AN2615

Application note

A high precision, low cost, single supply ADC for

positive and negative input voltages

Introduction

In general the ADC embedded in the ST7 microcontroller is enough for most applications.

But, in some cases it is necessary to measure both positive and negative voltages. This

requires an external ADC with this particular capability. Most external ADCs require a dual

supply to be able to do this. However, microcontroller-based applications usually only have a

positive supply available.

This application note describes a technique for implementing an ADC for measuring both

positive and negative input voltages while operating from a single (positive) supply. This

converter is based on a voltage-to-time conversion technique. Like other slope converters,

this ADC also uses an integrating capacitor, but the measured time is inversely proportional

to the input voltage. An additional comparator with a voltage reference is used to improve

conversion accuracy.

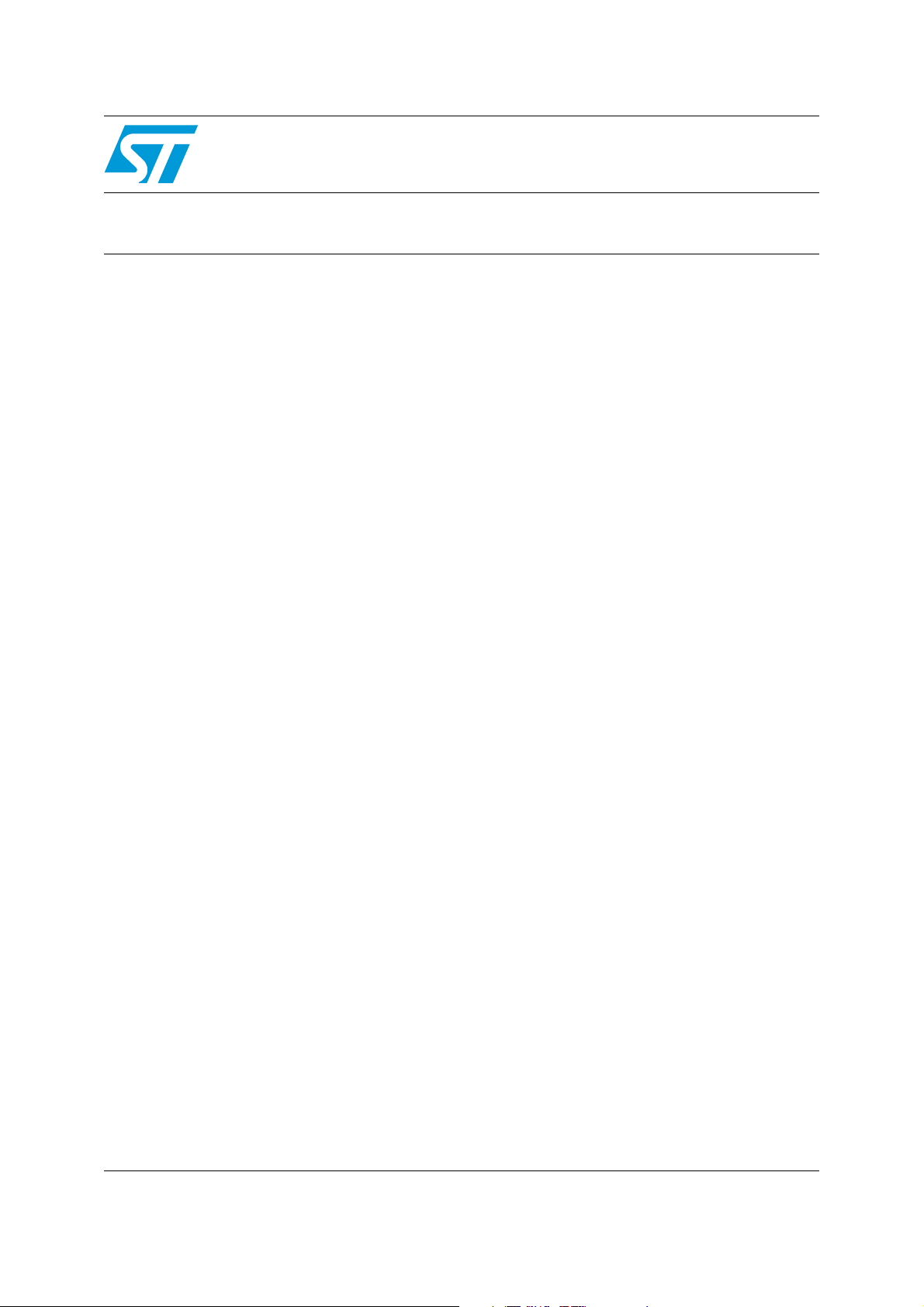

As shown in the circuit diagram (Figure 1 on page 6), the converter is implemented using an

integrating capacitor, resistor, external op-amp, comparators and some microcontroller I/O

pins. The ST72F264 microcontroller is used in this application note as an example, but the

implementation is feasible using any ST7 microcontroller. The 16-bit timer of the

microcontroller measures the time using its input capture pins (PB0 and PB2). These pins

are connected to the output of the Comp1 and Comp2 comparators. The I/O pins PB1 and

PB3 are used to switch the M1 and M2 switches on or off. The circuit could also work with a

microcontroller equipped with an 8-bit timer. Only a small modification to the software would

be needed.

August 2007 Rev 1 1/37

www.st.com

Contents AN2615

Contents

1 Circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Theory of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Advantage of using two comparators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Circuit analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5V

vs time diagram for different input voltages . . . . . . . . . . . . . . . . . 10

out

6 Characteristics of different slope converters . . . . . . . . . . . . . . . . . . . . 11

6.1 Single-slope converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.1.1 Single-slope converter timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.2 Dual-slope converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.2.1 Dual-slope converter timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.3 Solution presented in this application note . . . . . . . . . . . . . . . . . . . . . . . . 13

7 Error analysis/constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.1 Input offset voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.2 Correction factor for the product of R*C . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.3 Value of charging resistance R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.4 Charging capacitor C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.5 16-bit timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.6 Effect of temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.7 Comparator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8 Voltage references . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

9 Hardware setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

10 Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

11 Result . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2/37

AN2615 Contents

11.1 Positive input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

11.2 Negative input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

11.3 Effect of the capacitor value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

12 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

13 References and bibliography . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Appendix A Input stage conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

A.1 Case 1: Voltage measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

A.2 Case 2: Current measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Appendix B Application board schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Appendix C Bill of materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Appendix D Software flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

D.1 Code size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

14 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3/37

List of tables AN2615

List of tables

Table 1. Results for positive input voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 2. Results for negative input voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 3. Bill of materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 4. Code size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 5. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4/37

AN2615 List of figures

List of figures

Figure 1. Circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2. Relationship between Vout and time for a given input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 3. Timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 4. V

Figure 5. Single-slope converter circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 6. Single-slope converter timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 7. Dual-slope converter circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 8. Dual-slope converter timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 9. V

Figure 10. Voltage reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 11. Hardware setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 12. Algorithm flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 13. Results for positive input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 14. Measured vs input for positive voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 15. Error vs input for positive input voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 16. Results for negative input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 17. Measured vs input for negative voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 18. Error vs input for negative input voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 19. Results for positive input with a 10 µF capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 20. Voltage measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 21. Potential divider . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 22. Use of input buffer for voltage measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 23. Current measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 24. Application board schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

vs time for different input voltages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

out

versus time in AN2615 solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

IN

5/37

Circuit diagram AN2615

1 Circuit diagram

Figure 1. Circuit diagram

PB1

M1

I

358

R

C

Amp

S

Comp1

358

V

out

D

V3

PB0

1. V1 < V2 < V3

V1

R

PB3

M2

V

IN

V2

358

Comp2

PB2

6/37

AN2615 Theory of operation

2 Theory of operation

V

is the input voltage. The voltages across resistor R are the reference voltage V1 and the

in

input voltage V

op-amp. Therefore, for a given input voltage, the current flowing through resistor R is

constant. Let this current be I.

Current I charges the capacitor C, and output starts increasing in a positive direction for the

input V

<= V1 (input Vin > V1 charges in the opposite direction).

in

The output is captured at two instants using the two output comparators at voltage

references V

respectively. The final reading of time T

The input voltage is calculated from this difference through the formulae given in the circuit

analysis.

This technique can only be used where the input voltage varies slowly, otherwise the

charging of the capacitor is non-linear.

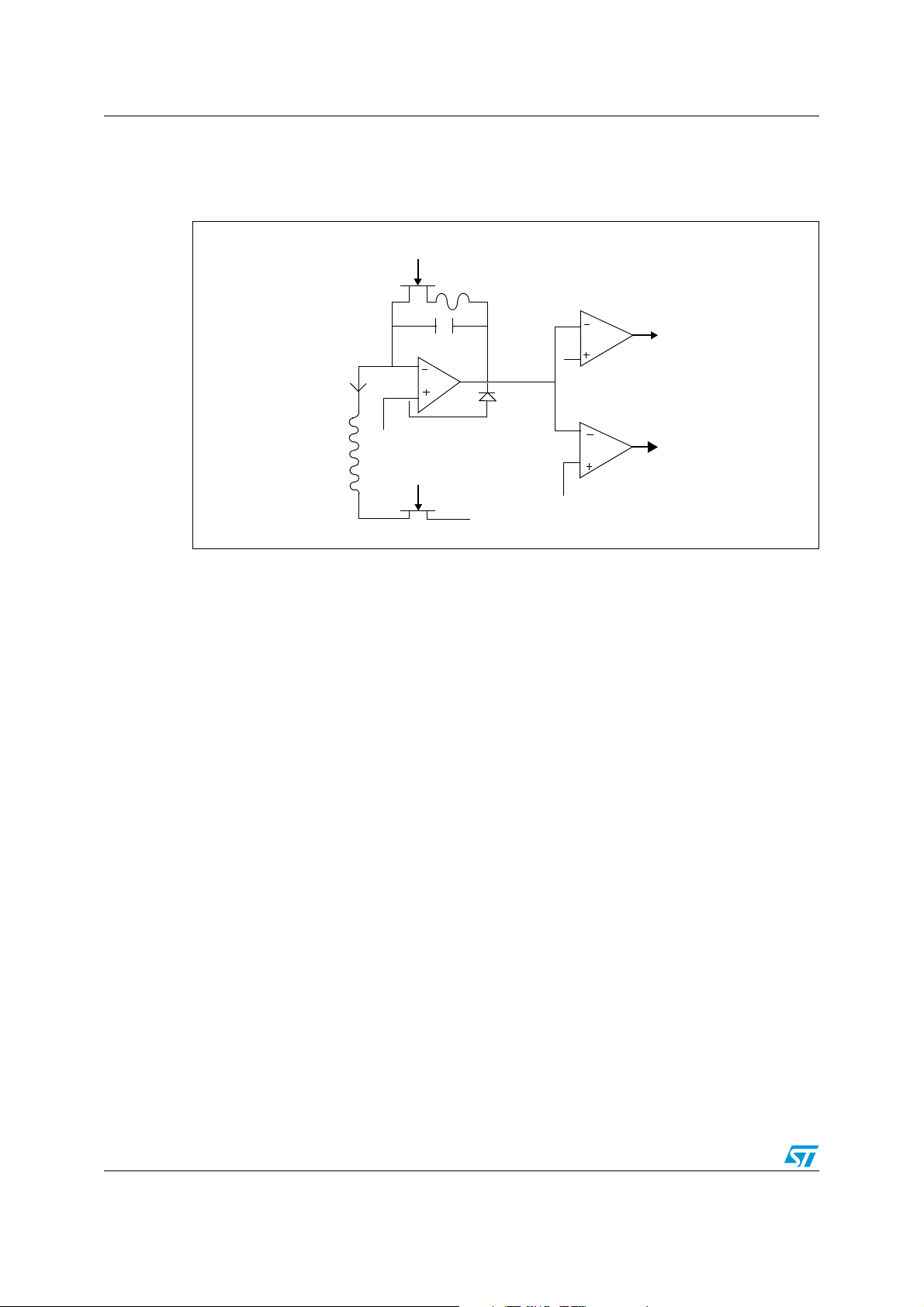

2.1 Advantage of using two comparators

. Due to the properties of the op-amp, V1 is output on the inverting pin of the

in

and V3. The time corresponding to voltage levels V2 and V3 are T2 and T3

2

is taken as the difference of T3 and T2.

m

The purpose of using the second comparator (comp2) can be understood from the diagram

below (Figure 2), which shows the relationship between the op-amp output (Amp in

Figure 1: Circuit diagram on page 6) and the time for a given input value.

Figure 2. Relationship between V

V

out

V3

V2

V1

and time for a given input

out

Point o f

uncertainty

T2

T

m

T3

Time (t)

The time is measured as the difference of the two timer readings (T3 -T2) for the same

slope. So factors like the residual voltage of the capacitor ( V

(0+)) and any other constant

c

errors (like the effect of output offset voltage) on the output side of the op-amp are

subtracted. So its performance is better than a single-slope converter.

7/37

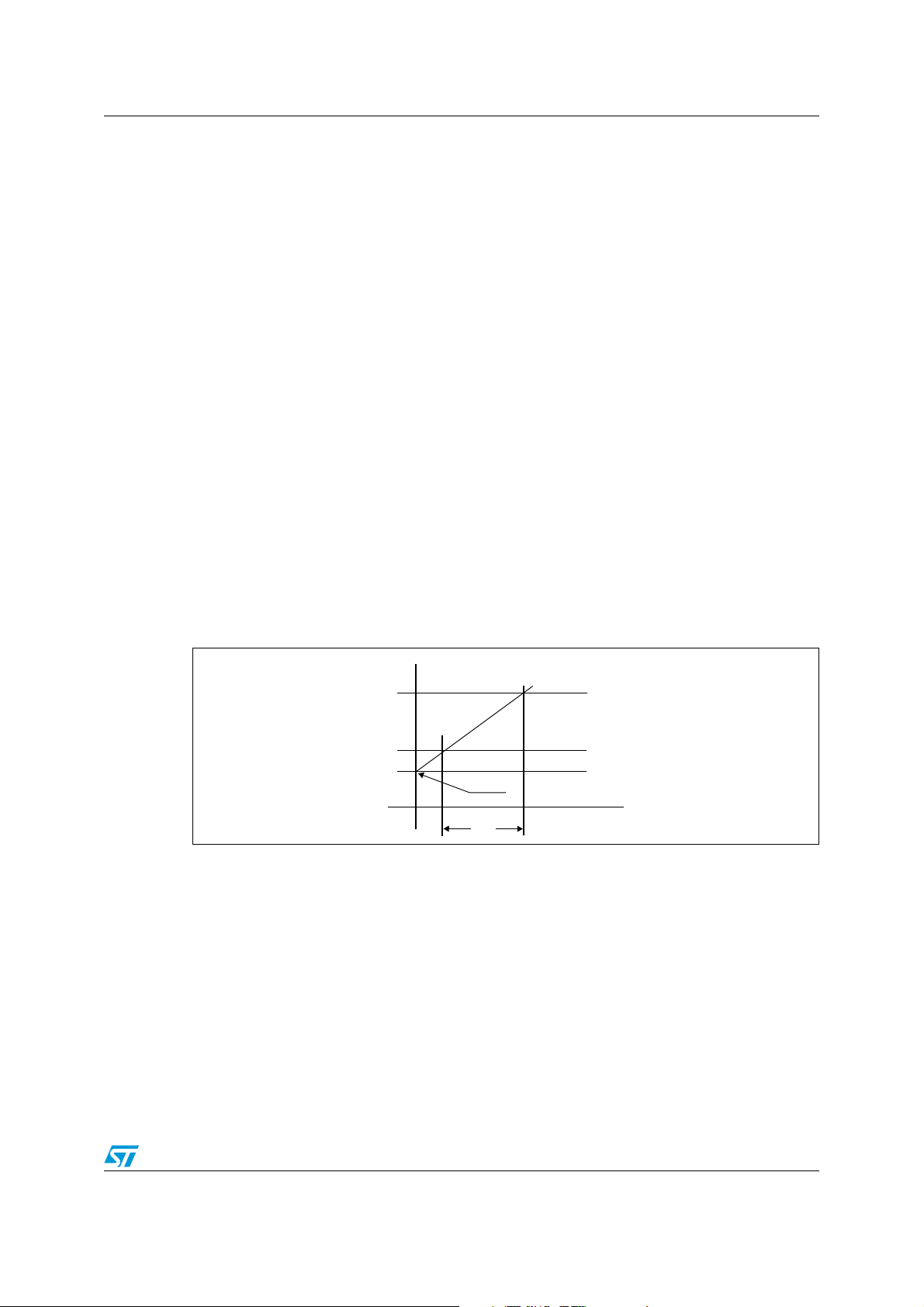

Timing diagram AN2615

3 Timing diagram

Figure 3 shows the overall operation of the ADC. Initially the capacitor is in the reset state

(M1- on and M2- off), the op-amp output V

comparators, Comp1 and Comp2 is high.

Capacitor charging can be started by switching M1 - off and M2 - on. When the charging

starts, V

rises. When V

out

becomes greater than V2, a falling edge occurs on Comp1. This

out

causes an input capture at pin PB2 and software reads the timer value T

When V

becomes greater than V3, a falling edge occurs on Comp2. Again this causes an

out

input capture at pin PB0 and software reads the timer value T

The capacitor is discharged by switching M1 - on and M2- off. After this, the ADC can be

kept in reset condition by switching M1 - on and M2 - off or we can continue repeating the

same process and make more measurements.

Figure 3. Timing diagram

is at V1 and so, the output of both

out

2

.

3

.

V

out

V3

V2

V1

Comp1

Comp2

M1

M2

Charging

0

T2

time

T

m

Discharg.

time

T3

Settling

time

Time (t)

T

m

8/37

AN2615 Circuit analysis

4 Circuit analysis

In this analysis, it is assumed that there is no noise present and the i/p offset voltage of the

op-amp is negligible.

I = (V

– Vin)/R = C * dVc/dt

1

Where, V

Applying the Laplace transform:

or,

Applying the inverse Laplace transform, we get

As shown in Figure 3: Timing diagram on page 8

So,

And,

Equation (2) and equation (3) can both be used as the characteristic equation for this

converter, but factors like Vc(0+) and other constant errors remain present. But if we use

both comparators, then we can remove these factors by subtracting equation (2) and

equation (3).

= V

c

(V

– Vin)/s * R = C * (s Vc(s) – Vc (0+))

1

(V

– Vin)/s2 = (R * C) * ( Vc (s) - Vc(0+)/s)

1

(V

– Vin) * T = (R * C) * ( Vc(t) - Vc(0+) ) ------------------- (1)

1

At T = T

– V1 and current ‘I’ is constant for a given input.

out

, Vc(T2) = V2 – V

2

1

And, at T =T3, Vc (T3)= V3 – V1

(V

– Vin) * T2 = (R * C) * (V2 – V1 - Vc(0+)) ------------------- (2)

1

(V

– Vin) * T3 = (R * C) * (V3 – V1 - Vc(0+)) ------------------- (3)

1

After subtracting equation (2) from equation (1) and rearranging we get:

V

= V1 - (R * C) *( V3 – V2 )/(T3 –T2) ------------------- (4)

in

Let measured time T

V

= V1 - (R * C) * ( V3 – V2 )/T

in

By using equation (5) we can measure the value of V

- T2 = Tm and we get:

3

m

9/37

------------------- (5)

depending on the value of T3 and T2.

in

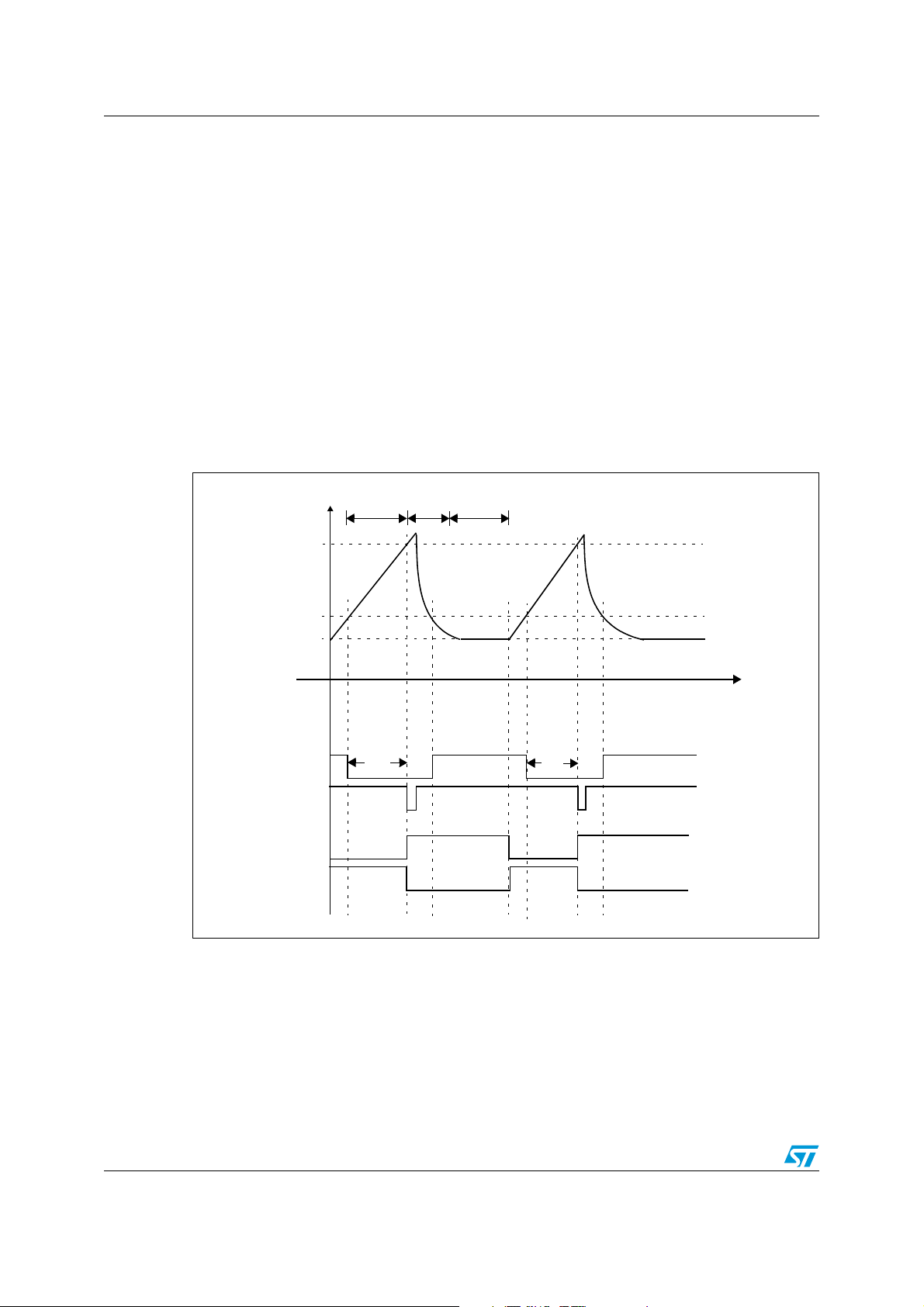

V

vs time diagram for different input voltages AN2615

out

5 V

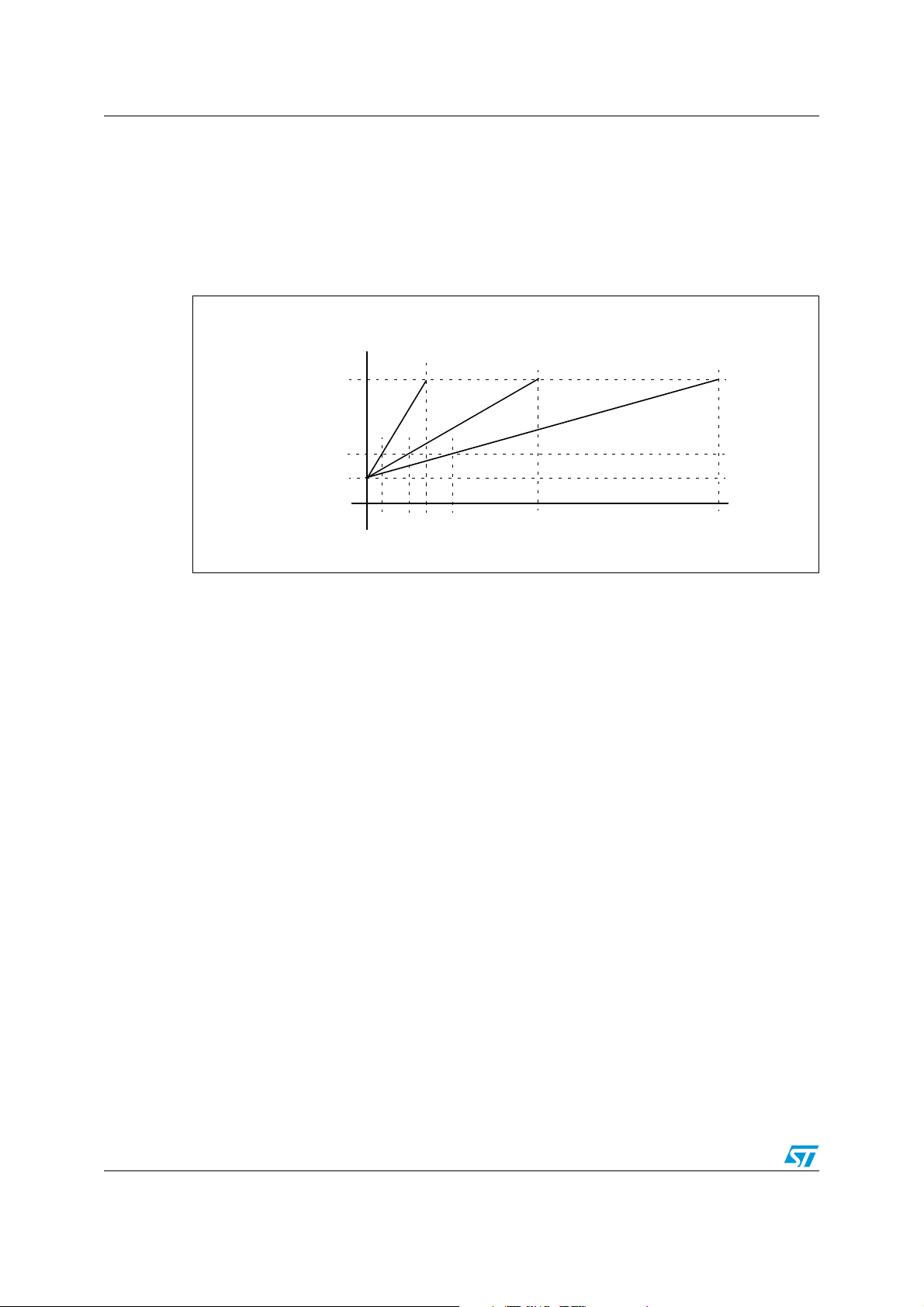

In Figure 4, we can see the relationship between the V

voltages. From the figure, it is clear that the conversion time for a negative input voltage is

less than the time taken for a positive input voltage.

Figure 4. V

1. T

2. This ADC works for the range Vin <= V1 but if the input voltage is greater than V1 the direction of current I is

3. For negative voltage currents I, that depend on the difference V

vs time diagram for different input voltages

out

and time for different input

out

vs time for different input voltages

out

Effective time Tm = T - T’

< 0 Vin =0 Vin > 0

V

in

V3

V

out

V2

V1

T1’ T2’ T1 T3’ T2

Time (t)

1: for Vin < 0; Tm2: for Vin = 0; and Tm3: for Vin > 0 (where Tin1 < Tin2 < Tin3)

m

inverted and the capacitor starts charging in the opposite direction and conversion never takes place.

- Vin, is high, so the charging time for

negative voltages is less than the positive voltages.

1

T3

10/37

AN2615 Characteristics of different slope converters

6 Characteristics of different slope converters

6.1 Single-slope converter

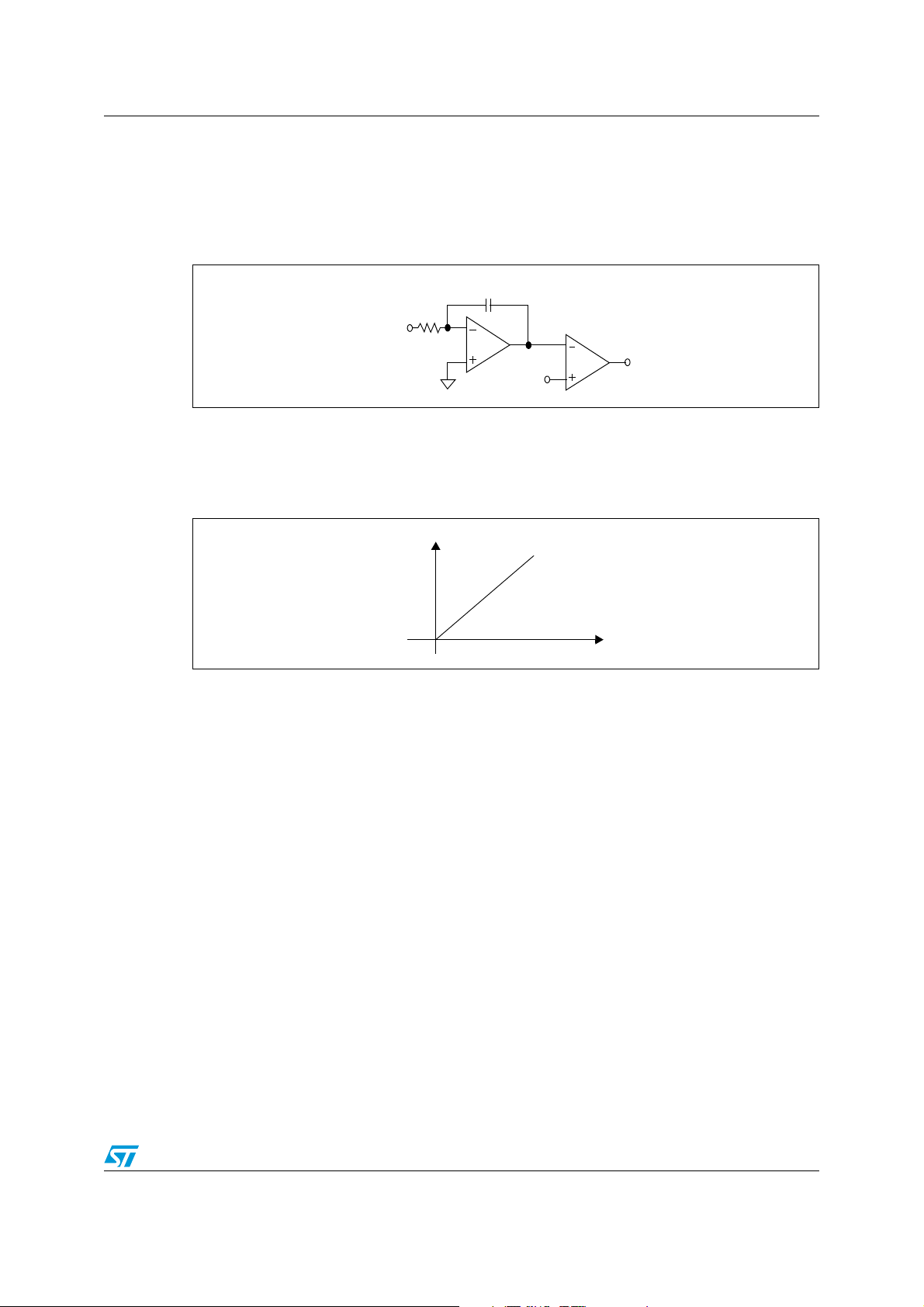

Figure 5. Single-slope converter circuit diagram

C

R

-V

ref

V

INT

V

in

6.1.1 Single-slope converter timing diagram

Here Vin is directly proportional to the time measured.

Figure 6. Single-slope converter timing diagram

V

in

Time

1. Here Vin = K * T

m

The major sources of conversion errors are the correction factor for the R*C product and the

input offset voltage.

A single-slope converter requires a dual supply voltage op-amp to be able to measure the

positive and negative voltages.

11/37

Characteristics of different slope converters AN2615

6.2 Dual-slope converter

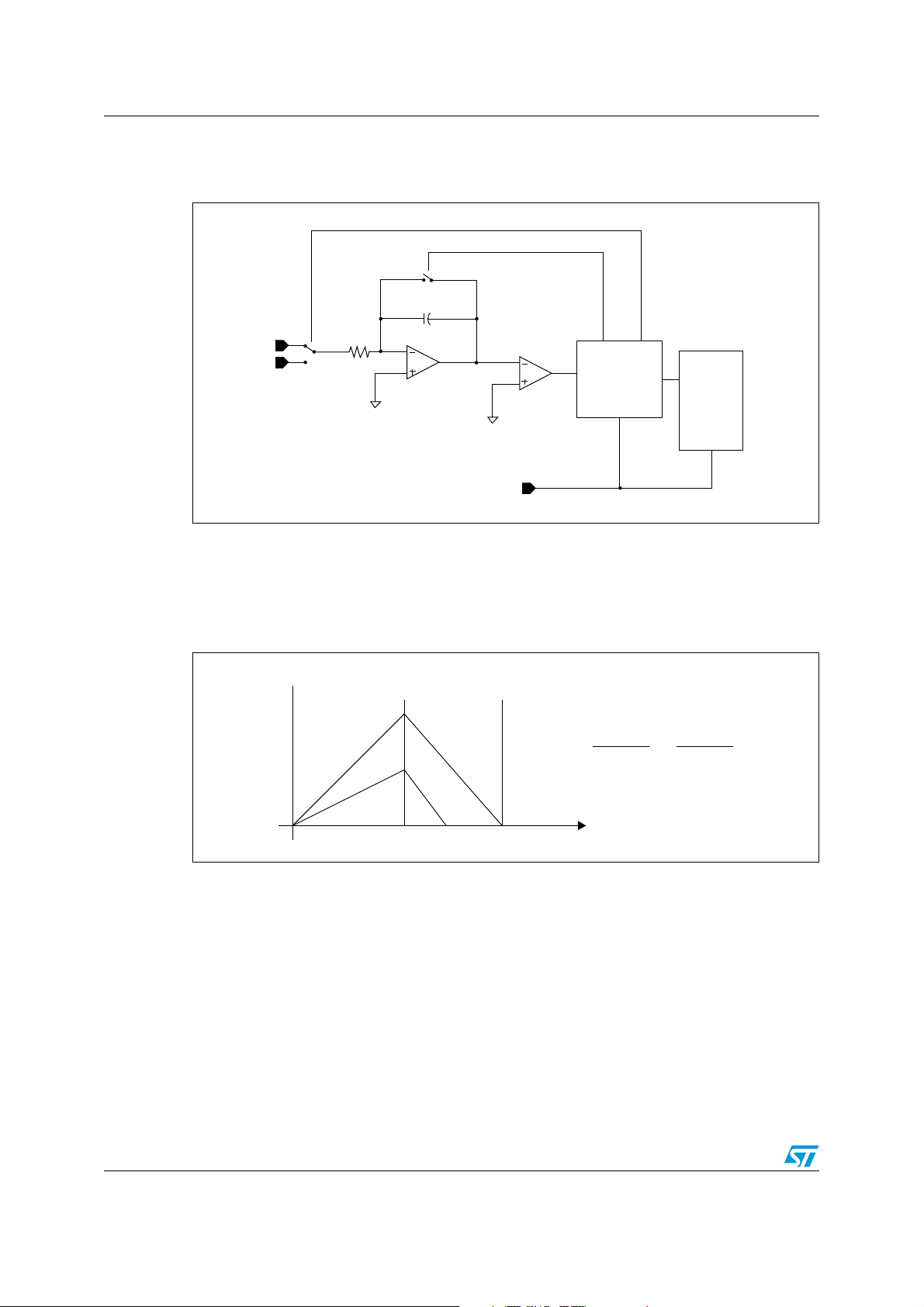

Figure 7. Dual-slope converter circuit diagram

S0

-V

in

V

ref

S1

R

1

out

3

2

gnd

gnd

6.2.1 Dual-slope converter timing diagram

As shown in Figure 8 a dual-slope ADC has a charging phase followed by a fixed rate

discharging phase.

Figure 8. Dual-slope converter timing diagram

Charging phase Fixed-rate discharge

Vin1

V

2

in

-V

ref

-V

ref

clk

Control logic

S1 S2

1

out

2

cmp

ctr

enbl

clk

clk

Counter

V

in

V

ref

=

T

charge

T

discharge

The advantage of a dual-slope ADC is that it is not dependent on the correction factor for the

R*C product. However, the input offset voltage problem still persists and this ADC also

requires a dual supply op-amp to be able to measure positive and negative voltages.

12/37

Time

AN2615 Characteristics of different slope converters

6.3 Solution presented in this application note

In this application note, a single supply ADC for positive and negative input voltages is

described. It's input voltage is proportional to the inverse of the time measured. We can see

in Figure 9 below that as the input voltage becomes closer to V1, the conversion time also

increases. For an input of V

input voltage range depends on the value of V1 and the maximum delay that the application

can tolerate.

, the conversion time is infinite (1/T

1

= 0 in Figure 9). So the

m

Figure 9. V

1. Vin = V1 - (R * C) * (V3 -V2) /T

versus time in AN2615 solution

IN

V

in

+V

Positive

input

V

1

ref

V0

-V

ref

m

Negative

input

Total input range (+V

1/T

m

ref

to -V

)

ref

The significant advantage of this ADC is its ability to measure positive and negative input

voltages operating from single supply, while other solutions require a dual supply. Also this

converter does not require any negative voltage reference. Again, as in the single slope

converter, the major sources of error are the correction factor for R*C product and the input

offset voltage.

As shown Figure 9, the ADC is capable of measuring the input voltage ranging +V

where the absolute value of V

the value of V

.

1

is mod (V

ref

) < V1 so the input voltage range depends on

ref

ref

to -V

ref,

13/37

Error analysis/constraints AN2615

7 Error analysis/constraints

This ADC can be used for measuring any slowly varying input (voltage/current), for example

battery monitoring, and for measuring positive and negative input voltages. But, besides the

need for accurate power supply and voltage references, the following factors also affect the

accuracy of the conversion.

7.1 Input offset voltage

As mentioned previously, the output offset voltage is subtracted from the input, but the input

offset voltage of the op-amp (Amp) still remains present and is directly added to V

measurement purposes, let us refer to the input offset voltage of the op-amp as K

7.2 Correction factor for the product of R*C

As the value of the R and C changes with time and temperature, the factor R * C also

changes. Let the correction factor be K

Then eq(5) becomes,

V

= V1 + K

in

The coefficients K

values. These factors can also be compensated by software calibration techniques (like

using look-up tables or storing some known values). In the present example the first method

is used to calculate these coefficients.

offset

offset

– K

gain

and K

* (R * C) *(V3 -V2)/Tm ------------------ (6)

can be calculated by measuring Tm for two known input

gain

gain

.

. For

1

offset

.

7.3 Value of charging resistance R

If the charging resistance ‘R’ is too high then the current ‘I’ is comparable to the input bias

current of the op-amp, which can affect the output. Also if it is too low then the current

flowing through it is significant so the capacitor is charged very fast. This affects the

measurement accuracy of the ADC.

7.4 Charging capacitor C

Up to this point we have assumed that capacitor C discharges completely from the previous

conversion. However, this is not so in actual practice and a few millivolts worth of charge

(which adds to the offset voltage), may remain on the capacitor. This effect is called

capacitor dielectric absorption and varies depending on the capacitor's dielectric material

voltage to which it was charged during the last charge cycle and the amount of time the

capacitor has had to discharge. Also due to this effect, the output of the capacitor may not

be linear over the whole conversion range. So it is very important to choose the right

capacitor for your requirements. While Teflon capacitors exhibit the lowest dielectric

absorption, polystyrene and polyethylene are also excellent. Ceramic, glass and mica are

fair, while tantalum and electrolytic types are poor choices for A/D applications.

Also, as integrating ADC’s are dependent on the integration of the current flowing through

capacitor C, they do the averaging. So, the larger the value of the capacitor, the longer the

14/37

AN2615 Error analysis/constraints

conversion time and the better the accuracy. In conclusion, there is always a trade-off

between conversion time and accuracy.

7.5 16-bit timer

A 16-bit timer is used as the counter that measures the conversion time. Overflows are also

taken into account, so we can also use an 8-bit timer. The resolution of the ADC depends on

the operating frequency of the timer.

7.6 Effect of temperature

The value and characteristics of each component varies with temperature. The effect of

temperature can be broadly categorized as ‘offset drift’ and ‘gain drift’. So we need to

compensate the ADC for each significant change in temperature.

7.7 Comparator

The comparators are the cornerstone of the A/D conversion process. The ability of the

comparator to detect small voltage/current changes makes the comparator very important in

the A/D conversion process. Any degradation of the intended behaviour of the comparator,

which is most usually caused by unwanted noise, leads to the degradation of the ADC’s

ability to measure low voltages.

15/37

Voltage references AN2615

8 Voltage references

The following circuit is used to produce the different voltage references.

Figure 10. Voltage reference

V

DD

+5V

Gnd

R1

R2

C1

C2

V

ref

16/37

AN2615 Hardware setup

9 Hardware setup

Figure 11. Hardware setup

ST72

TD0

RS232 communication

Hyper terminal

RS232

interface

V

in

0134.85 mV

Multimeter

V

DD

External

ADC

Gnd

Comp1

M1

Comp2

M2

V

DD

PB0

PB1

PB2

PB3

Gnd

Application board

The external ADC is interfaced to the ST7 microcontroller The input capture pins PB0 and

PB2 are used for capturing the pulse from the comparators at two instants (when the output

is equal to V

and V3 respectively), while PB1 and PB3 are used for controlling the voltage

2

at the gate of the M1 and M2 switches (on/off the MOSFET). The results of the A/D

conversion are displayed on the Windows hyper terminal application through an RS232-SCI

interface. The general schematics of the board are given in Appendix B: Application board

schematics on page 31.

17/37

Algorithm AN2615

10 Algorithm

Figure 12. Algorithm flowchart

Start

Initialize I/O,timer and SCI

Calibrate the ADC

Count = 16

1 second delay

Start conversion

Conversion complete?

Ye s

No

Start new conversion

1 second delay

Convert the timer reading in to voltage and send the

result on the PC through SCI-RS232 interface

Decrement count

Count > = 0?

Ye s

Calculate the average and display on the

PC through SCI-RS 232 interface

No

18/37

AN2615 Result

11 Result

The result is given for a capacitor value of 100 µF. So the conversion time is long. The

conversion time can be reduced by choosing a capacitor with a lower value but accuracy is

also reduced. Other parameters are as follows:

R = 10 K, V

So:

R * C = (10 K) * (100 µF) = 1 s

= 1.5 V, V2 = 2V and V3 = 3 V

1

The input range is taken as +1V to -1V, where mod (V

The conversion time is in the range 1 to 3 s. The settling time (as shown in Figure 3: Timing

diagram on page 8) is fixed at 1s. The ADC is calibrated by reading two known input

voltages afterwhich K

voltage source.

11.1 Positive input

In Figure 13, an example of the readings measured by the converter, which are sent to the

hyper terminal, are shown. T

value in terms of voltage. The difference of the maximum and minimum value among the 16

values is also shown.

Figure 13. Results for positive input

offset

) (= 1 V) is less than V1.

ref

and K

avg

are calculated. The input voltage Vin is taken from a

gain

is the average of 16 conversions, and V

is the calculated

avg

19/37

Result AN2615

In Ta bl e 1 , the readings are shown for positive input voltages ranging from 0 to 1 V. V

voltage measured by the multimeter. V

measured

(equal to V

) is the average voltage

avg

is the

in

measured by the converter in a loop of 16. The last column shows the difference in the

maximum and minimum readings of the values measured by the converter in the loop. This

shows the variations recorded in the readings.

Table 1. Results for positive input voltages

Sl no

V

in

(taken from multimeter)

V

measured

(mV)

Difference (mV)

(V

measured

- Vin)

(mV)

1 8.93 8.93 0 0.45

2 18.94 18.98 0.04 0.25

3 28.82 28.87 0.05 0.21

4 38.72 38.78 0.06 0.39

5 49.07 49.13 0.06 0.46

6 58.93 59.02 0.09 0.38

7 68.82 68.92 0.1 0.08

8 79.12 79.25 0.13 0.39

9 88.98 89.07 0.09 0.33

10 98.85 98.98 0.13 0.12

Error in max and min

input measured in the

loop (mV)

11 108.75 108.9 0.15 0.37

12 119.05 119.19 0.14 0.43

13 128.95 129.13 0.18 0.29

14 138.57 138.76 0.19 0.24

15 158.75 158.96 0.25 0.25

16 178.97 179.18 0.21 0.4

17 198.68 198.91 0.23 0.1

18 218.83 219.1 0.27 0.37

19 239.08 239.35 0.27 0.34

20 258.55 258.83 0.28 0.14

21 278.8 279.11 0.31 0.19

22 299.02 299.34 0.32 0.31

23 318.68 319.09 0.41 0.37

24 338.93 339.29 0.36 0.35

25 358.38 358.78 0.4 0.39

26 378.62 378.98 0.36 0.36

27 398.85 399.25 0.4 0.27

28 438.84 439.23 0.39 0.15

29 478.64 478.93 0.29 0.35

20/37

AN2615 Result

Table 1. Results for positive input voltages (continued)

Error in max and min

input measured in the

loop (mV)

Sl no

(mV)

V

in

(taken from multimeter)

V

measured

(mV)

Difference (mV)

(V

measured

- Vin)

30 498.75 499.23 0.48 0.09

31 519 519.41 0.41 0.32

32 538.69 539.1 0.41 0.28

33 558.91 559.3 0.39 0.11

34 578.63 579.03 0.4 0.3

35 598.65 599.01 0.36 0.28

36 638.6 638.99 0.39 0.26

37 678.93 679.3 0.37 0.14

38 718.6 718.93 0.33 0.14

39 758.61 758.93 0.32 0.23

40 798.53 798.83 0.3 0.17

41 838.7 838.94 0.24 0.19

42 858.49 858.68 0.19 0.2

43 878.55 878.72 0.17 0.13

44 898.76 898.92 0.16 0.19

45 918.53 918.61 0.08 0.13

46 938.46 938.55 0.09 0.15

47 958.68 958.72 0.04 0.1

48 978.4 978.38 -0.02 0.14

49 998.63 998.56 -0.07 0.14

50 1018.8 1018.68 -0.12 0.18

21/37

Result AN2615

Figure 14 shows the relationship between the voltage measured by the ADC V

(average of the 16 readings measured by the converter) and the input voltage V

Figure 14. Measured vs input for positive voltages

measured

.

in

Figure 15 shows the relationship between the error voltage (as given in Ta bl e 1 in the

column ‘difference (V

measured

- Vin’)) and the input voltage Vin.

Figure 15. Error vs input for positive input voltages

Note: It may be seen from the readings in Tab le 1 and Figure 15, that for the positive input

between 0 to 1 V the maximum error is around 500 µV for an average of 16 conversions.

Thus the difference between the maximum and minimum values in a loop of 16 is around

500 µV. This shows that averaging has increased accuracy. The accuracy without averaging

is approx 1mV.

The variations of the 16 values may be due to changes in the input voltage itself, as the time

taken for 16 readings is very long (around 16 s).

22/37

AN2615 Result

11.2 Negative input

Similar to the positive input voltages, the readings for negative input voltage are taken in a

loop of 16 as shown in Figure 16.

Figure 16. Results for negative input

23/37

Result AN2615

Ta bl e 2 shows the readings for negative input voltages ranging from 0 to -1 V with the same

parameter notations as Table 1: Results for positive input voltages on page 20.

Table 2. Results for negative input voltages

Sl

no

(taken from multimeter)

Vin (mV)

V

measured

(mV)

Difference (mV)

(V

measured

- Vin)

Error in max and min input

measured in the loop (mV)

1 -9.23 -9.17 0.06 0.43

2 -18.92 -18.84 0.08 0.14

3 -28.96 -29.04 -0.08 0.27

4 -38.76 -38.89 -0.13 0.38

5 -49.03 -49.14 -0.11 0.37

6 -58.88 -59 -0.12 0.24

7 -68.74 -68.9 -0.16 0.8

8 -79.03 -79.2 -0.17 0.22

9 -88.88 -89.06 -0.18 0.34

10 -98.76 -98.96 -0.2 0.4

11 -128.87 -129.13 -0.26 0.32

12 -148.76 -149.07 -0.31 0.32

13 -178.9 -179.21 -0.31 0.39

14 -198.6 -198.94 -0.34 0.11

15 -218.73 -219.12 -0.39 0.43

16 -248.59 -249.04 -0.45 0.2

17 -268.81 -269.32 -0.51 0.46

18 -298.91 -299.51 -0.6 0.15

19 -318.61 -319.25 -0.64 0.38

20 -348.67 -349.37 -0.7 0.37

21 -378.42 -379.23 -0.81 0.23

22 -398.71 -399.57 -0.86 0.48

23 -418.45 -419.33 -0.88 0.25

24 -448.52 -449.5 -0.98 0.47

25 -478.36 -479.41 -1.05 0.26

26 -498.56 -499.69 -1.13 0.4

27 -538.52 -539.73 -1.21 0.38

28 -578.4 -579.8 -1.4 0.47

29 -618.63 -620.1 -1.47 0.19

30 -658.52 -660.17 -1.65 0.53

31 -698.51 -700.28 -1.77 0.26

32 -738.65 -740.44 -1.79 0.16

24/37

AN2615 Result

Table 2. Results for negative input voltages (continued)

Sl

no

(taken from multimeter)

33 -778.54 -780.59 -2.05 0.37

34 -818.25 -820.42 -2.17 0.43

35 -858.27 -860.61 -2.34 0.56

36 -898.57 -901.07 -2.5 0.2

37 -938.31 -940.94 -2.63 0.67

38 -978.21 -981.03 -2.82 0.43

Vin (mV)

V

measured

(mV)

Figure 17 shows the relationship between measured voltages V

readings measured by the converter) and input voltage V

Difference (mV)

(V

measured

- Vin)

(as measured by the multimeter)

in

Error in max and min input

measured in the loop (mV)

measured

(average of the 16

for negative voltages.

Figure 17. Measured vs input for negative voltages

Figure 18. Error vs input for negative input voltages

Figure 18, shows that for negative input voltages varying from 0 to -1 V, the maximum error

is around -2.89 mV for -1 V input. An error of 0.5 mV occurs for an input value of -269 mV

25/37

Result AN2615

and it increases gradually afterwards. The maximum difference between the maximum and

minimum value in a loop is around 600 µV. So, the accuracy of the average value measured

is around 3 mV. Without averaging, accuracy is around 3.6 mV.

11.3 Effect of the capacitor value

As discussed in Section 7: Error analysis/constraints on page 14, reducing the R*C time

constant by reducing the value of R or C, reduces the accuracy. Readings were taken with a

10 µF capacitor and accuracy of the ADC was found to be reduced. Figure 19 gives an

example of readings with a 10 µF capacitor.

Figure 19. Results for positive input with a 10 µF capacitor

Figure 19 shows that variation in the readings taken in a loop of 16 is around 5 - 6 mV which

is approximately 10 times higher than the readings for the 100 µF. This indicates that there is

always a trade-off between conversion time and the desired accuracy.

26/37

AN2615 Conclusion

12 Conclusion

This application note presents a technique for implementing a positive supply ADC, capable

of measuring slowly-varying positive and negative input voltages with high precision.

Accuracy of the converter depends on the different parameters involved. Greater accuracy

can be achieved with careful board design, more precise components and by taking into

consideration all the factors discussed in the document.

27/37

References and bibliography AN2615

13 References and bibliography

The following articles and reports provide useful information:

1. AN1636, Understanding and minimising ADC conversion errors

2. Comparators and bistable circuits, ECE60L lecture notes, winter 2002

3. Selecting the right buffer operational amplifier for an A/D converter, application report

SLOA050, August 2000, Texas instruments

4. MOSFET device physics and operation by T Ytterdal, Y Cheng and TA Fjeldly,

John Wiley and sons, ISBN: 0-471-49869-6

5. Comparators and offset cancellation techniques by Jieh-Tsorng Wu, 2003, National

Chiao-Tung University Department of Electronics Engineering

6. Reducing noise in data acquisition systems by Fred R Schraff, PE IOtech Inc., adapted

from an article that appeared in the April 1996 edition of SENSORS magazine,

Helmers Publishing

7. How do ADCs work? by Martin Rowe, senior technical editor, 7/1/2002, Test and

Measurement World

© 2003,

28/37

AN2615 Input stage conditions

Appendix A Input stage conditions

The ADC described here can be used for measuring both voltage and current with slight

changes in set-up in each case.

A.1 Case 1: Voltage measurement

There are two ways in which the input voltage appears at the ADC input. The first way is that

input comes directly from a voltage source as shown in Figure 20.

Figure 20. Voltage measurement

O/p

C

V1

R

I

R1

V

IN

Gnd

In Figure 20 above, there are no problems. However, if the input comes from a potential

divider circuit as shown in Figure 21, the effective input voltage V

across R2 due to the current I and current I

.

in

is the result of the drop

in

Figure 21. Potential divider

I

V

IN

R2

R1

I

in

In this case an input buffer has to be used to overcome the problem (see Figure 22: Use of

input buffer for voltage measurement on page 30).

29/37

Input stage conditions AN2615

Figure 22. Use of input buffer for voltage measurement

O/p

C

V1

V

R

I

V

IN

IN

A.2 Case 2: Current measurement

Figure 23 shows the current measurement circuit.

Figure 23. Current measurement

O/p

C

V1

R

I

V

in

IN

R

sense

sense

I

V

= (Iin + I) * R

in

I = (V

- Vin)/R = V1/(R * (1 + R

1

= Iin * (1 + I/Iin) * R

sense

sense

/R)) ------------ (2)

sense

The following points should be kept in mind while using R

1. R

2. R

should be chosen to correspond with the range of the current to be measured.

sense

affects the effective value of current I. To minimize its effect, it should be

sense

negligible compared to R. Otherwise ADC has to be compensated.

------------ (1)

:

30/37

AN2615 Application board schematics

Appendix B Application board schematics

Figure 24. Application board schematics

PB2

1

VDD

VDD

VDD

84

VDD

2

3

V3

C11

C10

100nF

R7

2k2

C8

100nF

R4

3k3

C6

100nF

R2

3k5

100nF

R5

3k3

V2

C9

100nF

R6

2k2

V1

C7

100nF

R3

1k5

VDD

D3

R13

1E

V1

Q2

MOSFET N

23

V2

U4

LM358

PB0

1

8

2

3

C14

1

R10

10K

PB1

U3

LM358

100uF

23

7

4

6

5

J7

V3

Q1

MOSFET N

1

VIN

PB3

SCI_RDI

J6

SCI_TDO

J8

VDD

7

9

13

14

SCI

2

1

2

1

T2OUT

R2OUT

R1OUT

T1OUT

R2IN

T2IN10T1IN

R1IN

U5

8

11

12

SCI1_RDISCI1_TDO

C18

1 2

J5

RTS

SCI_RTS

162738495

C13

16

VCC

C1+1V+

C1-3C2+4C2-5V-

2

C19

1uF 16V

100nF

15

GND

6

1uF 16V

DB9

GND

ST3232

C21

1uF 16V

VDD

C20

1uF 16V

VDD

2

1

J2

U1

D1

DC POWER

100nf

C5

C4

10uf/25v

R1

330E

D2

220uf/25v

220uf/25v

100nf

JACK

LED-Green-3mm

GND

VCC

1

2

J3

5V MAX

VDD

C3

3

Vout

LM7805

GND

2

Vin

1

C2

C1

IN400 7

J1

9~14V DC

100nF

VDD C12

31

30

26

29

32

PA128PA227PA3

PA0

VSS

VDD

ICCSEL

RESET1OSC12OSC2

SS/PB74SCK/PB65MISO/PB56MOSI/PB47NC8NC

U2

3

RESET

1 2

J4

Y1

16MHz

R9

1k

S1

C15

R8

4k7

100pf

24

NC25NC

ST72F264

9

C17

22pf

C16

22pf

PA423PA522PA621PA7

PB3

PB211PB112PB013PC514PC415PC3

10

PB3

PB2

PB1

SCI_TDO

20

19

17

PC0

PC118PC2

16

PB0

PB2

PB0

R11

10k

R12

10k

VDD

31/37

Bill of materials AN2615

Appendix C Bill of materials

Ta bl e 3 gives the bill of material for each block of the schematics shown in Figure 24.

Table 3. Bill of materials

Block Designator Part type/number Description

R13 1E Resistor

R10 10 kΩ Resistor

U3 LM358 Dual op-amp

ADC

U4 LM358 Dual op-amp

C14 100 µF Capacitor

Q2 STB100NF03L N - MOSFET

Q1 STB100NF03L N - MOSFET

D3 IN4007 Diode

C8 100 nF Capacitor

C9 100 nF Capacitor

Voltage references

SCI

C10 100 nF Capacitor

C11 100 nF Capacitor

C7 100 nF Capacitor

C6 100 nF Capacitor

R6 2.2 kΩ Resistor

R7 2.2 kΩ Resistor

R5 3.3 kΩ Resistor

R4 3.3 kΩ Resistor

R2 3.5 kΩ Resistor

R3 1.5 kΩ Resistor

U5 ST3232 Line driver

C18 1µF 16 V Capacitor

C19 1µF 16 V Capacitor

C20 1µF 16 V Capacitor

C21 1µF 16 V Capacitor

J5 jumper CON-2

J7 jumper CON-2

J6 jumper CON-2

C13 100 nF Capacitor

J8 DB9 9 pin connector

32/37

AN2615 Bill of materials

Table 3. Bill of materials (continued)

Block Designator Part type/number Description

R12 10 kΩ Resistor

R11 10 kΩ Resistor

Micro setup

Crystal

Reset

U2 ST72F264 Micro-controller

C12 100 nF Capacitor

Y1 16 MHz Crystal oscillator

C17 22 pF Capacitor

C16 22 pF Capacitor

R9 1 kΩ Resistor

R8 4.7 kΩ Resistor

C15 100 pF Capacitor

S1 Push button Micro switch

J4 CON-2 jumper

C4 10 µF/25 V Capacitor

C5 100 nF Capacitor

C1 100 nF Capacitor

DC power

C3 220 µF/25 V Capacitor

C2 220 µF/25 V Capacitor

R1 330E Resistor

J1 DC - Jack DC - Jack

D2 LED 3mm LED-green

U1 LM7805 Voltage regulator

D1 IN4007 Diode

J2 jumper CON-2

J3 Power connector 2 pin connector

33/37

Software flow AN2615

Appendix D Software flow

The f

chosen is 8 MHz. K

CPU

offset

and K

are calculated by taking a reading for two known

gain

inputs. The flow of software, used to implement the algorithm, is as follows:

1. The I/O pins, timer, SCI (Tx @ 9600 baud rate) and some global variables used in the

ADC are initialized.

2. A string is transmitted to check that the SCI is working well.

3. Settling time is fixed at 1 s for f

= 8 MHz.

CPU

4. Some initial readings are taken and ignored while the ADC stabilizes.

5. The control enters an infinite loop.

6. Inside the infinite loop, there is a loop in which the ADC captures the timer values 17

times. However, the first reading is ignored.

7. The remaining 16 captured values are converted into corresponding voltages (up to 10

µV precision) and then transmitted to a PC for display by the hyper terminal after being

converted into a buffer of ASCII characters.

8. The average of 16 timer readings is taken and sent to the hyper terminal as a time

value and a corresponding voltage in the same manner as described above.

9. The difference between the maximum and minimum captured value is also sent to the

hyper terminal in the same way as in step 8.

10. The software enters an ‘IF’ loop ‘if (mCount == 18)’, where the ADC is reset in order to

measure the next input value. Again, a few readings are ignored while the ADC

stabilizes. The counter and other global variables are also initialized.

11. The software re-enters the loop of 17 conversions and executes step 6 to step 9. This

process continues until the system is reset manually.

34/37

AN2615 Software flow

D.1 Code size

The software given is for guidance only. Here the display is done for up to 10 µV precision.

The user can modify and use their own code for display of the data. Tabl e 4 summarizes the

code size. Depending on the compiler and memory placement, these values can change.

The RAM requirements are not provided and the user has the choice to place the variables

as global or local.

.

Table 4. Code size

No. Function name Code size ( bytes)

ADCSys

1 Acquisition 128

2 Start_Capturing 7

3 Reset_ADC 5

4 ADC_InitializeVar 29

5 IsCaptured 13

6 Delay_Second 44

7 IO_Init 37

8 TimerA_Init 47

9 Timer_Interrupt_Routine 170

Main

10 main 1493

11 TIMERA_IT_Routine 38

12 Conversion_TimerReadingToREALInput 116

13 SCI_Init 25

14 SCI_SendBuffer 30

15 SCI_IsTransmissionCompleted 8

16 Dummy_Capturing 26

Note: Some floating point operations are used in this software for display purposes only. It is left to

the user to use the floating point operation or not as per his application requirement.

35/37

Revision history AN2615

14 Revision history

Table 5. Document revision history

Date Revision Changes

23-Aug-2007 1 Initial release

36/37

AN2615

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

37/37

Loading...

Loading...