Page 1

AN2623

Application note

Evaluation board

for off-line forward converter based on L5991

Introduction

This application note gives a practical example of a 160 W, isolated, forward converter using

the L5991, high frequency current mode PWM controller. Design procedures for both the

power stage and controller are presented.

Generally for this power level the norm ICE61000-3-2 imposes the use of a PFC preregulator stage, but some countries do not require compliance to this norm. The forward

converter presented here does not have a PFC.

Figure 1. 160 W off-line forward converter, evaluation board

October 2007 Rev 1 1/25

www.st.com

Page 2

Contents AN2623

Contents

1 Basis of forward topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Main characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Design circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Primary controller: L5991 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Output filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Output diodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4 Power transformer design and MOSFET choice . . . . . . . . . . . . . . . . . . . . 9

3.5 Feedback loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Experimental results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1 High frequency ripple of output voltage and load regulation . . . . . . . . . . 16

4.2 Dynamic load test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.3 Start-up behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.4 Wake-up time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.5 Short circuit test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.6 Thermal measurement and global efficiency . . . . . . . . . . . . . . . . . . . . . . 22

5 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2/25

Page 3

AN2623 List of figures

List of figures

Figure 1. 160 W off-line forward converter, evaluation board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. Basic forward converter topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 3. Reset circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 4. Electrical schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 5. Vds and Ids of STW12NK90Z in full load condition at different input voltages . . . . . . . . . 15

Figure 6. High frequency ripple of output voltage in full load condition at different input voltages. . . 16

Figure 7. Output voltage behavior against the load and the V

Figure 8. Behavior of system under dynamic load at different input voltages . . . . . . . . . . . . . . . . . . 18

Figure 9. Behavior of system under dynamic load at different input voltages . . . . . . . . . . . . . . . . . . 19

Figure 10. Wake-up time of the system at different input voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 11. Behavior of the system in short circuit condition at different input voltages . . . . . . . . . . . . 21

Figure 12. Efficiency of the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

in

3/25

Page 4

Basis of forward topology AN2623

R

R

R

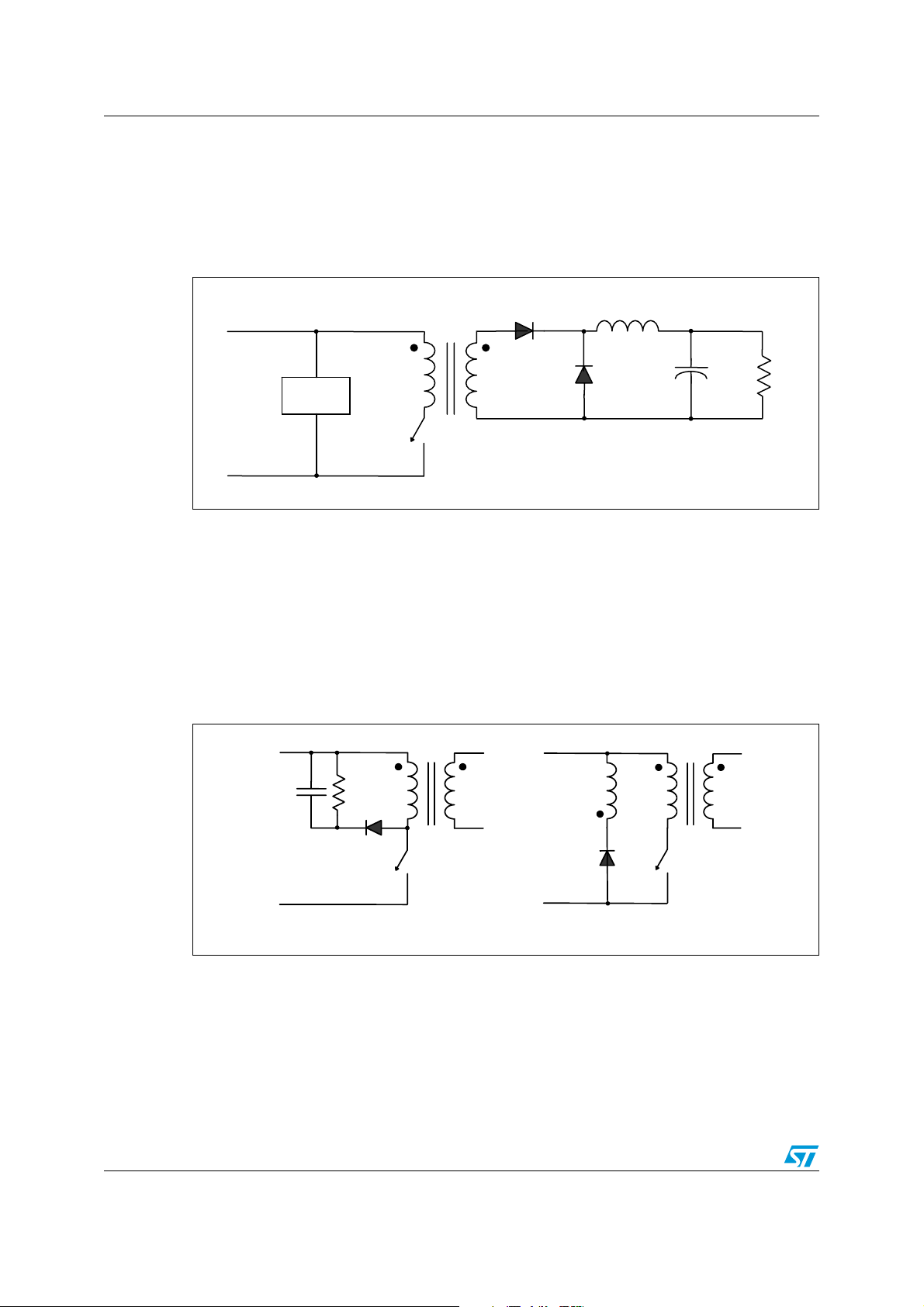

1 Basis of forward topology

A forward converter is typically used in off-line applications in the 100 W - 300 W power

range. A simplified schematic of the forward converter can be seen in Figure 2.

Figure 2. Basic forward converter topology

D

1

V

d

Reset

Circuit

L

V

D

2

C

0

_

_

A natural limitation of the forward converter is the need to completely reset the transformer,

cycle by cycle, before the next MOSFET switches on. Different circuits are used for this

purpose with advantages and drawbacks. The two simplest and most commonly used reset

schemes are: the RCD reset circuit and the reset auxiliary winding both shown in Figure 3

(a-b). In the design presented in this document, the reset winding was used. It is

advantageous with respect to efficiency because the energy stored in the magnetizing

inductor goes back to the input and is not lost as using an RCD snubber net. The drawback

of the reset circuit is that, generally, a higher voltage Power Mosfet is needed. In the present

design a 900 V MOSFET was used.

Figure 3. Reset circuits

C

R

N

1

D

(a) (b)

The primary controller IC used is the L5991. It is based on a standard current mode PWM

controller and includes features such as programmable soft start, adjustable duty cycle

limitation and a standby function that reduces the switching frequency when the converter is

lightly loaded. The standby function, in this case, is not used to prevent the transformer from

saturation. The output voltage regulation is obtained through a voltage reference and an

error amplifier (TL1431) placed at the secondary side. A charge pump connected to an

auxiliary winding guarantees a stable supply at the controller itself.

4/25

N

2

N

R

N

1

D

R

N

2

Page 5

AN2623 Main characteristics

2 Main characteristics

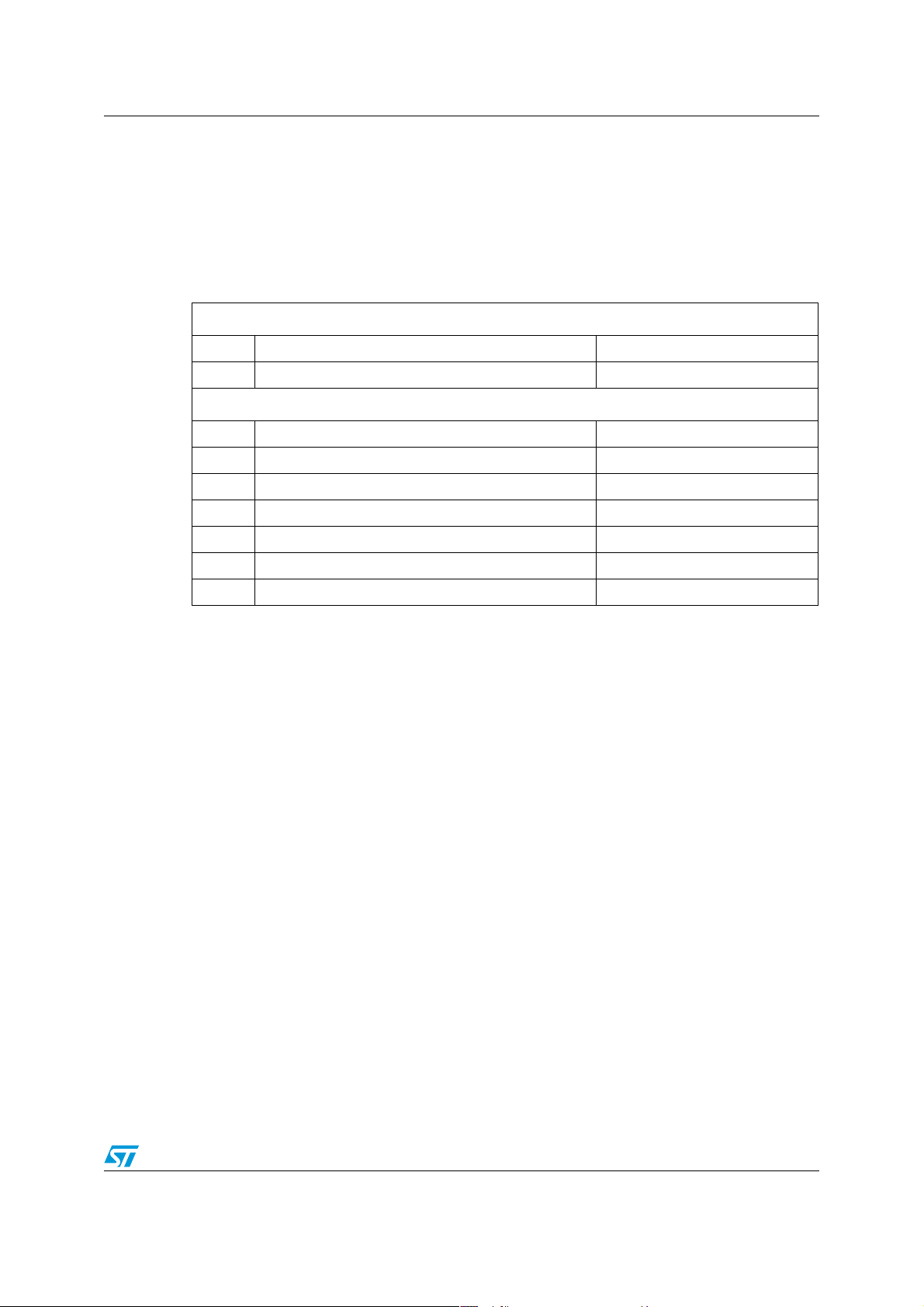

The design procedure is presented in this section and we will refer to the electrical

schematic in Figure 4. The power supply electrical specifications are shown in Tabl e 1

below.

Table 1. Input and output parameters

Input parameters

f

V

line

in

Input voltage 88 ÷ 290 V

Line frequency 50/60 Hz

Output parameters

V

out

I

out

P

out

Output voltage 35 V

Output current 4.5 A max continuous, 0.45 A min

Output power 160 W max

Efficiency at full load 80%

∆V

% Max tolerance on output voltage 3%

out

∆V

T

out HF

A max

Max output voltage ripple at switching frequency 350 mV

Maximum ambient temperature 70 °C

RMS

5/25

Page 6

Main characteristics AN2623

e

e

e

e

e

e

Figure 4. Electrical schematic

1

2

J2

CON2J2CON2

R5

15 kOhm

R5

15 kOhm

+

+

C1

L1

390 uH-5A

L1

390 uH-5A

DN1

DN1

BYT16P-400 heatsink

BYT16P-400 heatsink

16

T1

T1

5

C1

270uF, ESR=42 mOhm, 50 V

270uF, ESR=42 mOhm, 50 V

143

1

4

8

7

R3

R3

5.6 kOhm

5.6 kOhm

TRAN_ISDN_06

TRAN_ISDN_06

0

R6

R6

12

OPTO 1

OPTO 1

43

R7

R7

C8

1.2 kOhm

1.2 kOhm

ISO1

ISO1

Q1

Q1

20 kOhm

20 kOhm

6 nFC86 nF

3

TL 431

TL 431

......1

......1

2 1

R9

R9

R10

R10

1.153 kOhm (+/- 1%)

1.153 kOhm (+/- 1%)

0

<Doc> <R

<Doc> <R

<Doc> <R

<Doc> <R

<Doc> <R

<Doc> <R

A

A

A

A

A

A

Title

Size Document Number Rev

Title

Size Document Number Rev

Title

Size Document Number Rev

Title

Size Document Number Rev

Title

Size Document Number Rev

Title

Size Document Number Rev

3

LFILTERIN1

LFILTERIN1

HT3545-472Y4R0-T01

HT3545-472Y4R0-T01

FUSE14AFUSE1

4A

D1

STTH110

D1

STTH110

0

1

600V-6A

600V-6A

DIODE BRIDGE1

DIODE BRIDGE1

4

0

-+

-+

2

CB1

CB1

2 3

47 nF X2 Cap

47 nF X2 Cap

1 4

CA1

CA1

NTC1

NTC1

47 nF X2 Cap

47 nF X2 Cap

1

2

J1

CON2J1CON2

+

+

C4

C4

330 uF, 450V

330 uF, 450V

+

+

C3

C3

+

+

C2

C2

100 uF, 450V

100 uF, 450V

2.5 Ohm

2.5 Ohm

R1

220 kOhm, 1/4W

R1

220 kOhm, 1/4W

100 uF, 450V

100 uF, 450V

C5

C5

2.2 nF Y1 Cap

2.2 nF Y1 Cap

R2

R2

220 kOhm,1/4W

220 kOhm,1/4W

0

C6

R4

R4

50 Ohm-1/2W

50 Ohm-1/2W

D2

33nFC633nF

D3

1N4148D21N4148

+

+

C7

C7

15VD315V

10uF, 20V

10uF, 20V

STW12NK90Z-heatsink

STW12NK90Z-heatsink

Rg

Rg

10 OHM1

10 OHM1

0

14

16

15

DIS

ST-BY

DC-LIM

Sync1RCT2DC3Vref4Vfb5Vcomp6SS7Vcc

U1

RA1

4.7 kOhm

RA1

4.7 kOhm

13

12

ISEN

SGND

RDOWN1

RDOWN1

CT1

CT1

4.7 nF

4.7 nF

R8

R8

2.2 kOhm

2.2 kOhm

11

PGND

RUP1

RUP1

4.7 kOhm

4.7 kOhm

3.6 kOhm

3.6 kOhm

0.21 Ohm

0.21 Ohm

C10

C10

C9

9

10

Vc

Vout

8

100 pF

100 pF

100 pFC9100 pF

L5991U1L5991

C12

C12

+

+

C11

C11

C13

C13

33 nF

33 nF

1 nF

1 nF

22uF, 25V

22uF, 25V

0

0

0 0

0

0 0

6/25

Page 7

AN2623 Design circuit

3 Design circuit

This section describes the design of the major parts of the circuit.

3.1 Primary controller: L5991

As previously stated, the L5991 is used as the primary controller and its components must

first be selected. Refer to the L5991 datasheet for the choice of the two resistors (R

and one capacitor (C

oscillator in normal operation (f

established that the device must work at the unique frequency (in this case R

) which allows setting separately the operating frequency of the

T

) and in standby mode (fsb). In this application, it was

osc

B

kHz in normal and in standby operation. This frequency is calculated using R

following formula:

Equation 1

f

osc

-------------------------------------------------------------- -=

C

T

1

0.693 RAKT+⋅()⋅

, RB )

A

→ ∝ ) of 60

in the

A

where K

T

=5%T

d

=160 Ω and CT is calculated fixing the discharge oscillator capacitor time

T

sw

Equation 2

Establishing a D

max

method that allows implementing the slope compensation, if needed, was used.

The duty cycle limitation is obtained by applying the following voltage to pin3 :

Equation 3

fixing (refer to Figure 4) R

3.2 Output filter

Admitting a max current ripple on the inductor ∆I

necessary to select an inductor value according to Equation 4:

Equation 4

T

30 109–KtCtCt4.7= nF RA5.6 k Ω=,⇒⋅+⋅=

d

= 50%, L5991 allows obtaining this last value in two different ways. The

2D

–()

52

V

3

=4.70 kΩ, we can then immediately calculate R

up

V

– V

2minVdiode

L

-------------------------------------------------------

out

∆I

out

max

V32.17 V=⇒–=

=3.60 kΩ.

down

equal to 20% of I

Lout

out

D

max

------------- -

f

sw

342 µH=⇒⋅=

L

out

–

outMAX

, it is

The RMS (root mean square) current through the inductor is given by Equation 5:

Equation 5

I

RMS Lout–

2

I

out

2

∆

out

-------------+ I

12

RMS Lout–

4.58 A=⇒=

7/25

Page 8

Design circuit AN2623

The peak current through the inductor is:

Equation 6

I

Peak Lout–

I

out∆ILoutIPeak Lout–

5.4 A==+=

According to these results, L

whose inductance value is L

According to the max high frequency voltage ripple (∆

specifications, the necessary minimum capacitor value (C

was chosen as the Coil Craft's inductor PCV-1-394-05L

out

=390 µH.

out

=350 mV) from the electrical

VoutHF

in the Figure 4) and its maximum

1

admitted ESR (Equivalent Series Resistance) are calculated as follows:

Equation 7

C

outmin

V

out

--------------------- -

∆V

outHF

-------------------- -

⋅

8f

1D

sw

–

max

---------------------- -

L

out

C

outmin

4.5 µF=⇒⋅⋅=

1

2

Equation 8

∆V

outHF

max

--------------------- -

∆I

out

ESR

max

388 mΩ=⇒=

ESR

The RMS current through the output capacitor must not exceed the current rate of the

selected capacitor and is calculated as:

Equation 9

I

RMS Cout–

2

I

RMS Lout–

According to these requirements a C

out=C1

2

I

– I

out

RMS Cout–

860 mA=⇒=

=270 µF (capacitance value) 63 V (Voltage rate)

ZL series Rubycon electrolytic capacitor was selected with an ESR of 42 mΩ and max

current capability of 1495 mA.

3.3 Output diodes

The maximum reverse voltages across the rectifier diode and the free wheeling diode (D1D2 in the Figure 2) can be calculated as:

Equation 10

V

1max

V

diodeF

---------------- V

n

V

---------------- V

V

diodeR

Equation 11

V

dropF

and V

are, respectively, the voltage drop in the freewheeling diode and in the

dropR

rectifier diode, when they are forward biased, and n=1.25 is the turn ratio between the

primary and the secondary winding of the transformer. Considering that the voltage drops in

the two diodes are the same, we can conclude from Equation 10 that V

The maximum RMS and the average currents through the rectifier diode are calculated as:

8/25

dropFVdiodeR

1max

n

dropRVdiodeR

328V=⇒–=

⇒–=

diodeR

= V

diodeF

.

Page 9

AN2623 Design circuit

Equation 12

I

RMSdiodeRIout

1

⎛⎞

D

max

I

AVGdiodeRIoutDmax

------

1

⎝⎠

12

out

⎛⎞

------------ -

⋅+

⎝⎠

I

out

2.25 A=⋅=

I

RMSdiodeR

3.2 A=⇒⋅⋅=

2

∆I

and for the free wheeling diode:

Equation 13

V

dcmin

D

min

D

max

------------------ -

V

dcmax

11.5 I

RMSdiodeFIout

1D

–()1

min

1

⎛⎞

------

12

⋅+

⎝⎠

2

∆I

out

⎛⎞

------------ -

⎝⎠

I

out

4.23A=⋅⋅=⇒=⋅= %

Equation 14

I

AVGdiodeFIout

1D

–()3.825 A=⋅=

min

In Equation 12, 13, and 14 the currents are calculated in Full Load condition considering

the worst case for each diode and can be used to calculate the maximum power dissipation

for each diode.

To reduce the number of components, the size of the board, and to minimize power losses,

the ST double fast recovery rectifier BYT16P-400 was selected.

Although the two diodes inside the same package are always working complementarily, in

order to choose the heat sink, the total power losses in the worst case can be calculated as

if, instead of two diodes there is only one that flows through the whole current of the

inductor:

Equation 15

1

⎛⎞

------

1

⎝⎠

12

out

⎛⎞

------------

⋅+

⎝⎠

I

out

5.53 W=⋅⋅⋅=

Considering T

temperature T

2

R+

P

totDiodeVtIout

AmbMax

Jmax

= 70 °C, the power losses just calculated, and the maximum junction

(see diode datasheets) of the selected diode, it is possible to determine

I

out

d

2

I

∆

the total thermal resistance of the diode:

Equation 16

T

–

jmaxTAmbMax

R

thmax

The R

of the select diode, so a heat sink with thermal resistance R

max

that results is lower than the max junction to ambient thermal resistance R

thmax

--------------------------------------------

P

lossesR

15° C== /W

≅ 13 °C must be added.

thSN

3.4 Power transformer design and MOSFET choice

Ideally in a forward converter, the energy flows forward from the primary side to the

secondary side without any storage in the transformer. But the real transformer does not

have infinite magnetizing inductance, so during the on-time of the power MOSFET some

energy is stored in the magnetic core. The proper magnetic core and the primary winding

turn number have to be selected in order to avoid core saturation. The proper magnetic core

and primary winding turn number must be selected taking into account that some energy is

also dissipated in the magnetic core.

thJ-A

9/25

Page 10

Design circuit AN2623

An empirical formula that gives an indication regarding the needed area Product for

magnetic core that has to be selected for the application is shown in Equation 17:

Equation 17

AP

11.1 Pi⋅

⎛⎞

min

-------------------------------------------- -

⎝⎠

0.141 B∆ f

⋅⋅

==

sw

1.47 cm

4

where ∆B is maximum flux density swing in Tesla for normal operation and its typical value is

within 0.2-0.3T in the case of the forward converter. This value has to be chosen in order to

avoid saturation and to limit core losses; we chose 0.2T. The selected core is ETD39

(AP=2.2cm

transformer's max temperature rise ∆Τ

4

, Ae=125 mm2) in N27 material. Considering this kind of core and the

=40 °C, the maximum allowed total power loss is:

max

Equation 18

T∆

P

LOSTtrasfTOTAL

-----------------------

R

thCORE

2.5 W==

and the result of the relative max allowed core loss:

Equation 19

2P

⋅

LOSTtrasfTOTAL

-------------------------------------------------------

P

fe

2+

k

1

1.21 W==

is the ∆B swing exponent relative at N27 material) so the real value of the maximum flux

(k

1

density swing is:

Equation 20

1

-----

k

P

⎛⎞

LOSTtrasfTOTAL

B∆ 2

(k

is the loss coefficient of N27 material, K2 is the frequency exponent of N27 material and

0

V

is the effective volume of ETD39's core). The minimum primary turns is given by:

e

-------------------------------------------- -

⎜⎟

⎝⎠

Vek0f

⋅⋅

1

k

2

sw

0.146 T=⋅=

Equation 21

V

⋅

dcminDmax

-------------------------------------- -

A

efsw

B∆⋅⋅

42==

and we chose N

=42.

1

N

1min

The turn ratio n between primary and secondary side is defined as:

Equation 22

N

V

1

dcmin

------ -

n

where N

output voltage and V

N

2

and N2 are the number of turns of the primary and secondary side, V

1

is the diode rectifier voltage drop. The secondary turns number is

dropR

=36. The magnetizing inductance of the primary side is given by:

----------------- -

N

V

2

2min

D

⋅

maxVdcmin

-------------------------------------- -

V

+

outVdropR

1.15====

is the

out

Equation 23

L

mAL

where A

is the inductance for turn square in nH/turns2.

L

10/25

N

2

109–Lm3.8 mH≅⇒⋅⋅=

1

Page 11

AN2623 Design circuit

Considering that the total instantaneous current at the primary side is

Equation 24

i

t() i′2t() imt()+=

1tot

where i’

(t) is the secondary winding current during ton reported at primary side and im(t) is

2

the magnetizing current.

The magnetizing current expression is:

Equation 25

V

inmin

t()

----------------

L

m

t⋅=

i

m

And its peak value is:

Equation 26

V

⋅

inminfsw

mpk

------------------------------- -=

L

⋅

mDMAX

I

The peak value for the i‘

(t) is:

2

Equation 27

And the value for i‘

(t) at switch-on is:

2

′

I

⎛⎞

2pk

I

out

⎝⎠

------- -+

Equation 28

I

′

2min

⎛⎞

⎝⎠

I

out

I∆

------- -–

2

The ripple current at the primary side is:

Equation 29

mpk

′

I

2pk

∆ I

I

1

The rms value for the current at the primary side is:

Equation 30

′

I

1totRMS

In this case neglecting the i

D

(t) , from (Equation 24), it is possible to write following formula:

m

⎛⎞

I

()2I1I

⋅=

MAX

2min

⎝⎠

Equation 31

I

RMSdiodeR

I

1totRMS

-----------------------------

n

I∆

1

0

-- -

⋅=

n

2

1

0

-- -

⋅=

n

′

I

–+=

2min

2min

1

2

-- -

∆⋅+⋅∆+

I

1

3

′

2.75 A=≅

Considering (Equation 18) and (Equation 19), the maximum allowed copper power losses in

the windings transformer can be immediately calculated. It is possible to select the diameter

for primary and secondary winding; we have chosen d

=0.25 mm and d2=0.8 mm.

1

11/25

Page 12

Design circuit AN2623

Considering that for the L5991 the maximum allowed voltage value at the current sense (IS,

pin n°13) is 1 V, it is possible to determine the value of the current sense resistor (R

in

9

Figure 4):

Equation 32

1

--------------------- -

R

9

I

1totpeak

0.23 Ω==

where I

1totpeak

is the peak value of i

1tot

(t) .

The maximum turn ratio k between primary and reset winding, as known in technical

literature, in order to achieve the complete demagnetization of the transformer is the

following:

Equation 33

k

max

---------------------- -

D

max

k

max

1=⇒=

1D

–

max

Choosing

Equation 34

N

R

-------

k

the necessary number of turns for reset winding is N

and average current of reset diode are given by (I

0.96==

N

1

=41.The maximum reverse voltage

R

AVE-1°magn

is the magnetizing average

current of the primary side):

Equation 35

V

REV R–

V

DCmax

kV

DCmax

806 V=+⋅=

Equation 36

I

AVE 1° magn–

I

AVE R–

---------------------------------- -

k

0.11 A==

The Bipolar ultrafast diode STTH110 was chosen. Concerning the MOSFET the maximum

drain voltage is:

Equation 37

with V

dropReset

V

drainMax

V

as the voltage drop in the reset diode. The max rms drain current is:

–()

dcMaxVdropReset

Equation 38

I

drainRMSItot1RMS

so the Zener-protected SuperMESH Power Mosfet STW12NK90Z was chosen. Calculating

the estimated total MOSFET power losses, it is easy to concludethat a substantial heatsink

(around R

12/25

≤ 5 °C/W) is necessary.

th

1

⎛⎞

-- -

⎝⎠

k

V

dcMax

838V=+⋅=

=

Page 13

AN2623 Design circuit

2

3.5 Feedback loop

Since current mode control is employed using the L5991 current mode controller, the power

stage of the forward converter exhibits a single output pole due to the output capacitor and

load combination, along with a zero due to the ESR of the output capacitor. The goal of the

compensator is to achieve a slope of -20 db/decade for the closed loop gain, with a phase

margin greater than 45 degrees at the crossover frequency. To achieve good dc regulation, a

high low-frequency gain is another requirement for the compensator. For continuous

conduction mode operation, the transfer function of the forward converter (power stage) is:

Equation 39

s

⎛⎞

1

-----+

⎝⎠

ω

z

G1s() G

-------------------- -

⋅=

1o

⎛⎞

1

⎝⎠

s

-----+

ω

p

where (referring to Figure 4)

● G

● R

● R

● n is the turn ratio between the primary and secondary side

●

●

is the power block gain and results in

1o

is the effective total load resistance of the controlled output defined as

0

is the current sense resistance

9

----------------------------------------- -=

ESR

1

⋅

1

⋅

coutCout

out

ω

z

ω

------------------------- -=

p

R0C

G

1o

nR

⋅

0

-----------------=

3R

⋅

9

R

0

In order to reach the objective previously stated at the beginning of this section, the

feedback compensation network transfer function, using L5991, is obtained as:

Equation 40

s

1

------- -+

ω

1

zc

----------------- -

Cs() C

⋅⋅=

0

1

where (referring to Figure 4)

● C

● CTR is the current transfer ratio of the optocoupler

● R

● R

● C

● ω

● ω

● C

is the feedback block gain and results in

0

is the upper resistance of the out voltage divider of feedback net

5

is the polarization resistance of the optocoupler

3

and R7 are the capacitance and the resistance of the TL431's feedback net

8

---------------------=

is the zero of the feedback net ⇒ to compensate ω

zc

is the pole of the feedback net ⇒ to compensate ω

pc

is the capacitor connected at COMP pin of L5991

12

ω

zc

R

ω

--------------------------------------- -=

pc

12 10

-- -

s

s

------- -+

ω

pc

12 103CTR⋅⋅

-------------------------------------------=

C

0

R

1

⋅

7C8

1

3

⋅⋅

C

⋅⋅

5C8R3

12

p

z

V

out

------------- -=

P

0

13/25

Page 14

Design circuit AN2623

f

c

--- -

3

fc0.1 f

fzc1600 Hz=⇒

swfc

Choosing the crossover frequency it is possible to place

compensator zero f

3fcf⇒pc15 k Hz=⋅

.

Considering R

C

=1 nF, C8=6 nF, R7=20 kΩ .

12

around and the compensator pole fpc above

zc

=5.6 kΩ, R5=15 kΩ, CTR=1 Ω were calculated, choose the following values:

3

5kHz=⇒⋅≅

14/25

Page 15

AN2623 Experimental results

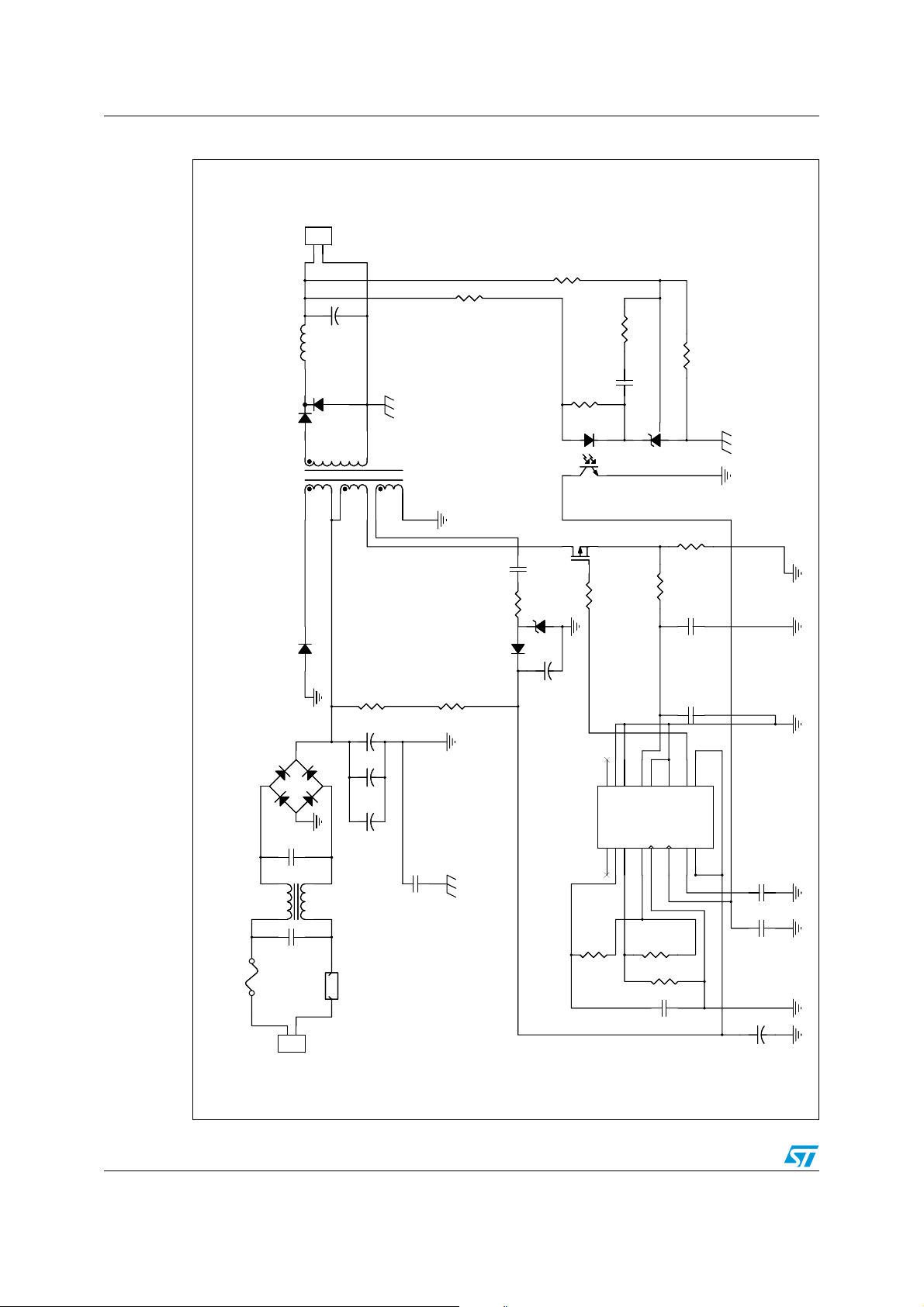

4 Experimental results

The schematic of the tested board is given in Figure 4. The graphs in Figure 5 show the

drain voltage and current at the minimum, nominal and maximum input mains voltage during

nominal operation at full load.

Figure 5. V

and Ids of STW12NK90Z in full load condition at different input

ds

voltages

Vin=88 V

ac

Vin=220 V

ac

Vin=290 V

ac

Purple: drain voltage

Brown: drain current

15/25

Page 16

Experimental results AN2623

The drain peak voltage (570 V) assures a reliable operation of the STW12NK90Z with a

good margin against the maximum B

VDSS

.

4.1 High frequency ripple of output voltage and load regulation

Figure 6 shows the high frequency ripple of output voltage at minimum, nominal and

maximum input voltages.

Figure 6. High frequency ripple of output voltage in full load condition at different

input voltages

V

=88 V

in

ac

16/25

Vin=220 V

Vin=290 V

ac

ac

Page 17

AN2623 Experimental results

V

V

Apart the voltage spike, the voltage ripple of the output (at full load) for every input voltage is

given in Table 2 .

Table 2. Value of high frequency output ripple at full load condition

Vin(V) V

(mV) V

outHF

outHF

%

88 176 0.5

220 240 0.69

290 324 0.9

Figure 7 shows the behavior of the output voltage regulation against the load. It is easy to

see from the graph that, changing the load, the output voltage is practically constant.

Figure 7. Output voltage behavior against the load and the V

34.78

34.76

34.74

34.72

34.7

34.68

34.66

O u tp u t V o ltag e (V )

34.64

34.62

0.1 0.45 2.3 4.5

Io ut( A)

in

Vin=88V

Vin=220

Vin=290

17/25

Page 18

Experimental results AN2623

4.2 Dynamic load test

The graphs in Figure 8 show the output voltage regulation against a dynamic load variation

(between max load and 10% max load).

Figure 8. Behavior of system under dynamic load at different input voltages

V

=88 V

in

ac

Vin=220 V

Vin=290 V

ac

ac

Blue: Vcomp (voltage on pin 6 of L5991)

Green: output voltage

Brown: output current

18/25

Page 19

AN2623 Experimental results

4.3 Start-up behavior

Figure 9 shows rising slopes at full load of the output voltage at nominal, minimum and

maximum input main voltages. As shown in the graphs, the rising times are fairly constant.

Figure 9. Behavior of system under dynamic load at different input voltages

Vin=88 V

Vin=220 V

ac

ac

Vin=290 V

ac

Blue: Vcomp (voltage on pin 6 of L5991)

Green: output voltage

Brown: output current

19/25

Page 20

Experimental results AN2623

4.4 Wake-up time

Figure 10 shows the waveforms with wake-up time measures at nominal, minimum and

maximum input voltages. Obviously due to the circuit characteristics, the wake-up time is not

constant but it is dependent on the input voltage. The measured time at 88 V

290 V

are (respectively) 2.48 sec, 780 ms and 580 ms which are rather common values for

ac

this kind of power supply.

Figure 10. Wake-up time of the system at different input voltages

V

=88 V

in

, 220 Vac and

ac

ac

20/25

V

in

V

in

=220 V

=290 V

ac

ac

Page 21

AN2623 Experimental results

4.5 Short circuit test

All tests have been done at nominal, maximum and minimum input voltages. For all

conditions the drain voltages are always below B

waveforms, the circuit starts to work in hiccup mode. Because the working time and the idle

time are imposed by the charging and discharging time of the auxiliary capacitor C11 (refer

to Figure 4), they are proportional to the input mains voltage.

Figure 11. Behavior of the system in short circuit condition at different input

voltages

. As clearly indicated in the

VDSS

V

in

=88 V

ac

As expected the circuit protects itself as well.

V

=220 V

=290 V

CC

ac

ac

in

V

in

Blue: V

Brown: output voltage

Purple: drain voltage

21/25

Page 22

Experimental results AN2623

)

)

A

A

4.6 Thermal measurement and global efficiency

One of the most critical parts of the power supply is the MOSFET. As previously seen at the

end of Section 3.4: Power transformer design and MOSFET choice a heatsink is necessary.

To verify the correct thermal behavior of the MOSFET, it was checked at maximum load and

maximum input voltage. The device reaches the thermal steady state of 94 °C.

Figure 12 shows the global efficiency in function of the input voltage for two values of load.

From the graph, we can conclude that the board has good efficiency. In absolute terms the

minimum value is around 80% for V

The technical requirements for this converter have been respected.

Figure 12. Efficiency of the system

87.00

86.00

85.00

84.00

83.00

82.00

81.00

80.00

79.00

78.00

Global Efficiency (%

77.00

76.00

=290 V and the maximum is around 86% for Vin=88 V.

in

Load=4.5

Load=2.3

88 220 290

In put volt a ge (V

Table 3. Bill of material

Item Quantity Reference Properties

1 1 1 TL 431 STMicroelectronics part

2 2 CB1 47 nF X2 Cap

CA1 47 nF X2 Cap

31 CT1 4.7 nF

4 1 C1 270 µF, ESR=42 mΩ, 50 V, electrolytic capacitor

5 2 C2 100 µF, 450 V, electrolytic capacitor

C3 100 µF, 450 V, electrolytic capacitor

6 1 C4 330 µF, 450 V, electrolytic capacitor

7 1 C5 2.2 nF, Y1 Cap

81 C6 33 nF

9 1 C7 10 µF, 20 V electrolytic capacitor

10 1 C8 6 nF

11 2 C9 100 pF ceramic capacitor

C10 100 pF ceramic capacitor

12 1 C11 22 µF, 25 V, electrolytic capacitor

13 1 C12 1 nF ceramic capacitor

22/25

Page 23

AN2623 Experimental results

Table 3. Bill of material (continued)

Item Quantity Reference Properties

14 1 C13 33 nF ceramic capacitor

15 1 Diode bridge1 600 V - 6 A

16 1 DN1 BYT16P-400 STMicroelectronics part + heatsink

17 1 D1 STTH110 STMicroelectronics part

18 1 D2 Diode 1N4148

19 1 D3 Diode Zener Vz=15 V

20 1 FUSE1 4 A

21 1 ISO1 OPTO 1-PC817

22 2 J1 CON2

J2 CON2

23 1 LFILTERIN1 Common Choke, 15 mA

24 1 L1 Inductor, 390 µH-5A

25 1 NTC1 2.5 Ω

26 1 Q1 STW12NK90Z - STMicroelectronics part + heatsink

27 2 RUP1 4.7 kΩ

RA1 4.7 kΩ

28 1 RDOWN1 3.6 kΩ

29 1 R1 220 kΩ, 1/4 W

30 1 R2 220 kΩ,1/4 W

31 1 R3 5.6 kΩ

32 1 R4 50 Ω -1/2 W

33 1 R5 15 kΩ

34 1 R6 1.2 kΩ

35 1 R7 20 kΩ

36 1 R8 2.2 kΩ

37 1 R9 0.21 Ω

38 1 R10 1.153 kΩ

39 1 T1 Transformer

40 1 U1 L5991 STMicroelectronics part

41 1 Rg 10 Ω

23/25

Page 24

Revision history AN2623

5 Revision history

Table 4. Document revision history

Date Revision Changes

29-Oct-2007 1 Initial release

24/25

Page 25

AN2623

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

25/25

Loading...

Loading...