Page 1

AN2510

Application note

Combo IC for PFC and ballast control

Introduction

A new control IC, the L6585D, has been designed to manage electronic ballasts for

fluorescent lamps. It includes both Power Factor Correction and half-bridge sections and

embeds a wide range of features to provide an energy saving and cost effective solution.

The high-voltage single chip approach optimizes the management of lamp critical conditions

such as the pre-heating and ignition of start up and fault and lamp replacement. The internal

logic, guided by precise internal references and timings, is able to carry out all of these

phases. The PFC section has superior performance in terms of harmonic content

mitigation. High Power Factor (PF) and Total Harmonic Distortion (THD) reduction are

obtained as required by international norms, especially concerning Universal input voltage

operations.

Particular care has been given to pre-heating and ignition phases prior to lamp start up in

order to ensure the proper filament warming up and extend lamp life.

Innovative circuitry allows an improved control of the lamp voltage during ignition as well as

protection against failures due to lamp aging.

The use of this new control IC simplifies the industrialization of electronic ballasts which

increases application reliability and reduces its dimensions and cost.

March 2007 Rev 1 1/22

www.st.com

Page 2

Contents AN2510

Contents

1 L6585 Integrated circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Device blocks description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Start-up and shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 PFC section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2.1 Error amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2.2 Over-voltage and feedback disconnection detection . . . . . . . . . . . . . . . . 6

2.2.3 Zero Current Detection and triggering block . . . . . . . . . . . . . . . . . . . . . . 7

2.2.4 Multiplier block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2.5 Current comparator and choke saturation detection . . . . . . . . . . . . . . . . 8

2.2.6 Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Oscillator and pre-heating / ignition / run mode sequencing . . . . . . . . . . . 8

2.4 Half-bridge current sensing: lamp voltage / power control . . . . . . . . . . . . . 9

2.4.1 Controlled lamp voltage/current during ignition . . . . . . . . . . . . . . . . . . . . 9

2.4.2 Over-current protection during run mode . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5 End of life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.5.1 End-of-life detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.6 Re-lamp comparator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3 L6585 Biasing circuitry (pin by pin) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1 Pin1 OSC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2 Pin2 RF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3 Pin3 EOI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.4 Pin4 TCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.5 Pin5 EOLP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.6 Pin6 EOLR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.7 Pin7 CTR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.8 Pin8 MULT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.9 Pin9 COMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.10 Pin10 INV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.11 Pin11 ZCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.12 Pin12 PFCS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2/22

Page 3

AN2510 Contents

3.13 Pin13 PFG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.14 Pin14 HBCS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.15 Pin15 GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.16 Pin16 LSD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.17 Pin17 V

CC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.18 Pin18 OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.19 Pin19 HSD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.20 Pin20 BOOT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3/22

Page 4

L6585 Integrated circuit AN2510

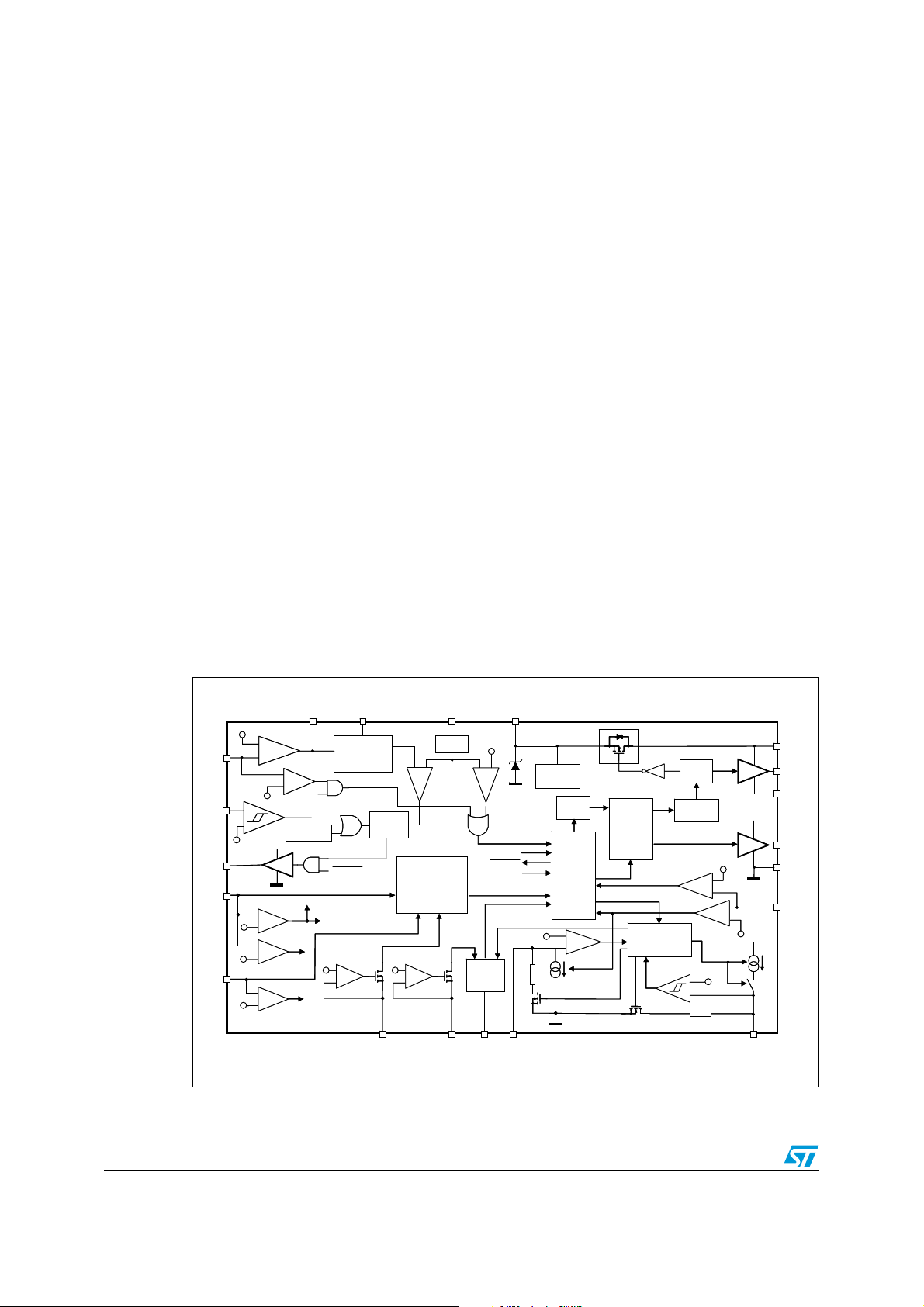

1 L6585 Integrated circuit

Designed in High-voltage BCD Off-line technology, the L6585D embeds a PFC controller, a

half-bridge controller, the relevant drivers, and the logic necessary to build an electronic

ballast.

The advanced and precise logic circuitry, combined with the programmability of the End-ofLife windows comparator, makes the L6585D compliant with either "lamp-to-ground" or

"block capacitor-to ground" configurations.

Another outstanding feature is the possibility of controlling the ignition lamp voltage.

The pre-heating and ignition durations are independently adjustable as well as the halfbridge switching frequencies for each operating phase (pre-heating, ignition and normal

mode).

Other features (half-bridge over-current with frequency increase, PFC over-voltage) allow

building a reliable and flexible solution with a reduced part count.

The PFC section achieves current mode control operating in Transition Mode. The highly

linear multiplier includes a special circuit, able to reduce AC input current distortion, that

allows wide-range mains operation with an extremely low THD, even over a large load

range.

The PFC output voltage is controlled by a voltage-mode error amplifier and a precise

internal voltage reference.

The driver of the PFC is able to provide 300 mA source and 600 mA sink and the drivers of

the half-bridge provide 290 mA source and 480 mA sink.

Figure 1. Block diagram

COMP MULT PFCS Vcc

COMP MULT PFCS Vcc

2.5V

2.5V

E/A

ZCD

ZCD

PFG

PFG

CTR

CTR

EOLR

EOLR

E/A

+

+

_

1.2V

1.2V

0.7V

0.7V

3.4V

3.4V

0.75V

0.75V

4.63V

4.63V

_

Vcc

Vcc

STARTER

STARTER

DIS

DIS

RELAMP

RELAMP

INV

INV

MULTIPLIER

MULTIPLIER

and THD

and THD

OPTIMIZER

OPTIMIZER

OL

OL

S

S

PFSTOP

PFSTOP

OL

OL

OVP

OVP

2V

2V

R

R

Q

Q

COMPARATOR

COMPARATOR

2V

2V

+

+

_

_

PWM

PWM

COMP.

COMP.

WINDOW

WINDOW

& REF.

& REF.

LEB

LEB

+

+

EOL

EOL

VCO

VCO

1.7V

1.7V

_

_

CHOKE

CHOKE

SAT.

SAT.

PFSTOP

PFSTOP

OVP

OVP

BOOT

Vcc

Vcc

0.9V

0.9V

Vcc

Vcc

BOOT

HSD

HSD

OUT

OUT

LSD

LSD

GND

GND

HBCS

HBCS

17V

17V

UV

UV

SYNCHRONOUS

DEAD

DEAD

TIME

TIME

CONTROL

CONTROL

LOGIC

LOGIC

SYNCHRONOUS

BOOTSTRAP DIODE

BOOTSTRAP DIODE

DRIVING

DRIVING

LOGIC

LOGIC

HB STOP

HB STOP

MANAGEMENT

MANAGEMENT

DETECTION

DETECTION

LATCH

LATCH

DIS

DIS

1.9V

1.9V

TIMING

TIMING

HVG

HVG

DRIVER

DRIVER

LEVEL

LEVEL

SHIFTER

SHIFTER

LVG DRIVER

LVG DRIVER

4.6

4.6

1.5

1.5

1.6V

1.6V

EOLP

EOLP

4/22

OSC EOIRF

OSC EOIRF

Tch

Tch

Page 5

AN2510 Device blocks description

2 Device blocks description

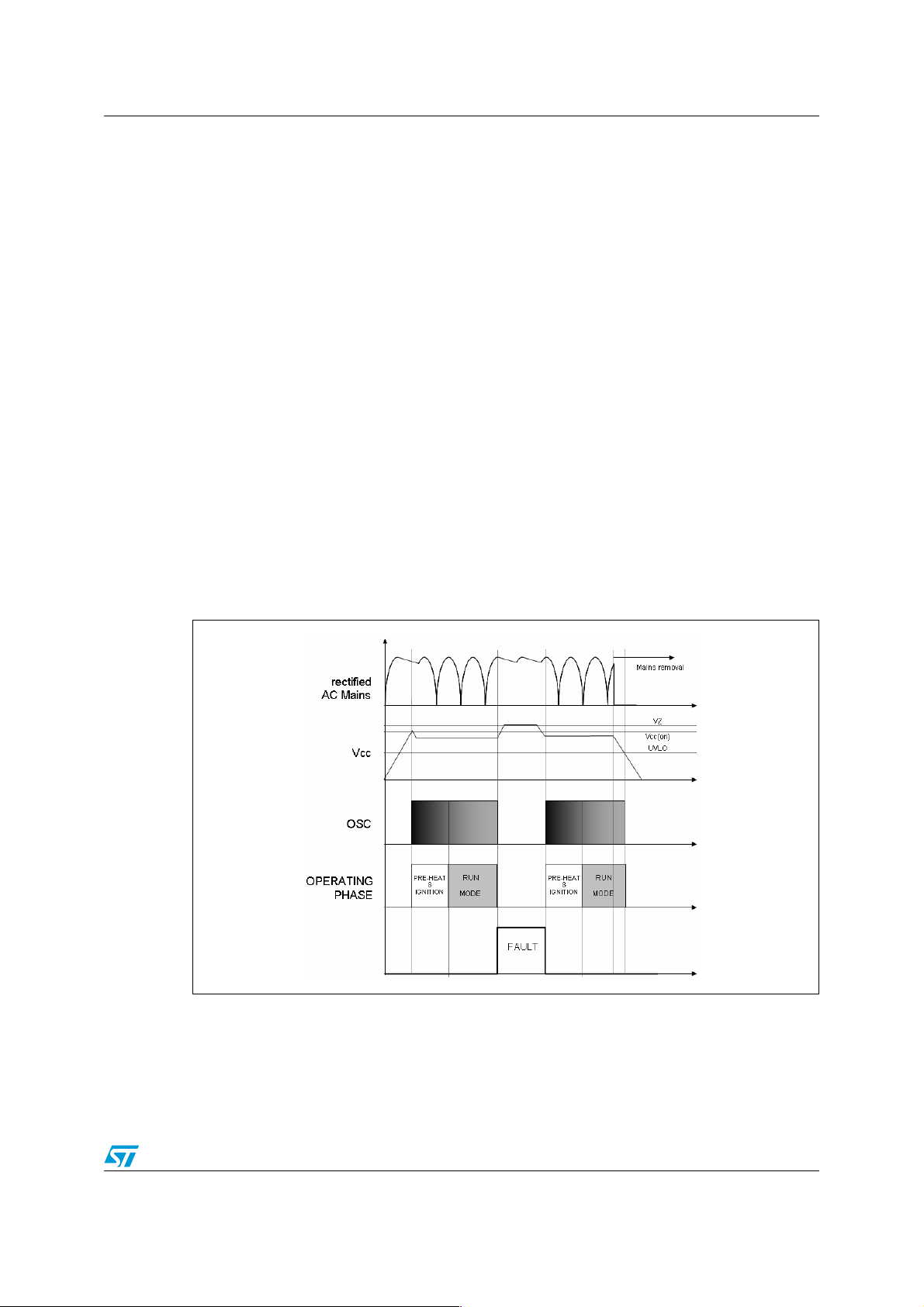

2.1 Start-up and shutdown

During start-up, the chip is supplied through a resistive path from the rectified AC Mains

voltage whereas during normal operation, a charge pump or a self-supply winding (as well

as an auxiliary converter) can provide the required current.

As the voltage at Vcc pin reaches the turn-on threshold (Vcc(ON)), the chip is enabled and

(unless a lamp absence is detected) the oscillator starts switching at a frequency set by

values of C

The Half-Bridge and the PFC sections start at almost the same time. As the

synchronization signal at pin ZCD is not yet generated by the external ZCD circuit, an

internal structure forces the PFC gate driver to switch for the first switching cycles. The

pulses are generated at a typical frequency of 15 kHz.

OSC

and R

RUN

and R

PRE

.

At shutdown, when the V

decreases below the UVLO threshold (either in case of Mains

CC

removal or in case of fault), the following conditions are met:

● all drivers are off;

● EOI pin is discharged (the internal switch is on);

● RF reference is disabled;

● Tch is discharged.

Figure 2. Start-up and shutdown sequences

5/22

Page 6

Device blocks description AN2510

2.2 PFC section

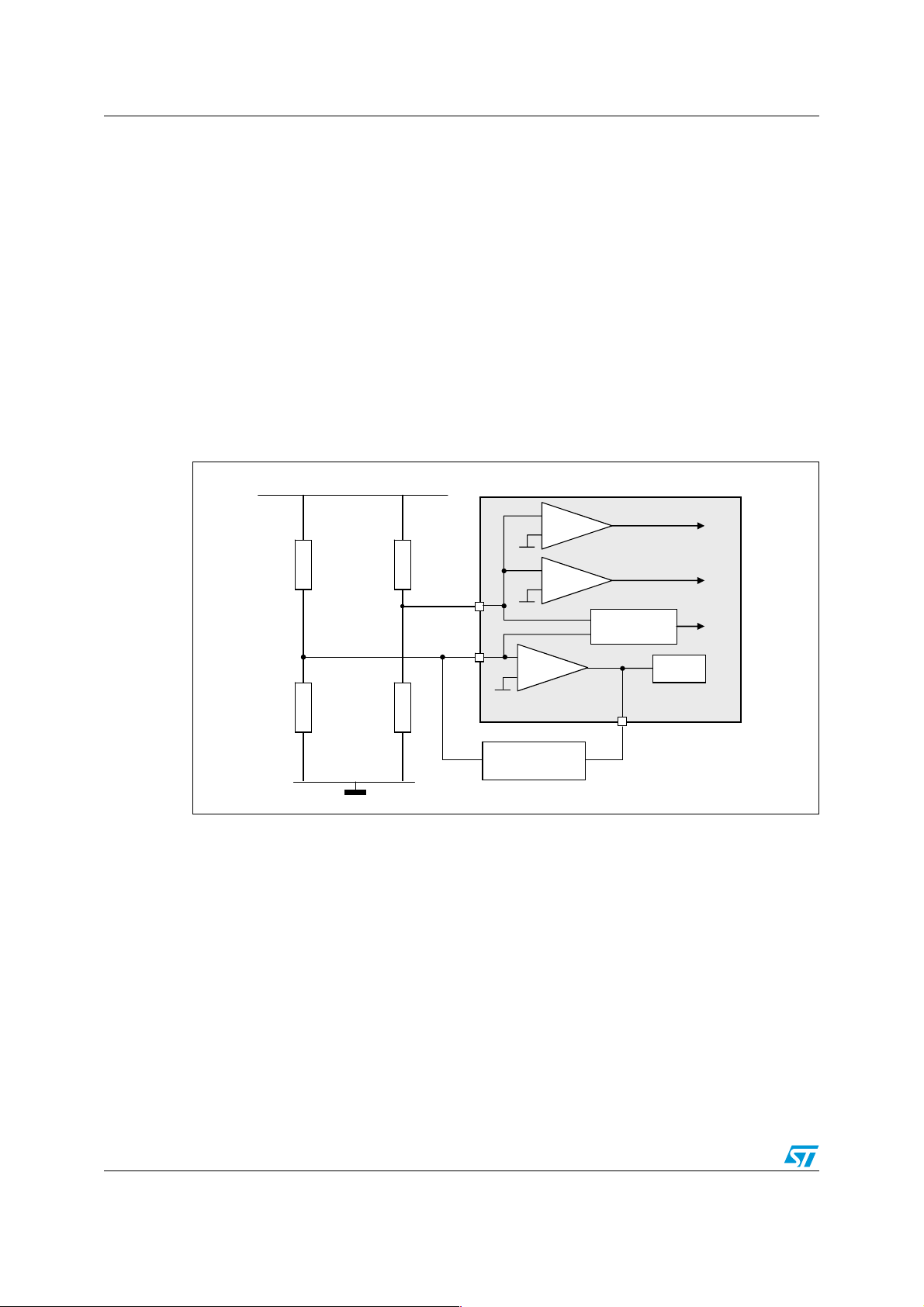

2.2.1 Error amplifier

The Error Amplifier (E/A) is used for frequency compensation. The inverting input (INV) is

connected by an external divider to the output bus and compares a partition of the boosted

output DC voltage, Vo, with the internal reference in order to maintain the pre-regulator

output DC voltage constant.

The compensation network, placed between pins INV and COMP (E/A output), is usually

done with a feedback capacitor. The E/A bandwidth will be extremely low because the

output of the E/A must be constant over a line half-cycle to achieve high PF.

The dynamics of the E/A output is internally clamped so that it can swing between 2.25 V

and 4.2 V in order to speed up the recovery after the E/A saturates low due to an overvoltage or saturates high because of an over-current.

Figure 3. Error amplifier, feedback divider and CTR

PFC OUTPUT

PFC OUTPUT

OVP

OVP

DISABLE

DISABLE

MULT

MULT

R1

R1

R2

R2

RHOVP

RHOVP

RLOVP

RLOVP

CTR

CTR

INV

INV

+

+

_

_

3.4V

3.4V

_

_

+

+

0.8V

0.8V

_

_

+

+

AMPLIFIER

NETWORK

NETWORK

AMPLIFIER

2.5V

2.5V

COMPENSATION

COMPENSATION

ERROR

ERROR

COMP

COMP

OPEN LOOP

OPEN LOOP

DETECTION

DETECTION

2.2.2 Over-voltage and feedback disconnection detection

The device is provided with a double over-voltage protection (OVP).

In case of over-voltage, the output of the E/A will tend to saturate low, but the E/A response

is very slow, so it will take a long time to go into saturation. On the other hand, an overvoltage must be corrected immediately.

A fast OVP detector, based on a different concept, is necessary.

The maximum voltage allowed for the PF output bus (VOVP) is defined by the resistive

divider connected to the pin CTR (Figure 3):

6/22

Page 7

AN2510 Device blocks description

Equation 1

R

HOVP

V

OVPVTH

⎛⎞

1

------------------+

•=

⎝⎠

R

LOVP

where V

is the CTR internal comparator input reference (3.4 V typ.)

TH

Moreover if the over-voltage lasts so long that the output of E/A goes below 2.25 V, the PF

gate driver is stopped until the E/A output goes back into its linear region.

If instead, the over-voltage is due to feedback disconnection (for example R1, Figure 3 fails

open), these two structures work together. In fact if the V

simultaneously the INV voltage falls below 1.2 V, typ. (due to the fact that the E/A source

capability is limited) the IC stops in a latched condition.

2.2.3 Zero Current Detection and triggering block

The Zero Current Detection (ZCD) block switches on the external PFC MOSFET as the

voltage across the boost inductor reverses, just after the current through the boost inductor

has gone to zero. This feature allows TM operation.

As the circuit is running, the signal for ZCD is obtained with an auxiliary winding on the

boost inductor. As at start-up no signal is coming from the ZCD, a circuit is needed that

turns on the external MOSFET. This is done with an internal starter, which forces the driver

to deliver a pulse to the gate of the MOSFET, producing also the signal for arming the ZCD

circuit.

The repetition rate of the starter is greater than ≅ 15 kHz and this maximum frequency must

be taken into account at design time.

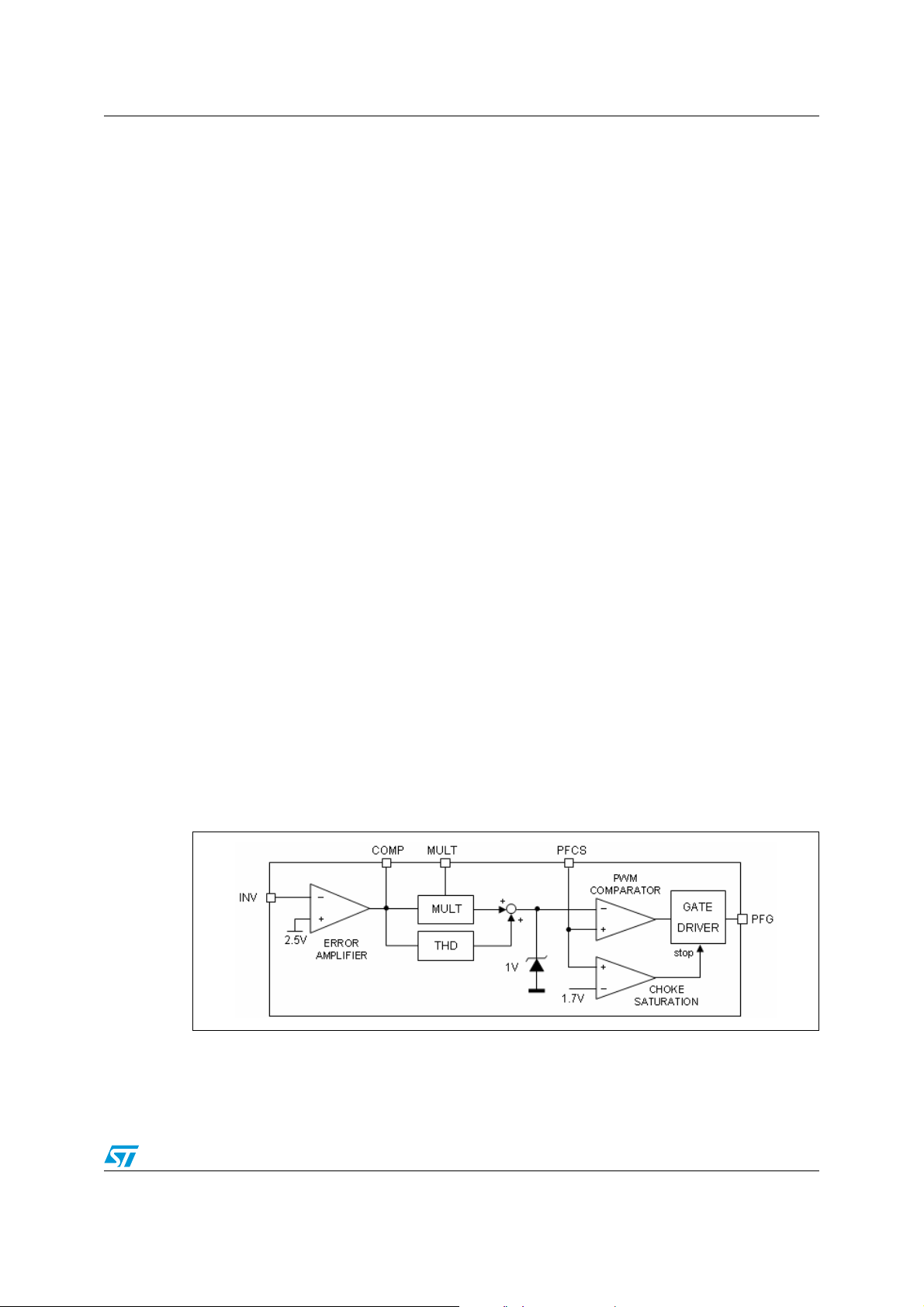

2.2.4 Multiplier block

threshold is crossed and

OVP

The multiplier (see Figure 4) has two inputs. The first one takes a partition of the

instantaneous rectified line voltage and the second one takes the output of the E/A. If this

voltage is constant (over a given line half-cycle), the output of the multiplier will be shaped

as a rectified sinusoid too. This is the reference signal for the current comparator, which sets

the MOSFET peak current cycle by cycle.

Figure 4. Multiplier, current sense and choke saturation

7/22

Page 8

Device blocks description AN2510

2.2.5 Current comparator and choke saturation detection

The current comparator (see Figure 4) senses the voltage across the current sense resistor

(Rs) and, by comparing it with the programming signal delivered by the multiplier,

determines the exact time that the external MOSFET is to be switched off.

The output of the multiplier is internally clamped to 1 V, (typ.). Current limiting occurs if the

voltage across Rs reaches this value.

A second comparator is integrated also in this block in order to prevent choke saturation

(see Figure 4 and Figure 5).

Boost inductor's hard saturation may be a fatal event for a PFC pre-regulator. The current

upslope becomes so large (50-100 times steeper, see Figure 5) that, during the current

sense propagation delay, the current may reach abnormally high values.

The device is provided with a second comparator on the PFC current sense pin that stops

and latches off the IC if the voltage on the pin, normally limited within 1.1 V, exceeds 1.7 V.

In this way there can be abnormal current only for one cycle. After that the system is

stopped and enabled to restart only after recycling the input power, that is when the Vcc

voltage of the L6585D goes below the UVLO threshold. System safety will be considerably

increased.

Figure 5. PFC choke saturation

2.2.6 Driver

A totem pole buffer, with 300mA source and 600 mA sink capability, allows driving an

external MOSFET. A pull-down circuit holds the output low when the device is in UVLO

conditions, to ensure that the external MOSFET cannot be turned on accidentally.

2.3 Oscillator and pre-heating / ignition / run mode sequencing

As the IC supply voltage (Vcc) reaches Vcc(on), the half-bridge starts oscillating and the

capacitor (C

current generator. When the voltage at T

generator switches off, and C

time constant R

During this time, the pin EOI is forced to ground and the switching frequency is set by the

oscillator capacitor together with the parallel of R

description in the following chapter.

8/22

) connected to TCH is charged with a constant current through the internal

D

discharges following an exponential decrease steered by the

, that defines the pre-heating time.

D*CD

D

pin reaches V

CH

RUN

and R

(4.63 V), the above current

CHP

(for the relationship, see pin

PRE

Page 9

AN2510 Device blocks description

When the voltage at pin TCH drops down to 1.53 V (typ.), the pin EOI is driven in high

impedance state and C

by C

IGN*RPRE

that defines the ignition time. At the same time the pin TCH is connected to

ground through an internal low resistance that rapidly discharges C

is exponentially charged according to the time constant τ given

IGN

.

D

The exponential trend of the current sunk by the pin RF generates a similar variation

(reduction) of the switching frequency. The voltage across the lamp increases linearly as

well as the current flowing through it.

As the voltage at EOI exceeds 1.9 V, the chip enters Run mode and remains in this condition

unless one of the protections (all enabled in this mode) is triggered.

Figure 6. Oscillator and starting sequence

2.4 Half-bridge current sensing: lamp voltage / power control

The information about the lamp current can be obtained by reading the voltage across the

sense resistor. This circuitry is enabled at the end of the pre-heating phase and it enriches

the L6585D with two features:

2.4.1 Controlled lamp voltage/current during ignition

If the V

This allows both limiting the ignition lamp voltage to a selectable (and safe) value and

preventing the risk of working below the resonance frequency of the L

(no saturation and no capacitive mode). The sense resistor value defines the maximum

current that can flow during ignition. With some calculations it is possible to find the relevant

lamp voltage (which must be higher than the nominal lamp voltage) and the corresponding

frequency, that is, the operating point on the resonance curve.

high threshold is crossed, then the chip reacts with a small frequency increase.

HBCS

BALLAST

- C

RES

circuit

9/22

Page 10

Device blocks description AN2510

Figure 7. Lamp voltage growth during ignition

Whenever the HBCS voltage reaches the internal threshold HBCSH, a two-step sequence

starts:

1. The internal current generator at the pin T

is turned on which charges CD (up to 4.6

CH

V) and starts a Tch charge/discharge cycle;

2. As long as the HBCS voltage exceeds the threshold, a controlled current pulse is sunk

by the EOI pin stopping the C

capacitor charge. This has the effect of stopping the

IGN

half-bridge switching frequency shift which limits the lamp voltage.

Tch acts as a counter. If the lamp ignites before TCH reaches 1.53 V (Figure 8 left), that is,

EOI has exceeded 1.9 V, then:

● EOI internal switch opens and its voltage moves asymptotically to 2 V

● The switching frequency reaches the operating frequency

● When TCH reaches 1.53, it will be discharged

If instead at the first low-side conduction cycle after the T

reaches 1.53 (EOI pin is still

CH

below 1.9 V), the HBCS threshold is still crossed, it means that the lamp hasn't ignited after

a time length equal to the pre-heat time (Figure 8 right). Such situations typically happen

with old lamps. In this case the oscillator stops, the chip enters low consumption mode, and

this condition is latched until the mains supply voltage is removed or a re-lamp is detected.

10/22

Page 11

AN2510 Device blocks description

Figure 8. Ignition as the lamp gets older

2.4.2 Over-current protection during run mode

If the HBCSL threshold is crossed, the TCH internal generator is turned on as well as the

one at pin EOI causing a frequency increase. This implements a CURRENT-CONTROL

structure (Figure 9 left). Simultaneously the internal T

C

up to 4.63 V and then released. If, despite the frequency increase, the over-current

D

generator is activated to charge the

CH

condition lasts for a whole Tch charge/discharge cycle, the IC is stopped and enters

shutdown mode by latching this condition until either a re-lamp or an UVLO (mains

removal). During run mode another protection is active: a second comparator (HBCSH) on

the pin HBCS detects anomalous current flow through the sense resistor such as the spikes

generated by the capacitive mode. The crossing of this second threshold latches the IC

(Figure 9 right).

Figure 9. Current control in run mode

11/22

Page 12

Device blocks description AN2510

2.5 End of life

2.5.1 End-of-life detection

This function has been designed to detect the aging of the lamp with particular attention to

the effect appearing as asymmetric rectification. The idea is to measure the variation of the

DC component of the lamp voltage that can be either positive or negative. A window

comparator has been introduced (centered around V

when the EOL-R voltage is higher than V

+ VW/2 or lower than V

SET

two standard ballast configurations (lamp-to-ground and block capacitor-to-ground) require

different features to the EOL detecting circuit, the implemented structure is compliant to both

thanks to the programmability of the window comparator. In particular through the resistor

connected to the EOLP pin, it is possible to select the sensing mode (with fixed reference or

reference to tracking with the PFC output bus) and the window amplitude (see the "pin

biasing" paragraph for further details).

● Lamp-to-ground (Figure 10, right): a resistive divider (R

across the lamp that, under normal conditions, is an AC signal with zero average value

whereas in case of asymmetric rectification, the DC value can shift either in a positive

or negative direction. As the L6585D doesn't have a negative rail, we must shift the

external signal. This can be done using two Zener diodes connected back-to-back

between the EOL pin and the center of the resistive divider. The Zener voltages should

differ by an amount as close as possible to the double of the internal reference to have

a symmetrical detection. It can easily obtained from the following equations:

–V

–V

where V

UP

= V

UP

DOWN

and V

+ W/2 + VZ1 + V

REF

= V

DOWN

- W/2 - VZ2 - VR1

REF

are the VK values (equal in absolute value) that trigger the window

R2

comparator. Figure 10 shows an example of asymmetric rectification with positive shifting.

with amplitude "VW") that triggers

REF

and RE2) senses the voltage

E1

- VW/2. Although the

REF

Figure 10. Window comparator for rectifying effect detection

R

R

R

P1

P1

P1

R

R

R

P2

P2

P2

EOLP

EOLP

EOLP

+ W/2

+ W/2

+ W/2

–W/2

–W/2

–W/2

FH

FH

FH

INTERNAL

INTERNAL

INTERNAL

FIXED REF.

FIXED REF.

FIXED REF.

INPUT

INPUT

INPUT

(100Hz or 120Hz)

(100Hz or 120Hz)

(100Hz or 120Hz)

BOOT

BOOT

BOOT

HSD

HSD

HSD

EOLR

EOLR

EOLR

OUT

OUT

OUT

LSD

LSD

LSD

CTR

CTR

CTR

WINDOW

WINDOW

WINDOW

COMPARATOR

COMPARATOR

COMPARATOR

AMPLITUDE

AMPLITUDE

AMPLITUDE

or R

or R

or R

R

R

R

FL

FL

FL

HVBUS

HVBUS

HVBUS

PFC

PFC

PFC

OUT

OUT

OUT

V

V

V

CB

CB

CB

CTR

CTR

CTR

V

V

V

REF

REF

REF

V

V

V

EOLR

EOLR

EOLR

V

V

V

REF

REF

REF

HV BUS

HV BUS

HV BUS

C

C

C

BOOT

BOOT

BOOT

CTR

CTR

CTR

FIXED REF.

FIXED REF.

FIXED REF.

WINDOW

WINDOW

WINDOW

COMPARATOR

COMPARATOR

COMPARATOR

AMPLITUDE

AMPLITUDE

V

V

V

LAMP

LAMP

LAMP

V

V

V

K

K

K

R

R

R

E1

E1

E1

R

R

R

E2

E2

E2

PFC

/2

PFC

/2

PFC

/2

OUT

OUT

OUT

AMPLITUDE

EOLP

EOLP

EOLP

C

C

C

BLOCK

BLOCK

BLOCK

R

R

R

V

V

V

LAMP

LAMP

LAMP

V

+ W/2 + V

V

+ W/2 + V

V

+ W/2 + V

REF

REF

REF

V

V

V

K

K

K

V

– W/2 – VZ1–V

V

– W/2 – VZ1–V

V

– W/2 – VZ1–V

REF

REF

REF

V

V

V

+ W/2

+ W/2

+ W/2

REF

REF

REF

V

V

V

REF

REF

REF

V

–W/2

V

–W/2

V

–W/2

REF

REF

REF

V

V

V

EOLR

EOLR

EOLR

INTERNAL

INTERNAL

INTERNAL

INPUT

INPUT

INPUT

or R

or R

or R

FL

FL

FL

BOOT

BOOT

BOOT

FH

FH

FH

Z1

Z1

Z1

EOLR

EOLR

EOLR

+ V

+ V

+ V

HSD

HSD

HSD

OUT

OUT

OUT

LSD

LSD

LSD

C

C

C

BOOT

BOOT

BOOT

V

V

V

V

V

V

Z2

Z2

Z2

Z1

Z1

Z1

R2

R2

R2

R2

R2

R2

HV BUS

HV BUS

HV BUS

R

R

R

E2

E2

E2

C

C

C

BLOCK

BLOCK

V

V

V

V

V

V

K

K

K

BLOCK

LAMP

LAMP

LAMP

R

R

R

E1

E1

E1

12/22

Page 13

AN2510 Device blocks description

● Block capacitor-to-ground (Figure 10 left): in this case the resistive divider is placed

across the block capacitor to sense its DC voltage. The asymmetric effect appears as

a shifting of this DC value that under normal conditions equals one half of the PFC

output voltage. A problem is that the ripple at twice the Mains frequency superimposed

on the PFC nominal voltage (the amplitude of this depends on the bulk capacitor value)

as well as any drop on the same voltage (Mains dips, missing cycle etc.) are present

also on the block capacitor voltage and they must be rejected by the end-of-life

detection circuit. For this reason a differential sense is necessary where the reference

for EOLR is not fixed but brings this information. In particular the reference for EOLR is

obtained by the CTR voltage value. The dividers R

and RE2 and RP1 and RP2 must

E1

be designed to make EOL-R voltage equal to CTR under nominal conditions. The

rejection of the PFC output voltage low frequency ripple allows using a smaller bulk

capacitance. The pin EOLP allows choosing:

– the EOL reading method: tracking reference or fixed reference;

– the EOL window amplitude (2 options).

To avoid an immediate intervention of the EOL protection, a filtering is introduced. As long

as the fault condition persists, the Tch internal generator charges the C

up to 4.63 V and

D

then it opens. If this fault condition is still present when the Tch voltage decreases down to

1.53, then the half bridge is stopped.

This fault condition drives the chip in an idle state characterized by low consumption.

Exiting from this condition is enough to cycle the re-lamp comparator. The discharge of the

Vcc voltage below the UVLO threshold leads to a reset of this condition.

2.6 Re-lamp comparator

A second comparator has been introduced on the pin EOL-R. A voltage higher than the

internal threshold is read as lamp absence so the chip suddenly stops switching, enters idle

mode (low consumption), and is ready for a new pre-heating/ignition sequence as soon as

a new lamp is inserted.

In this idle mode the consumption of the chip is reduced so that the current flowing through

the resistors (connected to the high voltage bus for the start-up) is enough to keep the Vcc

voltage above the UVLO threshold. After a re-lamp (that is, the EOL-R voltage is below the

re-lamp threshold), a new pre-heating/ignition sequence restarts.

Figure 11. Re-lamp comparator

OSC

EOL-R

Tch

13/22

Page 14

L6585 Biasing circuitry (pin by pin) AN2510

3 L6585 Biasing circuitry (pin by pin)

3.1 Pin1 OSC

Pin 1 is one of the two oscillator inputs. The value of the capacitor connected to ground

defines the half-bridge switching frequency in each operating state. Typically 330 pF/470 pF

capacitance values are used. The negative lead of the capacitor must be connected to a

signal ground, not affected by noise or spikes (for example, like those of the return path of

the half-bridge low side MOSFET) in order to maintain the oscillator accuracy.

3.2 Pin2 RF

Pin 2 is a 2 V reference able to source up to 240 µA (min.). The current sunk by this pin,

combined with the oscillator capacitance defines the half-bridge switching frequency in each

operating state.

A resistor connected to ground sets the run frequency while during pre-heating the

switching frequency is set by the parallel of the above resistance with the one connected

between pins RF and EOI (that is, a short circuit during pre-heating) according to the

following formula:

Equation 2

Equation 3

Where K is 1.328

The design flux is:

1. Choose Cosc

2. Set R

3. Set R

4. Set C

in order to obtain the desired run frequency;

RUN

in order to obtain the desired pre-heating frequency

PRE

in order to obtain the desired ignition time (see pin 3 description).

IGN

3.3 Pin3 EOI

Pin 3 is a multi-function pin. During pre-heating the pin is internally shorted to ground by the

logic so the resistor connected between and ground (R

frequency. During ignition it becomes high impedance. The ignition time is the time

necessary to the pin voltage to exponentially rise from zero to 1.9V. The growth is steered by

the R

PRE*CIGN

heating frequency, C

time constant. As the R

f

PRE

f

RUN

fixes the ignition time.

IGN

-----------------------------------------------------------------=

()C

R

PRERRUN

PRE

K

||

-----------------------------------------=

R

RUNCOSC

•

OSC

K

•()

) sets the pre-heating switching

PRE

value has already been chosen to set the pre-

14/22

Page 15

AN2510 L6585 Biasing circuitry (pin by pin)

3.4 Pin4 TCH

Pin 4 is the time counter and it is activated at pre-heating as well as after a protection

triggering (HBCS crossing during ignition / run mode, window comparator at EOL). To

achieve this, a RC parallel network is connected between this pin and ground. Firstly an

internal current generator (i

becomes high impedance and the R

both the pre-heating (T

of:

–T

–T

, charge time: pin voltage from 0 to 4.63 V →

CH

, discharge time: pin voltage from 4.63 V to 1.5 V →

DIS

So:

Equation 4

T

Sensible values for C

are from 220 nF to 1 µF; for example, choosing CD=680 nF, to obtain

D

a pre-heating of 1 s, we need:

) charges the above network up to 4.63 V after which the pin

ch

) and fault persistence (T

PRE

PRETCOUNT

discharge take place. The TCH cycle representing

DCD

C

D

-------- -

4.63 RD+• CDIn

I

CH

) time durations equals the sum

COUNT

C

D

CH

4.63

⎛⎞

-----------

••==

⎝⎠

-------- -

I

T

1.5

CH

4.63•=

DIS

RDCD• In

T

4.63

⎛⎞

-----------

•=

⎝⎠

1.5

Equation 5

3.5 Pin5 EOLP

Pin 5 is a 2 V reference and allows programming the window comparator of the pin 6

(EOLR) according to Ta bl e 1 :

Table 1. Window comparator settings

EOLP Reference Window amplitude

R

> 620 K Fixed 2.5 V ± 720 mV

EOLP

220 K = R

75 K = R

22 K = R

EOLP

EOLP

EOLP

3.6 Pin6 EOLR

C

D

PRE

CDIn

•

-------- -

I

CH

4.63

-----------

1.5

4.63•–

1.2M==

T

---------------------------------------------- -

R

D

= 270 K Tracking with CTR ± 220 mV

= 91 K Fixed 2.5 V ± 220 mV

= 27 K Tracking with CTR ± 720 mV

Pin 6 is the input of both the window comparator and a re-lamp comparator. Concerning the

window comparator, in case of tracking with CTR (suitable when the block capacitor is

referred to ground) the center is the same voltage as the pin CTR (V

). The resistive

CTR

divider connected across the block capacitor must be set such that, under normal

conditions:

15/22

Page 16

L6585 Biasing circuitry (pin by pin) AN2510

T

Equation 6

R

EL

---------------------------

V

EOLR

V

BLOCKDC

•=

RELRHL+

where V

BLOCKDC

output voltage. The 100/120 Hz ripple can be neglected because it is rejected by the

sensing structure.

3.7 Pin7 CTR

Pin 7 is a multifunction pin, connected to a resistive divider to the PFC output bus:

● PFC over-voltage

– In case of PFC output overshoot (for example at start-up) that causes a threshold

crossing, the PFC section stops switching until the voltage at the pin falls below

3.26 V. This is helpful because the bandwidth of the PFC error amplifier is narrow

so the control loop is not fast enough to properly react.

● Feedback disconnection

– The OVP function described above (together with the static one embedded in the

PFC error amplifier) is able to handle "normal" over-voltage conditions (those

resulting from an abrupt load/line change or occurring at start-up). In case of overvoltage generated when the upper resistor of the feedback output divider fails

open, the control loop can no longer read the information on the output voltage

and will force the PFC pre-regulator to work at maximum ON time. If this occurs

(that is, the pin INV falls below 1.2 V) and the CTR detects an OVP, the gate drive

activity is immediately stopped, the device is shut down, its quiescent

consumption is reduced below 250 µA, and the condition is latched as long as the

supply voltage of the IC is above the UVLO threshold;

● Reference for EOL in case of tracking reading.

is the DC value of the block capacitor voltage that is, one half of the PFC

Disable: by forcing the pin below 0.75 V an immediate unlatched shut-down is activated.

3.8 Pin8 MULT

Pin 8 is the second multiplier input. It will be connected, through a resistive divider, to the

rectified mains to get a sinusoidal voltage reference. The multiplier can be described by the

relationship: where V

V

CS

kV

COMP

2.5V–()• V

for the current sense, k is the multiplier gain, V

V

is the voltage on pin 8.

MULT

3.9 Pin9 COMP

Pin 9 is the output of the E/A and also one of the two inputs of the multiplier. A feedback

compensation network, placed between this pin and INV (10), reduces the bandwidth so to

avoid the attempt of the system to control the output voltage ripple (100-120 Hz). In the

simplest case, this compensation is just a capacitor, which provides a low frequency pole as

well as a high DC gain. A simple criterion to define the capacitance value is to provide ~60

dB attenuation at 100 Hz:

16/22

•=

MUL

COMP

(Multiplier output) is the reference

CS

is the voltage on pin 9 (E/A output) and

Page 17

AN2510 L6585 Biasing circuitry (pin by pin)

Equation 7

10

C

COMP

------------------------- -=

•

2 π• R

1

3.10 Pin10 INV

Pin 10 leads to both the inverting input of the E/A and to the open loop (feedback

disconnection) circuit. A resistive divider (Figure 3) will be connected between the regulated

output voltage of the boost and the pin. The internal reference on the non-inverting input of

the E/A is 2.5 V so R1 and R2 (Figure 3) will be then selected as follows:

Equation 8

R

2

V

PFOUT

⎛⎞

2.5 1

•=

⎝⎠

------ -+

R

1

3.11 Pin11 ZCD

Pin 11 is the input to the Zero Current Detector circuit. The ZCD pin will be connected to the

auxiliary winding of the boost inductor through a limiting resistor. The ZCD circuit is

negative-going edge-triggered. When the voltage on the pin falls below 0.7 V the PWM

latch is set and the MOSFET is turned on. To do so, however, the circuit must be armed first.

Prior to falling below 0.7 V the voltage on pin 11 must experience a positive-going edge

exceeding 1.4 V (due to MOSFET's turn-off). The maximum main-to-auxiliary winding turn

ratio, m, has to ensure that the voltage delivered to the pin during MOSFET's OFF-time is

sufficient to arm the ZCD circuit. Then:

3.12 Pin12 PFCS

Pin 12 is the inverting input of the current sense comparator. As the voltage across the

sense resistor (proportional to the instantaneous inductor current) crosses the threshold set

by the multiplier output, the power MOSFET is turned off. The MOSFET will stay in OFFstate until the PWM latch is set again by the ZCD signal. An internal circuit (LEB, leading

edge blanking) blanks the comparator for 200 ns in order to avoid undesired MOSFET turnoff due to the initial spike, present when the PFC is not operating in ZVS (that is when the

instantaneous voltage is higher than Vout/2).

The sense resistor value is calculated as follows:

V

CSpk

----------------

R

≤

S

–

The power dissipated in Rs, is given by:

–

I

Rspk

P

RSRSIQrms2

VO 2 V

--------------------------------------------------------

≤

m

•=

•–

irms max()

1.4

17/22

Page 18

L6585 Biasing circuitry (pin by pin) AN2510

The internal 1.16 V (max.) zener clamp on the non-inverting input of the PWM comparator

sets a current limitation threshold, so that the maximum current through Rs can be as high

as:

I

RSpkmax

This will be the maximum inductor current as well, therefore one must make sure that the

boost inductor does not saturate at this current level, which is very likely to be reached when

the boost converter is powered on (especially at low line) or powered off.

1.16

-----------=

R

s

3.13 Pin13 PFG

Pin 13 is the output of the driver. The pin is able to drive an external MOSFET with 300 mA

source and 600 mA sink capabilities.

3.14 Pin14 HBCS

Pin 14 is the half bridge current sense pin with 2-levels of current controls. The current

flowing in the HB MOSFET is sensed by a resistor. The resulting voltage is applied to this

pin. During the run mode both the low threshold (0.91 V) and the high threshold (1.6 V) are

active. In case of low thresholds crossing, the IC reacts with a self-adjusting frequency

increase in order to limit the half-bridge (lamp) current. In case of high threshold crossing

because of current spikes (due for example to capacitive mode / cross-conduction), the

L6585D latches to avoid damage to the MOSFET. During ignition only the high threshold

(1.6 V) is active. In case of crossing thresholds during the frequency shift, the IC reacts with

a self-adjusting frequency increase in order to limit the lamp voltage and prevent operation

below resonance.

3.15 Pin15 GND

This pin acts as the current return both for the signal internal circuitry and for the gate drive

current. When layouting the printed circuit board, these two paths should run separately.

3.16 Pin16 LSD

Pin 16 is the output of the half-bridge low side driver. The pin is able to drive an external

MOSFET with 290 mA source and 480 mA sink capabilities.

3.17 Pin17 V

Pin 17 is the supply of the device. This pin will be externally connected to the start-up circuit

(usually, one resistor connected to the rectified mains) and to the self-supply circuit.

Whatever the configuration of the self-supply system, a capacitor will be connected between

this pin and ground. To start the L6585D, the voltage must exceed the start-up threshold (15

V max.). Below this value the device does not work and consumes less than 350 µA from

Vcc. This allows the use of high value start-up resistors (in the hundreds kΩ), which reduces

18/22

CC

Page 19

AN2510 L6585 Biasing circuitry (pin by pin)

power consumption and optimizes system efficiency at low load, especially in wide range

mains applications.

When operating, the current consumption (of the device only, not considering the gate drive

current) rises to a value depending on the operating conditions but never exceeding 4.5 mA.

The device keeps on working as long as the supply voltage is over the UVLO threshold (11

V max). If the Vcc voltage exceeds 17.7 V max, an internal zener diode, 30 mA rated, will be

activated that clamps the voltage. In that case the power consumption of the device will

increase considerably, but there is no harm as long as the current is below the maximum

rating.

3.18 Pin18 OUT

Pin 18 is the High Side Driver Floating Reference. This pin must be connected close to the

source of the high side power MOS or IGBT.

3.19 Pin19 HSD

Pin 19 is the output of the half-bridge high side driver. The pin is able to drive an external

MOSFET with 290 mA source and 480 mA sink capabilities.

3.20 Pin20 BOOT

The supply of the high voltage section is obtained by means of a bootstrap circuitry. This

solution normally requires a high voltage fast recovery diode for charging the bootstrap

capacitor. In the L6585D a patented integrated structure replaces this external diode. It is

done by means of a high voltage DMOS, driven synchronously with the low side driver

(LVG), with a diode connected in series. To drive the synchronized DMOS it is necessary a

voltage higher than the supply voltage VS. This voltage is obtained by means of an internal

charge pump. The diode connected in series to the DMOS has been added to avoid

undesirable turn on it. The introduction of the diode prevents any current from flowing from

the BOOT pin to the VCC one if the supply is quickly turned off when the internal capacitor

of the pump is not fully discharged. The bootstrap driver introduces a voltage drop during

the recharging time of the capacitor C

with the frequency and with the size of the external power MOS. It is the sum of the drop

across the R

small and can be neglected. Increasing the frequency must be taken into account. In fact the

drop, reducing the amplitude of the driving signal, can significantly increase the R

the external power MOS (and so the dissipation). To be considered that in resonant power

supplies when we increase the frequency the current in mosfet's drain decreases. The

power dissipated by mosfet during the on-time is equal to Pcond=(Rds,on)*(Idrain)^2: then

Pcond is reduced when frequency is higher.

and of the diode threshold voltage. At low frequency this drop is very

DSON

(when the low side driver is on), which increases

boot

DSON

of

19/22

Page 20

L6585 Biasing circuitry (pin by pin) AN2510

Table 2. Fault conditions

Fault Condition IC behavior Action required

Lamp absence

than 4.63 V

(re-lamp

comparator)

Run mode: EOL-R voltage higher

than 4.63 V

At turn-on: EOL-R voltage higher

End of life

EOL-R voltage outside the limits of

window comparator

Ignition: HBCS threshold

Half-bridge

current sense

Run mode: HBCSL threshold

Run mode: HBCSH threshold

Shutdown CTR voltage lower than 0.8 V

– The T

charge does not start (no

CH

ignition)

– All drivers stopped

– IC low consumption (V

clamped)

cc

– All drivers stopped

– IC low consumption (V

(1)

–T

CH

cycle

(reset if the fault

clamped)

cc

disappears)

– All drivers stopped at the end of

cycle

T

CH

– IC low consumption (VCC

clamped)

–T

CH

cycle

with lamp voltage

(1)

control

– In case of HBCS at the end of the

cycle, all drivers stopped

T

CH

– IC low consumption (V

cycle

(1)

with lamp voltage

–T

CH

clamped)

cc

control (frequency increase)

– In case of HBCS at the end of the

TCH cycle, all drivers stopped

– IC low consumption (V

clamped)

cc

– All drivers stopped

– IC low consumption (V

clamped)

cc

– All drivers stopped

– IC low consumption (V

clamped)

cc

Lamp replacement

(EOL-R below 4.63 V)

Re-lamp cycle

Re-lamp cycle

Re-lamp cycle

Re-lamp cycle

(2)

(2)

(2)

(2)

When the CTR voltage

returns above 0.8 V,

the IC driver restarts

with a pre-heating

sequence

Choke

saturation

PFCS voltage higher than 1.6 V

– All drivers stopped

– IC low consumption (V

clamped)

cc

Re-lamp cycle

(2)

When the CTR voltage

Over-voltage of

PFC output

CTR voltage higher than 3.4 V

(typ.)

PFC driver stopped

returns below 3.26 V

(typ.), the PFC driver

restarts

PFC open loop

(feedback

disconnection)

1. T

cycle: charge of the TCH voltage up to 4.63 V and discharge down to 1.53 V following the RDCD time constant;

CH

2. Re-lamp cycle: the voltage at EOL-R pin must be first pulled above 4.63 V and then released below it; this typically happens

in case of lamp replacement. After a re-lamp cycle, a new pre-heating sequence will be repeated.

3. This fault actually is a "board" fault so a lamp replacement is not effective to restart the ballast

CTR voltage higher than 3.4 V

(typ.) and INV voltage lower than

1.2 V (typ.)

– All drivers stopped

– IC low consumption (V

clamped)

cc

Re-lamp cycle

(2)(3)

20/22

(3)

Page 21

AN2510 Revision history

4 Revision history

Table 3. Revision history

Date Revision Changes

26-Mar-2007 1 First issue

21/22

Page 22

AN2510

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

22/22

Loading...

Loading...