Page 1

AN2528

Application note

Very wide input voltage range 6 W SMPS for metering

Introduction

This document presents the design of a universal input power supply for metering

applications. The design is mainly based on the following ST parts: an L6565 PWM driver

and STC04IE170HP as the main switch. It is linked with the release of the STEVA LIP001Vxx demo board (see Figure 1 below). The design is a complete solution for a 5 W

single output SMPS, which is widely used as a power supply in metering applications.

However the design method can be applied to an SMPS suitable for other applications

working on a three-phase mains and it can easily be upgraded for higher ou tput power.

The ESBT base driving circuit as well as guidelines for the optimization of the power

dissipation are given.

The influence of parasitic capacitances of the transformer on the ESBT is also explained in

detail.

Finally, the most important waveforms and thermal results are given in Section 5 and

Section 6. They demonstrate the benefits of using a QR flyback with ESBT.

Refer to AN1889 and AN2254 for the overall design of an auxiliary power supply using

ESBT in flyback QR with L6565, while refer to AN2454 fo r the small signal power switch

model with all parasitic components.

Figure 1. STEVAL-ISA030V1

July 2007 Rev 1 1/21

www.st.com

Page 2

Contents AN2528

Contents

1 Design specifications and schematic diagram . . . . . . . . . . . . . . . . . . . 4

2 Flyback stage design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Parasitic capacitances and related issues . . . . . . . . . . . . . . . . . . . . . . . 8

4 Base drive circuit design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5 Experimental results: waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6 Experimental results: efficiency and further considerations . . . . . . . 15

7 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2/21

Page 3

AN2528 List of figures

List of figures

Figure 1. STEVAL-ISA030V1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. Complete schematic diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 3. The small signal equivalent circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 4. ESBT base driving network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 5. DC current gain. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 6. Dynamic collector-source saturation voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 7. 110

Figure 8. 110

Figure 9. 110

Figure 10. 110

Figure 11. 380

Figure 12. 380

Figure 13. 380

Figure 14. 380

Figure 15. 600

Figure 16. 600

Figure 17. 600

Figure 18. 600

Figure 19. V

Figure 20. 110

Figure 21. 380

Figure 22. 600

Figure 23. 600

Figure 24. PCB picture top view (components and copper) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 25. PCB picture top view components and bottom layer copper . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 26. PCB picture top view components and bottom layer copper . . . . . . . . . . . . . . . . . . . . . . . 20

V

input voltage overall1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

ac

V

input voltage overall2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

ac

V

input voltage- storage highlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

ac

V

input voltage turn-off highlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

ac

V

input voltage overall1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

ac

V

input voltage overall2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

ac

V

input voltage storage time highlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

ac

V

input voltage - turn-on highlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

ac

V

input voltage overall1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

ac

V

input voltage overall2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

ac

V

input voltage turn-off highlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

ac

V

input voltage turn-on highlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

ac

vs T

comp

V

input voltage, max load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

ac

V

input, max load: frequency reduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

ac

V

input, max load: further frequency reduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

ac

V

input, max load: increased OFF- time highlight . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

ac

(minimum OFF-time) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Blank

3/21

Page 4

Design specifications and schematic diagram AN2528

1 Design specifications and schematic diagram

The table below lists the converter specification data and the main parameters fixed for the

demo board.

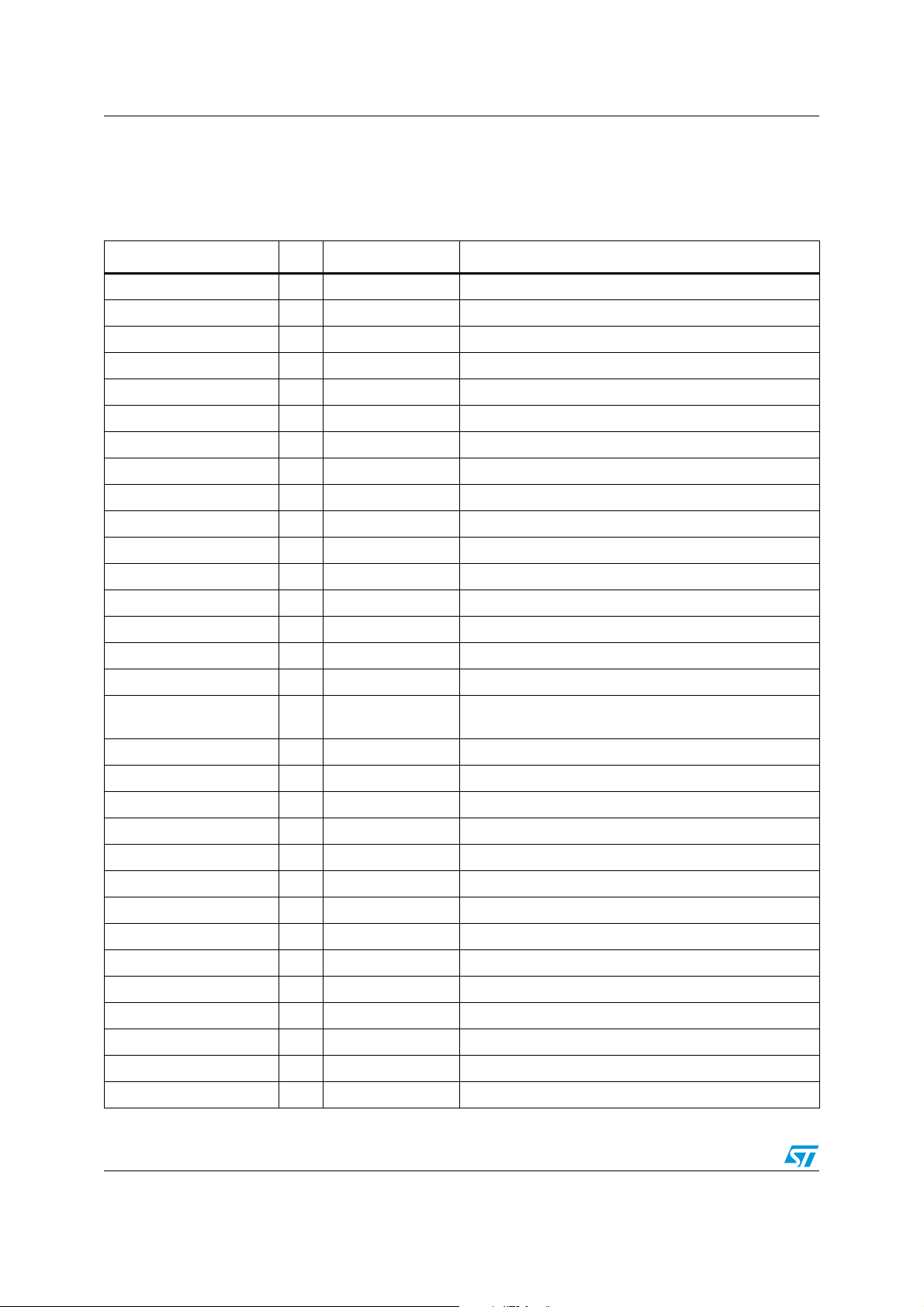

Table 1. Converter specification and p r eliminary choices

Symbol Description Values

V

inmin

V

in

V

out

P

out

η Converter efficiency @ max load > 80%

F Minimum switching frequency ≅

V

fl

V

spike

Rectified minimum input voltage 150

Rectified maximum input voltage 850

Output voltage 14 V/430 mA

Maximum output power 6 W

30 kHz

Reflected flyback voltage 250 V

Max over voltage limited by clamping circuit 150 V

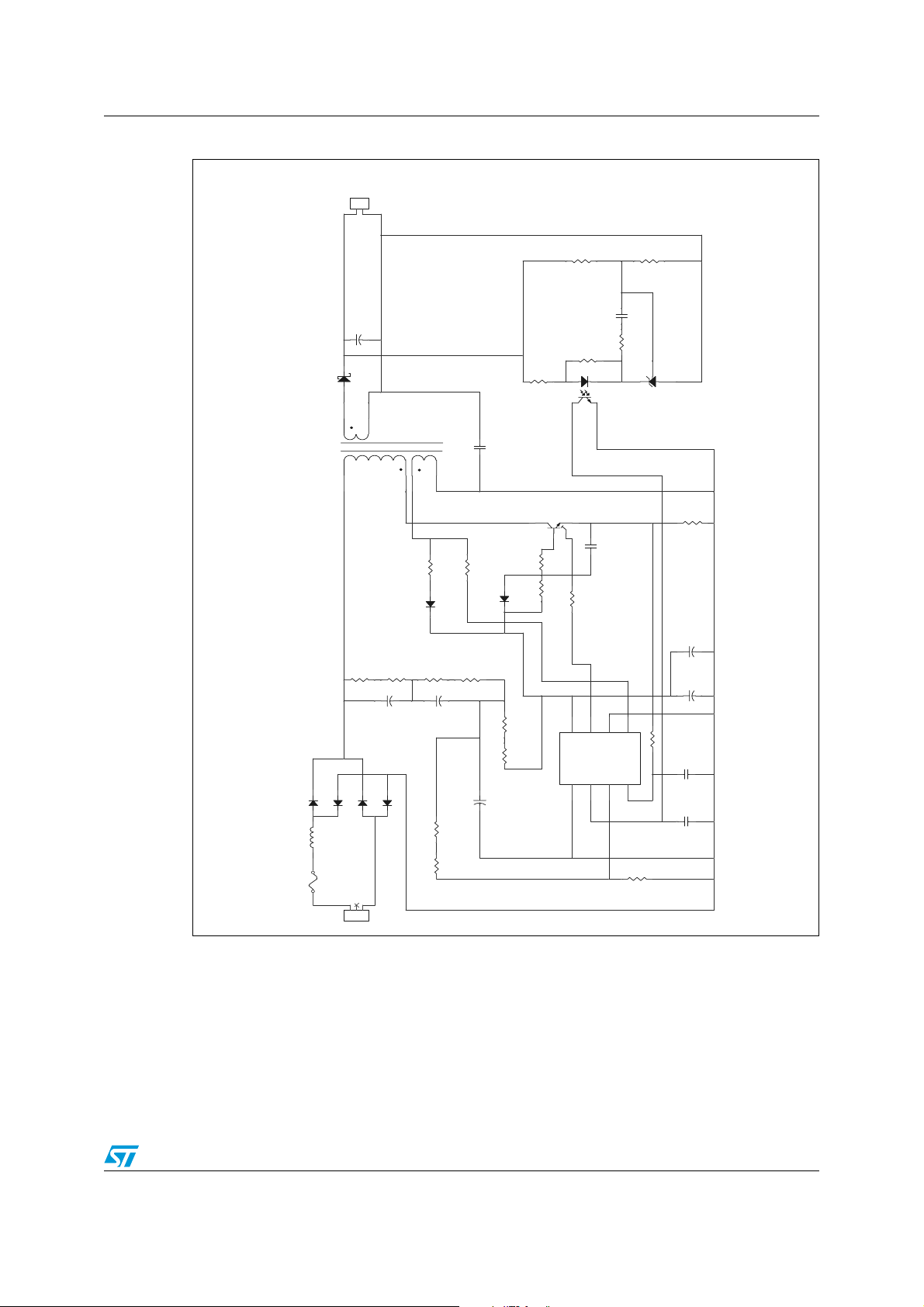

A schematic diagram of the SMPS is given in Figure 2. The most relevant components are:

1. HV ESBT main switch and simple driving circuit

2. L6565 QR PWM driver to get the best efficiency

3. Special transformer construction with very low parasitic capacitance

4/21

Page 5

AN2528 Design specifications and schematic diagram

Figure 2. Complete schematic diagram

J2

Phoenix 2 pin12

R14

14V @ 0.43A

C1

330uF/25V

+

D7

C5

.0022uF

AC

Y1 cap

13

LL4148

R11

ISO1

H11A817

Q1

R12

R24

D3

STPS3L60U

A C

35T

7

6

7

6

T1

1

CSM 2010-104

1

48T

2

2

334

27T

R6

1/ 1/8W

D6

LL4148

9T

4

R8

47k/ 1/ 8W

AC

11K/ 1/ 8W

R21

2.4K/ 1/8W

10nF

C7

R17

R15

1.2K/ 1/8W

1.5K/ 1/8W

12

43

STC04IE170HP

4

2

C6

10/ 1206

R13

2.2K/ 1206

22/ 1206

10nF

4.7K/ 1/8W

U2

TL431_ARC

R

A C

R23

4.7/ 1/4W

C11

22uF/25V

+

R2

R1

AC

STTH112U

STTH112U

D1

D2

D4 STTH112U

A C

M600X

L1

F1

TR5FU S E

1 2

J1

100K/ 1206

100K /1206

+

C2

33uF/450V

AC

D5

STTH112U

A C

123

Phoenix 3 pin

R7

R3

100K/ 1206

100K/ 1206

+

C3

33uF/450V

R5

1M

R4

1M

100K/1206

R10

R9

100K/ 1206

+

C4

33uF/450V

8

6

7

5

GD

Vcc

U1

INV

L6565

1

ZCD

GND

Vff

COMP

CS

3

2

4

R18

22K

C10

47uF/25V

+

R22 330

4.7nF

C9

3.3nF

C8

5/21

Page 6

Flyback stage design AN2528

2 Flyback stage design

Well known to all SMPS designers, the voltage stress on the device (power switch) is given

by:

Equation 1

V

V

off

inmaxVflVspike

where V

= flyback voltage = (V

fl

out

+ V

F, diode

collector due caused by leakage inductance. This over-voltage is not limited by any

clamping network in order to minimize as much as possible the solution cost using also the

very large margin available which has been fixed to 200 V. N

primary side while Ns is the number of turns on the main output secondary winding.

Now, taking into account a 300 V margin, the maximum flyback voltage that can be chosen

is:

Equation 2

V

BV V

fl

– V

inmax

– V

spike

minarg

After the calculation of the flyback voltage, we can proceed with the next step in the

converter design. The turns ratio between primary and secondary side is calculated with the

following formula:

––=

) * Np/Ns and V

1700 850– 200– 300 350V=–=–=

is the over-voltage on the

spike

is the number of turns on the

p

Equation 3

N

------ -

N

p

s

V

+

outVF diode,

fl

---------------------------------------- -

V

350

--------------- -

14 1+

23.3===

As a first approximation, since t he turn-on of the device occurs immediately after the energy

stored on the primary side, inductance is completely transferred to the secondary side:

Equation 4

V

• VflT

dcminTonmax

•=

reset

and

Equation 5

Where T

is the maximum on time, T

onmax

transformer inductance and T

T

results in:

onmax

T

is the switching time. Combining the two previous formulas

S

– TS=

onmaxTreset

is the time needed to demagnetize the

reset

Equation 6

VflT

•

T

onmax

------------------------------ -

V

S

+

dcminVfl

14µs≅=

The next step is to calculate the peak current. The output power is set to 6 W and the

desired transformer efficiency must be set by the designer (at least 80% in this case).

Excluding the energy losses on the input diode bridge, on the power switch and on the

secondary side rectifier, the following approximate formula can be used:

6/21

Page 7

AN2528 Flyback stage design

N

Equation 7

1

-- -

LPI

P

1.25 P

IN

•

OUT

2

------------------------------=

T

s

1

2

••

P

2

-- -

V

• T

dcmin

2

---------------------------------------------------------- -==

L

PTS

2

•

onmax

•

Hence

Equation 8

2

V

dcmin

------------------------------------------------ -

L

P

2.5 T

T

•

• P

•

S

2

onmax

OUT

14.7mH==

From here we can now calculate the peak current on primary.

Equation 9

V

•

dcminTonmax

-------------------------------------------

I

P

L

P

143mA≈=

To keep the transformer size v ery small and to get a very effe ctiv e cost solution , we pref er to

slightly increase the minimum working frequency in order to decrease the primary

inductance.

In order to hav e a 15 mH indu ctance and to k e ep an EF20 co re, a lo t of turns are needed on

the primary side. This can generate either not enough space on the EF20 core to

accomodate such a high number of windings or the remaining space is not large enough to

ensure good design. These considerations might induce designing a smaller primary

inductance value accepting a higher switching frequency.

There is no contraindication in using a smaller primary inductance which leads to a higher

minimum switching frequency and theoretically also to a higher maximum frequency.

Howev er the maxim um switching frequency is then limited not only by the inductance value,

but also by the L6565 PWM driver. When using an L6565, the internal blanking time limits

the minimum off-time and, in turn, the maximum switching frequency. To better understand

this phenomenon, please refer to the L6565 datasheet and to the next paragraphs.

After bench tests and fine tuning we used a transformer with the following specs:

Equation 10

L

7.5mH=

P

Equation 11

------ -

N

p

23.8=

s

N

------------

N

aux

p

18.87=

The part number of the transformer is CSM 2010-104 from Cramer.

In the next Section 3, we see from bench verification that the real minimum working

frequency is 50 kHz even if the inductance is 7.5 mH but with a peak current of about

250 mA.

7/21

Page 8

Parasitic capacitances and related issues AN2528

3 Parasitic capacitances and related issues

In a flyback converter stage it is important to take into account the parasitic capacitances

since their influence may affect the correct operation of the converter itself. Figure 2 shows

the small signal equivalent model of a main switch, transformer and main parasitic effects.

The parasitic capacitances between the ESBT collector and ground are mainly due to three

components (see Figure 2):

1. C

2. C

3. C

Usually transistors are mounted on a heat-sink by interposing an insulation layer. The heat-

sink has to be grounded either for safety reasons, or to minimize the RFI. The resulting total

parasitic capacitance C is equal to C

additional and non-negligible s witch-on po wer dissip ation. Large para sitic capacitances ma y

cause ringing and produce noise problems. The effect of parasitic capacitances is worse at

higher input voltages, like those observed in a 3-phase power supply.

Figure 3. The small signal equiv alent circuit

, the primary inter-winding capacitance;

1

, the intrinsic capacitance of ESBT between its collector and source;

2

, the parasitic capacitance between the collector of the ESBT and the heat-sink.

3

+ C2 +C3. C may be large enough to produce

1

+

Cbus

ESBT

T

I nsula ion Pad

Heatsink

C1

ESBT

C3

C2

T

C1

Ic1

Heatsink

ESBT

C2

Ic

T

Ic2

C3

Ic3

Considering that the power managed by the system is low, another goal to achieve is to

keep the power dissipation very low on every part on the system. Our target is to get less

than 1.5 W power loss on the switch. Achieving this target leads to two benefits: high

efficiency and no need of heat-sink (cost reduction).

Therefore the effect of C

additional power dissipation during switch-on and does not affect system stability. C

must not be considered in this case. C2 is related only to

3

has

1

the most important effect on flybac k con verter design. We hav e only tw o w a ys t o reduce C

1. Parasitic transformer inter-winding capacitance

2. Layout parasitic capacitance

Care is needed when designing the layout and building the transformer.

:

1

8/21

Page 9

AN2528 Base drive circuit design

4 Base drive circuit design

Let's have a closer look at the very simple base drive network used in this application.

Normally in applications such SMPS, where the load is variable, the collector current varies

as well. It is very important to provide a base current to the device that is correla ted with the

collector current in order to avoid the over saturation of the de vice at low load and to

optimize its performance in terms of power dissipation. This implies the use of a driving

network which allows getting a base current proportional to the collector current. For

additional information about the ESBT proportional base driving method, refer to AN2131.

Since in our application we must take into account power dissipation and simplicity as well,

we have pr eferred the simplest and least expensive driving network which is shown in

Figure 4. This choice also satisfies power dissipation requirements.

To set the R

value some considerations must be done. First of all, ref er to the hFE curve of

CC

STC04IE170HP (Figure 5).

Figure 4. ESBT base driving network

Referring to the calculations in Section 2, the collector peak current is 250 mA. At this

current value the ESBT gain is about 20, so that theoretically just 250 / 20 = 12.5 mA should

be enough to drive the base. This is true for very long conduction time. In the present

example the dynamic phenome non can occur du e t o th e re lati vely high switching fr eq ue ncy

(higher than 50 kHz) and even more to the small conduction time.

This concept is illustrated in Figure 6. It is extracted from the STC04IE170HP datasheet and

shows that, right after the turn-on, the V

needs some time to reach the V

CS

CSSAT

value. This

time is proportional to the collector current amount. That is why a peak base current is

absolutely mandatory to have a low voltage drop during conduction as soon as possible.

For further details about the driving network, please refer to AN2454.

9/21

Page 10

Base drive circuit design AN2528

Figure 5. DC current gain

Figure 6. Dynamic collector-source saturation voltage

To maximize performances, a base capacitor C

Note that, using the driving network shown in Figure 4, a quasi total recovery of energy to

drive the base is achieved. During the storage time the collector current comes out from the

base and is stored in the base capacitor. If the capacitor is small enough, the voltage across

it reaches the V

and after that the current flows to the Vcc capacitor.

cc

To set the time duration of the base current spike, the following appr oximate formula is

useful:

Equation 12

t

peak

Since R

=10 Ω (see below), if the peak has to be about 300 ns

B

Equation 13

C

B

The aim of R

is to dampen the ringing on the base current at the end of its peak. It is

B

chosen as a compromise between a dampi ng effect and additional power dissipation on it.

10/21

3R

• CB•=

t

peak

---------------- -

3R

•

B

has been inserted.

B

B

10nF==

Page 11

AN2528 Experimental results: waveforms

Ten is big enough to remove any ringing and the additional power dissipation on it is

practically negligible due to the very low current flowing through it. Finally, knowing that V

cc

is about 15 V:

Equation 14

15V

CC

-------------------- -

12.5mA

1.2KΩ==

R

After bench verification a final R

forecasted one flows into the base (higher I

during the peak (much lower I

of 2.2 kΩ has been fixed. A smaller base current than the

CC

ratio for a very short time).

C/IB

ratio) compensated by a higher base current

C/IB

5 Experimental results: waveforms

The following f igures sho w t he main w a veforms in steady state condition at full load. Notice

the behavior of the base current with an initial high peak pulse needed t o minimize th e eff ect

of the dynamic saturation voltage.

Figure 7. 110 V

input voltage overall1

ac

Figure 8. 110 V

input voltage overall2

ac

11/21

Page 12

Experimental results: waveforms AN2528

Figure 9. 110 Vac input voltage- storage highlight

Figure 10. 110 V

Figure 11. 380 V

input voltage turn-off highlight

ac

input voltage overall1

ac

12/21

Page 13

AN2528 Experimental results: waveforms

Figure 12. 380 Vac input voltage overall2

Figure 13. 380 V

Figure 14. 380 V

input voltage storage time highlight

ac

input voltage - turn-on highlight

ac

13/21

Page 14

Experimental results: waveforms AN2528

Figure 15. 600 Vac input voltage overall1

Figure 16. 600 V

Figure 17. 600 V

input voltage overall2

ac

input voltage turn-off highlight

ac

14/21

Page 15

AN2528 Experimental results: efficiency and further considerations

Figure 18. 600 Vac input voltage turn-on highlight

The importance of having a very good transformer in the turn-on highlight at high input

voltage can be better observed. The collector cur rent leading edge at turn-on is evident in

this condition. The peak amplitude has to be controlled or it can lead to premature turn-off of

the PWM driver with consequent instability. This issue has been deeply discussed in

Section 3.

6 Experimental results: efficiency and further

considerations

Table 2 summarizes the thermal and loss data. All information refers to max load. An

excellent result is the very high efficiency also at the highest input voltage. The case

temperature of ESBT is fine even in the worst case, with consequent low power dissipation

on it.

Table 2. Power dissipation and efficiency

VinAC (V) Tc (°C) Ptot (W) Efficiency

110 (V) 34 0.3 80%

400 (V) 49 0.8 66%

600 (V) 73 1.6 55%

To get the thermal performances shown, a special feature of the bi polar ha s been positively

utilized.

In a standard QR mode of operation, when the input voltage rises higher and higher, the

switching losses should increase since the frequency is increasing. For this reason the

L6565 provides the frequency foldback function that limits the minimum OFF-time.

An added feature is given by the storage time of ESBT, that helps to further reduce the

frequency while increasing the Input Voltage and/or reducing the load. This frequency

15/21

Page 16

Experimental results: efficiency and furt her considerations AN2528

reduction at high input voltage is very effective in improving the overall efficiency, since the

higher turn-on and turn-off voltages make the switching losses critical.

Thanks to the storage time (lasting about 1.5 µs under this condition), that adds a delay to

the current on-time, the minimum on-time is much longer than the one impo se d by the

L6565.

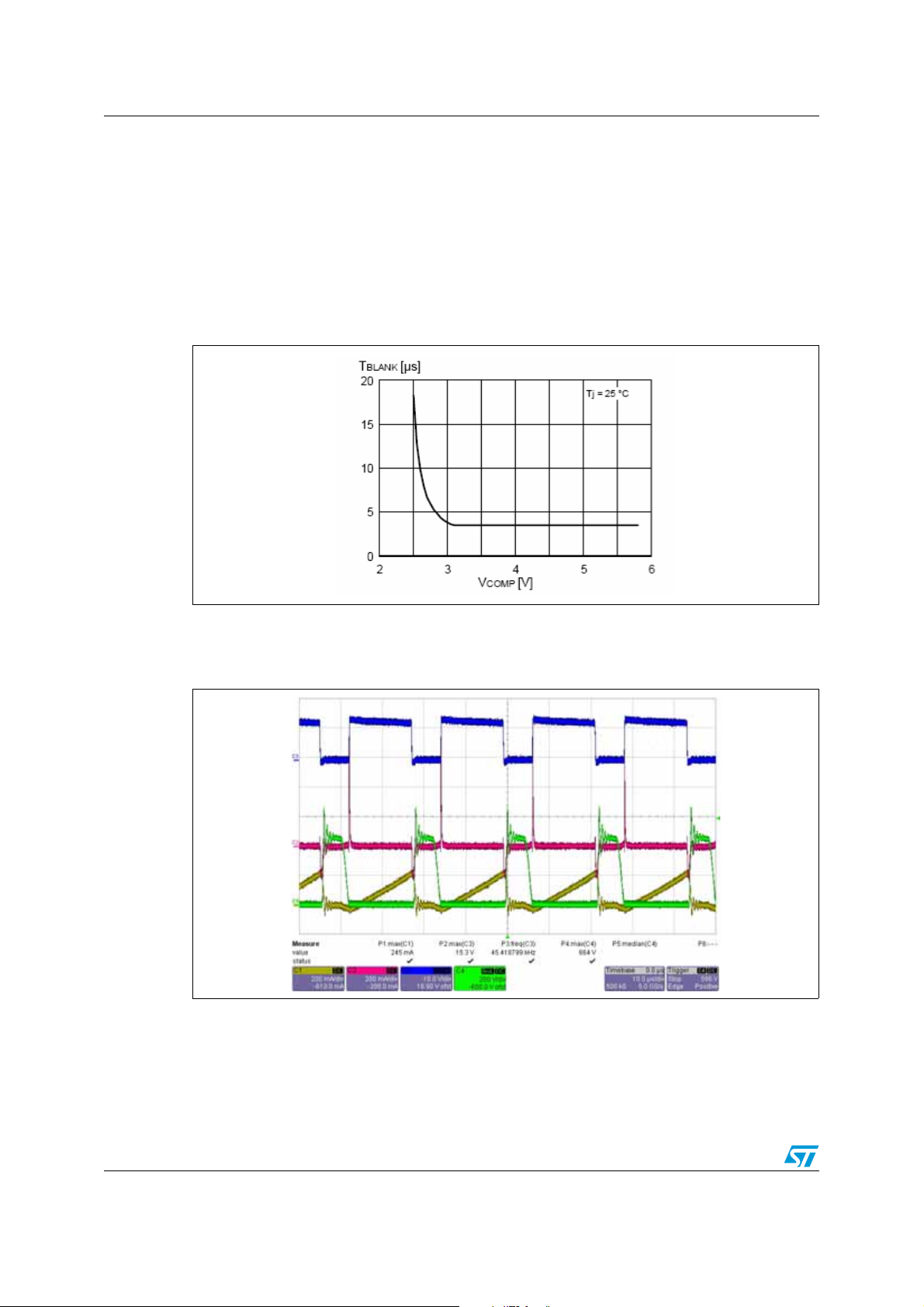

This leads to a lower V

value, and as a consequence, to a longer minimum OFF-time

comp

(see Figure 19 below). The system then works in advance at lower frequency as soon as

the input voltage increases or the load decreases.

Figure 19. V

comp

vs T

(minimum OFF-time)

Blank

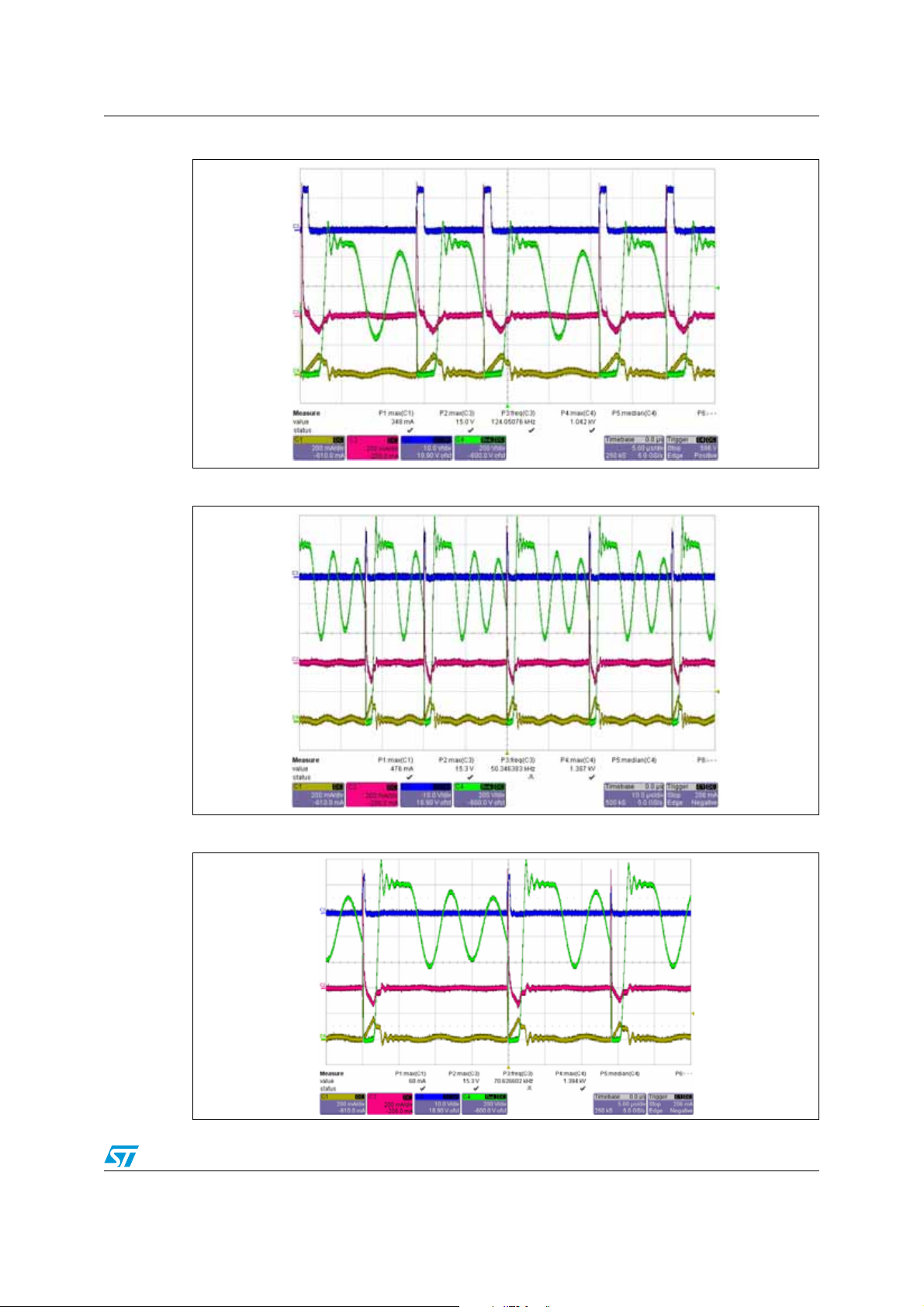

In the next figures the frequency reduction as a consequence of an increased input voltage

is shown.

Figure 20. 110 V

input voltage, max load

ac

From Figure 21 the frequency is reduced due to the storage time presence at 380 V

becoming more and more evident at higher input voltage, 600 V

This "enhanced" frequency foldback created by the storage time allows keeping the total

power dissipation on the device very low regardless of the very high voltage needed to

sustain.

16/21

ac

,

ac

.

Page 17

AN2528 Experimental results: efficiency and further considerations

Figure 21. 380 Vac input, max load: frequency reduction

Figure 22. 600 V

Figure 23. 600 V

input, max load: further frequency reduction

ac

input, max load: increased OFF- time highlight

ac

17/21

Page 18

Bill of materials AN2528

Appendix A Bill of materials

Table 3. Bill of materials

Reference Qty Value/part number Description

C1 1 330 µF / 25V Electrolytic capacitor

C2, C3, C4 3 33 µF / 450V Electrolytic capacitor

C5 1 .0022 µF ceramic capacitor, 440 V

C6, C7 2 10 nF / 50 V ceramic capacitor, 50 V, X7R

C8 1 3.3 nF / 50 V ceramic capacitor, 50 V, X7R

C9 1 4.7 nF / 50 V ceramic capacitor, 50 V, X7R

C10 1 47 µF / 25 V Electrolytic capacitor

C11 1 22 µF / 25 V Electrolytic capacitor

D1, D2, D4, D5 4 STTH112U STMicroelectronics, diode rectifier, 1200 V, 1 A

D3 1 STPS3L60 STMicroelectronics, diode power schottky, 60 V, 3 A

D6, D7 2 LL4148 SMD 1206

F1 1 TR5Fuse Serie TR5 250 mA / 250 V

ISO1 1 H11A817 Phototransistor Optocouplers, Fairchild

J1 1 Phoenix 3 pin

J2 1 Phoenix 2 pin

L1 1 M600X Radiali, 470 µH

Q1 1 STC04IE170HP

R1, R2, R3, R7, R9, R10 6 100 K SMD 1206

R4, R5 2 1 M SMD 1206

R6 1 1 SMD 1206

R8 1 47 K SMD 1206

STMicroelectronics, emitter switched Bipolar transistor,

4 A, 1700 V

, 2 KV

ac

R11 1 1.5 K SMD 1206

R12 1 10 SMD 1206

R13 1 22 SMD 1206

R14 1 11 K SMD 1206

R15 1 1.2 K SMD 1206

R17 1 4.7 K SMD 1206

R18 1 22 K SMD 1206

R21 1 2.4 K SMD 1206

R22 1 330 SMD 1206

R23 1 4.7 / 1/2 W Resistor, carbon film, 350 V, 0.5 W, 5%

18/21

Page 19

AN2528 PCB layout

Table 3. Bill of materials (continued)

Reference Qty Value/part number Description

T1 1 CSM 2010-104 CRAMER [sample]

U1 1 L6565 STMicroelectronics, Q-resonant SMPS controller

U2 1 TL431C STMicroelectronics, Shunt Reference, 2,5 V, 1 to 100 mA

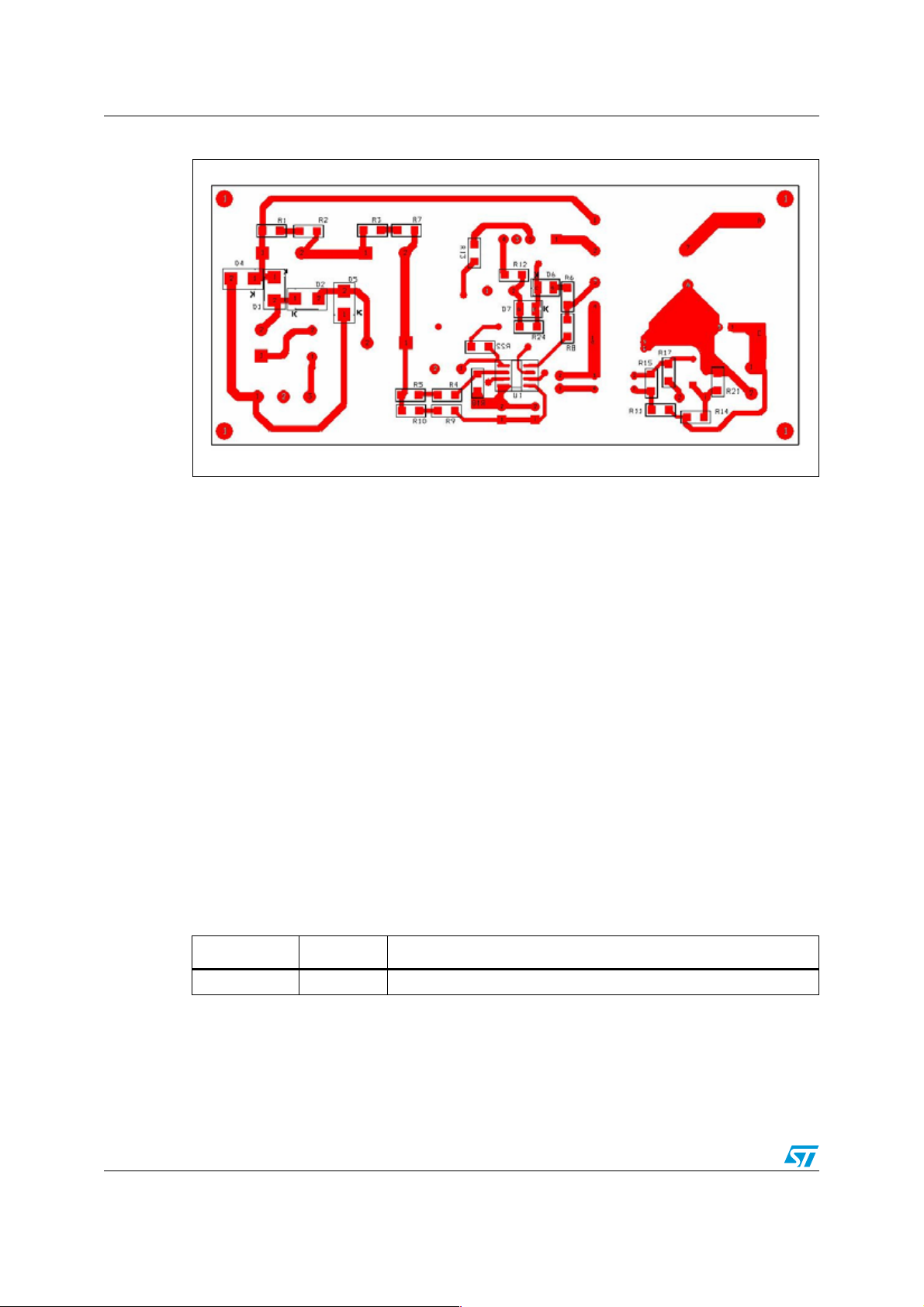

Appendix B PCB layout

Figure 24. PCB picture top view (components and copper)

Figure 25. PCB picture top view components and bottom layer copper

19/21

Page 20

References AN2528

Figure 26. PCB picture top view components and bottom layer copper

7 References

● STMicroelectronics application note AN1889 "ESBT STC03DE120 IN 3-PHASE

AUXILIARY POWER SUPPLY”

● STMicroelectronics application note AN1262 "OFFLINE FLYBACK CONVERTERS

DESIGN METHODOLOGY WITH THE L6590 FAMILY"

● STMicroelectronics application note AN2131 "HIGH POWER 3-PHASE AUXILIARY

POWER SUPPLY DESIGN BASED ON L5991 AND ESBT STC08DE150"

● STMicroelectronics L6565 datasheet

● STMicroelectronics STC04IE170HV datasheet

● "Switching Power Supply Design", McGraw-Hill, Inc.

8 Revision history

Table 4. Revision history

Date Revision Changes

05-Jul-2007 1 First issue

20/21

Page 21

AN2528

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely res ponsibl e fo r the c hoic e, se lecti on an d use o f the S T prod ucts and s ervi ces d escr ibed he rein , and ST as sumes no

liability whatsoever relati ng to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third pa rty p ro duc ts or se rv ices it sh all n ot be deem ed a lice ns e gr ant by ST fo r t he use of su ch thi r d party products

or services, or any intellectua l property c ontained the rein or consi dered as a warr anty coverin g the use in any manner whats oever of suc h

third party products or servi ces or any intellectual propert y contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICUL AR PURPOS E (AND THEIR EQUIVALE NTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJ URY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST fo r the ST pro duct or serv ice describe d herein and shall not cr eate or exten d in any manne r whatsoever , any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in vari ous countries.

Information in this document su persedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of compan ie s

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - Fran ce - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

21/21

Loading...

Loading...