Page 1

AN2604

Application note

STM32F101xx and STM32F103xx RTC calibration

Introduction

The real-time clock (RTC) precision is a requirement in most embedded applications, but

due to external environment – temperature change, frequency variation of the crystal that

clocks the RTC – the RTC precision may not be as accurate as expected.

The RTC embedded in the STM32F101xx and STM32F103xx comes with a digital clock

calibration circuit suitable for manufacturing environments, that allows applications to

compensate for crystal and tempe rature v ariations . This applica tion note discusses the R TC

calibration basics and explai ns how RTC calibration can be us ed to improve timekeeping

accuracy.

August 2007 Rev 1 1/14

www.st.com

Page 2

Contents AN2604 - Application note

Contents

1 RTC calibration basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Crystal accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Methodology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Calculating the needed amount of calibration . . . . . . . . . . . . . . . . . . . 10

3 Calculating calibration over a temperature range . . . . . . . . . . . . . . . . 11

4 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2/14

Page 3

AN2604 - Application note List of tables

List of tables

Table 1. Calibration table: compensation values in ppm and seconds per month (3 0 days) . . . . . . . 7

Table 2. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3/14

Page 4

List of figures AN2604 - Application note

List of figures

Figure 1. Typical crystal accuracy plotted against temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2. RTC calibration clock output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. Crystal accuracy over a temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4/14

Page 5

AN2604 - Application note RTC calibration basics

1 RTC calibration basics

1.1 Crystal accuracy

The term “quartz-accurate” has become a familiar phrase used to describe the accuracy of

many time keeping functions. Quartz oscillators provide an accuracy far superior to that of

other conventional oscillator designs, but they are not perfect. Quartz crystals are sensitive

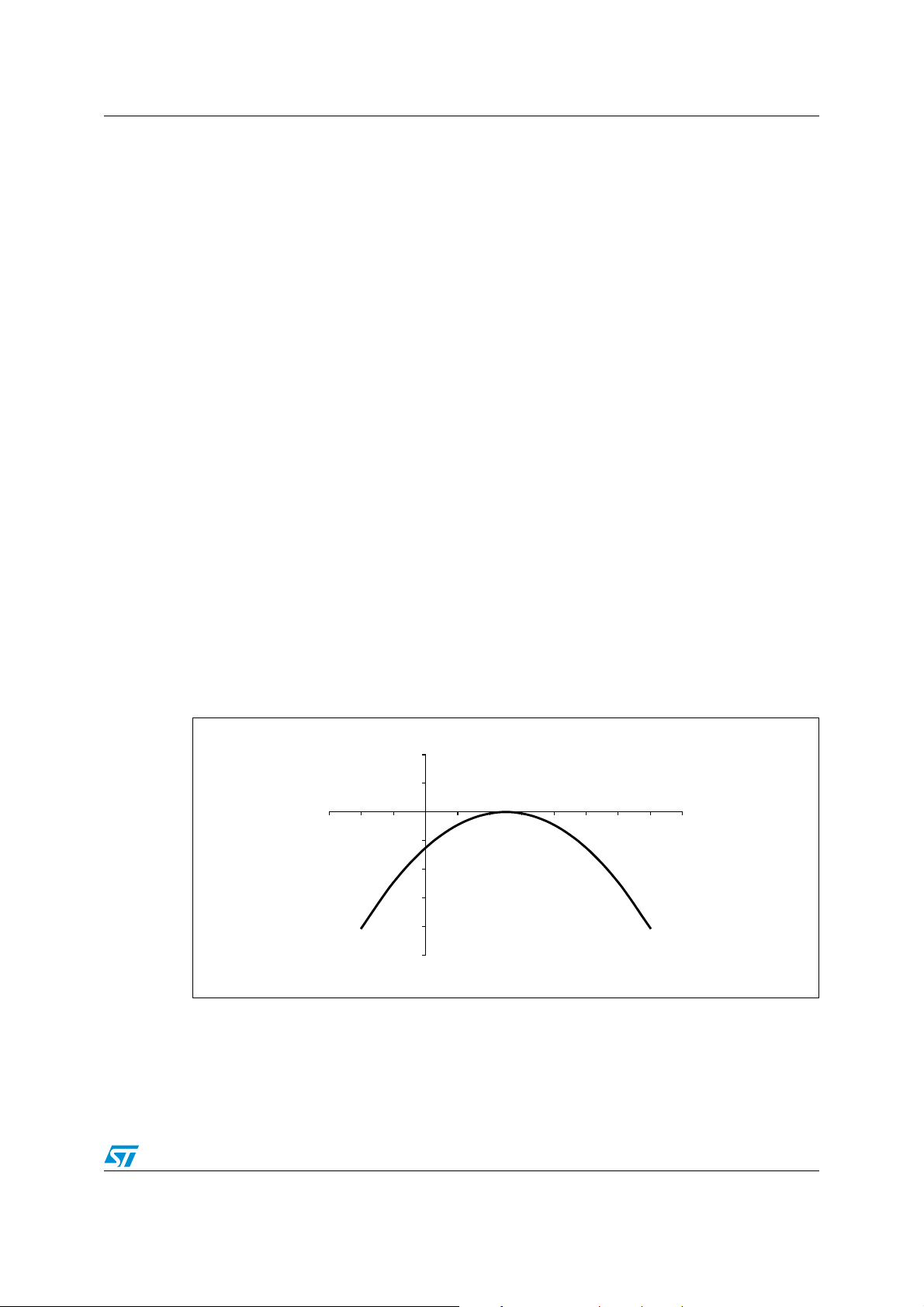

to temperature variations. Figure 1 shows the relationship between accuracy (acc),

temperature (T) and curvature (K) for a typical 32.768 kHz crystal. The curve follows the

general formula given below:

acc k T To–()

● To = 25 °C ± 5 °C

● K = –0.040 ppm/°C

×=

Note: The variable K is crystal-dependent, the value indicated here is for the crystal mounted on

the STM3210B-EVAL board. Refer to the crystal manufacturer for more details on this

parameter.

The clocks used in most applications require a high degree of accuracy, and there are

several factors involved in achieving this accuracy. Typically most crystals are compensated

for by adjusting the load capacitance of the oscillator. This method, though effective, has

several disadvantages:

1. it requires external components (trim capacitors)

2. it can increase the oscillator current (a major factor in battery-supported applications)

2

, where:

2

Instead of this crude analog method, STM32F10xxx products use a digital calibration

feature that gives the user software control over the calibrati on proced ur e , a nd make it userfriendly.

Figure 1. Typical crystal accuracy plotted against temperature

40

20

Temperature (˚C)

ai14625

–30 –20 –10

0

0

–20

–40

–60

–80

–100

10 20 30 40 50 60 70 80

Accuracy (ppm)

5/14

Page 6

RTC calibration basics AN2604 - Application note

1.2 Methodology

The RTC of STM32F10xxx products is driven by a quartz crystal-controlled oscillator with a

nominal frequency of 32.768 kHz. The crystal oscillator is one of the most accurate circuits

to provide a fixed frequency. There are two causes of clock error:

1. temperature variation

2. crystal variation

As mentioned previously, most clock chips compensate for crystal frequency and

temperature variations by using cumbersome trim capacitors. The STM32F10xxx design

employs periodic counter correcti ons. The digital calibration circuit r emoves 0 to 127 cycles

every 2

upon the value that has been loaded into the seven least significant bits of the BKP’s RTC

clock calibration register. Since the RTC clock calibration register is in the backup domain,

the calibration value is not lost even if the device is powered off provided that a battery is

connected to the V

Figure 2. RTC calibration clock output

20

clock cycles (see Figure 2.). The number of times the pulses are b lanked depends

pin.

BAT

CAL[6:0]bits in

BKP_RTCCR register

HSE/128

LSE

32 768 Hz

ANTI_TAMP

512 Hz output

for frequency test

1. The clock output on the ANTI_TAMP pin is the RTC clock before calibration, so its value is not changed by

the calibration.

Oscillator

Enabled by CCO bit in

BKP_RTCCR register

LSI

RTCCLK

Div64

Clock

calibration

RTC

ai14626

Each calibration step has the effect of subtracting 1 oscillator cycle every 1 048 576 (220)

actual oscillator cycles. That is, 0.954(1000000/2

20

) ppm of adjustment per calibration step

in the calibration register. As a result, the oscillator clock can be slowed down from 0 to

121 ppm.

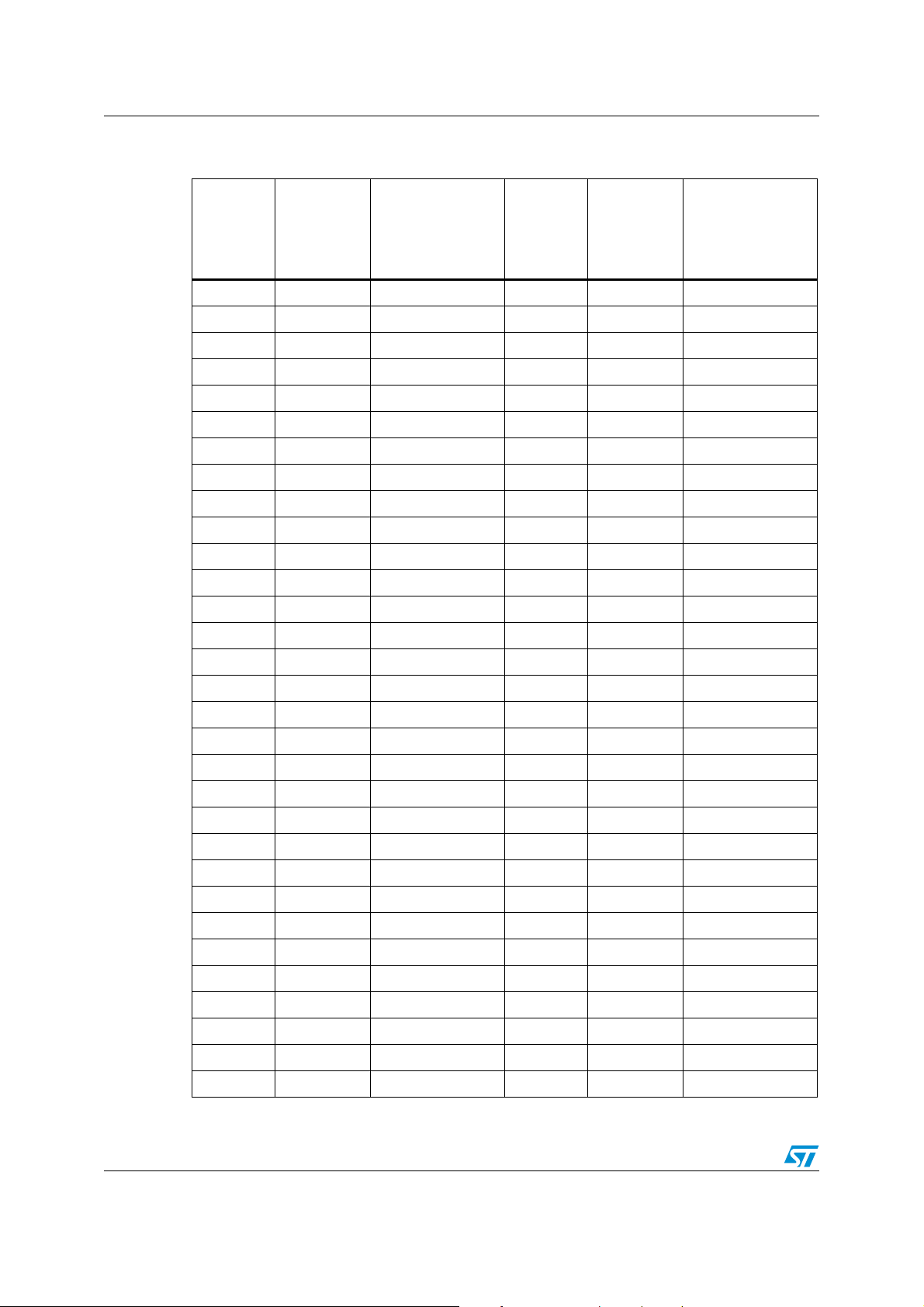

Table 1 on page 7 shows how many ppm and seconds per month (30 days) each bit

represents in real time.

6/14

Page 7

AN2604 - Application note RTC calibration basics

Table 1. Calibration table: compensation values in ppm and seconds per month

(30 days)

Calibration

value

Value in ppm

rounded to

the nearest

ppm

Value in seconds

per month (30

days) rounded to

the nearest

second

Calibration

value

Value in ppm

rounded to

the nearest

ppm

Value in seconds

per month (30

days) rounded to

the nearest

second

00 0 6461 158

11 2 6562 161

22 5 6663 163

33 7 6764 166

4 4 10 68 65 168

5 5 12 69 66 171

6 6 15 70 67 173

7 7 17 71 68 176

8 8 20 72 69 178

9 9 22 73 70 180

10 10 25 74 71 183

11 10 27 75 72 185

12 11 30 76 72 188

13 12 32 77 73 190

14 13 35 78 74 193

15 14 37 79 75 195

16 15 40 80 76 198

17 16 42 81 77 200

18 17 44 82 78 203

19 18 47 83 79 205

20 19 49 84 80 208

21 20 52 85 81 210

22 21 54 86 82 213

23 22 57 87 83 215

24 23 59 88 84 218

25 24 62 89 85 220

26 25 64 90 86 222

27 26 67 91 87 225

28 27 69 92 88 227

29 28 72 93 89 230

30 29 74 94 90 232

7/14

Page 8

RTC calibration basics AN2604 - Application note

Table 1. Calibration table: compensation values in ppm and seconds per month

(30 days) (continued)

Value in ppm

Calibration

value

31 30 77 95 91 235

32 31 79 96 92 237

33 31 82 97 93 240

34 32 84 98 93 242

35 33 87 99 94 245

36 34 89 100 95 247

37 35 91 101 96 250

38 36 94 102 97 252

39 37 96 103 98 255

40 38 99 104 99 257

41 39 101 105 100 260

42 40 104 106 101 262

43 41 106 107 102 264

44 42 109 108 103 267

rounded to

the nearest

ppm

Value in seconds

per month (30

days) rounded to

the nearest

second

Calibration

value

Value in ppm

rounded to

the nearest

ppm

Value in seconds

per month (30

days) rounded to

the nearest

second

45 43 111 109 104 269

46 44 114 110 105 272

47 45 116 111 106 274

48 46 119 112 107 277

49 47 121 113 108 279

50 48 124 114 109 282

51 49 126 115 110 284

52 50 129 116 111 287

53 51 131 117 112 289

54 51 133 118 113 292

55 52 136 119 113 294

56 53 138 120 114 297

57 54 141 121 115 299

58 55 143 122 116 302

59 56 146 123 117 304

60 57 148 124 118 307

61 58 151 125 119 309

8/14

Page 9

AN2604 - Application note RTC calibration basics

Table 1. Calibration table: compensation values in ppm and seconds per month

(30 days) (continued)

Value in ppm

Calibration

value

62 59 153 126 120 311

63 60 156 127 121 314

rounded to

the nearest

ppm

Value in seconds

per month (30

days) rounded to

the nearest

second

Calibration

value

Value in ppm

rounded to

the nearest

ppm

Value in seconds

per month (30

days) rounded to

the nearest

second

As described above, the STM32F10xxx RTC clock calibration circuit subtracts cycles only

from crystal clocks. And based on the fact that the RTC prescaler value is set by default to

32 768, faster crystal frequencies (> 32 768 Hz) can be calibrated whereas slower crystal

frequencies (< 32 768 Hz) cannot be compensated for. So only crystal frequencies in the

range [32 772, 32 768] can be calibrated.

Since the crystal frequency may vary about 32.768 kHz, a solution may be considered that

consists in setting the RTC presca ler to 32 766 ( instead of 32 768). The crystal frequency is

thus compared to 32 766 instead of 32 768. In this w ay, a crystal frequency in the range [32

770, 32 766] can be compensated.

Throughout the rest of the document, the considered RTC prescaler value will be 32 766.

9/14

Page 10

Calculating the needed amount of calibration AN2604 - Application note

2 Calculating the needed amount of calibration

To establish how much calibration is required in a given application, a method specially

suited to manufacturing en vironments is retained. It inv olv es the use of the R TC clock outp ut

mode, which derives a 512 Hz signal from t he cloc k divider ch ain as indica ted in Figure 2 on

page 6. This signal can be used to measure the accuracy of the crystal oscillator.

This method can be divided up into the following steps:

1. Enable the low speed external oscillator (LSE), select the LSE as the RTC clock

source, then enable the RTC clock.

2. Enable the RTC clock output with a fre quency divided by 64, on the ANTI_TAMP pin for

crystal frequency measurement. This is achieved by setting the CCO bit in

BKP_RTCCR.

3. Calculate the crysta l fre quen cy deviation in ppm. The deviation in ppm can be quickly

calculated by dividing the measured deviation from 511.968 Hz by 511.968 and, by

multiplying the result by 1 million. Find the nearest calibration value using Table 1 on

page 7. This table is a direct look- up table for calibration values based upon variation

values expressed in ppm.

4. Load the calibration value in the RTC calibration register to compensate for the crystal

deviation.

Note: To set the RTC prescaler to 32 766, write 32 765 into the RTC prescaler load register.

For example, if the frequency measured during the test mode is 511.982 Hz, the delta is

0.014. By dividing by 511.968 and multiplying by 1 million, the result is 27.35 ppm. In this

case, the nearest compensation value is 28. The inaccuracy will be reduced from 27.35 ppm

(~71 seconds per month) to 0.65 ppm (~1.7 second per month).

Note: Since RTC calibration is based on removing clock cycles, it does not improve counting over

short periods of time, it only improves counting over long periods. For example counting a

1/100 s using the RTC will be more accurate without calibration than with calibration. Since

calibration cycle removal may or not occur during the considered time frame, the resulting

value may change significantly. So depending on the application it may be better not to use

calibration.

10/14

Page 11

AN2604 - Application note Calculating calibration over a temper ature range

3 Calculating calibration over a temperature range

The calibration procedure described so far aims at calculating the correction for a specific

temperature. This section pro vides a procedur e for minimizing the frequency v ariation ov er a

wider temperature range. This involves adjusting the frequency curve so that there is an

equal amount of error above and below the zero (0) ppm point. Figure 3 on page 11 shows

how the frequency error can be minimized over a given temperature range.

The variables in the equation: (see Section 1.1 on page 5) are the

acc k T To–()

×=

following:

acc = Accuracy, in ppm, of the frequency, at the turnover temperature

K = Curvature characteristic = –0.04 ppm/°C

To = Turnover temperature in degrees Celsius = 25 °C ± 5 °C

T = Working temperature in degrees Celsius

For example, if a device shows a deviation of +27 ppm at room temperature, but the

operating temperature is 40 °C in the applicatio n, the equation ma y be used to calculate the

required calibration value as follows:

acc 27ppm 0.04ppm–()°C

acc 18ppm=

2

2

2

⁄()40° C25° C–()

×+=

2

Since the accuracy deviat ion is 18 ppm, the nearest calibrati on v alue as indicated in Table 1

on page 7, is 19.

Figure 3. Crystal accuracy over a temperature range

40

30

20

–30 –20 –10

10

0

0

10 20 30 40 50 60 70 80

–10

–20

–30

–40

–50

–60

–70

–80

–90

Accuracy (ppm)

After calibration

Temperature ˚C

Before calibration

ai14629

11/14

Page 12

Conclusion AN2604 - Application note

4 Conclusion

The STM32F10xxx RTC digital clock calibration feature allows the user to adjust the clock

accuracy during manufacturing (or later) at minimal cost. This feature also provides a

method whereby “drift” (due to temperature variation) can be corrected and/or anticipated.

However, the method described in this application note is applicable only if the RTC

prescaler is set to 32 766 (instead of 32 768).

12/14

Page 13

AN2604 - Application note Revision history

5 Revision history

Table 2. Document revision history

Date Revision Changes

31-Aug-2007 1 Initial release.

13/14

Page 14

AN2604 - Application note

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely res ponsibl e fo r the c hoic e, se lecti on an d use o f the S T prod ucts and s ervi ces d escr ibed he rein , and ST as sumes no

liability whatsoever relati ng to the choice, selection or use of the ST products and servi c es described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third pa rty p ro duc ts or se rv ices it sh all n ot be deem ed a lice ns e gr ant by ST fo r t he use of su ch thi r d party products

or services, or any intellectua l property c ontained the rein or consi dered as a warr anty coverin g the use in any manner whats oever of suc h

third party products or servi ces or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICUL AR PURPOS E (AND THEIR EQUIVALE NTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJ URY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST fo r the ST pro duct or serv ice describe d herein and shall not cr eate or exten d in any manne r whatsoever , any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document su persedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of compan ie s

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

14/14

Loading...

Loading...