Page 1

AN2512

Application note

Three-phase meter based STPM01, VIPer12A

Introduction

This application note describes how to design a three-phase meter using STPM01 as the

measuring device and a VIPer12A based SMPS (Switch Mode Power Supply).

STPM01 is a metering ASSP implemented in an advanced 0.35 µm BCD6 technology. It is

designed for the effective measurement of active, reactive and apparent energies, Vrms,

Irms, instantaneous voltage and current, frequency in power line systems that use the

current transformer, Rogowski coil and/or shunt principle.

This device can be used as a standalone on-board metering device in single-phase energy

meter applications or as a peripheral in a microprocessor based single- or three-phase

meter.

In a standalone configuration STPM01 outputs a pulse train signal having a frequency

proportional to the active power used, while in peripheral mode STPM01 is used in a

microprocessor based application. In this case, measured data are read at a fixed time

interval from the device internal registers by means of SPI interface processed by a

microcontroller.

In the following paragraphs a circuit description is explained, with particular focus on the

power supply section, the three-phase design, and the clock management network. Then,

the power calculation algorithm is discussed and finally some layout hints and experimental

results are shown.

This application note should be used in conjunction with the STPM01 and VIPer12A

datasheet.

Three phase block diagram

April 2007 Rev 1 1/38

www.st.com

Page 2

Contents AN2512

Contents

1 Application description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Circuit description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Power supply circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Phase circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.1 Current sensing circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4.2 Anti-aliasing filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4.3 Voltage sensing circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4.4 Crosstalk cancellation network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.5 Clock management network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 Communication with microprocessor . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Power calculation algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 STPM01 SPI Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 STPM01 Initialization (latching) and reading (shifting) . . . . . . . . . . . . . . . 14

3.3 Data record structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.4 Data integrity checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.5 Unpacking of data records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.6 Processing of phase energy values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.7 Three-phase energy calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.8 Pulse generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4 Layout rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5 Experimental results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.1 Phase one results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2 Phase two results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.3 Phase three results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.4 Voltage and frequency influence on phase three . . . . . . . . . . . . . . . . . . . 24

6 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2/38

Page 3

AN2512 List of figures

List of figures

Figure 1. Top layer circuit schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2. SMPS circuit schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 3. Phase circuit schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 4. Clock management network schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 5. Connectors schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 6. Flow chart of phase reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 7. Timing for data records reading in 3 phase system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 8. Data records reconstruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 9. STPM01 data register structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 10. Typical profile of output of an energy integrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 11. Graph of experimental results of phase n.1 tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 12. Graph of experimental results of phase n.2 tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 13. Graph of experimental results of phase n.3 tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 14. Graph of voltage and frequency influence on phase n.3 . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 15. Instantaneous voltage (or current) in one voltage cycle of a three-phase system . . . . . . . 25

Figure 16. Per-phase powers in (a) delta-connected load and (b) wye-connected load . . . . . . . . . . . 26

Figure 17. Two-wattmeter method in star- or delta-connected load. . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 18. The wattmeter connections in the three-phase four-wire loads . . . . . . . . . . . . . . . . . . . . . 28

3/38

Page 4

Application description AN2512

1 Application description

Three-phase meters (which derive as particular cases from poly-phase systems), are most

commonly used in practical industrial applications, and in a few cases also for domestic use.

This three-phase meter can be used as a reference board to build a Class 0,5 three-phase

microprocessor based meter for power line systems 3-Wire DELTA service, 4-Wires DELTA

and WYE service. It uses a multi-chip topology, in which each phase is monitored using a

single-phase device.

In this way, three STPM01 have been used with a common clock network. The power supply

is implemented in fly-back topology using a VIPer12A.

The meter cannot be used in standalone mode and a management/supervisory board must

be used for energy integration and data displaying. Such a control board should be plugged

in the connector J2 (referring to board schematics below), while the connector J1 is used for

calibration purposes in association (or conjunction) with the STPMxx parallel

programmer/reader released with the application.

1.1 Operating conditions

Table 1. Operating conditions

Value Min Max Unit

V

NOM

I

NOM/IMAX

f

LIN

T

AMB

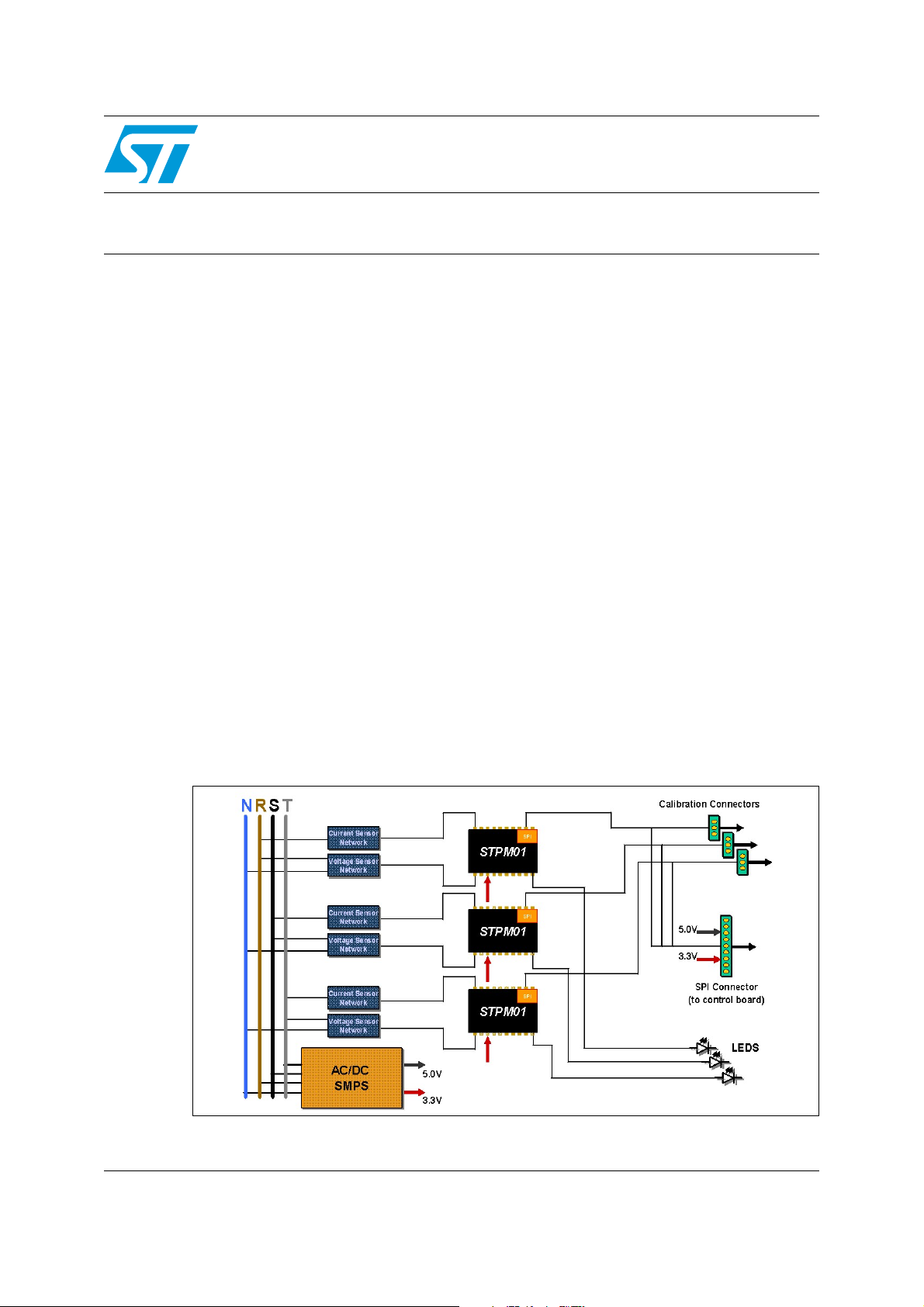

1.2 Circuit description

The meter consists of one board divided into the following sections:

● Power supply management circuit

● Phase circuit

● Clock management network

● Connectors.

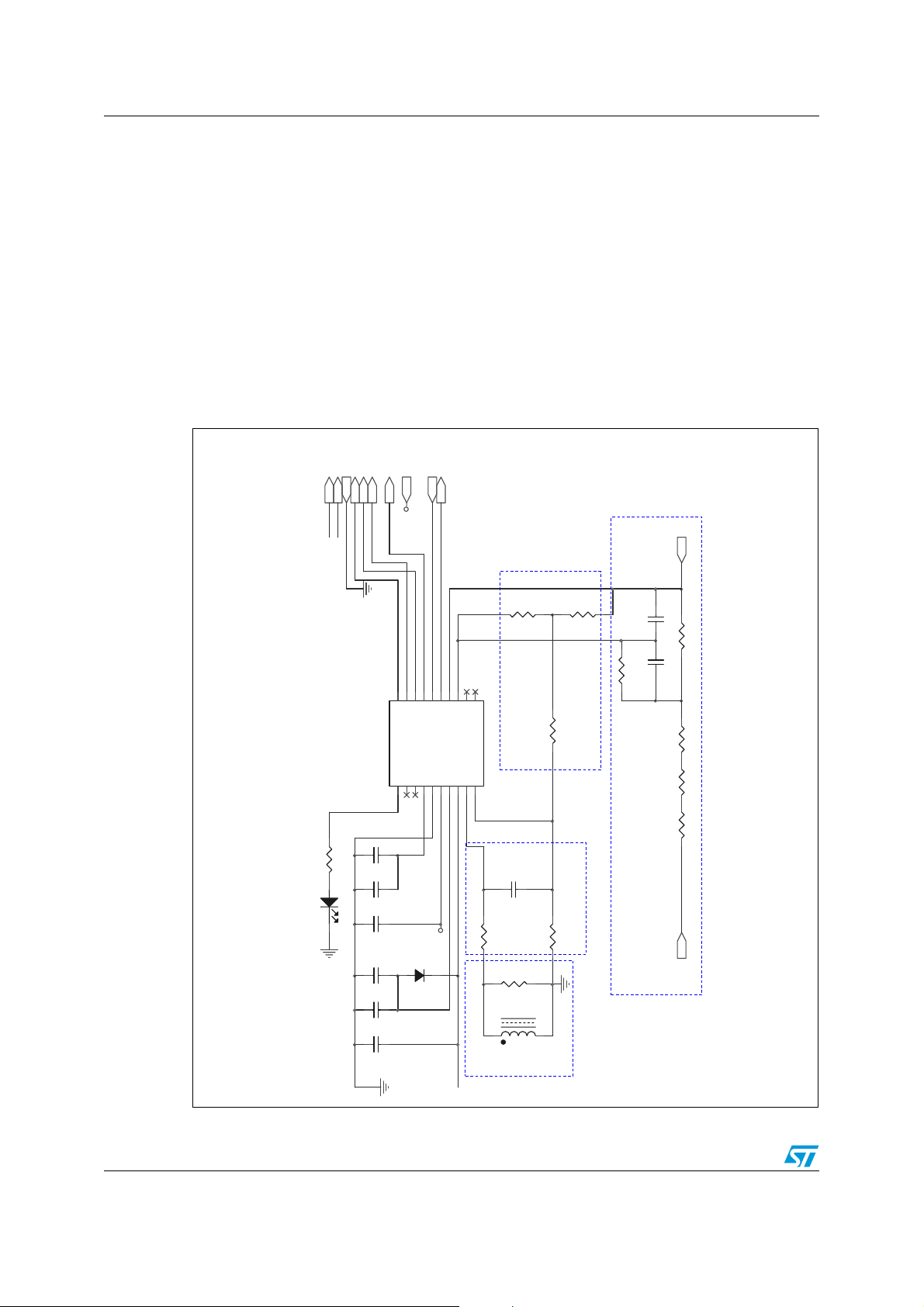

The schematic of the board is shown in Figure 1.

80 480 V

530A

45 65 Hz

- 40 +85 °C

RMS

RMS

4/38

Page 5

AN2512 Application description

Figure 1. Top layer circuit schematic

5V

J2

PHASE_1

P1

P

N

N

VDD

VDD

GND

CLKIN

CLKIN CLKOU T

PHASE

PHASE_2

P2 VOTPL2

P

N

N

VDD

VDD

P3

N

GND

CLKIN CLKOUT

PHASE

PHASE_3

P

N

VDD

GND

CLKIN CLKOUT

PHASE

U8A

C1

4.194304MHz

15pF

R1

1M

C2

15pF

74HC14A/SO

1 2

34

U8B

Y1

74HC14A/SO

VDD

VOTPL1

VOTP

SDA

SDA

SCSL1

SCS

SCL

SCL

LEDL1

LED

SYN

SYN

VOTP

SDA

SDA

SCSL2

SCS

SCL

SCL

LEDL2

LED

SYN

SYN

VOTPL3

VOTP

SDA

SDA

SCSL3

SCS

SCL

SCL

LEDL3

LED

SYN

SYN

SCL

SDA

SYN

SCSL1

SCSL2

SCSL3

LEDL1

LEDL2

LEDL3

J14

1 2

VOTPL1

3 4

VOTPL2

5 6

VOTPL3

JUMPER3

J13

1 2

SCSL1

3 4

SCSL2

5 6

SCSL3

SCSJUMPER

J7 1 J111

J8 1

J9 1

J10 1

1

2

3

4

5

6

7

8

9

10

11

VDD

12

13

14

15

16

17

18

19

20

CON20

J1

VOTP

1

2

3

SDA

4

SCS

5

SCL

6

7

SYN

8

9

VDD

10

SMPS

P1

P1

P2

P2

P3

P3

N

N

SMPS

5V

5V

VDD

3.3V

GND

J121

J51

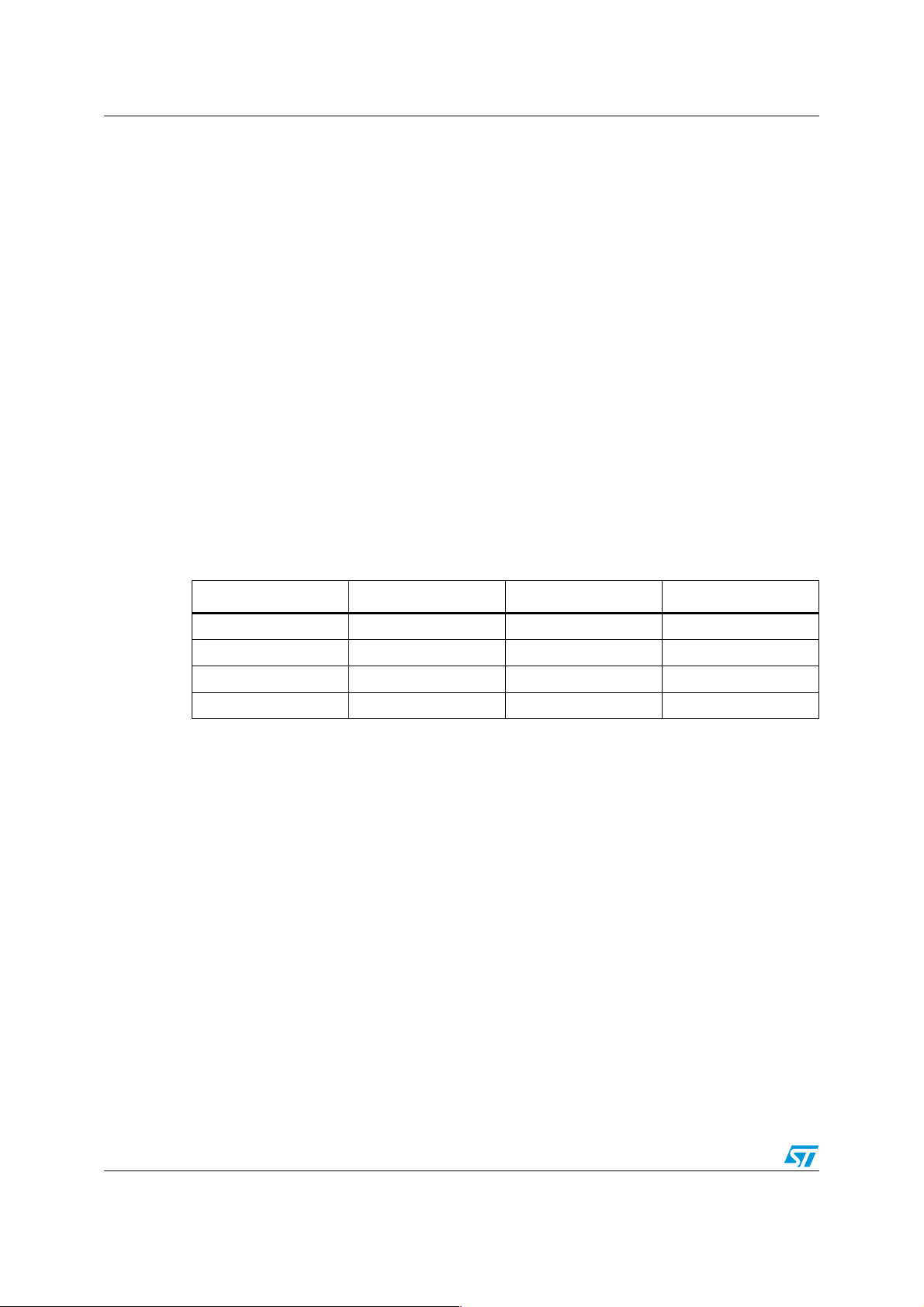

1.3 Power supply circuit

A 3-phase 4-wire bridge is used for mains rectification because the neutral rectification is

needed to ensure proper operation in case of missing neutral connection or neutral misswiring.

A varistor is connected between each line and neutral to guarantee pulse voltage test

immunity according to the EN62052-11 standard.

The input EMI filter is a simple, undamped LC-filter for both differential and common mode

noise suppression.

The circuit for input voltage limiting is connected between the input EMI filter and the bulk

capacitor C4. Such a circuitry includes a Power MOSFET and a self driven control section.

The MOSFET Q1 is a standard N-Channel 500 V 3.3 Ω in D-PAK package, mounted on a

small copper area to improve thermal performance. The self driven control section consists

of a voltage divider and zener diodes. The resistors R1, R2 and R3 ensure the gate-source

charge for the switch, while the zener diodes D3 and D4 set the maximum voltage value

(360 V) across the bulk capacitor.

An NTC limits the inrush current and ensures Q1 operation inside its safe operating area.

The Flyback converter is based on VIPer12A, a product in the VIPerX2A family, which

combines a dedicated current mode off-line PWM controller with a high voltage power

MOSFET on the same silicon chip. The switching frequency is fixed at 60 kHz by the IC

internal oscillator in order to optimize the transformer size and cost. The transformer

reflected voltage has been set to 60 V, providing enough margin for the leakage inductance

voltage spike and no snubber circuit is needed which allows consequent cost savings.

As soon as the voltage is applied on the input of the converter, the high voltage start-up

current source connected to the drain pin is activated and starts to charge the V

capacitor

dd

C8 through a constant current of 1 mA. When the voltage across this capacitor reaches the

V

on threshold (about 14 V), the VIPer12A starts to switch. During normal operation the

dd

5/38

Page 6

Application description AN2512

smart power IC is powered by the auxiliary winding of the transformer via the diode D7. No

spike killer for the auxiliary voltage fluctuations is needed thanks to the wide range of the

V

pin (9-38 V). The primary current is measured using the integrated current sensing for

dd

current mode operation.

The output rectifier D6 has been chosen in accordance with the maximum reverse voltage

and power dissipation. In particular a 0.5A-80 V Schottky diode, type TMBAT49, has been

selected.

The output voltage regulation is performed by secondary feedback on the 5 V output

dedicated to the display, while the 3.3 V output, dedicated to the logic part and the

microcontroller, is linearly post-regulated from the 5 V output. This operation is performed by

a very low drop voltage regulator, L4931ABD33, in SO-8 package. The voltage regulator

delivers up to 100 mA, ensuring good reliability with no heat sink. The feedback network

ensures the required insulation between the primary and secondary sections. The

optotransistor directly drives the VIPer12A feedback pin which controls the IC operation.

A small LC filter has been added to the 5 V output in order reduce the high frequency ripple

with reasonable output capacitors value.

The Flyback transformer is a layer type based on E13 core and N27 ferrite, manufactured by

Pulse Eldor, and ensures safety insulation in accordance with the EN60950.

For more info on the power supply, please refer to AN2264, "Three-Phase SMPS for low

power applications with VIPer12A". The schematic of the power supply section is shown in

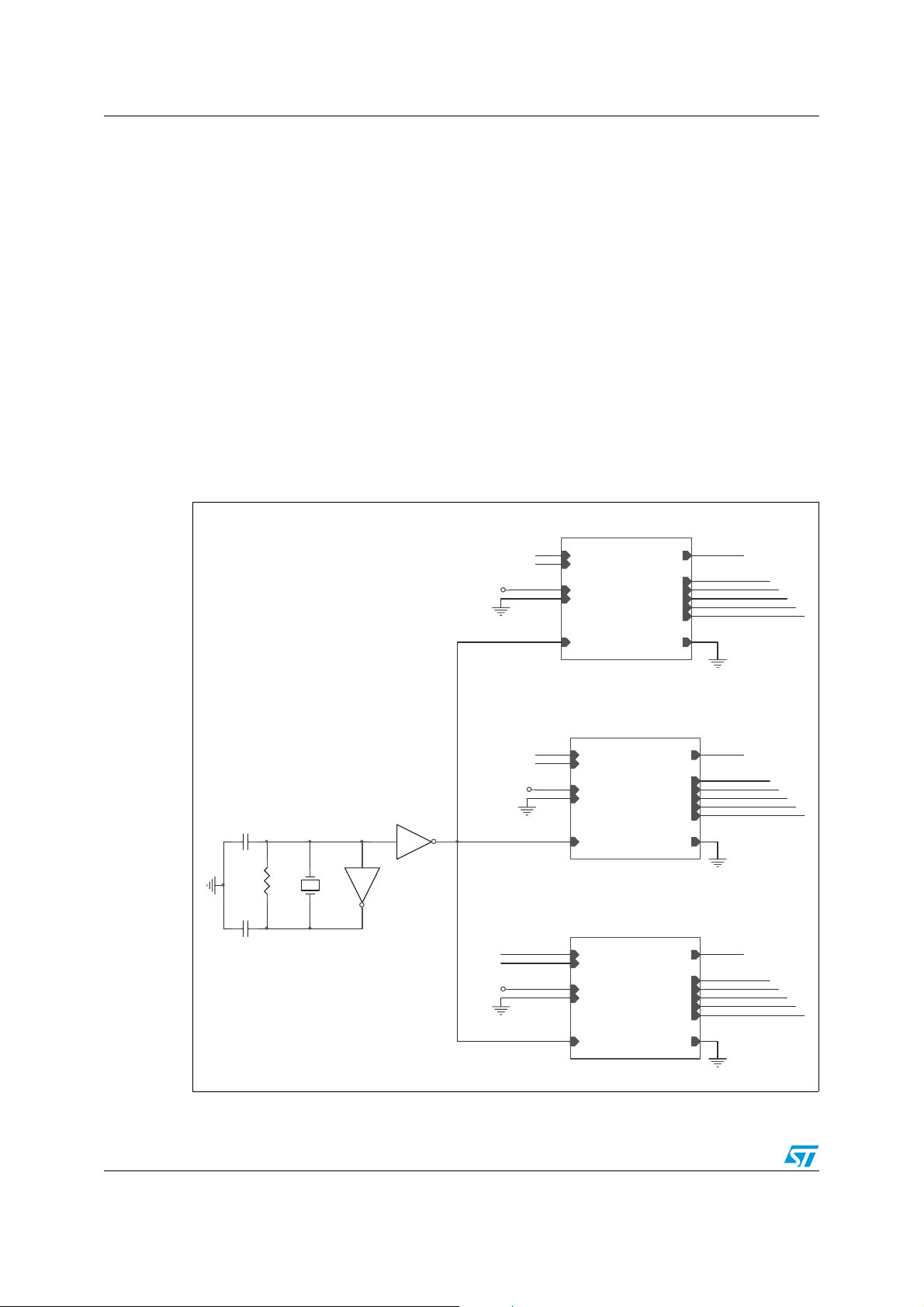

Figure 2.

6/38

Page 7

AN2512 Application description

Figure 2. SMPS circuit schematic

P2

N

P3

P1

R62 22E 1W

SO5K275/275V

R64 22E 1W

RV3

4

-+

1

BRIDGE

3

10uF 50V

C21

D9

180V

3

FB

Vdd

VIPer12AS/SO-8

2

S

1

S

47nF 50V SMD

C24

3 1

R25

4.7K 1% SM D

U4

TS2431

2

100nF 50V SMD

+

4

U5

5

D

6

D

7

D

8

D

5.6K

R24

4

3

PC817

12

C23

GND

LL4148

220E SMD

U3

R21

R22

1K SMD

4.7K 1% SM D

D7

180V

10E SMD

R20

D10

5

R23

2

GND

3

GND

6

GND

7

GND

5

INHIB

1000uF 50V

C20

+

R63 22E 1W

2

1

BRIDGE

D8

220nF 630V

C19

330k

4

U2 L4931ABD33

VOUTVIN

3.3V@100mA

18

220nF 630V

C16

R59

330k

R60

ZMM 15/S OD-80

C18 2.2uF450V

+

2

6

330uF 25V

22uF 16V

100nF SMD

3.3V

SO5K275/275V

SO5K275/275V

RV2

4

-+

3

R58

330k

120E

1

D4

1

T1

10

D5

TMBAT49

C14

+

L3

10uH 125mA SMD

C15

+

C17

5V@10mA

5V

R61 22E 1W

RV1

2

D3

1mH

L2

NTC1

4 3

Q1 STD5nk40Z

C22

2nF/2kV (Y1)

7/38

Page 8

Application description AN2512

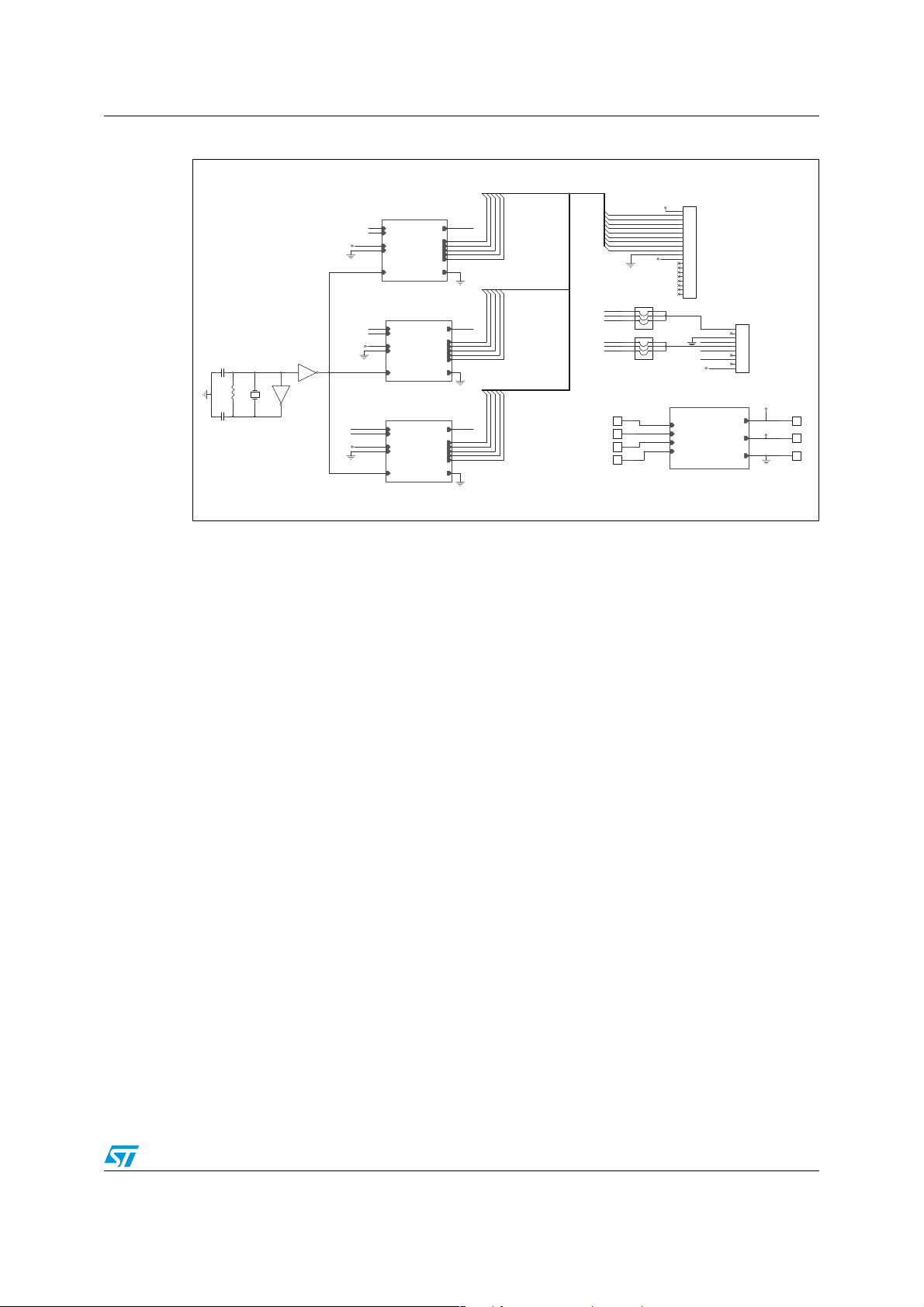

1.4 Phase circuit

This paragraph explains the implementation of the phase network which performs the power

calculation.

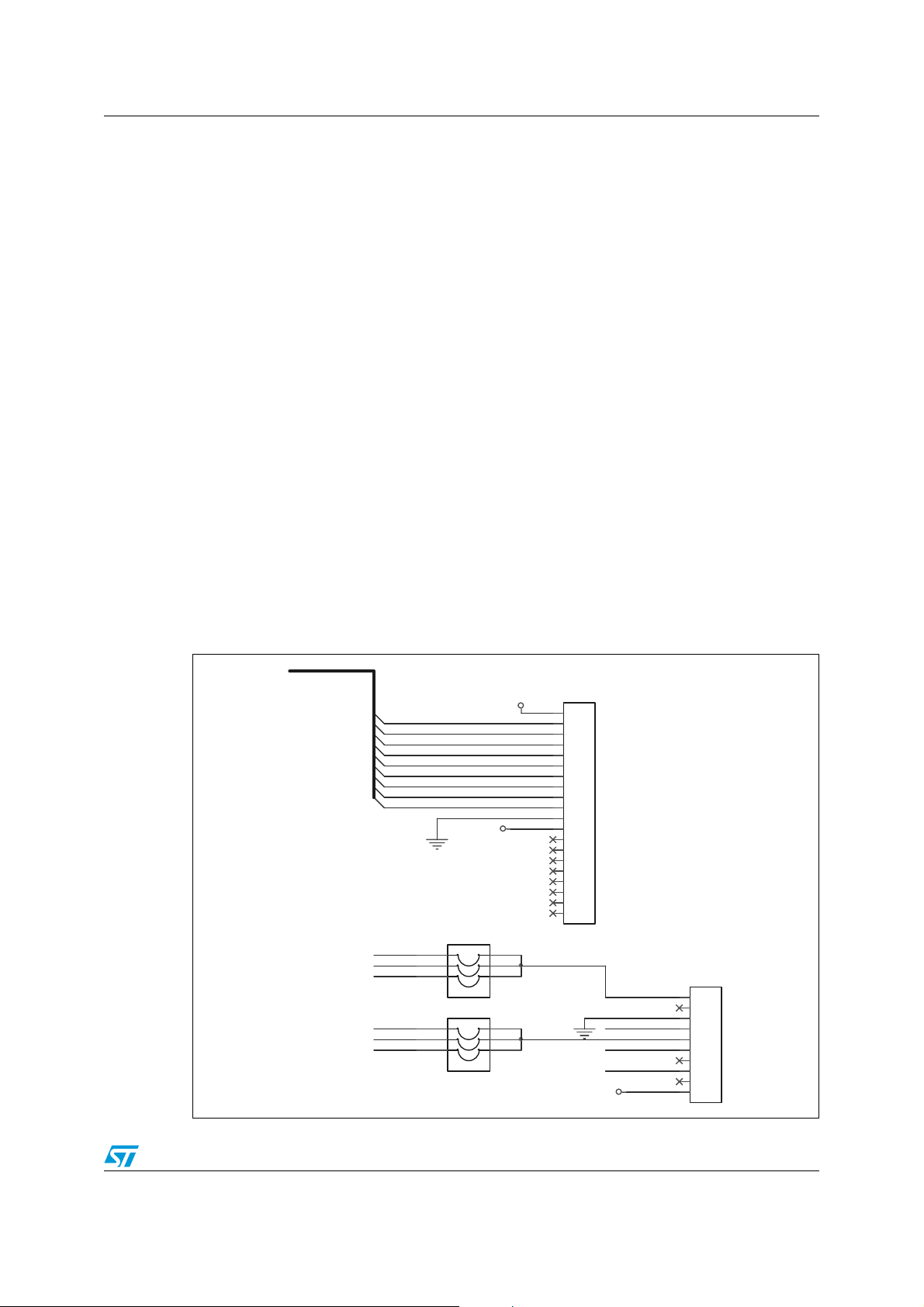

The three phases are identical. Figure 3 shows the implementation of the STPM01 used for

energy calculation of each phase.

The schematic can be divided into the following subsets:

● Current sensing circuit (1)

● Anti-aliasing Filter (2)

● Voltage Sensing Circuit (3)

● Crosstalk Cancellation Network (4).

Figure 3. Phase circuit schematic

SDA

SCS

SCL

SYN

LED

VOTP

GND

VDD

CLKI N

CLKOUT

GND

LED

VOTP

SDA

LED

R2 750

12

D1

VDD

SCL

SYN

SCS

R10

150K

R9

2,2K

C12

0

C11

R13

2.2M

4

2

R8 1k

C8

C7

C6

C5

C4

C3

Scl

Sda

U1

led

MON

1245687

20

1MY

1nF

1nF

D2

1MY

1nF

1nF

R7

12131416171531819

Vip

Vin

Iln2

Syn

Scs

CLKin

CLKout

Vdda

STPM01_TSSOP20

Votp

Ilp1

Iln1 Ilp2

9

10 11

C9

10nF

R5 1k

R6

3.4

CT

L1

1

VOTP

MOP

Vddd

Vss

Vcc

VDD

LL4148

N

N

33nF

4.7u

R17 470

R16

200K

R15

270K

R14

270K

P

P

3

8/38

Page 9

AN2512 Application description

1.4.1 Current sensing circuit

The STPM01 has two external current sensing circuits, primary and secondary current

channels.

Normally, the second current circuit is used in single-phase meter implementation when the

anti-tamper feature is required. In this way it is possible to read also the current flowing into

the neutral wire to have a comparison with the current flowing into the line wire and detect

possible tampers.

In this application only the primary channel has been used. As a consequence, the

configuration of STPM01 is:

● PST= 2 if a current transformer is used (this is the case of this meter);

● PST= 0 (or 1) if a Rogowski coil is used

in the latter case ADDG bit can be used to have a further gain of x8.

The current channel uses a current transformer to sense mains current. The burden resistor

is used to produce a voltage between VIN1 and VIP1 proportional to the current measured.

1.4.2 Anti-aliasing filter

The anti-aliasing filter is a low-pass filter. It has a negligible influence on the voltage drop

between IIN1 and IIP1. Its aim is to reduce the distortion caused by the sampling, also

called aliasing, by removing the out-of-band frequencies of the input signal before sampling

it with the analog-to-digital converter.

Filtering is easily implemented with a resistor-capacitor (RC) single-pole circuit which

obtains an attenuation of -20dB/dec.

1.4.3 Voltage sensing circuit

A resistor divider is used as voltage sensor.

The 740 kΩ resistor is separated into three, 2x270 kΩ and 1x200 kΩ, in-series resistors,

which ensure that a high voltage transient does not bypass the resistor. This also reduces

the potential across the resistors, thereby decreasing the possibility of arcing. The following

resistors are used to implement resistor divider:

● R=R14+R15+R16=740 KΩ,

● R5=470 Ω.

Capacitor C11 and resistance (R19+ R15) create a filter which prevents Electromagnetic

Interference (EMI).

1.4.4 Crosstalk cancellation network

The voltage front-end handles voltages of considerable amplitude, which makes it a

potential source of noise. Disturbances are readily emitted into current measurement

circuitry where they interfere with the actual signal to be measured. Typically, this produces

a non-linear error at small signal amplitudes and non-unity power factors. At unity power

factor, voltage and current signals are in phase and crosstalk between voltage and current

channels merely appears as a gain error, which can be calibrated. When voltage and

current are not in phase, crosstalk has a non-linear effect on the measurements, which

cannot be calibrated.

9/38

Page 10

Application description AN2512

Crosstalk is minimized by means of good PCB planning and the proper use of filter

components in the crosstalk network. Recommended filter components are shown in

Figure 3. The network subtracts a signal proportional to the voltage input from the current

input. This prevents cross talking within the STPM01.

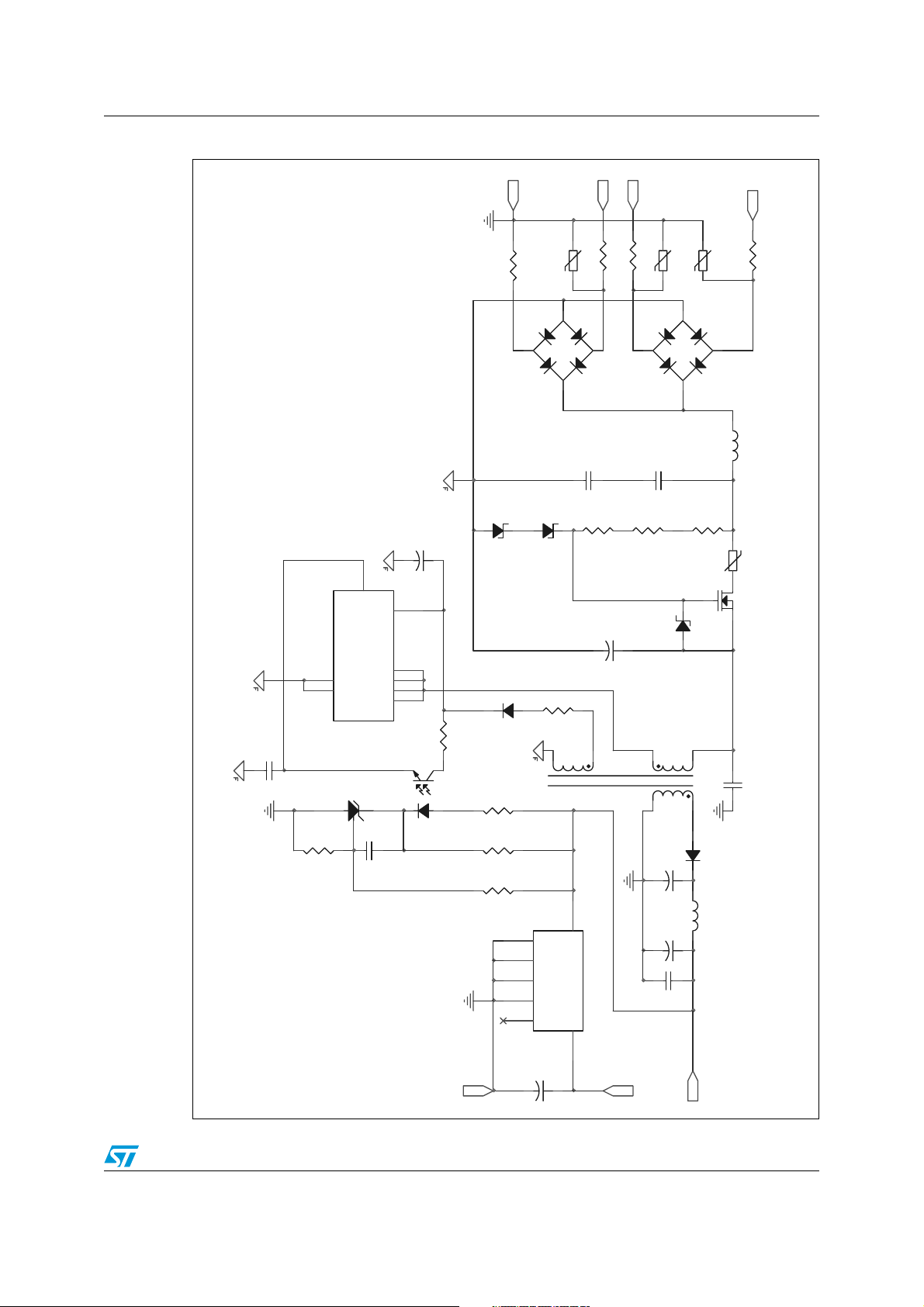

1.5 Clock management network

4.194 MHz quartz is used to supply the clock to the three STPM01 devices. Figure 4 shows

the schematic of the enhanced clock network which prevents EMI influences.

A discrete inverter network is used to change the impedance of the common node of the

three blocks. The output of the inverter prevents the second order antenna effect of the

node.

The CLKOUT pins are grounded to guarantee the current loop.

To select the measurement frequency range, MDIV must be set to 0 in the configuration

register of STPM01. If an 8 MHz quartz is used, this bit must be changed to 1.

Figure 4. Clock management network schematic

PHASE_1

VDD

CLKI N

P1

P

N

N

VDD

GND

CLKI N CLKOUT

PHASE

VOTP

SDA

SCS

SCL

LED

SYN

VOTPL1

SDA

SCSL1

SCL

LEDL1

SYN

U8A

34

74HC14A/SO

1 2

U8B

74HC14A/ SO

C1

15pF

C2

15pF

4.194304MHz

R1

1M

Y1

10/38

VDD

PHASE_2

P2 VOTPL2

N

VDD

P3

N

P

N

VDD

GND

CLKI N CLKOUT

PHASE

PHASE_3

P

N

VDD

GND

CLKI N CLKOUT

PHASE

VOTP

SDA

SCS

SCL

LED

SYN

VOTP

SDA

SCS

SCL

LED

SYN

SDA

SCSL2

SCL

LEDL2

SYN

VOTPL3

SDA

SCSL3

SCL

LEDL3

SYN

Page 11

AN2512 Communication with microprocessor

2 Communication with microprocessor

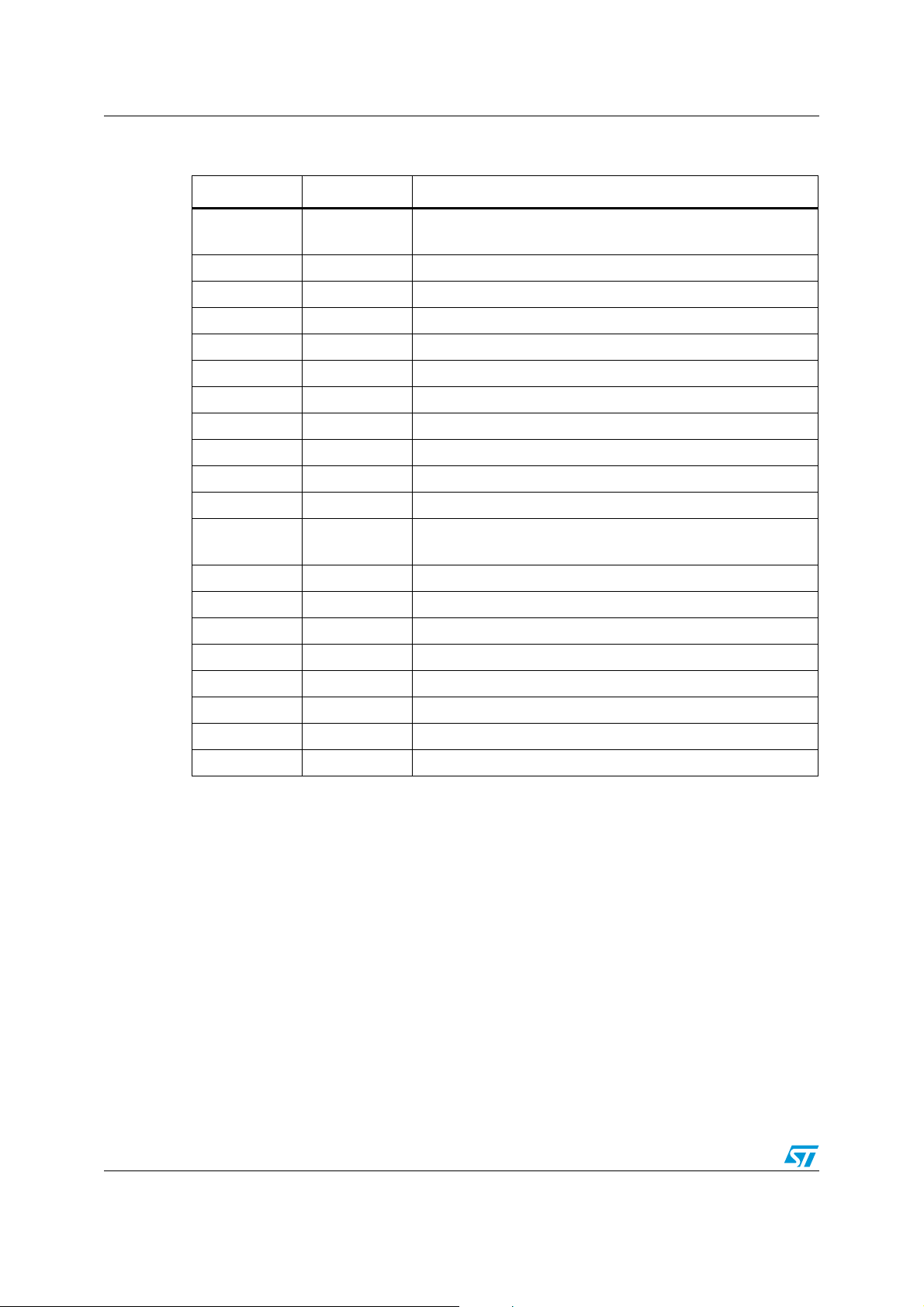

A control board with embedded microprocessor should be connected to connector J2 of

module using 20-wire flat cable. Ta bl e 2 below describes the pin-out of the connector.

Each STPM01 has an SPI communication port implemented by four multi-purpose pins.

Through the J2 connector, the control board can read data records or it can access the

mode or configuration signals of each metering device by means of dedicated protocol.

Each pin can draw up to 4 mA at +3.0 V from the control module. The selection of the device

to be read is done acting on one of the three SCSLx (STPM01 device select) pins.

By default, the STPM01 is configured in peripheral mode by setting configuration bits

APL = 0.

This implies also the following output settings:

● watchdog reset signal on MON pin;

● zero-crossing (ZCR) on MOP pin;

● a pulse train with frequency proportional to the power consumption on LED pin.

To display the information on the power consumption, it is either possible to feed three

LEDs, each one showing the information on one phase, from the LED pins of the three

measurement devices, or the control board can generate an LED signal to show the global

power consumption by reading and manipulating energy information from the three STPM01

registers. In this case, the control board may also recalibrate any result read from the

module through appropriate software.

Figure 5. Connectors schematic

SCL

SDA

SYN

SCSL1

SCSL2

SCSL3

LEDL1

LEDL2

LEDL3

VOTPL1

VOTPL2

VOTPL3

SCSL1

SCSL2

SCSL3

VDD

J14

1 2

3 4

5 6

JUMPER3

J13

1 2

3 4

5 6

SCSJUMPER

5V

J2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

CON20

VDD

VOTP

SDA

SCS

SCL

SYN

J1

1

2

3

4

5

6

7

8

9

10

11/38

Page 12

Communication with microprocessor AN2512

Table 2. J2 connector pin description

Pin No. Pin name Functional description

1. 5 V

2. SCL SPI Interface Pin

3. SDA SPI Interface Data Pin

4. SYN SPI Interface Pin

5. SCSL1 Phase n.1 SPI enable signal

6. SCSL2 Phase n.2 SPI enable signal

7. SCSL3 Phase n.3 SPI enable signal

8. LEDL1 LED output of Phase n.1

9. LEDL2 LED output of Phase n.2

10. LEDL3 LED output of Phase n.3

11. GND Signal reference level 0 V and power supply return

12. VDD

13. --- NC

14. --- NC

15. --- NC

16. --- NC

17. --- NC

18. --- NC

Up to 25 mA can be drawn from this pin

Up to 100 mA can be drawn from this pin

Power out of +5.0 V

Power out of +3.3 V

19. --- NC

20. --- NC

A host system can communicate with each measurement module (actually, with the

STPM01) using SPI interface, through connector J2. The STPM01 always acts as an SPI

slave while the host system acts as an SPI master. An application control board or an

external system can be considered as host.

Connector J1 is used in the evaluation phase to connect the measurement module to a PC

through the STPM01 parallel Programmer/Reader hardware interface.

This allows the user to set temporarily or permanently the internal STPM01 registers using a

dedicated GUI. Jumpers J13 and J14 select which of the three devices will be accessed.

The VOTP pin on the connector J1 is used when a host wants to permanently write some

configuration bits in the metering device. In this case, a +15 V power level must be present

on the VOTP. This level must be delivered from the host itself because the module does not

have an on-board charge pump.

Ta bl e 3 shows the pin description of the connector J1.

12/38

Page 13

AN2512 Power calculation algorithm

Table 3. J1 connector pin description

Pin no. Pin name Functional description

1. VOTP

2. --- NC

3. GND Signal reference level 0V and power supply return

4. SDA SPI Interface Data Signal

5. SCS SPI Enable Signal

6. SCL SPI Interface Clock Signal

7. --- NC

8. SYN SPI Interface Signal

9. --- NC

10. VDD

Power supply Input of +15.0 V during permanent write to OTP

Up to 100 mA can be drawn from this pin

3 Power calculation algorithm

3.1 STPM01 SPI Interface

The STPM01 SPI interface supports a simple serial protocol, which is implemented in order

to enable communication between a host system (microcontroller or PC) and the device.

Three tasks can be performed with this interface:

● Remote resetting the device

● Reading data records

● Writing the Mode bits and the configuration bits (temporarily or permanently).

cells

Power Out of +3.3 V

Four pins of the device are dedicated to this purpose: SCS, SYN, SCL, and SDA. SCS, SYN

and SCL are all input pins while SDA can be input or output according to whether the SPI is

in write or read mode.

The condition under which SCS, SYN and SCL inputs are set to high level determines the

idle state of the SPI interface and no data transfer occurs.

● SCS: enables SPI operation when low. The microcontroller uses this pin to multiplex

the reading of the three devices.

● SYN: when SCS is low, the SYN pin status selects whether the SPI is in read (SYN=1)

or write mode (SYN=0). When SCS is high and SYN is also high, the results of the

input or output data are transferred to the transmission latches.

● SCL: is the clock pin of the SPI interface. This pin function is also controlled by the SCS

status. If SCS is low, SCL is the input of serial bit synchronization clock signal. When

SCS is high, SCL is also high determining the idle state of the SPI.

● SDA: is the Data pin. If SCS is low, the operation of SDA is dependent on the status of

SYN pin. If SYN is high, SDA is the output of serial bit data (read mode). If SYN is low,

SDA is the input of serial bit data signal (write mode). If SCS is high, SDA is idle.

13/38

Page 14

Power calculation algorithm AN2512

In this chapter the readings of data records will be treated in case of 3 phase usage of

STPM01, in particular we will refer to the flow chart in Figure 6.

Figure 6. Flow chart of phase reading

3.2 STPM01 Initialization (latching) and reading (shifting)

There are two phases of reading the STPM01 data called latching and shifting.

Latching is used to sample results into transmission latches by initiating an active pulse on

SYN while SCS is idle. The pulse length of SYN must be longer than 2 periods of the

measurement clock (that is, t

The latching phase has to be done at the same time for all the STPM01 devices keeping the

SCSLx lines in idle state in order to read the information coming from each phase at the

same moment.

Shifting starts when SCS becomes active (low). At the beginning of this phase, another,

much shorter pulse (t

- t4 = 30 ns) should be applied to SYN. An alternative way to read

5

shifted data is to extend the pulse on SYN into the second phase of reading (from t

Latching and shifting finish at the last rise of SYN (shown by the t

these readings are completed, the STPM01 is reset.

It is possible to read data, by applying 32 serial clocks per data record. Up to 8 data records

can be read this way from each device. Switching to another device is possible enabling the

corresponding SCS line. Note that, enabling multiple SCS lines corrupts the information

received causing parity error. So, in any case, two or more devices cannot be enabled at the

same time.

In order to maximize the reliability of the readings, each data structure can be read twice

and compared. This is possible just by restarting the shifting procedure, then applying the

clock signal on the SCL pin one more time, keeping the corresponding SCS pin in active

state (low).

- t1 more than 500 ns).

2

line in Figure 7). After

5

to t5).

1

14/38

Page 15

AN2512 Power calculation algorithm

Figure 7. Timing for data records reading in 3 phase system

● t

→ t2: Latching Phase. Interval value>2/f

1

●

t2 → t3: Data latched, SPI idle. Interval value>30 ns

● t

→ t4: Enable SPI for read operation. Interval value > 30 ns

3

● t

→ t5: Serial clock counter is reset. Interval value > 30 ns

4

● t

→ t6: SPI reset and enabled for read operation. Interval value > 30 ns

5

● t

: Internal data transferred to SDA

7

● t

: SDA data is stable and can be read

8

● t

: End of phase 1 reading, begin of Phase 2 reading

9

● t

● t

: End of phase 2 reading, begin of Phase 3 reading

10

: End of phase 3 reading, stop of STPM01 shifting

11

CLK

3.3 Data record structure

Every data record is 4 bytes long. The 1st readout byte of data record is the Least

Significant Byte (LSB). Each byte can be further divided into a most and least significant

nibble (msn, lsn). The msn of the 4th byte of data value holds the parity code rather than

useful data. In fact, every data record consists of 4-bit parity code and 28-bit data value

where the parity code is computed from the data value which makes total of 32 bits or 4

bytes.

The Figure 8 below shows top down how bytes of data record are output from the SDA and

how they should be re-organized by the host to retrieve useful information.

15/38

Page 16

Power calculation algorithm AN2512

Figure 8. Data records reconstruction

8 bit SPI reading order

1stbyte - LSB

msb lsb

7 07 0 7 07 0

parity nibble 28 bit data

7 07 0 7 07 0

4thbyte - MSB

parity nibble

msb lsb

7 07 015 815 823 1623 1600 2424

32 bits register assembling

The data records have a fixed position of reading and no addressing of records is needed. It

is up to the host to decide how many records should be read out from the device.

Figure 9 shows the records position within the default sequence of reading, their name and

information contained.

Figure 9. STPM01 data register structure

16/38

Page 17

AN2512 Power calculation algorithm

3.4 Data integrity checks

Each bit of parity nibble is defined as odd parity of all seven corresponding bits of data

nibbles. In order to check the data record integrity, the application might execute the

following C code, given as an example:

int BadParity (unsigned char *bp)

{

register unsigned char prty; /* temporary register */

prty = *bp, /* take the 1st byte of data */

prty ^= *(bp+1), /* XOR it with the 2nd byte*/

prty ^= *(bp+2), /*and with the 3rd byte */

prty ^= *(bp+3), /*and with the 4th byte */

prty ^= prty<<4, prty &= 0xF0; /* combine and remove the lower nibble */

return (prty != 0xF0); /*returns 1, if bad parity */

}

if (BadParity(dap) || BadParity(drp) || /* DAP and DRP. data record*/

BadParity(dsp) || BadParity(dfp) || /* DSP and DFP data record */

BadPari

BadParity(cfl) || BadParity(cfh)) /* CFL and CFH data record */

/* code for repeat of reading sequence should be entered here */ ;

ty(dev) || BadParity(dmv) || /* DEV and DMV data record */

If the parity nibble check fails, the reading task should be repeated but, this time, without

request of latching, otherwise a new data is latched and the previous reading is incorrectly

lost. In a very harsh EMI environment, it would be good practice to read the data records

twice and then compare both readings. This way the probability of detecting bad readings is

significantly improved. A single bad data reading can be discarded because no meaningful

information is lost as long the reading frequency is about 30 ms.

3.5 Unpacking of data records

After each data record is read correctly, its parity nibble and possible padding bits should be

masked out and then it should be unpacked to retrieve each information as indicated in

Figure 9. The momentary values of current and voltage should be considered as signed

integers, while all the other values as unsigned integers.

Below an example of readings and unpacking of the data is given (MSBF is cleared, that is,

the device reads most significant bit first).

● DAP 65 7A 7C 82: parity = 8, type0 energy=27C7A, status = 65

● DRP 52 7A 0C 90: parity = 9, reactive energy=00C7A, frequency high byte = 52

● DSP 25 00 8C E2: parity = E, apparent energy=28C00, frequency low byte = 25

17/38

Page 18

Power calculation algorithm AN2512

● DFP 00 06 6E 22: parity = 2, type1 energy = 26E06, mode signals = 00

● DEV BB B3 07 DD: parity = D, i

● DMV 3F AF AA CA: parity = C, i

● CFL 01 00 00 E0: parity = E, configuration bits low part = 0000001

● CFH 00 00 00 F0: parity = F, configuration bits high part = 0000000

= 1B3BB, u

RMS

= AF3F, u

MOM

RMS

MOM

= 638

= AAA

The metering device computes wide-band active energy which is type0 by default and

fundamental harmonic active energy which is type1 by default. The configuration bit FUND

can be used to select which becomes type0 or type1, by default FUND = 0.

Ta bl e 4 shows the meaning of "status" byte in the DAP data record.

Table 4. STPM01 status bit description

Bit no. Bit name

0. BIL

Functional

description

No load

condition

Condition

BIL = 0: No load condition not detected

BIL = 1: No load detected

1. BCF Σ∆ Signal status BCF= 0: Σ∆ signals alive

BCF= 1: one or both Σ∆ signals are stacked

2. BFR

Line frequency

range

BFR = 0: Line frequency inside the 45 Hz-65 Hz range

BFR = 1: Line frequency out of range

3. BIT

Tamper

condition

BIT = 0: Tamper not detected

BIT = 1: Tamper detected

4. MUX

Current channel

selection

MUX = 0: Primary current channels selected by the tamper

module

MUX = 1: Secondary current channels selected by the

tamper module

5. LIN

Trend of the line

voltage

LIN = 0: line voltage is going from the minimum to the

maximum value (∆v/∆t >0)

LIN = 1: line voltage is going from the maximum to the

minimum value (∆v/∆t < 0)

6. PIN

Output pin

check

PIN = 0: the output pins are consistent with the data

PIN = 1: the output pins are different with the data, this

means some output pin is forced to 1 or 0

7. HLT Data validity HLT = 0: the data records reading are valid

HLT = 1: the data records are not valid. A reset occurred and

Normally, a host reads the DAP data record first but, if a "Precharge" command is sent to the

module before the beginning of the reading task, the DEV data record is read first. This way,

faster reading of RMS and momentary values is possible.

18/38

a restart is in progress.

Page 19

AN2512 Power calculation algorithm

3.6 Processing of phase energy values

Within each STPM01 metering device the sources of energy values are implemented as 20bit up/down counters. The value of such counters eventually rolls over if the direction of

power is not changing too often, which is normally the case. For example, if the maximal

possible positive power (360 V * 33 A = 12 kW) is measured by one of the phases, the

internal counter would count up and reach its maximal value (0xFFFFF) in about 1.2

seconds then the value rolls over to zero (0x00000) at once and starts to count up again. A

sawtooth shape of values is produced, see Figure 10. For the negative power, the counter

counts down, showing the same behavior. The slope of the shape is proportional to

measured power which may change its value and direction at any moment. Also, if power is

absolutely less than No-Load Condition limit, selected by LTCH, the counter stops. For the

calculation of the value of the least significant bit of counters, please refer to the STPM01

datasheet.

An application should recognize rollovers. A rollover from high to low should be recognized.

If the msn of the energy value of two consecutive readings changes from 0xF to 0x0 or, if

change from 0x0 to 0xF is detected, a low to high rollover is recognized. To ensure detection

of change, an application should successfully read the energy values at least every 0.1

second but, for security reasons, at least 30 readings per second should be performed.

Figure 10. Typical profile of output of an energy integrator

Using an msn of energy value as a rollover code is convenient because it is stored in the

MSB of data record accompanied with the parity code. Therefore it is easily unpacked and

checked for the characteristic values. When rollover is detected, a 0x00100000 should be

added to the energy reading with rollover code 0x0.

To compute a single phase energy it is recommended to use the following procedure.

The software should implement a 32-bit integrator. The integrator is divided into two stages:

● frac 32-bit signed integer variable;

● integ 32-bit signed integer variable.

The other variables to be used are:

● old 32-bit signed integer variable;

● new 32-bit signed integer variable;

● quot 16-bit unsigned integer variable;

● quant 16-bit signed integer variable.

Each time the host receives a new reading, the 20-bit energy value is stored in the new

variable, and the difference between the new and old energy values is stored in the quant

variable. The value of frac is derived by adding to itself the quant value. Before the next

19/38

Page 20

Power calculation algorithm AN2512

reading, the old variable should be updated with the new value for the next quant

computation.

When frac collects a preset amount of energy (that is, 10 Wh, absolute, with the

corresponding integer value stored as a threshold variable), the integ value should be

changed by 1 bit and the frac value changed according to the threshold value. The preset

threshold value must be set according to the value of the least significant bit of the internal

energy counter (for more detail, please refer to the STPM01 datasheet).

If the time difference of two consecutive readings is known, an applied power can be

computed easily as: p = quant/∆t.

This procedure should be repeated for each energy type (active, reactive, apparent and

fundamental active).

If an LED output from MCU is required, the resolution of the energy count must be increased

by dividing the value of quant by 16 and adding it in 16 times to frac. A reminder of such

division can be added to the frac value immediately, while the quotient quot (quant/16) can

be added later 16 times but faster. A timer interrupt service routine is the best place to

implement these calls. This way, output pulse generation of signal LEDs, which is used for

meter accuracy check, with 2 ms resolution is possible (given that 2 consecutive readings

occur every 32 ms).

This calculation should be done for each type of energy (Active wide band, Reactive,

Apparent and active fundamental). For more details on single phase energy calculation,

please refer to AN2159 "SPI Communication for comprehensive energy reading of the

STPM01".

3.7 Three-phase energy calculation

The above procedure refers to one of the phases of a three-phase meter.

To calculate the global amount of energy in a three-phase system, it is necessary to define

an array of the above variables structure, where the number of elements is four, one for each

phase energy and one for the total energy, which is given by the sum of the three-phase

energies.

In Appendix A an example of the definition of the variables used in a practical application is

shown.

3.8 Pulse generation

From the first stage of integration of total active energy counter (referred to as frac), and

according to the number of pulses per kWh desired as output, a pulse train is generated to

feed an LED.

Three more LEDs are fed from the LED pins of STPM01 devices to display power

consumption of the respective phase.

20/38

Page 21

AN2512 Layout rules

4 Layout rules

Noise rejection is the main issue to work on when a three-phase multi-chip approach has

been chosen. In this case layout plays a crucial role.

Here some rules to follow in layout phase:

● Components positioning

The components of measuring section (STPM01, Current Transformers, passive

components) are placed using the same layout for each phase. The phases are placed in a

symmetrical scheme. In this way reduction of the cross talking can be achieved.

The Current transformer is placed very close to the correspondent STPM01 to minimize the

captured noise.

● Components routing

The passive components belonging to the analogue input channels must be placed between

the sensor and the STPM01 always respecting a symmetrical scheme.

Particular care should be given for the voltage channel path because the voltage inputs are

normally relatively further from the corresponding STPM01.

● Quartz

The crystal network has been placed in the middle of the board ensuring a completely

symmetrical path between the devices. A copper plate has been used under the Crystal

both on the TOP and on the BOTTOM side of PCB.

● Copper plate

The copper plate area should be extended under the entire digital section and under the

crystal oscillator which provides the clock for the three STPM01.

21/38

Page 22

Experimental results AN2512

5 Experimental results

The tests have been conducted considering In =10 A, Vn = 220 V, f = 52 Hz, where In is the

nominal current and Vn is the nominal voltage.

5.1 Phase one results

Table 5. Experimental results of phase n.1 tests

I (A) e%min e%av e%max PF 0,5C PF 0,5L Stmin Stmax

0,05 -1,841 -1,257 -0,724

0,1 -0,259 -0,119 0,123 -1 1

0,25 0,277 0,282 0,336 -1 1

0,5 0,114 0,152 0,177 -0,5 0,5

5 0,038 0,047 0,052 0,04 0,03 -0,5 0,5

10 0,032 0,036 0,041 -0,5 0,5

20 0,016 0,019 0,022 -0,5 0,5

30 0,045 -0,5 0,5

45 0,06 -0,5 0,5

Figure 11. Graph of experimental results of phase n.1 tests

1,5

1

0,5

0

p[%]

-0,5

-1,5

0,05 0,1 0,25 0,5 5 10 20 30 45

-1

I[A]

22/38

Page 23

AN2512 Experimental results

5.2 Phase two results

Table 6. Experimental results of phase n.2 tests

I (A) e%min e%av e%max PF 0,5C PF 0,5L Stmin Stmax

0,05 -1,841 -1,257 -0,724

0,1 -0,259 -0,119 0,123 -1 1

0,25 0,277 0,282 0,336 -1 1

0,5 0,114 0,152 0,177 -0,5 0,5

5 0,038 0,047 0,052 0,04 0,03 -0,5 0,5

10 0,032 0,036 0,041 -0,5 0,5

20 0,016 0,019 0,022 -0,5 0,5

30 0,045 -0,5 0,5

45 0,06 -0,5 0,5

Figure 12. Graph of experimental results of phase n.2 tests

1,5

1

0,5

0

p[%]

-0,5

-1,5

0,05 0,1 0,25 0,5 5 10 20 30 45

-1

5.3 Phase three results

Table 7. Experimental results of phase n.3 tests

I (A) e%min e%av e%max PF 0,5C PF 0,5L Stmin Stmax

0,05 2,14

0,1 -0,45 -1 1

0,25 -0,04 -1 1

0,5 0,09 -0,5 0,5

5 0 0,03 0,04 -0,5 0,5

I[A]

10 -0,5 0,5

20 -0,5 0,5

23/38

Page 24

Experimental results AN2512

Table 7. Experimental results of phase n.3 tests (continued)

I (A) e%min e%av e%max PF 0,5C PF 0,5L Stmin Stmax

30 -0,5 0,5

45 -0,5 0,5

Figure 13. Graph of experimental results of phase n.3 tests

5.4 Voltage and frequency influence on phase three

Table 8. Voltage influence on phase n.3

I = 0,1 A f = 52 Hz

Ve%Stmin

240 -0,22 -0,65

220 -0,45 -0,65

180 -0,47 -0,65

120 -0,58 -0,65

Table 9. Frequency influence on phase n.3

I = 5 A V = 220 V

fe%Stmin

45 -0,41 -0,4

52 0 -0,4

65 -0,41 -0,4

I = 5 A V = 220 V

24/38

Page 25

AN2512 Three-phase systems

Figure 14. Graph of voltage and frequency influence on phase n.3

0,1

-0,1

-0,3

p[%]

-0,5

-0,7

0,1

-0,1

p[%]

-0,3

-0,5

240 220 180 120

45 52 65

Appendix A Three-phase systems

Three-phase is a common method of electric power transmission. It is a type of polyphase

system used to power motors and many other devices.

I[A]

I[A]

The currents are sinusoidal functions of time, all at the same frequency but with different

phases. In a three-phase system the phases are spaced equally, giving a phase separation

of 120°. The frequency is typically 50 Hz in Europe and 60 Hz in the US and Canada.

Figure 15. Instantaneous voltage (or current) in one voltage cycle of a three-phase

system

The three phases could be supplied over six wires, with two wires reserved for the exclusive

use of each phase. However, they are generally supplied over three or four wires:

● Three phases, 3-Wire DELTA service which has no neutral and 220 V between phases

25/38

Page 26

Three-phase systems AN2512

● Three phases, 4-Wires DELTA and WYE service which has 220 V between phase-

neutral and 380 V phase-phase.

A.1 Power in three-phase AC circuits

Let's assume that the angle between the phase voltage and the phase current is θ, which is

equal to the angle of the load impedance. Considering the load configurations given in

Figure 16, the phase power and the total power can be estimated easily.

Figure 16. Per-phase powers in (a) delta-connected load and (b) wye-connected load

(a)

(b)

In the case of Figure 16 (a), the total active power is equal to three times the power of one

phase:

Equation 1

P1P2P3PV

•θcos•====

lineIphase

Equation 2

P

Total

3P 3V

•θcos•==

lineIphase

Since the line current in the balanced delta-connected loads is:

Equation 3

I

line

3I

•=

phase

If this equation is substituted into Equation 2, the total active load becomes:

Equation 4

P

Total

In Figure 16 (b), however, the impedances contain the line currents I

current, I

) and the phase voltages.

phase

3V

• I

line

•θcos•=

line

(equal to the phase

line

Equation 5

V

V

phase

line

------------=

3

26/38

Page 27

AN2512 Three-phase systems

Therefore, the phase active power and the total active power are:

Equation 6

P1P2P3PV

•θcos•====

phaseIline

Equation 7

P

Total

3P 3V

phaseIline

θcos••==

If the relationship between the phase voltage and the line voltage is used, the total active

power becomes identical to the Equation 4 developed. This means that the total power in

any balanced three-phase load (∆- or Y-connected) is given by Equation 4. Similarly, the

total reactive and the total apparent power in the three-phase balanced ac circuits can be

given by:

Equation 8

Q

Total

3V

lineIline

θsin••=

Equation 9

S

Total

3V

lineIline

•=

A.2 Power measurement techniques

In the three-phase power systems, one, two, or three wattmeters can be used to measure

the total power. A wattmeter may be considered to be a voltmeter and an ammeter

combined in the same box, which has a deflection proportional to V

the angle between the voltage and current. A wattmeter has two voltage and two current

terminals, which have + or - polarity signs. Three power measurement methods utilizing the

wattmeters are described next, and are applied to the balanced three-phase ac load.

A.2.1 Two-Wattmeter method

This method can be used in a three-phase three-wire balanced or unbalanced load system

that may be connected ∆ or Y. To perform the measurement, two wattmeters are connected

as shown in Figure 17.

Figure 17. Two-wattmeter method in star- or delta-connected load

cosθ, where θ is

rmsIrms

27/38

Page 28

Three-phase systems AN2512

In the balanced loads, the sum of the two wattmeter readings gives the total power. This can

be proven in a star-connected load mathematically using the power reading of each meter

as:

Equation 10

P1V12I1• 30°θ–()cos• V

• 30°θ–()cos•==

lineIline

Equation 11

P

2V32I3

• 30°θ–()cos• V

• 30°θ–()cos•==

lineIline

Equation 12

P

TotalP1P2

3V

lineIline

θcos••=+=

If the difference of the readings is computed,

Equation 13

P2P1– V

• 30°θ–()cos• V

lineIline

• 30°θ–()V

lineIline

•θsin=cos•–=

lineIline

which is 1/√3 times the total three-phase reactive power. This means that the two-wattmeter

method can also indicate the total reactive power in the three-phase loads and also the

power factor.

A.3 Three-Wattmeter method

This method is used in a three-phase four-wire balanced or unbalanced load. The

connections are made with one meter in each line as shown in Figure 18. In this

configuration, the total active power supplied to the load is equal to the sum of the three

wattmeter readings.

Equation 14

Figure 18. The wattmeter connections in the three-phase four-wire loads

P

Total

P1P2– P3–=

28/38

Page 29

AN2512 Example of source code

A.4 One-Wattmeter method

This method is suitable only in three-phase four-wire balanced loads. The connection of the

wattmeter is similar to the drawing given in Figure 18. The total power is equal to three times

the reading of only one wattmeter that is connected between one phase and the neutral.

Appendix B Example of source code

The C code below shows an example of handling energy value (either active type 0, type1,

reactive or apparent) after it has been read, unpacked and stored into register new. For

signed wide-band Active energy as an example, a pointer named e should be loaded with

&ActWB then, EnergyQuant() should be called. This function checks for rollover and

computes a quant of energy. Later, EnergyUpdate() is called. This function updates the

fractional part of integrator first (frac). If the fractional part reaches a certain limit, it is

subtracted from the fractional part and the integer part (integ) of integrator increments. The

value of the limit and the direction of subtraction and increment depends on the sign of

quant.

Some applications may have positive and negative energy integrators or quadrant

integrators for Apparent energy. All this influences an implementation of both functions. With

a proper limit value for the fractional part, one can prescribe a suitable bit weight of the

integer part of the integrator.

For example if the limit is set to 0x00140000 (with a device calibrated to provide 128000

pulses/kWh) then the lsb of the integer part represents exactly 0.01 kWh.

Below is an example of source code.

/* definition of STPM01 registers structure */

typedef struct STPM {

long int DAP[3];

long int DRP[3];

long int DSP[3];

long int DFP[3];

long int DEV[3];

long int DMV[3];

long int CFL[3];

long int CFH[3];

} STPM_Struct;

/* definition of energy integrator structure */

typedef struct energ {

long int old[4]; /* previous energy value */

int quot[4]; /* quant/16 */

int quant[4]; /* new - old, measure of power */

29/38

Page 30

Example of source code AN2512

long int frac[4]; /* fraction part of energy integrator */

long int integ[4]; /* integer part of energy integrator */

} ENERG;

/* definition of variables for internal registers values */

char status[3];

char mode[3];

int freq[3];

int uRMS[3];

int iRMS[3];

int uMOM[3];

int iMOM[3];

long int active0[4];

long int active1[4];

long int reactive[4];

long int apparent[4];

/* allocation for all types of energies */

long int new; /* energy value to be handled */

ENERG *e; /* -> energy integrator */

ENERG Ac

ENERG Reactive; /* Reactive energy */

ENERG ActFund; /* Active fundamental energy */

ENERG Apparent; /* Apparent energy */

/* definition of constant */

#define ELIMIT 0x140000 /* produces 0.01 kWh resolution in case of 128000 pulses per

kWh */

/*----------------------------------------------------------------------------------

ROUTINE NAME : EnergyQuant

INPUT/OUTPUT : None/None

DESCRIPTION : Energy quant computing function (version for signed energy

integration). Checks for rollovers and compute quant as difference between new and

old value. Returns a negative sign of quant.

----------------------------------------------------------------------------------*/

tWB; /* Active wide band energy */

int EnergyQuant(Long int *new)

{

long int NewTemp;

char i,Temp;

30/38

Page 31

AN2512 Example of source code

if (ReadSTPM01Falg == 0){

for (i = 0; i < 3; i ++){

NewTemp = * new;

e->old[i] = NewTemp;// save the value for the first time reading

new ++; //next data

}

e->quot[0] = 0;

e->quot[1] = 0;

e->quot[2] = 0;

}

else{

e->quant[3] = 0;

for (i = 0; i <3; i++ ){

NewTemp = *new; // Rollover high to low occurs when MSB goes from F to 0

if (NewTemp >= e->old[i]){

if ((NewTemp - e->old[i]) >= 0x80000){ //roll over, negative energy

e->quant[i] = 0x100000 + e->old[i] -NewTemp;

e->quant[3] -= e->quant[i];//total ernergy minus the negative energy

}

else{

e->quant[i] = NewTemp - e->old[i]; //positive energy

e->quant[3] += e->quant[i]; //add the positive energy to the total energy

}

}

els

e{

if ((e->old[i] - NewTemp) >= 0x80000) { //roll over, positive energy

e->quant[i] = 0x100000 + NewTemp - e->old[i];

e->quant[3] += e->quant[i]; //total ernergy plus the positive energy

}

else{

e->quant[i] = e->old[i] - NewTemp; //negative energy

e->quant[3] -= e->quant[i]; //total energy minus the negative energy

}

}

e->old[i] = NewTemp;// save the value for next time

new ++; //next data

}

}

31/38

Page 32

Example of source code AN2512

if (e->quant[3] > 0xf0000000) //for test purpose

e->quant[3] = 0;

e->quot[3] = e->quant[3] >> 4;

Temp = e->quant[3] & 0x0f;//save the residue

e->frac[3] += Temp;

Accuracy_Error_Count ++;

if (Accuracy_Error_Count == 3){

Accuracy_Error_Count = 0;

if (e->quant[0] >= 2)

e->quant[0] -= 2;

}

led_frac += e->quant[0] & 0x0f;

e->quot[2] = e->quot[1];

e->quot[1] = e->quot[0];

e->quot[0] = e->quant[0] >> 4;

}

/*--------------------------------------------------------------------------------

ROUTINE NAME : EnergyUpdate

INPUT/OUTPUT : None/None

DESCRIPTION : Energy update function (version for signed energy integration)If quant

is negative, subtract o

frac reaches ELIMIT

---------------------------------------------------------------------------------*/

int EnergyUpdate(void)

{

PM_u8 i;

e = &ActWB; // active WB energy calculation

for (i = 0; i < 3; i++){

e->frac[i] += (Long int)e->quot[i];// add quot to frac

if (e->quant[i] < 0){ // is quant negative?

if (e->frac[i] > (-ELIMIT))

return(0); // yes, is within the limit?

else {

e->frac[i] += ELIMIT;

(e->integ[i])--; // no, subtract it and increment

therwise add its value from the integrator. Returns true when

32/38

Page 33

AN2512 Example of source code

}

}

else {

if (e->frac[i] < ELIMIT)

return(0); // no, is within the limit?

else {

e->frac[i] -= ELIMIT;

(e->integ[i])++; // no, subtract it and increment

}

}

}

e->frac[3] += (long int)e->quot[3]; // add quot to frac

led_frac += (Long int)e->quot[0];

if (led_frac >= MeterConstant) { //MeterConstant = 0x1f400 //128000 0x4000)

GPIO0->PD ^= 0x1000; //GPIO0.12 Active engergy output

led_frac -= MeterConstant; //0x4000;

}

if (e->frac[3] >= ELIMIT) {

e->frac[3] -= ELIMIT;

(e->integ[3])++; // no, subtract it and increment

lTotal[0] ++;

}

/*caculat

return(1); // return limit has been reached

}

e the 3 phase total energy, and generate the output pulse*/

33/38

Page 34

BOM list AN2512

Appendix C BOM list

Table 10. BOM list

Index Qty Ref.

12 C1,C2

C3, C4, C6, C7, C13,

212

36

46

5 3 C11, C21, C31 4.7 µF No mounted

61 C34

71 C35

8 2 C36, C39

9 2 C37, C43

10 1 C38

11 1 C40

12 1 C41

13 1 C42

C14, C16, C17, C23,

C24, C26, C27

C5, C8, C15, C18,

C25, C28

C9, C12, C19, C22,

C29, C32

Value / generic part

number

SMT C0G ceramic

capacitor,15 pF 50 V

SMT X7R ceramic

capacitor,1000 pF 50 V

X7R SMT ceramic

capacitor, 1 µF 16 Vdc

SMT X7R ceramic

capacitor,10 nF 50 V

Rubycon aluminium

radial Lead Electrolytic

Capacitor ZL Series

56 mR 995 mA 20%

330 µF 25 V

Rubycon aluminium

radial Lead Electrolytic

Capacitor ZA Series

270 mR 350 mA 20%

22UF 16 V

SMD ceramic capacitor

220 nF 630 V 20%

220NF 630 V

SMT X7R ceramic

capacitor,100 nF 50 V

Radyal Electrolytic

capacitor 2.2 µF 400 V

Radyal Electrolytic

capacitor 1000 µF 25 V

Radyal Electrolytic

capacitor 10 µF 50 V

Y1 suppression ceramic

cap, 2.2 nF 250 Vac

Package

0805

0805

0805

0805

2220 TDK

0805

Diameter:

10 mm Lead

s pa c i ng :

5 mm

Diameter:

13 mm Lead

s pa c i ng :

5 mm

Diameter:4

mm Lead

spacing:

2.5 mm

Manufacture’s

ordering code/

orderable part

number

Supplier Sup-

plier’s

order-

ing code

Rubycon

Rubycon

CERAMITE RS 214-5903

34/38

Page 35

AN2512 BOM list

Table 10. BOM list (continued)

Index Qty Ref.

14 1 C44

15 3 D1,D3,D5

16 4 D2,D4,D6,D14

17 2 D7,D12

18 1 D8

19 1 D9

20 2 D11,D13

21 1 J1

22 1 J2

23 7

24 2 J13, J14

25 3 L1,L2,L3

26 1 L4

27 1 L5

28 1 NTC1

29 1 Q1

J5,J7,J8,J9,J10,J11,

J12

Value / generic part

number

SMT X7R ceramic

capacitor 47NF 50 V

SMD LED low current

superred

Small signal SMD diode

LL4148

SMT Diode Bridge

1000 V 1 A

Mini-Melf Zener diode

15 V 0.5 W 5%

Small Signal Schottky

Diode 80 V 0.5 A

TMBAT49

DO-41 Zener diode

180 V 2 W 5%

5 way 2 row header, 0.1

in pitch 7 mm pin (10 PIN

connector)

10 way 2 row header, 0.1

in pitch 7 mm pin (20

PIN connector)

1 way header, 7 mm pin

(1 PIN connector)

3 way 2 row header,

0.1in pitch 7 mm pin (6

PIN connector for

jumper)

Current transformer for

indirect connection

without dc-tolerance

CT 1:2000

Axial BC inductor,

1000 µH 130 mA

Signal-Use SMD

Inductor 10 µH 125 mA

NTC inrush current

suppressor, 50 R 2 A

N-CHANNEL 500 V -

2.8 Ω - 2.3 A Zener-

Protected

SuperMESH™Power

MOSFET

STD3NK50Z

Supplier Sup-

plier’s

order-

Package

Manufacture’s

ordering code/

orderable part

number

ing code

0805

P-LCC-2 OSRAM Distrelec 631039

1206

General

semiconductor

SMD Mini-

Melf 1206

MELF Glass STMicroelectronics

DO41

THT

THT

THT

THT

VAC

THT

THT axial Epcos RS 191-0712

0805 TDK

THT RS 210-673

DPAK STMicroelectronics

www.vacuumschm

elze.de

RS 269-344

35/38

Page 36

BOM list AN2512

Table 10. BOM list (continued)

Manufacture’s

Index Qty Ref.

Value / generic part

number

Package

ordering code/

orderable part

number

30 3 RV1,RV2,RV3 SO5K275/275 V Epcos

31 1 R1

32 3 R2,R18,R34

33 7

34 3 R6,R22,R38

35 3 R7,R23,R39

36 3 R9,R25,R41

37 3 R10,R26,R42

38 3 R13,R29,R45

39 6

40 3 R16,R32,R48

41 3 R17,R33,R49

42 1 R52

43 1 R53

44 2 R55,R57

45 1 R56

46 3 R58,R59,R60

47 4 R61,R62,R63,R64

R5,R8,R21,R24,R37,

R40,R54

R14,R15,R30,R31,R

46,R47

S MT c h ip r es is t or

1 MOhm 1% 0.125 W

SMT chip resistor,

750 Ohm 1% 0.125 W

S MT c h ip r es is t or

1 Kohm 1% 0.125 W

MMA 0204 Professional

MELF resistors 3.3 Ohm

1%

SMT chip resistor

150 KOhm 1% 0.125 W

MMA 0204 Professional

M EL F r es is to rs

2.2 MOhm 1%

SMT chip resi stor

2,2 Kohm 1% 0.125 W

S MT c h ip r e si s to r,

0 Ohm 0.125 W

MMA 0204 Professional

MELF resis to rs

270 KOhm 1% SMD

MMA 0204 Professional

MELF resis to rs

200 KOhm 1% SMD

MMA 0204 Professional

MELF resistors 470 Ohm

1% SMD

SMT chip re si st or

10 Ohm 1% 0.125 W

SMT chip resistor

220 Ohm 1%

0.125 W

SMT chip resi stor

4.7 KOhm 1% 0.125 W

SMT chip resi stor

5.6 Kohm 1% 0.125 W

SMT chip resistor

330 kOhm 5% 0.25 W

ROX1S metal oxide film

resistor 22 Ohm 1 W

0805

0805

0805

1206 Beyschlag

0805

1206 Beyschlag

0805

0805

1206 Beyschlag

1206 Beyschlag

1206 Beyschlag

0805

0805

0805

0805

1206

axial Neohm

Supplier Sup-

plier’s

order-

ing code

Distrelec 730096

Distrelec 713014

Distrelec 713154

Distrelec 713132

Distrelec 713129

Distrelec 713066

RS 214-0920

36/38

Page 37

AN2512 Revision history

Table 10. BOM list (continued)

Index Qty Ref.

48 1 T1

49 3 U1,U2,U3

50 1 U4

51 1 U5 Opto-isolator PC817 DIP6

52 1 U6

53 1 U7

54 1 U8

Value / generic part

number

E13 TIW Switch mode

transformer

Programmable single

phase energy metering

IC with tamper detection

STPM01FTR_TSSOP20

Very low drop voltage

regulators 3.3 V WITH

INHIBIT 300 mA 1%

L4931ABD33

Programmable shunt

voltage reference 1%

TS2431

Low power OFF-Line

SMPS Primary Switcher

VIPer12AS-E

HEX SCHMITT inverter

M74HC14

Package

TSSOP20 STMicroelectronics

SOT23-3 STMicroelectronics

Manufacture’s

ordering code/

orderable part

number

Pulse

THT

SO-8 STMicroelectronics

SO-8 STMicroelectronics

SOP STMicroelectronics

(www.pulseeng.

com)

Supplier Sup-

plier’s

order-

ing code

55 1 Y1 Crystal 4.194304 MHZ Auris

6 Revision history

Table 11. Revision history

Date Revision Changes

17-Apr-2007 1 First issue

Distrelec 335026

37/38

Page 38

AN2512

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

38/38

Loading...

Loading...