Page 1

AN2559

Application note

System power supply board for digital solutions

Introduction

This document describes a power supply reference board designed for powering digital

applications, such as CPUs, FPGAs, memories, etc. The main purpose of the board is to

illustrate the basic principles used for the design of the power supply and to give designers a

usable prototype for testing and use.

The trend in recent years in the supplying of power to MCUs, CPUs, memories, FPGAs, etc.

is to reduce the supply voltage, increase the supply current and provide different voltage

levels for different devices in one platform. A typical example of this situation is the FPGA.

The FPGA contains a core part which works at a low level voltage, the interface part placed

between the core and the output, the system part, etc. It is important to note that each

FPGA family has a slightly different voltage level and the trend is to decrease the voltage for

each new family. The lowest operating voltage currently available is 1 V, and this can be

expected to decrease to 0.9 V or 0.8 V in the near future. A similar situation exists with other

digital applications. Typically, the main CPU, memory and interfaces require different supply

voltage levels. Low operating voltages also present another challenge - transient. Digital

devices are typically sensitive to voltage level. If the voltage drops below or crosses over a

specific limit, the device is reset. This limit is typically ± 3 or ± 5%. On the other hand, digital

device consumption can change very quickly (several amps in a few hundred nanoseconds).

A power supply must be able to react very quickly with a minimum of over (or under) voltage,

especially in cases where very low output voltage is required. There is additional stress

placed on power supplies for digital applications in the industrial environment.

The industrial standard bus is 24 V, but this voltage fluctuates and the maximum input

voltage level required can reach 36 V. Additional surge protection is also a mandatory part of

power supply input for industrial applications.

The goal of the board described in this application note is to cover all of the issues outlined

above. It is intended mainly to satisfy industrial input requirements (operating voltages up to

36 V) and generate several output voltages for mid-range power applications (up to several

amps). The main output voltage level can simply be set.

September 2007 Rev 1 1/35

www.st.com

Page 2

Contents AN2559

Contents

1 Main characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Input part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 PM6680A block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.0.1 Power management block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.0.2 Start-up/enable block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.0.3 Step-down parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 DC-DC converters based on the L5970AD . . . . . . . . . . . . . . . . . . . . . . . 14

3.2 Reset circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4 PCB layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5 Bill of materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6 Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.1 PM6680A block - measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.1.1 Efficiency and light load consumption modes . . . . . . . . . . . . . . . . . . . . 23

6.1.2 Output voltage ripple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.1.3 Start-up sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.1.4 Transient response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2 L5970AD blocks - measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.2.1 Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.2.2 Output voltage ripple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2.3 Transient . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2/35

Page 3

AN2559 List of figures

List of figures

Figure 1. The STEVAL-PSQ001V1 demo board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2. Block diagram of System Supply board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 3. Schematic of input part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 4. Location and correct polarity of the input supply connector on the board . . . . . . . . . . . . . . 6

Figure 5. Electrical diagram of the PM6680A section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 6. The placement of the jumpers for start-up/enable settings. . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 7. Skip mode connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 8. Output connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 9. Jumper placement for V

Figure 10. Jumper placement for V

Figure 11. Output voltages of L5970A parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 12. Schematic of the two SMPS’s based on the L5970AD . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 13. Jumper placement for enable/disable function of analog output and output3 . . . . . . . . . . 16

Figure 14. Schematic of the reset circuit and board placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 15. PCB top layer layout and first internal layer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 16. PCB second internal layer and bottom layer layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 17. Efficiency of the dual step-down converter at full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 18. PM6680A consumption at no load condition, in the different modes . . . . . . . . . . . . . . . . . 24

Figure 19. Output voltage ripple in different modes of light load operation . . . . . . . . . . . . . . . . . . . . . 24

Figure 20. Output voltage ripple of V

Figure 21. Output voltage ripple of V

Figure 22. Output voltage ripple of V

Figure 23. Output voltage ripple of V

Figure 24. Start-up without setting the sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 25. Start-up with a set sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 26. Load transient response on V

Figure 27. Load transient response on V

Figure 28. Efficiency of output 3, by input voltage level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 29. Efficiency of analog output, by input voltage level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 30. Analog 5 V - output voltage ripple. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 31. V

- output voltage ripple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

SYS

Figure 32. Analog 3.3 V - output voltage ripple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 33. V

2.5 V - output voltage ripple. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

AUX

Figure 34. Transient response of V

Figure 35. Transient response of V

voltage level setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

CORE

voltage level setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

I/O

at the minimum input voltage (5 V) . . . . . . . . . . . . . . . . . . 25

CORE

at the maximum output voltage (36 V) . . . . . . . . . . . . . . . 25

CORE

at the minimum input voltage (5 V) . . . . . . . . . . . . . . . . . . . . 25

I/O

at the maximum input voltage (36 V). . . . . . . . . . . . . . . . . . . 26

I/O

output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

CORE

output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

I/O

based on the L5970AD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

SYS

generated by the LDO KF25 . . . . . . . . . . . . . . . . . . . . . . . . . 33

AUX

3/35

Page 4

Main characteristics AN2559

1 Main characteristics

The main characteristics of the SMPS are listed below:

● Input: 5 V - 36 V DC, surge protection

● Outputs: the performance of the 6 outputs are described in Tab le 1 below.

Table 1. Output voltages (positive version)

Label V

Output1 (V

) Selectable from:

CORE

0.9, 1.0, 1.2, 1.5, 1.8 or 2.5 V

Output2 (V

) Selectable from:

I/O

1.0, 1.2, 1.5, 1.8, 2.5 V or 3.3 V

Output3 V

Output3 V

SYS

AUX

3.3 V 0.4 A (0.8 A peak) 4%

2.5 V 0.4 A 2%

OUT

4 A continuous

6 A peak

2 A continuous

3 A peak

I

max Tolerance

OUT

3%

3%

Analog 5 V 5 V 0.8 A 4%

Analog 3.3 V 3.3 V 0.15 A 2%

4/35

Page 5

AN2559 Description

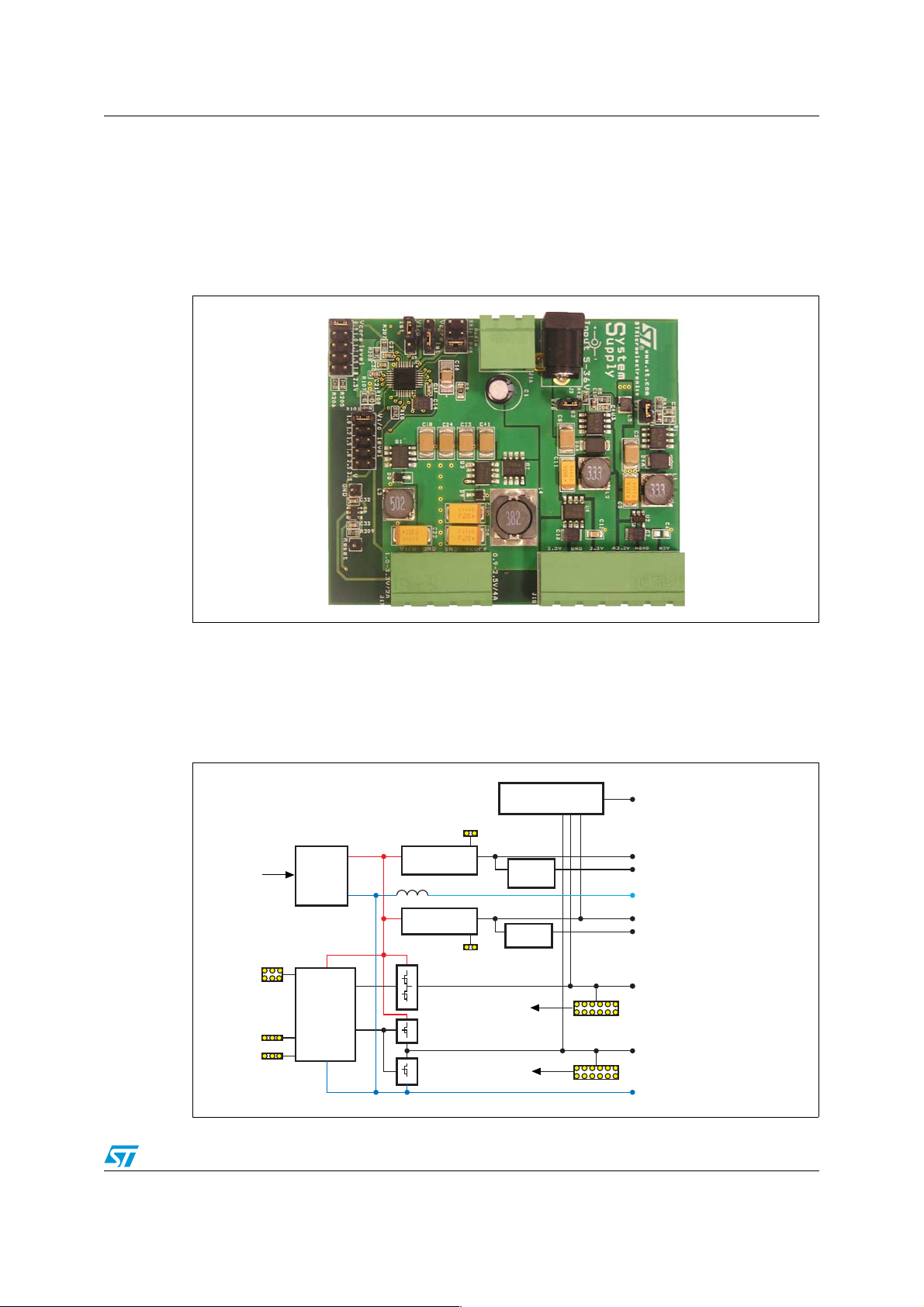

2 Description

The System Supply board described in this application note is a dedicated design which

illustrates a typical solution for complete system supply, and can also be used as a direct

supply for customer solutions during the design process.

Figure 1. The STEVAL-PSQ001V1 demo board

The block diagram of the System Supply board is shown in Figure 2. There are four DC-DC

converters, two linear regulators and a reset circuit. These parts are split into five relatively

independent units: the input part, a dual DC-DC converter based on the PM6680A and

generating 2 outputs (Output 1 and Output 2), two single DC-DC converters based on the

L5970A (Output 3 and Output 4) with linear regulator, and the reset circuit.

Figure 2. Block diagram of System Supply board

Reset signal

Analog

5 V analog 500 mA

3.3 V analog 150 mA

Output 3

V

3.3 V 400 mA

sys

V

2.5 V 400 mA

aux

Output 2

V

1.0 - 3.3 V 2 A

i/o

V

voltage settings

i/o

Output 1

V

0.9 - 2.5 V 4 A

core

V

voltage settings

core

AI12693

Input

5 - 36 V

Input

protection

Skip mode

settings

PM6680A

V

core

Vi/o

E/D + start up

sequence settings

E/D analog

L5970AD

L5970AD

E/D V

FB V

FB V

sys

i/o

core

STM6719

LK112

M33

KF25

+ V

aux

5/35

Page 6

Description AN2559

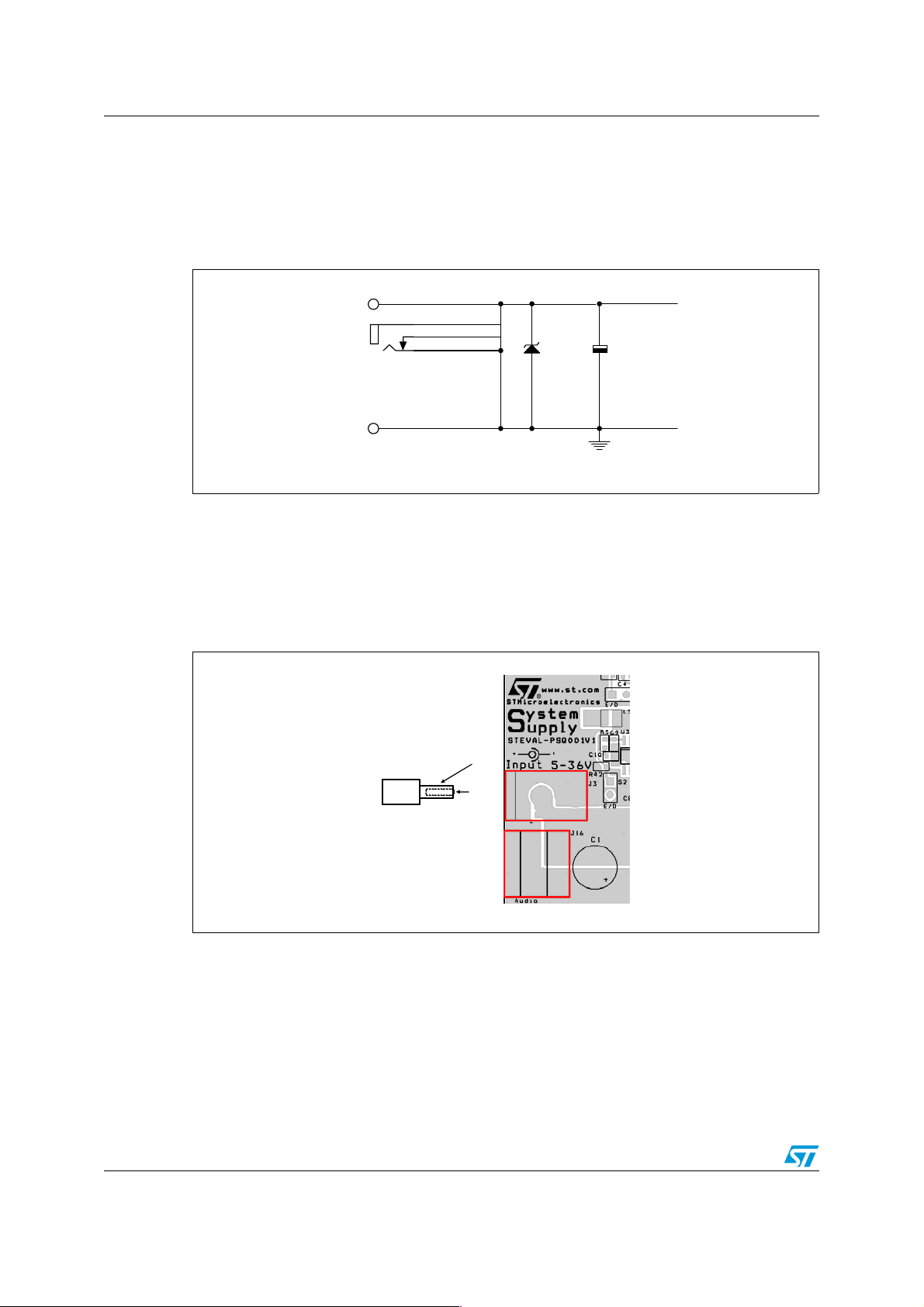

2.1 Input part

The input part shown in Figure 3 consists of the input connectors (industrial - J16 or power

jack - J3), input storage capacitor (C1) and transil (D1). The input electrolytic capacitor and

transil serve to reduce input voltage spikes (surge).

Figure 3. Schematic of input part

Vin

J16

J3

Figure 4 displays the placement of the input connectors on the board. The board can be

supplied either from the jack connector (J3) or the industrial removable terminal plate (J16).

The polarity of the input voltage must be correctly applied in accordance with the illustration

in Figure 4. If the connection is made incorrectly, the input protection D1 shorts the input

voltage. It should be pointed out that the total input current is about 4 A at maximum output

power and minimum input voltage.

1

2

3

D1

SM6T39AC147 µF / 50 V

AI12691

Figure 4. Location and correct polarity of the input supply connector on the board

-

+

+

-

+

+

6/35

Page 7

AN2559 PM6680A block

3 PM6680A block

Figure 5. Electrical diagram of the PM6680A section

core

S13

1 V

V

S14

1.2 V

S15

1.5 V

S16

1.8 V

S17

2.5 V

R206

6.8 kΩ

R205 200R

C29

330 µF /

6.3 V

C24

4.7µF / 50 V / X7R

C34 12 nF

R38 3.3 kΩ

L4 3.8 µH / 6 A

C23

R2762 kΩ

4.7µF / 50 V / X7R

Vin

SHDN

Q2

STS7NF60L

D10

4V7

51 kΩ

R29

C17

100 nF

C16

R9

3.3 Ω

Vin

VLDO

3.3 µF / 35 V

C15

470 nF

C14

4.7 µF / 10 V

C25

100nF

D7

BAW56/SOT

R37 47R

Vin

R210R

R26

23

10R

BOOT1

Vin

19

LDO5

18

CC

V

31

BOOT2

9

R25

10R

C31

220 nF

R230R

100 nF

C19

4

STS4DNF60

Q1

6

5

C18

4.7 µF / 50 V/X7R

C41

4.7 µF / 50 V/X7R

D9

STPS1L40

Q3

STS7NF60L

R220R

R19 1 kΩ

21

20

29

15

14

PGND

LGATE1

HGATE122PHASE1

CSENSE1

HGATE210PHASE211LGATE213CSENSE212V5SW17OUT28COMP22PGOOD227FB27SHDN

R240R

R10 1.8 kΩ

2

7

138

D8

STPS1L40

R40100 kΩ

L3 5.0 µH / 3 A

C35 10 nF

R39 3.3 kΩ

R110

4.7 kΩ

R105

S8

2.5 V

R109 3.3 kΩ

S12

1.8 V

S11

1.5 V

S10

1.2 V

io

S9

1 V

V

R208

820 kΩ

R201

1 kΩ

2 kΩ

9.1 kΩ

R202

R207

R203

3 kΩ

R204

3 kΩ

22 µF / 6.3 V

C40

330 µF / 6.3 V

C28

R20 680R

C27

C26 2.2 nF

OUT1

R11 560R

200R

120 pF

VLDO

R3210 kΩ

VLDO

16

26

28

30

FB1

NC

COMP1

R28 10 kΩ

VLDO

C20 1.8 nF

C22

330 µF / 6.3 V

C39

22 µF / 6.3 V

R104

R106

R103

R102

R101

6

SGND11SGND2

PGOOD1

3 kΩ

6.8 kΩ

3 kΩ

2 kΩ

1 kΩ

S7

3

FSEL

S6

SKIP

24

S5

32

VREF

EN1

25

EN2

4

5

2

3

SHDN

1

U5

PM6680

S3

VLDO

C21

91 pF

R108

820 kΩ

R107

9.1 kΩ

C30

100 nF

SKIP mode

S4

1

2

R36

51 kΩ

CH1 EN/SUS

3

R35

51 kΩ

CH2 EN/SUS

R31 10 kΩ

R3410 kΩ

AI14512

7/35

Page 8

PM6680A block AN2559

The PM6680A block is most important part of board. It contains two DC-DC converters.

Each output has a selectable output voltage level. The first converter is capable of delivering

up to 4 A for each voltage level, while the second converter can deliver up to 2 A on the

output.

Both converters are controlled by the PM6680A device. The PM6680A is a dual step-down

controller specifically designed to provide extremely high efficiency conversion, with lossless current sensing. The constant on-time architecture assures fast load transient response

and the embedded voltage feed-forward provides nearly constant switching frequency

operation. An embedded integrator control loop compensates the DC voltage error due to

the output ripple. The pulse skipping technique increases efficiency at very light loads.

Moreover, a minimum switching frequency of 33 kHz is selectable to avoid audio noise

issues. The PM6680A provides a selectable switching frequency, allowing either 200 / 300

kHz, 300 / 400 kHz or 400 / 500 kHz operation of the two switching sections. The output

voltages OUT1 and OUT2 can be adjusted from 0.9 V to 5 V and from 0.9 V to 3.3 V,

respectively. A detailed description of this device can be found in the datasheet.

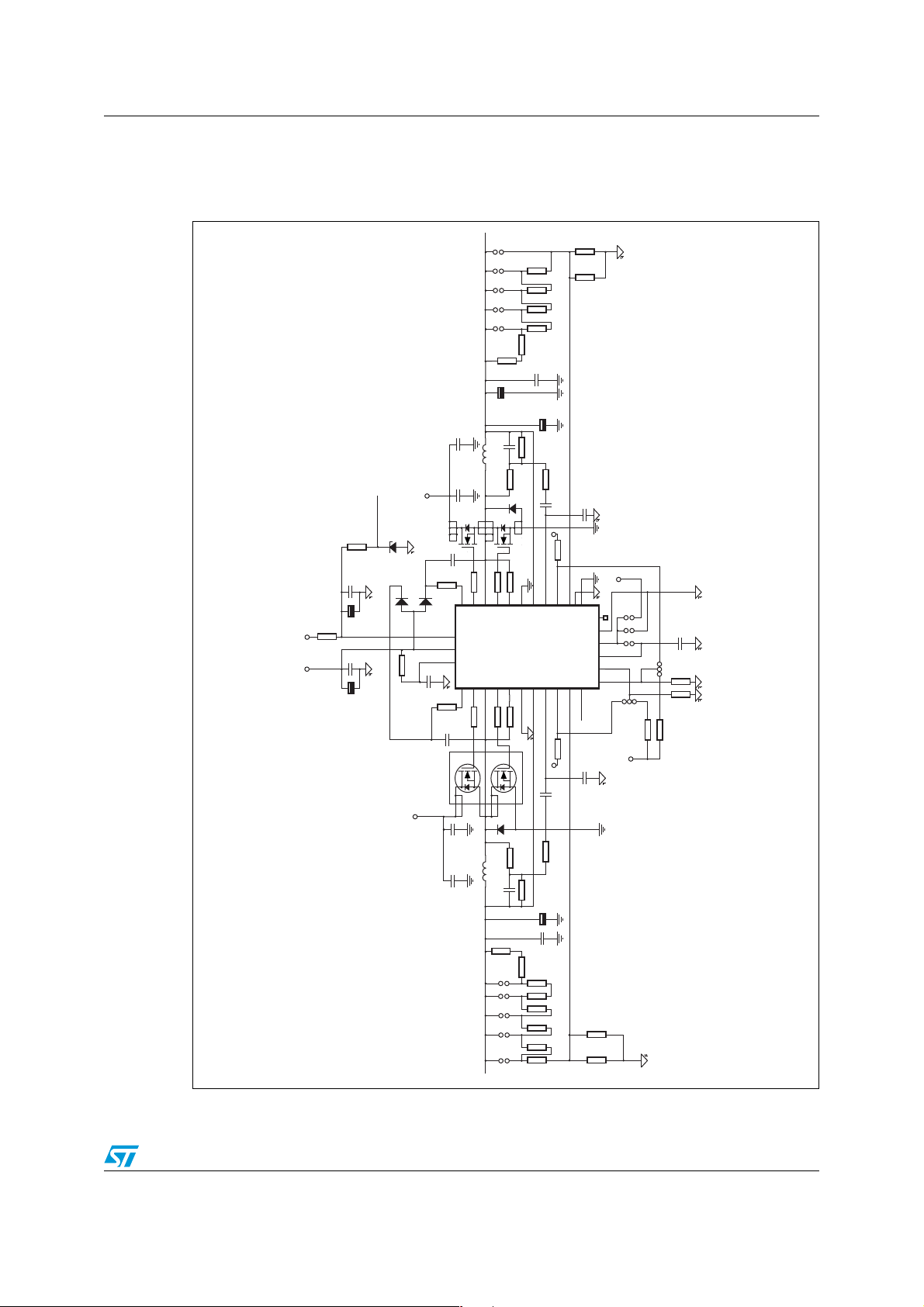

Figure 5 shows the full electrical diagram of the block with the PM6680A that controls the

two DC-DC converters. The components around the PM6680A form several functional

blocks: the power management block, V

step down block, V

CORE

step down block and

I/O

start-up/enable control system block.

3.0.1 Power management block

The PM6680A has two supply voltage inputs - VCC and VIN. The VCC pin should be

connected to the 5 V bus (maximum input voltage is 6 V, minimum 4.5 V) and it is dedicated

for the supply of the chip itself. The V

it is used inside the chip for two reasons. The first is to supply the integrated LDO. The

second is the fact that the controller must sense the converter input voltage level for proper

functioning of the converter.

The V

pin is supplied from the integrated LDO (connected output of LDO and VCC) on the

CC

reference board. The V5SW feature of the LDO is disabled.

The power management block consists of components C14 - C17, C31, R9, R29, R37 and

D10. The important parts of the power management block of the device are the low pass

filters (R9, C16, C17 and R37, C31) applied to reduce the influence of transience on the

device V

and VIN main power inputs. The resistor R29 and the diode D10 generate the

CC

SHDN (shut down) signal, which is active in low level. This signal activates the PM6680A

immediately after V

is connected to the input. The V

IN

simultaneously with activation of the SHDN pin.

3.0.2 Start-up/enable block

The PM6680A has several inputs and outputs dedicated to the control of each channel.

Each channel has an independent Enable signal (EN - active in high level) and "power good"

signal (PGOOD - open collector) activated by channel in cases where the output voltage is

within 10% tolerance. These control pins can be used either for simple enabling/disabling or

for delaying the start-up of one channel rather than another.

pin should be connected to the input power bus and

IN

and LDO signals start to work

REF

The jumpers S3 and S4 with resistors R28, R31, R32, R34, R35 and R36 are used for

systems independently allowing either enabling or disabling of each channel or setting up a

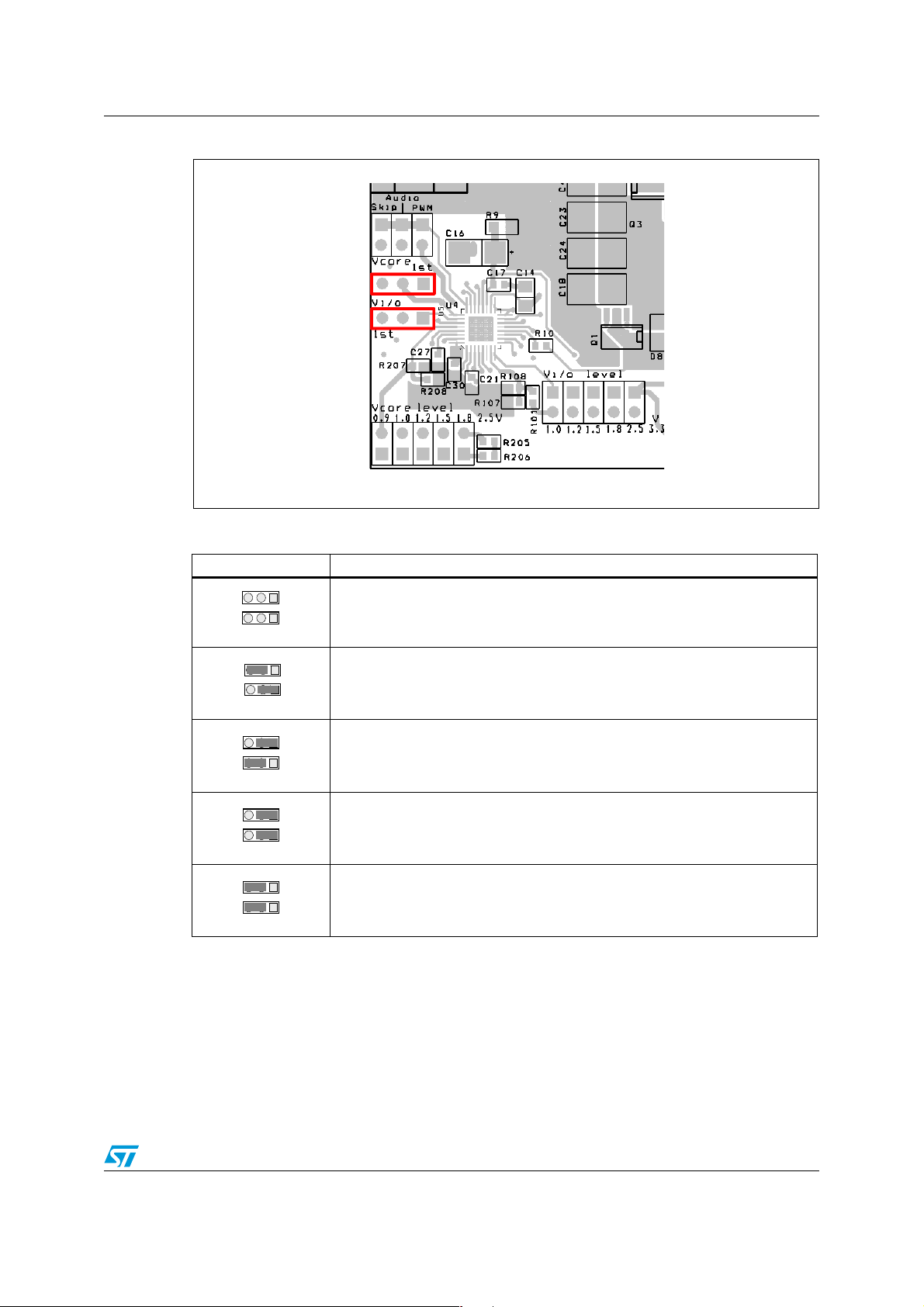

different start-up sequence of both channels. Figure 6 displays the placement of jumpers S3

and S4 on the board, and the settings are shown in Ta b le 2 .

8/35

Page 9

AN2559 PM6680A block

V

V

V

V

V

V

V

V

V

V

V

V

Figure 6. The placement of the jumpers for start-up/enable settings

Table 2. Start-up/enable jumper settings

Jumper settings Function

Vi/o

Vi/o

1st

1st

Vi/o

Vi/o

Vi/o

Vcore

Vcore

1st

1st

Both channels are disabled. An open connector for each channel means

that the channel is disabled.

core

core

core

1st

1st

1st

Vi/o

Vi/o

Vi/o

1st

1st

1st

core

core

core

1st

1st

1st

Both channels are disabled.

Both channels are enabled and start at same time.

core

core

core

1st

1st

1st

Vi/o

Vi/o

Vi/o

core

core

core

1st

1st

1st

Vi/o

Vi/o

Vi/o

V

voltage starts first, and V

CORE

V

voltage starts first, and V

I/O

starts second.

I/O

starts second.

CORE

The Skip mode connector (shown in the schematic as S5 - S7) is dedicated for the control of

Skip mode. This connector setting is common for both channels. Figure 7 shows the

placement of the Skip mode connector, while the settings are shown in Tabl e 3 . There are

three possible settings. Standard Skip mode, No Audible mode or PWM mode. In Standard

Skip mode the converter reduces the switching frequency at light load to maintain good

efficiency even in this condition. There is no lower limit for switching frequency. In No

Audible mode the converter reduces switching frequency at light load, but this frequency

never drops below 30 kHz to avoid possible audible noise caused by the mechanical

9/35

Page 10

PM6680A block AN2559

construction of passive components (inductors or ceramic capacitors). In PWM mode the

converter maintains a constant switching frequency independently on the load.

The FSEL pin the PM6680A dedicated for operating frequency setting is connected to GND.

This means that the switching frequency of the V

frequency of V

is 300 kHz.

I/O

branch is 200 kHz and switching

CORE

Figure 7. Skip mode connector

Table 3. Skip mode connector jumper settings

Jumper settings Function

Audio

Audio

Audio

Skip PWM

Skip PWM

Skip PWM

Audio

Audio

Audio

Skip PWM

Skip PWM

Skip PWM

Audio

Audio

Audio

Skip PWM

Skip PWM

Skip PWM

3.0.3 Step-down parts

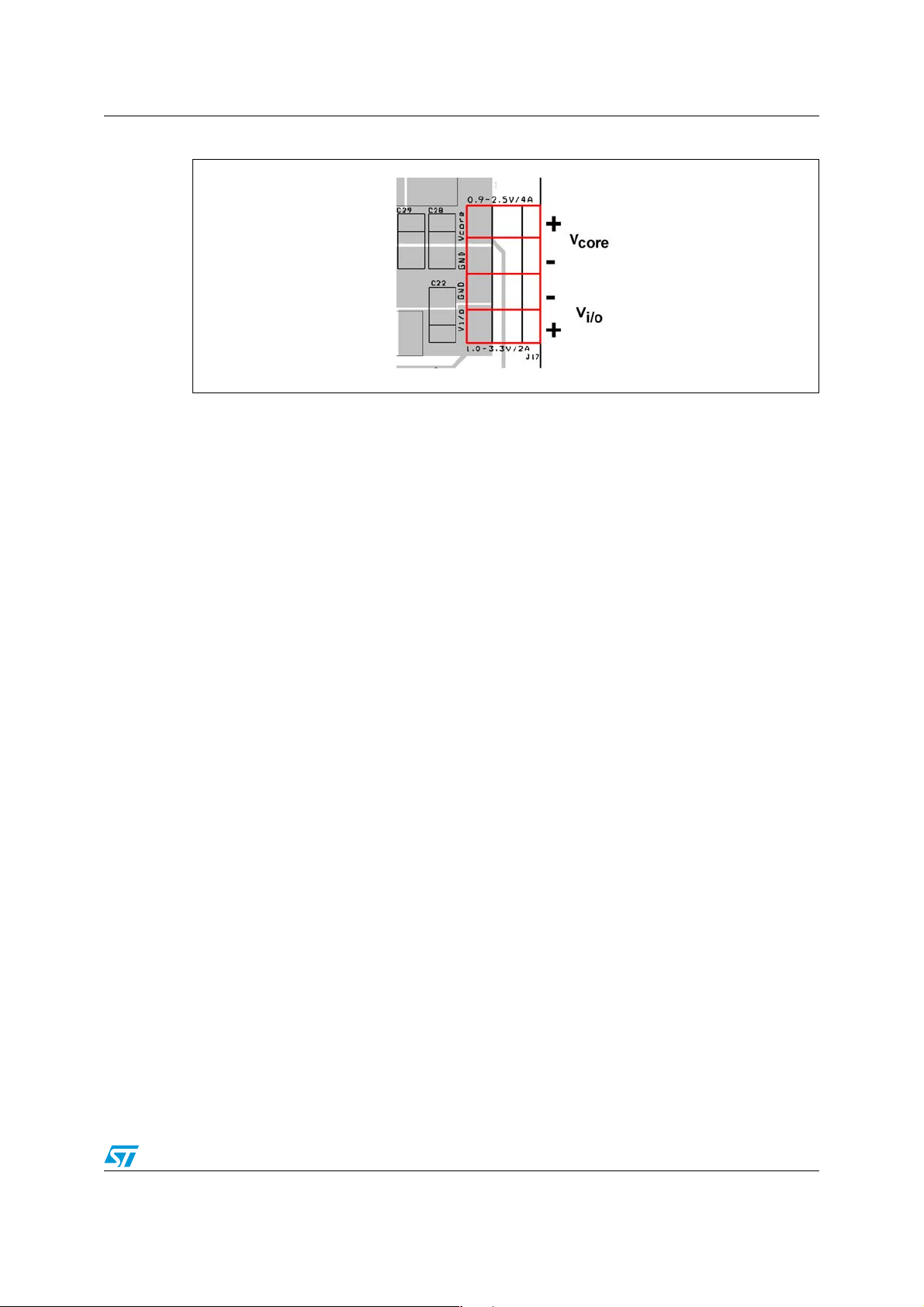

The PM6680A is a dual step-down controller and drives two step-down converters. The

schematic of both channels are almost identical, with only a few small differences. Since

each channel is for a different output power, the main difference is in the components’

values. Figure 8 displays the output connector polarities of the PM6680A section.

Skip mode at light load.

No Audible Skip mode at light load (frequency never drops below 30 kHz).

PWM mode. Constant frequency even at light or zero load.

10/35

Page 11

AN2559 PM6680A block

Figure 8. Output connector

The power components of the step-down part are input capacitors (C23, C24 or C18, C41),

the half bridge driver containing two N-channel MOSFETs (Q2, Q3 or Q1), inductors (L4 or

L3) and output capacitors (C28, C29, C40 or C22, C39).

Ceramic high-capacitance capacitors are used as input capacitors. 60 V MOSFETs are

used for the half bridge driver. A relatively high breakdown voltage is used to guarantee

operation in industrial applications. Because the V

output is designed for lower currents

I/O

(2 A), both MOSFETs are integrated in one SO-8 package (Q1 - STS4NF60). This helps to

reduce the size on the PCB. Two discrete MOSFETs (STS7NF60) are used for the V

CORE

higher power output (4 A). Schottky diodes are also used in each channel (D9 or D8). These

diodes work mainly during dead time and are not mandatory for proper functioning, but their

application increases efficiency.

The 5 µH inductor (L3) is used for the V

output with saturation current at 3 A. The inductor

I/O

L4 has value of 3.8 µH with saturation current at 6 A.

A combination of tantalum low ESR and ceramic type are used as output capacitors.

Ceramic capacitors help to reduce total output ESR and reduce total output voltage ripple.

The PM6680A includes a half bridge driver for each channel. The external bootstrap diode

and capacitor must be applied (D7, C19 or C25) in order to drive the gates of the high side

MOSFETs.

The feedback signal is generated by the output voltage divider (R10x or R20x). The board

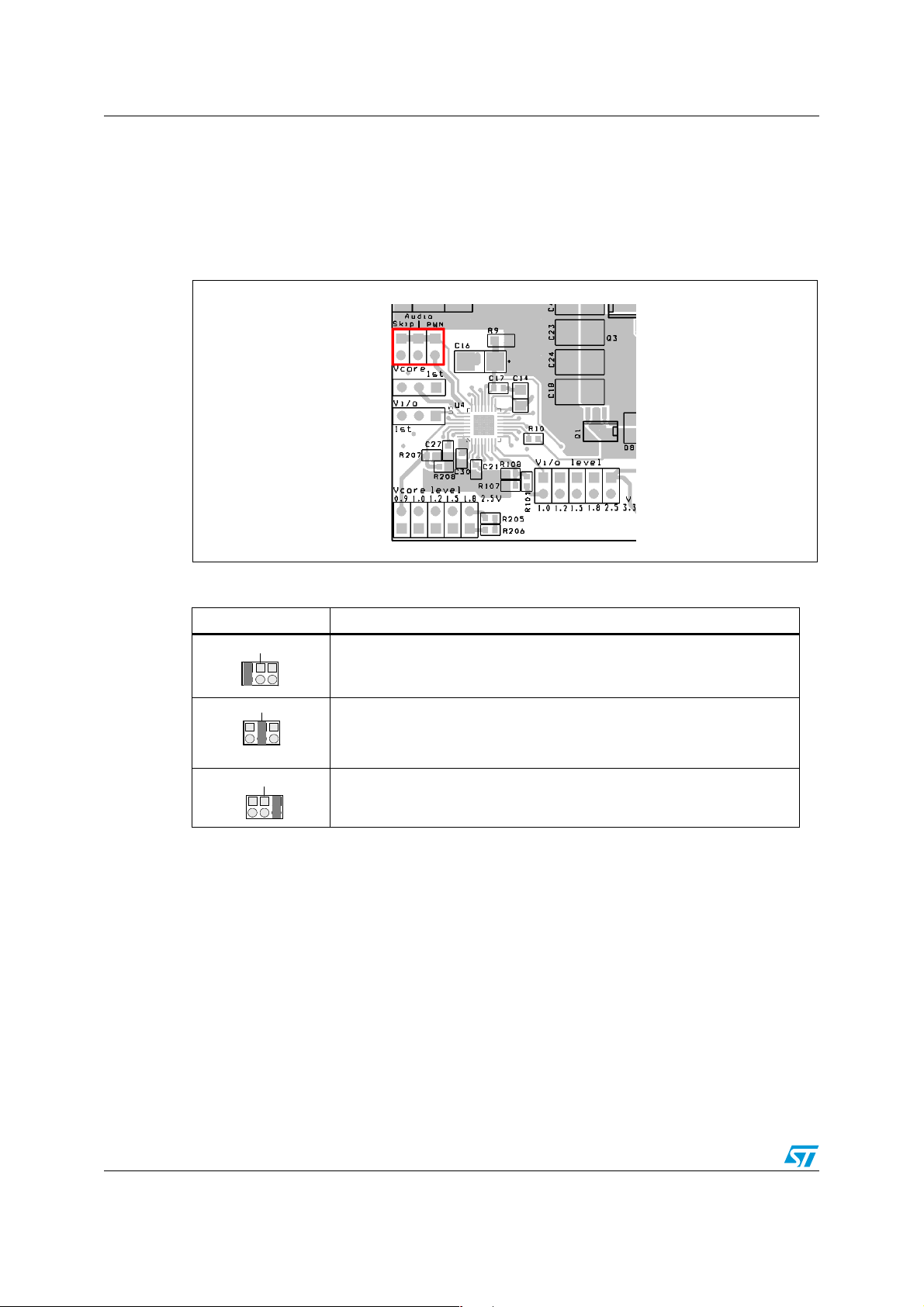

allows the setting of different output voltages for both channels. Figure 9 and Figure 10

display the output voltage connector placement on the board for each channel. The jumper

settings are shown in Tabl e 4 and Tab l e 5, respectively.

In classic Constant On Time control, the system regulates the valley value of the output

voltage and not the average value. In this condition, the output voltage ripple is a source of

DC static error. To compensate for this error, an integrator network is introduced in the

control loop by connecting the signal output voltage to the COMP1/COMP2 pin through a

capacitor (C20 or C26). An additional R-C network (R11 and C21 or R20 and C27) is

implemented as a low pass filter to reduce noise on the input of the COMP pin.

Since the feedback signal of the SMPS working in Constant On Time control is directly

connected to the PWM comparator, the stability of the SMPS is more sensitive to noise

injected into the FB signal. It is possible to attenuate the affect of the noise to stabilize the

SMPS by implementing the so called "Virtual ESR" network, which increases the amplitude

of the feedback ripple voltage and improves signal-to-noise ratio. The Virtual ESR network

does not increase the output ripple voltage. It is recommended to use the Virtual ESR

network in cases where the output voltage ripple is below 30 mV. However, it is necessary to

11/35

Page 12

PM6680A block AN2559

take into consideration that the influence of noise on the performance of the SMPS strictly

depends on the PCB layout. Therefore, the 30 mV is an indicative value. Virtual ESR

Networks are applied for each channel on the reference board described in this application

note. The main reason for this is the fact that the SMPS based on the PM6680A device can

generate different output voltages at a wide input voltage range. As output voltage ripple

depends also on input and output voltage level, there are configurations where the Virtual

ESR network could be mandatory. Virtual ESR networks consists of R40, R39, C35 or R27,

R38 or C34. The ESR network can be removed to observe influence of ESR network to

board function. To remove the Virtual ESR Network, R40 and R27 must be removed and

R39 and R38, respectively, must be shorted.

Figure 9. Jumper placement for V

Table 4. V

voltage level jumper settings

CORE

Jumper settings V

voltage level setting

CORE

CORE

2.5 V

1.8 V

1.5 V

1.2 V

1.0 V

0.9 V

12/35

Page 13

AN2559 PM6680A block

Figure 10. Jumper placement for V

Table 5. V

voltage level jumper settings

I/O

Jumper settings V

voltage level setting

I/O

CORE

3.3 V

2.5 V

1.8 V

1.5 V

1.2 V

1.0 V

13/35

Page 14

PM6680A block AN2559

3.1 DC-DC converters based on the L5970AD

There are two converters based on the L5970AD on the System Supply board: the analog

output and V

connector J18.

Figure 11. Output voltages of L5970A parts

output voltage. Figure 11 shows the arrangement of output voltages on

SYS

The L5970AD is a step-down monolithic power switching regulator with a switch current limit

of 1.5 A, capable of delivering more than 1 A of DC current to the load depending on the

application conditions. The output voltage can be set from 1.235 V to 35 V. The device uses

an internal P-channel D-MOS transistor (with a typical RDS

of 200 mΩ) as a switching

ON

element to avoid the use of a bootstrap capacitor and to guarantee high efficiency. An

internal oscillator fixes the switching frequency at 500 kHz to minimize the size of external

components. Having a minimum input voltage of only 4.4 V, it is particularly suitable for 5 V

buses, found in all computer-related applications. Pulse-by-pulse current limiting with

internal frequency modulation offers effective constant current short circuit protection.

The schematic of both SMPS’s is displayed in Figure 12. As the schematic shows, designing

with the L5970AD is very simple. It consists of a power part, feedback and enable/disable

connectors. The power part contains an input capacitor (C2 or C8 - ceramic is

recommended), an inductor (L1 or L2), an output capacitor (C5 or C11) and a freewheeling

diode (D4 or D6). The feedback part consists of a voltage divider (R2, R3, R4 or R6, R7, R8)

and a compensation RC network (R1, C3, C4 or R5, C9, C10).

14/35

Page 15

AN2559 PM6680A block

Figure 12. Schematic of the two SMPS’s based on the L5970AD

sys

aux

V

V5A

V3A3

4

OUT

LK112_33

SHDN1GND2BYPASS

IN

U2

5

R3

20 kΩ

R2

120 kΩ

33 µH / 1. 5 A

L1

1

5

FB

INH

OUT

GND

REF

V

CC

U1 L5970AD

V

COMP

8

SYNC

4

R1

3

C7

10 µF / 6 V

C5

R4

D4

3

7

6

2

4.7 kΩ

GNDA

C6

100 nF

47 µF / 10 V

5.6 kΩ

Vin

R4 1 51 kΩ

STPS2L40

EN

analog

V

S1

C4

22 nF

V

C13

10 µF / 4 V

1

GND

VOUT

7

6

GND

3

GND

2

GND

VIN

INH

U4 KF25_SOI C8

8

5

C12

100 nF

R7

240 kΩ

C11

100 µF / 6 V

R6

18 kΩ

R8

10 kΩ

L2 3 3 µH / 1.5 A

1

OUT

CC

U3 L5970AD

V

8

4

D6

5

FB

COMP

STPS2L40

INH

3

7

GND

6

REF

V

2

SYNC

C10

22 nF

4.7 kΩ

R5

AI12694

Vin

R4 2 51 kΩ

EN

sys

S2 V

C3

220 pF

C2

4.7 µF / 5 0 V

L5 10 µH / 1 A

Vin

C9

220pF

4.7 µF / 5 0 V

C8

Both converters can be switched on or off using the inhibit pin of L5970AD connected to

jumpers S1 and S2. If the jumper is left open, the DC-DC converter will not operate. Thus

the jumper must be shorted for the converter to operate (see Figure 13 for board placement

of the jumper and Tab l e 6 for the jumper settings).

15/35

Page 16

PM6680A block AN2559

Figure 13. Jumper placement for enable/disable function of analog output and

output3

Table 6. Jumper settings for enable/disable function of analog output and output3

Jumper settings V

E/DE/D

CORE

Analog disable

There is an LDO linear regulator (U2 and U4) on the output of each DC-DC converter. The

LK112_33 is a 3.3 V linear regulator in a SOT23-5 package. The KF25 is a very low dropout

regulator with an output voltage of 2.5 V and output current of up to 400 mA.

3.2 Reset circuit

The board also features a reset circuit which supervises the output voltages. It is based on

the STM6719 series of low voltage / low supply supervisors, which are designed to monitor

three system power supply voltages. Two monitored supplies (V

(factory trimmed) thresholds (V

externally adjustable RSTIN threshold (0.626 V internal reference). If any of the three

monitored voltages drop below its factory-trimmed or adjustable thresholds, or if MR is

asserted to logic low, an RST is asserted (driven low). Once asserted, RST is maintained at

Low for a minimum delay period after ALL supplies rise above their respective thresholds

and MR returns to High. This device is guaranteed to be in the correct reset output logic

state when V

pin SOT23 package.

and / or V

CC1

E/DE/D

E/DE/DE/D

E/DE/DE/D

Analog enable

Output3 disable

Output3 enable

and V

and V

RST1

is greater than 0.8 V. This device is available in a standard 6-

CC2

). The third voltage is monitored using an

RST2

CC1

) have fixed

CC2

16/35

Page 17

AN2559 PM6680A block

Figure 14 shows the schematic and placement of the reset part on the board. Typically in

real applications the reset circuit senses if the supply voltage drops below about 10% of

nominal value. This feature cannot be implemented on the System Supply board due to the

fact that the output voltage is selectable, while the reset voltage is factory set. There are

several types of reset circuits in the STM6719 family (see datasheet). Of these, the

STM6719TGWB6F was selected as optimal. The voltage thresholds of this device are

3.075 V, 1.11 V and 0.626 V.

Figure 14. Schematic of the reset circuit and board placement

V

sys

V

V

io

core

C32

1 nF

U6

STM6719TEWB6F

6

V

4

V

5

RSTIN

3

MR

C33

1 nF

CC1

CC2

RST

V

SS

2

R209

110 kΩ

1

J14 Reset

J15 Reset GND

AI12695

17/35

Page 18

PCB layout AN2559

4 PCB layout

The System Supply board utilizes a four-layer PCB. The copper layout of each layer is

shown in Figure 15 and Figure 16. The top and bottom layers show also the placement of

the components. To reduce the size of board while maintaining the ability to change some

components, size 0603 was used for the majority of the passive components. All views of

the PCB are from top side.

Figure 15. PCB top layer layout and first internal layer

Figure 16. PCB second internal layer and bottom layer layout

18/35

Page 19

AN2559 Bill of materials

5 Bill of materials

Table 7. Bill of materials

Item Part Description Type Size Manufacturer Part number

1 C1 47 µF / 50 V TH 6.3 x 11 E47M/50VMXA RM5

2 C2 4.7 µF / 50 V SMD 1812 AVX 18125C475KAT2A

3 C3 220 pF SMD 0603

4 C4 22 nF SMD 0603

5 C5 100 µF / 10 V SMD C AVX TPSC107M010X0150

6C6 N.A.

7 C7 10 µF / 6 V SMD B CTS 10M / 6.3 V

8 C8 4.7 µF / 50 V SMD 1812 AVX 18125C475KAT2A

9 C9 220 pF SMD 0603

10 C10 22 nF SMD 0603

11 C11 100 µF / 10 V SMD C AVX TPSC107M010X0150

12 C12 100 nF SMD 0805

13 C13 10 µF / 6.3 V SMD B CTS 10 M / 6.3 V

14 C14 6.8 µF / 10 V SMD B CTS 6 M 8 / 10 V

15 C15 470 nF SMD 0805

16 C16 3.3 µF / 50 V SMD 1812 C1210C335K5RAC

17 C17 100 nF SMD 0603

18 C18 4.7 µF / 50 V / X7R SMD 1812 AVX 18125C475KAT2A

19 C19 100 nF SMD 0603

20 C20 1.8 nF SMD 0603

21 C21 100 pF SMD 0603

22 C22 330 µF / 6.3 V SMD D AVX TPSD337M006X0045

23 C23 4.7 µF / 50 V / X7R SMD 1812 AVX 18125C475KAT2A

24 C24 4.7 µF / 50 V / X7R SMD 1812 AVX 18125C475KAT2A

25 C25 100 nF SMD 0603

26 C26 2.2 nF SMD 0603

27 C27 120 pF SMD 0603

28 C28 330 µF / 6.3 V / 45 mΩ SMD D AVX TPSD337M006X0045

29 C29 330 µF / 6.3 V / 45 mΩ SMD D AVX TPSD337M006X0045

30 C30 100 nF SMD 0603

31 C31 220 nF SMD 0805

32 C32 1 nF SMD 0603

19/35

Page 20

Bill of materials AN2559

Table 7. Bill of materials (continued)

Item Part Description Type Size Manufacturer Part number

33 C33 1 nF SMD 0603

34 C34 12 nF SMD 0603

35 C35 10 nF SMD 0603

36 C39 22 µF / 6.3 V SMD 1206 AVX 12066D226KAT2A

37 C40 100 µF / 6.3 V SMD 1210 AVX 12104D107MAT2A

38 C41 4 µF 7 / 50 V / X7R SMD 1812 AVX 18125C475KAT2A

39 D1 SM6T39A SMD SMB ST SMA6T39A

40 D4 STPS2L40 SMD SMB ST STPS2L40

41 D6 STPS2L40 SMD SMB ST STPS2L40

42 D7 BAW56/SOT SMD SOT23

43 D8 STPS1L40M SMD DO216-AA ST STPS1L40M

44 D9 STPS1L40M SMD DO216-AA ST STPS1L40M

45 D10 4.7 V SMD SOD80

46 S1 Header 1 x 2 TH

47 S2 Header 1 x 2 TH

48 S3 Header 1 x 3 TH

49 S4 Header 1 x 3 TH

50 V

51 V

level Header 2 x 5 TH

I/O

level Header 2 x 5 TH

CORE

52 Skip Header 2 x 3 TH

53 J3 Jack - PCB TH

54 J14 Header 1 x 1 TH

55 J15 Header 1 x 1 TH

56 J16 Ind. Con. 2 TH Ph. Con. MSTBA 2,5 / 2-G-5,08

57 J17 Ind. Con. 4 TH Ph. Con. MSTBA 2,5 / 4-G-5,08

58 J18 Ind. Con. 6 TH Ph. Con MSTBA 2,5 / 6-G-5,08

59 L1 33 µH / 1.5 A SMD Coilcraft MSS7341-333MLB

60 L2 33 µH / 1.5 A SMD Coilcraft MSS7341-333MLB

61 L3 5.0 µH / 3 A SMD Coilcraft MSS7341-502MLB

62 L4 3.8 µH / 6 A SMD Coilcraft MSS1038-382NLB

63 L5 1 µH / 1 A SMD Coilcraft ME3220-102MLB

64 Q1 STS4DNF60 SMD ST STS4DNF60L

65 Q2 STS7NF60L SMD ST STS7NF60L

66 Q3 STS7NF60L SMD ST STS7NF60L

67 R1 4. 7 kΩ SMD 0603

20/35

Page 21

AN2559 Bill of materials

Table 7. Bill of materials (continued)

Item Part Description Type Size Manufacturer Part number

68 R2 36 kΩ / 1% SMD 0603

69 R3 200 kΩ/ 1% SMD 0603

70 R4 10 kΩ / 1% SMD 0603

71 R5 4.7 kΩ SMD 0603

72 R6 18 kΩ / 1% SMD 0603

73 R7 240 kΩ / 1% SMD 0603

74 R8 10 kΩ / 1% SMD 0603

75 R9 3.3 Ω SMD 0805

76 R10 1.8 kΩ SMD 0603

77 R11 560 Ω SMD 0603

78 R110 4.7 kΩ / 1% SMD 0603

79 R19 1 kΩ SMD 0603

80 R20 680 Ω SMD 0603

81 R21 0 Ω SMD 0603

82 R22 0 Ω SMD 0603

83 R23 0 Ω SMD 0603

84 R24 0 Ω SMD 0603

85 R25 10 Ω SMD 0603

86 R26 10 Ω SMD 0603

87 R27 62 kΩ SMD 0603

88 R28 10 kΩ SMD 0603

89 R29 51 kΩ SMD 0603

90 R31 10 kΩ SMD 0603

91 R32 10 kΩ SMD 0603

92 R34 10 kΩ SMD 0603

93 R35 51 kΩ SMD 0603

94 R36 51 kΩ SMD 0603

95 R37 47 Ω SMD 0603

96 R38 3.3 kΩ SMD 0603

97 R39 3.3 kΩ SMD 0603

98 R40 100 kΩ SMD 0603

99 R41 51 kΩ SMD 0603

100 R42 51 kΩ SMD 0603

101 R101 1 k

102 R102 2 kΩ / 1% SMD 0603

Ω / 1% SMD 0603

21/35

Page 22

Bill of materials AN2559

Table 7. Bill of materials (continued)

Item Part Description Type Size Manufacturer Part number

103 R103 3 kΩ / 1% SMD 0603

104 R104 3 kΩ / 1% SMD 0603

105 R105 200 Ω / 1% SMD 0603

106 R106 6.8 kΩ / 1% SMD 0603

107 R107 9.1 kΩ / 1% SMD 0603

108 R108 820 kΩ / 1% SMD 0603

109 R109 3.3 kΩ / 1% SMD 0603

110 R201 1 kΩ / 1% SMD 0603

111 R202 2 kΩ / 1% SMD 0603

112 R203 3 kΩ / 1% SMD 0603

113 R204 3 kΩ / 1% SMD 0603

114 R205 200 Ω / 1% SMD 0603

115 R206 6.8 kΩ / 1% SMD 0603

116 R207 9.1 kΩ / 1% SMD 0603

117 R208 820 kΩ / 1% SMD 0603

118 R209 51 kΩ SMD 0603

119 U1 L5970AD SMD SO-8 ST L5970AD

120 U2 LK112_33 SMD SOT23-5 ST LK112M33TR

121 U3 L5970AD SMD SO-8 ST L5970AD

122 U4 KF25_SOIC8 SMD SO-8 ST KF25BD-TR

123 U5 PM6680A SMD

124 U6 STM6719TEWB6F SMD SOT23-6 ST STM6719TGWB6F

VFQFPN-

32 5X5

ST PM6680A

22/35

Page 23

AN2559 Measurements

6 Measurements

The performance and properties of each part of the board is indicated in the measurements

below. These measurements were performed for the PM6680A and L5971AD blocks

independently.

6.1 PM6680A block - measurements

The performance measurements of the PM6680A part focus mainly on efficiency, light load

consumption, output ripple and transients.

6.1.1 Efficiency and light load consumption modes

Since the device consists of three power parts (two controllers and one LDO) it makes

sense to measure total efficiency. Figure 17 displays how efficiency depends on input

voltage level at full load output (V

Figure 17. Efficiency of the dual step-down converter at full load

Efficency (%)

2.5 V / 4 A, V

CORE

3.3 V / 2 A).

I/O

100.0

90.0

80.0

70.0

60.0

50.0

40.0

30.0

20.0

10.0

0.0

0 5 10 15 20 25 30 35 40

Vin (V)

AI12696

The efficiency is in the range of 83 - 91%. It should be noted that the total efficiency strictly

depends on the performance of each component. The System Supply board was designed

to satisfy a wide input voltage range. Therefore, 60 V MOSFETS are used on the board. If

the input voltage of the end application is less (up to 30 V for instance), efficiency can be

improved by using lower RDS

30 V MOSFETs in the same package. The expected

ON

efficiency gain is about 3 - 4%.

The PM6680A can work in several modes with regard to light load. These options are mainly

used for battery applications where relatively high consumption at light load can drain the

battery even when no power is requested. The PM6680A allows three modes (see 3.0.2):

PWM, No Audible Noise and Skip. Figure 18 shows the consumption of the board for

different modes of the PM6680A. There is no load on the output and other parts of the

SMPS are disabled.

23/35

Page 24

Measurements AN2559

Figure 18. PM6680A consumption at no load condition, in the different modes

lin (mA)

70.0

60.0

50.0

40.0

30.0

20.0

10.0

0.0

0 5 10 15 20 25 30 35 40

PWM

No Audible

SKIP

Vin (V)

In analyzing the data in Figure 18, it should be noted that the consumption is slightly

increased by several passive components which generate inhibit of the L5970ADs. Total

consumption of these parts at 35 V on the input is about 1.5 mA. This is not compensated

for in the chart in Figure 18. It is possible to see the effect of the different operating modes of

the converter by observing the output ripple voltage waveforms in Figure 19. These

measurements are made under the following conditions: V

output set to 2.5 V, no load,

CORE

at 12 V on the input.

Figure 19. Output voltage ripple in different modes of light load operation

AI12697

6.1.2 Output voltage ripple

Output voltage ripple depends on the current ripple flowing through the choke. The current

ripple depends on the input and output voltage levels. Therefore, it is mandatory to measure

the output voltage ripple for different input and output voltage conditions. Figure 20 shows

the output voltage ripple of V

displays the output voltage ripple of V

shows the output voltage ripple of V

displays the output voltage ripple of V

figures represent the minimum and maximum output voltages at maximum load (0.9 V and

2.5 V at 4 A for V

24/35

and 1 V and 3.3 V at 2 A for V

CORE,

at the minimum input voltage (5 V), while Figure 21

CORE

CORE

I/O

I/O

at the maximum output voltage (36 V). Figure 22

at the minimum input voltage (5 V), and Figure 20

at the maximum input voltage (36 V). All of the

).

I/O

Page 25

AN2559 Measurements

Figure 20. Output voltage ripple of V

Figure 21. Output voltage ripple of V

at the minimum input voltage (5 V)

CORE

at the maximum output voltage (36 V)

CORE

Figure 22. Output voltage ripple of V

at the minimum input voltage (5 V)

I/O

25/35

Page 26

Measurements AN2559

Figure 23. Output voltage ripple of V

at the maximum input voltage (36 V)

I/O

Figure 24. Start-up without setting the sequence

Figure 25. Start-up with a set sequence

26/35

Page 27

AN2559 Measurements

6.1.3 Start-up sequence

The correct start-up sequence of the supply voltage is typically requested by the FPGA

device. Therefore, there it is possible to set a dedicated start-up sequence on the System

Supply board (see 3.0.2. Figure 24) shows the start-up sequence waveform of V

V

outputs when the jumpers described in Tab l e 2 are set in accordance with line 3 in the

I/O

CORE

and

table.

The waveforms shown in Figure 25 illustrate different start-up sequences in accordance with

the jumper settings displayed in Tabl e 2 , lines 4 and 5.

6.1.4 Transient response

Transient response refers to the behavior of the output voltage when the load changes fast.

This test was also performed on the outputs of the PM6680A branch. The load was changed

between maximum and zero load (0 ↔ 2 A on V

output). The input voltage was 12 V and output voltage was 3.3 V and 2.5 V, respectively.

The repetition of load change was 500 Hz. The results of the measurements are shown in

Figure 26 and Figure 27. The voltage spikes caused by increasing the load are quite low. It

is possible to observe that the converter reacts very fast to a rising load and the

undervoltage is small (left waveform in figures). If the load is decreasing fast the overvoltage

spikes appear on the output (right side of picture). This effect depends partly on the reaction

of the controller and partly on the parameters of the output filter. There is remaining energy

stored in the inductor and if the load decreases this energy should be stored in the output

capacitor. This effect can be reduced by either reducing the value of the inductor (to reduce

the amount of energy stored in the inductor), or by increasing the value of the output

capacitor (a higher capacitance is capable of absorbing more energy from the inductor).

output and 0 ↔ 4 A on the V

I/O

CORE

Figure 26. Load transient response on V

CORE

output

27/35

Page 28

Measurements AN2559

Figure 27. Load transient response on V

output

I/O

28/35

Page 29

AN2559 Measurements

6.2 L5970AD blocks - measurements

6.2.1 Efficiency

The L5970AD is a powerful converter with very good performance and efficiency. Because a

diode is used as a low side switch, however, the efficiency is a slightly less compared to a

synchronous converter such as the PM6680A. Theoretically, the efficiency declines when

output voltage is decreasing and input voltage is increasing. Figure 28 displays the

efficiency of Output 3, depending on the input voltage at full load (800 mA). Figure 29

displays the same measurement for the Analog output. The efficiency of the Analog output

is better thanks to the higher output voltage level. The efficiency of the Analog output

voltage was measured in a range of 7 - 35 V. It should be noted that the output voltage is

5 V, so the device does not work as a switching converter in cases where the input and

output voltage are similar or lower than the required output. In this case the L5973AD works

with 100% duty cycle.

Figure 28. Efficiency of output 3, by input voltage level

Efficency (%)

90.0

80.0

70.0

60.0

50.0

40.0

30.0

20.0

10.0

0.0

0 5 10 15 20 25 30 35 40

Vin (V)

AI12698

29/35

Page 30

Measurements AN2559

Figure 29. Efficiency of analog output, by input voltage level

Efficency (%)

100.0

90.0

80.0

70.0

60.0

50.0

40.0

30.0

20.0

10.0

0.0

0 5 10 15 20 25 30 35 40

Vin (V)

AI14500

6.2.2 Output voltage ripple

The output voltage ripple of the switching parts of the Analog and V

Figure 30 and Figure 31. The measurements were made for different input voltages,

because the current ripple influence on the output voltage ripple depends on the input

voltage level. The output voltage ripple on the 3.3 V Analog output and the V

displayed in Figure 32 and Figure 33. As these outputs are generated by LDOs, the output

voltage ripple is the same (independent) for all input voltages, and is very low. Therefore,

only one output voltage ripple image is shown in the figures 32 and 33. All of the

measurements were taken at full output load.

Figure 30. Analog 5 V - output voltage ripple

outputs are shown in

SYS

output are

AUX

30/35

Page 31

AN2559 Measurements

Figure 31. V

- output voltage ripple

SYS

Figure 32. Analog 3.3 V - output voltage ripple

31/35

Page 32

Measurements AN2559

Figure 33. V

2.5 V - output voltage ripple

AUX

32/35

Page 33

AN2559 Measurements

6.2.3 Transient

Transient responses were measured only for V

displayed in Figure 34 and Figure 35. The transient waveforms of the L5970AD section

show the response time. The most visible difference between the L5970AD in classic

voltage mode and the PM6680A working in Constant On Time mode is the reaction when

there is a fast load increase. Whereas the PM6680A reacts asfast as possible on the rising

load, the L5970AD will wait short time as the compensation network is implemented in

feedback loop (see Figure 24 and Figure 25).

Figure 34. Transient response of V

based on the L5970AD

SYS

AUX

and V

. The transient responses are

SYS

Figure 35. Transient response of V

generated by the LDO KF25

AUX

33/35

Page 34

References AN2559

7 References

1. Datasheet PM6680A

2. Datasheet L5970AD

3. Datasheet LK112

4. Datasheet KF25

5. STM6719

6. AN1330 - designing with the L5970D, 1 A high efficiency DC-DC converter.

8 Revision history

Table 8. Document revision history

Date Revision Changes

25-Sep-2007 1 Initial release

34/35

Page 35

AN2559

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

35/35

Loading...

Loading...