Page 1

AN2511

Application note

PMBusTM interface using ST7 I2C

Introduction

The PMBusTM (power management bus) is an open standard protocol that defines a means

of communicating with power conversion and other devices. The PMBus protocol helps to

establish the first truly open communications standard for the digital control of power

systems. Implemented over the industry-standard SMBus (system management bus) serial

interface, the PMBus protocol facilitates the programming, control and real-time monitoring

of compliant power conversion products.

This application note describes how to use the ST7 I

communication. The firmware of this application performs the PMBus bus protocols

mentioned in PMBusTM power system management protocol specification v1.0. The device

chosen here is ST72264G1 which has multi-master I

as the PMBus master. It controls the PMBus compatible slaves. The firmware described in

this application note is in C language.

To show the PMBus capabilities of ST7, a dedicated demonstration board is developed. This

board consists of the ST72F264G1 microcontroller and it works with PC hyperterminal. The

objective of this demonstration board is to show to the user the features and capabilities of

PMBus features using ST7 I

results of this demonstration board interfaced with Artesyn's PMBus module are shown in

this application note.

2

C peripheral, to support the standard PMBus commands. The

2

C peripheral for PMBus

2

C capability. This microcontroller acts

August 2010 Doc ID 13286 Rev 2 1/43

www.st.com

Page 2

Contents AN2511

Contents

1 PMBus introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 PMBus protocol description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.1 SMBus version 1.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.2 Extensions to SMBus version 1.1 specification . . . . . . . . . . . . . . . . . . . . 6

1.2 Hardwired signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.1 Electrical interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.2 Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Implementation of PMBus using ST7 I2C . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Firmware architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.1 I2C initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.2 Slave address and command code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.3 Read and write operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 PMBus commands and source code . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 PMBus commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Source code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.3 Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.4 Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4 PMBus interfacing results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.1 Interfacing with Artesyn module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2 Interfacing with SiLabs module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5 PMBus demonstration board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.1 System requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.2 Software setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.3 Hardware setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6 Using the demonstration board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1 Normal operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1.1 Selection of communication speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1.2 Selection of packet error checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2/43 Doc ID 13286 Rev 2

Page 3

AN2511 Contents

6.1.3 Selection of slave address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1.4 Selection of read/write mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.1.5 Single read mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.1.6 Continuous read mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.1.7 Write mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.1.8 Group command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.2 Error conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.2.1 Invalid command code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.2.2 Communication timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7 Hardware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.1 Schematic and layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.2 Bill of materials (BOM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.3 Demonstration board photo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Appendix A Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

A.1 RS232 configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Doc ID 13286 Rev 2 3/43

Page 4

List of tables AN2511

List of tables

Table 1. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 2. ON_OFF_CONFIG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 3. CLEAR_FAULTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 4. RESTORE_DEFAULT_ALL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 5. STORE_USER_ALL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 6. VOUT_MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 7. VOUT_COMMAND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 8. VOUT_MAX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 9. VOUT_MARGIN_HIGH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 10. VOUT_MARGIN_LOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 11. VOUT_OV_WARN_LIMIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 12. VOUT_UV_WARN_LIMIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 13. IOUT_OC_FAULT_LIMIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 14. IOUT_OC_WARN_LIMIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 15. OT_FAULT_LIMIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 16. OT_FAULT_RESPONSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 17. OT_WARN_LIMIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 18. TON_DELAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 19. TON_RISE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 20. TOFF_DELAY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 21. TOFF_FALL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 22. STATUS_BYTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 23. STATUS_WORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 24. STATUS_VOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 25. STATUS_IOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 26. STATUS_TEMPERATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 27. STATUS_MFR_SPECIFIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 28. READ_VOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 29. READ_IOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 30. READ_TEMPERATURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 31. PMBUS_REVISION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 32. MFR_ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 33. MFR_MODEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 34. MFR_REVISION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 35. MFR_LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 36. MFR_DATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 37. MFR_SERIAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 38. MFR_SPECIFIC_00 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 39. MFR_SPECIFIC_01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 40. MFR_SPECIFIC_02 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 41. PMBus interfacing with Artesyn module: results. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 42. PMBus interfacing with SiLabs module: results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 43. Bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 44. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4/43 Doc ID 13286 Rev 2

Page 5

AN2511 List of figures

List of figures

Figure 1. Interface diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 2. Flowchart: I

Figure 3. Flowchart: data length calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 4. Flowchart: read operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 5. Flowchart: write operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 6. PC hyperterminal application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 7. Baud rate configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 8. Hyperterminal settings - ASCII setup configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 9. Hyperterminal message to show company name and selection of communication speed 30

Figure 10. PEC selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 11. Slave address entry message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 12. Wrong slave address entry - response 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 13. Wrong slave address entry - response 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 14. Options to select read/ write mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 15. Single read operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 16. Continuous read operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 17. Write mode command code entry message from hyperterminal . . . . . . . . . . . . . . . . . . . . 32

Figure 18. Write mode data entry message from hyperterminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 19. Write mode operation example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 20. Read operation to check data writing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 21. Group command code entry message from hyperterminal. . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 22. Group command operation example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 23. Invalid command message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 24. Example of invalid command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 25. Communication timeout message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 26. Demonstration board schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 27. Top view layout of the demonstration board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 28. Bottom view layout of the demonstration board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 29. STEVAL-ISQ002V1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 30. Pin description of RS232 D9 connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2

C initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Doc ID 13286 Rev 2 5/43

Page 6

PMBus introduction AN2511

1 PMBus introduction

1.1 PMBus protocol description

The PMBus protocol is intended to cover a wide range of power system architectures and

converters.

PMBus devices must use the system management bus (SMBus), version 1.1. Implemented

over the industry-standard SMBus serial interface, the PMBus protocol facilitates the

programming, control and real-time monitoring of compliant power conversion products.

1.1.1 SMBus version 1.1

The system management bus (SMBus) is a two-wire interface through which various system

component chips can communicate with each other and with the rest of the system. It is

based on the principles of operation of I

For more information about SMBus, refer to AN1713, available from www.st.com.

1.1.2 Extensions to SMBus version 1.1 specification

1. Block write-block-read process call

To support certain commands of the PMBus command language, PMBus devices must

support the "Block write-block-read process call" described in Section 5.5.8 of Version

2.0 of the SMBus Specification.

2. Host notify protocol

PMBus devices may support the host notify protocol described in Section 5.5.9 of

Version 2.0 of the SMBus Specification. If a PMBus device supports the host notify

protocol, the two data bytes sent to the host are the same as the data bytes returned by

the STATUS_WORD command.

3. Group command protocol

PMBus devices must support the group command protocol. The group command

protocol is used to send commands to more than one PMBus device. The commands

are received in one transmission. When the devices detect the STOP condition that

ends the command, they all begin executing the command they received.

4. Addressing

PMBus devices use seven bit addresses.

5. Packet error checking (PEC)

Support for the SMBus packet error checking (PEC) protocol is optional.

2

C.

1.2 Hardwired signals

1.2.1 Electrical interface

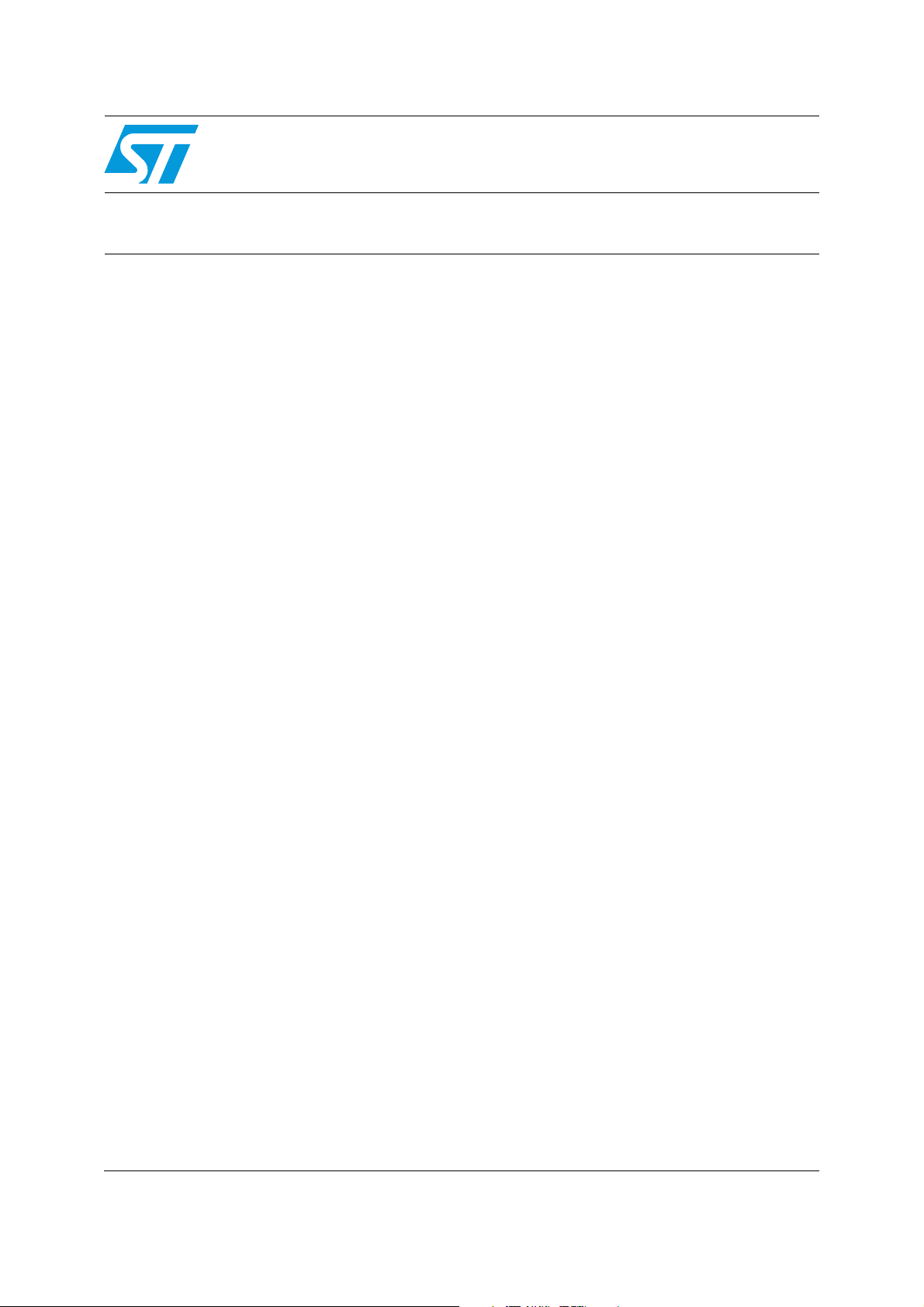

The following diagram shows the interface between different PMBus devices. ST72264G1 is

the selected microcontroller, which has a multi-master I

acts as PMBus master. It communicates with any compatible PMBus slave using a 4-pin

interface. SMBC is the clock from the master. SMBD is the data pin. Both SMBC and SMBD

should be pulled up with a 4.7 kΩ resistor. SMBALERT is the SMBus alert pin, which helps

6/43 Doc ID 13286 Rev 2

2

C interface. This microcontroller

Page 7

AN2511 PMBus introduction

the slave to alert the master whenever it wants to communicate. The control pin is used to

switch ON or OFF a PMBus slave.

Figure 1. Interface diagram

The CONTROL signal is an input signal on a power converter. It is used to turn the unit on

and off in conjunction with commands received via the serial bus. It can be configured as an

active high or active low signal through the ON_OFF_CONFIG command (refer to

Section 3.1).

This signal is optional but recommended.

1.2.2 Timing

No specific requirements are made when a PMBus device must respond to a state change

of a hardwired signal.

PMBus Master

(ST72F264G1)

SMBC (SCL)

SMBD (SDA)

SMBA (PA3)

CONTROL (PC0)

PMBus Slave

SMBC

SMBD

SMBA

CONTROL

Doc ID 13286 Rev 2 7/43

Page 8

Implementation of PMBus using ST7 I2C AN2511

2 Implementation of PMBus using ST7 I2C

2.1 Firmware architecture

This section explains sequence of operation for different software modules.

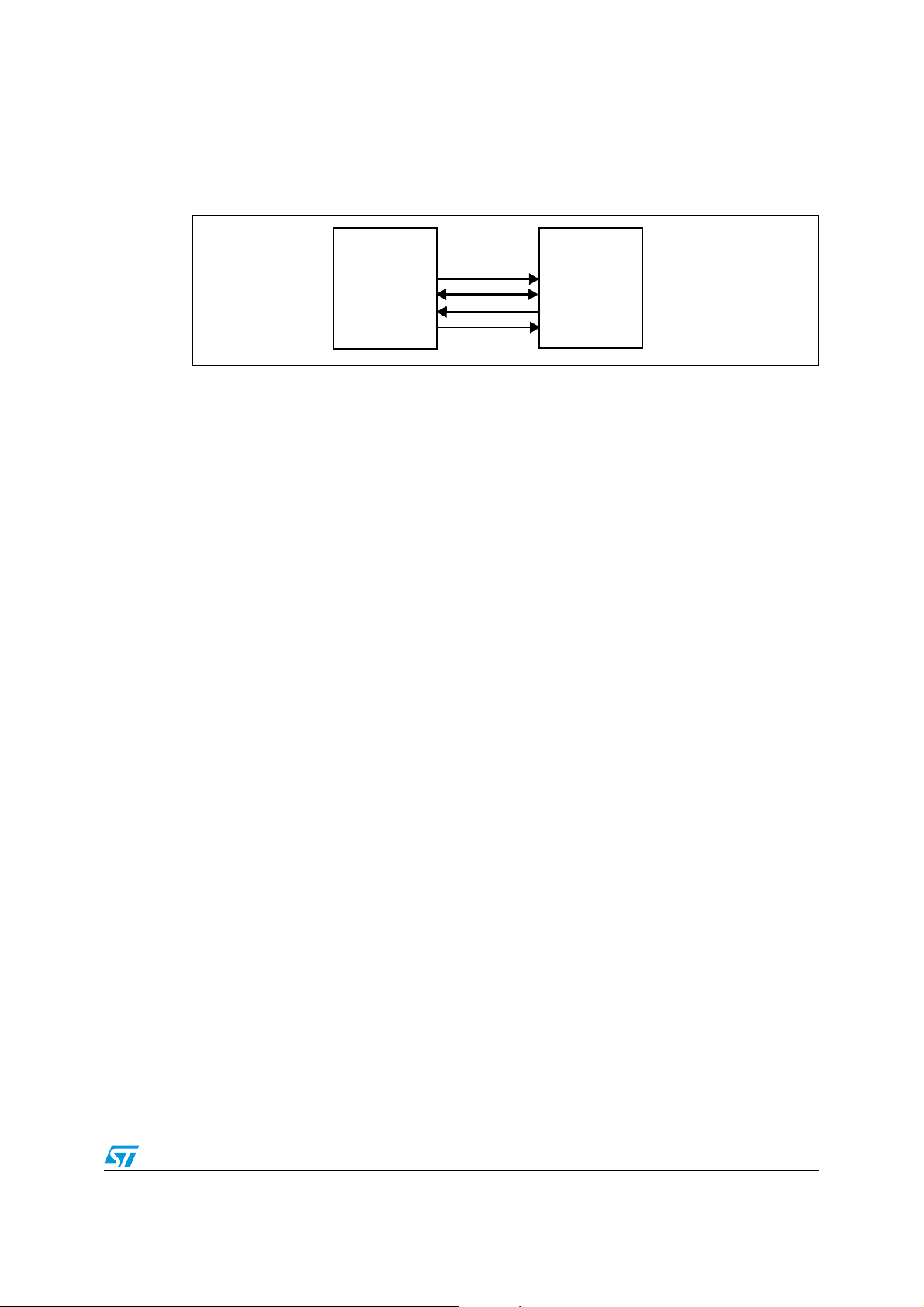

2.1.1 I2C initialization

To use ST7 I2C for PMBus communication, the peripheral is initialized for 100 kHz

communication speed. The I

2

C is configured with an address of 0x30, as it can act as a

slave due to its multi-master capability. The following flowchart shows the sequence.

Figure 2. Flowchart: I

2

C initialization

Initialize I

OAR1 and OAR2 registers

Configure slave addresses

Enable I

acknowledge in I2CCR register

Set communication speed as

100kHz in I2CCCR register

START

2

C CR, CCR,

in OAR1 and OAR2

2

C peripheral and

STOP

The above flowchart is implemented in the function PMBus_Init.

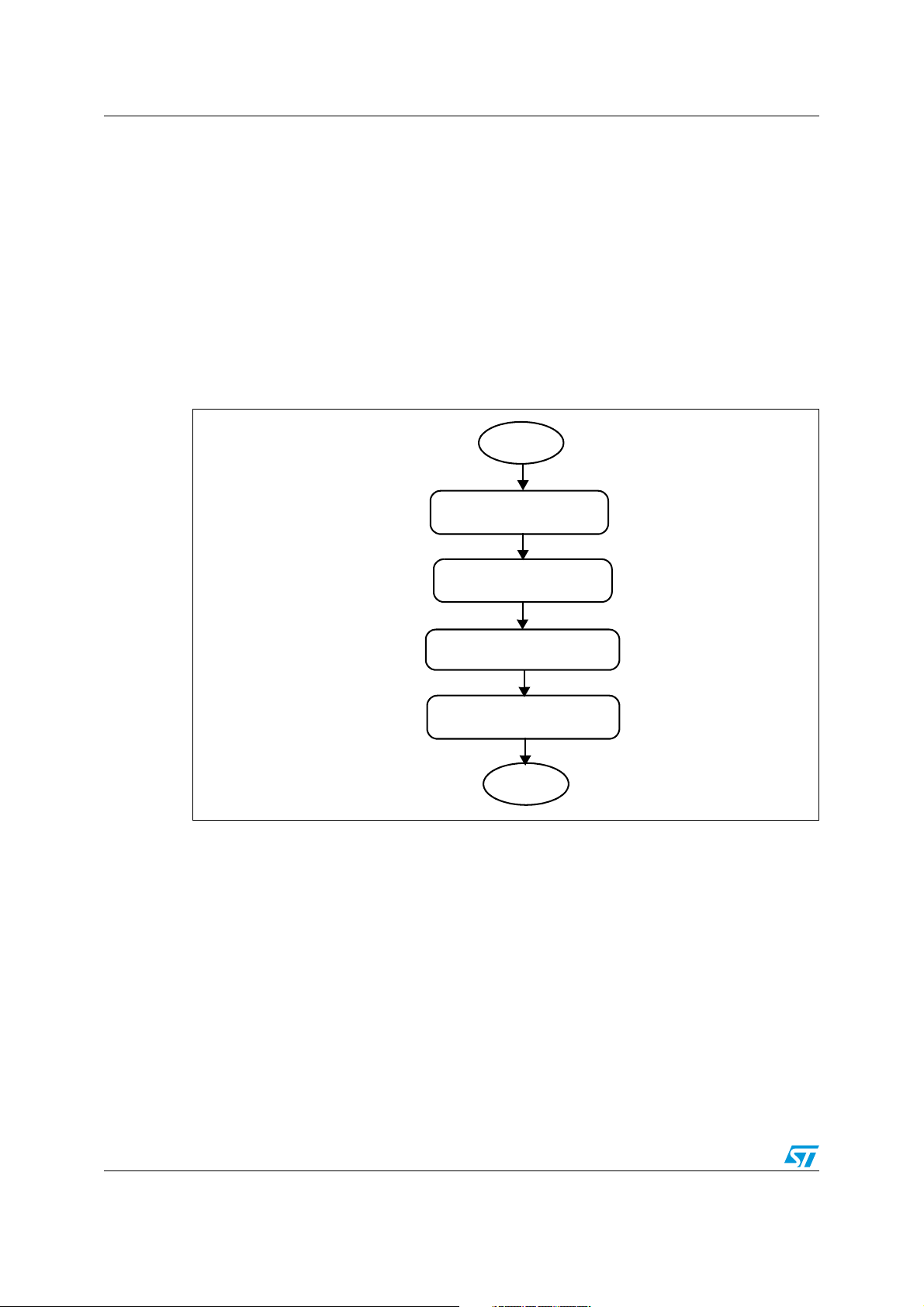

2.1.2 Slave address and command code

The PMBus master addresses the slave with a 7-bit address. Once the slave device

acknowledges the address, the command code is sent corresponding to the PMBus

command and SMBus protocol (refer to Section 3.1).

Then, the microcontroller decodes the command code as shown in the following sequence.

Simultaneously, the SMBus_Mode variable is updated.

8/43 Doc ID 13286 Rev 2

Page 9

AN2511 Implementation of PMBus using ST7 I2C

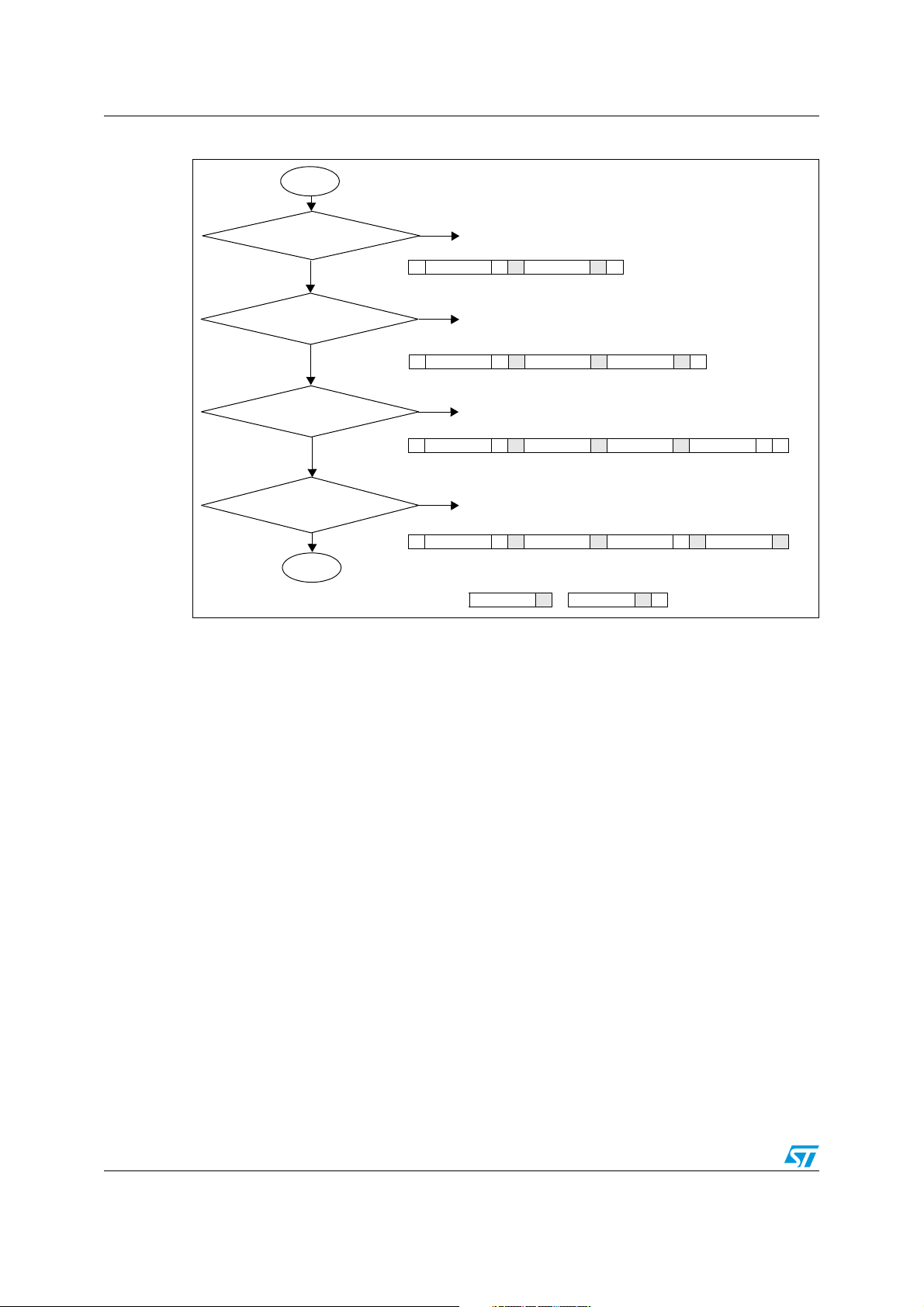

Figure 3. Flowchart: data length calculation

START

Check if command code equal

to Block protocol

No

Check if command code equal

to Byte protocol

Ye s

Ye s

Update

SMBus_Mode

for Block Command

Byte Count=1,

Update

SMBus_Mode

for Byte Command

Byte Count=6,

No

Byte Count=2,

Check if command code equal

to word protocol

No

Ye s

Update

SMBus_Mode

for Word Command

STOP

Inside both PMBus_CommandRead and PMBus_CommandWrite functions,

PMBus_DataLengthCalc is called which calculates the data length based on the

command code received.

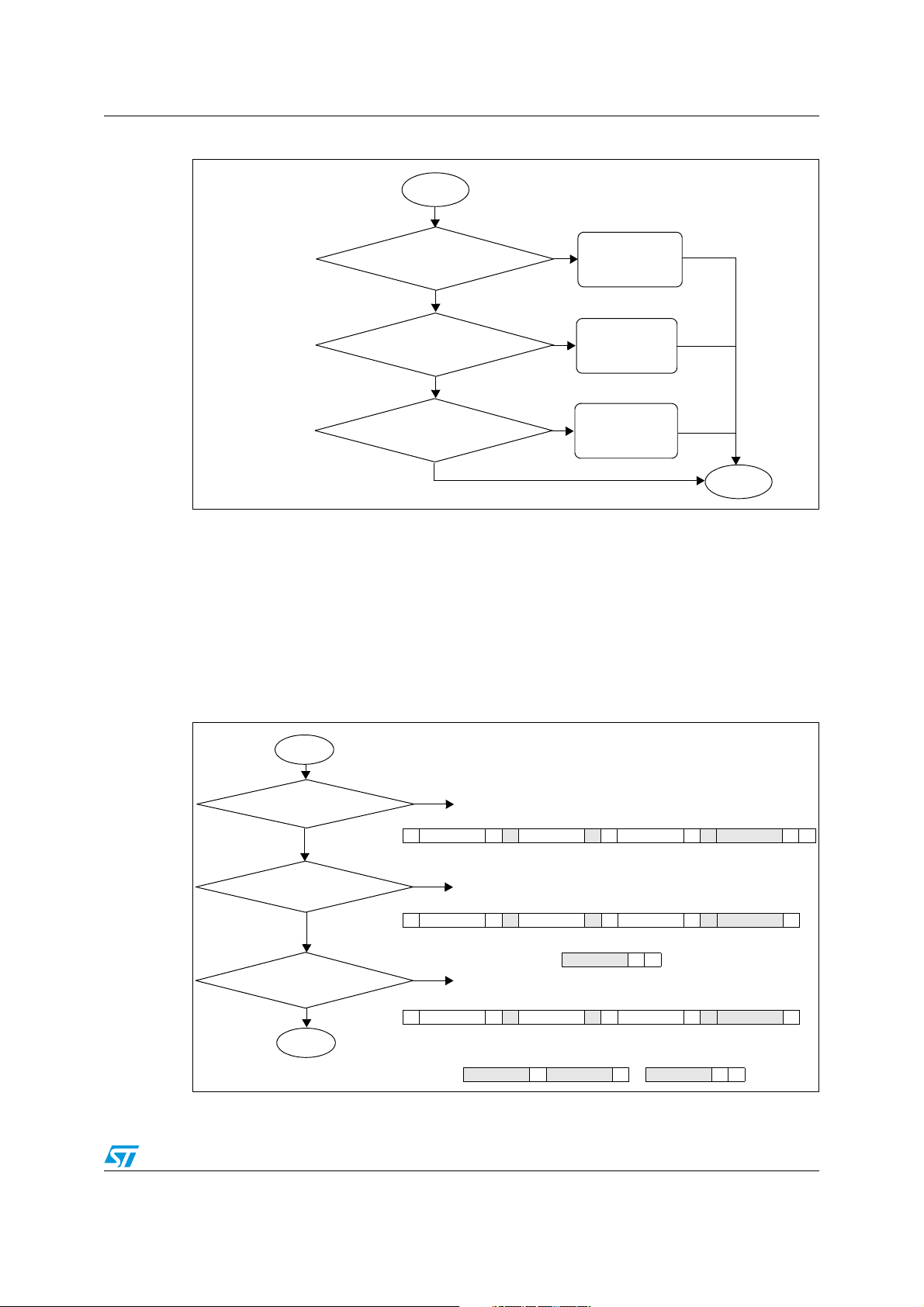

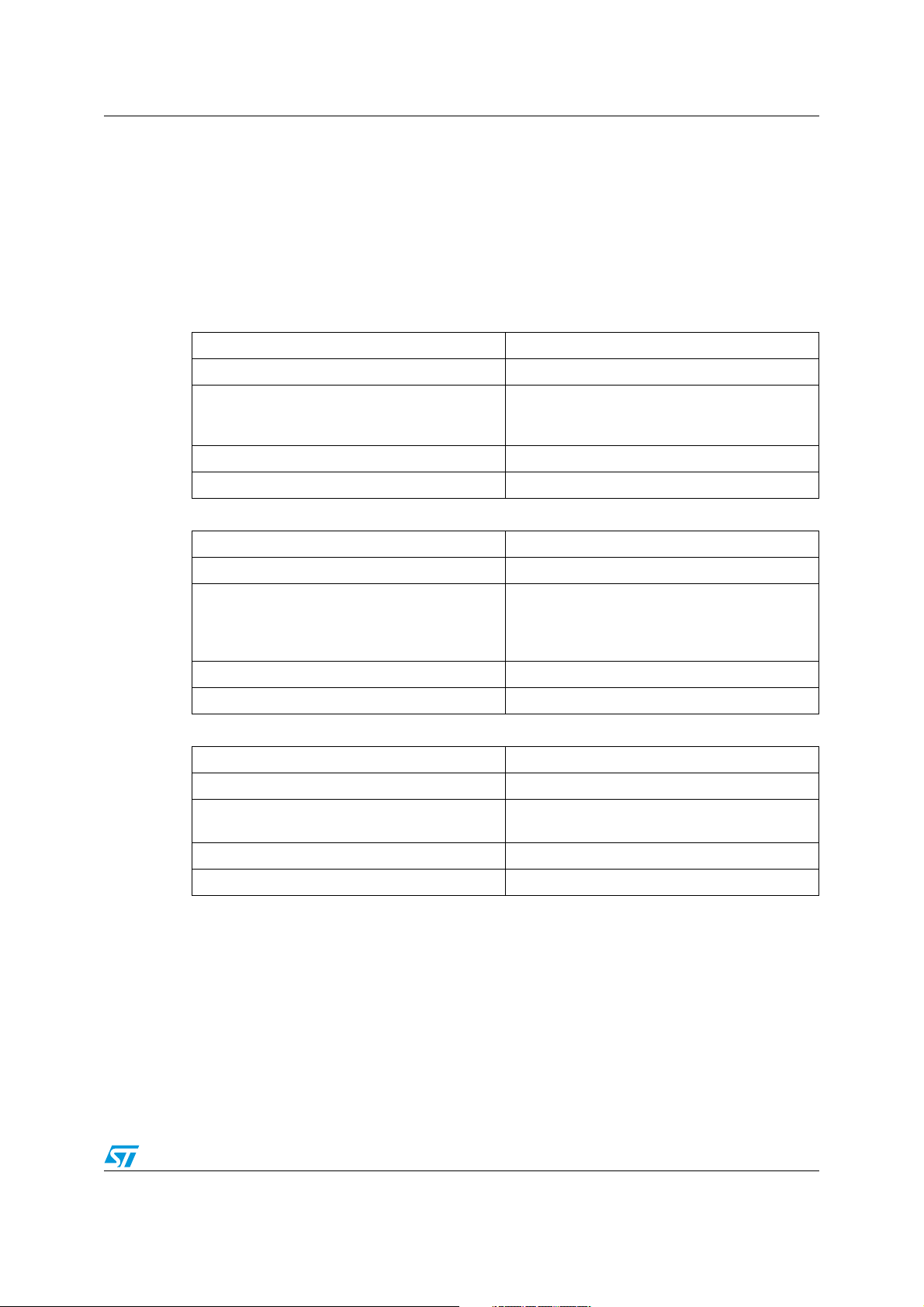

2.1.3 Read and write operation

PMBus master performs read/ write operations with the slave device. Depending on the

command code, either PMBus_CommandRead or PMBus_CommandWrite is called. Inside

this function, the SMBus transaction type is selected as shown in the following sequence.

Figure 4. Flowchart: read operation

START

Check if SMBus_Mode for

Byte command

No

Check if SMBus_Mode for Word

command

No

Check if SMBus_Mode for

Send Block command

No

STOP

Ye s

SMBus Read byte protocol

1711811711811

S Slave Address Wr

Ye s

SMBus Read word protocol

171181171181

S Slave Address Wr

Ye s

SMBus Read block protocol

171181171181

S Slave Address Wr

A Command Code A S Slave Address Rd A Data Byte A P

A Comm and Code A S Slave Address Rd A Data Byte Low A ...

811

Data Byte High A P

A Com mand Code A Sr Slave Address Rd A Count Byte = 1 A ...

8181...811

Data Byte 1 A Data Byte 2 A ... Data Byte N A P

Doc ID 13286 Rev 2 9/43

Page 10

Implementation of PMBus using ST7 I2C AN2511

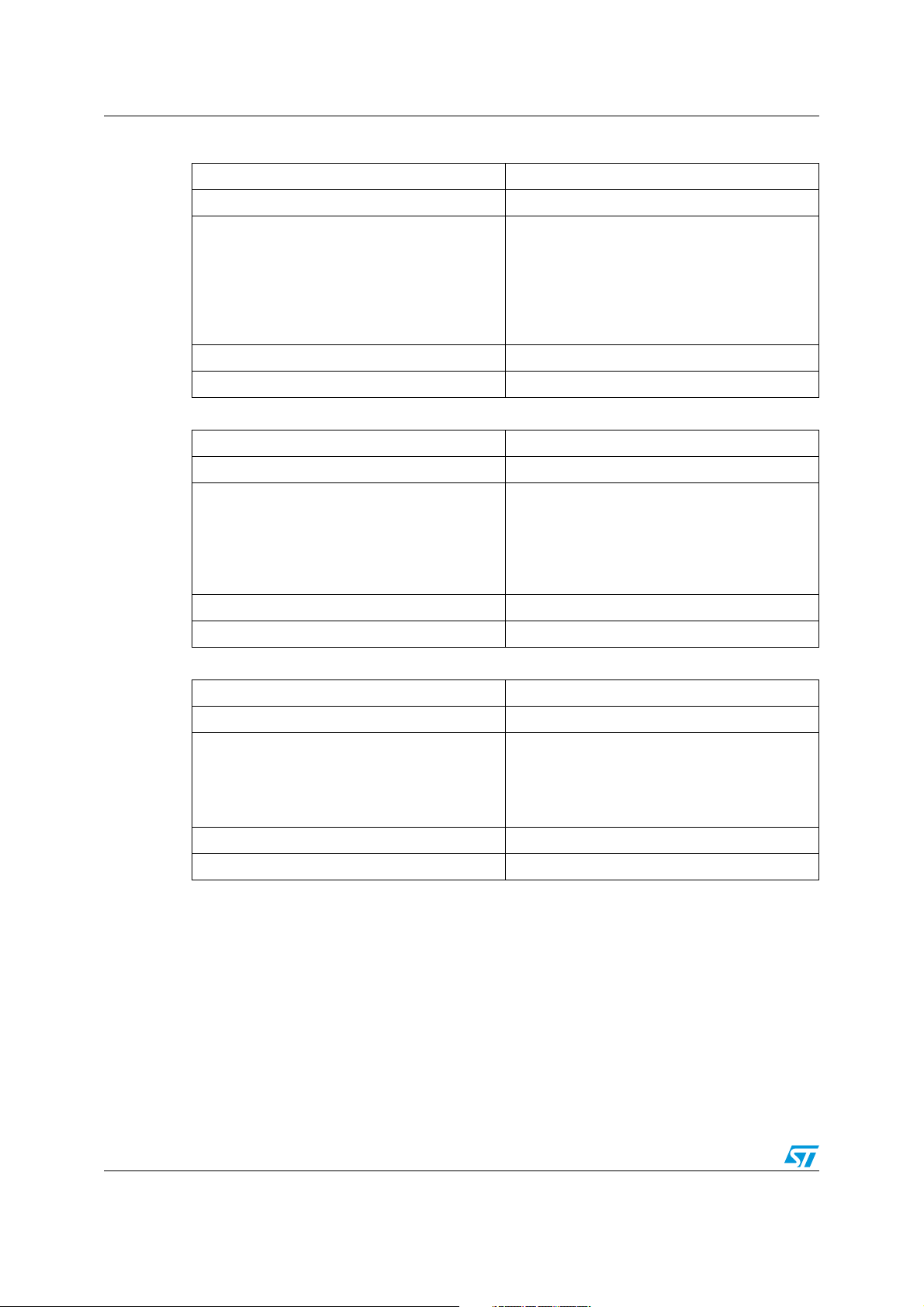

Figure 5. Flowchart: write operation

START

Check if SMBus_Mode for

Send Byte command

No

Check if SMBus_Mode for Write

Byte command

Check if SMBus_Mode for Write

Word command

No

Check if SMBus_Mode for

Write Block command

No

STOP

Ye s

SMBus Send byte protocol

1711811

S Slave Address Wr

Ye s

SMBus Write byte protocol

171181811

S Slave Address Wr

Ye s

SMBus Write word protocol

17118181811

S Slave Address Wr

Ye s

SMBus Write block protocol

17118181181

S Slave Address Wr

A Data Byte AP

A Comma nd Code A Data Byte AP

A Comma nd Code A Data Byte Low A Dat a Byte HIgh A P

A Command Co de A Byte Count = N Rd A Data Byte 1 A ...

81...811

Data Byte 2

A ... Data Byte N AP

During the PMBus communication, if there are any errors in communication (acknowledge

2

failure, arbitration loss, bus error or SMBus timeout), the I

C peripheral is disabled. It is re-

initialized again inside the PMBus write/ read functions.

In case the SMBus Alert pin is pulled low by the slave to inform the master that it wants to

communicate, the slave address is programmed with the alert response address (0x18).

This is acknowledged by the slave that alerted the master. After the communication between

the master and slave is complete, the slave address is programmed with the user-defined

slave address. The default value of this user-defined address is 0x30.

In case of group operation, the write operation flowchart is followed without the stop

condition.

10/43 Doc ID 13286 Rev 2

Page 11

AN2511 PMBus commands and source code

3 PMBus commands and source code

3.1 PMBus commands

The Part II - command language document of PMBus™ Power System Management

Protocol Specification v1.0 provides the list of PMBus commands. This driver supports the

following list of commands. For each command a table is given.

Table 1. Operation

Command name OPERATION

Command code 01h

The OPERATION command is used to turn the

Description

SMBus transaction type Read/ Write byte

Number of data bytes 1

Table 2. ON_OFF_CONFIG

Command name ON_OFF_CONFIG

Command code 02h

unit on and off in conjunction with the input from

the CONTROL (OUTEN) pin.

The ON_OFF_CONFIG command configures the

Description

combination of CONTROL (OUTEN) pin input

and serial bus commands needed to turn the unit

on and off.

SMBus transaction type Read/ Write byte

Number of data bytes 1

Table 3. CLEAR_FAULTS

Command name CLEAR_FAULTS

Command code 03h

Description

CLEAR_FAULTS is used to clear any fault bits

that have been set.

SMBus transaction type Send byte

Number of data bytes 0

Doc ID 13286 Rev 2 11/43

Page 12

PMBus commands and source code AN2511

Table 4. RESTORE_DEFAULT_ALL

Command name RESTORE_DEFAULT_ALL

Command code 12h

The RESTORE_DEFAULT_ALL command

instructs the PMBus device to copy the entire

contents of the non-volatile default store memory

Description

SMBus transaction type Send byte

Number of data bytes 0

Table 5. STORE_USER_ALL

Command name STORE_USER_ALL

Command code 15h

Description

SMBus transaction type Send byte

to the matching locations in the operating

memory. Any items in default store that do not

have matching locations in the operating memory

are ignored.

The STORE_USER_ALL command instructs the

PMBus device to copy the entire contents of the

operating memory to the matching locations in

the non-volatile user store memory. Any items in

operating memory that do not have matching

locations in the user store are ignored.

Number of data bytes 0

Table 6. VOUT_MODE

Command name VOUT_MODE

Command code 20h

VOUT_MODE command, used for commanding

and reading output voltage, consists of a three bit

Description

mode (only linear format is supported.) and a

five-bit parameter representing the exponent

used in output voltage Read/Writes.

SMBus transaction type Read/ Write byte

Number of data bytes 1

12/43 Doc ID 13286 Rev 2

Page 13

AN2511 PMBus commands and source code

Table 7. VOUT_COMMAND

Command name VOUT_COMMAND

Command code 21h

Description

SMBus transaction type Read/ Write word

Number of data bytes 2

Table 8. VOUT_MAX

Command name VOUT_MAX

Command code 24h

Description

SMBus transaction type Read/ Write word

Number of data bytes 2

Table 9. VOUT_MARGIN_HIGH

Command name VOUT_MARGIN_HIGH

Command code 25h

Description

VOUT_COMMAND is used to set the output

voltage, in volts (linear format).

The VOUT_ MAX command sets an upper limit

on the output voltage the unit can command

regardless of any other commands or

combinations.

This VOUT_MARGIN_HIGH command loads the

unit with the voltage to which the output is to be

changed when the OPERATION command is set

to "Margin High".

SMBus transaction type Read/ Write word

Number of data bytes 2

Table 10. VOUT_MARGIN_LOW

Command name VOUT_MARGIN_LOW

Command code 26h

This VOUT_MARGIN_LOW command loads the

Description

unit with the voltage to which the output is to be

changed when the OPERATION command is set

to "Margin Low".

SMBus transaction type Read/ Write word

Number of data bytes 2

Table 11. VOUT_OV_WARN_LIMIT

Command name VOUT_OV_WARN_LIMIT

Command code 42h

Doc ID 13286 Rev 2 13/43

Page 14

PMBus commands and source code AN2511

Table 11. VOUT_OV_WARN_LIMIT (continued)

The VOUT_OV_WARN_LIMIT command sets the

value of the output voltage at the sense or output

Description

SMBus transaction type Read/ Write word

Number of data bytes 2

Table 12. VOUT_UV_WARN_LIMIT

Command name VOUT_UV_WARN_LIMIT

Command code 43h

Description

SMBus transaction type Read/ Write word

Number of data bytes 2

Table 13. IOUT_OC_FAULT_LIMIT

Command name IOUT_OC_FAULT_LIMIT

pins that causes an output voltage high warning.

This value is typically less than the output

overvoltage threshold.

The VOUT_UV_WARN_LIMIT command sets the

value of the output voltage at the sense or output

pins that causes an output voltage low warning.

This value is typically greater than the output

undervoltage fault threshold

Command code 46h

The IOUT_OC_FAULT_LIMIT command sets the

Description

value of the sense output current, in amps (literal

format), that causes an overcurrent fault.

SMBus transaction type Read/ Write word

Number of data bytes 2

Table 14. IOUT_OC_WARN_LIMIT

Command name IOUT_OC_WARN_LIMIT

Command code 4Ah

The IOUT_OV_WARN_LIMIT command sets the

Description

SMBus transaction type Read/ Write word

Number of data bytes 2

Table 15. OT_FAULT_LIMIT

Command name OT_FAULT_LIMIT

Command code 4Fh

Description

value of the output current that causes an output

overcurrent warning.

The OT_FAULT_LIMIT command sets the value

of the sense temperature, in °C (literal format),

that causes an overtemperature fault

14/43 Doc ID 13286 Rev 2

Page 15

AN2511 PMBus commands and source code

Table 15. OT_FAULT_LIMIT (continued)

SMBus transaction type Read/ Write word

Number of data bytes 2

Table 16. OT_FAULT_RESPONSE

Command name OT_FAULT_RESPONSE

Command code 50h

The OT_FAULT_RESPONSE command instructs

Description

SMBus transaction type Read/ Write byte

Number of data bytes 1

Table 17. OT_WARN_LIMIT

Command name OT_WARN_LIMIT

Command code 51h

Description

the device on what action to take in response to

an overtemperature fault.

The OT_WARN_LIMIT command sets the value

of the sense temperature, in °C (literal format),

that causes an overtemperature warning.

SMBus transaction type Read/ Write word

Number of data bytes 2

Table 18. TON_DELAY

Command name TON_DELAY

Command code 60h

The TON_DELAY sets the time, in ms, from when

Description

a start condition is received (CONTROL signal

asserted and a valid OPERATION command

received) until the output voltage starts to rise.

SMBus transaction type Read/ Write word

Number of data bytes 2

Table 19. TON_RISE

Command name TON_RISE

Command code 61h

The TON_RISE sets the time, in ms, from when

Description

the output starts to rise until the voltage has

entered the regulation band.

SMBus transaction type Read/ Write word

Number of data bytes 2

Table 20. TOFF_DELAY

Command name TOFF_DELAY

Command code 64h

Doc ID 13286 Rev 2 15/43

Page 16

PMBus commands and source code AN2511

Table 20. TOFF_DELAY (continued)

The TOFF_DELAY sets the time, in ms, from

when a stop condition is received (CONTROL

Description

SMBus transaction type Read/ Write word

Number of data bytes 2

Table 21. TOFF_FALL

Command name TOFF_FALL

Command code 65h

Description

SMBus transaction type Read/ Write word

Number of data bytes 2

Table 22. STATUS_BYTE

Command name STATUS_BYTE

Command code 78h

Description

SMBus transaction type Read byte

signal negated or a valid OPERATION command

received) until the unit stops transferring energy

to the output.

The TOFF_FALL sets the time, in ms, from the

end of the turnoff delay time until the voltage is

commanded to zero. Note that this command can

only be used with a device whose output can sink

enough current to cause the output voltage to

decrease at a controlled rate.

The STATUS_BYTE command returns one byte

of information with a summary of the most critical

faults

Number of data bytes 1

Table 23. STATUS_WORD

Command name STATUS_WORD

Command code 79h

The STATUS_WORD command returns two

Description

bytes of information with a summary of the units

fault condition.

SMBus transaction type Read word

Number of data bytes 2

:

Table 24. STATUS_VOUT

Command name STATUS_VOUT

Command code 7Ah

Description

The STATUS_VOUT commands returns one byte

with status information on Vout.

16/43 Doc ID 13286 Rev 2

Page 17

AN2511 PMBus commands and source code

Table 24. STATUS_VOUT (continued)

SMBus transaction type Read byte

Number of data bytes 1

Table 25. STATUS_IOUT

Command name STATUS_IOUT

Command code 7Bh

Description

SMBus transaction type Read byte

Number of data bytes 1

Table 26. STATUS_TEMPERATURE

Command name STATUS_TEMPERATURE

Command code 7Dh

Description

SMBus transaction type Read byte

Number of data bytes 1

STATUS_IOUT commands returns one byte with

status information on Iout.

STATUS_TEMPERATURE commands returns

one byte with status information on temperature.

Doc ID 13286 Rev 2 17/43

Page 18

PMBus commands and source code AN2511

Table 27. STATUS_MFR_SPECIFIC

Command name STATUS_MFR_SPECIFIC

Command code 80h

STATUS_MFR_SPECIFIC commands returns

Description

SMBus transaction type Read byte

Number of data bytes 1

Table 28. READ_VOUT

Command name READ_VOUT

Command code 8Bh

Description

SMBus transaction type Read word

Number of data bytes 2

Table 29. READ_IOUT

Command name READ_IOUT

Command code 8Ch

Description

SMBus transaction type Read word

Number of data bytes 2

Table 30. READ_TEMPERATURE

Command name READ_TEMPERATURE

Command code 8Dh

Description

SMBus transaction type Read word

Number of data bytes 2

one byte with the manufacturer specific status

information.

The READ_VOUT command returns the actual

measured output voltage in the same format as

set by the VOUT_MODE command.

The READ_IOUT command returns the

measured output current in amperes.

Up to three temperature readings can be

returned for each device.

18/43 Doc ID 13286 Rev 2

Page 19

AN2511 PMBus commands and source code

Table 31. PMBUS_REVISION

Command name PMBUS_REVISION

Command code 98h

PMBUS_REVISION command stores or reads

Description

SMBus transaction type Read byte

Number of data bytes 1

Table 32. MFR_ID

Command name MFR_ID

Command code 99h

Description

SMBus transaction type Read/Write block

Number of data bytes 7

Table 33. MFR_MODEL

Command name MFR_MODEL

the revision of the PMBus to which the device is

compliant.

The MFR_ID commands loads the unit with

ASCII characters that contain the manufacturer's

ID (name, abbreviation or symbol that identifies

the unit's manufacturer). This is typically only

done once at the time of manufacture.

Command code 9Ah

The MFR_MODEL command loads the unit with

Description

ASCII characters that contain the manufacturer's

model number. This is typically done once at the

time of manufacture.

SMBus transaction type Read/Write block

Number of data bytes 6

Table 34. MFR_REVISION

Command name MFR_REVISION

Command code 9Bh

The MFR_REVISION command loads the unit

Description

with ASCII characters that contain the

manufacturer's revision number. This is typically

done once at the time of manufacture.

SMBus transaction type Read/Write block

Number of data bytes 2

Doc ID 13286 Rev 2 19/43

Page 20

PMBus commands and source code AN2511

Table 35. MFR_LOCATION

Command name MFR_LOCATION

Command code 9Ch

The MFR_REVISION command loads the unit

Description

SMBus transaction type Read/Write block

Number of data bytes 2

Table 36. MFR_DATE

Command name MFR_DATE

Command code 9Dh

Description

SMBus transaction type Read/Write block

Number of data bytes 6

Table 37. MFR_SERIAL

Command name MFR_SERIAL

with ASCII characters that contain the

manufacturer's revision number. This is typically

done once at the time of manufacture.

The MFR_DATE command loads the unit with

ASCII characters that identify the unit's date of

manufacture. This is typically done once at the

time of manufacture.

Command code 9Eh

Description

The MFR_SERIAL command loads the unit with

a serial number to uniquely identify the unit

SMBus transaction type Read/Write block

Number of data bytes 6

Table 38. MFR_SPECIFIC_00

Command name MFR_SPECIFIC_00

Command code D0h

Description

The MFR_SPECIFIC_00 command provides

access control for NVM register writes.

SMBus transaction type Read byte

Number of data bytes 1

20/43 Doc ID 13286 Rev 2

Page 21

AN2511 PMBus commands and source code

Table 39. MFR_SPECIFIC_01

Command name MFR_SPECIFIC_01

Command code D1h

Description

The MFR_SPECIFIC_01 command provides

access control for configuration register writes.

SMBus transaction type Read byte

Number of data bytes 1

Table 40. MFR_SPECIFIC_02

Command name MFR_SPECIFIC_02

Command code D2h

Description

The MFR_SPECIFIC_02 is a manufacturer

defined command.

SMBus transaction type Read byte

Number of data bytes 1

3.2 Source code

The source code is attached in the zip file along with the application note. This source code

is organized as shown below.

' Workspace directory

' Debug

' object files, list files, map files, executable files (.elf), hex code

(.s19)

' Sources

' Main.c: Contains main source code. In this file, PMBus interface functions

are called (refer to section 3.3).

' Main.h: Contains prototype of all functions used in Main.c.

' PMBus.c: Contains functions for PMBus write and read operation. The data

length calculator function and I2C and Alert signal interrupt sub-

routines are also written inside this file.

' PMBus.h: Contains prototype of all functions and enumerated data

' SMBus_Master.c: Contains source code for differnet SMBus master

' SMBus_Master.h: Contains prototype of all functions and enumerated data

' st72264g1.h: Contains register mapping for ST72F264G1 device.

' ST7_hr.h: Contains hardware register bit definitions for ST7 MCU

' ST7_Config.h: Contains compiler selection, peripheral register inclusion,

' interrupt_vector.c: Contains general Interrupt vector table for ST7 devices

types used in PMBus.c.

transaction bus protocols.

types used in SMBus_Master.c.

header files inclusion for linking, macros for assembly instructions

and Fcpu Definition.

Doc ID 13286 Rev 2 21/43

Page 22

PMBus commands and source code AN2511

3.3 Example

This section explains how to use the PMBus driver. An example operation of write/ read

commands are shown.

/*****************************************************************************

COPYRIGHT 2005 STMicroelectronics

Source File Name : Main.c

Group : IMS Systems Lab

Author : Telecom Team

Date First Issued: 01/09/2006

-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-

THE SOFTWARE INCLUDED IN THIS FILE IS FOR GUIDANCE ONLY. STMicroelectronics

SHALL NOT BE HELD LIABLE FOR ANY DIRECT, INDIRECT OR CONSEQUENTIAL

DAMAGES WITH RESPECT TO ANY CLAIMS ARISING FROM USE OF THIS SOFTWARE.

-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*********************************Documentation**********************************

General Purpose - Contains main source code. In this file, the PMBus command files

are written.

******************************************************************************/

#include "ST7_config.h" /* Fcpu defined as 8MHz */

#include "main.h" /* Contains the global variables used in main.c */

#include "ST7_hr.h" /* Contains the register and flags for ST7 */

extern volatile unsigned int SMB_TimeCount; /* Time count variable */

#pragma space extern [] @tiny /* To force following variables into short

addressing memory */

extern unsigned char Data_Buff [32] ; /* Buffer to store data */

/* Variables to differentiate the different SMBus transaction types */

extern volatile unsigned char SMBus_Mode ;

extern volatile unsigned char SMB_Err_Status ; /* Error status */

/* Master to address slave with this

address */

static volatile unsigned char PMBus_SlaveAdd = 0x80;

/* Master to address slave with this

address */

static volatile unsigned char PMBus_SlaveAdd = 0x80;

/*----------------------------------------------------------------------------ROUTINE NAME : Main

INPUT : None

OUTPUT : None

DESCRIPTION : Using this file, user can write/ read PMBus commands.

COMMENTS : Programs jumpts into this routine when microcontroller is reset

-----------------------------------------------------------------------------*/

void main()

{

unsigned char temp ;

SMBs_Address_t PMBus_Err ; /* To check errors in PMBus communication */

/*----------------------- Port A configuration ----------------------------*/

PADDR &= (unsigned char)~PORTA_DEFAULT;

PADDR = PORTA_DEFAULT ; /* Other pins configured as floating input */

PAOR = (unsigned char)(PORTA_DEFAULT) ;

/*----------------------- Port C configuration ----------------------------*/

PCDDR = CONTROL ; /* PC0 floating input, others push pull output */

22/43 Doc ID 13286 Rev 2

Page 23

AN2511 PMBus commands and source code

PCOR = CONTROL ;

PCDR = CONTROL ;

/*----------------------- Alert Interrupt configuration ---------------------

----------*/

EnableInterrupts; /* Resets interrupt mask */

MISCR1 = 0x10 ; /* EI0 on falling edge low level for Alert interrupt */

/*---------------------PMBus communication configuration-------------------*/

while (1)

{

/* I2C configuration: ST7 I2C address 0x30, communication speed 100kHz */

PMBus_Init (SMBs_MISC, SLAVEADD, 0x40, 0x23);

/* Checking if an alert signal is received from slave */

if (SMBus_Mode & SMB_ARA)

{

/* ST7 I2C sends the alert response address to check which slave

alerted */

PMBus_Err = SMBm_ReceiveByte (ALERTRESPONSEADD, Data_Buff);

/* Alerted slave address will be used for any further communication */

PMBus_SlaveAdd = *Data_Buff ;

SMBus_Mode &= (unsigned char) ~SMB_ARA ;

}

Command_Code = 0x01; /* User should enter the PMBus command code here */

PMBus_CommandWrite (Command_Code); /* Writes data from Data_Buff */

Command_Code = 0x02; /* User should enter the PMBus command code here */

PMBus_CommandRead (Command_Code);

if (SMB_Err_Status)

{ /* I2C status register read to clear any

errors */

SMB_Err_Status = I2CSR2 ;

SMB_Err_Status = 0 ;

}

} /* End of while (1) */

} /* End of main */

3.4 Limitations

1. The SMBus driver used in this application note is tested only for write word, read word

and write block protocols with PEC disabled.

2. The SMBus driver doesn't meet the clock low extending feature of SMBus v1.1 due to

the limitation of the I

3. In case of PEC, when slave is acting as receiver, the ACK bit is not disabled if the PEC

received from master transmitter is different from slave. It is stored in the user address

as the last byte. It is the responsibility of the user to check the master PEC with the

slave PEC to decide on data validity.

/* Read data and store it in Data_Buff */

2

C peripheral.

Doc ID 13286 Rev 2 23/43

Page 24

PMBus interfacing results AN2511

4 PMBus interfacing results

This section describes the results of interfacing the demonstration board with Artesyn and

SiLabs modules.

4.1 Interfacing with Artesyn module

The following table shows the different PMBus commands and ST demonstration board

results compared to the Artesyn DPL20C PMbus module.

Table 41. PMBus interfacing with Artesyn module: results

Command

code

01 OPERATION Read/ write byte 1 80 80

02 ON_OFF_CONFIG Read/ write byte 1 14 14

03 CLEAR_FAULTS Send byte 0

12

15 STORE_USER_ALL Send byte 0

20 VOUT_MODE Read/ write byte 1 1 A 1 A

21 VOUT_COMMAND Read/ write word 2 00 60 00 60

24 VOUT_MAX Read/ write word 2 01 60 01 60

25 VOUT_MARGIN_HIGH Read/ write word 2 00 6 A 00 6 A

26 VOUT_MARGIN_LOW Read/ write word 2 00 56 00 56

42

43

46

4A

PMBus command

RESTORE_DEFAULT_

ALL

VOUT_OV_WARN_LIM

IT

VOUT_UV_WARN_LIM

IT

IOUT_OC_FAULT_LI

MIT

IOUT_OC_WARN_LIM

IT

SMBus transaction

type

Send byte 0

Read/ write word 2 00 6E 00 6E

Read/ write word 2 00 56 00 56

Read/ write word 2 00 19 00 19

Read/ write word 2 00 17 00 17

Number

of data

bytes

Data

(Si8250)

Data

(ST7)

4F OT_FAULT_LIMIT Read/ write word 2 00 78 00 78

50

51 OT_WARN_LIMIT Read/ write word 2 00 6E 00 6E

60 TON_DELAY Read/ write word 2 00 00 00 00

61 TON_RISE Read/ write word 2 00 0A 00 0A

64 TOFF_DELAY Read/ write word 2 00 00 00 00

65 TOFF_FALL Read/ write word 2 00 00 00 00

24/43 Doc ID 13286 Rev 2

OT_FAULT_RESPONS

E

Read/ write byte 1 B1 B1

Page 25

AN2511 PMBus interfacing results

Table 41. PMBus interfacing with Artesyn module: results (continued)

Command

code

78 STATUS_BYTE Read byte 1 41 41

79 STATUS_WORD Read word 2 00 41 00 41

7A STATUS_VOUT Read byte 1 00 00

7B STATUS_IOUT Read byte 1 00 00

7D

80

8B READ_VOUT Read word 2 00 01 00 01

8C READ_IOUT Read word 2 D7 C3 D7 C3

8D READ_TEMPERATURE Read word 2 00 20 00 1D

98 PMBUS_REVISION Read byte 1 01 01

99 MFR_ID Read block 7

9A MFR_MODEL Read block 6

9B MFR_REVISION Read/ write block 2 31 02 31 41

9C MFR_LOCATION Read/ write block 2 5A 02 5A 53

PMBus command

STATUS_TEMPERATU

RE

STATUS_MFR_SPECI

FIC

SMBus transaction

type

Read byte 1 00 00

Read byte 1 02 02

Number

of data

bytes

Data

(Si8250)

41 52 54 45

53 59 4E

44 50 4C 32

30 43

Data

(ST7)

41 52 54

45 53 59

4E

44 50 4C

32 30 43

9D MFR_DATE Read/ write block 6

9E MFR_SERIAL Read/ write block 6

D0 MFR_SPECIFIC_00 Read byte 1 28 28

D1 MFR_SPECIFIC_01 Read byte 1 10 10

D2 MFR_SPECIFIC_02 Read byte 1 0A 0A

4.2 Interfacing with SiLabs module

The following table shows the different PMBus commands and ST demonstration board

results compared to Silicon Labs Si8250 - TB module.

Table 42. PMBus interfacing with SiLabs module: results

Command

code

01 OPERATION Read/ write byte 1 C0 C0

02 ON_OFF_CONFIG Read/ write byte 1 1E 1E

PMBus command

SMBus transaction

type

Number

of data

bytes

32 34 30 33

36 06

31 32 33 34

35 06

Data

(Si8250)

32 34 30

33 36 36

31 32 33

34 35 36

Data

(ST7)

Doc ID 13286 Rev 2 25/43

Page 26

PMBus interfacing results AN2511

Table 42. PMBus interfacing with SiLabs module: results (continued)

Command

code

03 CLEAR_FAULTS Send byte 0

12 RESTORE_DEFAULT_ALL Send byte 0

15 STORE_USER_ALL Send byte 0

20 VOUT_MODE Read/ write byte 1 11 11

21 VOUT_COMMAND Read/ write word 2 7F F6 7F F6

24 VOUT_MAX Read/ write word 2 89 94 89 94

25 VOUT_MARGIN_HIGH Read/ write word 2 00 6A 00 6A

25 VOUT_MARGIN_HIGH Read/ write word 2 86 5C 86 5C

26 VOUT_MARGIN_LOW Read/ write word 2 79 90 79 90

42 VOUT_OV_WARN_LIMIT Read/ write word 2 89 94 89 94

43 VOUT_UV_WARN_LIMIT Read/ write word 2 76 58 76 58

4F OT_FAULT_LIMIT Read/ write word 2 EB 20 EB 20

50 OT_FAULT_RESPONSE Read/ write byte 1 00 00

51 OT_WARN_LIMIT Read/ write word 2 EA D0 EA D0

60 TON_DELAY Read/ write word 2 00 0A 00 0A

61 TON_RISE Read/ write word 2 00 32 00 32

PMBus command

SMBus transaction

type

Number

of data

bytes

Data

(Si8250)

Data

(ST7)

64 TOFF_DELAY Read/ write word 2 00 0A 00 0A

65 TOFF_FALL Read/ write word 2 00 C8 00 C8

78 STATUS_BYTE Read byte 1 04 04

79 STATUS_WORD Read word 2 00 04 00 04

7A STATUS_VOUT Read byte 1 00 00

7B STATUS_IOUT Read byte 1 00 00

7D STATUS_TEMPERATURE Read byte 1 20 20

80 STATUS_MFR_SPECIFIC Read byte 1 00 00

8B READ_VOUT Read word 2 80 4E 80 76

8C READ_IOUT Read word 2 D7 C3 00 00

8D READ_TEMPERATURE Read word 2 EF 56 EF 56

98 PMBUS_REVISION Read byte 1 00 00

D0 MFR_SPECIFIC_00 Read byte 1 67 67

D1 MFR_SPECIFIC_01 Read byte 1 EF EF

D2 MFR_SPECIFIC_02 Read byte 1 08 08

26/43 Doc ID 13286 Rev 2

Page 27

AN2511 PMBus demonstration board

5 PMBus demonstration board

To show the features of the ST7 I2C working as a PMBus, a demonstration board is

available on request. Please contact the nearest ST office to get this board. The evaluation

board has an ST72F264G1 MCU that has 4 KBytes Flash memory. All PMBus

functionalities are not shown, as this evaluation board has hyperterminal interface which

requires lot of messages to be stored in program memory.

5.1 System requirements

In order to use the PMBus demonstration board with the Windows operating system. The

PC should support hyperterminal software and RS232 communication using DB9

connector.

5.2 Software setup

To configure the PC hyperterminal software, the user should follow the steps as mentioned

below.

1. Click on Start -> Programs -> Accessories -> Communications -> HyperTerminal

as shown below.

Figure 6. PC hyperterminal application

2. Select the correct port in which RS232 (9-pin cable) is connected (refer to Section 3).

3. Configure the following baud rate (bits per second) in hyperterminal: File -> Properties

-> Connect to -> Configure. If the user configures any baud rate other than 38400,

then RS232 communication fails.

Doc ID 13286 Rev 2 27/43

Page 28

PMBus demonstration board AN2511

Figure 7. Baud rate configuration

4. Configure the following settings in hyperterminal: File -> Properties -> Settings ->

ASCII setup

Figure 8. Hyperterminal settings - ASCII setup configuration

5. Press call in hyperterminal to establish a connection with the board.

5.3 Hardware setup

To configure the hardware board, the user should follow these steps:

1. Jumper settings: There are four jumpers (JP1, JP2, JP3 and JP4) available on the

board. The detail of these connectors is as follows:

a) JP1: JP1 pins should be connected using the jumper if there is no pull-up

connected in the clock line of the I

pulled up with a resistor value of 4.7 kΩ.

b) JP2: JP2 pins should be connected using the jumper if there is no pull-up

connected in the data line of the I

pulled up with a resistor value of 4.7 kΩ.

c) JP3: JP3 is used to select the clock source for the ST7 microcontroller. From the

JP3 side, if the jumper is connected between pins 1 and 2 then the application

28/43 Doc ID 13286 Rev 2

2

C bus. Once connected, the I2C clock line is

2

C bus. Once connected, the I2C data line is

Page 29

AN2511 PMBus demonstration board

runs using the resonator clock (16 MHz). If the jumper is connected between pins

2 and 3 then the application is stopped and ST7 MCU can be re-programmed.

d) JP4: JP4 is used to select the power supply as described below. From the JP4

side, if the jumper is connected between pins 2 and 3 then the application runs

using the direct supply given from `POWER' connector. If the jumper is connected

between pins 1 and 2 then the application runs using the DC adapter supply given

from J1.

2. Power settings: The demonstration board can be powered by one of the following

options:

a) DC adapter: Connect a DC adapter to J1. The DC adapter should supply a

minimum of 7 V and maximum of 18 V, 1 A. This supply is regulated to 5 V supply

using an L7805 regulator.

b) Regulated supply: The user can use a direct 3 V to 5 V supply. The supply and

Gnd points should be connected to the `POWER' connector pins 1 and 2. Here,

`POWER' connector pin 1 is referred from the JP4 jumper side (from the right

side).

Doc ID 13286 Rev 2 29/43

Page 30

Using the demonstration board AN2511

6 Using the demonstration board

After installing the setup as explained in Section 1, the following message appears in

hyperterminal.

Figure 9. Hyperterminal message to show company name and selection of

communication speed

If there is any problem in getting the message, press the switch provided in the

demonstration board. This switch re-starts the application.

6.1 Normal operation

The following sections explain how to initiate PMBus communication and how to read/ write

PMBus commands with hyperterminal.

6.1.1 Selection of communication speed

After the message appears as shown in Figure 9, the user should enter 1 or 2 to select the

PMBus communication speed as 100 kHz or 400 kHz respectively. The default speed value

selected is 100 kHz.

If the user enters any other value other than 1 and 2, the previous speed value is retained.

6.1.2 Selection of packet error checking

After the message appears as shown in Figure 10, the user should enter 1 or 2 to enable

PEC and disable PEC respectively. If PEC is enabled, all address, command code and data

communications are checked through CRC-8 check. The default PEC value is PEC

disabled.

If the user enters any other value other than 1 and 2, the previous speed value is retained.

Figure 10. PEC selection

6.1.3 Selection of slave address

The user should enter the slave address of the PMBus device. The slave address should be

in hexadecimal format. The slave addresses of different competitor’s module are given

below. Artesyn DPL20C module: 0x30 SiLabs Si8250-TB module : 0x80.

The slave address could change from one device to another device. The user must refer to

the product datasheet and development kit documents to decide on the slave address. An

example entry of slave address with Artesyn DPL20C module is shown below.

30/43 Doc ID 13286 Rev 2

Page 31

AN2511 Using the demonstration board

Figure 11. Slave address entry message

If the user enters a wrong slave address then one of the following error messages shown in

Figure 12 or Figure 13 appears.

Figure 12. Wrong slave address entry - response 1

Figure 13. Wrong slave address entry - response 2

6.1.4 Selection of read/write mode

Data can be written into or data can be read back from the PMBus salve device connected.

The following figure provides the key option to select one of the modes.

Figure 14. Options to select read/ write mode

6.1.5 Single read mode

The user can press 1 to select read mode. Then the user can enter any command code with

reference to Section 3 to read byte/ word/ block of data. An example of this is shown below.

Figure 15. Single read operation

Doc ID 13286 Rev 2 31/43

Page 32

Using the demonstration board AN2511

6.1.6 Continuous read mode

The user can press 0 to read all PMBus commands. The lists of supported commands are

shown in the following figure.

Figure 16. Continuous read operation

Command codes 0xD0, 0xD1 and 0xD2 are not supported in continuous read mode. If the

user wants to read these commands, they can be read by using single read mode.

6.1.7 Write mode

The user can press 2 to select write mode. After the following figure appears, the user can

enter any command code with reference to Section 2.1 on page 8 to write byte/ word/ block

of data.

Figure 17. Write mode command code entry message from hyperterminal

Then the user can enter any command code with reference to Section 4 to write byte/ word/

block of data. The user can enter data after the following message.

Figure 18. Write mode data entry message from hyperterminal

Data should be entered in hex format. If the user wants to enter date/ serial numbers, they

should be entered in ASCII format.

32/43 Doc ID 13286 Rev 2

Page 33

AN2511 Using the demonstration board

For example, to enter a date as “15 -12-1991”, then data should be entered as

313531323931 (where 31h=ASCII ”1”, 35h=ASCII “5”, etc., and the date will read “151291”).

An example of this operation is shown below.

Figure 19. Write mode operation example

When reading back the date written using single read commands, the following message is

displayed:

Figure 20. Read operation to check data writing

6.1.8 Group command

The user can press 3 to select group command mode. In this demonstration board, the user

can write multiple commands for multiple slave addresses.

After Figure 21 appears, the user can enter any command code and data with reference to

Section 3.1: PMBus commands to write byte/ word/ block of data. The user can enter 5

commands and data for the group command. If the user wants to write less than 5

commands, the user can press * to terminate the group command operation.

Doc ID 13286 Rev 2 33/43

Page 34

Using the demonstration board AN2511

Figure 21. Group command code entry message from hyperterminal

An example of this operation is shown below.

Figure 22. Group command operation example

6.2 Error conditions

The following error conditions may be encountered during PMBus communication.

6.2.1 Invalid command code

If the user enters a command code that is not available in the list or enters an incorrect

option to select read/write options, the following error message appears:

Figure 23. Invalid command message

An example is shown in Figure 24.

34/43 Doc ID 13286 Rev 2

Page 35

AN2511 Using the demonstration board

Figure 24. Example of invalid command

6.2.2 Communication timeout

This error appears when the PMBus communication fails due to one of the following

reasons:

● The slave device doesn’t acknowledge the master

● The clock low interval exceeds the value of TTIMEOUT,MIN as defined by (SMBus

Specification 1.1)

● TLOW:SEXT and TLOW:MEXT conditions are not met

● Bus error or arbitration errors in PMBus communication

In these conditions, the following error message appears:

Figure 25. Communication timeout message

Doc ID 13286 Rev 2 35/43

Page 36

Hardware description AN2511

7 Hardware description

This section provides schematics, BOM (bill of materials), layout and picture of the

demonstration board.

7.1 Schematic and layout

The following figures show the schematic and layouts of the demonstration board.

Figure 26. Demonstration board schematic

*

*0

&

N

#

6

)##3%,

633

6$$

*0

K

K

2

2

3#,

3$!

2

2

2

2

#/.42/,

0!

4$/

2$)

3-"?!,%24

0#

)##$!4!

)###,+

0!0!

0!

0!

)##3%,

0#

0#

0#

0#

2$)0!

3#,0!

3$!0!

4$/0!

23 ).4%2&!#%

6

2/54

2/54

4/54

4/54

2).

4).

2).

4).

5

2$)

4$/

-#5

)## #/.

#/.

#

2

2%3%4

)##3%,

)##$!4!

)###,+

6##

*0

&

N

#

2

K

3

#

330"

2%3%4/3#/3#

3#+0"-)3/0"-/3)0"

5

2%3%4

/3#).

0"

0"

/3#

/3#

0"

0"

N&

-(Z

9

#

PF

#

PF

0#

0"0"

0"

0"0#

0#

0"

0"

34&'-

0#

0#

0#

0"

0"

6

$

3-$ ,%$

2

2

40

#

U&V

6

N&

40

#

6 6## 6$$

0!

'.$

0"

/

'

,#$442

)

5

&

N

0"

*

#

&!5,4

*

6^6

*!#+

0"

0"

#/.

*

0/7%2

0"

0"

*

#/.

-5,4)0(!3%

-!.!'%-%.4

/0%2!4)/.3

#/.

3$!

3#,

3-"?!,%24

#/.42/,

*

0-"53

).4%2&!#%

#/.

2%3%4

40

#/.

3%4

2%

#

6##

#

#6

##6

#

U& 6

K

)##

/3#).

/3#

0#

0#

0#

*

$"

N&

'.$

34#42

#

U& 6

#

U& 6

U& 6

0#

0#

0"

0"

%84 ).4%2&!#%

!-V

6

#/.

36/43 Doc ID 13286 Rev 2

Page 37

AN2511 Hardware description

Figure 27. Top view layout of the demonstration board

Figure 28. Bottom view layout of the demonstration board

Doc ID 13286 Rev 2 37/43

Page 38

7.2 Bill of materials (BOM)

The following table shows the BOM of the demonstration board.

Table 43. Bill of material

Capacitors: C2, C3, C9, C10, C11, C12, C13 100 nF 805 Any

Doc ID 13286 Rev 2 38/43

Table 43:

Reference

Capacitors: C7, C8 10 nF 805 Any

Capacitors: C5, C6 10 pF 805 Any

Capacitors: C1 330 nF 805 Any

Polarized capacitor (Axial): C4 100 µF/ 10 V RB-5.5 Any

Resistors: R1, R2, R3 4.7 kΩ 805 Any

Resistors: R4, R5 100 Ω 805 Any

Resistors: R6 220 Ω 805 Any

Resistors: R7 10 kΩ 805 Any

Connector: TP3 CON1 SIP-1 Any

Value / g e neri c par t

number

Package Manufacturer

Manufacturer’s

ordering code /

orderable part

number

AN2511 Hardware description

Supplier

Connectors: J2, J3, J4, JP1, JP2, POWER CON2 SIP-2 Any

Connectors: JP3, JP4 CON3 SIP-3 Any

Connector: J5 CON4 SIP-4 Any

Connector J7 CON7 SIP-7 Any

9 pin female RS232 connector: J6 DB9 DB9/F GM (801-036)

Crystal: Y1 16 MHz (KDS) XTAL-1 Any

Header: CON1 ICC IDC-10B Any

Power Jack connector: J1 JACK TAP_2.5 mm GM: K375A

Regulator: U1 L7805CD2T-TR TO-220 STMicroelectronics L7805CD2T-TR

SMD LED: D1 SMD LED LED-SMD Faichild

Page 39

39/43 Doc ID 13286 Rev 2

Table 43. Bill of material (continued)

Reference

MCU U2 ST72F264G1M6 SOL-28 STMicroelectronics ST72F264G1M6

RS232 level translator: U3 ST3232CTR SO-16 STMicroelectronics ST3232CTR

Switch S1 TACT SWITCH PUSH-4 Any

Diode: D2 1N5817 DO41 STMicroelectronics

ZENER diode: ZD1 SMAJ TO220 STMicroelectronics

Value / g e neri c par t

number

Package Manufacturer

Manufacturer’s

ordering code /

orderable part

number

Hardware description AN2511

Supplier

Page 40

Hardware description AN2511

7.3 Demonstration board photo

The following figure shows the picture of the demonstration board.

Figure 29. STEVAL-ISQ002V1

40/43 Doc ID 13286 Rev 2

Page 41

AN2511 Configuration

Appendix A Configuration

A.1 RS232 configuration

The following figure shows the pin description of the RS232 D9 connector.

Figure 30. Pin description of RS232 D9 connector

Doc ID 13286 Rev 2 41/43

Page 42

Revision history AN2511

Revision history

Table 44. Document revision history

Date Revision Changes

17-Apr-2007 1 Initial release.

– Modified: Figure 9, 10, 16, 17, 18, 19, 20, 23, 24, 25, 26, 29,

25-Aug-2010 2

Ta bl e 4 3

– Added: Figure 27, 28

– Minor text changes

42/43 Doc ID 13286 Rev 2

Page 43

AN2511

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2010 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 13286 Rev 2 43/43

Loading...

Loading...