Page 1

AN2627

Application note

ST8R00 syncronous boost

converter with output current cut-off function

Introduction

The ST8R00 family of synchronous step-up DC-DC converters with current output cut-off

function provide up to 1 A over an input voltage range of 4 V to 6 V and an output voltage

range of 6 V to 12 V.

The high switching frequency (1.2 MHz) allows the use of tiny surface-mount components.

Along with the resistor divider to set the output voltage value, an inductor and two capacitors

are required. A low output ripple is guaranteed by the current mode PWM topology and by

the use of low ESR surface-mounted ceramic capacitors.

The device is available in two versions: burst mode (ST8R00) and continuous mode

(ST8R00W).

The ST8R00 devices are thermal protected and available in the DFN8 4x4 package.

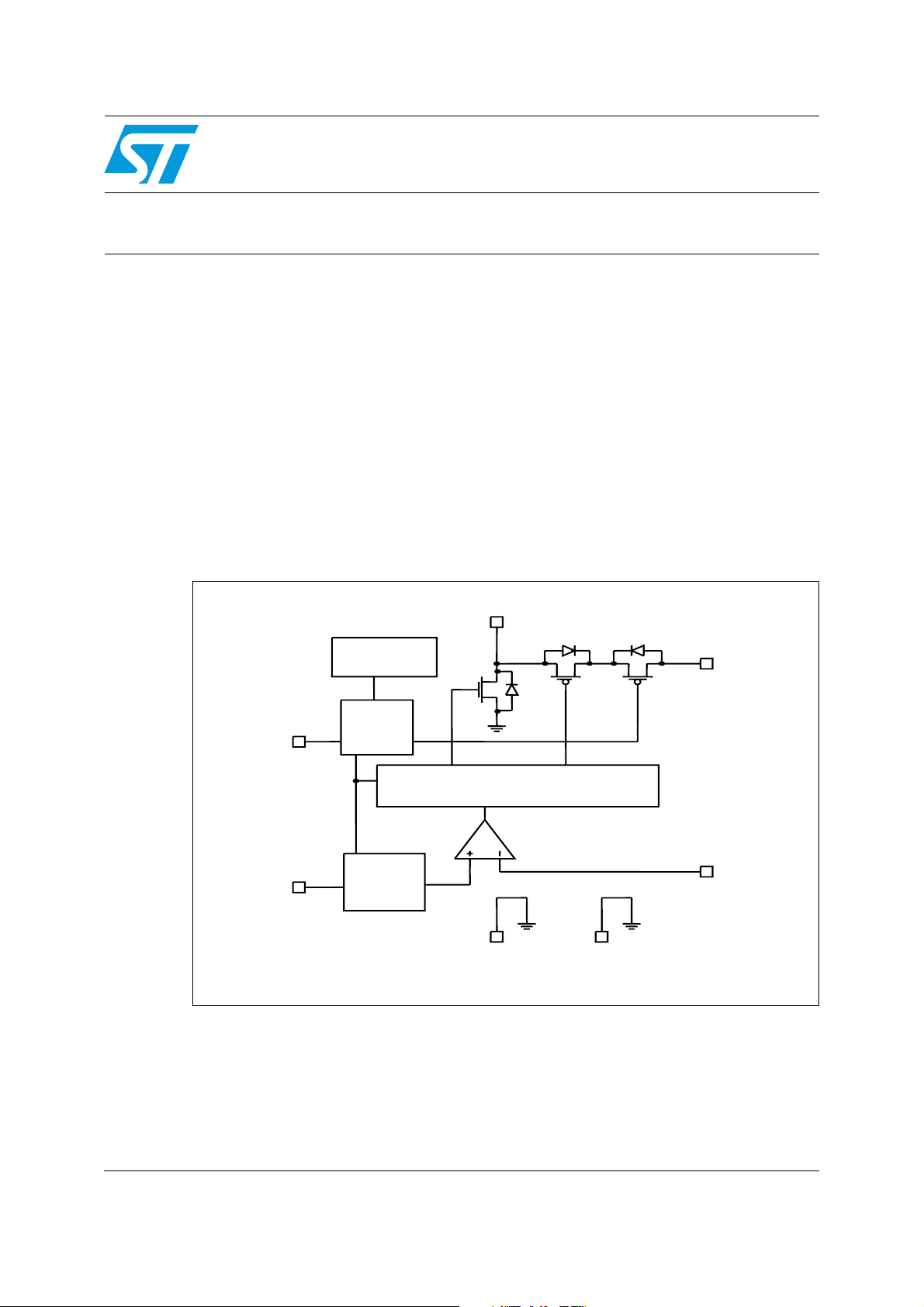

Figure 1. Simplified schematic diagram

INH

IN

Thermal

Inhibit

Vref

LX

Ns

PGND

PWM control

PGND

Ps

GND

OUT

Po

FB

AM00001v1

December 2009 Doc ID 13913 Rev 2 1/19

www.st.com

Page 2

Contents AN2627

Contents

1 ST8R00 description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Inhibit function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Selecting components for applications . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Output voltage selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Input capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Inductor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4 Output capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5 Layout considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Thermal considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Demonstration board usage recommendation . . . . . . . . . . . . . . . . . . . 13

4.1 External component selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1.1 Capacitor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1.2 Inductor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 BOM with most-used components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6 Footprint recommended data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2/19 Doc ID 13913 Rev 2

Page 3

AN2627 List of figures

List of figures

Figure 1. Simplified schematic diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

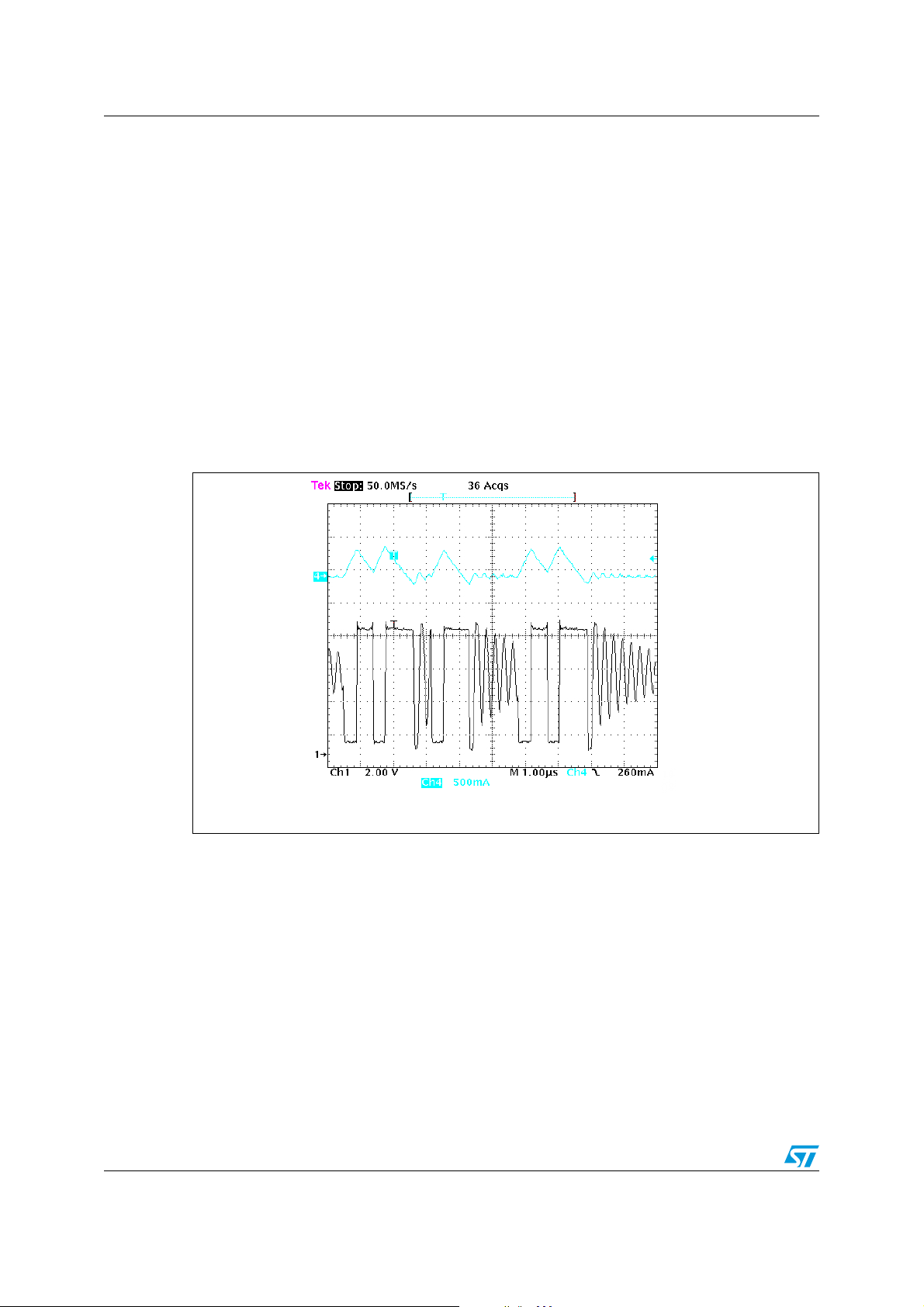

Figure 2. ST8R00 inductor current at light load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

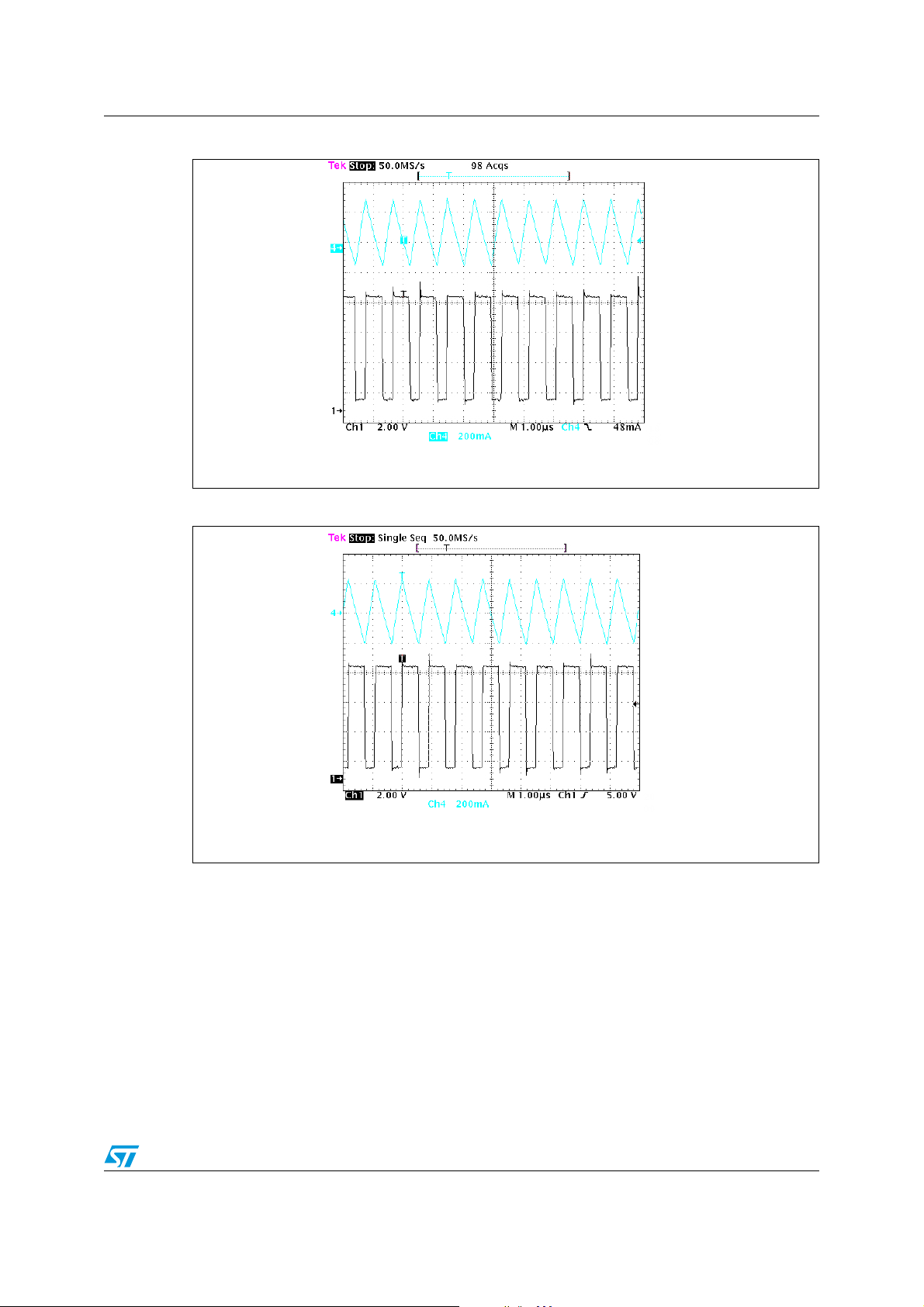

Figure 3. ST8R00W inductor current at light load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 4. ST8R00W inductor current at no load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

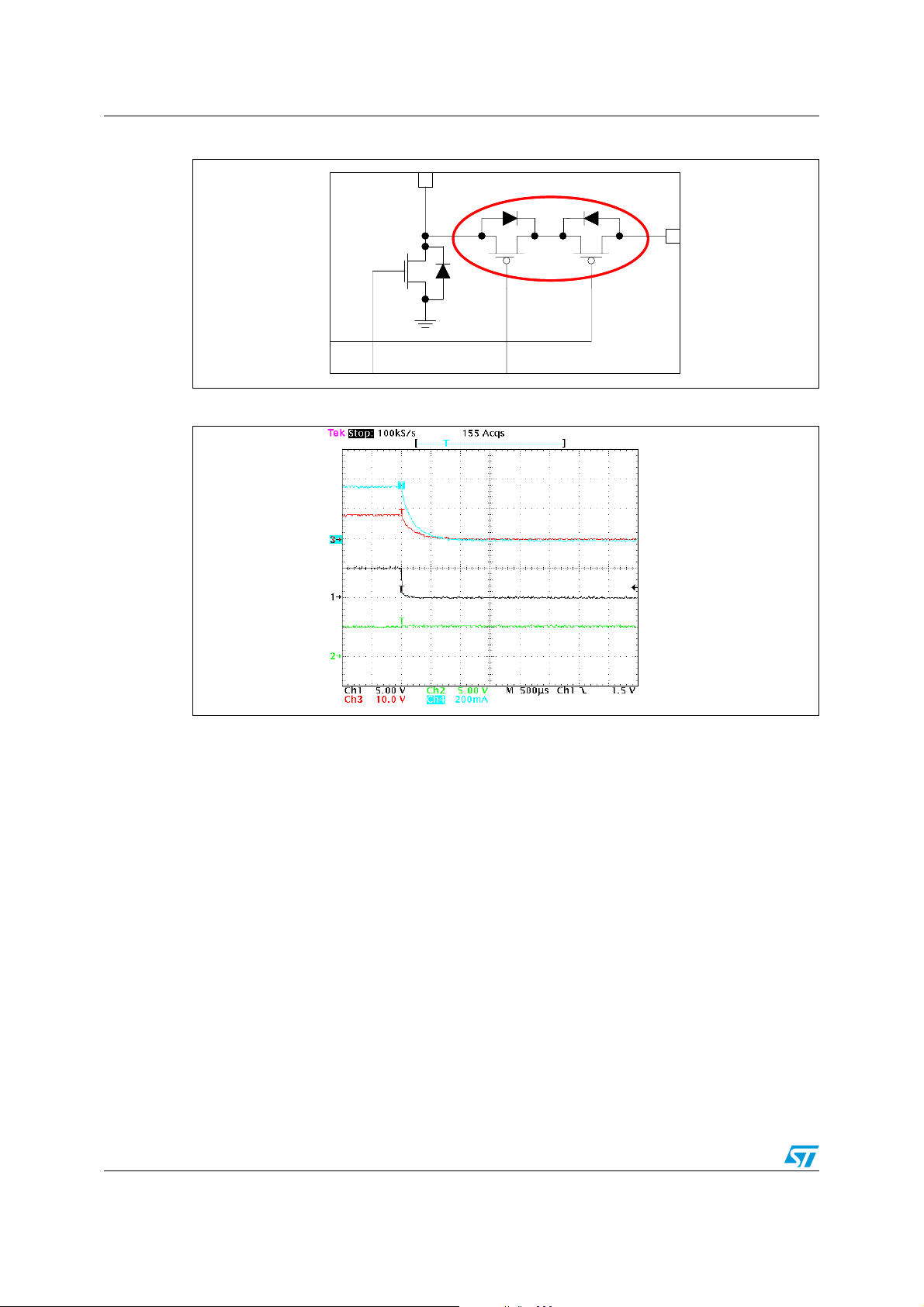

Figure 5. ST8R00 cut-off block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 6. Current cut-off function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 7. Inrush current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 8. ST8R00 application schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 9. Inhibit voltage vs. temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 10. Typical application schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 11. Voltage feedback vs. temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 12. Layout considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 13. The ST8R00 demonstration board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 14. Demonstration board layers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 15. Demonstration board schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 16. Efficiency vs. output current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 17. Efficiency vs. output voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 18. ST8R00 efficiency vs. inductor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 19. ST8R00W efficiency vs. inductor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 20. DFN8 4x4 recommended footprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Doc ID 13913 Rev 2 3/19

Page 4

ST8R00 description AN2627

1 ST8R00 description

The ST8R00 is a family of adjustable current mode PWM synchronous step-up DC-DC

converters with internal 1 A power switch. It represents a complete 1 A switching regulator

with internal compensation which eliminates the need for additional components.

The two devices in the family, the ST8R00 and ST8R00W, operate at light load in two

different ways. The ST8R00 works in power-save mode to achieve good efficiency, as

shown in Figure 2. The ST8R00W, in order to guarantee the lowest switching ripple,

operates in PWM (pulse width modulation) mode as show in Figure 3 and Figure 4.

At medium and high load current, both versions operate in PWM mode.

The thermal shutdown block turns off the regulator when the junction temperature exceeds

150 °C (typ), and the cycle-by-cycle current limiting provides protection against overcurrent

sink.

Figure 2. ST8R00 inductor current at light load

VIN=5 V, V

OUT

=8 V, I

=60 mA, Ch1=LX, Ch4=I

OUT

I

L

LX

L

4/19 Doc ID 13913 Rev 2

Page 5

AN2627 ST8R00 description

Figure 3. ST8R00W inductor current at light load

I

L

LX

VIN=5 V, V

OUT

=8 V, I

=60 mA, Ch1=LX, Ch4=I

OUT

L

Figure 4. ST8R00W inductor current at no load

I

L

LX

VIN=5 V, V

=8 V, no load Ch1=LX, Ch4=I

OUT

L

For proper functioning of the device, only a few components are required: an inductor, two

capacitors and the resistor divider. The inductor chosen must not saturate at the operating

peak current. Its value should be selected taking into account that a large inductor value

reduces output voltage ripple, while a smaller inductor can be selected when it is important

to reduce package size and the total cost of the application. Finally, the ST8R00 family has

been designed to work properly with X5R or X7R SMD ceramic capacitors both at the input

and at the output. These types of capacitors, thanks to their very low series resistance

(ESR), minimize the output voltage ripple. Other low ESR capacitors can be used in

accordance with application requirements without compromising the correct functionality of

the device.

This device features an output current cut-off function. Two P-channel MOSFETs in a backto-back configuration, as shown in Figure 5, stop the output current when the inhibit is low

(Figure 6).

Doc ID 13913 Rev 2 5/19

Page 6

ST8R00 description AN2627

Figure 5. ST8R00 cut-off block

LX

LX

OUT

OUT

Ns

Ns

PGND

PGND

Figure 6. Current cut-off function

Ps

Ps

Po

Po

Iout

Vout

Inh

Vin

Figure 7 shows the in-rush current at start-up. Initially, the C

discharged and the current limitation is due only to the equivalent series resistor of the

inductor, the power MOSFET parasitic diode and the cut-off MOSFETs’ R

the output voltage reaches the input voltage level, the device begins to switch and the

current is limited cycle by cycle.

6/19 Doc ID 13913 Rev 2

capacitor is completely

OUT

DS(ON)

. As soon as

Page 7

AN2627 ST8R00 description

Figure 7. Inrush current

=4.5 V, V

V

IN

OUT

=7 V, V

INH

1.1 Inhibit function

The ST8R00 family of devices also include an inhibit function (pin 6). When the INH voltage

is higher than 2 V, the device is ON and if it is lower than 0.8 V, the device is OFF.

The INH pin does not have an internal pull-up, which means that the pin cannot be left

floating.

from 0 V to 3 V, R

=13 Ω, L=10 µH, CIN=C

LOAD

Vout

Iin

LX

OUT

=10 µF

If the inhibit function is not used, the INH pin must be connected to V

in Figure 8 below.

Figure 8. ST8R00 application schematic

L

L

Vin

Vin

41

41

IN LX

Cin

Cin

Rinh

Rinh

Cinh

Cinh

IN LX

6

6

INH

INH

ST8R00

7

7

HV

HV

GND PGND

GND PGND

ST8R00

23

23

OUT

OUT

FB

FB

8

8

5

5

as in the schematic

IN

Vout

Vout

R1

R1

Cout

Cout

R2

R2

Doc ID 13913 Rev 2 7/19

Page 8

ST8R00 description AN2627

Figure 9. Inhibit voltage vs. temperature

2

1.8

1.6

1.4

1.2

1

0.8

Vinh [V]

0.6

0.4

0.2

Vin=4V, Vinh from 0 to 2V, Iout=50mA,

L=4.7µH, Cin=10µF, Cout=10µF

ON OFF

0

-75 -50 -25 0 25 50 75 100 125 150 175

T [°C]

8/19 Doc ID 13913 Rev 2

Page 9

AN2627 Selecting components for applications

2 Selecting components for applications

This section provides information to assist in the selection of the most appropriate

components for applications.

Figure 10 shows a typical application schematic diagram.

Figure 10. Typical application schematic

L

L

Vin

Vin

41

Cin

Cin

OFF ON

OFF ON

41

8

OUT

OUT

FB

FB

8

5

5

IN LX

IN LX

6

6

INH

INH

ST8R00

7

7

HV

HV

ST8R00

GND PGND

GND PGND

23

23

R1

R1

R2

R2

Vout

Vout

Cout

Cout

2.1 Output voltage selection

The output voltage can be adjusted from 6 V up to 12 V by connecting a resistor divider

between the output and the FB pin.

The resistor divider should be chosen in accordance with the following equation:

Equation 1

V

outVFB

The feedback voltage versus temperature is shown Figure 11 below.

It is recommended to use a resistor with a value in the range of 10 kΩ to 100 kΩ. Lower

values can be suitable as well, but will increase current consumption.

Figure 11. Voltage feedback vs. temperature

1.3

1.28

1.26

1.24

1.22

1.2

1.18

Vfb [mV]

1.16

1.14

1.12

1.1

-75 -50 -25 0 25 50 75 100 125 150 175

Vin=Vinh=5V, Iout=50mA,

L=4.7µH, Cin=10µF, Cout=10µF

R

1

1

------ -+=

with

V

1.22 V=

R

2

FB

T [°C]

Doc ID 13913 Rev 2 9/19

Page 10

Selecting components for applications AN2627

2.2 Input capacitor

The input capacitor must be able to provide AC ripple current to the inductor and to

withstand the maximum input operating voltage.

Another important function of the input capacitor is to limit noise and therefore the

interference with the other blocks connected to the same network.

The quality of these capacitors must to be quite high to minimize the power dissipation

generated by the internal ESR, thereby improving system reliability and efficiency.

Various capacitors can be considered:

● Ceramic capacitors - These capacitors usually have a higher RMS current rating for a

given physical dimension (due to the very low ESR). The drawback is the high cost of

capacitors with very large values.

● Electrolytic capacitor - The availability of small size tantalum capacitors with very low

ESR is increasing. However, they are subject to thermal damage if subjected to very

high current during charge. Since they can, in fact, be subjected to high surge current

when connected to the power supply, it is better to avoid using this type of capacitor for

the input filter of the device. Aluminum capacitors are not the best choice due to their

high ESR.

2.3 Inductor

The inductor value is very important because it establishes the ripple current. The

approximate inductor value is obtained with the following formula:

Equation 2

where T

usually fixed at 20-40% of I

is the ON time of the internal switch, given by D · TSW. The ripple current, ΔIL, is

ON

IN_MAX.

Equation 3

where η is the efficiency.

2.4 Output capacitor

The output capacitor is very important to satisfy the output voltage ripple requirement. To

reduce the output voltage ripple, a low ESR capacitor is required.

The output voltage ripple (V

RIPPLE

Vin

=

Δ

OUT_max

T

ON

I

L

⋅

VoutI

η⋅

Vin

I

IN_MAX

L ⋅

=

), in continuous mode is:

Equation 4

⎛⎞

V

RIPPLEIout

where F

10/19 Doc ID 13913 Rev 2

is the switching frequency.

SW

⋅=

ESR

⎝⎠

V

–()

outVin

------------------------------------------- -+

V

⋅⋅

outCoutFSW

Page 11

AN2627 Selecting components for applications

2.5 Layout considerations

Due to the high switching frequency and peak current, the layout is an important design step

for all switching power supplies. If the layout is not done carefully, important parameters

such as efficiency and output voltage ripple could be out of specification.

Short, wide traces must be implemented for main current and for power ground paths as

shown in bold in

IC pins as well as the inductor and output capacitor.

Figure 12. The input capacitor must be placed as close as possible to the

A common ground node minimizes ground noise, as shown in

The HV pin must be floating or connected to GND and the exposed pad of the package must

be connected to the common ground node.

Figure 12. Layout considerations

L

L

Vin

Vin

41

41

IN LX

IN LX

OUT

OUT

FB

FB

2

2

Cin

Cin

OFF ON

OFF ON

6

6

INH

INH

ST8R00

GND

GND

ST8R00

PGND

PGND

3

3

7

7

HV

HV

Figure 12.

8

8

5

5

R1

R1

R2

R2

Cout

Cout

Vout

Vout

Doc ID 13913 Rev 2 11/19

Page 12

Thermal considerations AN2627

3 Thermal considerations

The dissipated power of the device is related to three different sources:

● Switching losses due to the (not negligible) R

Equation 5

DSON_NON_N

OUT

and

Equation 6

. These are equal to:

DS(ON)

D)]²D1/(I[RP

⋅−⋅=

2

OUTDSON_PEQON_P

D)1(IRP

−⋅⋅=

where D is the duty cycle of the application and R

DS(ON)_PEQ=RDS(ON)_PS+RDS(ON)_PO

.

Note: the duty cycle is theoretically given by:

V

in

1

-------------–

V

out

but in practice it is quite higher than this value to compensate for the losses of the overall

application. For this reason, the switching losses related to the R

increase compared

DS(ON)

to an ideal case.

● Switching losses due to its turning on and off. These are calculated using the following

equation:

Equation 7

)t(t

+

OFFON

2

where tON and t

IVP ⋅⋅⋅=⋅

⋅⋅=

OUTINSW

are the overlap times of the voltage across the power switch and the

OFF

current flowing into it during the turn-on and turn-off phases. t

is the equivalent switching

R-F

FtIVF

SWF-ROUTINSW

time.

● Quiescent current losses:

Equation 8

IVP ⋅=

QINQ

where IQ is the quiescent current.

The overall losses are:

Equation 9

DSON_NTOT

OUT

The junction temperature of device will be:

Equation 10

where TA is the ambient temperature and R

thJA

ambient.

12/19 Doc ID 13913 Rev 2

2

OUTDSON_PEQ

PRTT ⋅+=

TOTthJAAJ

is the thermal resistance junction-to-

IVFtIVD)1(IRD)²D1/I(RP ⋅+⋅⋅⋅+−⋅⋅+⋅−⋅=

QINSWF-ROUTIN

Page 13

AN2627 Demonstration board usage recommendation

4 Demonstration board usage recommendation

The demonstration board shown in Figure 13 is provided with a Kelvin connection, so for

each pin there are two lines available: one used to supply or sink current, and the other used

to perform the needed measurement.

The ST8R00 inhibit pin does not have an internal pull-up, so the inhibit pin cannot be left

floating.

Figure 13. The ST8R00 demonstration board

Figure 14. Demonstration board layers

Top layer

The board has one inhibit pin available, located on the top left of the board.

The inhibit pin can be used to supply an external voltage higher than 2 V to turn on the

device, or an external voltage lower than 0.8 V to turn off the device.

Bottom layer

Doc ID 13913 Rev 2 13/19

Page 14

Demonstration board usage recommendation AN2627

4.1 External component selection

Figure 15 shows the schematic diagram of the demonstration board.

Figure 15. Demonstration board schematic

L

L

Vin

Vin

41

41

8

OUT

OUT

FB

FB

8

R1

R1

5

5

R2

R2

Cin

Cin

OFF ON

OFF ON

IN LX

IN LX

6

6

INH

INH

ST8R00

7

7

HV

HV

ST8R00

GND PGND

GND PGND

23

23

In order to obtain the needed output voltage, the resistor divider must be selected based on

the following formula:

Vout

Vout

Cout

Cout

Equation 11

Table 1. Recommended resistor divider

V

out

8 V 56 kΩ 10 kΩ

9.5 V 68 kΩ 10 kΩ

The resistors in Ta bl e 1 represent a good compromise in terms of current consumption and

minimum output voltage.

4.1.1 Capacitor selection

It is possible to use any X5R or X7R ceramic capacitor:

● C

● C

=10 µF (ceramic) or higher

IN

=10 µF (ceramic) or higher. It is possible to put several capacitors in parallel to

OUT

reduce the equivalent series resistance and improve the ripple present in the output

voltage.

4.1.2 Inductor selection

V

outVFB

R1

1

------- -+=

with

R2

R1 R2

VFB1.22 V=

Due to the high (1.2 MHz) frequency, it is possible to use very small inductor values. In the

demonstration board, the device was tested with inductors in the range of 1 µH to 10 µH,

with very good efficiency performance (see

Figure 18 and Figure 19).

Because the device is able to provide an operating output current of 1 A, we strongly

recommend the use of inductors capable of managing at least 3.5 A.

14/19 Doc ID 13913 Rev 2

Page 15

AN2627 Demonstration board usage recommendation

Figure 16. Efficiency vs. output current

100

90

80

70

60

50

Efficiency [%]

40

30

Vin=5V , Vinh=5V, L=4.7µH,

Cin=10µF, Cout=10µF, Vout=8V

ST8R00

ST8R00W

20

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Iout [A]

Figure 17. Efficiency vs. output voltage

100

95

90

85

80

75

70

Efficiency [%]

65

60

55

50

4.5 5.5 6.5 7.5 8.5 9.5 10.5 11.5 12.5

Vin=5V , Vinh=5V, L=4.7µH, Cin=10µF,

Cout=10µF, Iout=300mA

ST8R00

ST8R00W

Vout [V]

Figure 18. ST8R00 efficiency vs. inductor

100

90

80

70

60

50

Efficiency [%]

40

Vin=5V , Vinh=5V, Vout=8V,

Cin=10µF, Cout=10µF

30

20

0246810

Doc ID 13913 Rev 2 15/19

Iout=300mA

Iou t=0 .5A

Iou t=1 A

L [µH]

Page 16

BOM with most-used components AN2627

Figure 19. ST8R00W efficiency vs. inductor

100

90

80

70

60

50

Efficiency [%]

40

Vin=5V , Vinh=5V, Vout=8V,

Cin=10µF, Cout=10µF

30

Iou t=3 0 0mA

Iou t=0 .5A

Iou t=1 A

20

0246810

L [µH]

5 BOM with most-used components

Table 2. Bill of materials

Name Value Material Manufacturer Part numbers

C

IN

C

OUT

L 4.7 µH Coiltronics DR73-4R7

10 µF Ceramic Murata GRM31CR61E106KA12B

10 µF Ceramic Murata GRM31CR61E106KA12B

16/19 Doc ID 13913 Rev 2

Page 17

AN2627 Footprint recommended data

6 Footprint recommended data

Figure 20. DFN8 4x4 recommended footprint

Doc ID 13913 Rev 2 17/19

Page 18

Revision history AN2627

7 Revision history

Table 3. Document revision history

Date Revision Changes

13-May-2008 1 Initial release

03-Dec-2009 2 Modified Equation 9: on page 12.

18/19 Doc ID 13913 Rev 2

Page 19

AN2627

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2009 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 13913 Rev 2 19/19

Loading...

Loading...