Page 1

AN2606

Application note

STM32™ microcontroller system memory boot mode

Introduction

The bootloader is stored in the internal boot ROM memory (system memory) of STM32

devices. It is programmed by ST during production. Its main task is to download the

application program to the internal Flash memory through one of the available serial

peripherals (USART, CAN, USB, etc.). A communication protocol is defined for each serial

interface, with a compatible command set and sequences.

This document applies to the products listed in Ta b le 1 . They will be referred to STM32

throughout the document.

Table 1. Application products

Type Part number or product series

STM32F051x6, STM32F051x8

STM32 F1 Mainstream

Microcontroller

STM32 F2 Hi-performance

STM32F40xx and STM32F41xx

STM32L151xx, STM32F152xx, and

STM32F162xx

The main features of the bootloader are the following:

● It uses an embedded serial interface to download the code with a predefined

communication protocol

● It transfers and updates the Flash memory code, the data, and the vector table sections

This application note presents the general concept of the bootloader. It describes the

supported peripherals and hardware requirements to be considered when using the

bootloader of any STM32 device currently in production. However the specifications of the

low-level communication protocol for each supported serial peripheral are documented in

separate documents. For specifications of the USART protocol used in the bootloader

please refer to AN3155. For the specification of CAN protocol used in the bootloader please

refer to AN3154. For the specification of DFU (USB Device) protocol used in the bootloader

please refer to AN3156.

July 2012 Doc ID 13801 Rev 14 1/88

www.st.com

Page 2

Contents AN2606

Contents

1 Related documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 General bootloader description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Bootloader activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Exiting System memory boot mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Bootloader identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 STM32F100xx, STM32F101xx, STM32F102xx,

STM32F103xx, medium-density and

high-density value line bootloader . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Bootloader configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Bootloader hardware requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3 Bootloader selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.4 Bootloader version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5 STM32F105xx and STM32F107xx device bootloader . . . . . . . . . . . . . . 16

5.1 Bootloader configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2 Bootloader hardware requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.3 Bootloader selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.4 Bootloader version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.4.1 How to identify STM32F105xx/107xx bootloader versions . . . . . . . . . . 21

5.4.2 Bootloader unavailability on STM32F105xx/STM32F107xx devices

with a date code below 937 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.4.3 USART bootloader Get-Version command returns 0x20

instead of 0x22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.4.4 PA9 excessive power consumption when USB cable is plugged

in bootloader V2.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6 STM32F101xx and STM32F103xx XL-density device bootloader . . . . 24

6.1 Dual bank boot feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.2 Bootloader configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.3 Bootloader hardware requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2/88 Doc ID 13801 Rev 14

Page 3

AN2606 Contents

6.4 Bootloader selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.5 Bootloader version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7 STM32L15xx Medium-density Ultralow power device bootloader . . . 31

7.1 Bootloader configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.2 Bootloader hardware requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.3 Bootloader selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.4 Important considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.5 Bootloader version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8 STM32L15xx and STM32L16xx High-density ultralow power device

bootloader 36

8.1 Dual bank boot feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.2 Bootloader configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.3 Bootloader hardware requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.4 Bootloader selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.5 Important considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8.6 Bootloader version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9 STM32F205/215xx, and STM32F207/217xx bootloader . . . . . . . . . . . . 46

9.1 Bootloader V2.x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9.1.1 Bootloader configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9.1.2 Bootloader hardware requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.1.3 Bootloader selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9.1.4 Important considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

9.1.5 Bootloader V2.x versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.2 Bootloader V3.x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.2.1 Bootloader configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.2.2 Bootloader hardware requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

9.2.3 Bootloader selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

9.2.4 Important considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.2.5 Bootloader version V3.x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

10 STM32F405/415xx, and STM32F407/417xx bootloader . . . . . . . . . . . . 62

10.1 Bootloader configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10.2 Bootloader hardware requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Doc ID 13801 Rev 14 3/88

Page 4

Contents AN2606

10.3 Bootloader selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

10.4 Important considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

10.5 Bootloader version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

11 STM32F051x6 and STM32F051x8 device bootloader . . . . . . . . . . . . . . 71

11.1 Bootloader configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

11.2 Bootloader hardware requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

11.3 Bootloader selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

11.4 Important considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

11.5 Bootloader version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

12 Device-dependent bootloader parameters . . . . . . . . . . . . . . . . . . . . . . 75

13 Bootloader timing characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

13.1 USART bootloader timing characteristics . . . . . . . . . . . . . . . . . . . . . . . . . 77

13.2 USB bootloader timing characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . 82

14 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

4/88 Doc ID 13801 Rev 14

Page 5

AN2606 List of tables

List of tables

Table 1. Application products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

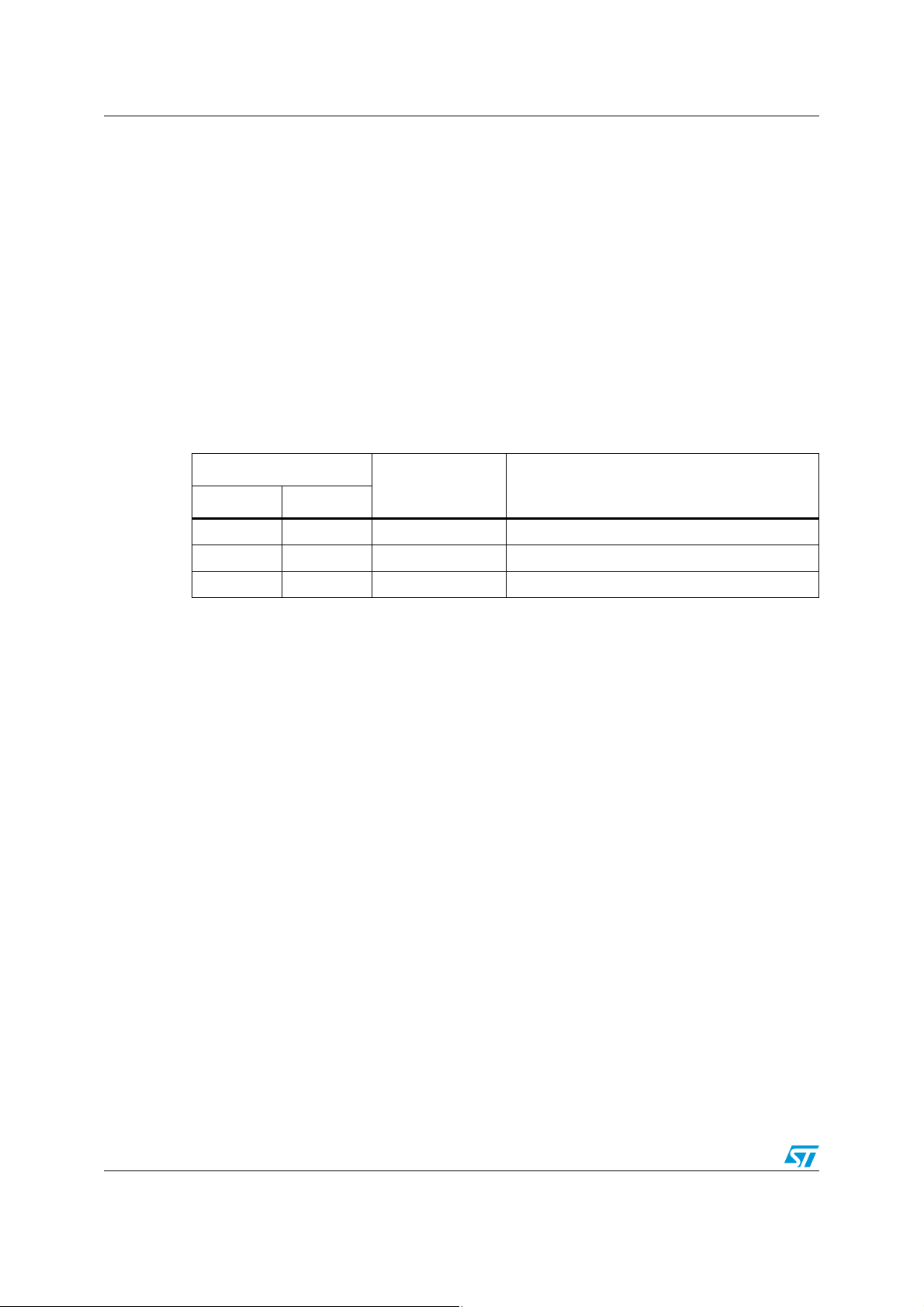

Table 2. Boot pin configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 3. Embedded bootloaders. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 4. STM32F10xxx configuration in System memory boot mode . . . . . . . . . . . . . . . . . . . . . . . 13

Table 5. STM32F10xxx bootloader versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 6. STM32F105xx/107xx configuration in System memory boot mode . . . . . . . . . . . . . . . . . . 16

Table 7. STM32F105xx and STM32F107xx bootloader versions. . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 8. Boot pin and BFB2 bit configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 9. STM32F10xxx XL-density configuration in System memory boot mode . . . . . . . . . . . . . . 26

Table 10. XL-density bootloader versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 11. STM32L15xxx configuration in System memory boot mode. . . . . . . . . . . . . . . . . . . . . . . . 31

Table 12. STM32L15xxx bootloader versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 13. Boot pin and BFB2 bit configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 14. STM32L1xx High-density configuration in System memory boot mode . . . . . . . . . . . . . . . 39

Table 15. STM32L1xx High-density bootloader versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 16. STM32F2xx configuration in System memory boot mode . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 17. STM32F2xx Voltage Range configuration using bootloader V2.x . . . . . . . . . . . . . . . . . . . 51

Table 18. STM32F2xx bootloader V2.x versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 19. STM32F2xx configuration in System memory boot mode . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 20. STM32F2xx Voltage Range configuration using bootloader V3.x . . . . . . . . . . . . . . . . . . . 60

Table 21. STM32F2xx bootloader V3.x versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Table 22. STM32F4xx configuration in System memory boot mode . . . . . . . . . . . . . . . . . . . . . . . . . 62

Table 23. STM32F4xx Voltage Range configuration using bootloader . . . . . . . . . . . . . . . . . . . . . . . 69

Table 24. STM32F4xx bootloader version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Table 25. STM32F51xx configuration in System memory boot mode . . . . . . . . . . . . . . . . . . . . . . . . 71

Table 26. STM32F051xx bootloader versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Table 27. Bootloader device-dependant parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Table 28. USART bootloader timings for low/medium/high-density and

value line devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Table 29. USART bootloader timings for XL-density line devices . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Table 30. USART bootloader timings for connectivity line devices (PA9 pin low) . . . . . . . . . . . . . . . 79

Table 31. USART bootloader timings for connectivity line devices (PA9 high). . . . . . . . . . . . . . . . . . 80

Table 32. USART bootloader timings for STM32L15xx medium-density

ultralow power devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Table 33. USART bootloader timings for STM32L15xx high-density

ultralow power devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Table 34. USART bootloader timings for STM32F205/215xx and

STM32F207/217xx devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Table 35. USART bootloader timings for STM32F405/415xx and

STM32F407/417xx devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Table 36. USART bootloader timings for STM32F051x6 and STM32F051x8 devices. . . . . . . . . . . . 82

Table 37. USB minimum timings for connectivity line devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Table 38. USB minimum timings for STM32L15xx high-density

ultralow power devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Table 39. USB minimum timings for STM32F205/215xx,

and STM32F207/217xx devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Table 40. USB minimum timings for STM32F405/415xx,

and STM32F407/417xx devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Doc ID 13801 Rev 14 5/88

Page 6

List of tables AN2606

Table 41. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6/88 Doc ID 13801 Rev 14

Page 7

AN2606 List of figures

List of figures

Figure 1. Bootloader for STM32F10xxx with USART1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 2. Bootloader selection for STM32F105xx and STM32F107xx devices . . . . . . . . . . . . . . . . . 20

Figure 3. Bootloader selection for STM32F10xxx XL-density devices. . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 4. Bootloader selection for STM32L15xxx devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 5. Bootloader selection for STM32L1xx High-density devices . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 6. Bootloader V2.x selection for STM32F2xx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 7. Bootloader V3.x selection for STM32F2xx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 8. Bootloader selection for STM32F4xx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 9. Bootloader selection for STM32F051xx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Figure 10. USART bootloader timing waveforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Figure 11. USB bootloader timing waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Doc ID 13801 Rev 14 7/88

Page 8

Related documents AN2606

1 Related documents

All the documents mentioned below are available from http://www.st.com:

● Datasheets

– Low, medium and high-density STM32F101xx and STM32F103xx datasheets

– Low, medium and high-density STM32F100xx and STM32F102xx datasheets

– STM32F105xx/107xx connectivity line datasheet

– XL-density STM32F101xx and STM32F103xx datasheets

– STM32L151xx and STM32F152xx datasheet

– STM32F162xx datasheet

– STM32F205xx STM32F207xx and STM32F215xx STM32F217xx datasheets

– STM32F405xx STM32F407xx and STM32F415xx STM32F417xx datasheets

– STM32F051x6 and STM32F051x8 devices datasheets

● Reference manuals

– STM32F101xx, STM32F102xx, STM32F103xx and STM32F105xx/107xx

reference manual (RM0008)

– Low, medium and high-density STM32F100xx value line reference manual

(RM0041)

– STM32L151xx, STM32L152xx, and STM32L162xx advanced ARM-based 32-bit

MCUs reference manual (RM0038)

– STM32F205xx, STM32F207xx, STM32F215xx and STM32F217xx advanced

ARM-based 32-bit MCUs reference manual (RM00033)

– STM32F405xx, STM32F407xx, STM32F415xx and STM32F417xx advanced

ARM-based 32-bit MCUs reference manual (RM00090)

– STM32F051xx advanced ARM-based 32-bit

● Flash programming manuals

– STM32F101xx, STM32F102xx, STM32F103xx and STM32F105xx/107xx Flash

programming manual (PM0042)

– Low, medium and high-density STM32F100xx value line Flash programming

manual (PM0063)

– XL-density STM32F101xx and STM32F103xx Flash programming manual

(PM0068)

– STM32L151xx, STM32L152xx, and STM32L162xx Flash programming manual

(PM0062)

– STM32F205xx, STM32F207xx, STM32F215xx and STM32F217xx Flash

programming manual (PM0059)

– STM32F405xx, STM32F407xx, STM32F415xx and STM32F417xx Flash

programming manual (PM0081)

8/88 Doc ID 13801 Rev 14

Page 9

AN2606 Glossary

2 Glossary

Low-density devices are STM32F101xx, STM32F102xx and STM32F103xx

microcontrollers where the Flash memory density ranges between 16 and 32 Kbytes.

Medium-density devices are STM32F101xx, STM32F102xx and STM32F103xx

microcontrollers where the Flash memory density ranges between 64 and 128 Kbytes.

High-density devices are STM32F101xx and STM32F103xx microcontrollers where the

Flash memory density ranges between 256 and 512 Kbytes.

Connectivity line devices are STM32F105xx and STM32F107xx microcontrollers.

Low-density value line devices are STM32F100xx microcontrollers where the Flash

memory density ranges between 16 and 32 Kbytes.

Medium-density value line devices are STM32F100xx microcontrollers where the Flash

memory density ranges between 64 and 128 Kbytes.

High-density value line devices are STM32F100xx microcontrollers where the Flash

memory density ranges between 256 and 5128 Kbytes.

XL-density devices are STM32F101xx and STM32F103xx microcontrollers where the

Flash memory density ranges between 768 Kbytes and 1 Mbyte.

Medium-density ultralow power devices are STM32L151xx and STM32L152xx

microcontrollers where the program memory density ranges between 64 and 128 Kbytes.

High-density ultralow power devices are STM32L151xx, STM32L152xx and

STM32L162xx microcontrollers where the program memory density size is 384 Kbytes

STM32F2xxx devices are STM32F215xx, STM32F205xx, STM32F207xx and

SMT32F217xx microcontrollers with a Flash memory density ranging from 128 to

1024 Kbytes.

STM32F4xxx devices are STM32F415xx, STM32F405xx, STM32F407xx and

SMT32F417xx microcontrollers with a Flash memory density ranging from 512 to

1024 Kbytes.

STM32F051xx devices are STM32F051x6, STM32F051x8 microcontrollers where the

Flash memory density ranges between 32 and 64 Kbytes.

Doc ID 13801 Rev 14 9/88

Page 10

General bootloader description AN2606

3 General bootloader description

3.1 Bootloader activation

The bootloader is automatically activated by configuring the BOOT0 and BOOT1 pins in the

specific “System memory” configuration (see Ta b l e 2) and then by applying a reset.

Depending on the used pin configuration, the Flash memory, system memory or SRAM is

selected as the boot space, as shown in Ta bl e 2 below.

In some products, BOOT1 is not an I/O but a bit in the option byte area. This is the case for

the STM32F05x devices where BOOT1 is configured through nBoot1 bit in the option bytes.

● When nBoot1 bit is set to 1, it corresponds to BOOT1 reset to 0 in Tab le 2

● When nBoot1 bit is reset to 0, it corresponds to BOOT1 set to 1 n Tab l e 2.

Table 2. Boot pin configuration

Boot mode selection pins

Boot mode Aliasing

BOOT1 BOOT0

X 0 User Flash memory User Flash memory is selected as the boot space

0 1 System memory System memory is selected as the boot space

1 1 Embedded SRAM Embedded SRAM is selected as the boot space

Ta bl e 2 shows that the STM32 microcontrollers enter System memory boot mode if the

BOOT pins are configured as follows:

● BOOT0 = 1

● BOOT1 = 0

The values on the BOOT pins are latched on the fourth rising edge of SYSCLK after a reset.

3.2 Exiting System memory boot mode

System memory boot mode must be exited in order to start execution of the application

program. This can be done by applying a hardware reset. During reset, the BOOT pins/bits

(BOOT0 and BOOT1) must be set at the proper levels to select the desired boot mode (see

Ta bl e 2 ). Following the reset, the CPU starts code execution from the boot memory located

at the bottom of the memory address space starting from 0x0000 0000.

10/88 Doc ID 13801 Rev 14

Page 11

AN2606 General bootloader description

3.3 Bootloader identification

Depending on the STM32 device used, the bootloader may support one or more embedded

serial peripherals used to download the code to the internal Flash memory. The bootloader

identifier (ID) provides information about the supported serial peripherals.

For a given STM32 device, the bootloader is identified by means of the:

1. Bootloader (protocol) version: version of the serial peripheral (USART, CAN, USB,

etc.) communication protocol used in the bootloader. This version can be retrieved

using the bootloader Get Version command.

2. Bootloader identifier (ID): version of the STM32 device bootloader, coded on one byte

in the 0xXY format, where:

– X specifies the embedded serial peripheral(s) used by the device bootloader:

X = 1: only one USART is used

X = 2: two USARTs are used

X = 3: two USARTs, one CAN and DFU are used

X = 4: two USARTs and DFU are used

– Y specifies the device bootloader version

Let us take the example of a bootloader ID equal to 0x10. This means that it is the

first version of the device bootloader that uses only one USART.

The bootloader ID is programmed in the last two bytes of the device system

memory and can be read by using the bootloader “Read memory” command or by

direct access to the system memory via JTAG/SWD.

The table below provides identification information about the bootloader embedded in

STM32 devices.

Table 3. Embedded bootloaders

Device

Low-density USART1 NA NA USART (V2.2)

Medium-density USART1 NA NA USART (V2.2)

High-density USART1 NA NA USART (V2.2)

Connectivity line

Medium-density

value line

High-density

value line

XL-density

Medium-density

ultralow power

line

Supported serial

peripherals

USART1 / USART2

(remapped) / CAN2

(remapped) / DFU (USB

Device)

USART1 V1.0 0x1FFFF7D6 USART (V2.2)

USART1 V1.0 0x1FFFF7D6 USART (V2.2)

USART1/USART2

(remapped)

USART1/USART2 V2.0 0x1FF00FFE USART (V3.0)

Bootloader ID

ID Memory location

NA NA

V2.1 0x1FFFF7D6 USART (V3.0)

Bootloader

(protocol) version

USART (V2.2

CAN (V2.0)

DFU(V2.2)

(1)

)

Doc ID 13801 Rev 14 11/88

Page 12

General bootloader description AN2606

Table 3. Embedded bootloaders (continued)

Bootloader ID

ID Memory location

V4.5 0x1FF01FFE

Bootloader

(protocol) version

USART (V3.1)/

DFU (V2.2)

Device

High-density

ultralow power

line

Supported serial

peripherals

USART1/USART2/DFU

(USB Device FS)

USART1/USART3 V2.0 0x1FFF77DE USART (V3.0)

STM32F2xxx

devices

STM32F4xxx

devices

STM32F051xx

devices

1. For connectivity line devices, the USART bootloader returns V2.0 instead of V2.2 for the protocol version.

For more details please refer to the "STM32F105xx and STM32F107xx revision Z" errata sheet available

from http://www.st.com.

USART1/USART3/CAN2/DF

U (USB Device FS)

USART1/USART3/CAN2/DF

U (USB Device FS)

V3.3 0x1FFF77DE

V3.1 0x1FFF77DE

USART1/USART2 V2.1 0x1FFF7FA6 USART (V3.1)

USART (V3.1)/

CAN (V2.0)/

DFU (V2.2)

USART (V3.1)/

CAN (V2.0)/

DFU (V2.2)

12/88 Doc ID 13801 Rev 14

Page 13

AN2606 STM32F100xx, STM32F101xx, STM32F102xx, STM32F103xx, medium-density and high-

4 STM32F100xx, STM32F101xx, STM32F102xx,

STM32F103xx, medium-density and

high-density value line bootloader

Throughout this section STM32F10xxx will be used to refer to low-density, medium-density,

high-density STM32F101xx and STM32F103xx devices, to low- and medium-density

STM32F102xx devices, to low-, medium-, and high-density STM32F100x, and to medium

and high-density value line devices.

4.1 Bootloader configuration

The bootloader embedded in STM32F10xxx devices supports only one interface: the

USART1.

The following table shows the required STM32F10xxx hardware resources used by the

bootloader in System memory boot mode.

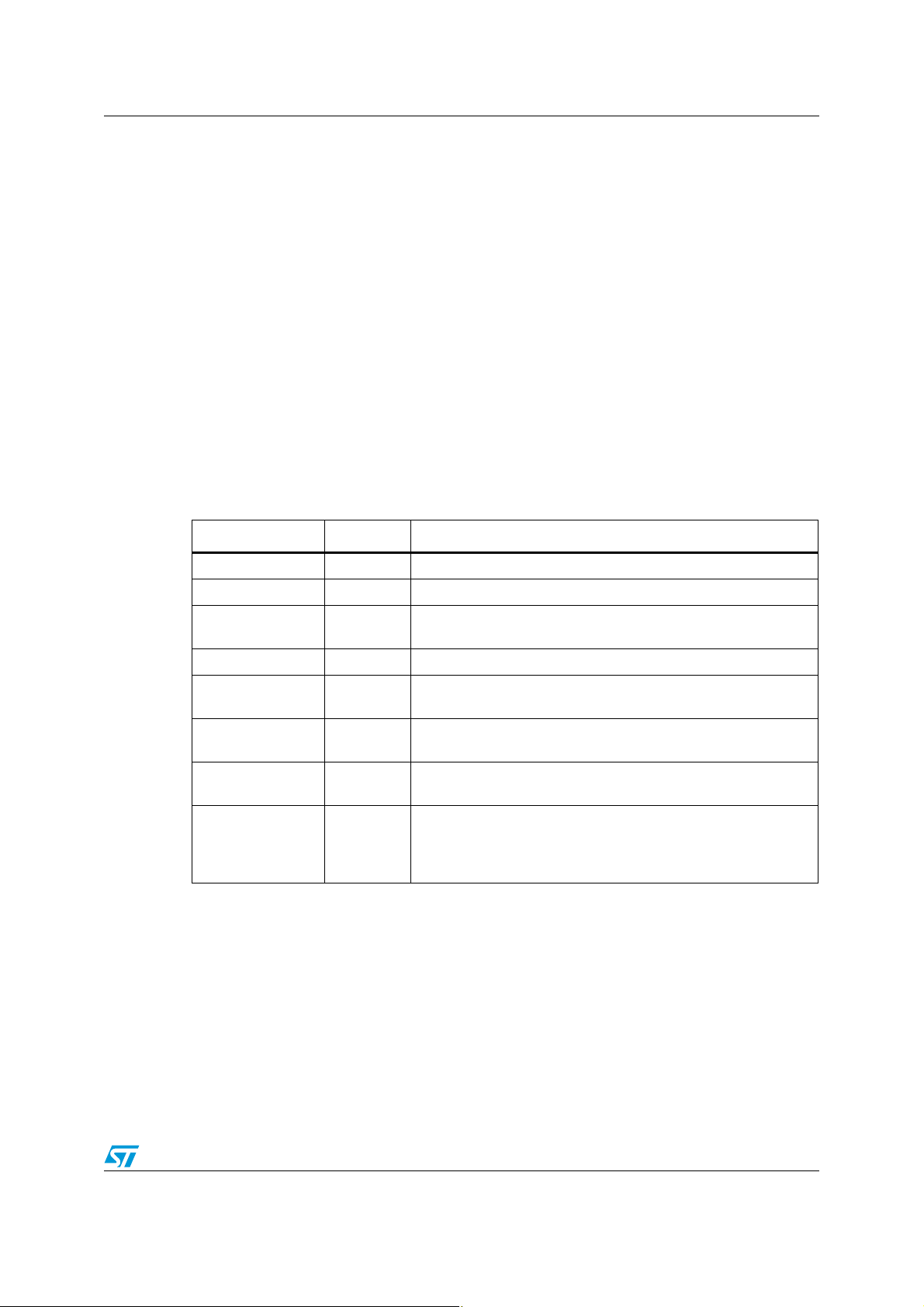

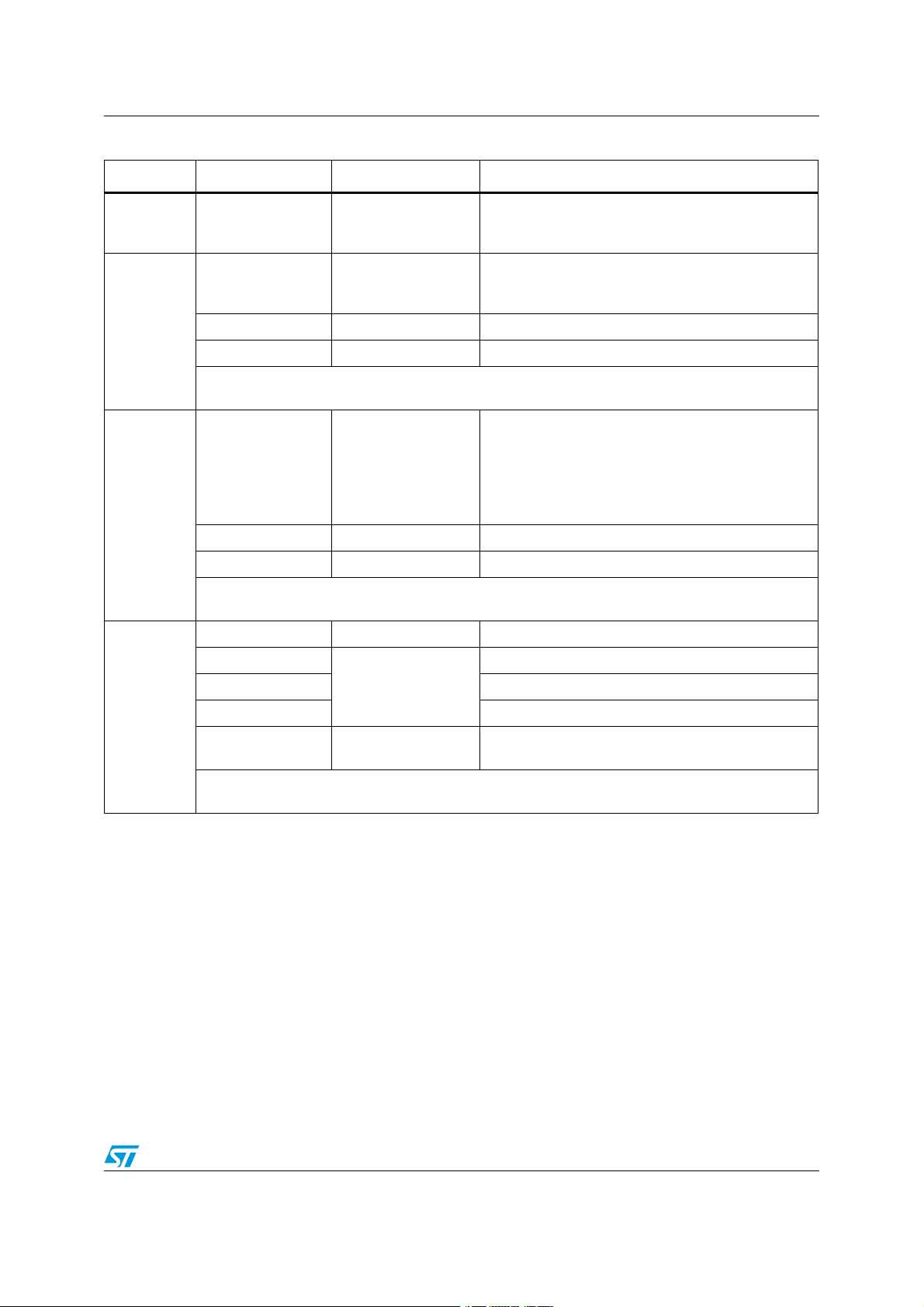

Table 4. STM32F10xxx configuration in System memory boot mode

Feature/Peripheral State Comment

Clock source HSI enabled The system clock is equal to 24 MHz using the PLL

USART1_RX pin Input PA10 pin: USART1 receives

USART1_TX pin

SysTick timer Enabled Used to automatically detect the serial baud rate from the host.

USART1 Enabled

RAM -

System memory -

IWDG -

Output

push-pull

PA9 pin: USART1 transmits

Once initialized the USART1 configuration is: 8-bits, even parity

and 1 Stop bit

512 bytes starting from address 0x2000 0000 are used by the

bootloader firmware

2 Kbytes starting from address 0x1FFF F000, contain the

bootloader firmware

The independent watchdog (IWDG) prescaler is configured to its

maximum value and is periodically refreshed to prevent

watchdog reset (in case the hardware IWDG option was

previously enabled by the user)

The system clock is derived from the embedded internal high-speed RC, no external quartz

is required for the bootloader code.

After downloading the application binary, if you choose to execute the Go command, the

peripheral registers used by the bootloader (shown in the above table) are not initialized to

their default reset values before jumping to the user application. They should be

reconfigured in the user application if they are used. So, if the IWDG is being used in the

application, the IWDG prescaler value has to be adapted to meet the requirements of the

application (since the prescaler was set to its maximum value by the bootloader).

Doc ID 13801 Rev 14 13/88

Page 14

STM32F100xx, STM32F101xx, STM32F102xx, STM32F103xx, medium-density and high-density

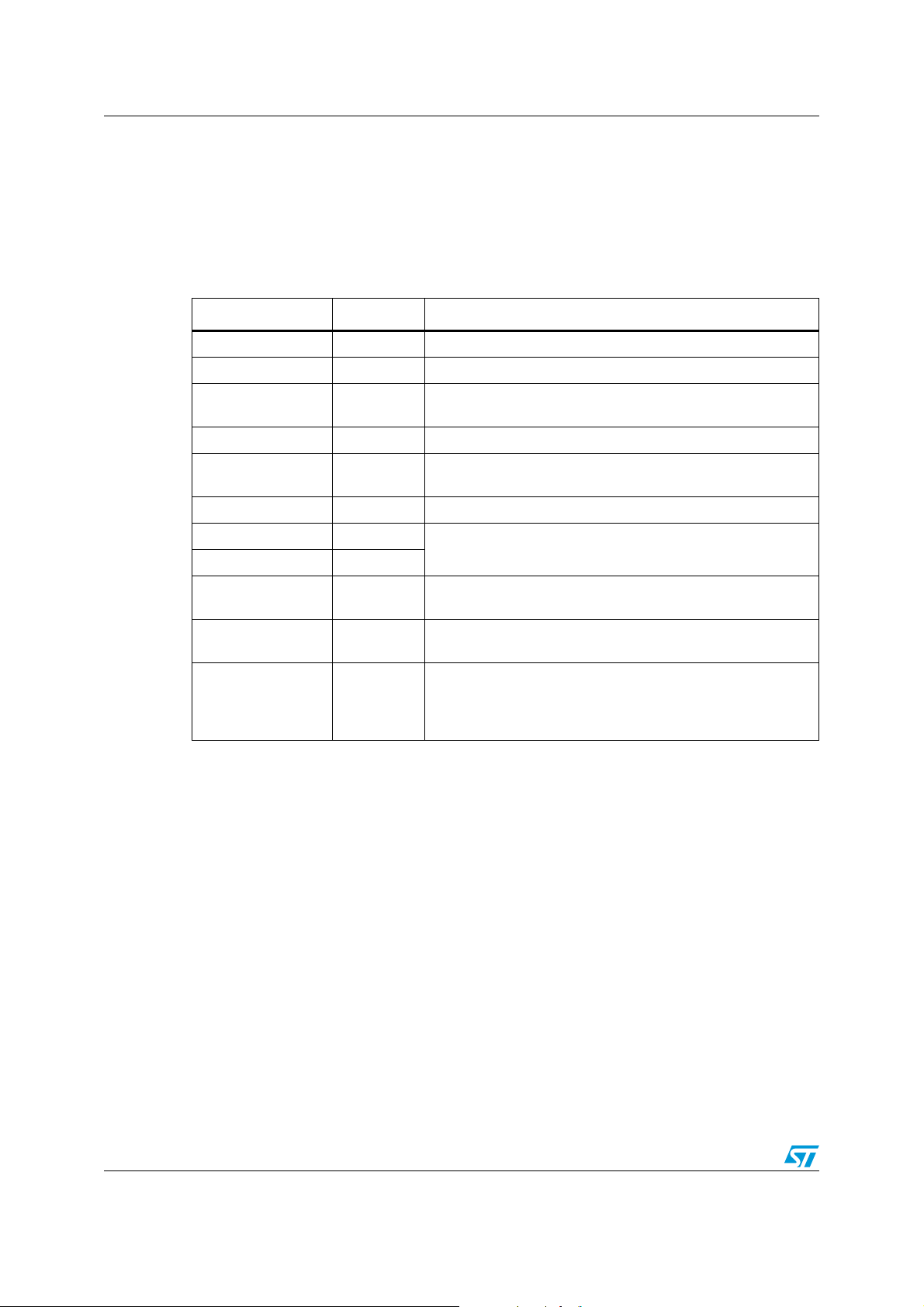

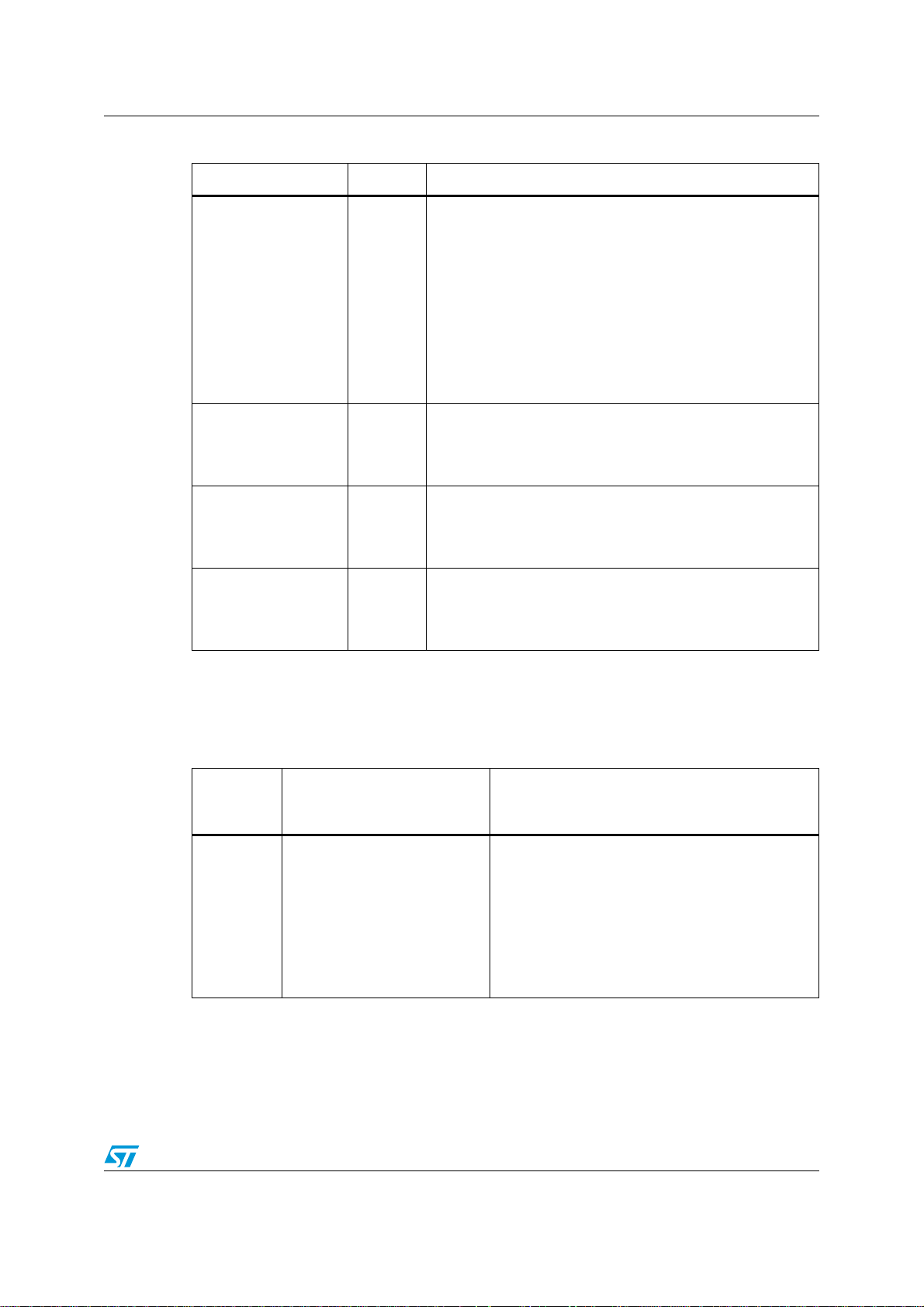

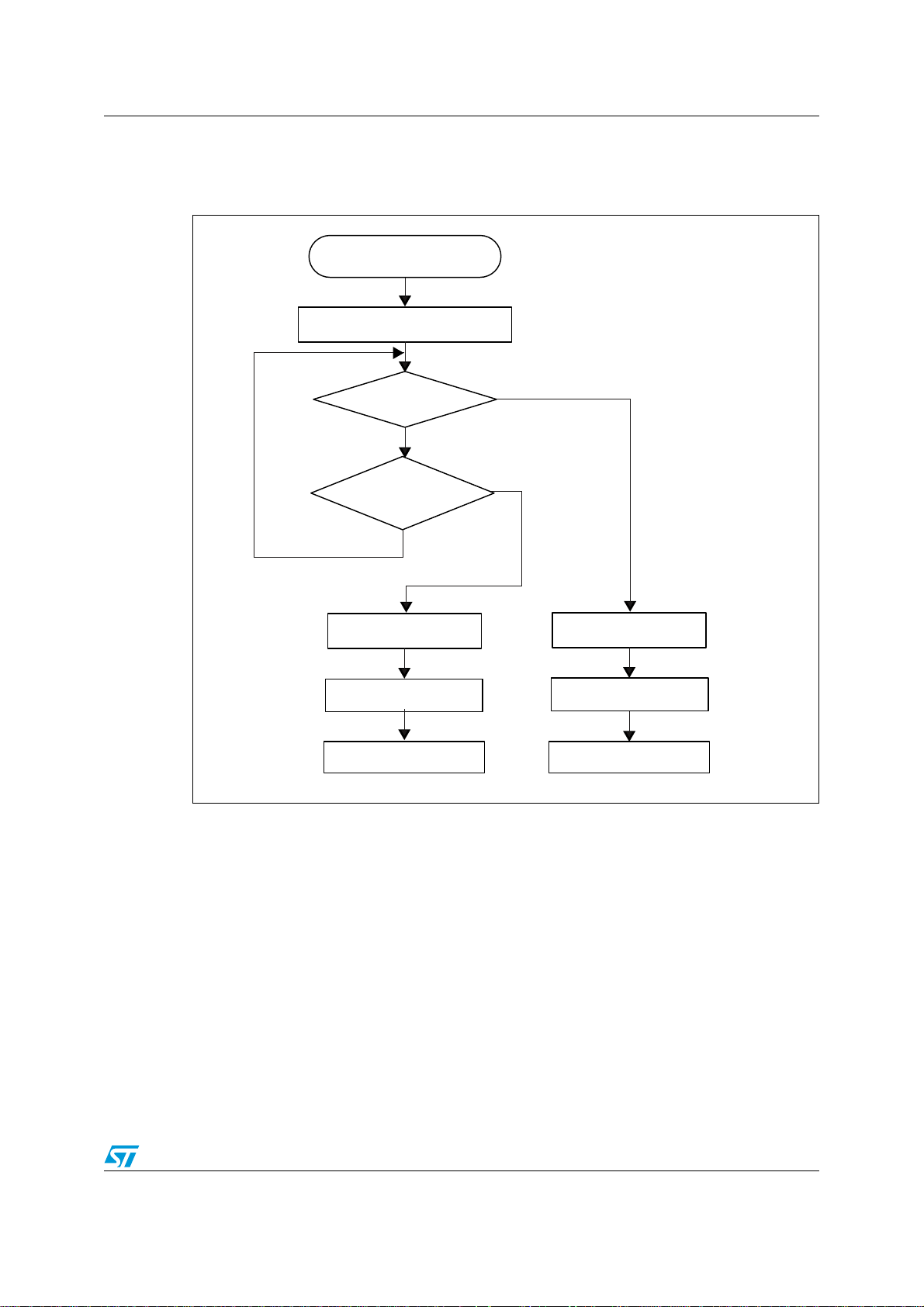

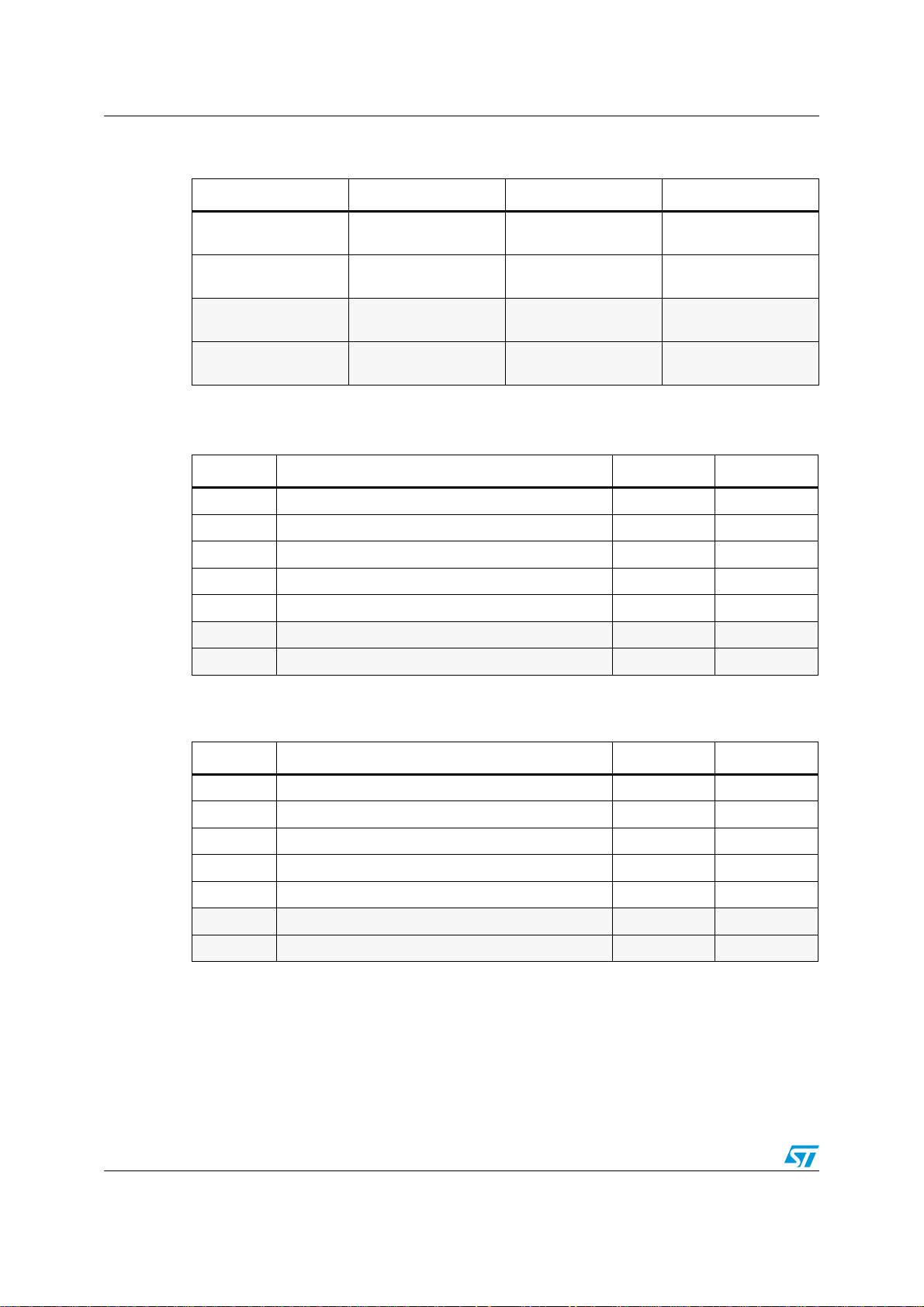

$ISABLEALLINTERRUPTSOURCES

3YSTEMRESET

#

#ONFIGUREINTERNAL2#MODE

7AITFOR&H

FROMHOST

!UTOBAUDRATESEQUENCE

SEND!#+BYTEDISABLE

UNUSEDPERIPHERALS

7AITFORA

COMMAND

'%4CMD

ROUTINE

2$CMD

ROUTINE

'/CMD

ROUTINE

OPTIONAL

LOADROUTINES

INTO2!-

*0TO?!DDRESS

AIB

4.2 Bootloader hardware requirements

The hardware required to put the STM32 into System memory boot mode consists of any

circuitry, switch or jumper, capable of holding the BOOT0 pin high and the BOOT1 pin low

during reset.

To connect to the STM32 during System memory boot mode, an RS232 serial interface

(example, ST3232 RS232 transceiver) has to be directly linked to the USART1_RX (PA10)

and USART1_TX (PA9) pins.

Note: USART1_CK, USART1_CTS and USART1_RTS pins are not used, therefore user can use

these pins for other peripherals or GPIOs.

For more details about hardware recommendations, refer to application note AN2586:

“STM32 hardware development: getting started”, available from the STMicroelectronics

website: http://www.st.com.

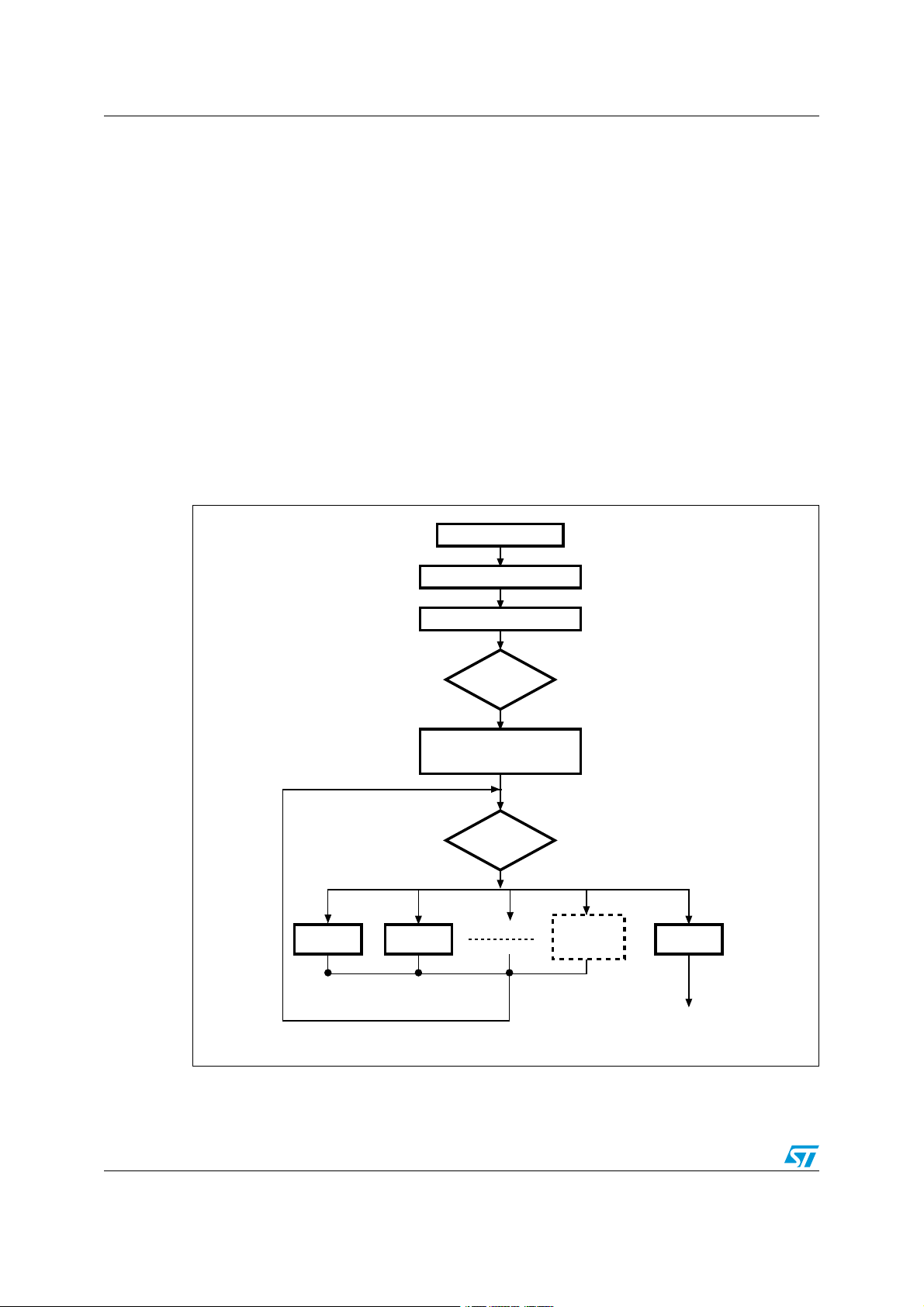

4.3 Bootloader selection

Figure 1. Bootloader for STM32F10xxx with USART1

'%4CMD

14/88 Doc ID 13801 Rev 14

OMMAND

RECEIVED

'/CMD

Page 15

AN2606 STM32F100xx, STM32F101xx, STM32F102xx, STM32F103xx, medium-density and high-

Once System memory boot mode is entered and the microcontroller has been configured as

described above, the bootloader code begins to scan the USART1_RX line pin, waiting to

receive the 0x7F data frame: one start bit, 0x7F data bits, even parity bit and one stop bit.

The duration of this data frame is measured using the Systick timer. The count value of the

timer is then used to calculate the corresponding baud rate factor with respect to the current

system clock.

Next, the code initializes the serial interface accordingly. Using this calculated baud rate, an

acknowledge byte (0x79) is returned to the host, which signals that the STM32F10xxx is

ready to receive user commands.

4.4 Bootloader version

Ta bl e 5 lists the bootloader versions of the STM32F10xxx devices.

Table 5. STM32F10xxx bootloader versions

Bootloader version number Description

V2.0 Initial bootloader version.

– Updated Go Command to initialize the main stack pointer

– Updated Go command to return NACK when jump address is in

V2.1

V2.2

the Option byte area or System memory area

– Updated Get ID command to return the device ID on two bytes

– Update the bootloader version to V2.1

– Updated Read Memory, Write Memory and Go commands to

deny access with a NACK response to the first 0x200 bytes of

RAM memory used by the bootloader

– Updated Readout Unprotect command to initialize the whole

RAM content to 0x0 before ROP disable operation

Doc ID 13801 Rev 14 15/88

Page 16

STM32F105xx and STM32F107xx device bootloader AN2606

5 STM32F105xx and STM32F107xx device bootloader

5.1 Bootloader configuration

The bootloader embedded in the STM32F105xx and STM32F107xx devices supports four

serial peripherals: USART1, USART2, CAN2, and DFU (USB). This means that four serial

peripherals are supported: USART1, USART2, CAN2 and DFU (USB).

The following table shows the hardware resources required by STM32F105xx and

STM32F107xx devices used by the bootloader in System memory boot mode.

Table 6. STM32F105xx/107xx configuration in System memory boot mode

Bootloader Feature/Peripheral State Comment

Common to

all

bootloaders

RCC

HSI enabled

HSE enabled

-

The system clock frequency is 24 MHz using the PLL.

This is used only for USART1 and USART2

bootloaders and during CAN2, USB detection for

CAN and DFU bootloaders (Once CAN or DFU

bootloader is selected, the clock source will be

derived from external crystal).

The external clock is mandatory only for DFU and

CAN bootloaders and it must provide one of the

following frequencies: 8 MHz, 14.7456 MHz or

25 MHz.

For CAN Bootloader, the PLL is used only to generate

48 MHz when 14.7456 MHz is used as HSE.

For DFU Bootloader, the PLL is used to generate a

48 MHz system clock from all supported external

clock frequencies.

The clock security system (CSS) interrupt is enabled

for the CAN and DFU bootloaders. Any failure (or

removal) of the external clock will generate system

reset.

The independent watchdog (IWDG) prescaler is

configured to its maximum value and is periodically

IWDG -

System memory -

RAM -

USART1 Enabled

USART1

bootloader

16/88 Doc ID 13801 Rev 14

USART1_RX pin Input PA10 pin: USART1 receive

USART1_TX pin Output push-pull PA9 pin: USART1 transmit

USART2_RX (PD6), CAN2_RX (PB5), OTG_FS_DM (PA11) and OTG_FS_DP (PA12) pins must be

kept at a high or low level during the detection phase.

refreshed to prevent watchdog reset (in case the

hardware IWDG option was previously enabled by the

user).

18 Kbytes starting from address 0x1FFF B000,

contain the bootloader firmware

4 Kbytes starting from address 0x2000 0000 are used

by the bootloader firmware.

Once initialized the USART1 configuration is: 8-bits,

even parity and 1 Stop bit

Page 17

AN2606 STM32F105xx and STM32F107xx device bootloader

Table 6. STM32F105xx/107xx configuration in System memory boot mode (continued)

Bootloader Feature/Peripheral State Comment

USART1 and

USART2

bootloaders

USART2

bootloader

CAN2

bootloader

DFU

bootloader

SysTick timer Enabled

USART2 Enabled

USART2_RX pin Input PD6 pin: USART2 receive (remapped pin)

USART2_TX pin Output push-pull PD5 pin: USART2 transmit (remapped pin)

USART1_RX (PA10), CAN2_RX (PB5), OTG_FS_DM (PA11) and OTG_FS_DP (PA12) pins must

be kept at a high or low level during the detection phase.

CAN2 Enabled

CAN2_RX pin Input PB5 pin: CAN2 receives (remapped pin)

CAN2_TX pin Output push-pull PB6 pin: CAN2 transmits (remapped pin)

USART1_RX (PA10), USART2_RX (PD6), OTG_FS_DM (PA11) and OTG_FS_DP (PA12) pins

must be kept at a high or low level during the detection phase.

USB OTG FS Enabled USB OTG FS configured in Forced Device mode

OTG_FS_VBUS pin

OTG_FS_DM pin PA11: USB Send-Receive data line

OTG_FS_DP pin PA12: USB Send-Receive data line

Interrupts Enabled

Input or alternate

function, automatically

controlled by the USB

OTG FS controller

Used to automatically detect the serial baud rate from

the host for USARTx bootloader.

Once initialized the USART2 configuration is: 8-bits,

even parity and 1 Stop bit. The USART2 uses its

remapped pins.

Once initialized the CAN2 configuration is: Baudrate

125 kbps, 11-bit identifier.

Note: CAN1 is clocked during the CAN bootloader

execution because in STM32F105xx and

STM32F107xx devices, CAN1 manages the

communication between CAN2 and SRAM.

PA9: Power supply voltage line

USB_OTG_FS interrupt vector is enabled and used

for USB DFU communication.

USART1_RX (PA10), USART2_RX (PD6) and CAN2_RX (PB5) pins must be kept at a high or low

level during the detection phase.

The system clock is derived from the embedded internal high-speed RC for USARTx

bootloader. This internal clock is used also for DFU and CAN bootloaders but only for the

selection phase. An external clock (8 MHz, 14.7456 MHz or 25 MHz.) is required for DFU

and CAN bootloader execution after the selection phase.

After downloading the application binary, if you choose to execute the Go command, all

peripheral registers used by the bootloader (shown in the above table) will be initialized to

their default reset values before jumping to the user application.

If the user application uses the IWDG, the IWDG prescaler value has to be adapted to meet

the requirements of the application (since the prescaler was set to its maximum value by the

bootloader).

Doc ID 13801 Rev 14 17/88

Page 18

STM32F105xx and STM32F107xx device bootloader AN2606

5.2 Bootloader hardware requirements

The hardware required to put the STM32F105xx and STM32F107xx into System memory

boot mode consists of any circuitry, switch or jumper, capable of holding the BOOT0 pin high

and the BOOT1 pin low during reset.

To connect to the STM32F105xx and STM32F107xx during System memory boot mode, the

following conditions have to be verified:

● The RX pins of the unused peripherals in this bootloader have to be kept at a known

(low or high) level, and should not be left floating during the detection phase as

described below:

– If USART1 is used to connect to the bootloader: the USART2_RX (PD6),

CAN2_RX (PB5), OTG_FS_DM (PA11) and OTG_FS_DP (PA12) pins have to be

kept at a high or low level and must not be left floating during the detection phase.

– If USART2 is used to connect to the bootloader: the USART1_RX (PA10),

CAN2_RX (PB5), OTG_FS_DM (PA11) and OTG_FS_DP (PA12) pins have to be

kept at a high or low level and must not be left floating during the detection phase.

– If CAN2 is used to connect to the bootloader: the USART1_RX (PA10),

USART2_RX (PD6), OTG_FS_DM (PA11) and OTG_FS_DP (PA12) pins have to

be kept at a high or low level and must not be left floating during the detection

phase.

– If DFU is used to connect to the bootloader: the USART1_RX (PA10),

USART2_RX (PD6) and CAN2_RX (PB5) pins have to be kept at a high or low

level and must not be left floating during the detection phase.

● Connection to the peripheral to be performed through:

– an RS232 serial interface (example, ST3232 RS232 transceiver) has to be directly

connected to the USART1_RX (PA10) and USART1_TX (PA9) pins when

USART1 is used, or to the USART2_RX (PD6) and USART2_TX (PD5) pins when

USART2 is used

– a CAN interface (CAN transceiver) has to be directly connected to the CAN2_RX

(PB5) and CAN2_TX (PB6) pins

– a certified USB cable has to be connected to the microcontroller (optionally an

ESD protection circuitry can be used)

The USART1_CK, USART1_CTS and USART1_RTS pins are not used, therefore the

application can use these pins for other peripherals or GPIOs. The same note is applicable

for USART2.

Once the USB Device is enabled, all its related pins are dedicated to USB communication

only, and cannot be used for other application purposes.

The user can control the BOOT0 and Reset pins from a PC serial applet using the RS232

serial interface which controls BOOT0 through the CTS line and Reset through the DCD

line. The user must use a full null modem cable. The necessary hardware to implement for

this control exists in the STM3210C-EVAL board. For more details about this, refer to

document: “STM3210C-EVAL board user manual”, available from the STMicroelectronics

website: http://www.st.com.

18/88 Doc ID 13801 Rev 14

Page 19

AN2606 STM32F105xx and STM32F107xx device bootloader

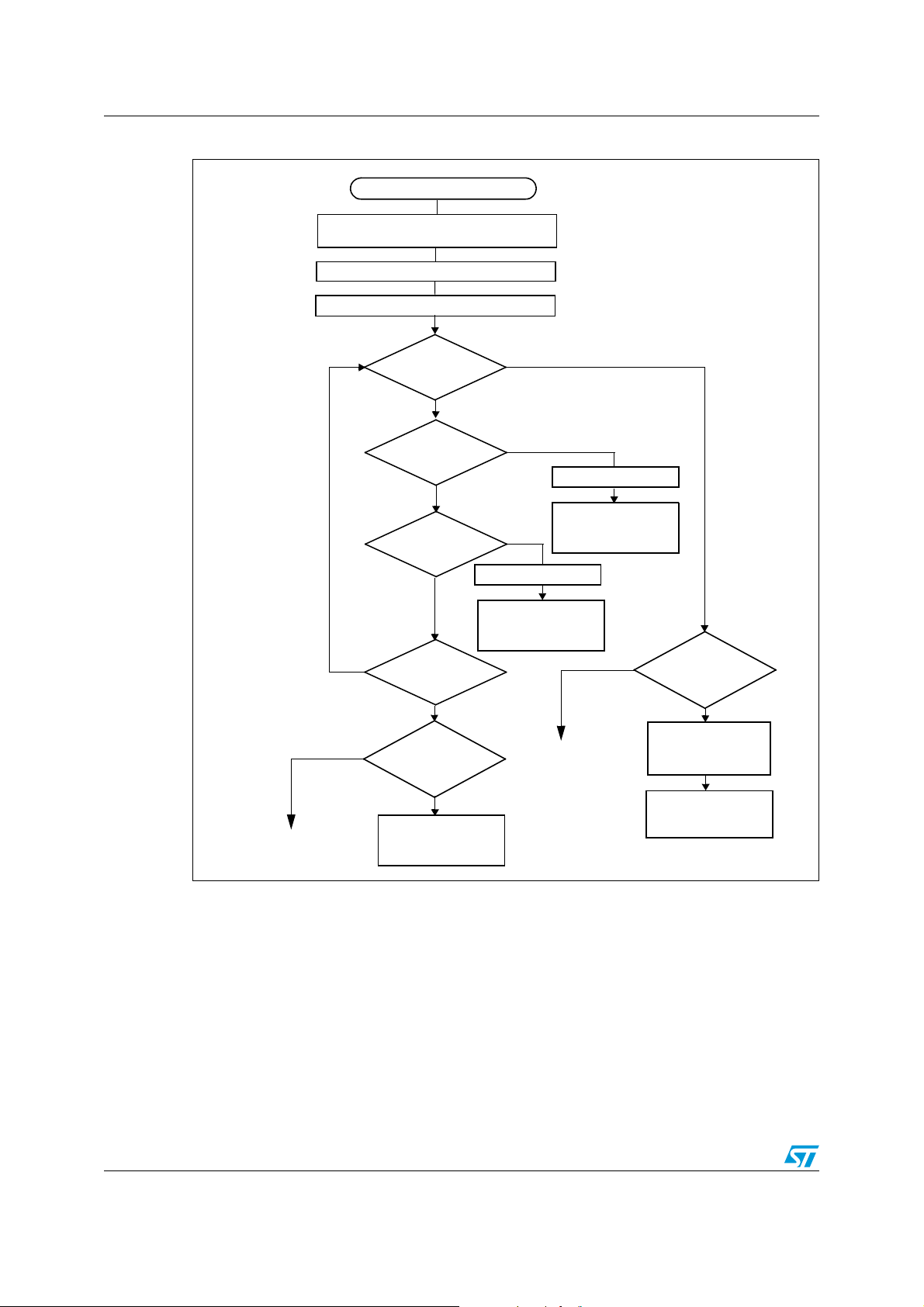

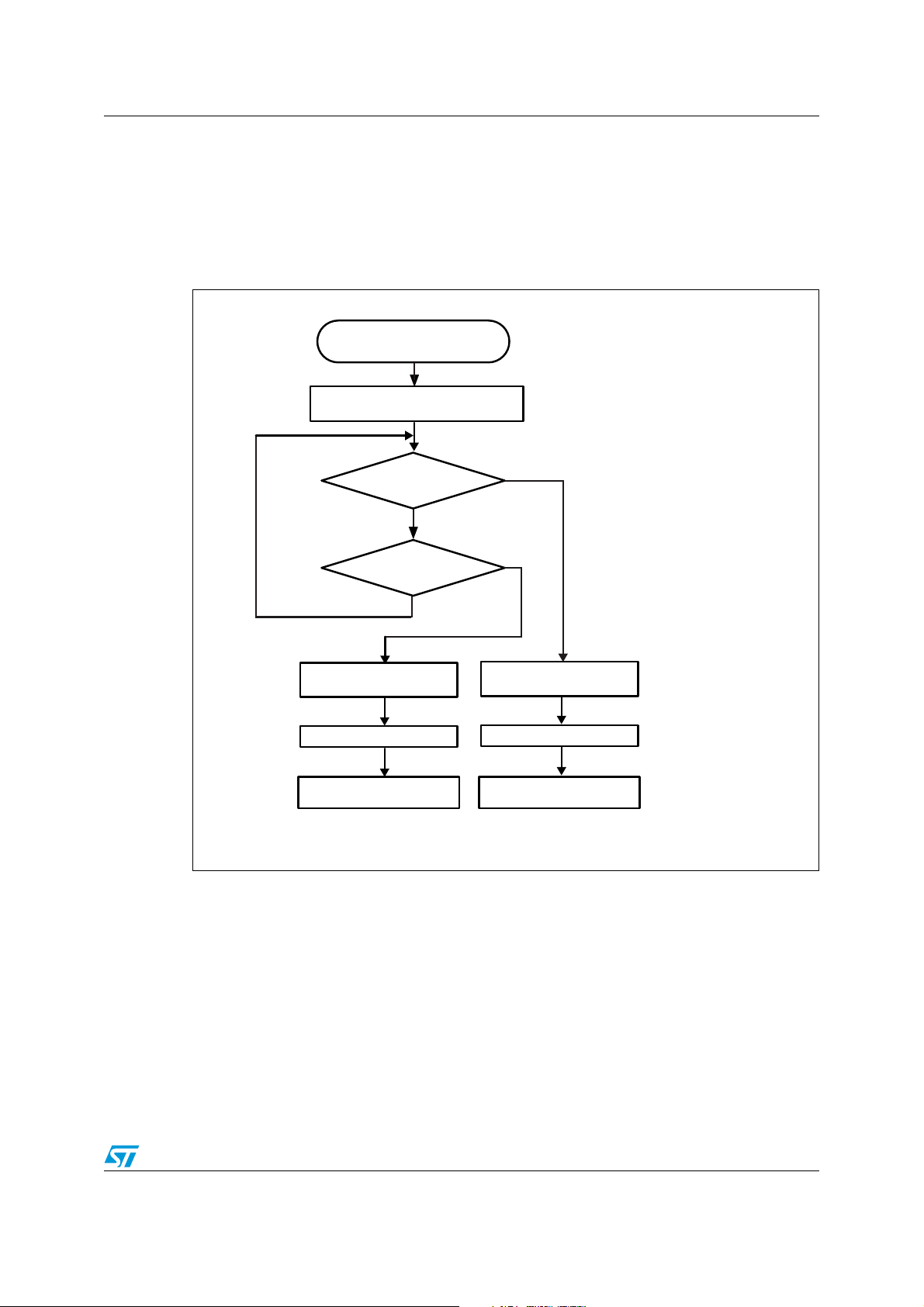

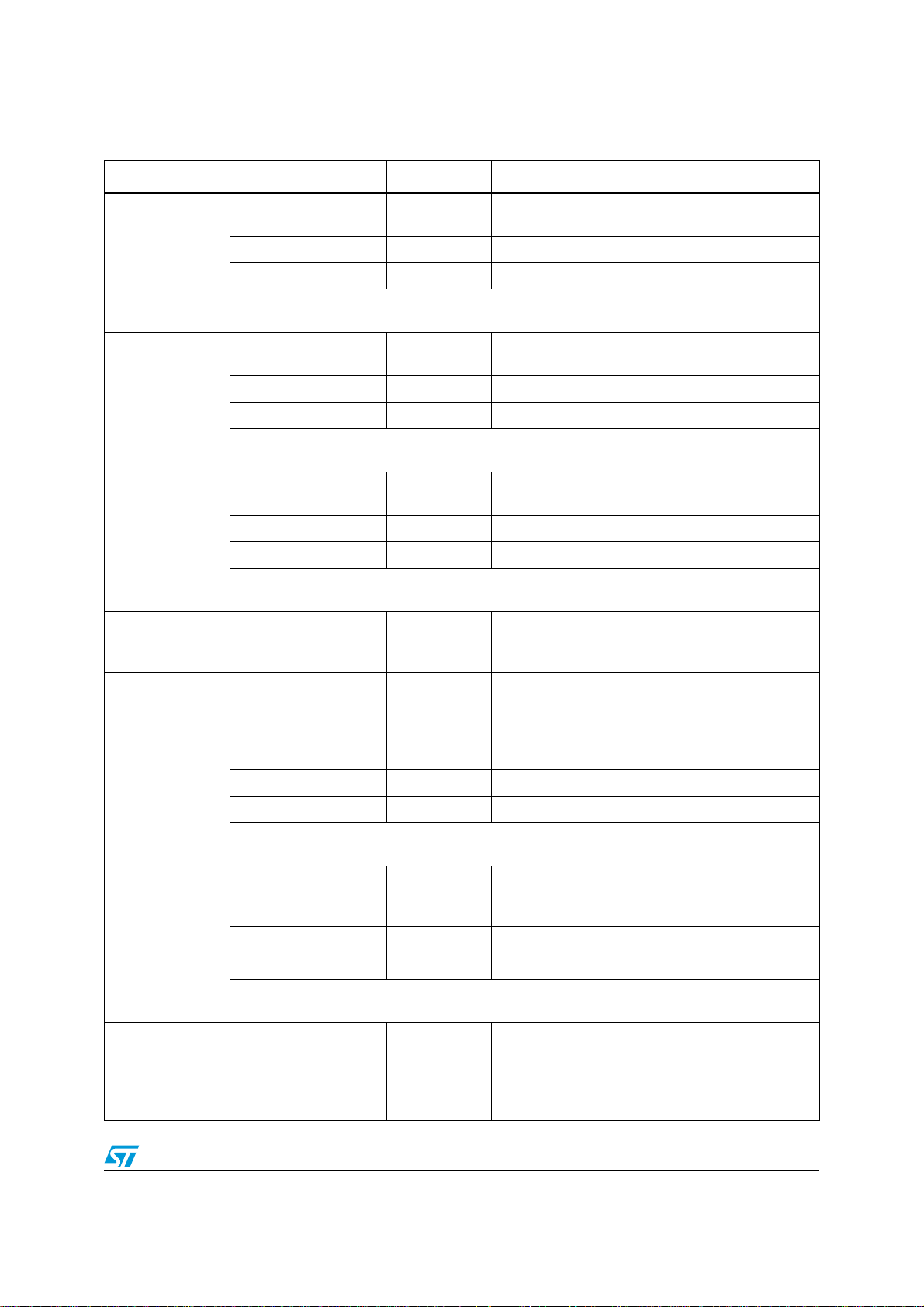

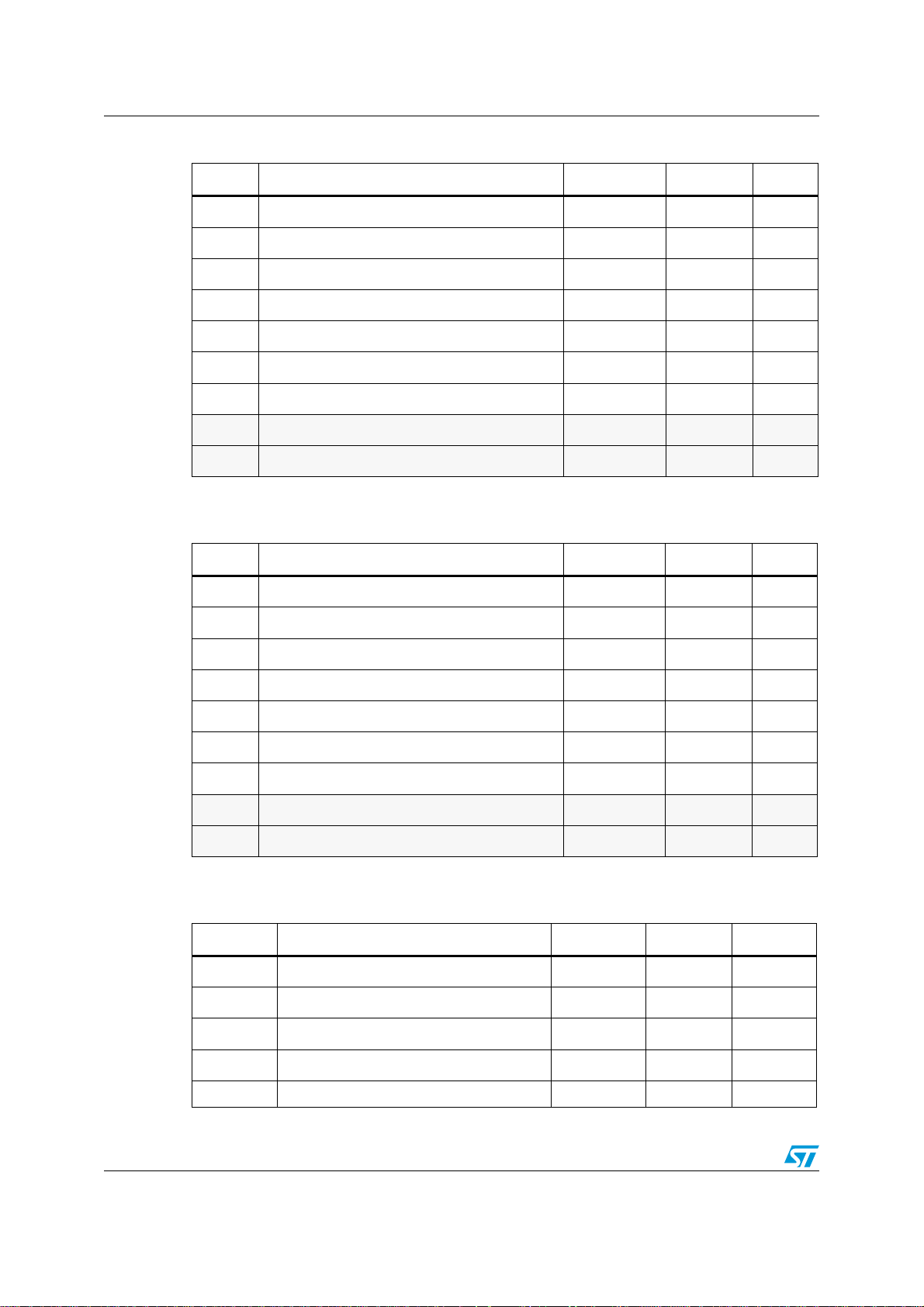

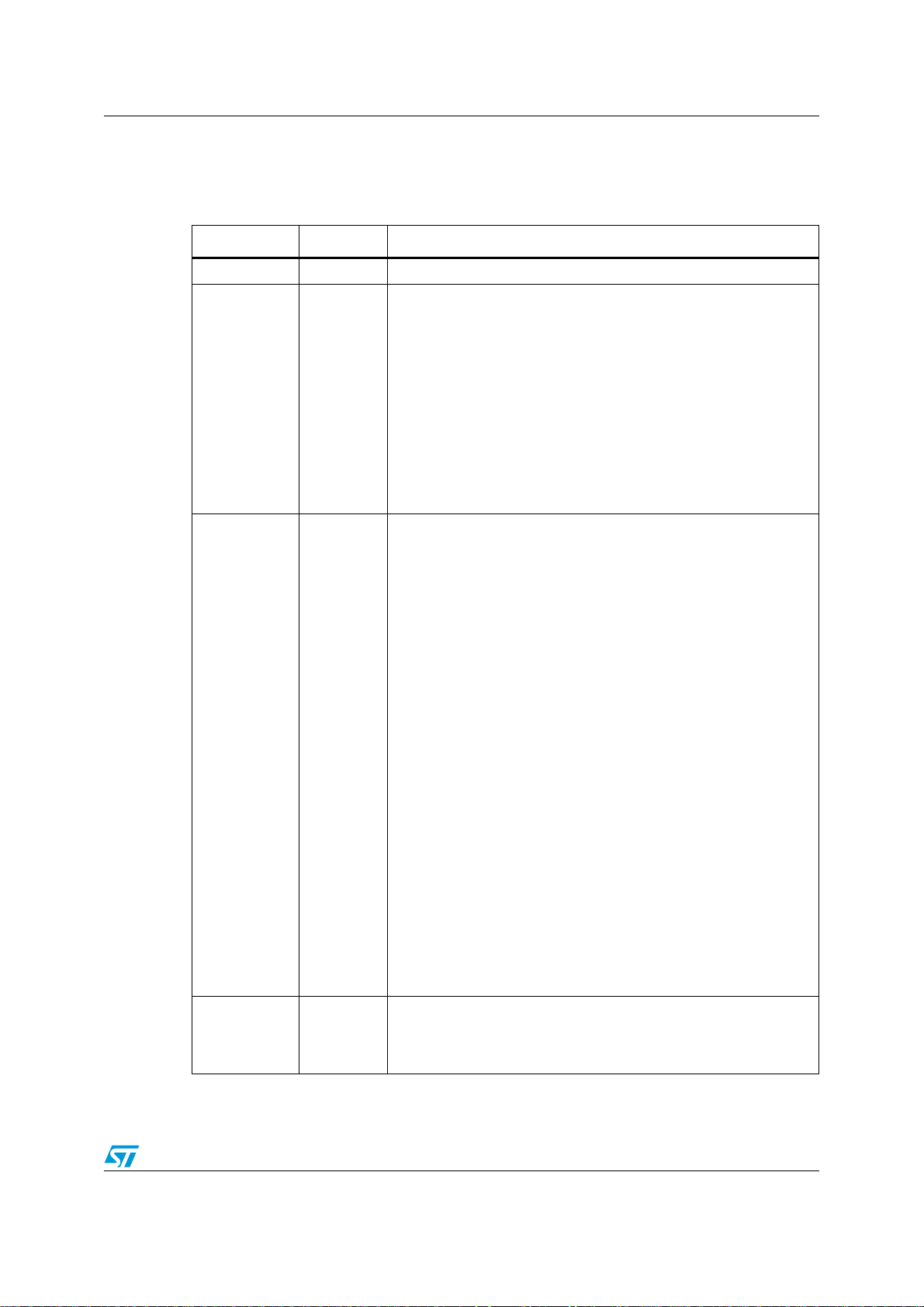

5.3 Bootloader selection

The STM32F105xx and STM32F107xx embedded bootloader supports four peripherals

interfaces: USART1, USART2, CAN2 and DFU (USB). Any one of these peripheral

interfaces can be used to communicate with the bootloader and download the application

code to the internal Flash.

The embedded bootloader firmware is able to auto-detect the peripheral interface to be

used. In an infinite loop, it detects any communication on the supported bootloader

interfaces.

Note: The RX pins of the peripherals not used in this bootloader must be kept at a known

(low or high) level and should not be left floating during the detection phase as

described below. Refer to Section 5.2: Bootloader hardware requirements for more

information.

To use the USART bootloader on USART1 or USART2, connect the serial cable to the

desired interface. Once the bootloader detects the data byte 0x7F on this interface, the

bootloader firmware executes the auto-baud rate sequence and then enters a loop, waiting

for any USART bootloader command.

To use the CAN2 interface, connect the CAN cable to CAN2. Once the bootloader detects a

frame on the CAN2_RX pin (PB5), the bootloader firmware enters a CAN loop and starts to

check the external clock frequency value, if the HSE is 8 MHz, 14.7456 MHz or 25 MHz

CAN bootloader firmware enters an infinite loop and waits until it receives a message,

otherwise a system reset is generated.

If a USB cable is plugged into the microcontroller’s USB interface at any time during the

bootloader firmware selection sequence, the bootloader then enters the DFU bootloader

loop waiting for any DFU bootloader command.

To use the USART or the CAN bootloader, it is mandatory that no USB cable is connected to

the USB peripheral during the selection phase. Once the USART or CAN bootloader is

selected, the user can plug a USB cable without impacting the selected bootloader

execution except commands which generate a system reset.

Once one interface is selected for the bootloader, all other interfaces are disabled.

The figure below shows the bootloader detection mechanism. More details are provided in

the sections corresponding to each peripheral bootloader.

Doc ID 13801 Rev 14 19/88

Page 20

STM32F105xx and STM32F107xx device bootloader AN2606

Figure 2. Bootloader selection for STM32F105xx and STM32F107xx devices

System reset

No

No

Generate system

reset

System init (clock, GPIOs, IWDG,

SysTick)

Configure CAN2

Configure USB

USB cable

detected

No

0x7F received on

USART1

No

0x7F received on

USART2

No

Frame detected on

CAN2_RX pin

Ye s

HSE = 8 MHz,

14.7456 MHz or

25 MHz

Ye s

Execute

BL_CAN_Loop for

CAN2

Ye s

Ye s

Ye s

Configure USART2

BL_USART_Loop for

Configure USART1

BL_USART_Loop for

Execute

USART2

Generate system

reset

Execute

USART1

No

HSE = 8 MHz,

14.7456 MHz or

25 MHz

Ye s

Reconfigure system

clock to 48 MHz and

USB clock to 48 MHz

Execute DFU boot-

loader using USB

interrupts

ai17514

20/88 Doc ID 13801 Rev 14

Page 21

AN2606 STM32F105xx and STM32F107xx device bootloader

5.4 Bootloader version

The table below lists the bootloader versions and the changes between all versions of the

STM32F105xx and STM32F107xx devices.

Table 7. STM32F105xx and STM32F107xx bootloader versions

Bootloader version

number

V1.0 Initial bootloader version.

V2.0

– Bootloader detection mechanism updated to fix the issue when GPIOs of

unused peripherals in this bootloader are connected to low level or left

floating during the detection phase.

For more details please refer to Section 5.4.2.

– Vector table set to 0x1FFF B000 instead of 0x0000 0000

– Go command updated (for all bootloaders): USART1, USART2, CAN2,

GPIOA, GPIOB, GPIOD and SysTick peripheral registers are set to their

default reset values

– DFU bootloader: USB pending interrupt cleared before executing the Leave

DFU command

– DFU subprotocol version changed from V1.0 to V1.2

– Bootloader version updated to V2.0

Description

– Fixed PA9 excessive consumption described in Section 5.4.4.

V2.1

V2.2

– Get-Version command (defined in AN3155) corrected. It returns 0x22

instead of 0x20 in bootloader V2.0. Refer to Section 5.4.3 for more details.

– Bootloader version updated to V2.1

– Fixed DFU option bytes descriptor (set to ‘e’ instead of ‘g’ because it is

read/write and not erasable).

– Fixed DFU polling timings for Flash Read/Write/Erase operations.

– Robustness enhancements for DFU bootloader interface.

– Updated Bootloader version to V2.2.

5.4.1 How to identify STM32F105xx/107xx bootloader versions

Bootloader V1.0 is implemented on devices which date code is below 937 (refer to

STM32F105xx and STM32F107xx datasheet for where to find the date code on the device

marking). Bootloader V2.0 and V2.1 are implemented on devices with a date code higher or

equal to 937.

There are two ways to distinguish between bootloader versions:

● When using the USART bootloader, the Get-Version command defined in AN2606 and

AN3155 has been corrected in V2.1 version. It returns 0x22 instead of 0x20 as in

bootloader V2.0.

● The values of the vector table at the beginning of the bootloader code are different. The

user software (or via JTAG/SWD) reads 0x1FFFE945 at address 0x1FFFB004 for

Doc ID 13801 Rev 14 21/88

Page 22

STM32F105xx and STM32F107xx device bootloader AN2606

bootloader V2.0 0x1FFFE9A1 for bootloader V2.1, and 0x1FFFE9C1 for bootloader

V2.2.

● The DFU version is the following:

– V2.1 in Bootloader V2.1

– V2.2 in Bootloader V2.2.

It can be read through the bcdDevice field of the DFU Device Descriptor.

5.4.2 Bootloader unavailability on STM32F105xx/STM32F107xx devices with a date code below 937

Description

The bootloader cannot be used if the USART1_RX (PA10), USART2_RX (PD6, remapped),

CAN2_Rx (PB5, remapped), OTG_FS_DM (PA11), and/or OTG_FS_DP (PA12) pin(s) are

held low or left floating during the bootloader activation phase.

The bootloader cannot be connected through CAN2 (remapped), DFU (OTG FS in Device

mode), USART1 or USART2 (remapped).

On 64-pin packages, the USART2_RX signal remapped PD6 pin is not available and it is

internally grounded. In this case, the bootloader cannot be used at all.

Workaround

● For 64-pin packages

None. The bootloader cannot be used.

● For 100-pin packages

Depending on the used peripheral, the pins for the unused peripherals have to be kept

at a high level during the bootloader activation phase as described below:

– If USART1 is used to connect to the bootloader, PD6 and PB5 have to be kept at a

high level.

– If USART2 is used to connect to the bootloader, PA10, PB5, PA11 and PA12 have

to be kept at a high level.

– If CAN2 is used to connect to the bootloader, PA10, PD6, PA11 and PA12 have to

be kept at a high level.

– If DFU is used to connect to the bootloader, PA10, PB5 and PD6 have to be kept at

a high level.

Note: This limitation applies only to STM32F105xx and STM32F107xx devices with a date code

below 937. STM32F105xx and STM32F107xx devices with a date code higher or equal to

937 are not impacted. See STM32F105xx and STM32F107xx datasheet for where to find

the date code on the device marking.

5.4.3 USART bootloader Get-Version command returns 0x20 instead of 0x22

Description

In USART mode, the Get-Version command (defined in AN3155) returns 0x20 instead of

0x20.

22/88 Doc ID 13801 Rev 14

Page 23

AN2606 STM32F105xx and STM32F107xx device bootloader

This limitation is present on bootloader versions V1.0 and V2.0, while it is fixed in bootloader

version 2.1.

Workaround

None.

5.4.4 PA9 excessive power consumption when USB cable is plugged in bootloader V2.0

Description

When connecting an USB cable after booting from System-Memory mode, PA9 pin

(connected to V

push-pull and forced to 0 since the USART peripheral is not yet clocked. As a consequence,

a current higher than 25 mA is drained by PA9 I/O and may affect the I/O pad reliability.

This limitation is fixed in bootloader version 2.1 by configuring PA9 as alternate function

push-pull when a correct 0x7F is received on RX pin and the USART is clocked. Otherwise,

PA9 is configured as alternate input floating.

Workaround

None.

=5 V) is also shared with USART TX pin which is configured as alternate

BUS

Doc ID 13801 Rev 14 23/88

Page 24

STM32F101xx and STM32F103xx XL-density device bootloader AN2606

6 STM32F101xx and STM32F103xx XL-density device

bootloader

Throughout this section STM32F10xxx XL-density is used to refer to XL-density

STM32F101xx and STM32F103xx devices.

6.1 Dual bank boot feature

For STM32F101xx and STM32F103xx XL-density devices (these devices have two Flash

memory banks: Bank 1 and Bank 2), an additional boot mechanism is available which allows

booting from Bank 2 or Bank 1 (depending on the BFB2 bit status (bit 19 in the user option

bytes @ 0x1FFFF800)).

1. When the BFB2 bit is reset, and the boot pins are configured to boot from the Flash

memory (BOOT0 = 0 and BOOT1 = x) then, after reset, the device boots from the

System memory and executes the embedded bootloader code which implements the

dual bank Boot mode:

a) First, the code checks Bank 2. If it contains a valid code (see Note: below), it

jumps to application located in Bank 2 and leaves the Bootloader.

b) If the Bank 2 code is not valid, it checks Bank 1 code. If it is valid (see “note”

below), it jumps to the application located in Bank 1.

c) If both Bank 2 and Bank 1 do not contain valid code (see “note” below), the normal

Bootloader operations are executed as described in the following sections (no

jump to Flash banks is executed). Refer to Figure 3: Bootloader selection for

STM32F10xxx XL-density devices for more details.

2. When the bit BFB2 is set (default state), the dual bank boot mechanism is not

performed.

Note: The code is considered as valid when the first data (at the bank start address, which should

be the stack pointer) points to a valid address into the internal SRAM memory (stack top

address). If the first address points to any other location (out of the internal SRAM) the code

is considered not valid.

A dual bank Boot mode example (FLASH\Dual_Boot) is provided within the STM32F10x

Standard Peripheral Library available on http://www.st.com.

24/88 Doc ID 13801 Rev 14

Page 25

AN2606 STM32F101xx and STM32F103xx XL-density device bootloader

For the STM32F101xx and STM32F103xx XL-density devices, the Flash memory, system

memory or SRAM is selected as the boot space, as shown in Tab le 8 below.

Table 8. Boot pin and BFB2 bit configuration

Boot mode

BFB2

bit

selection pins

BOOT1 BOOT0

Boot mode Aliasing

X 0 User Flash memory

1

0

0 1 System memory System memory is selected as the boot space

1 1 Embedded SRAM

X 0 System memory

0 1 System memory

1 1 Embedded SRAM

User Flash memory is selected as the boot

space

Embedded SRAM is selected as the boot

space

System memory is selected as the boot space

then dual bank mechanism is executed

System memory is selected as the boot space

then dual bank mechanism is executed

Embedded SRAM is selected as the boot

space

Ta bl e 8 shows that the XL-density devices enter System memory boot mode in two cases:

1. If the BOOT pins are configured as follows: BOOT0 = 1 and BOOT1 = 0

2. Or if:

a) the BFB2 bit is reset and

b) boot pins are configured as follows: BOOT0 = 0 and BOOT1 = x

Note: When conditions a, b, and c below are fulfilled, it is equivalent to configuring boot pins for

system memory boot (BOOT0 = 1 and BOOT1 = 0). In this case normal Bootloader

operations are executed.

a) BFB2 bit is reset

b) Both banks don’t contain valid code

c) Boot pins configured as follows: BOOT0 = 0 and BOOT1 = x

When the BFB2 bit is cleared, and Bank 2 and/or Bank 1 contain valid user application

code, the Dual Bank Boot is always performed (bootloader always jumps to the user code

and never continues normal operations).

Consequently, if you have cleared the BFB2 bit (to boot from Bank 2) then, to be able to

execute the Bootloader code, you have to:

- either, set the BFB2 bit to 1

- or, program the content of address 0x0808 0000 (base address of Bank2) and 0x0800

0000 (base address of Bank1) to 0x0

Doc ID 13801 Rev 14 25/88

Page 26

STM32F101xx and STM32F103xx XL-density device bootloader AN2606

6.2 Bootloader configuration

The bootloader embedded in STM32F10xxx XL-density supports two serial interfaces:

USART1 and USART2.

The following table shows the required hardware resources of STM32F10xxx XL-density

devices used by the bootloader in System memory boot mode.

Table 9. STM32F10xxx XL-density configuration in System memory boot mode

Feature/peripheral State Comment

Clock source HSI enabled The system clock is equal to 24 MHz using the PLL

USART1_RX pin Input PA10 pin: USART1 receives

USART1_TX pin

USART2_RX pin Input PD6 pin: USART2 receives (remapped pins)

USART2_TX pin

SysTick timer Enabled Used to automatically detect the serial baud rate from the host

Output pushpull

Output pushpull

PA9 pin: USART1 transmits

PD5 pin: USART2 transmits (remapped pins)

USART1 Enabled

USART2 Enabled

RAM -

System memory -

IWDG -

Once initialized the USART1/USART2 configuration is: 8-bits,

even parity and 1 Stop bit.

2 Kbytes starting from address 0x2000 0000 are used by the

bootloader firmware

6 Kbytes starting from address 0x1FFF E000, contain the

bootloader firmware

The independent watchdog (IWDG) prescaler is configured to

its maximum value and is periodically refreshed to prevent

watchdog reset (in case the hardware IWDG option was

previously enabled by the user)

The system clock is derived from the embedded internal high-speed RC, no external quartz

is required for the bootloader code.

After downloading the application binary, if you choose to execute the Go command, all

peripheral registers used by the bootloader (shown in Tab le 9 ) are initialized to their default

reset values before jumping to the user application.

If the user application uses the IWDG, the IWDG prescaler value has to be adapted to meet

the requirements of the application (since the prescaler was set to its maximum value by the

bootloader).

26/88 Doc ID 13801 Rev 14

Page 27

AN2606 STM32F101xx and STM32F103xx XL-density device bootloader

6.3 Bootloader hardware requirements

The hardware required to put the STM32F10xx XL-density devices into System memory

boot mode consists of any circuitry, switch or jumper, capable of holding the BOOT0 pin high

and the BOOT1 pin low during reset.

Note: As explained in Section 6.1: Dual bank boot feature, the System memory boot mode can

also be executed by software when the BFB2 bit is reset, both banks start addresses are

erased, and boot pins are configured to boot from Flash memory.

To connect to the STM32F10xx XL-density devices during System memory boot mode, the

following conditions have to be verified:

● The RX pin of the peripherals unused in this bootloader have to be kept at a known (low

or high) level, and should not be left floating during the detection phase as described

below:

– If the USART1 is used to connect to the bootloader: the USART2_RX (PD6) pin

has to be kept at a high or low level and must not be left floating during the

detection phase.

– If the USART2 is used to connect to the bootloader: the USART1_RX (PA10) pin

has to be kept at a high or low level and must not be left floating during the

detection phase.

● When the BFB2 bit is cleared, and Bank 2 and/or Bank 1 contain a valid user

application code, the Dual Bank Boot is always performed (bootloader always jumps to

the user code and never continues normal operations). Consequently, if you have

cleared the BFB2 bit (to boot from Bank 2), then to be able to execute the Bootloader

code, you have to:

– either, set the BFB2 bit to 1

– or, program the content of address 0x0808 0000 (base address of Bank2) and

0x0800 0000 (base address of Bank1) to 0x0

● Connection to the peripheral to be performed through:

– an RS232 serial interface (example, ST3232 RS232 transceiver) has to be directly

connected to the USART1_RX (PA10) and USART1_TX (PA9) pins when

USART1 is used, or to the USART2_RX (PD6) and USART2_TX (PD5) pins when

USART2 is used

The USART1_CK, USART1_CTS and USART1_RTS pins are not used, therefore the

application can use these pins for other peripherals or GPIOs. This is also applicable for

USART2.

Doc ID 13801 Rev 14 27/88

Page 28

STM32F101xx and STM32F103xx XL-density device bootloader AN2606

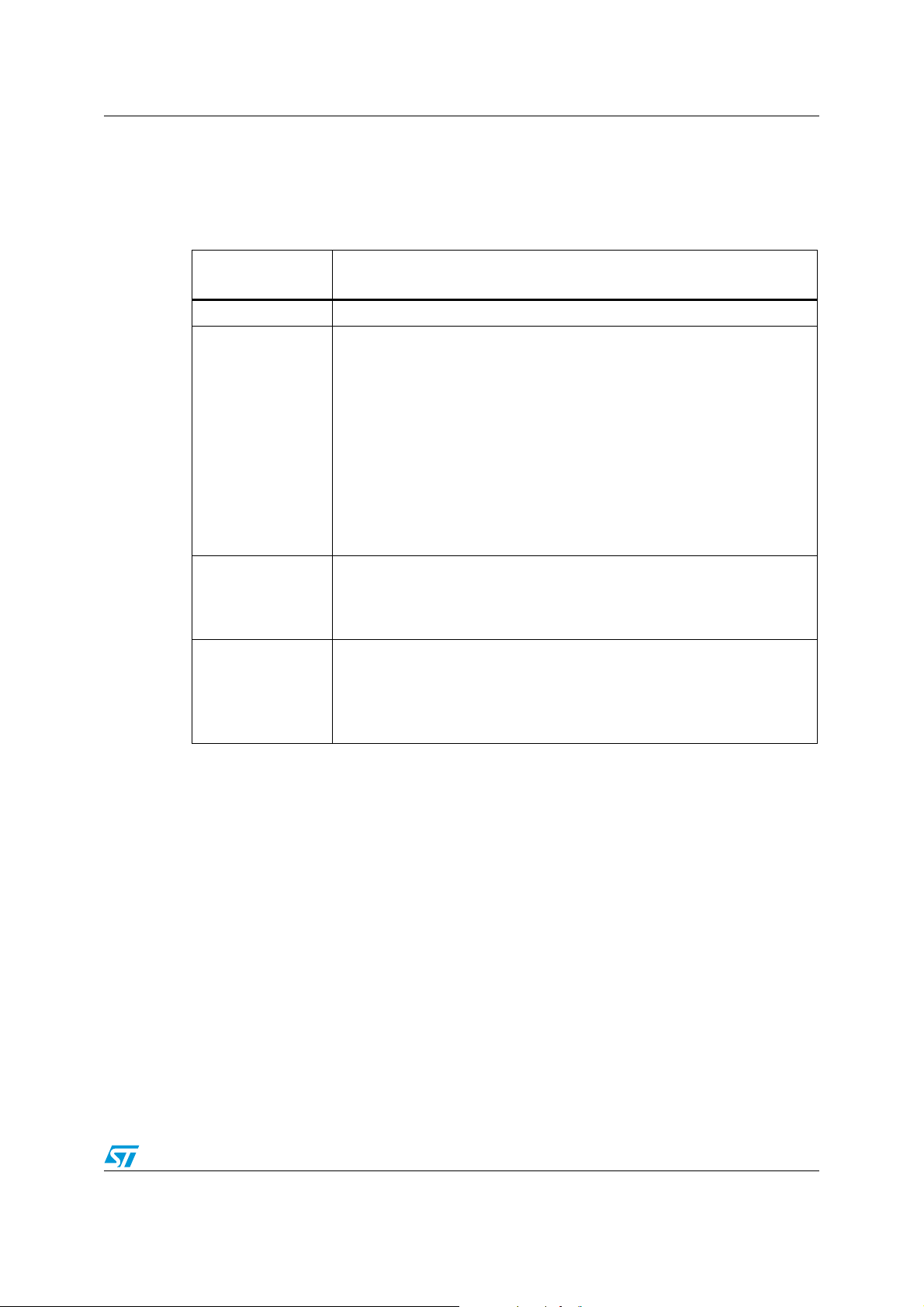

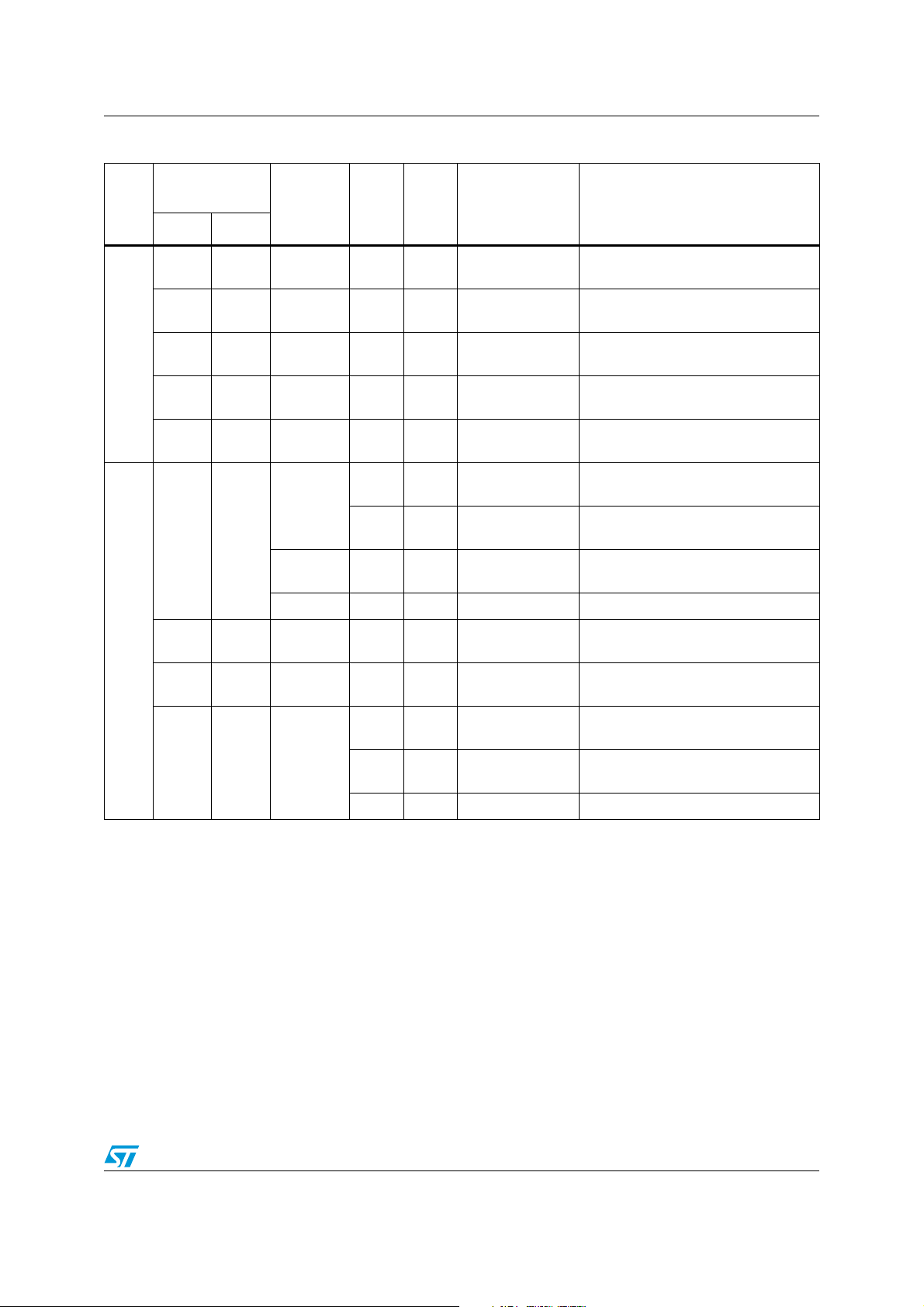

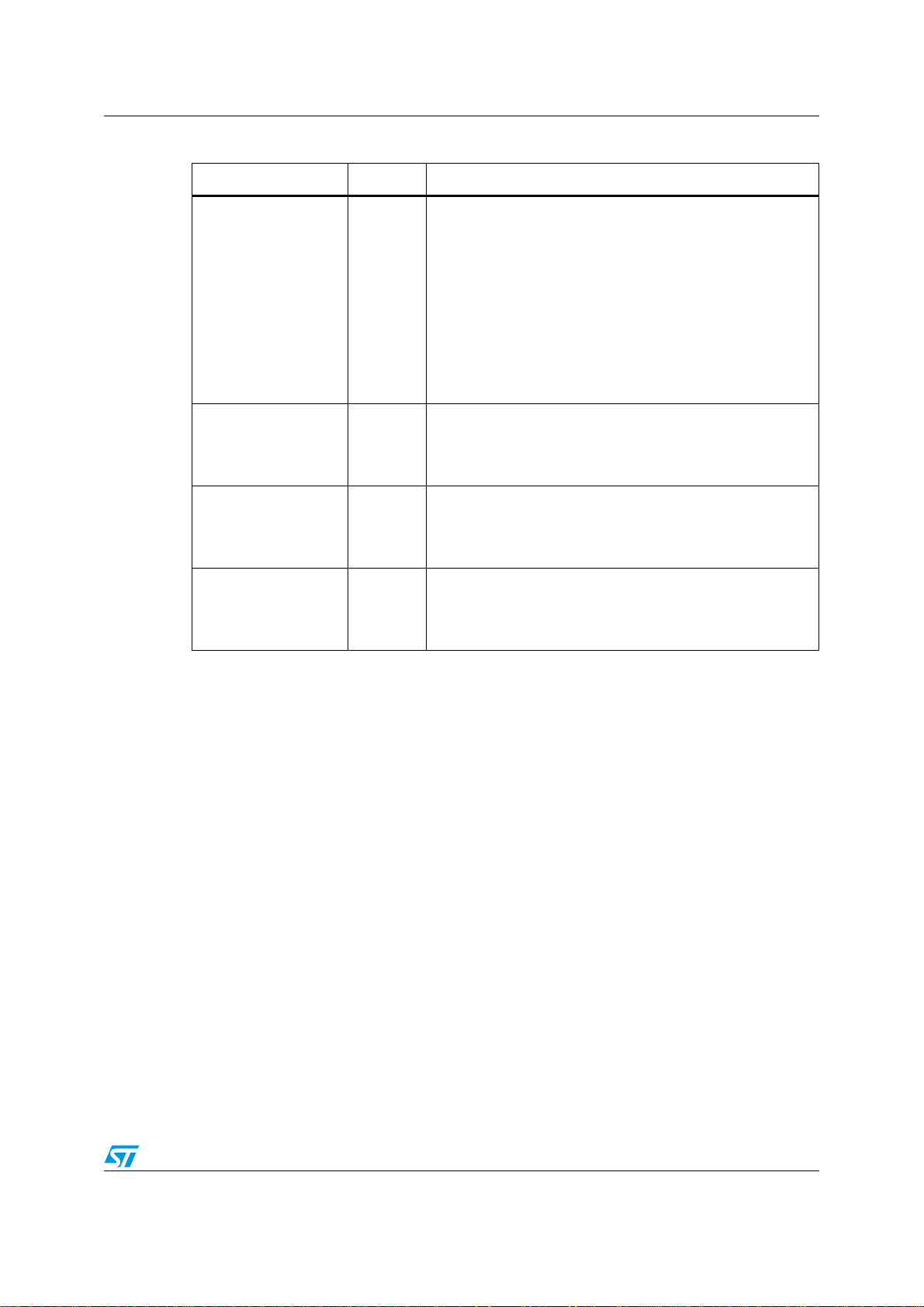

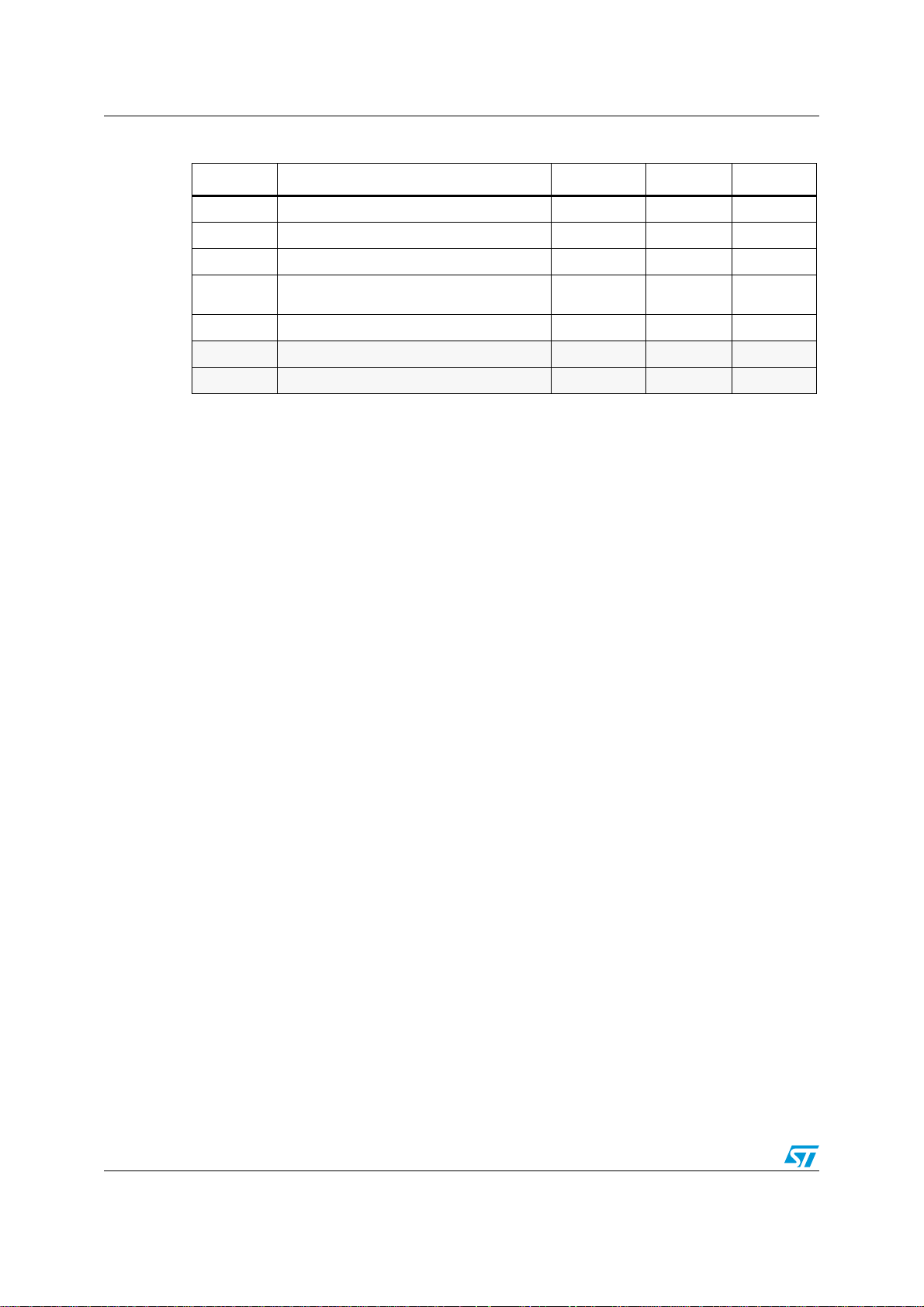

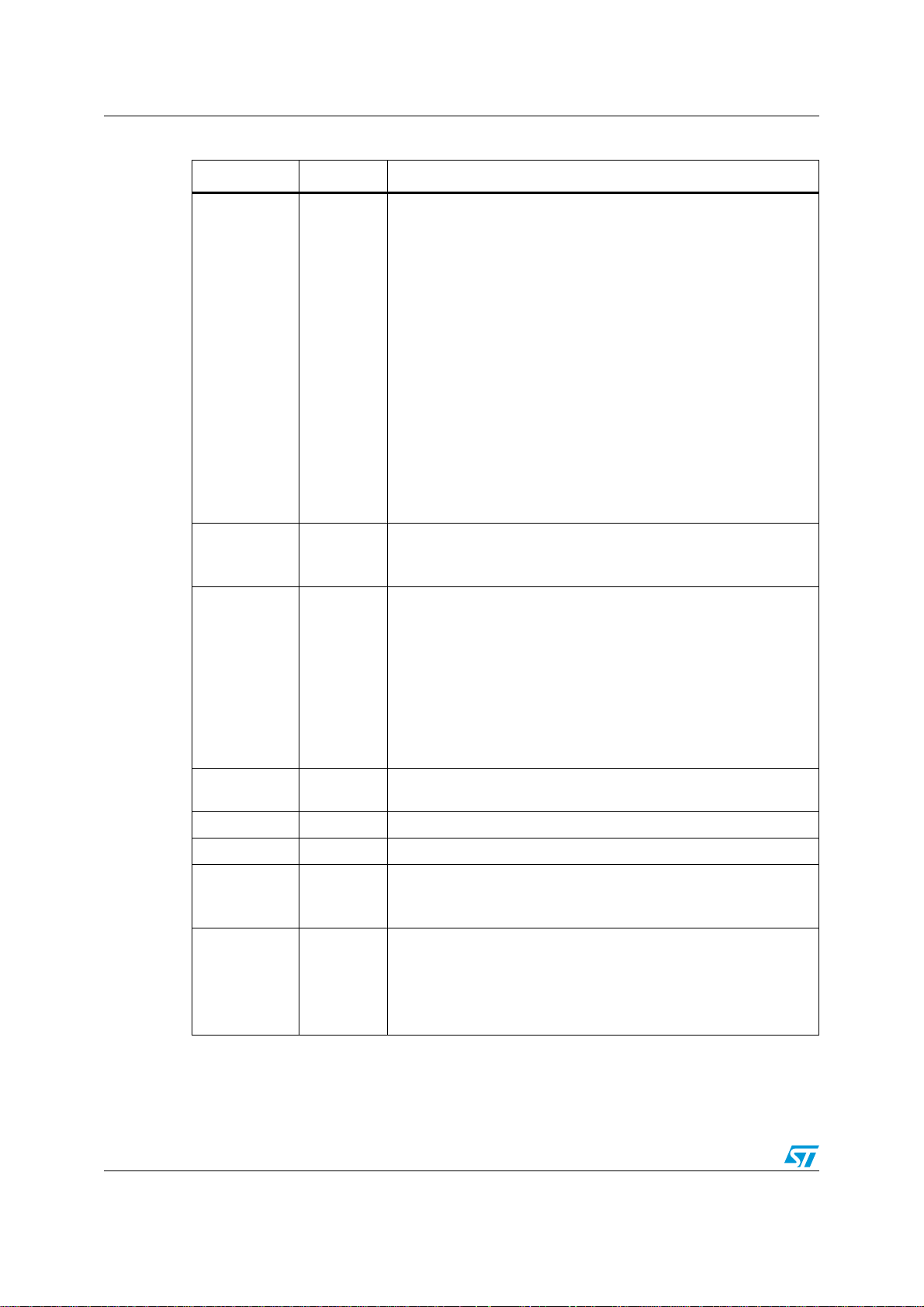

6.4 Bootloader selection

The STM32F10xx XL-density embedded Bootloader supports two peripheral interfaces:

USART1 and USART2. Any one of these peripheral interfaces can be used to communicate

with the bootloader and download the application code to the internal Flash.

The embedded Bootloader firmware is able to auto-detect the peripheral interface to be

used. In an infinite loop, it detects any communication on the supported bootloader

interfaces.

Note: The RX pins of the peripherals not used in this bootloader must be kept at a known

(low or high) level and should not be left floating during the detection phase as

described below. Refer to Section 6.3: Bootloader hardware requirements for more

information.

To use the USART bootloader on USART1 or USART2, connect the serial cable to the

desired interface. Once the bootloader detects the data byte 0x7F on this interface, the

bootloader firmware executes the auto-baudrate sequence and then enters a loop, waiting

for any USART bootloader command.

Once one interface is selected for the bootloader, the other interface is disabled.

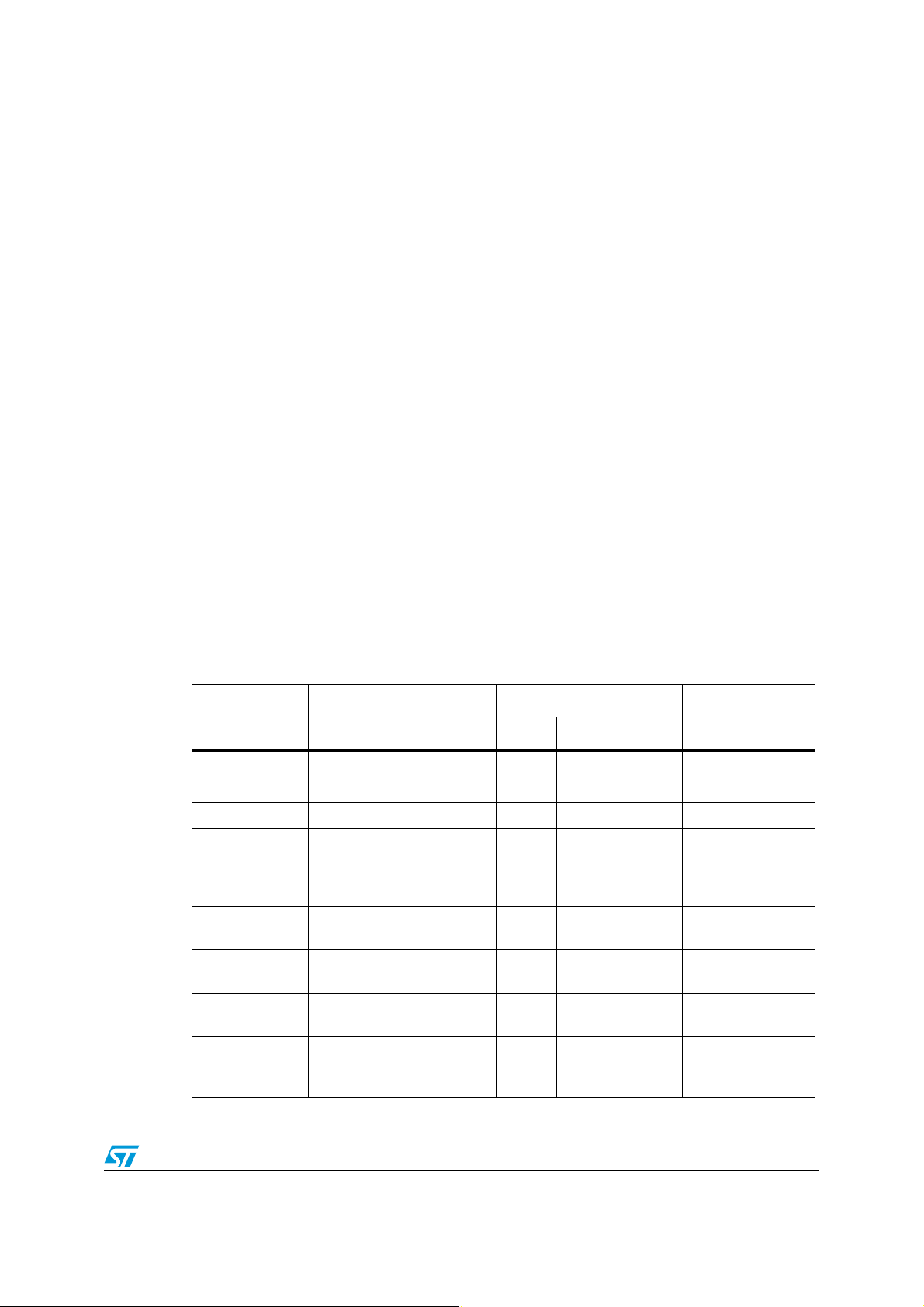

Figure 3 shows the bootloader detection mechanism. More details are provided in the

sections corresponding to each peripheral bootloader.

28/88 Doc ID 13801 Rev 14

Page 29

AN2606 STM32F101xx and STM32F103xx XL-density device bootloader

3YSTEM2ESET

"&"BITISRESET

"&"

)FVALUE XIS

WITHININT32!-ADDRESS

9%3

9%3

)FVALUE XIS

WITHININT32!-ADDRESS

*UMPTOUSERCODEIN

"ANK

*UMPTOUSERCODEIN

"ANK

./

./

#ONTINUENORMAL"OOTLOADER

EXECUTION

./

$ISABLEALLINTERRUPTSOURCES

3YSTEMINITCLOCK'0)/S)7$'

3YS4ICK

X&RECEIVED

ON53!24

X&RECEIVED

ON53!24

#ONFIGURE53!24

%XECUTE",?53!24?,OOP

FOR53!24

#ONFIGURE53!24

%XECUTE",?53!24?,OOP

FOR53!24

9%3

9%3

9%3

./

./

AI

Figure 3. Bootloader selection for STM32F10xxx XL-density devices

Doc ID 13801 Rev 14 29/88

Page 30

STM32F101xx and STM32F103xx XL-density device bootloader AN2606

6.5 Bootloader version

Ta bl e 1 0 lists the bootloader versions for the STM32F101xx and STM32F103xx XL-density

devices.

Table 10. XL-density bootloader versions

Bootloader version

number

V2.1 Initial bootloader version

Description

30/88 Doc ID 13801 Rev 14

Page 31

AN2606 STM32L15xx Medium-density Ultralow power device bootloader

7 STM32L15xx Medium-density Ultralow power device

bootloader

Through all this section STM32L15xxx will be used as reference to Medium-density

STM32L151xx and STM32L152xx ultralow power devices.

7.1 Bootloader configuration

The bootloader embedded in STM32L15xxx devices supports two serial interfaces:

USART1 and USART2 peripherals.

The following table shows the required hardware resources of STM32L15xx devices used

by the bootloader in System memory boot mode.

Table 11. STM32L15xxx configuration in System memory boot mode

Feature/Peripheral State Comment

Clock source HSI enabled The system clock is equal to 16 MHz

USART1_RX pin Input PA10 pin: USART1 receives

USART1_TX pin Output PA9 pin: USART1 transmits

USART2_RX pin Input PD06 pin: USART2 receives

USART2_TX pin Output PD05 pin: USART2 transmits

SysTick timer Enabled Used to automatically detect the serial baud rate from the host.

USART1 Enabled

USART2 Enabled

RAM -

System memory -

IWDG -

Power - Voltage range is set to Voltage Range 2

Once initialized the USART1 configuration is: 8-bits, even parity

and 1 Stop bit

Once initialized the USART2 configuration is: 8-bits, even parity

and 1 Stop bit

2 Kbytes starting from address 0x2000 0000 are used by the

bootloader firmware

4 Kbytes starting from address 0x1FF0 0000, contain the

bootloader firmware

The independent watchdog (IWDG) prescaler is configured to its

maximum value and is periodically refreshed to prevent

watchdog reset (in case the hardware IWDG option was

previously enabled by the user)

The system clock is derived from the embedded internal high-speed RC, no external quartz

is required for the bootloader code

After downloading the application binary, if you choose to execute the Go command, all

peripheral registers used by the bootloader (shown in the above table) are initialized to their

default reset values before jumping to the user application. If the user application uses the

IWDG, the IWDG prescaler value has to be adapted to meet the requirements of the

application (since the prescaler was set to its maximum value by the bootloader).

Doc ID 13801 Rev 14 31/88

Page 32

STM32L15xx Medium-density Ultralow power device bootloader AN2606

7.2 Bootloader hardware requirements

The hardware required to put the STM32L15xx devices into System memory boot mode

consists of any circuitry, switch or jumper, capable of holding the BOOT0 pin high and the

BOOT1 pin low during reset.

To connect to the STM32L15xx devices during System memory boot mode, the following

conditions have to be verified:

● The RX pins of the peripherals unused in this bootloader have to be kept at a known

(low or high) level, and should not be left floating during the detection phase as

described below:

– If USART1 is used to connect to the bootloader: the USART2_RX (PD6) pin has to

be kept at a high or low level and must not be left floating during the detection

phase.

– If USART2 is used to connect to the bootloader: the USART1_RX (PA10) pin has

to be kept at a high or low level and must not be left floating during the detection

phase.

● The peripheral to be used has to be connected through an RS232 serial interface

(example, ST3232 RS232 transceiver) which must be:

– Directly connected to the USART1_RX (PA10) and USART1_TX (PA9) pins when

USART1 is used

– Directly connected to the USART2_RX (PD6) and USART2_TX (PD5) pins when

USART2 is used

The USART1_CK, USART1_CTS and USART1_RTS pins are not used, therefore the

application can use these pins for other peripherals or GPIOs. The same note is applicable

for USART2.

The user can control the BOOT0 and Reset pins from a PC serial applet using the RS232

serial interface which controls BOOT0 through the CTS line and Reset through the DCD

line. The user must use a full null modem cable. The necessary hardware to implement for

this control exists in the STM32L152-EVAL board. For more details about this, refer to the

“STM32L152-EVAL board user manual” (UM1009), available from the STMicroelectronics

website: http://www.st.com.

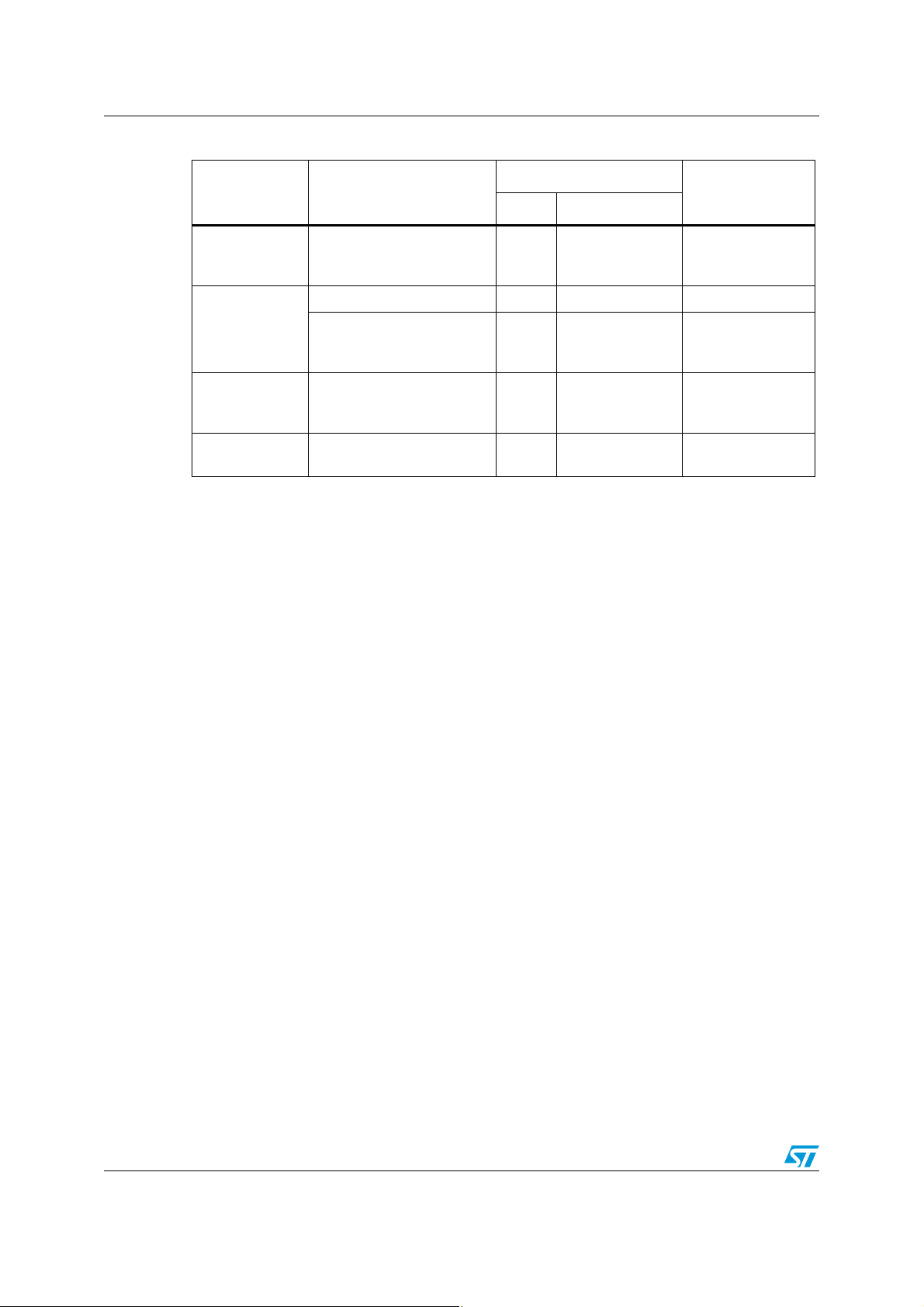

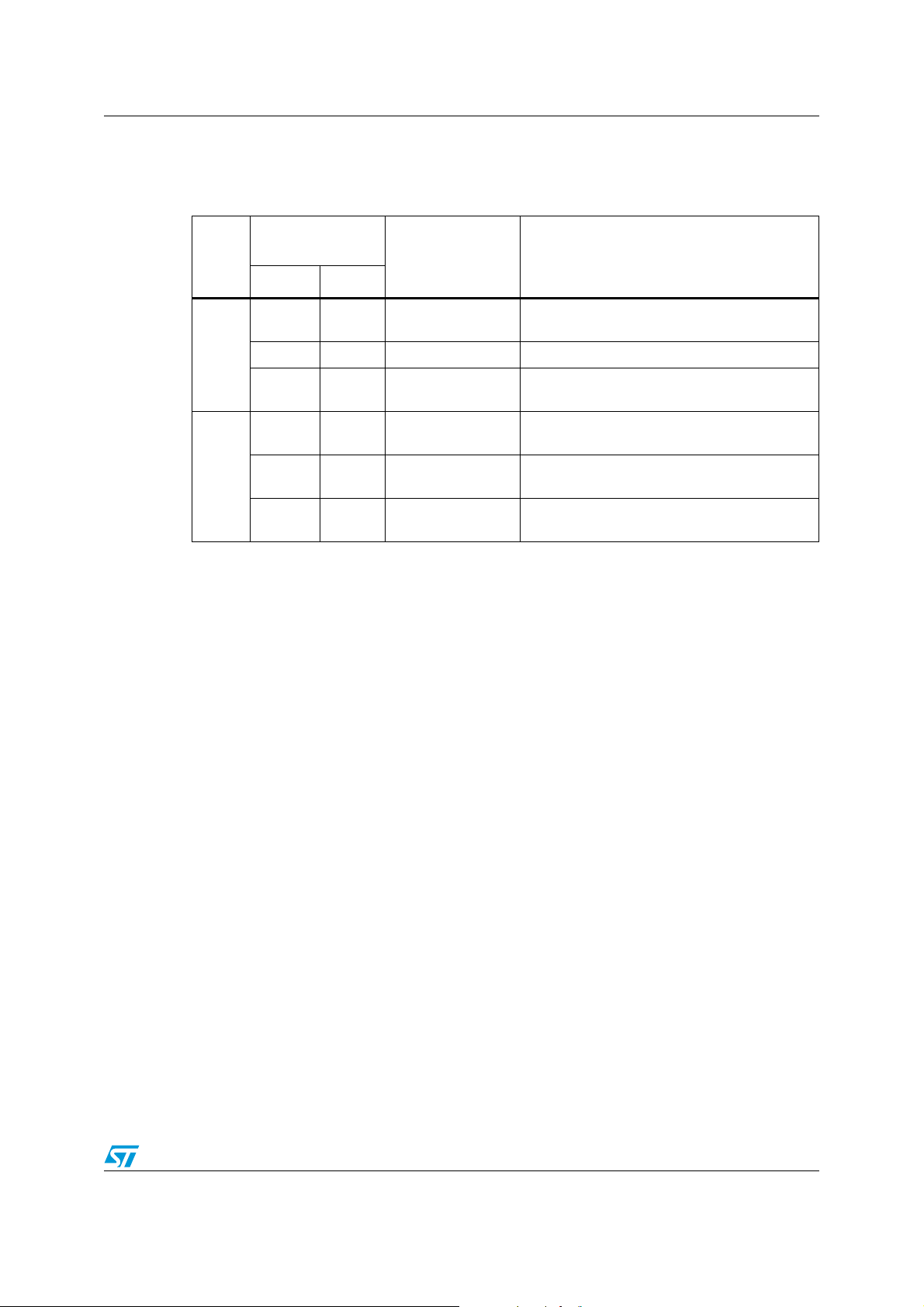

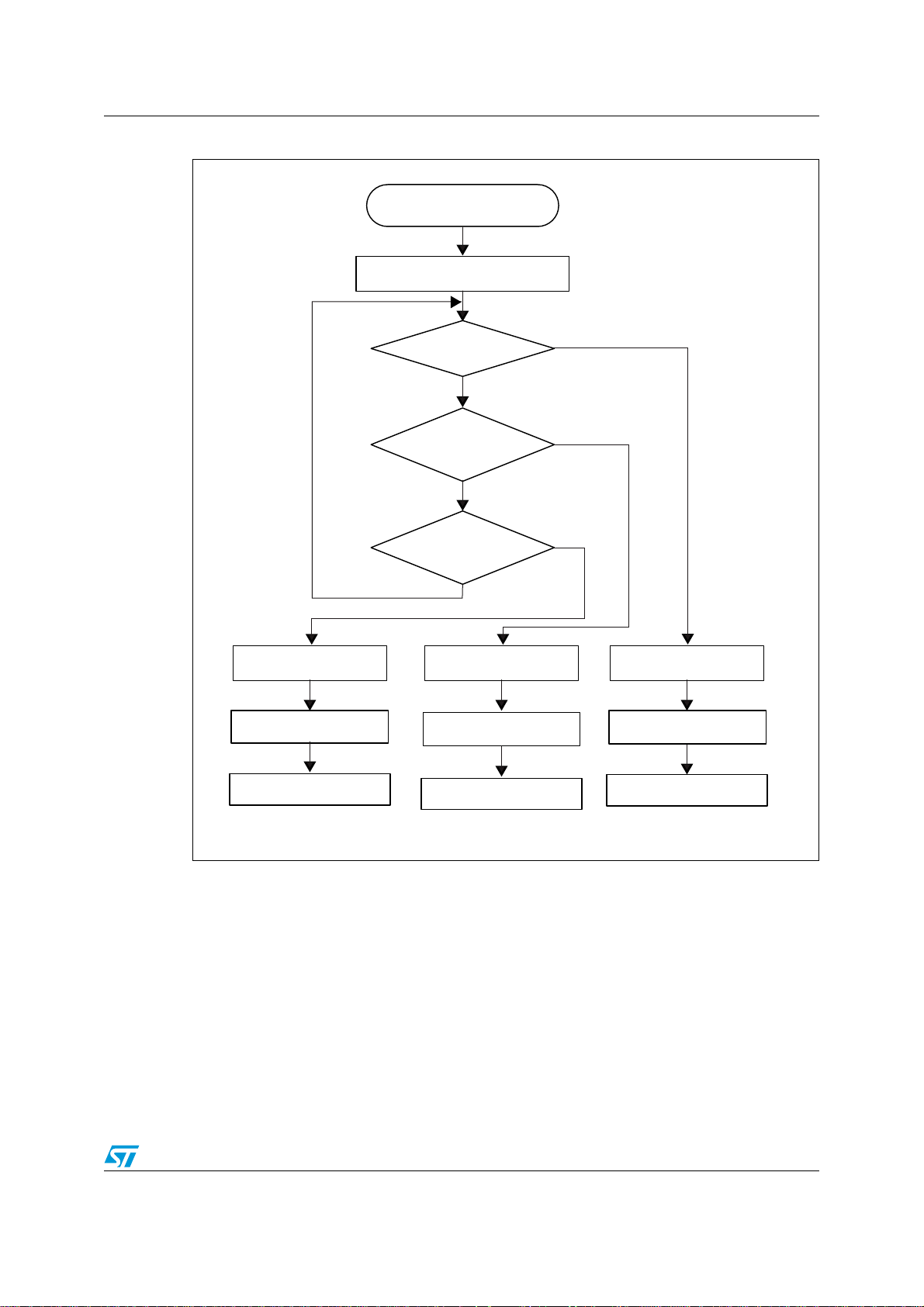

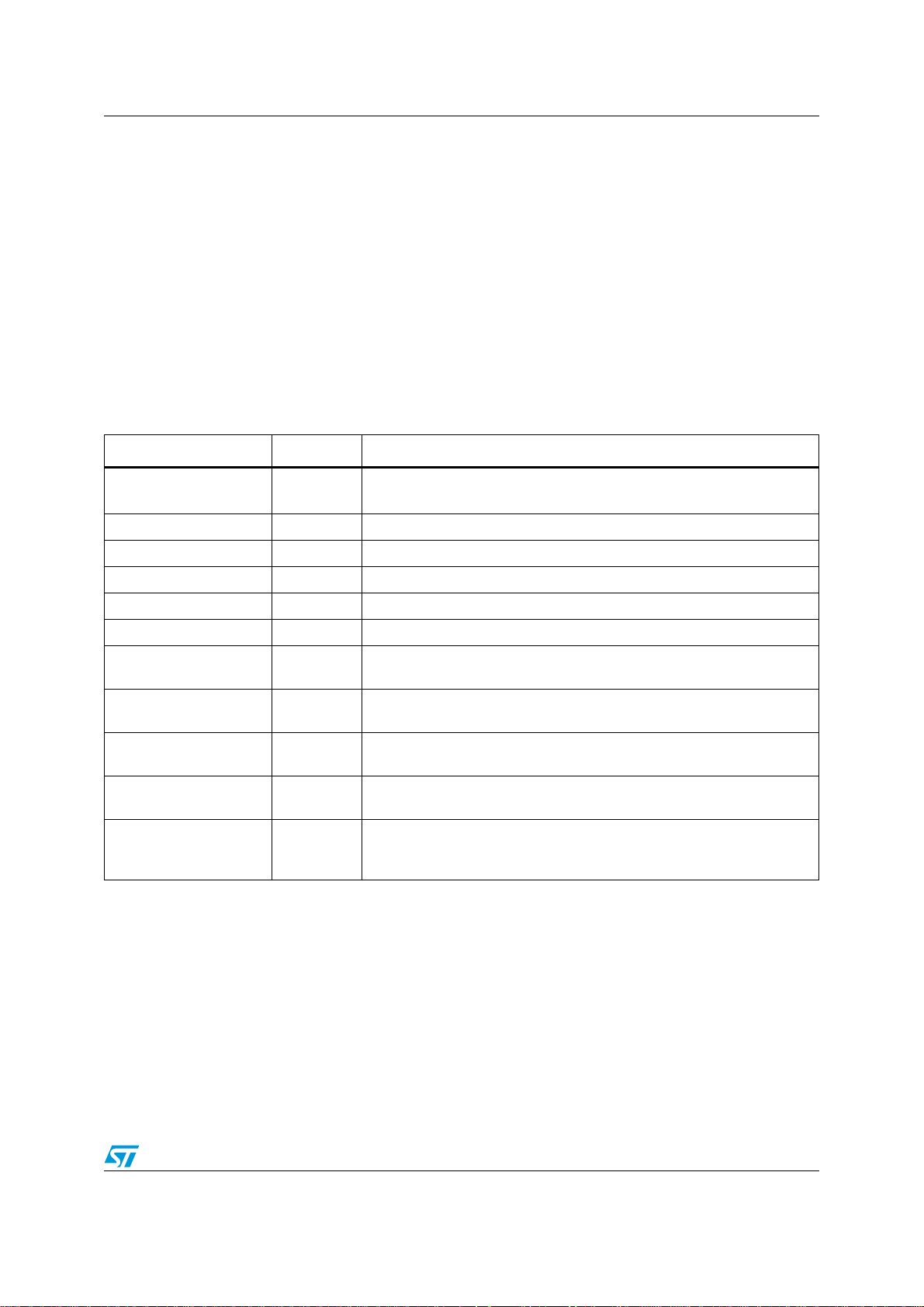

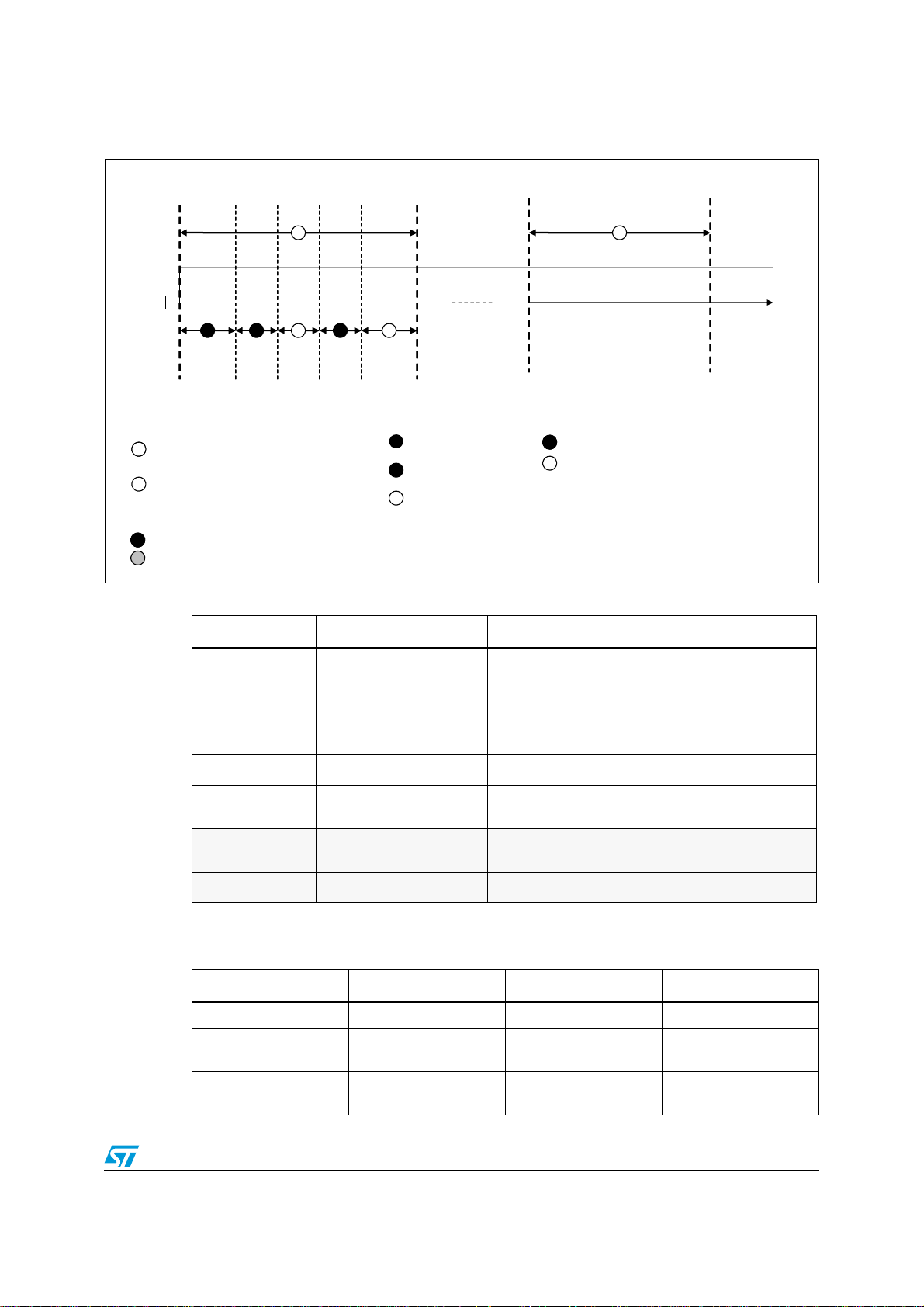

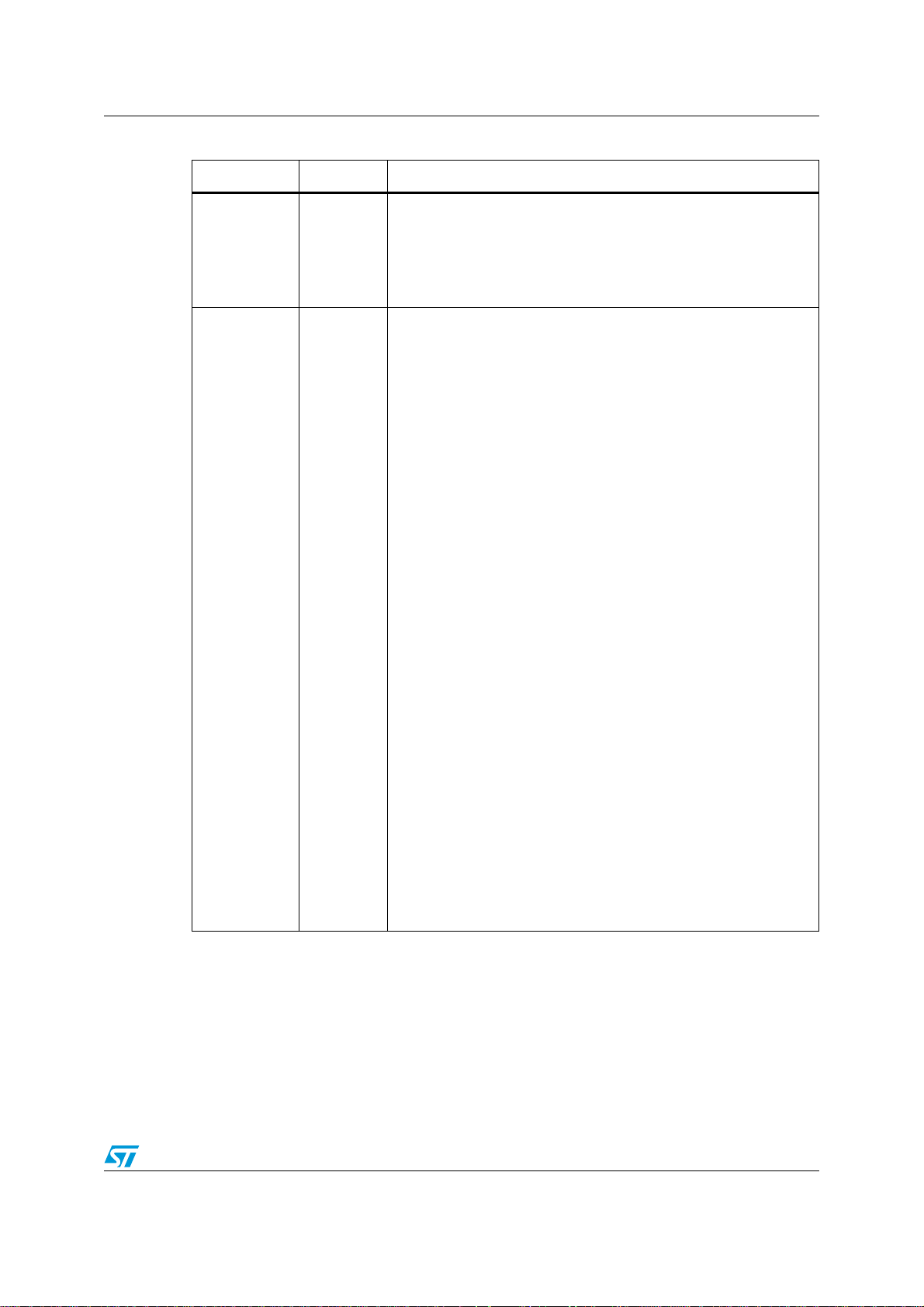

7.3 Bootloader selection

The STM32L15xx devices embedded bootloader supports two peripherals interfaces:

USART1 and USART2. Any one of these peripheral interfaces can be used to communicate

with the bootloader and download the application code to the internal Flash.

The embedded bootloader firmware is able to auto-detect the peripheral interface to be

used. In an infinite loop, it detects any communication on the supported bootloader

interfaces.

Note: The RX pins of the peripherals not used in this bootloader must be kept at a known

(low or high) level and should not be left floating during the detection phase as

described below. Refer to Section 7.2: Bootloader hardware requirements for more

information.

To use the USART bootloader on USART1 or USART2, connect the serial cable to the

desired interface. Once the bootloader detects the data byte 0x7F on this interface, the

32/88 Doc ID 13801 Rev 14

Page 33

AN2606 STM32L15xx Medium-density Ultralow power device bootloader

System reset

0x7F received

on USART1

0x7F received

on USART2

Configure USART1

Execute BL_USART_Loop

for USART1

Configure USART2

Execute BL_USART_Loop

for USART2

YES

NO

-36

System init (clock, GPIOs, IWDG,

SysTick

NO

Disable all interrupt

sources

Disable all interrupt

sources

YES

bootloader firmware executes the autobaudrate sequence and then enters a loop, waiting

for any USART bootloader command.

Once one interface is selected for the bootloader, the other interface is disabled.

The figure below shows the bootloader detection mechanism. More details are provided in

the sections corresponding to each peripheral bootloader.

Figure 4. Bootloader selection for STM32L15xxx devices

Doc ID 13801 Rev 14 33/88

Page 34

STM32L15xx Medium-density Ultralow power device bootloader AN2606

7.4 Important considerations

The bootloader of the Medium-density ultralow power devices has some specific features

that should be taken into consideration, as described below:

● In addition to standard memories (internal Flash, internal SRAM, option bytes and

System memory), the STM32L15xxx device bootloader firmware supports Data

Memory (4 Kbytes from 0x08080000 to 0x08080FFF). Refer to the PM0062

Programming manual for more information.

● Flash memory write operations are performed through a program memory half page

write operation. The bootloader firmware manages half page write operations at nonaligned addresses. Consequently, all write operations must only be Word-aligned (the

address should be a multiple of 4). The number of data to be written must also be a

multiple of 4 (non-aligned half page write addresses are accepted). Be aware of the

duration needed for a write operation by referring to the product datasheet.

● Data memory can be read and written but cannot be erased using the Erase

Command. When writing in a Data memory location, the bootloader firmware manages

the erase operation of this location before any write. A write to Data memory must be

Word-aligned (address to be written should be a multiple of 4) and the number of data

must also be a multiple of 4. To erase a Data memory location, you can write zeros at

this location.

● Option byte

Address is 0x1FF80000. They allow three levels of protection:

– Level 0

–Level 1

–Level 2

Refer to PM0062 programming manual for more details about protection levels.

● Read protect command corresponds to the Level 1 protection.

● Read unprotect command corresponds to the Level 0 protection.

● Mass erase command is not supported by STM32L15xxx device Bootloader firmware.

To perform a mass erase operation, two options are available:

– Erase all sectors one by one using the Erase command

– Set protection level to Level 1. Then, set it to Level 0 (using the Read protect

command and then the Read Unprotect command). This operation results in a

mass erase of the internal Flash memory (refer to Programming Manual PM0062

for more details).

34/88 Doc ID 13801 Rev 14

Page 35

AN2606 STM32L15xx Medium-density Ultralow power device bootloader

7.5 Bootloader version

The following table lists the STM32L15xxx bootloader versions.

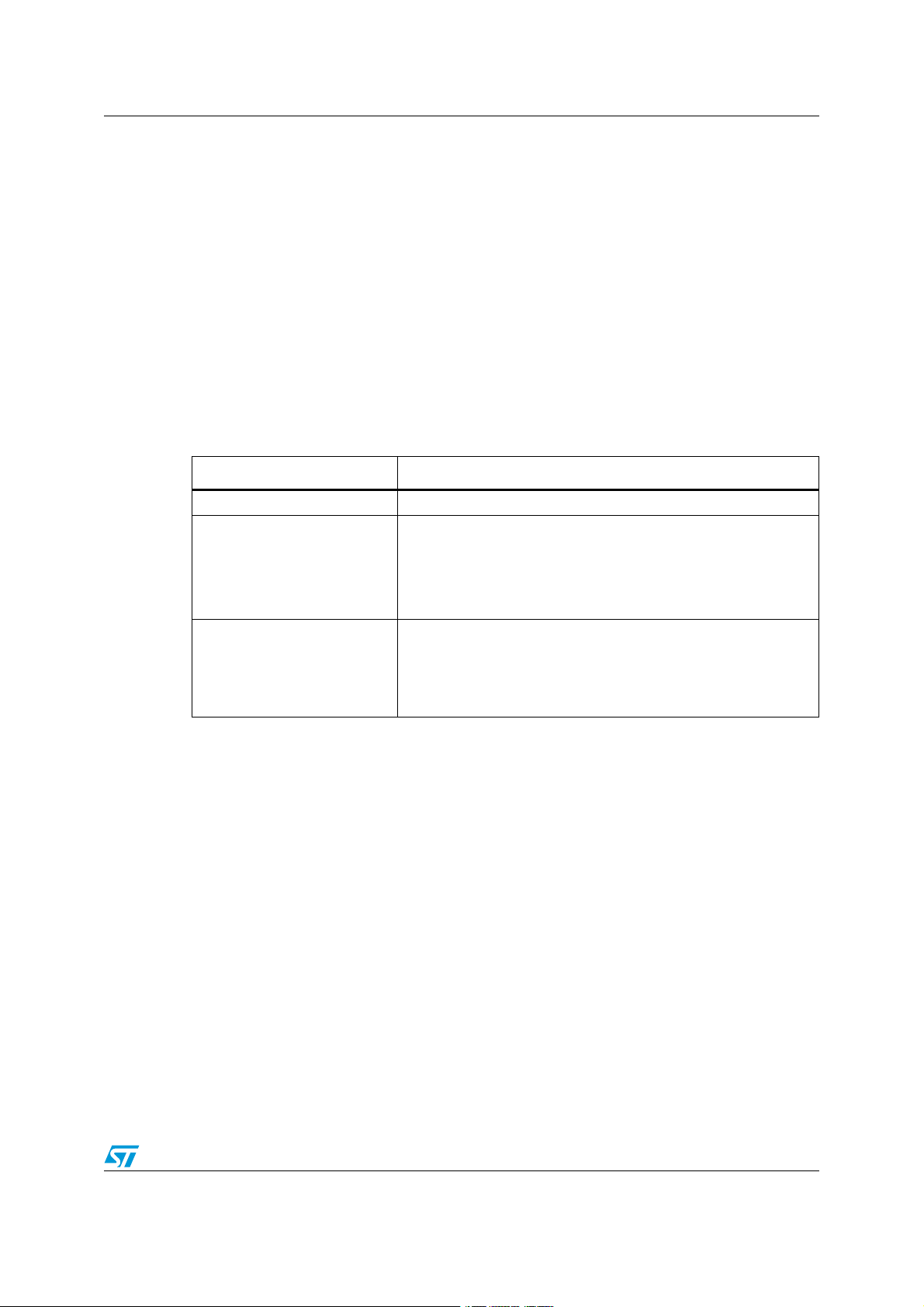

Table 12. STM32L15xxx bootloader versions

Bootloader

version

number

V2.0 Initial bootloader version.

1. If the “number of data - 1” (N-1) to be read/written is not equal to a valid command code (0x00, 0x01, 0x02,

0x11, 0x21, 0x31, 0x43, 0x44, 0x63, 0x73, 0x82 or 0x92), then the limitation is not perceived from the host

since the command is NACKed anyway (as an unsupported new command).

Description Known limitations

When a Read Memory command or Write Memory

command is issued with an unsupported memory

address and a correct address checksum (ie. address

0x6000 0000), the command is aborted by the bootloader

device, but the NACK (0x1F) is not sent to the host. As a

result, the next 2 bytes (which are the number of bytes to

be read/written and its checksum) are considered as a

new command and its checksum.

(1)

Doc ID 13801 Rev 14 35/88

Page 36

STM32L15xx and STM32L16xx High-density ultralow power device bootloader AN2606

8 STM32L15xx and STM32L16xx High-density ultralow

power device bootloader

Throughout this section, STM32L1xx High-density is used to refer to STM32L15xx and

STM32L16xx High-density ultralow power devices.

8.1 Dual bank boot feature

The STM32L1xx High-density devices have two Flash memory banks: Bank 1 and Bank 2.

They feature an additional boot mechanism which allows booting from Bank 2 or Bank 1

depending on BFB2 bit status (bit 7 in the user option bytes located at 0x1FF8 0004).

● When the BFB2 bit is reset and the boot pins are configured to boot from Flash

memory (BOOT0 = 0 and BOOT1 = x), after reset the device boots from the System

memory and executes the embedded bootloader code which implements the dual bank

Boot mode:

a) The code first checks Bank 2. If it contains a valid code (see note below), it jumps

to the application code located in Bank 2 and leaves the Bootloader.

b) If the Bank 2 code is not valid, it checks Bank 1 code. If it is valid (see note below),

it jumps to the application located in Bank 1.

c) If both Bank 2 and Bank 1 do not contain valid code (see note below), the normal

Bootloader operations are executed as described in the following sections and no

jump to Flash banks is performed. Refer to Figure 5: Bootloader selection for

STM32L1xx High-density devices for more details.

3. When BFB2 bit is set (default state), the dual bank boot mechanism is not performed.

Note: The code is considered as valid when the first data (at the bank start address, which should

be the stack pointer) points to a valid address into the internal SRAM memory (stack top

address). If the first address points to any other location (out of the internal SRAM) the code

is considered not valid.

A dual bank Boot mode example (FLASH\Dual_Boot) is provided within the STM32L1xx

Standard Peripheral Library available from http://www.st.Com.

For the STM32L1xx High-density devices, the Flash memory, system memory or SRAM is

selected as the boot space, as shown in Ta bl e 13 below.

36/88 Doc ID 13801 Rev 14

Page 37

AN2606 STM32L15xx and STM32L16xx High-density ultralow power device bootloader

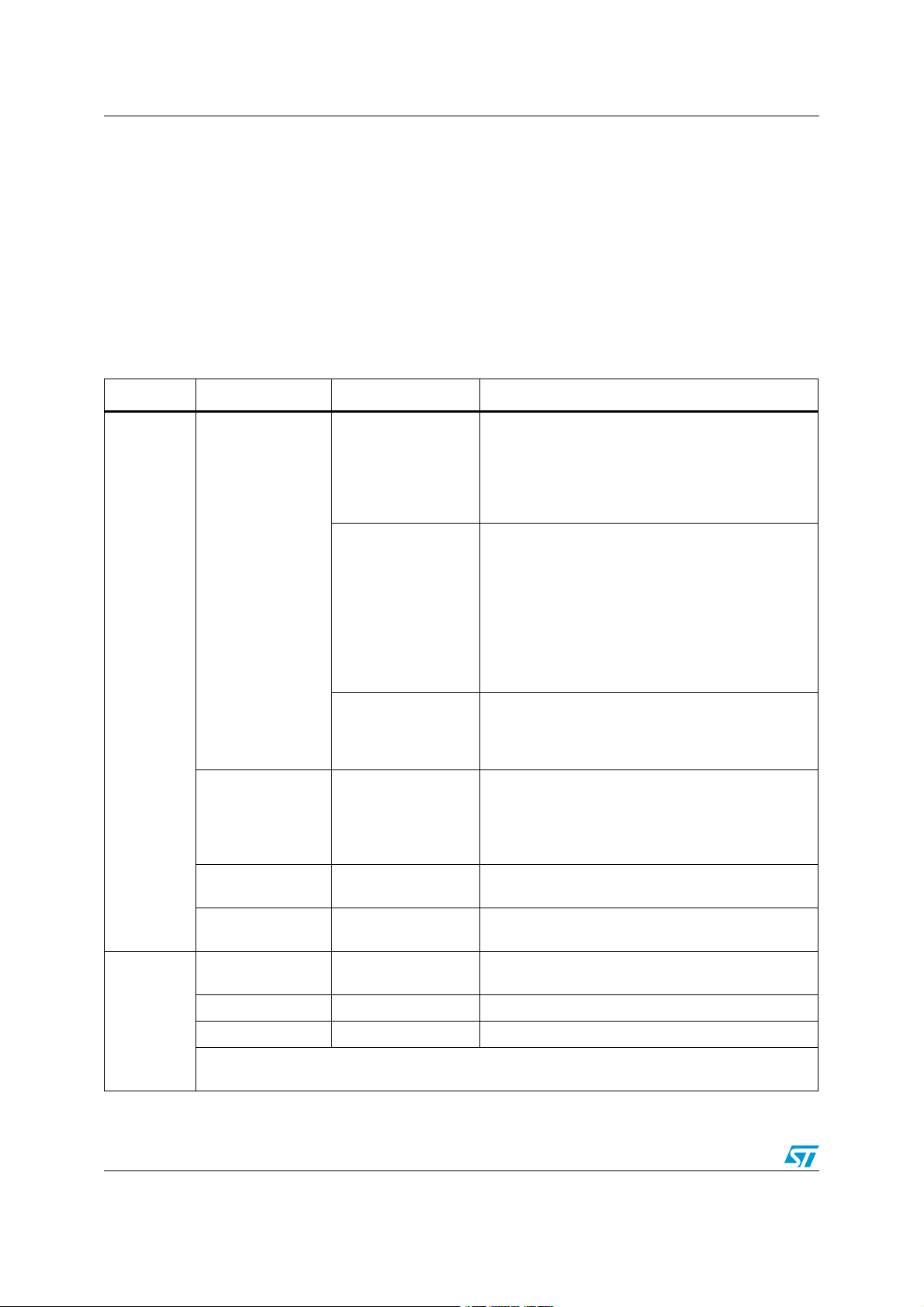

Table 13. Boot pin and BFB2 bit configuration

Boot mode

BFB2

bit

selection pins

Protection

level2

Bank2

Valid

Bank1

Val id

BOOT1 BOOT0

X0 X XX

0 1 No X X System memory

1

01 YesXX

1 1 No X X Embedded SRAM

11 YesXX

Yes X System memory

X

No Yes System memory

X0

No No No System memory

Boot mode Aliasing

User Flash

memory

User Flash memory Bank1 is

selected as the boot space

System memory is selected as the

boot space

User Flash

memory

User Flash memory Bank1 is

selected as the boot space

Embedded SRAM is selected as the

boot space

User Flash

memory

User Flash memory Bank1 is

selected as the boot space

User Flash memory Bank2 is

selected as the boot space

User Flash memory Bank1 is

selected as the boot space

System memory is selected as the

boot space

Yes No No System memory CPU blocked (halted)

0

0 1 No X X System memory

1 1 No X X Embedded SRAM

Yes X System memory

X1 Yes

No Yes System memory

System memory is selected as the

boot space

Embedded SRAM is selected as the

boot space

User Flash memory Bank2 is

selected as the boot space

User Flash memory Bank1 is

selected as the boot space

No No System memory CPU blocked (halted)

Ta bl e 1 3 shows that the STM32L1xx High-density devices enter System memory boot mode

in two cases:

● If the BOOT pins are configured as follows:

BOOT0 = 1 and BOOT1 = 0

● If the BFB2 bit is reset and protection Level2 is enabled

● If the BFB2 bit is reset and boot pins are configured as follows:

BOOT0 = 0 and BOOT1 = x

Doc ID 13801 Rev 14 37/88

Page 38

STM32L15xx and STM32L16xx High-density ultralow power device bootloader AN2606

Note: When the conditions a, b, and c described below are fulfilled, it is equivalent to configuring

boot pins for system memory boot (BOOT0 = 1 and BOOT1 = 0). In this case normal

Bootloader operations are executed.

a) BFB2 bit is reset

b) Both banks don’t contain valid code

c) Boot pins configured as follows: BOOT0 = 0 and BOOT1 = x

When the BFB2 bit is cleared, and Bank 2 and/or Bank 1 contain valid user application

code, the Dual Bank Boot is always performed (bootloader always jumps to the user code

and never continues normal operations).

Consequently, if you have cleared the BFB2 bit (to boot from Bank 2) then, to be able to

execute the Bootloader code, you have to:

– either, set the BFB2 bit to 1

– or, program the content of address 0x0803 0000 (base address of Bank2) and

0x0800 0000 (base address of Bank1) to 0x0.

8.2 Bootloader configuration

The bootloader embedded in STM32L1xx High-density devices supports three serial

interfaces: USART1, USART2 and DFU (USB)

The following table shows the required hardware resources of STM32L1xx High-density

devices used by the bootloader in System memory boot mode.

38/88 Doc ID 13801 Rev 14

Page 39

AN2606 STM32L15xx and STM32L16xx High-density ultralow power device bootloader

Table 14. STM32L1xx High-density configuration in System memory boot mode

Bootloader Feature/Peripheral State Comment

The system clock frequency is 16 MHz

using the HSI. This is used only for

USART1 and USART2 bootloaders and

HSI enabled

during USB detection for DFU bootloader

(once the DFU bootloader is selected, the

clock source will be derived from the

external crystal).

The external clock is mandatory only for

RCC

HSE enabled

DFU bootloader and it must be in the

following range: [24, 16, 12, 8, 6, 4, 3, 2]

MHz.

The PLL is used to generate the USB

48 MHz clock and the 32 MHz clock for the

system clock.

The clock security system (CSS) interrupt is

Common to all

bootloaders

-

enabled for the DFU bootloader. Any failure

(or removal) of the external clock generates

system reset.

The independent watchdog (IWDG)

prescaler is configured to its maximum

IWDG -

value and is periodically refreshed to

prevent watchdog reset (in case the

hardware IWDG option was previously

enabled by the user).

Power Voltage range is set to Voltage Range 2

USART1 bootloader

USART1 and

USART2 bootloaders

8 Kbytes starting from address

System memory -

0x1FF0 0000. This area contains the