

APB1 bus

RTC_CR

RTC_PRL

NVIC interrupt

controller

OWF

RTCCLK

rising

edge

counter

RTC_Second

RTC_Alarm

OWIE

SECF

SECIE

ALRF

ALRIE

Standby mode

exit from

powered in Standby

powered in Standby

not powered in Standby

not powered in Standby

powered in Standby

not powered in Standby

RTC_Alarm

WKP_STDBY

WKUP pin

Backup domain

PCLK1

Figure 3. RTC simplified block diagram

Doc ID 13922 Rev 2 17/43

Page 18

Real-time clock (RTC) AN2629

3.3.2 Resetting RTC registers

All system registers are asynchronously reset by a System Reset or Power Reset, except for

RTC_PRL, RTC_ALR, RTC_CNT, and RTC_DIV.

The RTC_PRL, RTC_ALR, RTC_CNT, and RTC_DIV registers are reset only by a Backup

Domain reset. Refer to the STM32F10xxx reference manual.

3.3.3 Reading RTC registers

The RTC core is completely independent from the RTC APB1 interface.

Software accesses the RTC prescaler, counter and alarm values through the APB1 interface

but the associated readable registers are internally updated at each rising edge of the RTC

clock resynchronized by the RTC APB1 clock. This is also true for the RTC flags.

This means that the first read to the RTC APB1 registers may be corrupted (generally read

as 0) if the APB1 interface has previously been disabled and the read occurs immediately

after the APB1 interface is enabled but before the first internal update of the registers. This

can occur if:

● A system reset or power reset has occurred

● The MCU has just woken up from Standby mode (see the STM32F10xxx reference

manual)

● The MCU has just woken up from Stop mode (see the STM32F10xxx reference

manual)

In all the above cases, the RTC core has been kept running while the APB1 interface was

disabled (reset, not clocked or not powered).

Consequently when reading the RTC registers, after having disabled the RTC APB1

interface, the software must first wait for the RSF bit (Register Synchronized Flag) in the

RTC_CRL register to be set by hardware.

Note that the RTC APB1 interface is not affected by WFI and WFE low-power modes.

3.3.4 Configuring RTC registers

To write in the RTC_PRL, RTC_CNT, RTC_ALR registers, the peripheral must enter

Configuration Mode. This is done by setting the CNF bit in the RTC_CRL register.

In addition, writing to any RTC register is only enabled if the previous write operation is

finished. To enable the software to detect this situation, the RTOFF status bit is provided in

the RTC_CR register to indicate that an update of the registers is in progress. A new value

can be written to the RTC registers only when the RTOFF status bit value is ‘1’.

Configuration procedure:

1. Poll RTOFF, wait until its value goes to ‘1’

2. Set the CNF bit to enter configuration mode

3. Write to one or more RTC registers

4. Clear the CNF bit to exit configuration mode

5. Poll RTOFF, wait until its value goes to ‘1’ to check the end of the write operation.

The write operation only executes when the CNF bit is cleared; it takes at least three

RTCCLK cycles to complete.

18/43 Doc ID 13922 Rev 2

Page 19

AN2629 Real-time clock (RTC)

RTC_CNT 0000

0001

RTC_PR

0002 0001 0000 0003 0002 0001 0000 0003

0002

RTC_ALARM

0002 0001 0000 0003

0003

0002 0001 0000 0003

0004

0002 0001 0000 0003

ALRF

can be cleared by software

RTC_Second

RTCCLK

0005

0002 0001 0000 0003

(not powered

in Standby)

1 RTCCLK

RTC_CNT FFFFFFFB

FFFFFFFC

RTC_PR

0002 0001 0000 0003 0002 0001 0000 0003

FFFFFFFD

RTC_Overflow

0002 0001 0000 0003

FFFFFFFE

0002 0001 0000 0003

FFFFFFFF

0002 0001 0000 0003

OWF

can be cleared by software

RTC_Second

RTCCLK

0000

0002 0001 0000 0003

(not powered

in Standby)

1 RTCCLK

3.3.5 RTC flag assertion

The RTC Second flag (SECF) is asserted on each RTC Core clock cycle before the update

of the RTC Counter.

The RTC Overflow flag (OWF) is asserted on the last RTC Core clock cycle before the

counter reaches 0x0000.

The RTC_Alarm and RTC Alarm flag (ALRF) (see Figure 4) are asserted on the last RTC

Core clock cycle before the counter reaches the RTC Alarm value stored in the Alarm

register increased by one (RTC_ALR + 1). The write operation in the RTC Alarm and RTC

Second flag must be synchronized by using one of the following sequences:

● Use the RTC Alarm interrupt and inside the RTC interrupt routine, the RTC Alarm

and/or RTC Counter registers are updated.

● Wait for SECF bit to be set in the RTC Control register. Update the RTC Alarm and/or

the RTC Counter register.

Figure 4. RTC second and alarm waveform example with PR=0003, ALARM=00004

Figure 5. RTC Overflow waveform example with PR=0003

Doc ID 13922 Rev 2 19/43

Page 20

Backup registers (BKP) AN2629

4 Backup registers (BKP)

4.1 Introduction

The backup registers are ten 16-bit registers for storing 20 bytes of user application data.

They are implemented in the backup domain that remains powered on by V

V

power is switched off. They are not reset when the device wakes up from Standby

DD

mode or by a system reset or power reset.

In addition, the BKP control registers are used to manage the Tamper detection feature and

RTC calibration.

After reset, the access to Backup registers and RTC is disabled and the Backup domain is

protected against possible parasitic write access.

The DBP bit must be set in the Power control register (PWR_CR) to enable access to the

Backup registers and RTC.

4.2 Features

● Ten 16-bit data registers.

● Status/control register for managing the anti-Tamper feature

● Calibration register for storing the RTC calibration value

when the

BAT

4.3 Tamper detection

The TAMPER pin generates a Tamper detection event when the pin changes from 0 to 1 or

from 1 to 0 depending on the TPAL bit in the Backup control register (BKP_CR). A tamper

detection event resets all data backup registers.

However to avoid losing Tamper events, the signal used for edge detection is logically

ANDed with the Tamper enable in order to detect a Tamper event in case it occurs before

the TAMPER pin is enabled.

● When TPAL=0: If the TAMPER pin is already high before it is enabled (by setting TPE

bit), an extra Tamper event is detected as soon as the TAMPER pin is enabled (while

there was no rising edge on the TAMPER pin after TPE was set)

● When TPAL=1: If the TAMPER pin is already low before it is enabled (by setting the

TPE bit), an extra Tamper event is detected as soon as the TAMPER pin is enabled

(while there was no falling edge on the TAMPER pin after TPE was set)

After a Tamper event has been detected and cleared, the TAMPER pin should be disabled

and then re-enabled with TPE before writing to the backup data registers (BKP_DRx) again.

This prevents software from writing to the backup data registers (BKP_DRx), while the

TAMPER pin value still indicates a Tamper detection. This is equivalent to a level detection

on the TAMPER pin.

Note: Tamper detection is still active when V

of the data backup registers, the TAMPER pin should be externally tied to the correct level.

power is switched off. To avoid unwanted resetting

DD

20/43 Doc ID 13922 Rev 2

Page 21

AN2629 Backup registers (BKP)

4.4 RTC calibration

For measurement purposes, the 32.768 kHz RTC clock can be output on the TAMPER pin.

This is enabled by setting the CCO bit in the RTC clock calibration register (BKP_RTCCR).

The clock can be slowed down by up to 121 ppm by configuring CAL[6:0] bits.

Doc ID 13922 Rev 2 21/43

Page 22

Power and wakeup time measurement AN2629

5 Power and wakeup time measurement

5.1 Introduction

This section describes the measurement of the STM32F10xxx low-power mode

consumptions and wake up timings. All described tests are made on the STM3210B

evaluation board (order code STM3210B-EVAL) and can easily be tailored to any other

hardware. This board is available for evaluation and testing purposes. Please contact your

local ST sales office for further details.

This section is divided into two main parts: the first describes power measurement and the

second handles the measurement of the time required by the STM32F10xxx to wake up

from the different low-power modes.

5.2 Power measurement

5.2.1 Context

This part describes how to measure the power consumption of the STM32F10xxx using the

firmware provided in the Zip file that comes with this application note. This firmware is

available in the CurrentMeasurements folder.

The CurrentMeasurements folder contains all the subdirectories and files that make up the

core of the application example:

● inc subfolder contains the example header files

● src subfolder contains the example source files

● project subfolder contains two projects that compile the example files:

– EWARMv5: contains the project for the EWARM toolchain

– RVMDK: contains the project for the RVMDK toolchain

– RIDE: contains the project for the RIDE toolchain

5.2.2 Detailed description

Power is measured in the following STM32F10xxx low-power modes:

● Sleep mode: power consumption in this mode depends on the used clock and the

active peripherals. So, to cover the whole applicative functionality of this mode,

measurements are made using different clock sources (HSI and HSE), clock

frequencies (from 125 kHz to 72 MHz) and APB peripheral configurations (all

peripheral clocks ON or all peripheral clocks OFF).

● Stop mode: power consumption in this mode is measured in the two possible

configurations of the Stop mode (Regulator in Run mode and Regulator in low-power

mode).

Note that for the Sleep and Stop modes, all unused I/O pins are configured as analog

pins. The Schmitt trigger input is thus deactivated, leading to zero consumption for

these I/O pins.

● Standby mode: power consumption in the standby mode is measured with RTC OFF

and with RTC ON.

Note: For more details on the different low-power modes please refer to Section 1: Power supply.

22/43 Doc ID 13922 Rev 2

Page 23

AN2629 Power and wakeup time measurement

Hardware environment

● Sleep, Stop and Standby (With RTC OFF): the measurement of the power

consumption is made by replacing jumper JP9 in the STM3210B-EVAL board by an

ammeter and by powering the board from an external supply, or by using the USB

cable.

● RTC powered by V

: the measurement is made by connecting an external power

BAT

supply to the pin 2 of jumper J11. The ammeter is then connected in series.

Firmware description

The firmware provided is divided into the following files:

● File main.c:

This file contains the main firmware body. The user can select the needed low-power

mode by uncommenting the respective line:

/* Define the Low power mode*/

//#define SLEEP

//#define SLEEP_ALLPERIPH_ENABLE

//#define SLEEP_ALLPERIPH_DISABLE

//#define STOP

//#define STOP_Regulator_ON

//#define STOP_Regulator_LowPower

//#define STANDBY

//#define RTC_ON

●

hw_config.c and hw_config.h files:

These files contain all functions related to the configuration of the STM32F10xxx (clock

configuration, peripheral enable/disable, I/O configuration, etc.).

To select the way the Sleep and Stop mode are entered (WFI or WFE), uncomment the

corresponding line in the hw_config.h file:

/* Define the entry to the low power mode */

//#define Entry_WFE

//#define Entry_WFI

To select the needed clock configuration for Sleep mode, uncomment the

corresponding line in the hw_config.h file:

/* Define the clock settings */

#define HSE_PLL_ON

#define HSE_PLL_ON_72MHz

//#define HSE_PLL_ON_48MHz

//#define HSE_PLL_ON_36MHz

//#define HSE_PLL_ON_24MHz

//#define HSE_PLL_ON_16MHz

//#define HSE_PLL_OFF

Doc ID 13922 Rev 2 23/43

Page 24

Power and wakeup time measurement AN2629

//#define HSE_PLL_OFF_8MHz

//#define HSE_PLL_OFF_4MHz

//#define HSE_PLL_OFF_2MHz

//#define HSE_PLL_OFF_1MHz

//#define HSE_PLL_OFF_500kHz

//#define HSE_PLL_OFF_125kHz

//#define HSI_PLL_ON

//#define HSI_PLL_ON_64MHz

//#define HSI_PLL_ON_48MHz

//#define HSI_PLL_ON_36MHz

//#define HSI_PLL_ON_24MHz

//#define HSI_PLL_ON_16MHz

//#define HSI_PLL_OFF

//#define HSI_PLL_OFF_8MHz

//#define HSI_PLL_OFF_4MHz

//#define HSI_PLL_OFF_2MHz

//#define HSI_PLL_OFF_1MHz

//#define HSI_PLL_OFF_500kHz

//#define HSI_PLL_OFF_125kHz

Note: 1 With both HSI and HSE clock sources, if the system clock frequency is equal to or less than

8 MHz, the PLL is turned off.

2 The Wakeup push-button of the STM3210B-EVAL board (connected to pin PA0 in the

STM32F10xxx) is used as the wakeup source for all low-power modes.

● stm32f10x_it.c file:

This file manages the interrupt service routine of the EXTI line 0 if the selected way of

entering the low-power mode is the WFI instruction.

24/43 Doc ID 13922 Rev 2

Page 25

AN2629 Power and wakeup time measurement

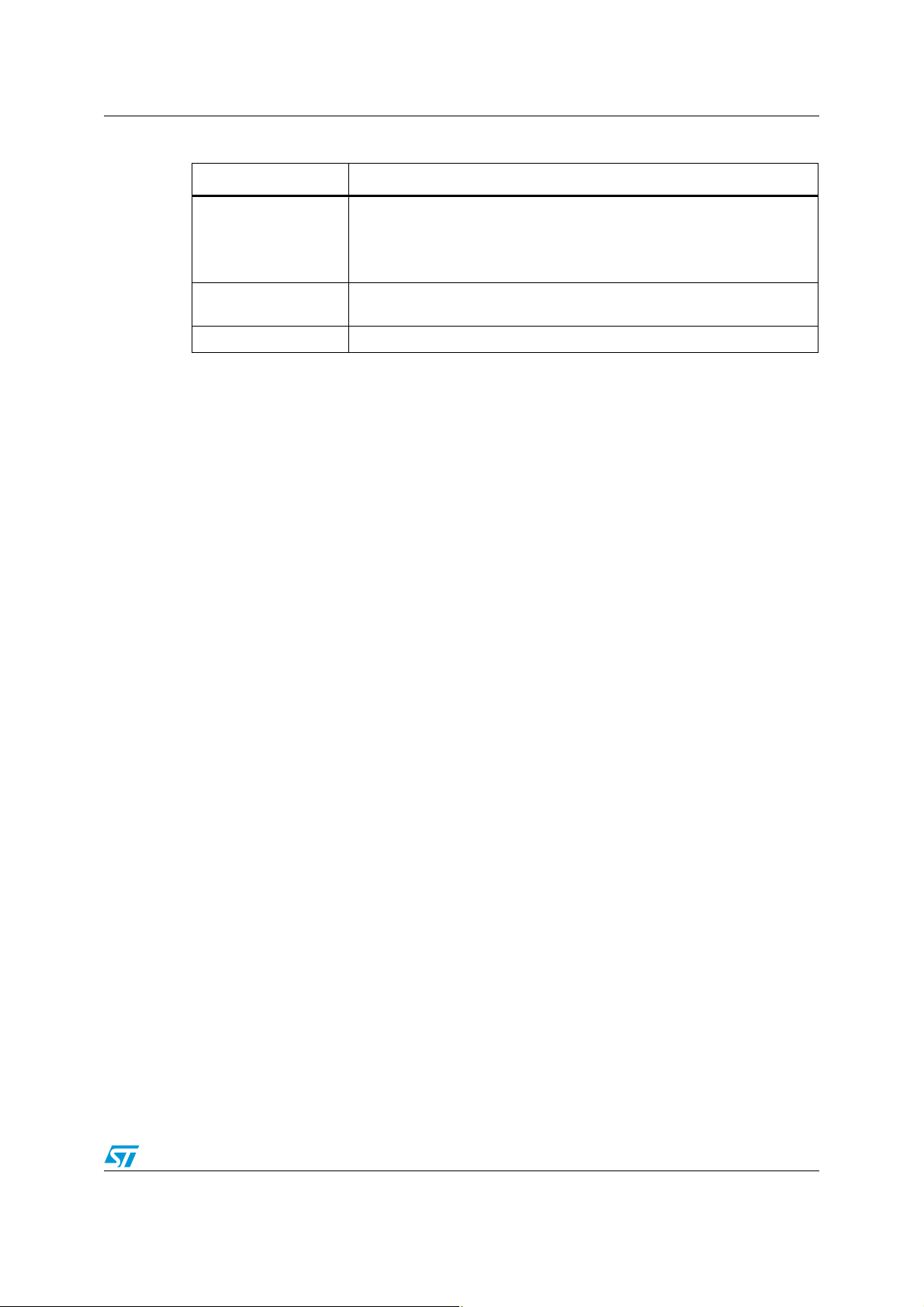

5.2.3 Measurement results

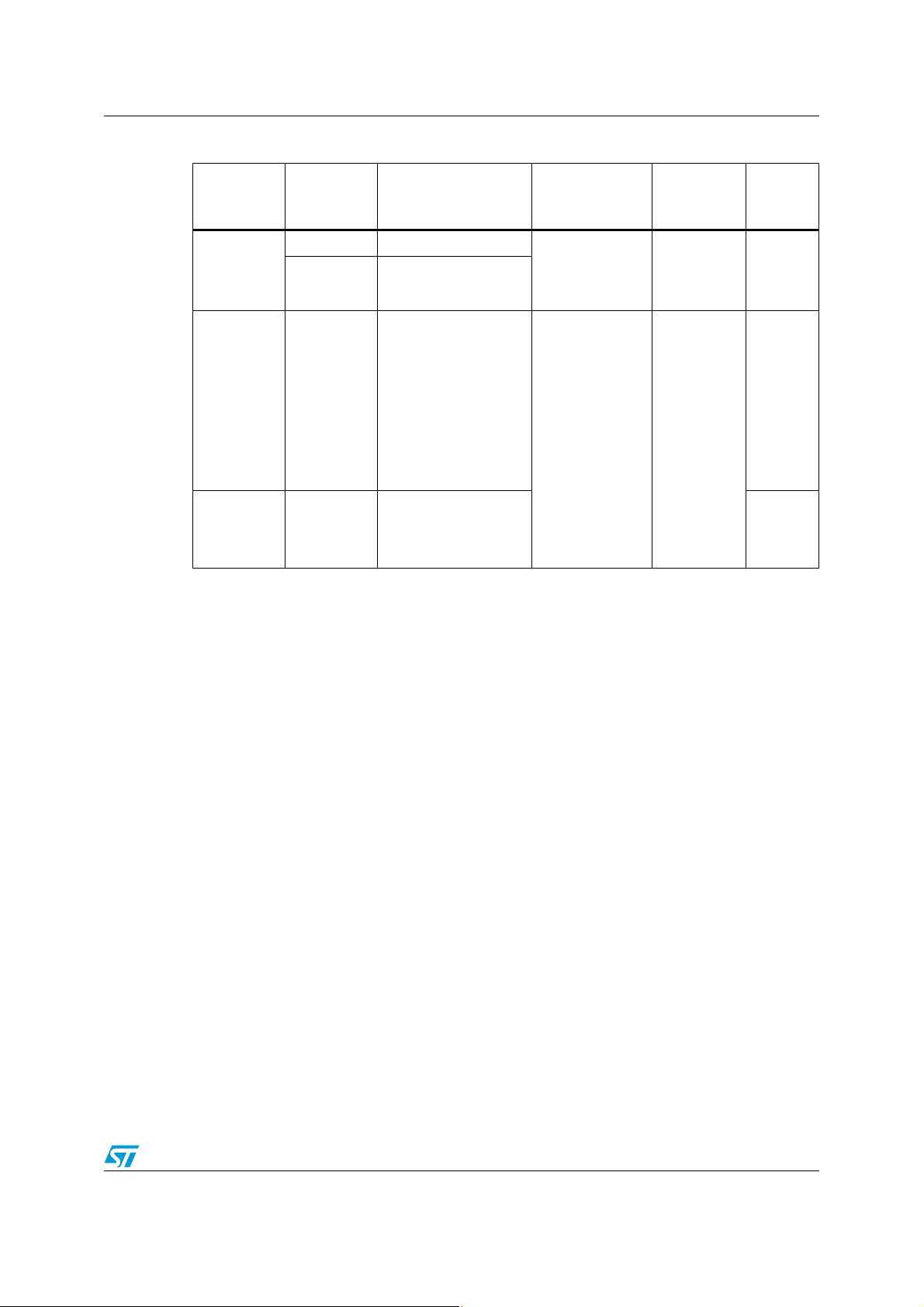

Ta bl e 6 and Tab le 7 summarize the measurement results of power consumption in the

Sleep, Stop and Standby modes.

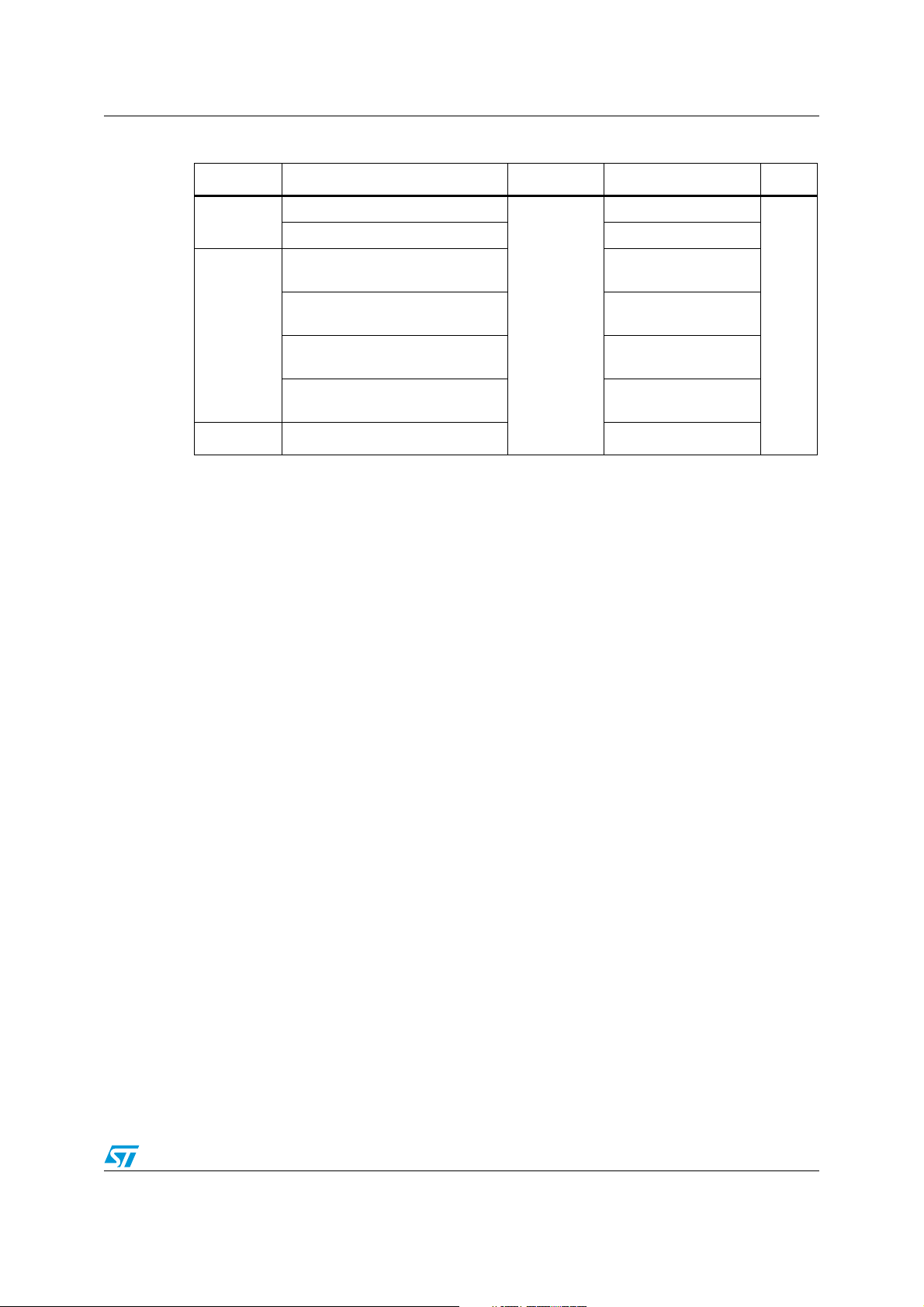

Table 6. Power measurement results in Sleep mode

Symbol Parameter Conditions f

Running on HSE,

AHB prescaler used

to reduce the

frequency

I

DD

Supply current

in Sleep mode

Running on high

speed internal RC

(HSI), AHB prescaler

used to reduce the

frequency

HCLK

All APB

peripherals

enabled

All APB

peripherals

disabled

72 MHz 14.4 5.5

48 MHz 9.9 3.9

36 MHz 7.6 3.1

24 MHz 5.3 2.3

16 MHz 3.8 1.8

8 MHz 2.1 1.2

4 MHz 1.6 1.1

2 MHz 1.3 1

1 MHz 1.11 0.98

500 kHz 1.04 0.96

125 kHz 0.98 0.95

64 MHz 12.3 4.4

48 MHz 9.3 3.3

36 MHz 7 2.5

24 MHz 4.8 1.8

16 MHz 3.2 1.2

8 MHz 1.6 0.6

4 MHz 1 0.5

2 MHz 0.72 0.47

unit

mA

1 MHz 0.56 0.44

500 kHz 0.49 0.42

125 kHz 0.43 0.41

Doc ID 13922 Rev 2 25/43

Page 26

Power and wakeup time measurement AN2629

Table 7. Power measurement for Stop and Standby modes

=

Symbol Parameter Conditions

Regulator in Run mode, lowspeed and high-speed internal

RC oscillators and high-speed

oscillator OFF (no independent

watchdog)

Regulator in Low Power mode,

low-speed and high-speed

internal RC oscillators and high-

I

Supply current

in Stop mode

DD

speed oscillator OFF (no

independent watchdog)

Supply current

in Standby

mode

Low-speed internal RC oscillator

and independent watchdog OFF,

low-speed oscillator and RTC

OFF

V

DD/VBAT

2.4 V

NA 24

NA 14

NA 2

VDD/V

BAT

3.3 V

=

Unit

µA

I

DD_VBAT

Backup domain

supply current

Low-speed oscillator and RTC

ON

5.3 Wakeup time measurement

5.3.1 Context

This part describes how to measure the time required by the STM32F10xxx to wake up from

different low-power modes, using the firmware provided with this application note. The

firmware is found in the Zip file in the WakeUpTiming folder

The WakeUp_Timing folder contains all the subdirectories and files that make up the core

of the application example:

● inc subfolder contains the example header files

● src subfolder contains the example source files

● project subfolder contains two projects that compile the example files:

– EWARMv5: contains the project for the EWARM toolchain

– RVMDK: contains the project for the RVMDK toolchain

– RIDE: contains the project for the RIDE toolchain

1.08 1.4

26/43 Doc ID 13922 Rev 2

Page 27

AN2629 Power and wakeup time measurement

5.3.2 Detailed description

The wakeup time is defined as follows:

● For Sleep and Stop modes: the wakeup time starts on setting the wakeup source (in

our case the Wakeup push-button of the STM3210B-EVAL board connected to pin

PA0) and ends:

– after the execution of the first instruction after the WFE (in the case of wakeup on

an external event) or

– after the execution of the first instruction of the interrupt service routine (in the

case of wakeup on an external interrupt)

● Standby mode: after waking up from Standby mode, program execution restarts in the

same way as after a Reset. So the wakeup time for the Standby mode is the time

between the selection of the wakeup source (Wakeup push-button) and the execution

of the first instruction of the code.

Note: For more details on the different low-power modes please refer to Section 1: Power supply.

Hardware environment

Pin PC6 is set to one after wakeup from the low-power modes, so, to measure the wakeup

time, an oscilloscope should be connected across the PC6 and PA0 pins. The wakeup time

is the time between the rising edge of PA0 (Wakeup button) and the rising edge of PC6.

Firmware description

The firmware provided is divided into the following files:

● main.c:

This file contains the main Firmware body. The user can select the low-power mode to

test by uncommenting the respective line:

/* Define the Low power mode*/

//#define SLEEP

//#define STOP_Regulator_ON

//#define STOP_Regulator_LowPower

//#define STANDBY

Before entering a low-power mode, PC6 is configured as an output push-pull (speed

50 MHz) and reset to the low level.

a) For the Sleep and Stop modes:

– in the case of WFE, a direct write to the BSRR (Bit Set Reset register) is

performed to set PC6 to the high level

– in case of WFI, the setting of PC6 is managed on the interrupt service routine of

the EXTI line 0

b) For the Standby mode, pin PC6 should be set at the code startup (this part of the

code is managed in the startup files. See below).

● tools startup file:

To measure the wakeup time for the Standby mode, it is first necessary to configure

and set the PC6 pin. To manage this, the following asm code is added to the tools

startup file:

; Set clock GPIOC (APB)

Doc ID 13922 Rev 2 27/43

Page 28

Power and wakeup time measurement AN2629

MOVW.W r3,#0x1000

MOVT.W r3,#0x4002

MOVS r1,#0x10

STR r1,[r3,#0x18]

; Set GPIOC config for Pin 6 in Output Push-Pull

MOVW.W r3,#0x1000

MOVT.W r3,#0x4001

MOVS r1,#0x03000000

STR r1,[r3,#0x00]

; GPIOC, GPIO_Pin_6, Bit_SET

MOVS r2,#0x40

STR r2,[r3,#0x10]

– Keil tool (RVMDK): this code is inserted in the startup_stm32f10x_md.s file before

the branch to the main.

– IAR tool (EWARM): this code is inserted in the startup_stm32f10x_md.s file in the

__low_level_init(void) function.

● hw_config.c and hw_config.h:

These files contain all functions related to the STM32F10xxx configuration (clock

configuration, I/O configuration, etc.). To select the way the Sleep and Stop mode are

entered (WFI or WFE), uncomment the corresponding line in the hw_config.h file:

/* Define the entry to the low power mode */

//#define Entry_WFE

//#define Entry_WFI

Note: For all measurements, the HSI is the Wakeup clock source.

● stm32f10x_it.c:

This file manages the interrupt service routine of the EXTI line 0 if the selected way of

entering the low-power mode is the WFI instruction.

5.3.3 Measurement results

Ta bl e 8 summarizes the wakeup time measurement results in Sleep, Stop and Standby

modes.

28/43 Doc ID 13922 Rev 2

Page 29

AN2629 Power and wakeup time measurement

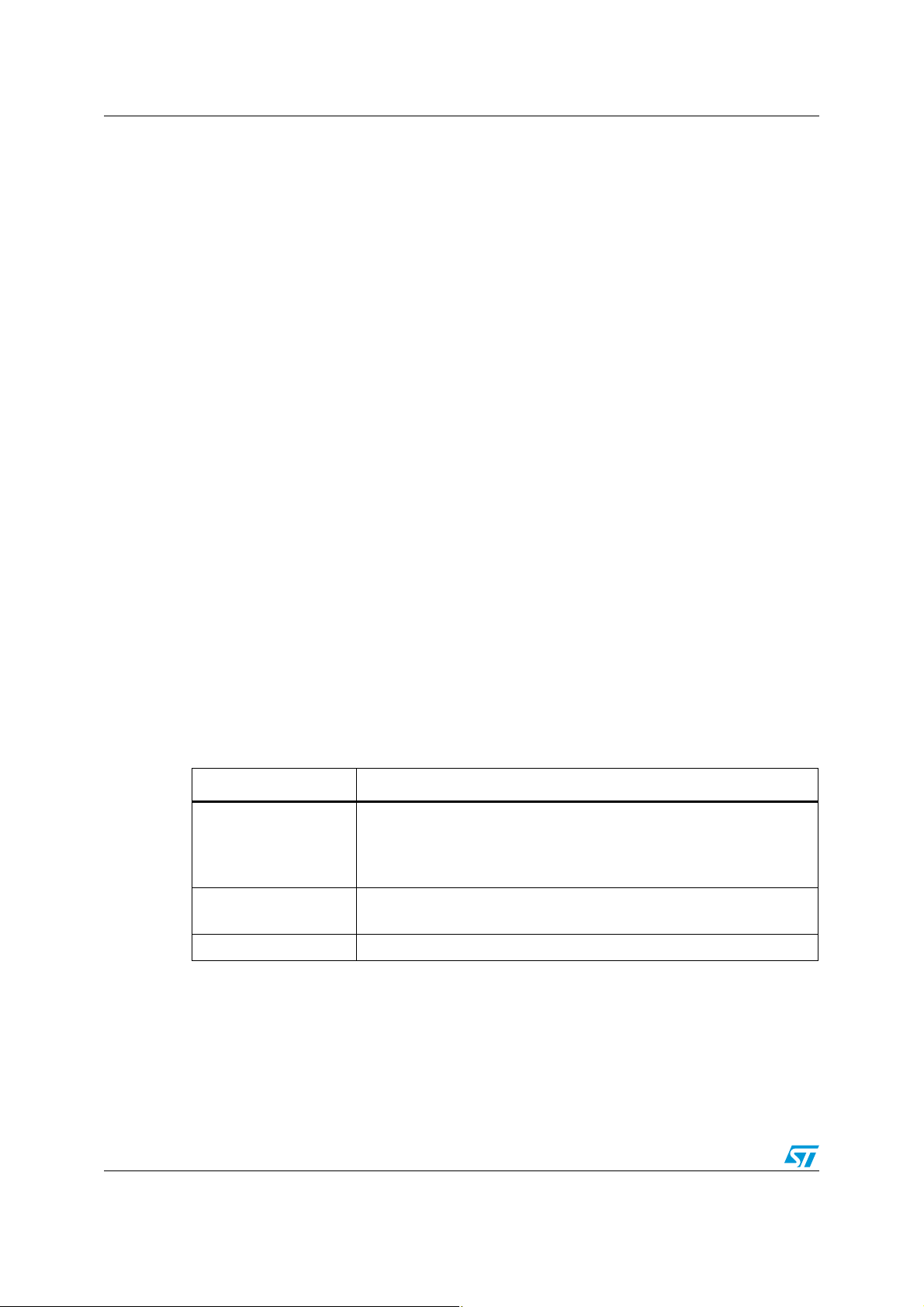

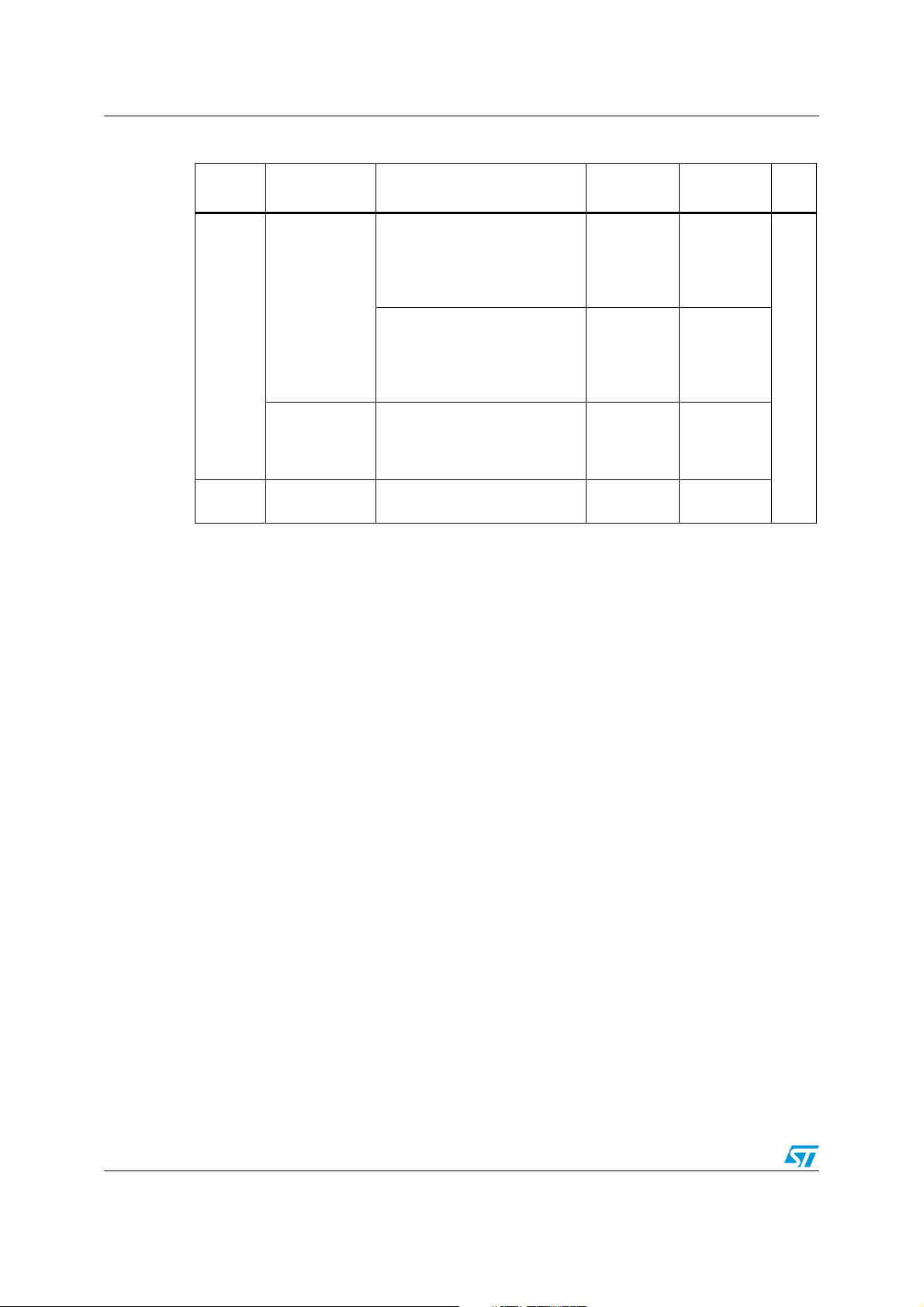

Table 8. Wakeup time measurement results

Symbol Parameter Conditions Typ Unit

t

WUSLEEP

t

WUSTOP

t

WUSTDBY

5.3.4 Conclusion

These different results show the trade-off between consumption and wakeup time in the

STM32F10xxx. Generally, the lower the power consumption, the longer the wakeup time.

The user should therefore try to find the best trade-off according to the application

constraints.

Wakeup from Sleep mode (WFE)

1.8

Wakeup from Sleep mode (WFI) 3.75

Wakeup from Stop mode (regulator

in run mode + WFE)

Wakeup from Stop mode (regulator

in run mode + WFI)

Wakeup from Stop mode (regulator

in Low power mode + WFE)

Wakeup from Stop mode (regulator

in Low power mode + WFI)

Wakeup on

HSI RC clock

3.52

5.42

5.32

7.21

Wakeup from Standby mode 50

µs

Doc ID 13922 Rev 2 29/43

Page 30

Optimizing power consumption in your application AN2629

6 Optimizing power consumption in your application

6.1 Introduction

According to the laws of physics, microcontroller power consumption increases with the

clock frequency. This is why the best ratio between consumption and performance has to be

found. In many applications, power consumption can be reduced by adjusting

system/peripheral frequency to the required performance. The STM32F10xxx offers the

Slow mode features to reach that aim. If no specific system/peripheral activity is required,

the low-power modes of the STM32F10xxx can be used.

This section describes how to use the Slow and Low-power modes to optimize consumption

according to the application requirement.

A software example is provided that gives a practical view of power optimization. With this

software, the user can measure the consumption of the STM32F10xxx with the different

optimization possibilities.

6.2 Using the advance clock configuration of the STM32F10xxx

6.2.1 Context

This section describes how to use the clock configuration of the STM32F10xxx, using a

firmware found in the Zip file delivered with this application note. This firmware is available in

the Run_Mode folder.

The Run_Mode folder contains all the subdirectories and files that make up the core of the

application example:

● inc subfolder contains the example header files

● src subfolder contains the example source files

● project subfolder contains two projects that compile the example files:

– EWARMv5: contains the project for the EWARM toolchain

– RVMDK: contains the project for the RVMDK toolchain

– RIDE: contains the project for the RIDE toolchain

6.2.2 Detailed description

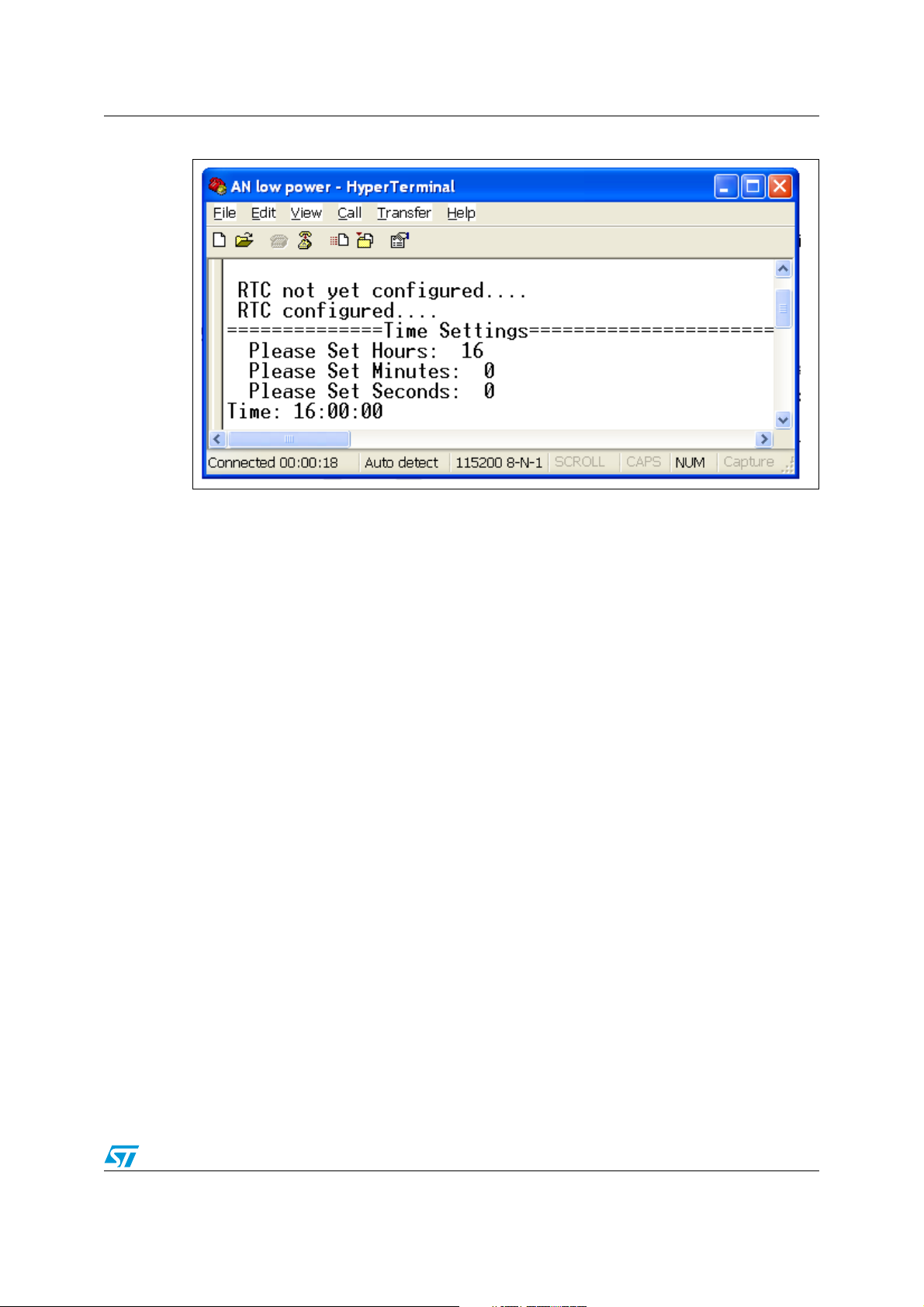

The program is a basic application that sends the time from RTC on a serial line (USART).

● At the beginning of the application, the user has to adjust the time using the

HyperTerminal for instance.

● Time is displayed on the terminal and refreshed every second. Practically, the RTC is

configured to generate an interruption every second.

● When the interruption occurs, the RTC counter is captured; the time is calculated and

sent through USART1.

Figure 6 below shows the HyperTerminal view of the time adjustment interface.

30/43 Doc ID 13922 Rev 2

Page 31

AN2629 Optimizing power consumption in your application

Figure 6. HyperTerminal time adjustment interface

Hardware environment

Use this example with STM32F10xxx evaluation board: refer to the user manual UM0426:

“STM3210B-EVAL evaluation board” to use the STM3210B-EVAL.

● The USART1 signals (RX, TX) must be connected to a DB9 connector using an RS232

transceiver.

● A null-modem female/female RS232 cable must be connected between the DB9

connector (CN6 on STM3210B-EVAL board) and the PC serial port.

● After connecting the power supply and the JTAG tools, the power consumption can be

measured by replacing Jumper JP9 by an ammeter.

Firmware description

● Launch this example with the used toolchain:

The standard tools can be used to run the example.

The .uv2 file used to launch the project with the RVMDK toolchain is contained in the

RVMDK folder.

Doc ID 13922 Rev 2 31/43

Page 32

Optimizing power consumption in your application AN2629

The .eww file, used to launch the project with the EWARM toolchain, is in the EWARM

folder.

● Configure HyperTerminal on the PC

– Word length = 8 bits

– One Stop bit

– No parity

– Baud rate = 115200 baud

– flow control: none

● Configure the firmware

In the header file (main.h) several #define can be selected to parameterize the

example. Using a #define, the user can measure by themselves the consumption

values provided in Tab le 9 .

–#define for APB1 and APB2 prescaler configuration:

#define ABP1_DIV4

#define ABP2_DIV2

#define ABP1_DIV8

#define ABP2_DIV8

–#define for peripheral selection (clock gating):

#define ALL_PERIPHERIALS_ENABLE

#define USART_ONLY

–#define for frequency selection:

#define HCLK_FREQ_72MHz /* Only with external oscillator */

#define HCLK_FREQ_8MHz

–#define for Prefetch Buffer or Half Cycle feature using:

#define PREFETCH_ON

#define HALF_CYCLE_ON

–#define for switching to Sleep mode while the application is waiting for the RTC

interrupt:

#define WFI_ON

–#define for External or Internal oscillator selection

#define HSI_ENABLE /* Use internal oscillator */

#define HSE_ENABLE /*Use external oscillator */

Caution: To reload the Flash memory after launching the low-power example, the boot pin

configuration must be changed from BOOT FLASH to BOOT RAM, and the reset button

must be pressed. This is because the debugger cannot take the hand when the

STM32F10xxx is in low-power mode.

Once this has been done, the boot pin must be configured back to BOOT FLASH.

Measurement is then started by disconnecting and reconnecting the power supply.

The power off/ power on reset sequence is necessary to avoid internal debug module

overconsumption.

32/43 Doc ID 13922 Rev 2

Page 33

AN2629 Optimizing power consumption in your application

6.3 Typical measurement results

Ta bl e 9 shows the measurements made with these examples.

Table 9. Example measurements

APB1 APB2 Peripheral Frequency Prefetch

DIV4 DIV2 ALL_ON 72 MHz ON OFF OFF HSE 33.35

DIV8 DIV8 ALL_ON 72 MHz ON OFF OFF HSE 27.85

DIV8 DIV8 USART 72 MHz ON OFF OFF HSE 25.13

DIV4 DIV2 USART 8 MHz ON OFF OFF HSE 9.23

DIV4 DIV2 USART 8 MHz OFF ON OFF HSE 6.42

DIV4 DIV2 USART 8 MHz OFF ON ON HSE 1.67

DIV4 DIV2 USART 8 MHz OFF ON ON HSI 1.09

6.4 Conclusion

To reduce power consumption, the STM32F10xxx has to be initialized with an optimized

configuration according to the used application. For this reason, the user must focus on the

application requirements and configure the STM32F10xxx accordingly.

This example shows the possible STM32F10xxx clock configurations that can be used to

optimize the power consumption of an application. They are described below:

● System and peripheral frequency

– If the application does not need to run at the maximum frequency, the user can

reduce HCLCK using the PLL or the prescaler divisor.

– The peripheral bus frequency can be reduce using the APB1 and APB2

prescalers.

Half

cycle

WFI Oscillator

Typical

consumption

at 25 °C in mA

Note: For more information on the clock tree, please refer to Figure 2 on page 15.

● Clock gating

– To optimize power consumption only peripherals used has to be clocked. That can

be done with clock gating configuration.

Note: For more information on clock gating please refer to the STM32F10xxx reference manual.

● Prefetch or half cycle features

– The prefetch feature is useful to enhance the performance. Using the prefetch

buffer in an application prevents the performance loss caused by the Flash

memory wait state.

– In applications that are not sensitive to Flash memory wait states, the half cycle

feature can be used to reduce consumption.

Doc ID 13922 Rev 2 33/43

Page 34

Optimizing power consumption in your application AN2629

Caution: Half cycle configuration is not available in combination with a prescaler on the AHB. The

clock system should be equal to the HCLK clock. This feature can therefore be used only

with a direct clock from the internal, 8 MHz RC (HSI) oscillator or with the HSE oscillator.

● Internal or external oscillator

– Using the internal oscillator instead of the external oscillator also reduces power

consumption. The maximum system clock frequency that can be attained,

however, is 64 MHz, and the accuracy is poorer than that of an external crystal

oscillator or a ceramic resonator.

Note: For more information on oscillators please refer to the STM32F10xxx reference manual.

● Sleep mode

Another way of reducing power consumption is to switch to the STM32F10xxx Sleep

mode when the application is waiting for an event or an interrupt.

This example shows the possible STM32F10xxx clock configurations that can be used to

optimize the power consumption of an application. They such as frequency selection, clock

gating, half cycle, internal oscillator and WFI mode, to optimize the power consumption of

your application.

34/43 Doc ID 13922 Rev 2

Page 35

AN2629 Using the Stop and Standby mode in battery-operated applications

7 Using the Stop and Standby mode in battery-

operated applications

7.1 Introduction

Some applications powered by a standard battery are not running all the time. For example,

industrial applications wait for information from a sensor to wake up and launch processes

and other tasks. In these applications, the microcontroller waits for an external event, and

needs to reduce its power consumption during this phase.

The Cortex-M3 core was designed to take these constrains into account and integrate

specific modes and instructions at core level.

The software provided with this application note gives two examples (WFE_Stop_Flash and

WFE_Stop_RAM) of how to use the STM32F10xxx in battery-operated applications. In

these examples the STM32F10xxx switches to the low-power mode as soon as the

application does not require processing, instead of remaining in Run mode with a low clock

frequency.

The two low-power modes are based on the Cortex-M3 core’s Deep Sleep feature and WFE

(Wait for Event) instruction.

7.2 Using Wait For Event & Stop Wait For Event

7.2.1 Context

This section describes how to use the Wait for Event instruction and the Stop mode of the

STM32F10xxx, using the firmware found in the Zip file delivered with this application note.

The firmware are available in the following folders: WFE_Stop_Flash and

WFE_Stop_RAM.

There are two projects that are exactly the same, except for the mapping in the product:

● WFE_Stop_Flash is strictly mapped in the Flash memory and runs from the Flash

memory

● WFE_Stop_Ram is downloaded in Flash memory, but some functions are remapped in

RAM at startup. How to remap code in RAM is explained in the toolset documentation.

The WFE_Stop_Flash and WFE_Stop_Ram folders contain all the subdirectories and files

that make up the core of the application example:

● inc subfolder contains the example header files

● src subfolder contains the example source files

● project subfolder contains two projects that compile the example files:

– EWARMv5: contains the project for the EWARM toolchain

– RVMDK: contains the project for the RVMDK toolchain

– RIDE: contains the project for the RIDE toolchain

Doc ID 13922 Rev 2 35/43

Page 36

Using the Stop and Standby mode in battery-operated applications AN2629

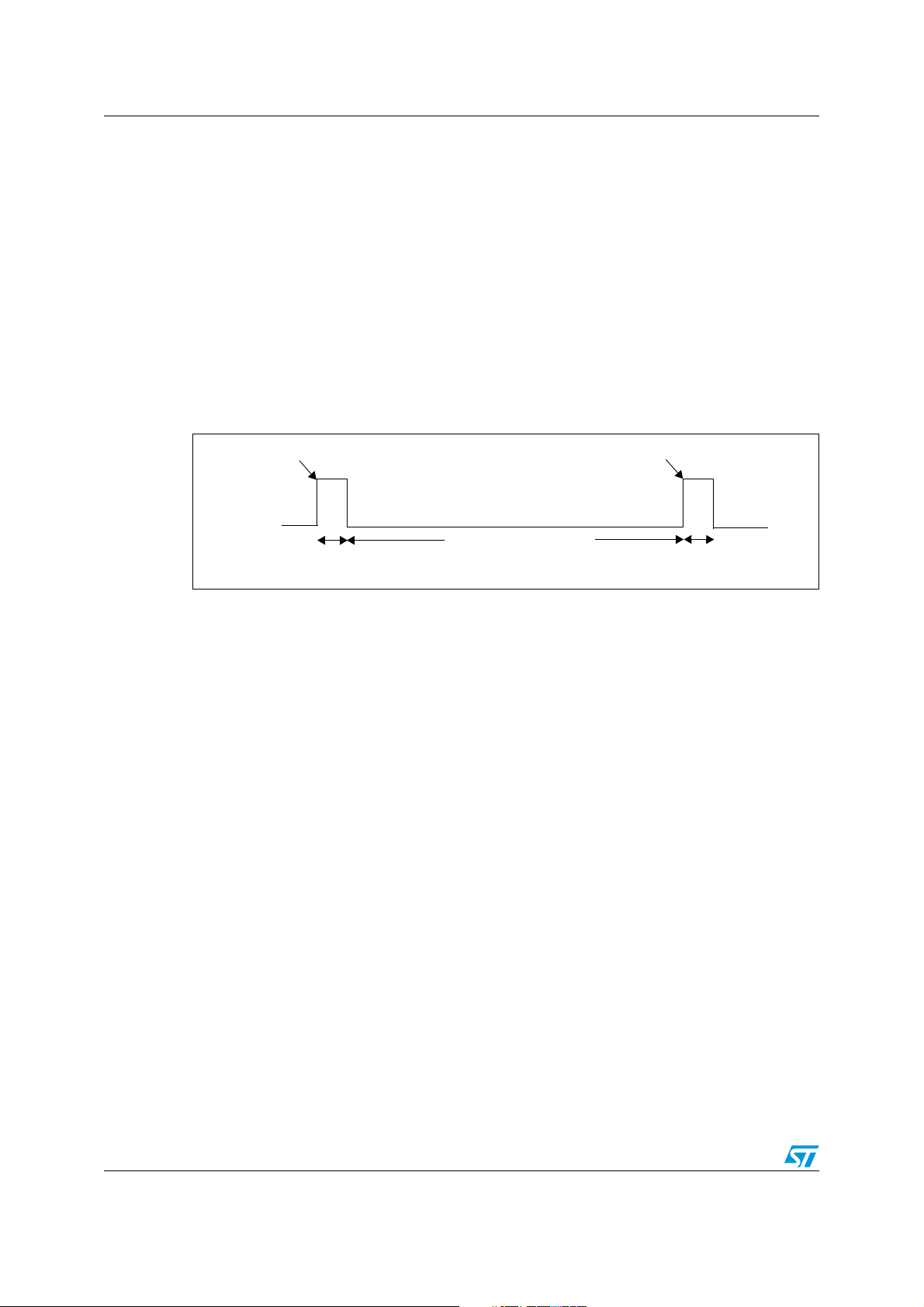

RTC alarm

ADC

WFE or STOP WFE mode

conversion

ADC

conversion

RTC alarm

PC1

ai14679

7.2.2 Detailed description

The example performs a periodic ADC conversion and stores the value in RAM buffer. It

uses Auto-Wakeup (AWU) from low-power mode as described in Section 1.2.7: Auto-

wakeup (AWU) from low-power mode on page 13.

● At the beginning, functions configure the clock, GPIO, RTC and ADC. These functions

are implemented at the end of the main.c and use the STM32F10xxx standard

peripheral library.

● The RTC is running and, each ADC conversion and storage are gated by the RTC

Alarm in the main loop.

● The RTC Alarm wakes up the STM32F10xxx from the WFE or STOP_WFE mode.

● the PC1 I/O shows the time taken by the ADC conversion and RTC Alarm register

reload.

Figure 7. WFE & STOP WFE

Hardware environment

Use this example with STM32F10xxx evaluation board: refer to the user manual UM0426:

“STM3210B-EVAL evaluation board” to use the STM3210B-EVAL.

After connecting the power supply and JTAG tools, the power consumption can be

measured by replacing Jumper JP9 by an ammeter.

Firmware description

● Launch this example with the used toolchain:

The standard tools can be used to run the example.

The .uv2 file used to launch the project with the RVMDK toolchain is contained in the

RVMDK folder.

The .eww file, used to launch the project with the EWARM toolchain, is in the EWARM

folder.

● Configure the firmware

At the beginning of the main.c, four #define can be selected to parameterize the

example:

–2 #define select the timing of the loop:

#define LOOP_20ms

#define LOOP_200ms

–2 more #define select the low-power mode:

#define WFE

#define STOP_WFE

– For the example to run, it is necessary to keep one #define of each type.

– After compiling the example, the STM32F10xxx Flash memory can be

downloaded.

36/43 Doc ID 13922 Rev 2

Page 37

AN2629 Using the Stop and Standby mode in battery-operated applications

Standby mode

conversion

ADC

conversion

RTC alarm

PC1

STM32

configuration

ADC

RTC alarm

STM32

configuration

ai14680

Caution: To reload the Flash memory after launching the low-power example, the boot pin

configuration must be changed from BOOT FLASH to BOOT RAM, and the reset button

must be pressed. This is because the debugger cannot take the hand while the

STM32F10xxx is in low-power mode.

Once this has been done, the boot pin must be configured back to BOOT FLASH.

Measurement is then started by disconnecting and reconnecting the power supply.

The power off/ power on reset sequence is necessary to avoid internal debug module

overconsumption.

7.3 Using the Standby mode in an applicative way

7.3.1 Context

This section describes how to use the Standby mode of the STM32F10xxx, using the

firmware found in the Zip file delivered with this application note. The firmware is available in

the Standby folder.

The Standby folder contains all the subdirectories and files that make up the core of the

application example:

● inc subfolder contains the example header files

● src subfolder contains the example source files

● project subfolder contains two projects that compile the example files:

– EWARMv5: contains the project for the EWARM toolchain

– RVMDK: contains the project for the RVMDK toolchain

7.3.2 Detailed description

This example performs a periodic ADC conversion and stores the value in RAM buffer. It

uses Auto-Wakeup (AWU) from low-power mode as described in Section 1.2.7: Auto-

wakeup (AWU) from low-power mode on page 13.

● At the beginning, functions configure the clock, GPIO, RTC and ADC. These functions

are implemented at the end of the main.c and use the STM32F10xxx standard

peripheral library.

● The RTC is running and the RTC Alarm wakes up the STM32F10xxx from Standby

mode.

● After each wakeup from Standby mode, the STM32F10xxx restarts from the reset state

and each ADC conversion is performed after the STM32F10xxx has been configured.

● the PC1 I/O shows the time taken by the ADC conversion and RTC Alarm register

reload but not the time taken by the STM32F10xxx to restart.

Figure 8. Standby

Doc ID 13922 Rev 2 37/43

Page 38

Using the Stop and Standby mode in battery-operated applications AN2629

Hardware environment

Use this example with STM32F10xxx evaluation board: refer to the user manual UM0426:

“STM3210B-EVAL evaluation board” to use the STM3210B-EVAL.

After connecting the power supply and JTAG tools, the power consumption can be

measured by replacing Jumper JP9 by an ammeter.

Firmware description

● Launch this example with the used toolchain:

The standard tools can be used to run the example.

The .uv2 file used to launch the project with the RVMDK toolchain is contained in the

RVMDK folder.

The .eww file, used to launch the project with the EWARM toolchain, is in the EWARM

folder.

● Configure the firmware

At the beginning of the main.c, two #define can be selected to parameterize the

example:

–2 #define select the timing of the loop:

#define LOOP_20ms

#define LOOP_200ms

– For the example to run, it is necessary to keep one #define of each type.

– After compiling the example, the STM32F10xxx Flash memory can be

downloaded.

Caution: To reload the Flash memory after launching the low-power example, the boot pin

configuration must be changed from BOOT FLASH to BOOT RAM, and the reset button

must be pressed. This is because the debugger cannot take the hand when the

STM32F10xxx is in low-power mode.

Once this has been done, the boot pin must be configured back to BOOT FLASH.

Measurement is then started by disconnecting and reconnecting the power supply.

The power off/ power on reset sequence is necessary to avoid internal debug module

overconsumption.

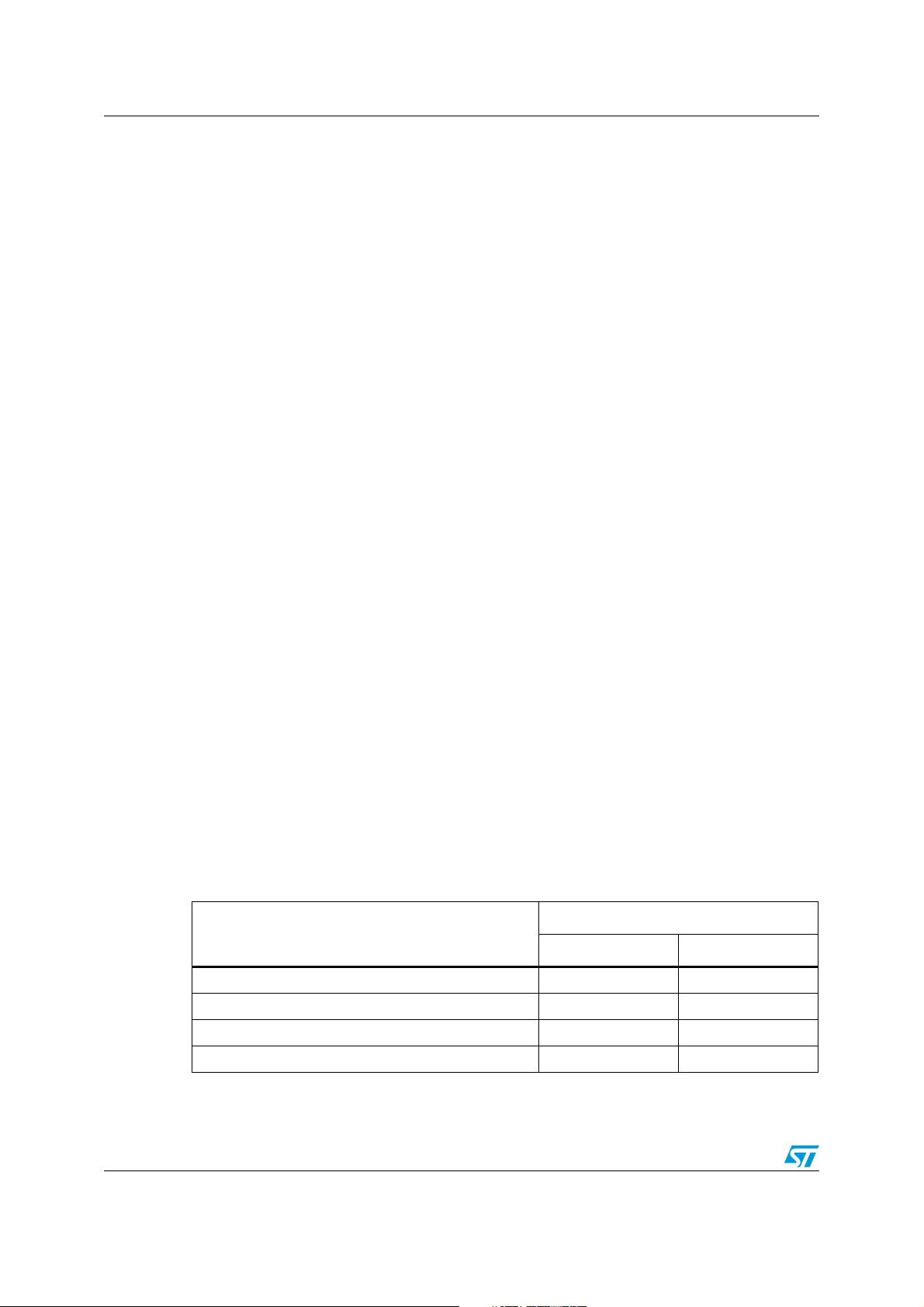

7.4 Typical measurement results

Ta bl e 1 0 shows the measurements made with these examples.

Table 10. Example measurements

Consumption with T

#define mode

20 ms 200 ms

WFE 1 mA 970 µA

STOP_WFE code loop running from Flash memory 58 µA 18.5 µA

STOP_WFE code loop remap in RAM 34.7 µA 16.2 µA

Standby 106 µA 14 µA

= +25 °C

A

38/43 Doc ID 13922 Rev 2

Page 39

AN2629 Using the Stop and Standby mode in battery-operated applications

7.5 Conclusion

These examples show that the Cortex-M3 integrates the very efficient Core-level

instructions for low-power applications (Sleep mode and Deepsleep mode), associated with

the low-power features of the STM32F10xxx (AWU, Stop, Low-power and Standby).

Measurements show that the trade-off between wakeup time and power consumption must

be taken into account:

● The Standby mode is more efficient in terms of power saving (3.6 µA), but the

application restarts each time from the reset states and the time to reinitialize the

application is not negligible. Indeed the initialization phase is done at 8 MHz and draws

power. If the repeated time loop is too short (20 ms), this mode is less efficient than the

Stop mode (106 µA versus 34.7 µA).

● The Stop mode is less efficient than the Standby mode in terms of low-power

consumption, but it has the advantage of keeping the context and the RAM contents. In

this example, if the repeated time loop is shorter than 200 ms, the Stop mode is more

efficient, especially if the loop code is remapped to run in RAM. If the loop lasts 200 ms

or more, however, the Standby mode becomes more advantageous.

Doc ID 13922 Rev 2 39/43

Page 40

Using the Backup domain in very low-power applications AN2629

8 Using the Backup domain in very low-power

applications

8.1 Introduction

This section describes how to use the STM32F10xxx backup registers and keep the benefit

of the low-power consumption of the Backup domain.

8.2 Using the Backup domain in an applicative way

8.2.1 Context

This section describes how to use the STM32F10xxx backup registers, using the same

firmware as the one used in Section 6.2 of this application note. It can be found in the Zip file

delivered with the application note, in the Run_Mode folder.

The Run_Mode folder contains all the subdirectories and files that make up the core of the

application example:

● inc subfolder contains the example header files

● src subfolder contains the example source files

● project subfolder contains two projects that compile the example files:

– EWARMv5: contains the project for the EWARM toolchain

– RVMDK: contains the project for the RVMDK toolchain

– RIDE: contains the project for the RIDE toolchain

8.2.2 Detailed description

The program is a basic application that sends the time from the RTC on a serial line

(USART). Every second, the time is stored into the backup registers. After a power on reset,

the contents of the backup registers are sent through the USART.

The time at which the power-off event occurred is displayed on the HyperTerminal as shown

in Figure 9.

Figure 9. HyperTerminal display of time

40/43 Doc ID 13922 Rev 2

Page 41

AN2629 Using the Backup domain in very low-power applications

For an exhaustive description see Chapter 6.2.2: Detailed description on page 30.

Hardware environment

Use this example with STM32F10xxx evaluation board: refer to the user manual UM0426:

“STM3210B-EVAL evaluation board” to use the STM3210B-EVAL.

● The USART1 signals (RX, TX) must be connected to a DB9 connector using an RS232

transceiver.